Page 1

VACON® 100 FAMILY

AC DRIVES

INSTALLATION

IN US AND CANADA

QUICK GUIDE

Page 2

Page 3

TOC

UL STANDARDS ON CABLING ...........................................................................4

CABLE AND FUSE SIZES, NORTH AMERICA .....................................................5

THE TECHNICAL DATA OF THE VACON® 100 FAMILY AC DRIVES ..............6

THE CABLE AND FUSE SIZES FOR VACON® 100 FAMILY

IN NORTH AMERICA, MAINS VOLTAGE 208-240 V AND 380-500 V ...................8

THE CABLE AND FUSE SIZES FOR VACON® 100 FAMILY

IN NORTH AMERICA, MAINS VOLTAGE 525-600 V ..........................................10

THE TIGHTENING TORQUES OF CABLE TERMINALS .....................................12

3

Page 4

UL STANDARDS ON CABLING

To obey the UL (Underwriters Laboratories) regulations, use a UL-approved

Class 1 copper wire with a minimum heat resistance of +140 or +167 °F.

You can use the drive on a circuit that gives a maximum of 100 000 rms

symmetrical amperes, and a maximum of 600 V AC, when the drive is

protected by Class T and J fuses.

The dimensions of the cables must agree with the requirements of the

National Electric Code (NEC) and the Canadian Electric Code (CEC).

• The cables must be PVC-isolated.

• The maximum ambient temperature is +86° F.

• The maximum temperature of the cable surface is +158° F.

• Use only cables with a concentric copper shield.

• The maximum number of parallel cables is 9.

When you use parallel cables, make sure that you obey the requirements of the

cross-sectional area and the maximum number of cables.

For important information on the requirements of the grounding conductor,

see the NEC and CEC.

For the correction factors for each temperature, see the instructions of the

NEC and CEC.

4

Page 5

CABLE AND FUSE SIZES, NORTH AMERICA

We recommend the fuse class T (UL & CSA). To make a selection of the

fuse voltage rating, refer to the mains. Refer also to local regulations, cable

installation conditions and cable specification. Do not use larger fuses than

what is recommended.

Make sure that the operation time of the fuse is less than 0.4 seconds. The

operation time agrees with the fuse type and the impedance of the supply

circuit. For more information on faster fuses, speak to the manufacturer. The

manufacturer can also recommend some high speed Class J (UL & CSA) fuse

ranges.

The solid state short circuit protection does not supply protection for the

branch circuit of the of the AC drive. To supply the branch circuit protection,

refer to the National Electric Code and the local regulations. Do not use other

devices than fuses to supply branch circuit protection.

NOTE!

The VACON® 100 FLOW and HVAC software do not have the

dynamic braking or the brake resistor functions.

5

Page 6

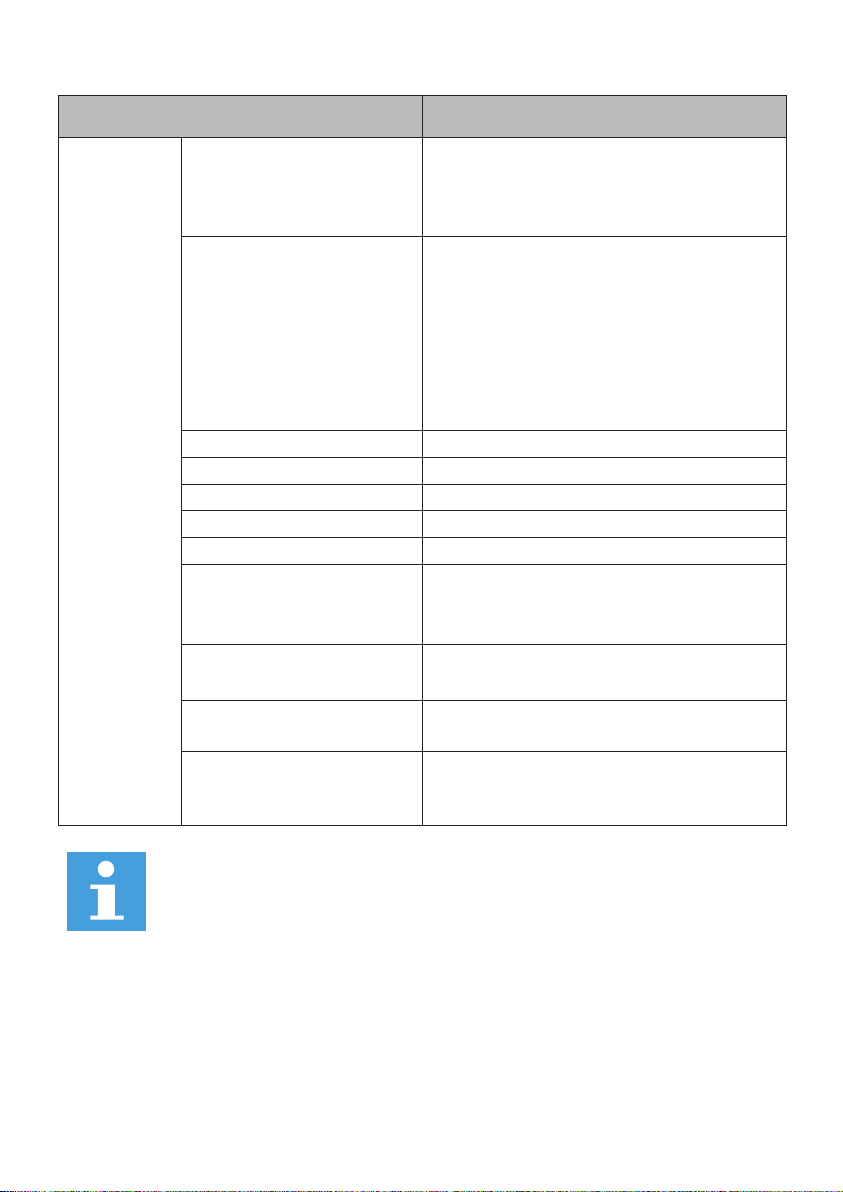

THE TECHNICAL DATA OF THE VACON® 100 FAMILY AC DRIVES

Technical item or function Technical data

Mains connection

Motor connection

Input voltage U

Input frequency 50-60 Hz, -5...+10%

Connection to mains Once per minute or less

Starting delay 6 s (MR4 to MR6), 8 s (MR7 to MR12)

Mains

Output voltage 0-U

Continuous output

current

Output frequency 0-320 Hz (standard)

Frequency resolution 0.01 Hz

in

208-240V, 380-500V, 525-600V,

525-690V,-10%…+10% *

• Mains types: TN, TT, and IT

• Short circuit current:

the maximum short circuit current

must be < 100 kA.

in

IL: Ambient temperature max. +40 °C

overload 1.1 x IL (1 min/10 min)

IH: Ambient temperature max. +50 °C

overload 1.5 x IH (1 min/10 min)

IH in 600/690 V drives and MR10-MR12:

Ambient temperature max. +40 °C

overload 1.5 x IH (1 min/10 min)

6

Page 7

Technical item or function Technical data

Mains voltage 240 V: 456 VDC

Protections

Overvoltage

trip limit

Undervoltage trip limit

Earth fault protection Yes

Mains supervision Yes

Motor phase supervision Yes

Overcurrent protection Yes

Unit overtemp. protection Yes

Motor overload protection

Motor stall protection Yes

Mains voltage 500 V: 911 VDC

Mains voltage 600 V: 1094 VDC

Mains voltage 690 V: 1258 VDC

Depends on mains voltage

(0.8775 x mains voltage):

Mains voltage 240 V: trip limit 211 VDC

Mains voltage 400 V: trip limit 351 VDC

Mains voltage 500 V: trip limit 438 VDC

Mains voltage 525 V: trip limit 461 VDC

Mains voltage 600 V: trip limit 527 VDC

Mains voltage 690 V: trip limit 606 VDC

Yes. **

The motor overload protection activates

at 110% of the full load current.

Motor underload

protection

Short-circuit protection of

+24 V and +10 Vreference

voltages

Yes

Yes

NOTE!

The UL approval is valid for input voltage up to 600 V.

* = 525-600 V or 690 V are not available for VACON® 100 HVAC.

** = For the motor thermal memory and the memory retention function to obey

the UL 61800-5-1 requirements, you must use the system software version

FW0072V007 for VACON® 100 INDUSTRIAL, FW0159V003 for VACON® 100 FLOW,

and FW0065V021 for VACON® 100 HVAC, or a newer version. If you use an older

system software version, you must install a motor overtemperature protection to

obey the UL regulations.

7

Page 8

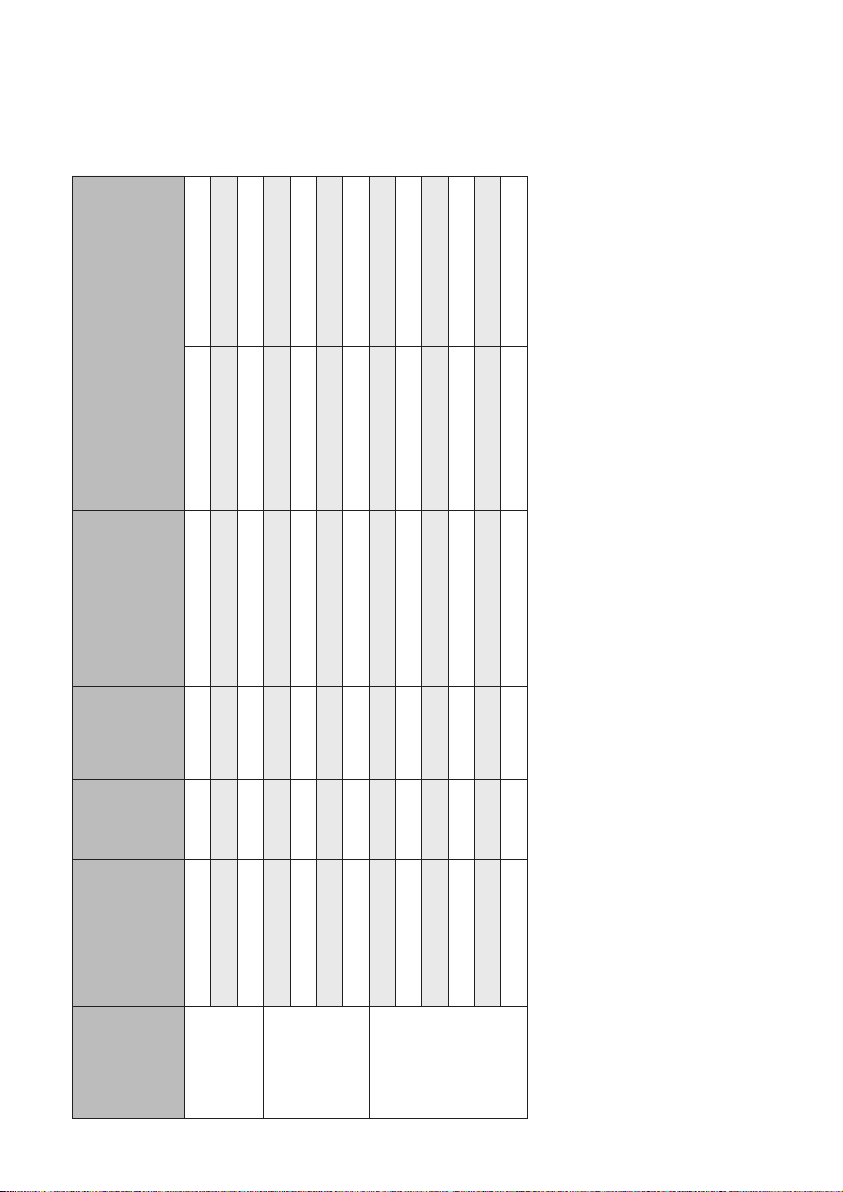

THE CABLE AND FUSE SIZES FOR VACON® 100 FAMILY

IN NORTH AMERICA, MAINS VOLTAGE 208240 V AND 380500 V

[AWG/kcmil]

Ground terminal

Terminal cable size

terminal

Mains cable

[AWG/kcmil]

and brake

Mains, motor

(Cu) [AWG]

resistor* cable

Fuse

(class

T/J) [A]

Type IL [A]

0003 2 / 0003 5 3.7 / 3.4 6 14 24-10 17-10

0004 2 / 0004 5 4.8 6 14 24-10 17-10

0006 2 / 0005 5 6.6 / 5.6 10 14 24-10 17-10

0008 2 / 0008 5 8.0 10 14 24-10 17-10

0011 2 / 0009 5 11.0 / 9.6 15 14 24-10 17-10

0012 2 / 0012 5 12.5 / 12.0 20 14 24-10 17-10

0018 2 / 0016 5 18.0 / 16.0 25 10 20-6 17-8

0024 2 / 0023 5 24.0 / 23.0 30 10 20-6 17-8

0031 2 / 0031 5 31.0 40 8 20-6 17-8

0038 5 38.0 50 4 13-0 13-2

0048 2 / 0046 5 48.0 / 46.0 60 4 13-0 13-2

0062 2 / 0061 5 ** 62.0 / 61.0 80 4 13-0 13-2

0075 2 / 0072 5 75.0 / 72.0 100 2 9-2/0 9-2/0

0088 2 / 0087 5 88.0 / 87.0 110 1 9-2/0 9-2/0

0105 2 / 0105 5 105.0 150 1/0 9-2/0 9-2/0

0140 2 / 0140 5 140.0 200 3/0 1 AWG-350 kcmil 1 AWG-350 kcmil

0170 2 / 0170 5 170.0 225 250 kcmil 1 AWG-350 kcmil 1 AWG-350 kcmil

0205 2 / 0205 5 205.0 250 350 kcmil 1 AWG-350 kcmil 1 AWG-350 kcmil

size

Enclosure

8

MR4

MR5

MR6

MR7

MR8

Page 9

Terminal cable size

Mains cable

and brake

Mains, motor

Fuse

Ground terminal

terminal

resistor* cable

(class

T/J) [A]

[AWG/kcmil]

[AWG/kcmil]

(Cu) [AWG]

Type IL [A]

Enclosure

size

0261 2 / 0261 5 261.0 350 2x250 kcmil 1 AWG-350 kcmil 1 AWG-350 kcmil

MR9

0310 2 / 0310 5 310.0 400 2x350 kcmil 1 AWG-350 kcmil 1 AWG-350 kcmil

0385 5 385 500 2x250 kcmil 1 AWG-350 kcmil 1 AWG-350 kcmil

0460 5 460 600 2x350 kcmil 1 AWG-350 kcmil 1 AWG-350 kcmil

MR10

0520 5 520 700 3x4/0 1 AWG-350 kcmil 1 AWG-350 kcmil

0590 5 590 800 3x250 kcmil 1 AWG-350 kcmil 1 AWG-350 kcmil

0650 5 650 2x400 4x4/0 1 AWG-350 kcmil 1 AWG-350 kcmil

0730 5 730 2x500 4x300 1 AWG-350 kcmil 1 AWG-350 kcmil

0820 5 820 2x600 4x350 1 AWG-350 kcmil 1 AWG-350 kcmil

MR12

0920 5 920 2x600 6x4/0 1 AWG-350 kcmil 1 AWG-350 kcmil

1040 5 1040 2x600 6x250 1 AWG-350 kcmil 1 AWG-350 kcmil

1180 5 1180 2x700 6x300 1 AWG-350 kcmil 1 AWG-350 kcmil

also possible to use a single cable if you obey the minimum cross-sectional area of the cable.

* = If you use a multi-conductor cable, 1 of the conductors of the brake resistor cable stays unconnected. It is

** = To obey the UL regulations with the 500 V drive, it is necessary to have cables with a +194 °F

heat resistance.

9

Page 10

THE CABLE AND FUSE SIZES FOR VACON® 100 FAMILY

IN NORTH AMERICA, MAINS VOLTAGE 525600 V

[AWG/kcmil]

Ground terminal

Terminal cable size

terminal

Mains cable

[AWG/kcmil]

brake resistor*

cable (Cu) [AWG]

Mains, motor and

10

Fuse

(class T)

Type IL [A]

Enclosure

[A]

size

0004 6 3.9 6 14 20-6 17-8

0006 6 6.1 10 14 20-6 17-8

MR5

0009 6 9.0 10 14 20-6 17-8

0011 6 11.0 15 14 20-6 17-8

(600V)

0007 7 7.5 10 12 13-0 13-2

0010 7 10.0 15 12 13-0 13-2

0013 7 13.5 20 12 13-0 13-2

0018 6 / 0018 7 18.0 20 10 13-0 13-2

MR6

0022 6 / 0022 7 22.0 25 10 13-0 13-2

0027 7 / 0027 7 27.0 30 8 13-0 13-2

0034 6 / 0034 7 34.0 40 8 13-0 13-2

0041 6 / 0041 7 41.0 50 6 9-2/0 9-2/0

0052 6 / 0052 7 52.0 60 6 9-2/0 9-2/0

MR7

0062 6 / 0062 7 62.0 70 4 9-2/0 9-2/0

0080 6 / 0080 7 80.0 90 1/0 1 AWG-350 kcmil 1 AWG-350 kcmil

0100 6 / 0100 7 100.0 110 1/0 1 AWG-350 kcmil 1 AWG-350 kcmil

MR8

0125 6 / 0125 7 125.0 150 2/0 1 AWG-350 kcmil 1 AWG-350 kcmil

Page 11

Terminal cable size

Mains cable

Mains, motor and

Fuse

Ground terminal

terminal

brake resistor*

(class T)

[AWG/kcmil]

[AWG/kcmil]

cable (Cu) [AWG]

[A]

Type IL [A]

Enclosure

size

0144 6 / 0144 7 144.0 175 3/0 1 AWG-350 kcmil 1 AWG-350 kcmil

0170 7 170.0 200 4/0 1 AWG-350 kcmil 1 AWG-350 kcmil

MR9

0208 6 / 0208 7 208.0 250 300 kcmil 1 AWG-350 kcmil 1 AWG-350 kcmil

0261 7 261.0 350 2xAWG2/0 1 AWG-350 kcmil 1 AWG-350 kcmil

0325 7 325.0 450 2x4/0 1 AWG-350 kcmil 1 AWG-350 kcmil

MR10

0385 7 385.0 500 2x250 kcmil 1 AWG-350 kcmil 1 AWG-350 kcmil

0416 7 416.0 600 2x300 kcmil 1 AWG-350 kcmil 1 AWG-350 kcmil

0460 7 460 2x300 4x2/0 1 AWG-350 kcmil 1 AWG-350 kcmil

0520 7 520 2x350 4x3/0 1 AWG-350 kcmil 1 AWG-350 kcmil

0590 7 590 2x400 4x4/0 1 AWG-350 kcmil 1 AWG-350 kcmil

MR12

0650 7 650 2x400 4x4/0 1 AWG-350 kcmil 1 AWG-350 kcmil

0750 7 750 2x450 4x300 1 AWG-350 kcmil 1 AWG-350 kcmil

0820 7 820 2x500 4x350 1 AWG-350 kcmil 1 AWG-350 kcmil

* = If you use a multi-conductor cable, 1 of the conductors of the brake resistor cable stays unconnected.

It is also possible to use a single cable if you obey the minimum cross-sectional area of the cable.

11

Page 12

THE TIGHTENING TORQUES OF CABLE TERMINALS

Tightening torque:

grounding conductor

the grounding clamps for

shield

the grounding

clamps for cable

Tightening torque:

12

Tightening torque:

the mains cable and

motor cable terminals

Type

size

Enclosure

Nm lb-in. Nm lb-in. Nm lb-in.

0.5-0.6 4.5-5.3 1.5 13.3 2.0 17.7

0003 2 - 0012 2

MR4

1.2-1.5 10.6-13.3 1.5 13.3 2.0 17.7

0003 5 - 0012 5

0018 2 - 0031 2

0016 5 - 0031 5

0004 6 - 0011 6

MR5

10 88.5 1.5 13.3 2.0 17.7

0048 2 - 0062 2

0038 5 - 0061 5

0018 6 - 0034 6

0007 7 - 0034 7

0075 2 - 0105 2

MR6

20 177 1.5 13.3 20 177

8 * / 5.6 ** 70.8 * / 49.6 ** 1.5 13.3 8 * / 5.6 ** 70.8 * / 49.6 **

0072 5 - 0105 5

0041 6 - 0062 6

0041 7 - 0062 7

0140 2 - 0205 2

0140 5 - 0205 5

MR7

MR8

0080 6 - 0125 6

0080 7 - 0125 7

Page 13

Tightening torque:

Tightening torque:

the grounding

grounding conductor

the grounding clamps for

shield

clamps for cable

Tightening torque:

the mains cable and

motor cable terminals

Type

size

Enclosure

Nm lb-in. Nm lb-in. Nm lb-in.

40 354 1.5 13.3 20 177

0261 2 - 0310 2

0261 5 - 0310 5

0144 6 - 0208 6

MR9

55-70 * 490-620 * 1.5 13.3 20 177

0144 7 - 0208 7

0385 5 - 0590 5

0261 6 - 0416 6

0261 7 - 0461 7

MR10

55-70 * 490-620 * 1.5 13.3 20 177

0650 5 - 1180 5

0460 6 - 0820 6

0460 7 - 0820 7

MR12

* = The tightening torque for a torx screw.

** = The tightening torque for an Allen screw.

13

Page 14

Page 15

Page 16

Download and read VACON® 100 Family

Installation manuals at:

http://drives.danfoss.com/knowledge-center/technical-documentation/

DPD01758E

Loading...

Loading...