Page 1

VACON® 100 FAMILY AC DRIVES

QUICK GUIDE

GUIDE RAPIDE

KURZANLEITUNG

GUIDA RAPIDA

GUÍA RÁPIDA

GUIA RÁPIDO

快速指南

PIKAOPAS

EN

FR

DE

IT

ES

PTBR

ZH

FI

Page 2

Page 3

TOC

COOLING / REFROIDISSEMENT / KÜHLUNG / RAFFREDDAMENTO /

REFRIGERACIÓN / REFRIGERAÇÃO / 冷却 / JÄÄHDYTYS ................................4

CABLE INSTALLATION / INSTALLATION DES CÂBLES / KABELINSTALLATION /

INSTALLAZIONE DEI CAVI / INSTALACIÓN DE LOS CABLES /

INSTALAÇÃO DO CABO / 电缆安装 / KAAPELIEN ASENNUS .........................5

CONTROL PANEL AND KEYPAD ........................................................................6

EN

CONTROL TERMINALS ......................................................................................7

BASIC MENU STRUCTURE ................................................................................8

FIRST STARTUP ...............................................................................................9

PANNEAU OPÉRATEUR ...................................................................................10

FR

BORNES DE COMMANDE ................................................................................11

STRUCTURE DE MENU DE BASE ...................................................................12

PREMIÈRE MISE EN SERVICE ........................................................................13

STEUERTAFEL UND TASTENFELD ..................................................................14

DE

STEUERANSCHLÜSSE .....................................................................................15

BASISMENÜSTRUKTUR ................................................................................16

ERSTES ANLAUFEN ........................................................................................17

PANNELLO DI CONTROLLO E PANNELLO DI COMANDO ...............................18

IT

MORSETTI DI CONTROLLO ..............................................................................19

STRUTTURA DI BASE DEI MENU ....................................................................20

PRIMO AVVIO ...................................................................................................21

CUADRO DE CONTROL Y PANEL .....................................................................22

ES

TERMINALES DE CONTROL ............................................................................23

ESTRUCTURA BÁSICA DE MENÚS .................................................................24

PRIMERA PUESTA EN MARCHA .....................................................................25

PT-

PAINEL DE CONTROLE E TECLADO ................................................................26

BR

TERMINAIS DE CONTROLE .............................................................................27

ESTRUTURA BÁSICA DO MENU .....................................................................28

PRIMEIRA INICIALIZAÇÃO ..............................................................................29

控制面板和键盘 ................................................................................................30

ZH

控制端子 ...........................................................................................................31

基本菜单结构 ...................................................................................................32

首次启动 ...........................................................................................................33

OHJAUSPANEELI .............................................................................................34

FI

OHJAUSLIITTIMET ...........................................................................................35

PERUSVALIKKORAKENNE ..............................................................................36

ENSIMMÄINEN KÄYNNISTYS..........................................................................37

DISPOSAL / MISE AU REBUT / ENTSORGUNG / SMALTIMENTO /

ELIMINACIÓN / DESCARTE / 处置 / HÄVITTÄMINEN ....................................... 38

3

Page 4

COOLING / REFROIDISSEMENT / KÜHLUNG / RAFFREDDAMENTO /

EN

REFRIGERACIÓN / REFRIGERAÇÃO / 冷却 / JÄÄHDYTYS

FR

DE

IT

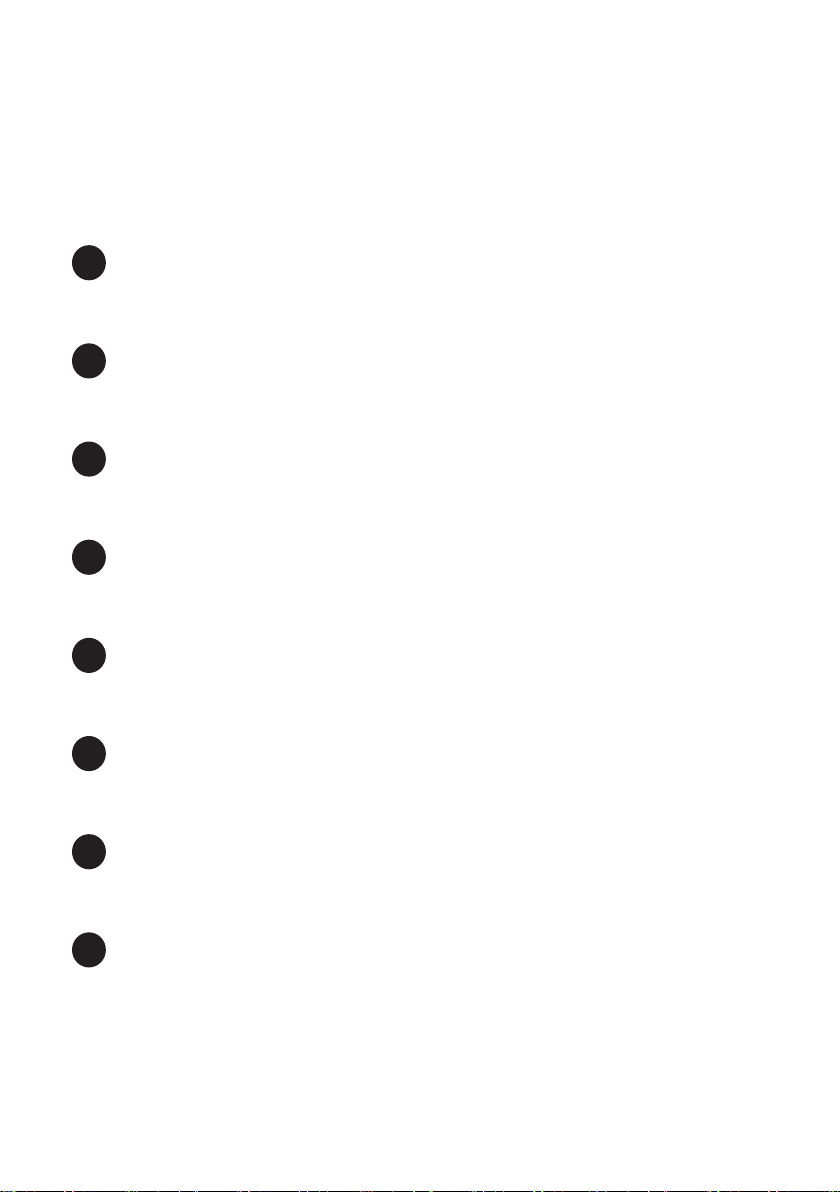

The minimum clearance [mm] around the drive

Dégagement minimal [mm] autour du convertisseur

Der Mindestabstand [mm] um den Umrichter herum

ES

PTBR

Distanza minima [mm] intorno all’inverter

La separación mínima [mm] alrededor del convertidor

Espaço livre mínimo [mm] ao redor do conversor

ZH

FI

变频器周围的间隙

Vähimmäisilmavälit [mm] taajuusmuuttajan ympärillä

FRAME A B C D

MR4 20 20 100 50

MR5 20 20 120 60

MR6 20 20 160 80

MR7 20 20 250 100

MR8 20 20 300 150

MR9 20 20 300 200

C

B

A

D

4

Page 5

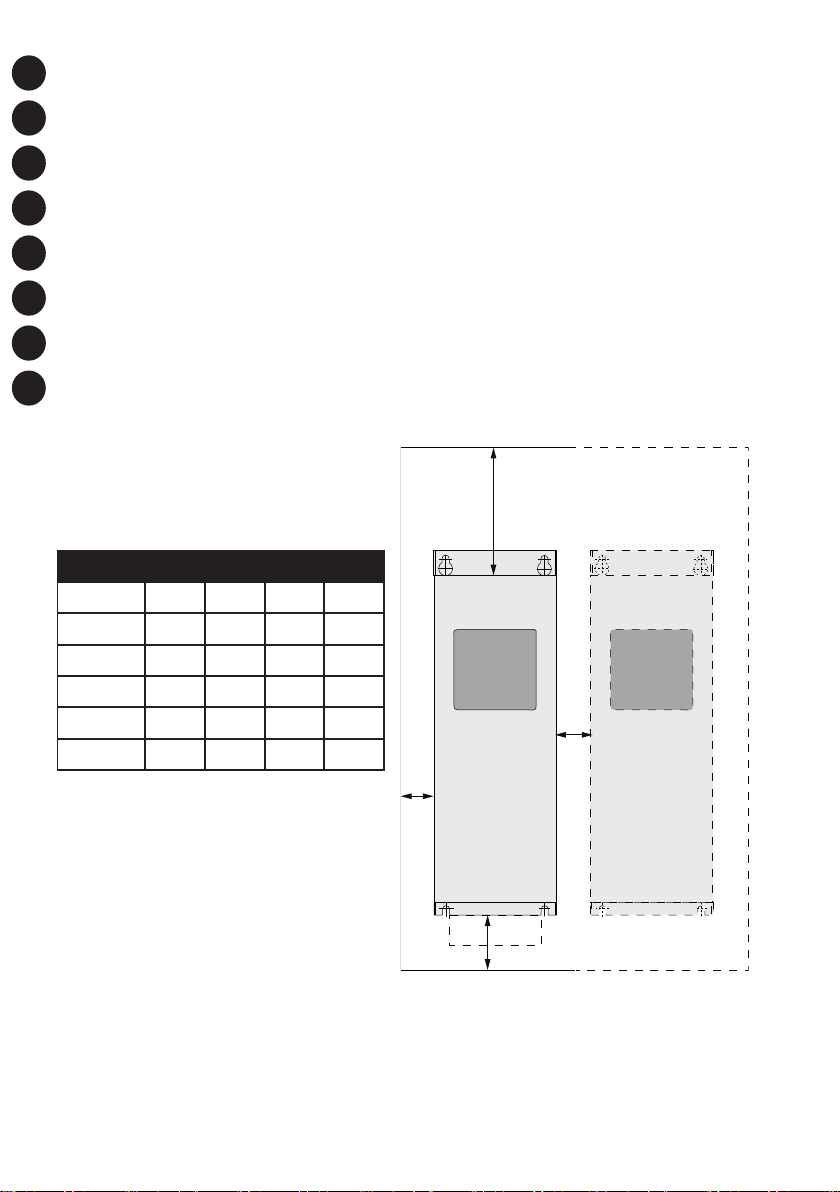

CABLE INSTALLATION / INSTALLATION DES CÂBLES /

KABELINSTALLATION / INSTALLAZIONE DEI CAVI /

INSTALACIÓN DE LOS CABLES / INSTALAÇÃO DO CABO /

电缆安装 / KAAPELIEN ASENNUS

EN

FR

DE

LI, L2, L3

Mains

Réseau

Netz

Rete elettrica

Red eléctrica

Rede elétrica

电源

Verkkovirta

L1 L2 L3 U V W

U, V, W

Motor

Moteur

Motor

Motore

Motor

Motor

电机

Moottori

The earth conductor

Le conducteur de terre

Erdungsleiter

Conduttore di terra

El conductor de toma a tierra

Condutor de aterramento

接地导线

Maadoitusjohdin

IT

ES

PTBR

ZH

FI

5

Page 6

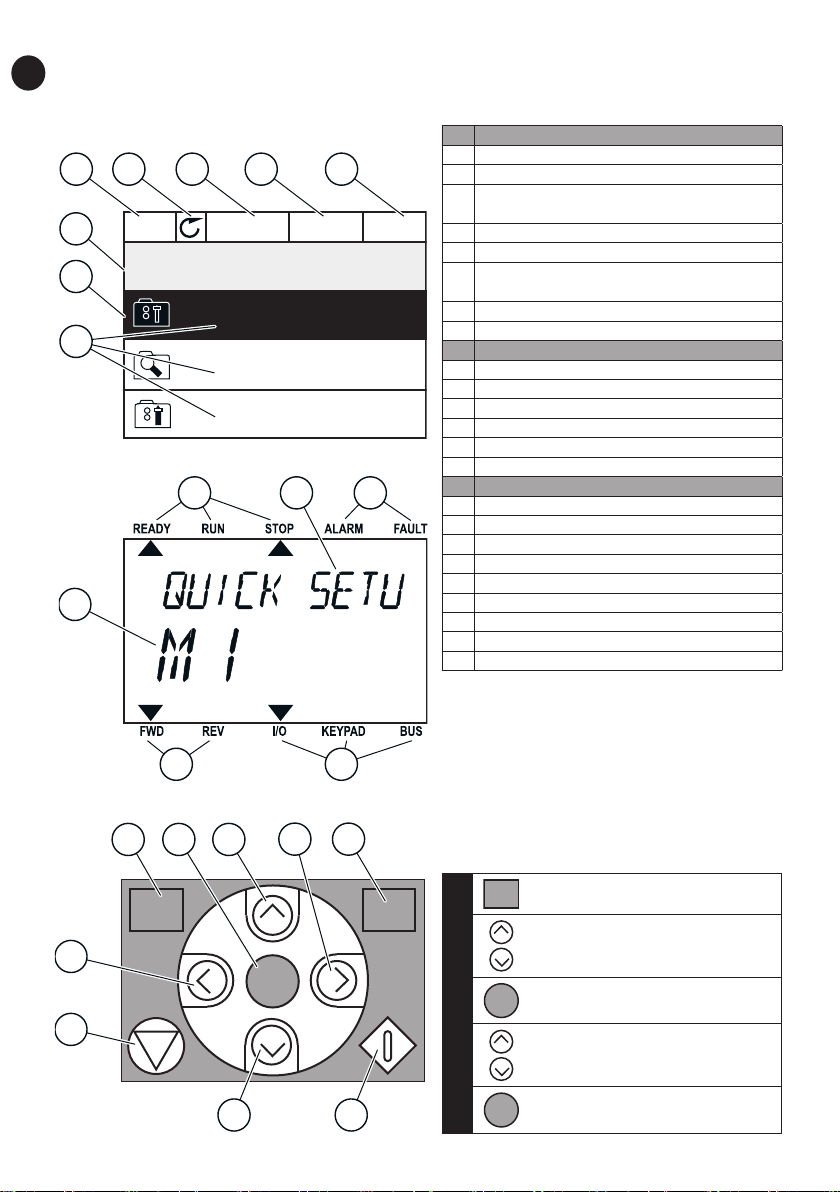

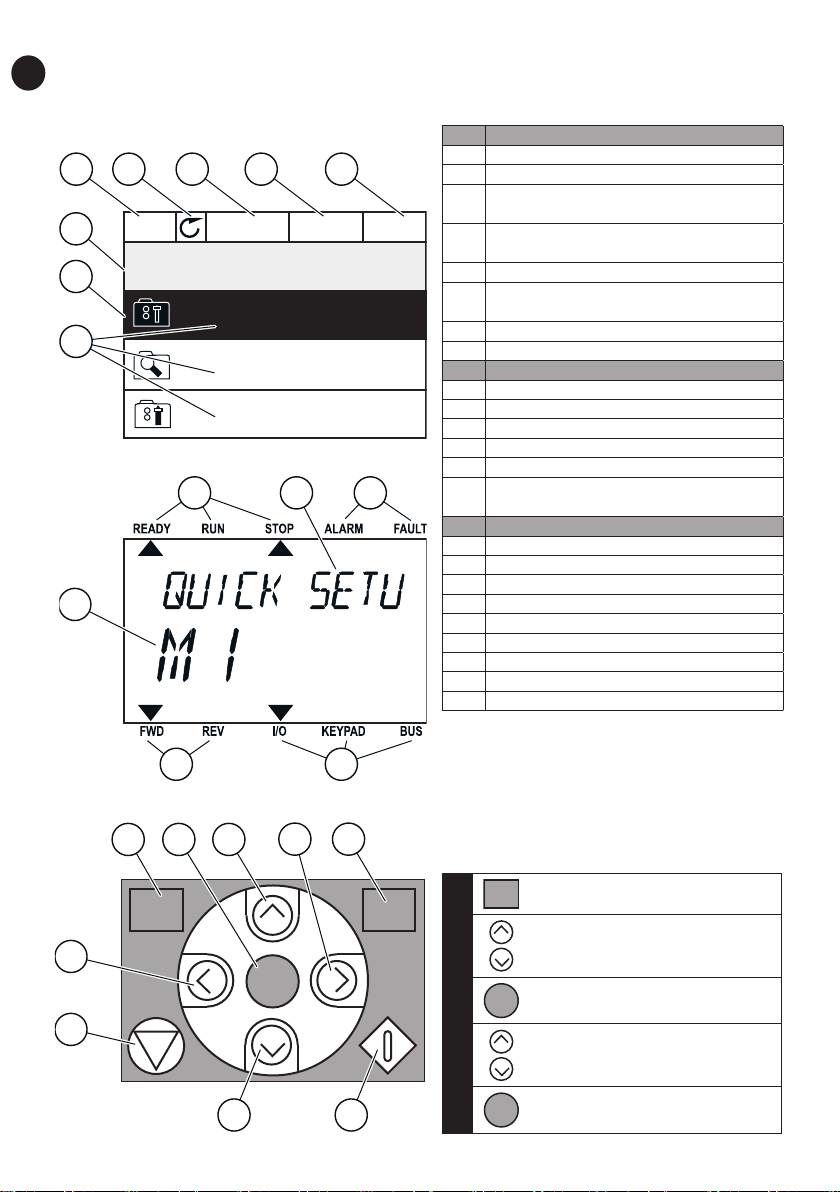

CONTROL PANEL AND KEYPAD

( 12 )

EN

A.

4 5 6 7 8

1

2

3

B.

12

STOP READY I/O

Main Menu

ID: M1

Quick Setup

( 17 )

Monitor

( 5 )

Parameters

9 10

11

A The graphical display

1 The location field

2 An activated group or item

The number of items in the group in

3

question

4 The first status field: STOP/RUN

5 The rotation direction

The second status field: READY/NOT

6

READY/FAULT

7 The alarm field

8 The control place

B The text display

9 The indicators of status

10 The indicators of alarm and fault

11 The name of the group or item

12 The current location in the menu

13 The indicators of the rotation direction

14 The indicators of the control place

C The buttons of the keypad

15 The BACK/RESET button

16 The OK button

17 The arrow button UP

18 The FUNCT button

19 The arrow button RIGHT

20 The START button

21 The arrow button DOWN

22 The STOP button

23 The arrow button LEFT

FUNCT (18)

C.

23

15

BACK

RESET

16 17

19

1413

18

FUNCT

Use it to change the rotation direction of

the motor, access the control page, and

change the control place.

Changing the control place:

FUNCT

1.

2.

‘Local/Remote’

OK

OK

3.

22

4.

6

21

20

5.

‘Local’ or ‘Remote’

OK

Page 7

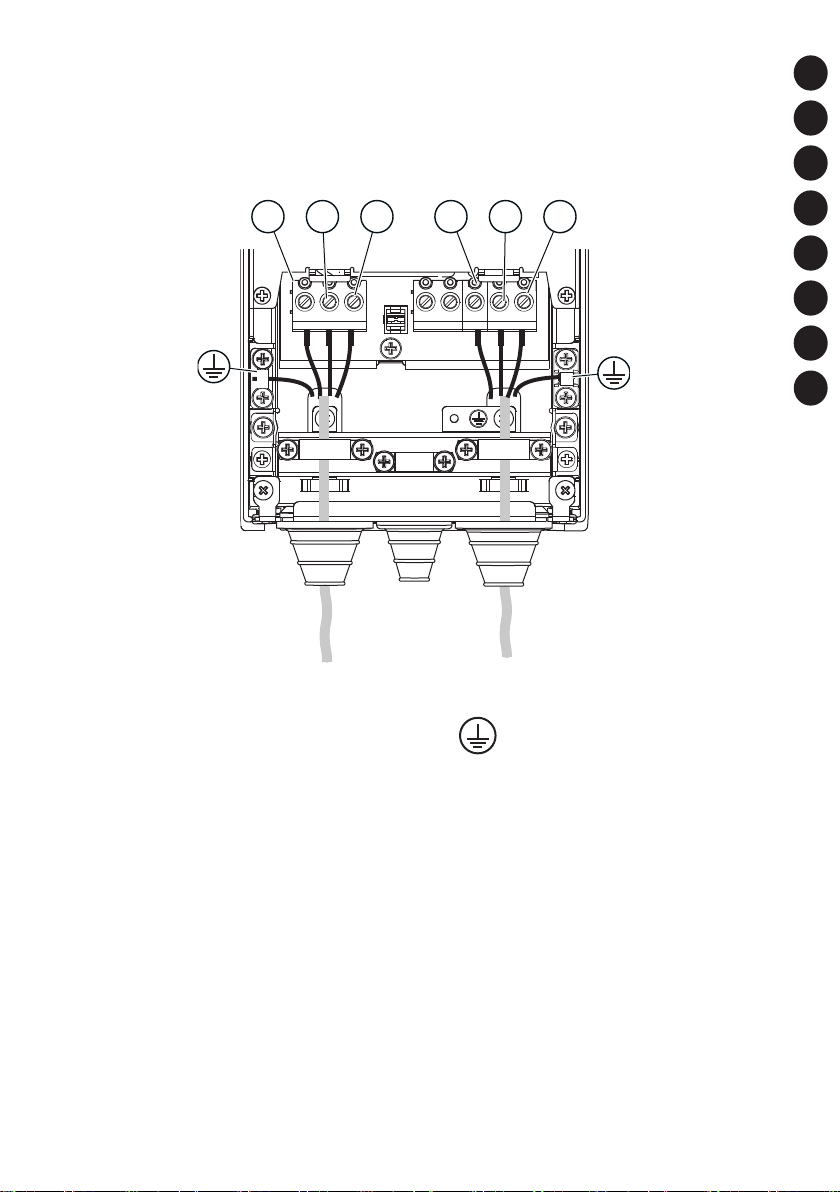

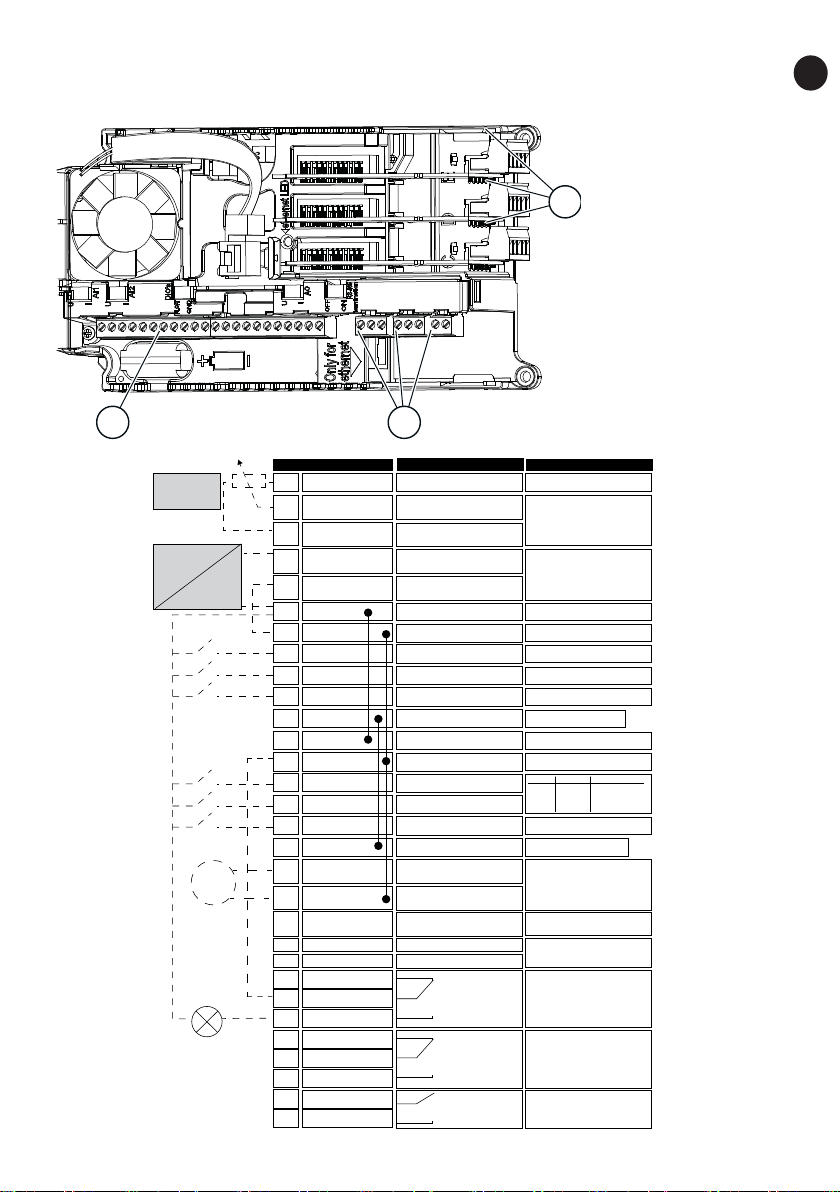

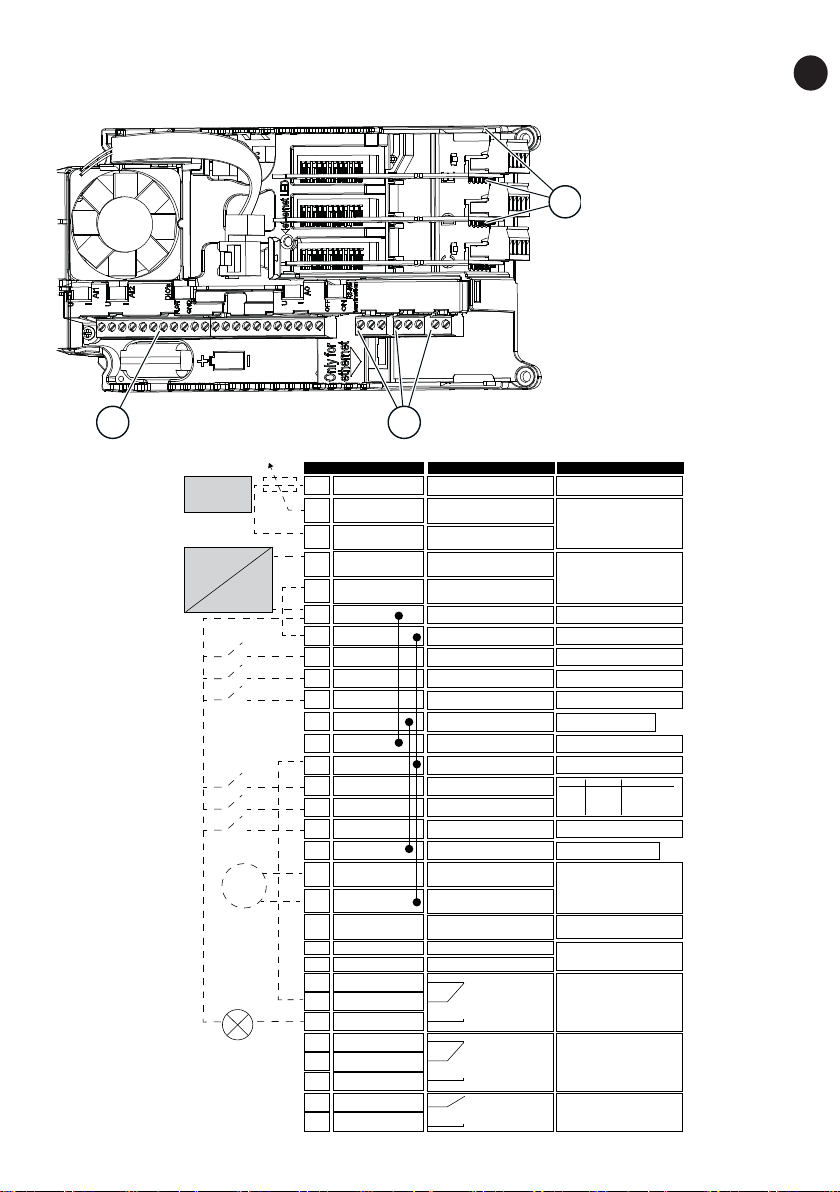

CONTROL TERMINALS

Standard I/O board

1. The terminals for

the standard I/O

connections

3

2. The terminals for 3

relay outputs or 2

relay outputs and

a thermistor

3. The option boards

EN

1

Reference

potentiometer

1...10kΩ

2-wire transmitter

Actual value

I = (0)4...20mA

mA

RUN

Terminal

+10 Vref

1

AI1+2

AI1-3

AI2+4

AI2-5

24Vout6

GND7

DI18

DI29

DI310

CM11

24Vout

12

GND13

DI414

DI515

DI616

17

CM

AO1+

18

AO1-/GND19

+24Vin30

RS485A

B

RS485

RO1 NC21

22

RO1 CM

RO1 NO23

RO2 NC24

25

RO2 CM

RO2 NO26

32

RO3 CM

RO3 NO33

2

Signal

Reference output

Analogue input,

voltage or current

Analogue input

common, (current)

Analogue input,

voltage or current

Analogue input

common, (current)

24V auxiliary voltage

I/O ground

Digital input 1

Digital input 2

Digital input 3

Common for DI1-DI6

24V auxiliary voltage

I/O ground

Digital input 4

Digital input 5

Digital input 6

Common for DI1-DI6

Analogue signal

(+output)

Analogue output

common / I/O ground

24V auxiliary

input voltage

Serial bus, negative

Serial bus, positive

Relay output 1

Relay output 2

Relay output 3

Description

Frequency reference

Frequency reference

Start forward

Start reverse

External fault

DI4 DI5 Freq. ref.

Open

Open

Closed

Open

Closed

Analog input 1

Open

Preset Freq. 1

Closed

Preset Freq. 2

Closed

Preset Freq. 3

Fault reset

Output frequency

Modbus RTU

BACnet, N2

RUN

FAU LT

READY

*)

*)

7

Page 8

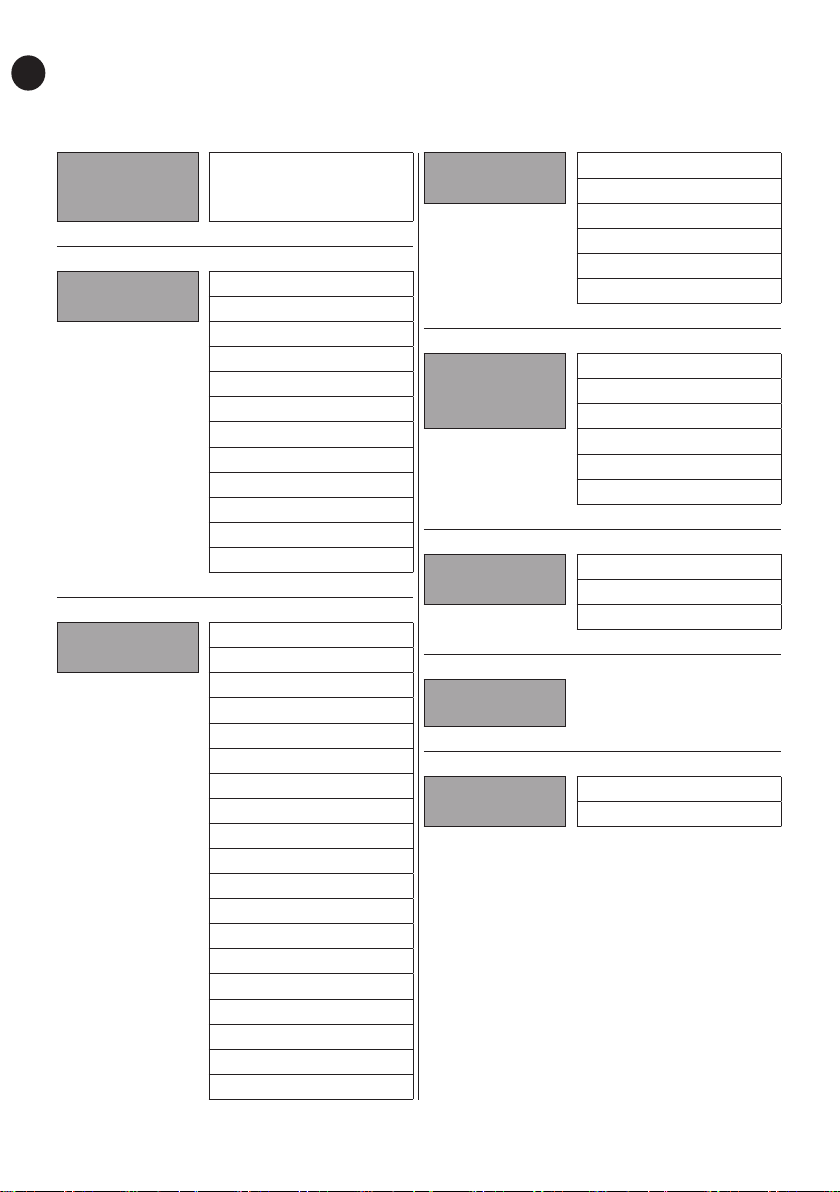

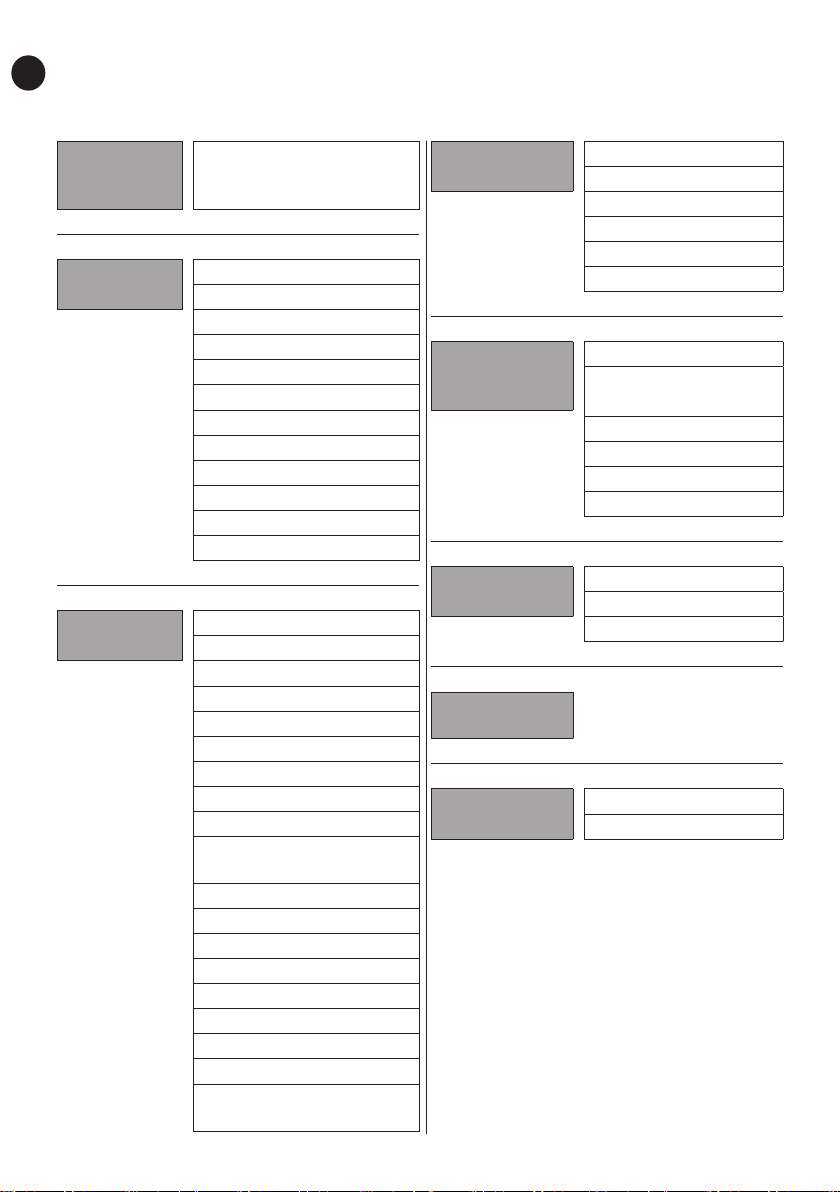

BASIC MENU STRUCTURE

EN

Main menu Submenus

M1

Quick setup

M2

Monitor

M3

Parameters

M1.1 Wizards

(Content depends on

P1.2, App select.)

M2.1 Multimonitor

M2.2 Trend Curve

M2.3 Basic

M2.4 I/O

M2.5 Temperat. inputs

M2.6 Extras/Advanced

M2.7 Timer Functions

M2.8 PID Controller

M2.9 Ext PID Controller

M2.10 Multi-Pump

M2.11 Mainten.count.

M2.12 Fieldbus data

M3.1 Motor Settings

M3.2 Start/Stop Setup

M3.3 References

M3.4 Ramps and Brakes

M3.5 I/O Configuration

M3.6 FB Data Mapping

M3.7 Prohibit Freq

M3.8 Supervisions

M3.9 Protections

M3.10 Automatic Reset

M3.12 Timer Functions

M3.13 PID Controller

M3.14 Ext PID Ctrl

M3.15 Multi-Pump

M3.16 Mainten. cntrs

M3.17 Fire Mode

M3.18 Motor Preheat

M3.20 Mechanical Brake

M3.21 Pump Control

Main menu Submenus

M4

Diagnostics

M5

I/O and

Hardware

M6

User Settings

M7

Favourites

M8

User Levels

M4.1 Active Faults

M4.2 Reset Faults

M4.3 Fault history

M4.4 Total Counters

M4.5 Trip Counters

M4.6 Software Info

M5.1 I/O and Hardware

M5.2...M5.4 Slots C,D,E

M5.5 Real Time Clock

M5.6 Power unit sett.

M5.7 Keypad

M5.8 RS-485

M6.1 Language select.

M6.5 Parameter Backup

M6.7 Drive Name

M8.1 User Level

M8.2 Access Code

8

Page 9

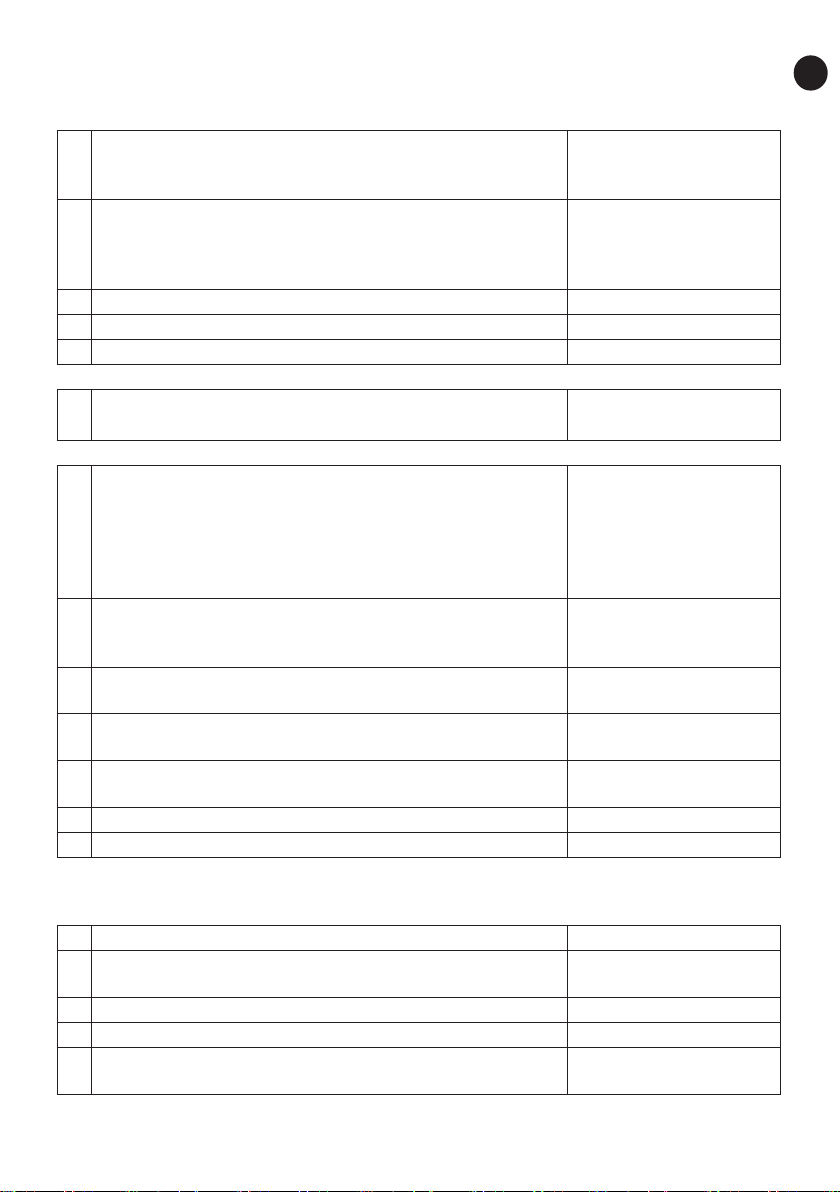

FIRST START-UP

The Start-up wizard tells you to give necessary data for the drive to control your procedure.

The selection is different

1 Language selection (P6.1)

2 Daylight saving* (P5.5.5)

3 Time* (P5.5.2) hh:mm:ss

4 Year* (P5.5.4) yyyy

5 Date* (P5.5.3) dd.mm.

* If a battery is installed, you see these steps.

6 Run Startup wizard?

To set the parameter values manually, make the selection No and push the OK button.

7 Make a selection of an application (P1.2 Application, ID212)

Set a value for P3.1.2.2 Motor Type (so that it agrees with

8

the nameplate)

Set a value for P3.1.1.1 Motor Nominal Voltage (so that it

9

agrees with the nameplate)

Set a value for P3.1.1.2 Motor Nominal Frequency (so that

10

it agrees with the nameplate)

Set a value for P3.1.1.3 Motor Nominal Speed (so that it

11

agrees with the nameplate)

12 Set a value for P3.1.1.4 Motor Nominal Current Range: Varies

13 Set a value for P3.1.1.5 Motor Cos Phi Range: 0.30-1.00

If you set Motor Type to Induction Motor, you see the next step. If your selection is PM

Motor, the value of parameter P3.1.1.5 Motor Cos Phi is set to 1.00 and the wizard goes

directly to step 14.

14 Set a value for P3.3.1.1 Minimum Frequency Reference Range: 0.00...P3.3.1.2 Hz

15 Set a value for P3.3.1.2 Maximum Frequency Reference

16 Set a value for P3.4.1.2 Acceleration Time 1 Range: 0.1...300.0 s

17 Set a value for P3.4.1.3 Deceleration Time 1 Range: 0.1...300.0 s

18 Run the Application wizard?

in all the language

packages

Russia

US

EU

OFF

Yes

No

Standard

Local/Remote

Multi-step speed

PID control

Multi-purpose

Motor potentiometer

PM motor

Induction motor

Reluctance motor

Range: Varies

Range: 8.00...320.00 Hz

Range: 24...19200

Range: P3.3.1.1...320.00

Hz

Yes

No

EN

9

Page 10

PANNEAU OPÉRATEUR

( 12 )

FR

A.

4 5 6 7 8

1

2

3

B.

12

STOP READY I/O

Main Menu

ID: M1

Quick Setup

( 17 )

Monitor

( 5 )

Parameters

9 10

11

A L’affichage graphique

1 Champ de localisation

2 Groupe ou élément activé

Nombre d’éléments dans le groupe

3

en question

Premier champ d’état :

4

ARRÊT/MARCHE

5 Sens de rotation

Deuxième champ d’état :

6

PRÊT/PAS PRÊT/DÉFAUT

7 Champ d’alarme

8 Source de commande

B L’affichage textuel

9 Indicateurs d’état

10 Indicateurs d’alarme et de défaut

11 Nom du groupe ou de l’élément

12 Emplacement actuel dans le menu

13 Indicateurs du sens de rotation

Indicateurs de la source de

14

commande

C Boutons du panneau opérateur

15 Touche BACK/RESET

16 Touche OK

17 Touche HAUT

18 Touche FUNCT

19 Touche DROITE

20 Touche MARCHE

21 Touche BAS

22 Touche ARRÊT

23 Touche GAUCHE

10

C.

23

22

15

BACK

RESET

16 17

21

OK

19

1413

18

20

FUNCT

FUNCT (18)

Utilisez cette touche pour inverser le sens

de rotation du moteur, accéder à la page

de commande et modifier la source de

commande.

Modification de la source de commande :

FUNCT

1.

2.

3.

4.

‘Local/Distance’

OK

‘Local’ ou ‘Distance’

OK

5.

Page 11

BORNES DE COMMANDE

Carte d'E/S standard

T

1. Bornes de connexion

d’E/S standard

2. Bornes des 3 sorties

3

relais ou 2 sorties

relais et une thermistance

3. Cartes en option

FR

1

Potentiomètre

de référen ce

1...10 kΩ

ransmetteur 2 fils

Valeur réelle

I = (0)4...20 mA

mA

MARCHE

1

2

3

4

5

24 Vsortie

6

7

8

9

10

11

24 Vsortie Tension auxiliaire 24 V

12

13

14

15

16

17

18

19

30

+24 Ventrée

A

B

21

22

23

24

25

26

32

33

2

Borne Type de signal Description

+10 Vref

AI1+

AI1-

AI2+

AI2-

GND Terre E/S

DI1

DI2 Entrée logique 2

DI3

CM

GND Terr

DI4

DI5

DI6

CM Commun pour DI1-DI6

AO1+

AO1-/GND

RS485 Bus série, négatif

RS485

RO1 NC

RO1 CM

RO1 NO

RO2 NC

RO2 CM

RO2 NO

RO3 CM

RO3 NO

Sortie de référence

Entrée analogique,

tension ou courant

Entrée analogique

commune, (courant)

Entrée analogique,

tension ou courant

Entrée analogique

commune, (courant)

Tension auxiliaire 24 V

Entrée logique 1

Entrée logique 3

Commun pour DI1-DI6

e E/S

Entrée logique 4

Entrée logique 5

Entrée logique 6

Signal analogique

(+ sortie)

Commun sortie

analogique / terre E/S

Tension entrée

auxiliaire 24 V

Bus série, positif

Sortie relais 1

Sortie relais 2

Sortie relais 3

Référence de fréquence

Référence de fréquence

Marche avant

Marche arri

Défaut externe

DI4 DI5 Ré f. fréquence

Ouvert Ouvert

Ouvert

Fermé

Ouvert

Fermé

Fermé

Fermé

Réarmement défaut

Fréquence de sortie

Modbus RTU

BACnet, N2

MARCHE

DÉFAUT

PRÊT

ère

Entrée analog. 1

Vitesse cste 1

Vitesse cste 2

Vitesse cste 3

*)

*)

11

Page 12

STRUCTURE DE MENU DE BASE

FR

principal

Configuration

Affichage

Paramètres

12

Menu

M1

rapide

M2

M3

Sous-menus

M1.1 Assistants

(le contenu dépend de P1.2,

Sél. applicatif)

M2.1 Multi-affichage

M2.2 Courbe tdce

M2.3 Base

M2.4 E/S

M2.5 Entrées temp.

M2.6 Extras/Avancé

M2.7 Fctions retardat

M2.8 Régulateur PID

M2.9 Régulateur PID ext.

M2.10 Multi-pompe

M2.11 Cptrs maintenance

M2.12 Donnée bus

M3.1 Param. moteur

M3.2 Cfg Marche/Arrêt

M3.3 Références

M3.4 Rampes/Freinages

M3.5 Configuration E/S

M3.6 Mappage données bus

M3.7 Fréq. interdite

M3.8 Supervisions

M3.9 Protections

M3.10 Réarmement

automatique

M3.12 Fctions retardat

M3.13 Régulateur PID

M3.14 Régulateur PID ext.

M3.15 Multi-pompe

M3.16 Cptrs maintenance

M3.17 Mode incendie

M3.18 Préchauff moteur

M3.20 Frein mécanique

M3.21 Commande de la

pompe

Menu

principal

M4

Diagnostics

M5

I/O and

Hardware

M6

Réglages utilis.

M7

Favoris

M8

Niveaux utilisat.

Sous-menus

M4.1 Défauts actifs

M4.2 Réarmemt défauts

M4.3 Historiq défauts

M4.4 Cpteurs sans RAZ

M4.5 Cpteurs avec RAZ

M4.6 Infos logiciel

M5.1 E/S et matériel

M5.2...M5.4

Emplacements C,D,E

M5.5 Horloge tps réel

M5.6 Régl.unit.puiss.

M5.7 Panneau opér.

M5.8 RS-485

M6.1 Sélection langue

M6.5 Sauvegarde param

M6.7 Nom convertiss.

M8.1 Niveaux utilisat.

M8.2 Code d’accès

Page 13

PREMIÈRE MISE EN SERVICE

L’assistant de mise en service vous demande de renseigner les données nécessaires pour

que convertisseur commande votre procédure.

La sélection est différente

1 Sélection de la langue (P6.1)

2 Heure d’été* (P5.5.5)

3 Heure* (P5.5.2) hh:mm:ss

4 Année* (P5.5.4) aaaa

5 Date* (P5.5.3) jj.mm.

* Vous pouvez voir ces étapes si une batterie est installée.

6 Exécuter l’Assistant de mise en service ?

Pour définir manuellement les valeurs des paramètres, sélectionnez Non et appuyez sur OK.

7 Sélection d’un applicatif (P1.2 Applicatif, ID212)

Spécifiez la valeur du paramètre P3.1.2.2 Type de moteur

8

(conformément à la plaque signalétique)

Spécifiez la valeur du paramètre P3.1.1.1 Tension nominale moteur

9

(conformément à la plaque signalétique)

Spécifiez la valeur du paramètre P3.1.1.2 Fréquence nominale

10

moteur (conformément à la plaque signalétique)

Spécifiez la valeur du paramètre P3.1.1.3 Vitesse nominale moteur

11

(conformément à la plaque signalétique)

12 Spécifiez la valeur du paramètre P3.1.1.4 Courant nominal moteur Plage : Variable

13 Spécifiez la valeur du paramètre P3.1.1.5 Cos phi moteur Plage : 0.30-1.00

Si la valeur de Type de moteur est Moteur à induction, l’étape suivante s’affiche. Si vous sélectionnez

Moteur AP, la valeur du paramètre P3.1.1.5 Cos Phi moteur est 1,00 et l’assistant passe directement

à l’étape 14.

Spécifiez la valeur du paramètre P3.3.1.1 Référence de fréquence

14

minimale

Spécifiez la valeur du paramètre P3.3.1.2 Référence de fréquence

15

maximale

16 Spécifiez la valeur du paramètre P3.4.1.2 Temps d’accélération 1 Plage : 0,1...300,0 s

17 Spécifiez la valeur du paramètre P3.4.1.3 Temps de décélération 1 Plage : 0,1...300,0 s

18 Démarrer l’Assistant d’applicatif ?

dans tous les packs

linguistiques

Russie

US

EU

OFF

Oui

Non

Standard

Local/Distance

Commande séquentielle

Régulation PID

Multi-configuration

Motopotentiomètre

Moteur à aimants

permanents (AP)

Moteur à induction

Moteur à réluctance

Plage : Variable

Plage : 8,00...320,00 Hz

Plage : 24...19200

Plage : 0,00...P3.3.1.2 Hz

Plage : P3.3.1.1...320,00 Hz

Oui

Non

FR

13

Page 14

STEUERTAFEL UND TASTENFELD

( 12 )

DE

A.

4 5 6 7 8

1

2

3

B.

12

STOP READY I/O

Main Menu

ID: M1

Quick Setup

( 17 )

Monitor

( 5 )

Parameters

9 10

11

A Das Grafik-Display

1 Das Positionsfeld

Aktivierte Gruppe oder aktiviertes

2

Element

Anzahl der Elemente in der

3

betreffenden Gruppe

Das erste Statusfeld: STOPP/

4

BETRIEB

5 Die Drehrichtung des Motors

Das zweite Statusfeld: BEREIT/

6

NICHT BEREIT/FEHLER

7 Das Alarmfeld

8 Das Steuerplatzfeld

B Das Text-Display

9 Die Statusanzeigen

10 Die Alarm- und Fehleranzeigen

Der Name der Gruppe oder des

11

Elements

12 Die aktuelle Position im Menü

13 Die Drehrichtungsanzeigen

14 Die Steuerplatzanzeigen

C Die Tasten des Tastenfelds

15 BACK/RESET-Taste

16 OK-Taste

17 Pfeiltaste NACH OBEN

18 FUNCT-Taste

19 Pfeiltaste NACH RECHTS

20 START-Taste

21 Pfeiltaste NACH UNTEN

22 STOP-Taste

23 Pfeiltaste NACH LINKS

14

C.

23

22

15

BACK

RESET

16 17

21

OK

19

1413

18

20

FUNCT

FUNCT (18)

Drehrichtung des Motors ändern,

Steuerungsseite aufrufen und Steuerplatz

ändern.

Ändern des steuerplatzes:

FUNCT

1.

2.

3.

4.

‘Ort/Fern’

OK

‘Ort’ oder ‘Fern’

OK

5.

Page 15

STEUERANSCHLÜSSE

Standard-E/A-Karte

1. Klemmen für die E/A

Standard anschlüsse

2. Klemmen für 3 Re-

3

laisausgänge oder 2

Relaisausgänge und

einen Thermistor

3. Optionskarten

DE

1

Sollwertpotentiome ter

1 bis 10 kΩ

2-Anschluss-Geber

Istwert

I = (0)4 bis 20 mA

mA

RUN

(BETRIEB)

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

30

A

B

21

22

23

24

25

26

32

33

2

Klemme Signal Beschreibung

+10 Vref

AI1+

AI1-

AI2+

AI2-

24 Vout

GND E/A Masse

DI1

DI2 Digitalei ngang 2

DI3

CM

24 Vout 24 V Hilfsspannung

GND E/A Masse

DI4

DI5

DI6

CM

AO1+

AO1-/GND

+24 Vin

RS485 Serieller Bus, negativ

RS485

RO1 NC

RO1 CM

RO1 NO

RO2 NC

RO2 CM

RO2 NO

RO3 CM

RO3 NO

Sollausgang

Analogeingang,

Spannung oder Strom

Gemeinsamer

Analogeingang, (Strom)

Analogeingang,

Spannung oder Strom

Gemeinsamer

Analogeingang, (Strom)

24 V Hilfsspannung

Digitalei ngang 1

Digitalei ngang 3

Gemeinsamer Bezug

für DI1-DI6

Digitalei ngang 4

Digitalei ngang 5

Digitalei ngang 6

Gemeinsamer

Bezug für DI1-DI6

Analogsignal

(+-Ausgang)

Gemeinsamer

Analogausgang / E/A-Masse

24 V

Hilfseingangsspannung

Serieller Bus, positiv

Relaisausgang 1

Relaisausgang 2

Relaisausgang 3

Frequenzsollwert

Frequenzsollwert

Sta

rt vorwärts

Start rückwärts

Externer Fehle r

DI4 DI5 Fre q.sollw.

Offen Offen

Geschlossen

Offen

Geschlossen

Fehlerquittierung

Analogeingang 1

Offen

Festfrequenz 1

Geschlossen

Festfrequenz 2

Geschlossen

Festfrequenz 3

Ausgangsfrequenz

Modbus RTU

BACnet, N2

RUN (BETRIEB)

FAULT (FEHLER)

READY (BEREIT)

*)

*)

15

Page 16

BASISMENÜSTRUKTUR

DE

Hauptmenü Untermenüs

M1

Schnellein-

stellungen

M2

Monitor

M3

Parameter

16

M1.1 Wizards

(Content depends on

P1.2, App select.)

M2.1 Multimonitor

M2.2 Trendkurve

M2.3 Basis

M2.4 E/A

M2.5 Temperat. Eingänge

M2.6 Extras/Erweitert

M2.7 Timerfunktionen

M2.8 PID-Regler

M2.9 Ext PID Controller

M2.10 Multi-Pump

M2.11 Wartungszähler

M2.12 Feldbusdaten

M3.1 Motoreinstellung

M3.2 Start/Stopp-Einst

M3.3 Sollwerte

M3.4 Rampen & Bremsen

M3.5 E/A-Konfiguration

M3.6 FB Datenzuordnung

M3.7 Freq.ausblendung

M3.8 Überwachungen

M3.9 Schutzfunktionen

M3.10 Automatische

Fehlerquittierung

M3.12 Timerfunktionen

M3.13 PID-Regler

M3.14 Ext. PID-Regler

M3.15 Multi-Pump

M3.16 Wartungszähler

M3.17 Brand-Modus

M3.18 Motor Vorheizung

M3.20 Mechanische

Bremse

M3.21 Pumpenregelung

Hauptmenü Untermenüs

M4

Fehlerspeicher

M5

E/A und

Hardware

M6

Benutzereinstell.

M7

Favoriten

M8

Anwendergruppen

M4.1 Aktive Fehler

M4.2 Fehler quittieren

M4.3 Fehlerspeicher

M4.4 Gesamtzähler

M4.5 RückstellbZähler

M4.6 Software-Info

M5.1 E/A und Hardware

M5.2 bis M5.4 St.pl.

C,D,E

M5.5 Echtzeituhr

M5.6 Leistungseinh.

Einst.

M5.7 Steuertafel

M5.8 RS-485

M6.1 Sprachwahl

M6.5 Parameter-Backup

M6.7 Name d. FU

M8.1 Anwendergruppe

M8.2 Zugangscode

Page 17

ERSTES ANLAUFEN

Der Anlaufassistent fordert Sie zur Eingabe der Daten auf, die der Umrichter zur Steuerung

Ihres Verfahrens benötigt.

1 Sprachenauswahl (P6.1)

2 Sommerzeit* (P5.5.5)

3 Zeit* (P5.5.2) hh:mm:ss

4 Jahr* (P5.5.4) JJJJ

5 Datum* (P5.5.3) tt.mm.

* Diese Schritte werden angezeigt, wenn eine Batterie eingebaut ist.

6 Anlaufassistenten ausführen?

Um die Parameterwerte manuell festzulegen, wählen Sie Nein bestätigen Sie mit OK.

7 Wählen Sie eine Anwendung (P1.2 Anwendung, ID212)

Stellen Sie den Wert für P3.1.2.2 Motortyp ein (siehe

8

Typenschild).

Stellen Sie den Wert für P3.1.1.1 Motornennspannung ein

9

(siehe Typenschild).

Stellen Sie den Wert für P3.1.1.2 Motornennfrequenz ein

10

(siehe Typenschild).

Stellen Sie den Wert für P3.1.1.3 Motornenndrehzahl ein

11

(siehe Typenschild).

12 Stellen Sie den Wert für P3.1.1.4 Motornennstrom ein. Bereich: variiert

13 Stellen Sie den Wert für P3.1.1.5 Motor Cos Phi ein. Bereich: 0.30-1.00

Wenn unter „Motortyp“ die Option Asynchronmotor ausgewählt wurde, wird der nächste Schritt

angezeigt. Falls PM-Motor ausgewählt wurde, wird für den Parameter P3.1.1.5 Motor Cos Phi der

Wert 1,00 eingestellt, und der Assistent fährt direkt mit Schritt 14 fort.

Stellen Sie den Wert für P3.3.1.1 Sollwert Mindestfrequenz

14

ein.

15 Stellen Sie den Wert für P3.3.1.2 Sollwert Höchstfrequenz ein. Bereich: P3.3.1.1 bis 320,00 Hz

16 Stellen Sie den Wert für P3.4.1.2 Beschleunigungszeit 1 ein. Bereich: 0,1 bis 300,0 s

17 Stellen Sie den Wert für P3.4.1.3 Bremszeit 1 ein. Bereich: 0,1 bis 300,0 s

18 Anwendungsassistenten ausführen?

Die Auswahl ist in

allen Sprachpaketen

unterschiedlich.

Russland

US

EU

AUS

Ja

Nein

Standard

Ort/Fern

Mehrstufige Drehzahl

PID-Regler

Mehrzweck

Motorpotentiometer

PM-Motor

Asynchronmotor

Reluktanzmotor

Bereich: variiert

Bereich: 8,00 bis 320,00 Hz

Bereich: 24...19200

Bereich: 0,00 bis P3.3.1.2 Hz

Ja

Nein

DE

17

Page 18

PANNELLO DI CONTROLLO E PANNELLO DI COMANDO

( 12 )

IT

A.

4 5 6 7 8

1

2

3

B.

12

STOP READY I/O

Main Menu

ID: M1

Quick Setup

( 17 )

Monitor

( 5 )

Parameters

9 10

11

A Il display grafico

1 Il campo della posizione

2 Un gruppo o un elemento attivato

Il numero di elementi nel gruppo in

3

questione

Il primo campo dello stato:

4

Arresto/Marcia

5 La direzione di rotazione del motore

Il secondo campo dello stato:

6

Pronto/Non pronto/Guasto

7 Il campo di allarme

8 Il campo della postazione di controllo

B Il display di testo

9 Gli indicatori di stato

10 Gli indicatori di allarme e guasto

11 Il nome del gruppo o dell’elemento

La posizione corrente nel menu

12

corrente

Gli indicatori della direzione di

13

rotazione

Gli indicatori della postazione di

14

controllo

C Pulsanti del pannello di comando

15 Pulsante BACK/RESET

16 Pulsante OK

17 Pulsante freccia Su

18 Pulsante FUNCT

19 Pulsante freccia Destra

20 Pulsante Avvio

21 Pulsante freccia Giù

22 Pulsante Arresto

23 Pulsante freccia Sinistra

18

C.

23

22

15

BACK

RESET

16 17

21

OK

19

1413

18

20

FUNCT

FUNCT (18)

Utilizzarlo per modificare la direzione di

rotazione del motore, per accedere alla

pagina di controllo e per scambiare le

postazioni di controllo.

Cambio della postazione di controllo:

FUNCT

1.

2.

3.

4.

‘Locale/Remoto’

OK

‘Locale’ o ‘Remoto’

OK

5.

Page 19

MORSETTI DI CONTROLLO

Scheda I/O standard

1. Morsetti per

connessioni I/O

standard

3

2. Morsetti per 3 uscite

relè o 2 uscite relè

e un termistore

3. Schede opzionali

IT

1

Potenziometro

di riferime nto

1 - 10 kΩ

Trasmettitore a 2 fili

Valore

effettivo

I = (0)4...20 mA

mA

MARCIA

Morsetto Segnale Descrizione

+10 Vref

1

2

AI1+

3

AI1-

4

AI2+

5

AI2-

24 Vout

6

7

GND Massa I/O

8

DI1

9

DI2 Ingresso digi

10

DI3

CM

11

24 Vout Tensione ausiliaria 24 V

12

GND Massa I/O

13

14

DI4

15

DI5

DI6

16

17

CM Comune per DI1-DI6

AO1+

18

19

AO1-/GND

30

+24 Vin

RS485 Bus seriale, negativo

A

B

RS485

21

RO1 NC

22

RO1 CM

23

RO1 NO

RO2 NC

24

25

RO2 CM

26

RO2 NO

32

RO3 CM

33

RO3 NO

2

Uscita di riferimento

Ingresso analogico,

tensione o corrente

Comune per ingresso

analogico (corrente)

Ingresso analogico,

tensione o corrente

Comune per ingresso

analogico (corrente)

Tensione ausiliaria 24 V

Ingresso digitale 1

Ingresso digitale 3

Comune per DI1-DI6

Ingresso digitale 4

Ingresso digitale 5

Ingresso digitale 6

Segnale uscita

analogica (+)

Comune per uscita

analogica/massa I/O

Tensione ingresso

ausiliario 24 V

Bus seriale, positivo

Uscita relè

Uscita relè 2

Uscita relè 3

tale 2

1

Riferimento di

frequenza

Riferimento di

frequenza

Marcia avanti

Marcia indietro

Guasto esterno

DI4 DI5 Ri f. freq.

Aperto Aperto

Chiuso

Aperto

Chiuso

Reset guasti

Ingresso anal. 1

Aperto

Vel prefissata 1

Chiuso

Vel prefissata 2

Chiuso

Vel prefissata 3

Frequenza di uscita

Modbus RTU

BACnet, N2

MARCIA

GUASTO

PRONTO

*)

*)

19

Page 20

STRUTTURA DI BASE DEI MENU

IT

Menu principale Sottomenu

M1

Config. rapida

M2

Monitor

M3

Parametri

M1.1 Proc Guidate

(il contenuto dipende

da P1.2, Selez. app)

M2.1 Multimonitor

M2.2 Curva trend

M2.3 Base

M2.4 I/O

M2.5 Ingressi

temperatura

M2.6 Extra/Avanzati

M2.7 Funzioni timer

M2.8 Controllore PID

M2.9 Controllore PIDEst

M2.10 Multi-pompa

M2.11 Manut. Contatori

M2.12 Dati bus campo

M3.1 Impostaz. motore

M3.2 Conf marcia/arr.

M3.3 Riferimenti

M3.4 Rampe e freni

M3.5 Configurazione I/O

M3.6 Mappatura dati FB

M3.7 Freq. proibita

M3.8 Supervisioni

M3.9 Protezioni

M3.10 Reset automatico

M3.12 Funzioni timer

M3.13 Controller PID

M3.14 Ctrl PIDEst

M3.15 Multi-pompa

M3.16 Contatori di manut.

M3.17 Fire mode

M3.18 Prerisc. motore

M3.20 FrenoMeccanico

M3.21 Controllo pompa

20

Menu principale Sottomenu

M4

Diagnostica

M5

I/O e

hardware

M6

Impostaz. utente

M7

Valori preferiti

M8

Livelli utente

M4.1 Guasti attivi

M4.2 Reset guasti

M4.3 Memoria guasti

M4.4 Contatori totali

M4.5 Contatori parziali

M4.6 Info software

M5.1 I/O e hardware

M5.2...M5.4 Slot C,D,E

M5.5 Orol. tmp reale

M5.6 Impost. unità pot.

M5.7 Pannello di comando

M5.8 RS-485

M6.1 Scelta della lingua

M6.5 Backup parametri

M6.7 Nome inverter

M8.1 Livello utente

M8.2 Codice accesso

Page 21

PRIMO AVVIO

La procedura guidata di avvio richiede l’inserimento dei dati necessari all’inverter per il

controllo della procedura.

IT

1 Scelta della lingua (P6.1)

2 Ora legale* (P5.5.5)

3 Ora* (P5.5.2) hh:mm:ss

4 Anno* (P5.5.4) aaaa

5 Data* (P5.5.3) gg.mm.

* Se è installata una batteria, vengono visualizzati i seguenti passaggi.

6 Eseguire la procedura guidata di avvio?

Per impostare manualmente i valori dei parametri, selezionare No e premere il pulsante OK.

7 Selezionare un’applicazione (P1.2 Applicazione, ID212)

Impostare un valore per P3.1.2.2 Tipo di motore (affinché

8

corrisponda alla targhetta)

Impostare un valore per P3.1.1.1 Tensione nominale del

9

motore (affinché corrisponda alla targhetta)

Impostare un valore per P3.1.1.2 Frequenza nominale del

10

motore (affinché corrisponda alla targhetta)

Impostare un valore per P3.1.1.3 Velocità nominale del

11

motore (affinché corrisponda alla targhetta)

Impostare un valore per P3.1.1.4 Corrente nominale del

12

motore

13 Impostare un valore per P3.1.1.5 Cosfi motore Gamma: 0.30-1.00

Se si imposta Tipo motore su Motore a induzione, viene visualizzato il passo successivo. Se si

seleziona Motore PM, il valore del parametro P3.1.1.5 Cosfi motore viene impostato su 1,00 e la

procedura guidata va direttamente al passo 14.

Impostare un valore per P3.3.1.1 Riferimento di frequenza

14

minima

Impostare un valore per P3.3.1.2 Riferimento di frequenza

15

massima

16 Impostare un valore per P3.4.1.2 Tempo di accelerazione 1 Gamma: 0,1...300,0 s

17 Impostare un valore per P3.4.1.3 Tempo di decelerazione 1 Gamma: 0,1...300,0 s

18 Eseguire la procedura guidata applicazione?

La selezione differisce in

tutti i pacchetti di lingue

Russia

US

UE

OFF

Sì

No

Standard

Locale/remoto

Velocità multi step

Controllore PID

Multifunzione

Motopotenziometro

Motore PM

Motore a induzione

Motore a riluttanza

Gamma: Varie

Gamma: 8,00...320,00 Hz

Gamma: 24...19200

Gamma: Varie

Gamma: 0,00...P3.3.1.2 Hz

Gamma: P3.3.1.1...320,00 Hz

Sì

No

21

Page 22

CUADRO DE CONTROL Y PANEL

( 12 )

ES

A.

4 5 6 7 8

1

2

3

B.

12

STOP READY I/O

Main Menu

ID: M1

Quick Setup

( 17 )

Monitor

( 5 )

Parameters

9 10

11

A La pantalla gráfica

1 El campo de ubicación

2 Un grupo o elemento activado

El número de elementos del grupo

3

en cuestión

El primer campo de estado:

4

PARO/MARCHA

5 El sentido de giro del motor

El segundo campo de estado:

6

LISTO/NO LISTO/FALLO

7 El campo de alarma

8 El campo del lugar de control

B La pantalla de texto

9 Los indicadores de estado

10 Los indicadores de alarmas y fallos

11 El nombre del grupo o elemento

12 La ubicación actual en el menú

13 Los indicadores del sentido de giro

14 Los indicadores del lugar de control

C Los botones del panel

15 El botón BACK/RESET

16 El botón OK

17 El botón de flecha ARRIBA

18 El botón FUNCT

19 El botón de flecha DERECHA

20 El botón START

21 El botón de flecha ABAJO

22 El botón STOP

23 El botón de flecha IZQUIERDA

22

C.

23

22

15

BACK

RESET

16 17

21

OK

19

1413

18

20

FUNCT

FUNCT (18)

Utilícelo para cambiar el sentido de giro

del motor, acceder a la página de control

y cambiar el lugar de control.

Cambio del lugar de control:

FUNCT

1.

2.

3.

4.

‘Local/Remoto’

OK

‘Local’ o ‘Remoto’

OK

5.

Page 23

TERMINALES DE CONTROL

Tarjeta de I/O estándar

T

1. Los terminales de

las conexiones de

I/O estándar

3

2. Los terminales de

tres salidas de relé

o dos salidas de relé

y un termistor

3. Las tarjetas

opcionales

ES

1

Potenciómetro

para referencia

1...10 kΩ

ransmisor de 2 cables

Valor actual

I = (0)4...20 mA

mA

MARCHA

Terminal Señal Descripción

+10 Vref

1

2

AI1+

3

AI1-

4

AI2+

5

AI2-

24 Vout

6

7

GND Tierra de I/O

8

DIN1

9

DIN2 Entrada digital 2

10

DIN3

CM

11

24 Vout Tensión auxiliar 24 V

12

TIERRA Tierra de I/O

13

14

DIN4

15

DIN5

DIN6

16

17

CM

AO1+

18

19

AO1-/GND

30

+24 Vin

RS485 Bus serie, negativo

A

B

RS485

21

RO1 NC

22

RO1 CM

23

RO1 NA

RO2 NC

24

25

RO2 CM

26

RO2 NA

32

RO3 CM

33

RO3 NA

2

Salida de referencia

Entrada analógica,

tensión o intensidad

Común de entrada

analógica

Entrada analógica,

tensión o intensidad

Común de entrada

analógica

Tensión auxil iar 24 V

Entrada digital 1

Entrada digital 3

Común para DIN1-DIN6

Entrada digital 4

Entrada digital 5

a digital 6

Entrad

Común para DIN1-DIN6

Salida analógica

(+salida)

Común de salida

analógica / Tierra I/O

Tensión de entrada

auxiliar 24 V

Bus serie, positivo

Salida de relé 1

Salida de relé 2

Salida de relé 3

Referencia

de frecuencia

Referencia

de frecuencia

Marcha directa

Marcha inversa

Fallo externo

ED4 ED5 Ref. de frec.

Abierto Abi erto

Cerrado

Abierto

Cerrado

Entrada analógica 1

Abie

rto

Frecuencia fija 1

Cerrado

Frecuencia fija 2

Cerrado

Reset de fallo

Frecuencia de salida

Frecuencia fija 3

Modbus RTU

BACnet, N2

MARCHA

FALLO

LISTO

*)

*)

23

Page 24

ESTRUCTURA BÁSICA DE MENÚS FIRST START-UP

ES

Guía rápida

Parámetros

24

Menú

principal

M1

M2

Monitor

M3

Submenús

M1.1 Asistentes (el contenido

depende de P1.2, Selecc.

aplicación)

M2.1 Multimonitor

M2.2 Gráficas

M2.3 Básico

M2.4 I/O

M2.5 Entradas Temperatura

M2.6 Extras/Avanzado

M2.7 Funciones de

temporizador

M2.8 Controlador PID

M2.9 Controlador PID externo

M2.10 Multibomba

M2.11 Contador

mantenimiento

M2.12 Datos de fieldbus

M3.1 Ajustes motor

M3.2 Modo Marcha/Paro

M3.3 Referencias

M3.4 Rampas y frenos

M3.5 Configuración de E/S

M3.6 Asignación datos FB

M3.7 Frec. prohibidas

M3.8 Supervisiones

M3.9 Protecciones

M3.10 Reset automático

M3.12 Funciones de

temporizador

M3.13 Controlador PID

M3.14 Ctrl. PID ext.

M3.15 Multibomba

M3.16 Mantenimiento

contadores

M3.17 Modo Anti-Incendio

M3.18 Caldeo Motor

M3.20 Freno mecánico

M3.21 Control bomba

Menú

principal

M4

Diagnóstico

M5

I/O

y hardware

M6

Ajustes de

usuario

M7

Favoritos

M8

Niveles

de usuario

Submenús

M4.1 Fallos activos

M4.2 Reset fallos

M4.3 Historial fallos

M4.4 Contadores total

M4.5 Cont. disparos

M4.6 Info software

M5.1 I/O y hardware

M5.2...M5.4 Ranuras

C,D,E

M5.5 Reloj tiemp real

M5.6 Ajustes

unidad de potencia

M5.7 Panel

M5.8 RS-485

M6.1 Selección de idioma

M6.5 Backup de

parámetros

M6.7 Nombre variador

M8.1 Nivel de usuario

M8.2 Código de acceso

Page 25

PRIMERA PUESTA EN MARCHA

El asistente de puesta en marcha le pide los datos necesarios para el convertidor con el fin

de controlar el procedimiento.

ES

1 Selección de idioma (P6.1)

2 Horario de verano* (P5.5.5)

3 Hora* (P5.5.2) hh:mm:ss

4 Año* (P5.5.4) aaaa

5 Fecha* (P5.5.3) dd.mm

* Si se ha instalado una batería, verá estos pasos.

6 ¿Iniciar el asistente de puesta en marcha?

Para establecer los valores de los parámetros manualmente, seleccione No y presione el botón OK.

7 Seleccionar una aplicación (P1.2 Aplicación, ID212)

Establecer un valor para P3.1.2.2 Tipo de motor (para que

8

coincida con la placa de características)

Establecer un valor para P3.1.1.1 Tensión nominal del motor

9

(para que coincida con la placa de características)

Establecer un valor para P3.1.1.2 Frecuencia nominal del

10

motor (para que coincida con la placa de características)

Establecer un valor para P3.1.1.3 Velocidad nominal del motor

11

(para que coincida con la placa de características)

Establecer un valor para P3.1.1.4 Intensidad nominal del

12

motor

13 Establecer un valor para P3.1.1.5 Cos phi motor Rango: 0.30-1.00

Si establece el tipo de motor en Motor Inducción, verá el siguiente paso. Si la selección es Imanes

permanentes, el valor del parámetro P3.1.1.5 Cos phi motor se establece en 1.00 y el asistente pasa

directamente al paso 14.

14 Establecer un valor para P3.3.1.1 Frecuencia mínima Rango: 0.00...P3.3.1.2 Hz

15 Establecer valor para P3.3.1.2 Frecuencia máxima Rango: P3.3.1.1...320,00 Hz

16 Establecer un valor para P3.4.1.2 Tiempo de aceleración 1 Rango: 0.1...300.0 s

17 Establecer un valor para P3.4.1.3 Tiempo de deceleración 1 Rango: 0.1...300.0 s

18 ¿Iniciar el Asistente de aplicación?

La selección es diferente

en todos los paquetes de

idiomas

Rusia

EE.UU.

UE

OFF

Sí

No

Estándar

Panel/Remoto

Multi-velocidad

Control PID

Multiobjetivo

Potenciómetro motorizado

Imanes permanentes

Motor Inducción

Motor de reluctancia

Rango: Varía

Rango: 8.00...320.00 Hz

Rango: 24...19200

Rango: Varía

Sí

No

25

Page 26

PT-

( 12 )

PAINEL DE CONTROLE E TECLADO

BR

A.

4 5 6 7 8

1

2

3

B.

12

STOP READY I/O

Main Menu

ID: M1

Quick Setup

( 17 )

Monitor

( 5 )

Parameters

9 10

11

A A exibição gráfica

1 O campo de localização

2 Um grupo ou item ativado

O número de itens no grupo em

3

questão

O primeiro campo de status:

4

PARADO/EM FUNCIONAMENTO

5 A direção de rotação do motor

O segundo campo de status:

6

PRONTO/NÃO PRONTO/FALHA

7 O campo de alarme

8 O campo de local de controle

B A exibição de texto

9 Os indicadores de status

10 Os indicadores de alarme e falha

11 O nome do grupo ou item

12 A localização atual no menu

13 Os indicadores da direção de rotação

14 Os indicadores do local de controle

C Os botões do teclado

15 O botão de voltar/redefinição

16 O botão OK

17 O botão de seta PARA CIMA

18 O botão FUNCT

19 O botão de seta PARA A DIREITA

20 O Botão INICIAR

21 O botão de seta PARA BAIXO

22 O botão PARAR

23 O botão de seta PARA A ESQUERDA

26

C.

23

22

15

BACK

RESET

16 17

21

OK

19

1413

18

20

FUNCT

FUNCT (18)

Use-o para alterar a direção de rotação

do motor, acessar a página de controle e

alterar o local de controle.

Alteração de local de controle:

FUNCT

1.

2.

3.

4.

‘Local/Remoto’

OK

‘Local’ ou ‘Remoto’

OK

5.

Page 27

TERMINAIS DE CONTROLE

Placa de E/S padrão

1. Terminais para as

conexões de E/S

padrão

3

2. Terminais para 3

saídas de relé ou 2

saídas de relé e um

termistor

3. Placas opcionais

PTBR

1

Potenciômetro

de referência

1...10kΩ

Transmissor de 2 fios

Valor real

I = (0)4...20mA

mA

RUN

Terminal Sinal Descrição

+10 Vref

1

2

AI1+

3

AI1-

4

AI2+

5

AI2-

24V saída

6

7

GND Terra E/S

8

DI1

9

DI2 Entrada digital 2

10

DI3

CM

11

24V saída Tensão auxiliar de 24V

12

GND Terra E/S

13

14

DI4

15

DI5

DI6

16

17

CM Comum para DI1-DI6

AO1+

18

19

AO1-/GND

30

+24V entrada

RS485

A

B

RS485

21

RO1 NC

22

RO1 CM

23

RO1 NO

RO2 NC

24

25

RO2 CM

26

RO2 NO

32

RO3 CM

33

RO3 NO

2

Saída de referência

Entrada analógica,

tensão ou corrente

Entrada analógica

comum, (corrente)

Entrada analógica,

tensão ou corrente

Entrada analógica

comum, (corrente)

Tensão auxiliar de 24V

Entrada digital 1

Entrada digital 3

Comum

para DI1-DI6

Entrada digital 4

Entrada digital 5

Entrada digital 6

Sinal analógico

(saída+)

Saída analógica

comum / terra E/S

Tensão de entrada

auxiliar de 24V

Barramento serial, negativo

Barramento serial, positivo

Saída de relé 1

Saída de relé 2

Saída de relé

Referência

de frequência

Referência

de frequência

Partida à frente

Partida reversa

Falha externa

DI4 DI5 Re f. freq.

Aberto Aberto

Aberto

Fechado

Aberto

Fechado

Fechado

Fechado

Reset de falha

Frequência de saída

Modbus RTU

BACnet, N2

RUN

FALHA

3

PRONTO

Entrada analógica 1

Freq. predefinida 1

Freq. predefinida 2

Freq. predefinida 3

*)

*)

27

Page 28

PT-

ESTRUTURA BÁSICA DO MENU

BR

principal

Configuração

Parâmetros

28

Menu

M1

rápida

M2

Monitor

M3

Submenus

M1.1 Assistentes

(o conteúdo depende

de P1.2, Seleção de

aplicativo)

M2.1 Multimonitor

M2.2 Curva de tendência

M2.3 Básico

M2.4 E/S

M2.5 Entradas de

temperatura

M2.6 Extras/Avançado

M2.7 Funções de

temporizador

M2.8 Controlador PID

M2.9 Controlador PID

externo

M2.10 Muitibomba

M2.11 Contador de

manutenção

M2.12 Dados do fieldbus

M3.1 Configurações do

motor

M3.2 Configuração de

Iniciar/Parar

M3.3 Referências

M3.4 Rampas e freios

M3.5 Configuração de E/S

M3.6 Mapeamento de

dados do FB

M3.7 Freq. proibida

M3.8 Supervisões

M3.9 Proteções

M3.10 Redefinição

automática

M3.12 Funções de

temporizador

M3.13 Controlador PID

M3.14 Controlador PID

externo

M3.15 Muitibomba

M3.16 Contadores de

manutenção

M3.17 Modo de fogo

M3.18 Preaquecimento do

motor

M3.20 Freio mecânico

M3.21 Controle de bomba

Menu

principal

M4

Diagnóstico

M5

E/S e

hardware

M6

Configurações

do usuário

M7

Favoritos

M8

Níveis de

usuário

Submenus

M4.1 Falhas ativas

M4.2 Redefinir falhas

M4.3 Histórico de falhas

M4.4 Contadores totais

M4.5 Contadores de

acionamento

M4.6 Informações de

software

M5.1 E/S e hardware

M5.2...M5.4 Slots C,D,E

M5.5 Relógio em tempo

real

M5.6 Configurações da

unidade de potência

M5.7 teclado

M5.8 RS-485

M6.1 Seleção de idioma

M6.5 Backup de

parâmetros

M6.7 Nome do conversor

M8.1 Nível de usuário

M8.2 Código de acesso

Page 29

PRIMEIRA INICIALIZAÇÃO

O Assistente de inicialização fornece a você os dados necessários para que o conversor

controle seu procedimento.

PTBR

1 Seleção de idioma (P6.1)

2 Horário de verão* (P5.5.5)

3 Hora* (P5.5.2) hh:mm:ss

4 Ano* (P5.5.4) aaaa

5 Data* (P5.5.3) dd.mm.

* Essas etapas serão exibidas se a bateria estiver instalada.

6 Executar Assistente de inicialização?

Para definir os valores dos parâmetros manualmente, faça a seleção Não e pressione o botão OK.

7 Faça a seleção de um aplicativo (P1.2 Aplicativo, ID212)

Defina um valor para P3.1.2.2 Tipo de motor (de forma que ele

8

corresponda à placa do motor)

Defina um valor para P3.1.1.1 Tensão nominal (de forma que

9

ele corresponda à placa do motor)

Defina um valor para P3.1.1.2 Frequência nominal (de forma

10

que ele corresponda à placa do motor)

Defina um valor para P3.1.1.3 Velocidade nominal (de forma

11

que ele corresponda à placa do motor)

12 Defina um valor para P3.1.1.4 Corrente nominal do motor Faixa: Varia

13 Defina um valor para P3.1.1.5 Cos Phi do motor Faixa: 0.30-1.00

Se você definir o Tipo de motor como Motor de indução, você verá a próxima etapa. Se a sua seleção

for Motor PM, o valor do parâmetro P3.1.1.5 Cos Phi do motor será definido como 1,00 e o assistente

pulará diretamente para a etapa 14.

Defina um valor para P3.3.1.1 Referência de frequência

14

mínima

Defina um valor para P3.3.1.2 Referência de frequência

15

máxima

16 Defina um valor para P3.4.1.2 Tempo de aceleração 1 Faixa: 0,1...300,0 s

17 Defina um valor para P3.4.1.3 Tempo de desaceleração 1 Faixa: 0,1...300,0 s

18 Executar o Assistente de aplicativo?

A seleção é diferente em

todos os pacotes de idioma

Rússia

EUA

UE

INATIVO

Sim

Não

Padrão

Local/Remoto

Velocidade multipasso

Controle de PID

Multifinalidade

Potenciômetro motorizado

Motor PM

Motor de indução

Motor de relutância

Faixa: Varia

Faixa: 8,00...320,00 Hz

Faixa: 24...19200

Faixa: 0,00...P3.3.1.2 Hz

Faixa: P3.3.1.1...320,00 Hz

Sim

Não

29

Page 30

控制面板和键盘

( 12 )

ZH

A.

4 5 6 7 8

1

2

3

B.

12

STOP READY I/O

ID: M1

Quick Setup

( 17 )

Monitor

( 5 )

Parameters

9 10

Main Menu

11

图形显示屏

A

位置字段

1

激活的组或项目

2

所述组中的项目数量

3

第一个状态字段

4

电机的旋转方向

5

第二个状态字段

6

警报字段

7

控制位置字段

8

文本显示屏

B

状态指示灯

9

警报和故障指示灯

10

的组或项目的名称

11

当前在菜单中的位置

12

旋转方向指示灯

13

控制位置指示灯

14

键盘上的按钮

C

“后退/重置”按钮

15

“确定”按钮

16

向上箭头按钮

17

FUNCT 按钮

18

向右箭头按钮

19

启动按钮

20

向下箭头按钮

21

停止按钮

22

向左箭头按钮

23

30

C.

23

22

15

BACK

RESET

16 17

21

OK

19

1413

18

20

FUNCT

FUNCT (18)

用于更改电机的旋转方 向、访问控制页面

和更改控制位置。有关 更多信息

更改控制位置:

FUNCT

1.

2.

3.

4.

‘本地/远程’

OK

‘本地’或 ‘远程’

OK

5.

Page 31

控制端子

I/O

1. 用于标准 I/O 连接

的端子

2. 用于 3 个继电器

3

输出或 2 个继电器

输出和 热敏电阻的

端子

3. 选件板

ZH

1

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

30

A

B

21

22

23

24

25

26

32

33

参考 电位计

1...10kΩ

2 线传送器

实际值

I = (0)4...20mA

mA

RUN

2

标准

端子 信 号

+10 Vref

AI1+

AI1-

AI2+

AI2-

24Vout

GND I/O 接地

DI1

DI2 数字 输入 2

DI3

CM

24Vout 24V 辅助电压

GND I/O 接地

DI4

DI5

DI6

CM DI1-DI6 共用

AO1+ 模 拟信号(+输出)

AO1-/GND

+24Vin

RS485 串 行 总线,负极

RS485

RO1 NC

RO1 CM

RO1 NO

RO2 NC

RO2 CM

RO2 NO

RO3 CM

RO3 NO

参考 输出

模 拟输入,电压或电流

公共模 拟输入(电流)

模 拟输入,电压或电流

公共 模 拟输入(电流)

24V 辅助电压

数字 输入 1

数字 输入 3

DI1-DI6 共用

数字 输入 4

数字 输入 5

数字 输入 6

公共 模 拟输出

/ I/O 接地

24V 辅助输入电压

串行 总线,正极

板

继电器输出

继电器输出

继电器输出

正向 启 动

反向 启 动

DI4 DI5 频率参考

打开 打开

关 闭

打开

关 闭

1

2

3

说明

频率参考

频率参考

外部 故障

打开

关 闭

关 闭

故障 重置

输出频率

Modbus RTU

BACnet, N2

RUN

FAULT

READY

模 拟输入 1

预设频率 1

预设频率 2

预设频率 3

*)

*)

31

Page 32

基本菜单结构

ZH

主菜 单 子菜 单

M1

快速 设置

M2

监控器

M3

参数

M1.1 向 导(内容取决

于 P1.2, 应用选择 )

M2.1 多重监控

M2.2 趋势曲线

M2.3 基本

M2.4 I/O

M2.5 温度输入

M2.6 其他/高 级值

M2.7 定 时器功能

M2.8 PID 控制器

M2.9 外部 PID 控制器

M2.10 多 泵

M2.11 维护计数 器

M2.12 现场总线数 据

M3.1 电机设置

M3.2 启动/停止 设置

M3.3 参考

M3.4 斜坡和制动

M3.5 I/O 配置

M3.6 FB 数据映射

M3.7 禁止频率

M3.8 监控

M3.9 保护

M3.10 自动重置

M3.12 定时器功能

M3.13 PID 控制器

M3.14 外部 PID 控制

M3.15 多 泵

M3.16 维护计数 器

M3.17 消防模式

M3.18 电机预热

M3.20 机械制动

M3.21 泵控制

主菜 单 子菜 单

M4

诊断

M5

I/O 和硬件

M6

用户设置

M7

收藏 夹

M8

用户级别

M4.1 活 动故障

M4.2 重置故障

M4.3 故障历史记录

M4.4 总计数器

M4.5 跳闸计数器

M4.6 软件信息

M5.1 I/O 和硬件

M5.2...M5.4

插槽 C、D、E

M5.5 实时时钟

M5.6 电源单元设 置

M5.7 键盘

M5.8 RS-485

M6.1 语言选择

M6.5 参数 备份

M6.7 变频器名 称

M8.1 用 户级别

M8.2 访问代码

32

Page 33

首次启动

启动向导可指导您为变频器提供必要的数据以便控制您的流程。

ZH

语言选择 (P6.1)

1

夏令时* (P5.5.5)

2

时间* (P5.5.2)

3

年* (P5.5.4)

4

日期* (P5.5.3)

5

* 如果已安装电池,则会显示这些步骤。

运行启动向导?

6

要手动设置参数值,请选择选项否并按 OK 按钮。

选择应用程序(P1.2 应用程序,ID212)

7

为 P3.1.2.2 电机类型设置一个值(使其与铭牌相符)

8

为 P3.1.1.1 电机标称电压设置一个值(使其与铭牌相符)

9

为 P3.1.1.2 电机标称频率设置一个值(使其与铭牌相符)

10

为 P3.1.1.3 电机标称速度设置一个值(使其与铭牌相符)

11

为 P3.1.1.4 电机标称电流设置一个值

12

为 P3.1.1.5 电机功率因数设置一个值

13

如果将电机类型设置为感应电机,则会显示下一个步骤。如果选择 永磁电机,则参数 P3.1.1.5

电机功率因数的值会被设置为 1.00,并且向导将直接跳转至步骤 14。

为 P3.3.1.1 最小频率参考设置一个值

14

为 P3.3.1.2 最大频率参考设置一个值

15

为 P3.4.1.2 加速时间 1 设置一个值

16

为 P3.4.1.3 减速时间 1 设置一个值

17

运行应用程序向导?

18

选项在所有语言包中各不

相同

俄罗斯

美国

欧洲

关

hh:mm:ss

yyyy

dd.mm.

是

否

标准

本地/远程

多级速度

PID 控制

多用途

电机电位计

永磁电机

感应电机

磁阻电机

范围:视情况变化

范围:8.00...320.00 Hz

范围:24...19200

范围:视情况变化

范围:0.30-1.00

范围:0.00...P3.3.1.2 Hz

范围:P3.3.1.1...320.00 Hz

范围:0.1…300.0 秒

范围:0.1…300.0 秒

是

否

33

Page 34

OHJAUSPANEELI

( 12 )

FI

A.

4 5 6 7 8

1

2

3

B.

12

STOP READY I/O

Main Menu

ID: M1

Quick Setup

( 17 )

Monitor

( 5 )

Parameters

9 10

11

A Graafinen paneeli

1 Sijaintikenttä

2 Valittu ryhmä tai kohde

3 Kohteiden lukumäärä ryhmässä

Ensimmäinen tilakenttä:

4

SEIS/KÄY

5 Pyörimissuunta

Toinen tilakenttä:

6

VALMIS / EI VALMIS / VIKA

7 Hälytyskenttä

8 Ohjauspaikka

B Tekstinäyttö

9 Tilan ilmaisimet

10 Hälytyksen ja vian ilmaisimet

11 Ryhmän tai kohteen nimi

12 Nykyinen sijainti valikossa

13 Pyörimissuunnan ilmaisimet

14 Ohjauspaikan ilmaisimet

C Ohjauspaneelin painikkeet

15 BACK/RESET-painike

16 OK-painike

17 Ylänuolipainike

18 FUNCT-painike

19 Oikea nuolipainike

20 Käynnistyspainike (Start)

21 Alanuolipainike

22 Pysäytyspainike (Stop)

23 Vasen nuolipainike

34

C.

23

22

15

BACK

RESET

16 17

21

OK

19

1413

18

20

FUNCT

FUNCT (18)

Tällä painikkeella voit muuttaa moottorin

pyörimissuuntaa, käyttää ohjaussivua ja

vaihtaa ohjauspaikan.

Paneelin valitseminen ohjauspaikaksi:

FUNCT

1.

2.

3.

4.

5.

‘Paikallisohjaus/etäohjaus’

OK

‘Paikallinen ohjaus’ tai

‘Etäohjaus’

OK

Page 35

OHJAUSLIITTIMET

1. Vakio-I/O-yhteyksien

ohjausliittimet

2. Liittimet kolmelle

3

relelähdölle

tai kahdelle

relelähdölle ja

termistorille

3. Lisäkortit

FI

1

Viitepotentiometri

1...10kΩ

Kaksijohdi nlähetin

Oloarvo

I = (0)4–20 mA

mA

KÄY

2

Liitin Signaali Kuvaus

1

+10 Vref

2

AI1+

3

AI1-

4

AI2+

5

AI2-

6

24 V:n lähtö

7

GND I/O maa

8

DI1

9

DI2 Digitaali tulo 2

10

DI3

CM

11

24 V:n lähtö 24 V:n apujännite

12

GND I/O maa

13

14

DI4

15

DI5

DI6

16

17

CM

AO1+

18

19

AO1-/MAA

30

+24 V:n tulo 24 V:n aputulojännite

RS485 Sarjaväylä, negatiivinen

A

B

RS485

21

RO1 NC

22

RO1 CM

23

RO1 NO

RO2 NC

24

25

RO2 CM

26

RO2 NO

32

RO3 CM

33

RO3 NO

Vakiolaaje nnuskortti

Ohjausjännite lähtö

Analogiatul o,

jännite tai vi rta

Yhteinen

analogiatulo (vi rta)

Analogiatul o,

jännite tai vi rta

Yhteinen

analogiatulo (vi rta)

24 V:n apujännite

Digitaalitul o 1

Digitaalitul o 3

einen tuloille DI1–DI6

Yht

Digitaalitul o 4

Digitaalitul o 5

Digitaalitul o 6

Yhteinen tuloille DI1–DI6

Analogialähtö ( +)

Yhteinen analogialähtö

/ I/O-maa

Sarjaväylä, positiivinen

Relel ähtö 1

Relel ähtö 2

Relel ähtö 3

Taajuusohje

Taajuusohje

Käy ete

en

Käy taakse

Ulkoinen vi ka

DI4 DI5 Taaj.ohje

Auki Auki

Kiinni

Auki

Kiinni

Vian kuittaus

Auki

Kiinni

Kiinni

Lähtötaajuus

Modbus RTU

BACnet, N2

KÄY

VIKA

VALMIS

Analogiatulo 1

Vakionopeus 1

Vakionopeus 2

Vakionopeus 3

*)

*)

35

Page 36

PERUSVALIKKORAKENNE

FI

Päävalikko Alivalikot

M1

Nopea

käyttöönotto

M2

Valvonta

M3

Parametrit

36

M1.1 Ohjatut toiminnot

(sisältö vaihtelee

parametrin P1.2 (Sovellus)

valinnan mukaan)

M2.1 Monivalvonta

M2.2 Trendikäyrä

M2.3 Perus

M2.4 I/O

M2.5 Lämpötilatulot

M2.6 Lisävalvonnat/

kehittyneet

M2.7 Ajastintoiminnot

M2.8 PID-säädin

M2.9 Ulkoinen PID-säädin

M2.10 Monipumppu

M2.11 Huoltolaskuri

M2.12 Kenttäväylädata

M3.1 Moottoriasetukset

M3.2 Käynnistys/

Pysäytysasetukset

M3.3 Ohjearvot

M3.4 Rampit ja jarrut

M3.5 I/O-konfiguraatio

M3.6 KV kartoitus

M3.7 Estotaajuudet

M3.8 Valvonnat

M3.9 Suojaukset

M3.10 Automaattinen

viankuittaus

M3.12 Ajastintoiminnot

M3.13 PID-säädin

M3.14 Ulkoinen PID-säädin

M3.15 Monipumppu

M3.16 Huoltolaskurit

M3.17 Fire Mode

M3.18 Moottorin

esilämmitys

M3.20 Mekaaninen jarru

M3.21 Pumpun ohjaus

Päävalikko Alivalikot

M4

Viat ja tiedot

M5

I/O ja laitteisto

M6

Käyttöasetukset

M7

Suosikit

M8

Käyttäjäryhmät

M4.1 Aktiiviset viat

M4.2 Kuittaa viat

M4.3 Vikahistoria

M4.4 Laskurit

M4.5 Väliaikalaskurit

M4.6 Ohjelmistotiedot

M5.1 I/O ja laitteisto

M5.2...M5.4 Paikat C, D, E

M5.5 Reaaliaika

M5.6 Tehoyksikön

asetukset

M5.7 Paneeli

M5.8 RS-485

M6.1 Kielivalinnat

M6.5 Parametrien aut.tall.

M6.7 Taajuusmuutt. nimi

M8.1 Käyttäjäryhmä

M8.2 Käyttäjäkoodi

Page 37

ENSIMMÄINEN KÄYNNISTYS

Ohjatut asetukset -toiminto kehottaa antamaan tiedot, joita taajuusmuuttaja tarvitsee

voidakseen ohjata toimintoja.

FI

1 Kielivalinta (P6.1)

2 Kesäaika* (P5.5.5)

3 Aika* (P5.5.2) hh:mm:ss

4 Vuosi* (P5.5.4) vvvv

5 Päivämäärä* (P5.5.3) pp.kk.

* Nämä vaiheet tulevat näkyviin, jos akku on asennettuna.

6 Käynnistä Ohjatut asetukset?

Jos haluat asettaa parametrien arvot manuaalisesti, valitse Ei ja paina OK-painiketta.

7 Valitse sovellus (P1.2 Sovellus, ID 212)

Aseta parametrin P3.1.2.2. (Moottorin tyyppi) arvo vastaamaan

8

moottorin arvokilven tietoja.

Aseta parametrin P3.1.1.1. (Moottorin nimellisjännite) arvo

9

vastaamaan moottorin arvokilven tietoja.

Aseta parametrin P3.1.1.2. (Moottorin nimellistaajuus) arvo

10

vastaamaan moottorin arvokilven tietoja.

Aseta parametrin P3.1.1.3. (Moottorin nimellisnopeus) arvo

11

vastaamaan moottorin arvokilven tietoja.

12 Aseta parametrin P3.1.1.4 (Moottorin nimellisvirta) arvo. Alue: Vaihtelee

13 Aseta parametrin P3.1.1.5 (Moottorin tehokerroin) arvo. Alue: 0.30-1.00

Jos moottorityypiksi valitaan Induktiomoottori, seuraava vaihe tulee näkyviin. Jos valinta on

Kestomagneettimoottori, parametrin P3.1.1.5 (Moottorin tehokerroin) arvoksi asetetaan 1,00 ja

Ohjatut asetukset -toiminto siirtyy suoraan vaiheeseen 14.

14 Aseta parametrin P3.3.1.1 (Minimitaajuusohje) arvo. Alue: 0,00–P3.3.1.2 Hz

15 Aseta parametrin P3.3.1.2 (Maksimitaajuusohje) arvo. Alue: P3.3.1.1–320,00 Hz

16 Aseta parametrin P3.4.1.2 (Kiihdytysaika 1) arvo. Alue: 0,1–300,0 s

17 Aseta parametrin P3.4.1.3 (Hidastusaika 1) arvo. Alue: 0,1–300,0 s

18 Käynnistä ohjattu sovellustoiminto?

Valinta on erilainen eri

kielipaketeissa.

Venäjä

US

EU

POIS

Kyllä

Ei

Vakio

Paikallisohjaus/etäohjaus

Multi-Step-nopeus

PID-ohjaus

Erikoiskäyttö

Moottoripotentiometri

Kestomagneettimoottori

Induktiomoottori

Reluktanssimoottori

Alue: Vaihtelee

Alue: 8,00–320,00 Hz

Alue: 24...19200

Kyllä

Ei

37

Page 38

DISPOSAL / MISE AU REBUT / ENTSORGUNG / SMALTIMENTO /

EN

ELIMINACIÓN / DESCARTE / 处置 / HÄVITTÄMINEN

FR

DE

Do not dispose of equipment containing electrical components together

IT

ES

PTBR

ZH

FI

with domestic waste. Collect it separately in accordance with local and

currently valid legislation.

Ne mettez pas les équipements contenant des composants électriques

au rebut avec les déchets domestiques. Collectez-les

séparément conformément aux législations locales en vigueur.

Entsorgen Sie keine Geräte, die elektrische Bauteile enthalten, im

Hausmüll. Sammeln Sie diese separat gemäß den lokalen und aktuell

geltenden Gesetzen.

Non smaltire le apparecchiature contenenti componenti elettrici insieme

ai rifiuti domestici. Smaltirle separatamente conformemente alla

normativa locale vigente.

38

No elimine equipos que contengan componentes eléctricos junto al resto

de los desechos domésticos. Separe los residuos conforme a

la normativa local vigente.

Não descarte equipamentos que contenham componentes elétricos junto

com o lixo doméstico. Colete separadamente de acordo com a legislação

local e atualmente válida.

请勿将含有电气组件的设备与生活垃圾一起处置。请按照适用的地方法规

单独回收。

Älä hävitä sähkökomponentteja sisältävää tuotetta tavallisen

kunnallisjätteen mukana. Lajittele ja kierrätä se erikseen noudattamalla

paikallisia ja muita voimassaolevia määräyksiä.

Page 39

Page 40

Download and read VACON® 100 Wall-mounted Drives Operating Guide at

Téléchargez et lisez le manuel d’installation de VACON® 100, convertisseurs de fréquence à montage mural, sur :

Lesen Sie die Bedienungsanleitung für den VACON® 100, frequenzumrichter zur wandmontage, das zum

Download bereitsteht unter:

Scaricare e leggere il Manuale di installazione VACON® 100, inverter a muro, all’indirizzo:

Descargue y lea el Manual de instalación de VACON® 100, unidades de montaje en pared, en:

Baixe e leia o Manual de Instalação do VACON® 100, conversores de frequência montados na parede, em:

可在以下位置下载和阅读 VACON® 100 壁挂式变频器安装手册:

Lataa ja lue VACON® 100 seinäkiinnitteiset taajuusmuuttajat käyttöohje:

www.danfoss.com -> Service and support -> Documentation

DPD01657D

Loading...

Loading...