vacon • 2

INDEX

Document: DPD00169A

Version release date: 13.8.09

Safety ....................................................................................................................... 3

Danger ......................................................................................................................................... 3

Warnings ..................................................................................................................................... 4

Earthing and earth fault protection ............................................................................................5

LonWorks - general info ..........................................................................................6

LonWorks technical data ..........................................................................................7

General ........................................................................................................................................ 8

Physical media and wiring .......................................................................................................... 9

Profiles ........................................................................................................................................ 9

Variable speed profile ................................................................................................................. 9

Layout, connections and installation ...................................................................... 9

LonWorks OPT-C4 option board ............................................................................................... 9

Connections .............................................................................................................................. 9

LED indications ......................................................................................................................... 10

Installation ............................................................................................................................... 11

Prepare for use through LonWorks ......................................................................................... 13

Commissioning ...................................................................................................... 16

I/O and Hardware menu (M5) ................................................................................................... 16

LonWorks board parameters ................................................................................................... 16

LonWorks interface ...............................................................................................17

XIF file .......................................................................................................................................17

General ......................................................................................................................................17

Input Network Variables ...........................................................................................................19

Output network variables .........................................................................................................22

Network configuration variables ..............................................................................................24

Fault tracing ..........................................................................................................26

Typical fault conditions .............................................................................................................26

Quick Setup ............................................................................................................27

Tel. +358 (0) 201 2121 • Fax +358 (0)201 212 205

Safety vacon • 3

1. SAFETY

This manual contains clearly marked cautions and warnings which are intended for your personal safety and to avoid any unintentional damage to the product or connected appliances.

Please read the information included in cautions and warnings carefully.

The cautions and warnings are marked as follows:

= DANGER! Dangerous voltage

= WARNING or CAUTION

= Caution! Hot surface

Table 1. Warning signs

1.1 Danger

The components of the power unit of Vacon 100 are live when the AC drive is

connected to mains potential. Coming into contact with this voltage is extremely

dangerous and may cause death or severe injury.

The motor terminals U, V, W and the brake resistor terminals are live when

Vacon 100 is connected to mains, even if the motor is not running.

After disconnecting the AC drive from the mains, wait until the indicators on the

keypad go out (if no keypad is attached see the indicators on the cover). Wait 5

more minutes before doing any work on the connections of Vacon100. Do not

open the cover before this time has expired. After expiration of this time, use a

measuring equipment to absolutely ensure that no

ensure absence of voltage before starting any electrical work!

The control I/O-terminals are isolated from the mains potential. However, the

relay outputs and other I/O-terminals may have a dangerous control voltage

present even when Vacon 100 is disconnected from mains.

Before connecting the AC drive to mains make sure that the front and cable covers of Vacon 100 are closed.

voltage is present.

Always

During a ramp stop (see the Application Manual), the motor is still generating

voltage to the drive. Therefore, do not touch the components of the AC drive

before the motor has completely stopped. Wait until the indicators on the keypad

go out (if no keypad is attached see the indicators on the cover). Wait additional 5

minutes before starting any work on the drive.

24-hour support +358 (0)40 837 1150 • Email: vacon@vacon.com

1

vacon • 4 Safety

1.2 Warnings

Vacon 100 AC drive is meant for fixed installations only.

Do not perform any measurements when the AC drive is connected to the mains.

The earth leakage current of Vacon 100 AC drives exceeds 3.5mA AC. According

to standard EN61800-5-1, a reinforced protective ground connection must be

ensured. See chapter 1.3.

If the AC drive is used as a part of a machine, the machine manufacturer is

responsible for providing the machine with a supply disconnecting device (EN

60204-1).

Only spare parts delivered by Vacon can be used.

At power-up, power brake or fault reset the motor will start immediately if the

start signal is active, unless the pulse control for

Futhermore, the I/O functionalities (including start inputs) may change if parameters, applications or software are changed.Disconnect, therefore, the motor if

an unexpected start can cause danger.

Start/Stop logic has been selected

.

The motor starts automatically after automatic fault reset if the auto restart

function is activated. See the Application Manual for more detailed information.

Prior to measurements on the motor or the motor cable, disconnect the motor

cable from the AC drive.

Do not touch the components on the circuit boards. Static voltage discharge may

damage the components.

Check that the EMC level of the AC drive corresponds to the requirements of

your supply network.

1

Tel. +358 (0) 201 2121 • Fax +358 (0)201 212 205

Safety vacon • 5

1.3 Earthing and earth fault protection

CAUTION!

The Vacon 100 AC drive must always be earthed with an earthing conductor connected to the

earthing terminal marked with .

The earth leakage current of Vacon 100 exceeds 3.5mA AC. According to EN61800-5-1, one or

more of the following conditions for the associated protective circuit shall be satisfied:

a) The protective conductor shall have a cross-sectional area of at least 10 mm2 Cu or 16

mm2 Al, through its total run.

b) Where the protective conductor has a cross-sectional area of less than 10 mm2 Cu or

16 mm2 Al, a second protective conductor of at least the same cross-sectional area

shall be provided up to a point where the protective conductor has a cross-sectional

area not less than 10 mm2 Cu or 16 mm2 Al.

c) Automatic disconnection of the supply in case of loss of continuity of the protective

conductor.

The cross-sectional area of every protective earthing conductor which does not form part of

the supply cable or cable enclosure shall, in any case, be not less than:

-2.5mm

-4mm

The earth fault protection inside the AC drive protects only the drive itself against earth faults

in the motor or the motor cable. It is not intended for personal safety.

Due to the high capacitive currents present in the AC drive, fault current protective switches

may not function properly.

2

if mechanical protection is provided or

2

if mechanical protection is not provided.

Do not perform any voltage withstand tests on any part of Vacon 100. There is a

certain procedure according to which the tests shall be performed. Ignoring this

procedure may result in damaged product.

24-hour support +358 (0)40 837 1150 • Email: vacon@vacon.com

1

vacon • 6 LonWorks - general info

2. LONWORKS - GENERAL INFO

Vacon 100 frequency converters can be connected to the LonWorks® network using a fieldbus

board. The converter can then be controlled, monitored and programmed from the Host system.

LONWORKS technology has been developed by Echelon Corporation. LONWORKS network is

used in applications like industry and building automation, controlling household electronics,

medical instrumentation and many others. The target of the LONWORKS network is to provide

a common vendor independent communication network for intelligent devices.

In a LONWORKS network, no central control or master-slave architecture is needed. Nodes on

a network communicate with each other using LonTalk® protocol. Interoperable nodes use

Standard Network Variable Types (SNVT) for communicating over the network. The definition

of an SNVT includes units, a range, and an increment. Vacon option board uses only Standard

Network Variable Types for the data types.

All network variables are either input (data is coming from the network to the device) or output

(data is sent to the network by the device) network variables. When network variables on different nodes on the network have been bound together by an installation tool, passing of data

is automatic between the right nodes. Only the same type of network variables can be bound

together, so it is very important to have compatible interfaces.

2

If you need further information related to LonWorks, please contact fieldbus@vacon.com

Tel. +358 (0) 201 2121 • Fax +358 (0)201 212 205

LonWorks technical data vacon • 7

3. LONWORKS TECHNICAL DATA

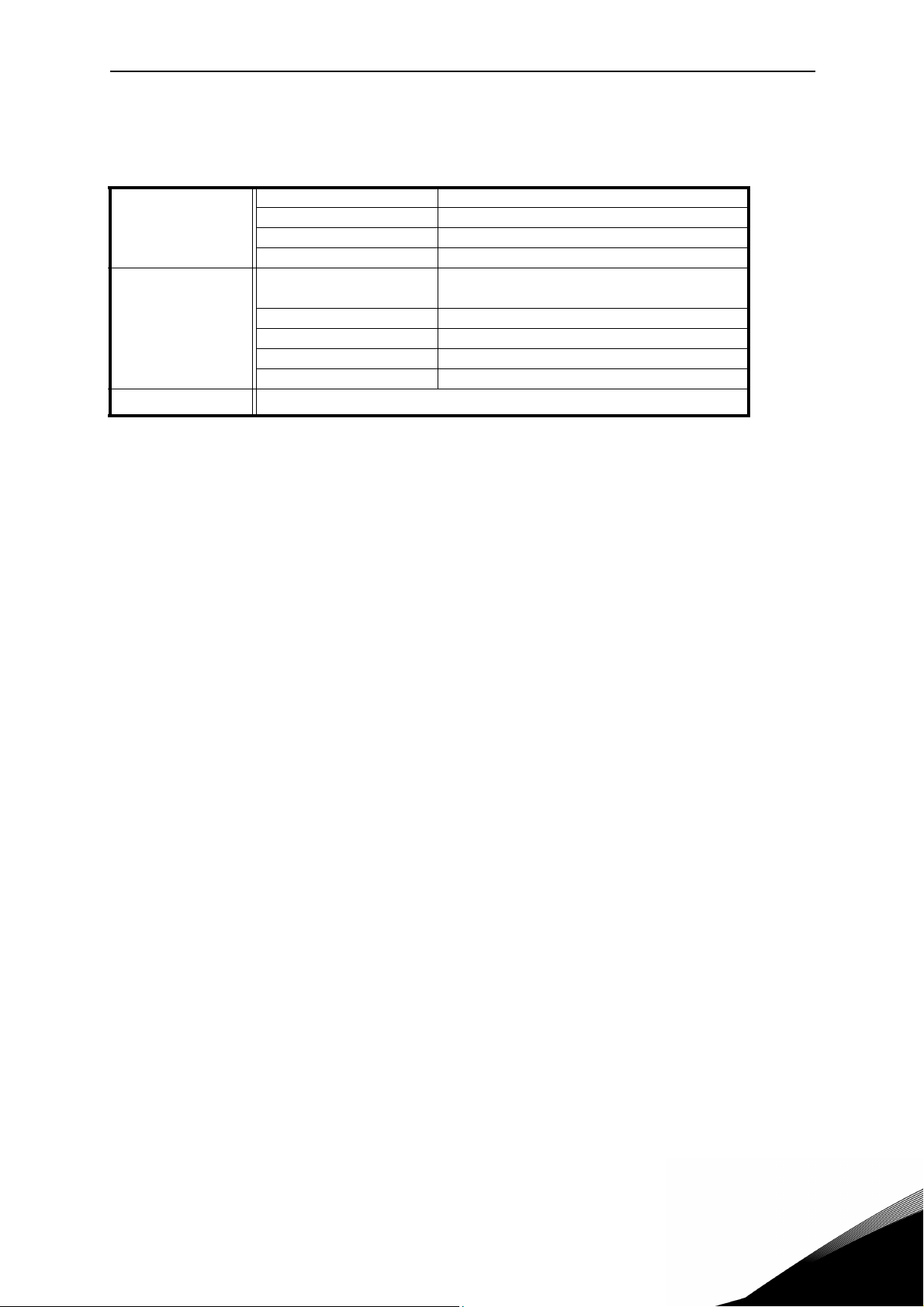

3.1 General

Interface Pluggable connector (5 mm)

Connections and

communications

Environment

Safety Fulfils EN50178 standard

Channel type TP/FT-10

Transfer cable Shielded Twisted Pair

Baud rate 78 Kbit/s

Ambient operating

temperature

Storing temperature -40°C…70°C

Humidity <95%, no condensation allowed

Altitude Max. 1000 m

Vibration 0.5 G at 9…200 Hz

-10°C…50°C

Table 2.

24-hour support +358 (0)40 837 1150 • Email: vacon@vacon.com

3

vacon • 8 LonWorks technical data

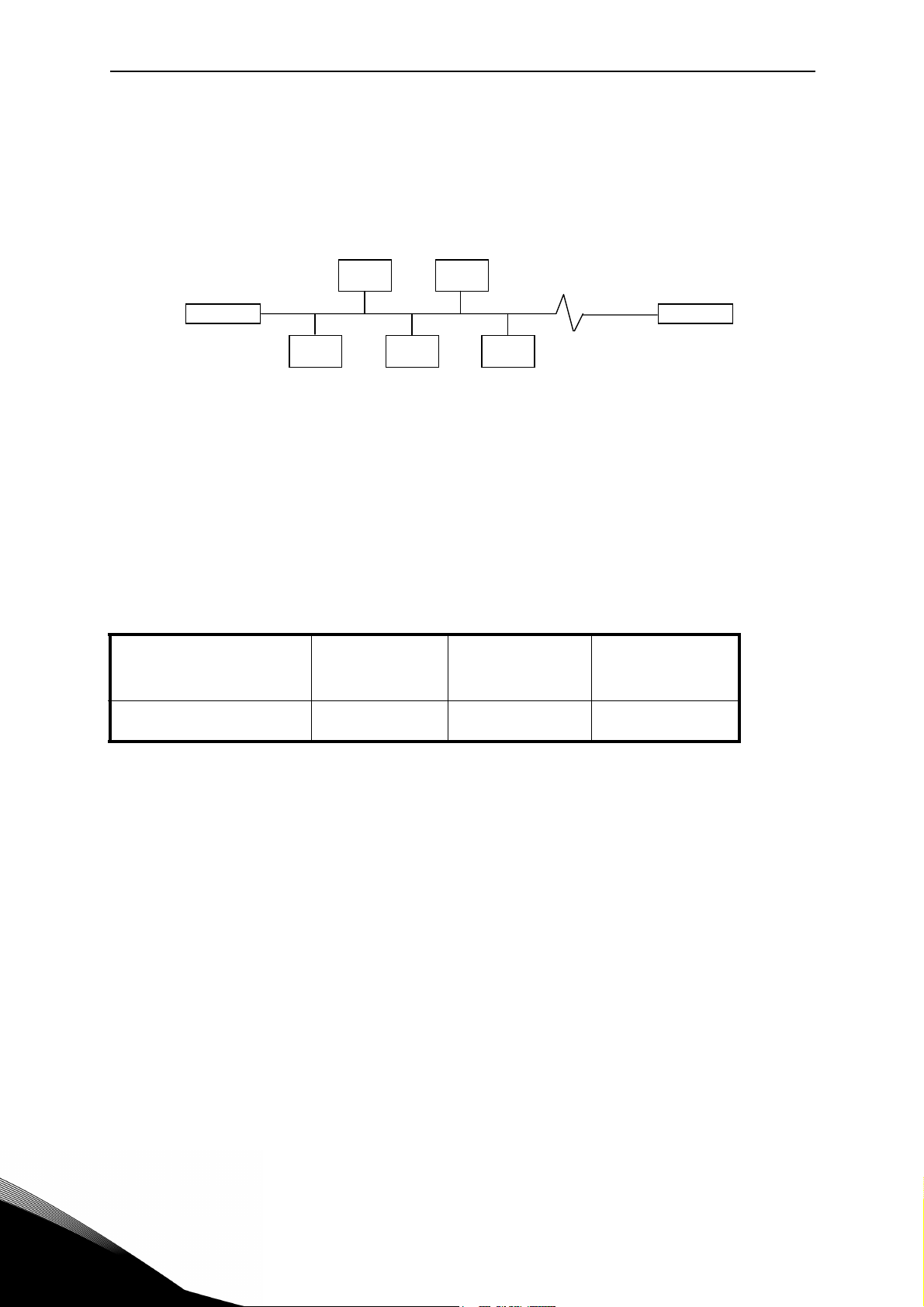

3.2 Physical media and wiring

LONWORKS networks can be implemented on many different physical media. Vacon OPT-C4 option

board is equipped with an FT-X1 transceiver supporting the Free Topology transformer coupled network, which allows the network wire to be connected as bus, star, loop or combination of these. This

media reaches a communication speed of 78kBits/s. The FT-X1 transceiver is compatible with Echelon's LPT-10 Link Power Transceiver, and these transceivers can communicate with each other on a

single twisted pair cable.

Termination Termin ation

Figure 1. Doubly terminated bus topology

The doubly terminated bus topology is recommended to be used. However, also singly termiated, star or loop topologies can be used with OPT-C4 option board.

Up to 64 FTT-10 transceiver nodes are allowed per network segment, the individual segments

can be connected together by a router. See Table 3 for possible cable types and cable lengths

for FTT-10. Even if unshielded cable types are possible to be used with this type of transceiver,

it is still highly recommended to use only shielded cables with frequency converters. Attention should be paid to proper grounding of the shield to ensure bus operation. Grounding of the

shield should be done at both ends of the cable.

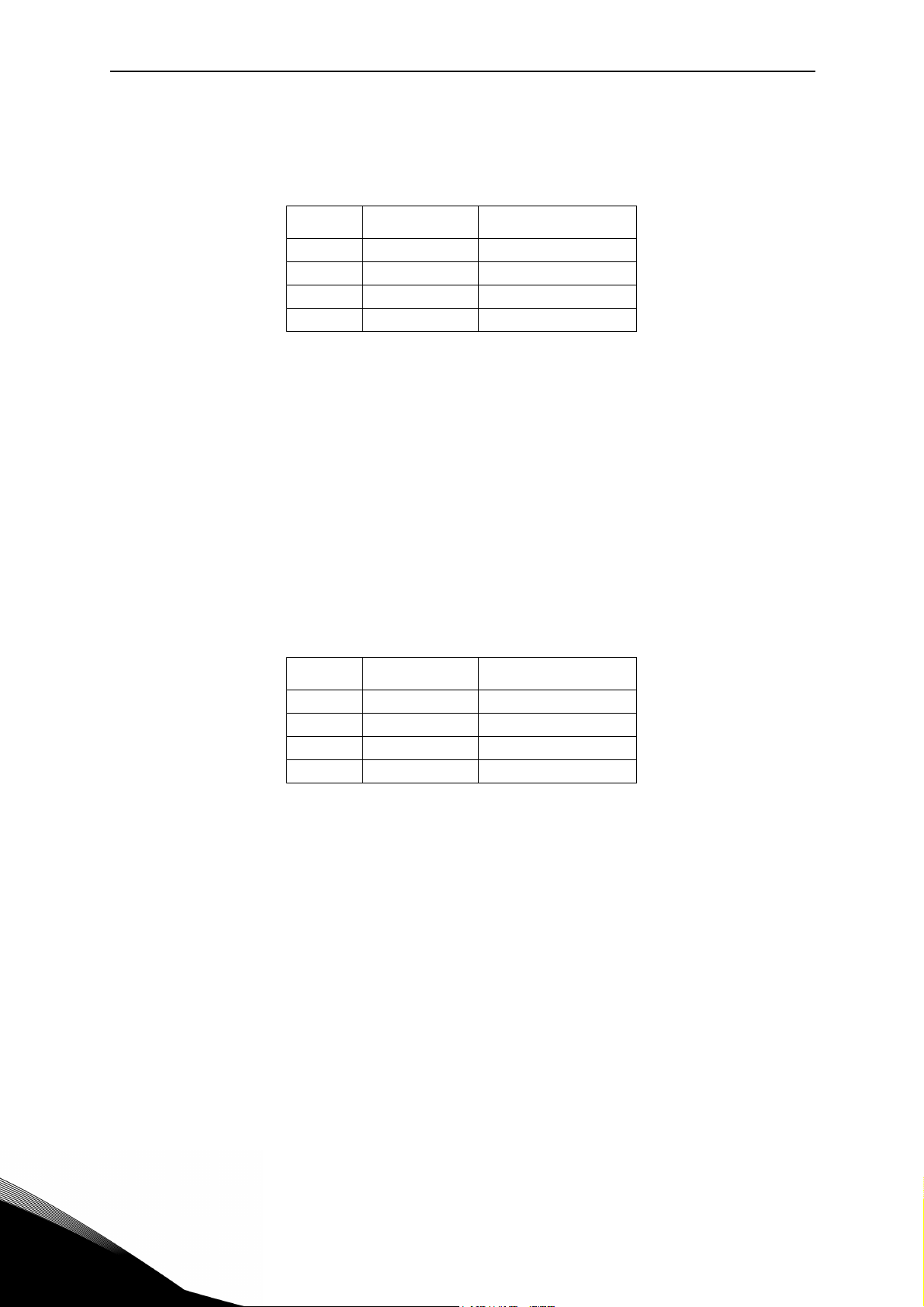

Cable type

JY (St) Y 2x2x0.8mm

LONAK 2x2x0,8 (shielded)

Max. doubly

terminated bus

length

900 m 500 m 320 m

Table 3.

Max. free

topology wire

length

Max. node-to-

node

distance

3.3 Profiles

LonMark Functional Profiles describe in detail the application layer interface, including the

network variables, configuration properties, and default and power-up behaviors required on

LonMark devices for specific, commonly used control functions.

3.3.1 Variable speed profile

Leading manufacturers of drive technology have jointly defined the LonMark profile. The profile specifies how the drives are to be parameterized and how the setpoints and actual values

are to be transmitted. This enables drives from different vendors to be exchanged. The profile

contains necessary specifications for speed control and positioning. It specifies the basic drive

functions while leaving sufficient freedom for application-specific expansions and further developments.

3

.

Tel. +358 (0) 201 2121 • Fax +358 (0)201 212 205

Layout, connections and installation vacon • 9

4. LAYOUT, CONNECTIONS AND INSTALLATION

Vacon LonWorks Fieldbus Board is connected to the fieldbus through 3-pin pluggable bus connector. The communication with the control board takes place through the standard Vacon Interface Board Connector.

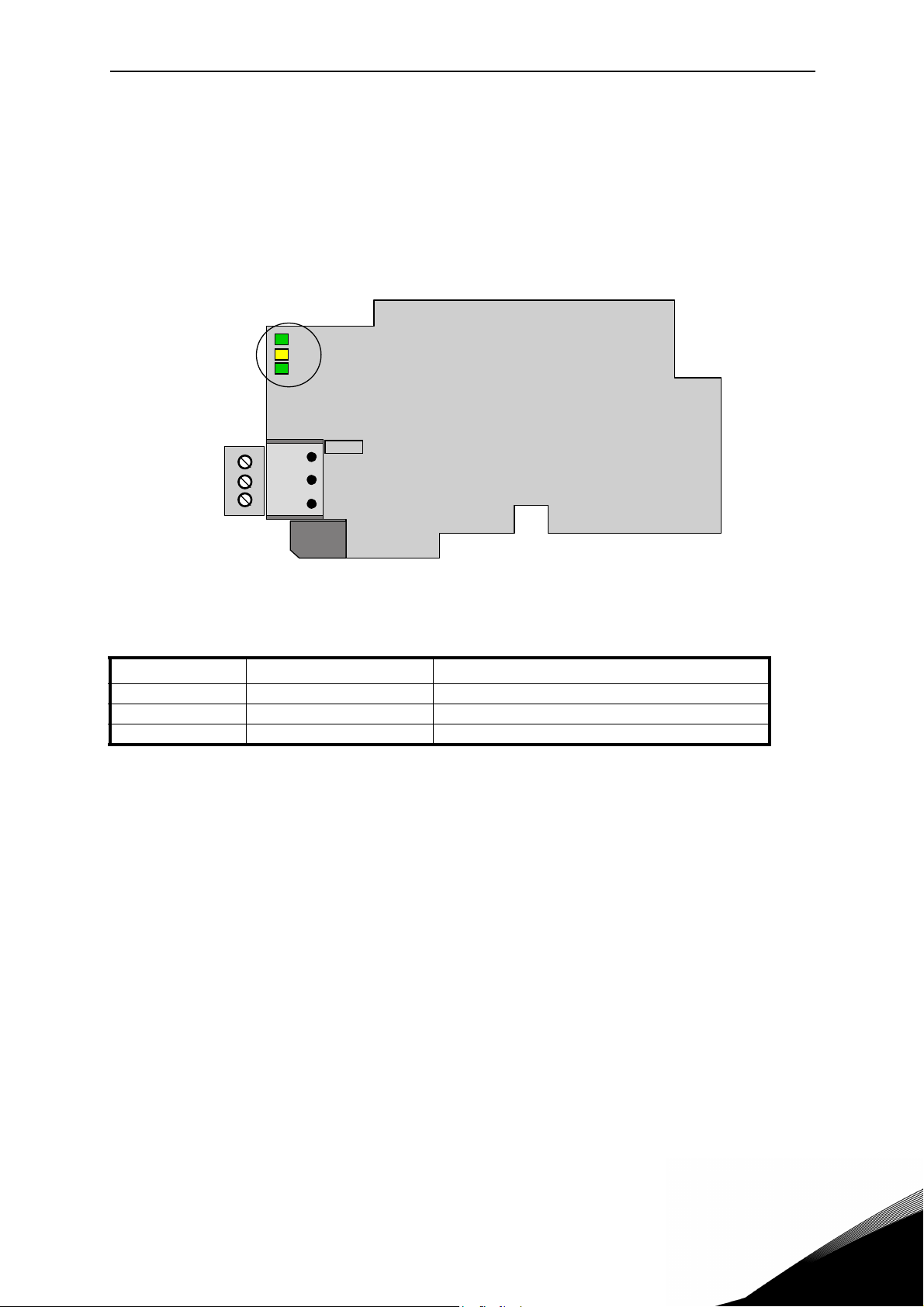

4.1 LonWorks OPT-C4 option board

H3

H2

H1

21

X5

22

23

Figure 2.

4.1.1 Connections

Signal Connector Description

A1 21 Data

A2 22 Data

Shield 23 Shield

Table 4.

24-hour support +358 (0)40 837 1150 • Email: vacon@vacon.com

4

vacon • 10 Layout, connections and installation

4.1.2 LED indications

The three LED indications (see Figure 2) next to the connector show the present statuses of the

Neuron (green H3), the LonWorks board (yellow H2) and the Fieldbus Module (green H1). From

the user's viewpoint, the first two are the most significant.

Neuron status (H3) GREEN

LED is Meaning: State code

OFF Configured 4

ON Applicationless and Unconfigured 3

Flashing Unconfigured 2

Board status LED (H2) YELLOW

LED is Meaning:

OFF Option board not activated

ON

Blinking fast

(once/1 s)

Blinking slow

(once/5 s)

Option board in initialisation state waiting for activation command from the frequency converter

Option board is activated and in RUN state

Option board is ready for external communication

Option board is activated and in FAULT state

Internal fault on option board

Bus status LED (H1) GREEN

LED is Meaning:

Fieldbus module is activated

OFF

ON

Blinking very fast

for 5s (once/0.2 s)

Blinking fast

(once/1 s)

Blinking slow

(once/5 s)

Parameters received and module activated

Module is waiting for messages from the bus

Fieldbus module is activated

Parameters received and module activated

Module is waiting for messages from the bus

Fieldbus module has received a wink request

Module is activated and receiving messages from the bus

Module is in FAULT state

No messages from Net within the watchdog time

Bus broken, cable loose

4

Tel. +358 (0) 201 2121 • Fax +358 (0)201 212 205

Layout, connections and installation vacon • 11

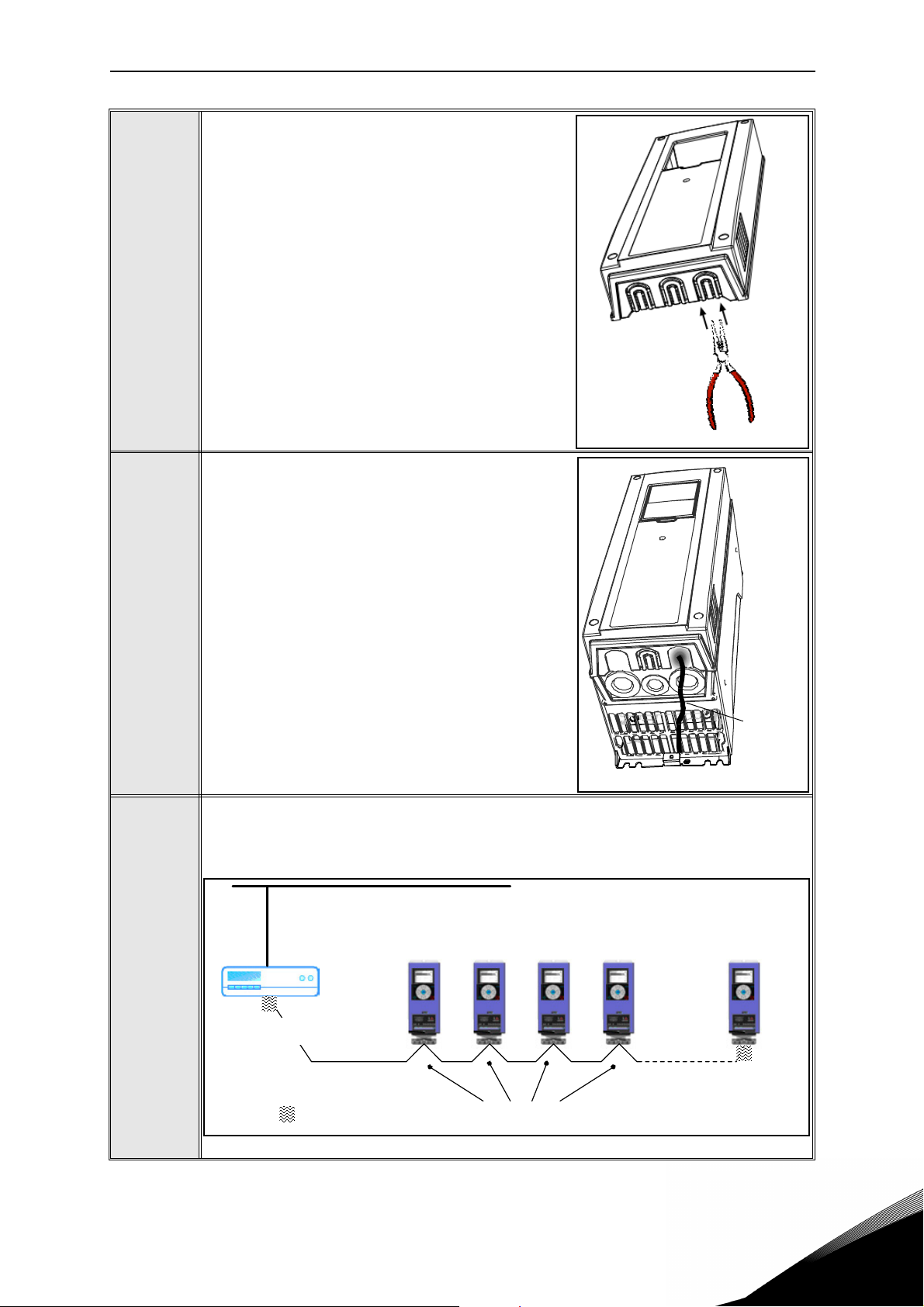

4.2 Installation

Open the cover of the AC drive.

1

DANGER

The relay outputs and other I/O-terminals may have a dangerous control voltage

present even when Vacon 100 is disconnected from mains.

24-hour support +358 (0)40 837 1150 • Email: vacon@vacon.com

4

vacon • 12 Layout, connections and installation

Make sure that the sticker on the connector of the board says “dv” (dual voltage).

This indicates that the board is compatible with Vacon 100. See below:

2

21

22

23

Slot coding

NOTE: Incompatible boards cannot be installed on Vacon 100. Compatible

boards have a slot coding that enable the placing of the board (see above)

Open the inner cover (1) to reveal the option board slots (D,E) and install the

fieldbus board (2) into slot D or E. Close the inner cover. See Figure below.

1

2

D

E

3

4

Tel. +358 (0) 201 2121 • Fax +358 (0)201 212 205

Layout, connections and installation vacon • 13

4.3 Prepare for use through LonWorks

Strip about 15 mm of the fieldbus cable (see specification on page 9) and cut off

the grey cable shield. Remember to do this for both bus cables (except for the

last device).

Leave no more than 10 mm of the cable outside the terminal block and strip the

cables at about 5 mm to fit in the terminals. See picture below.

10

5

4

Also strip the cable now at such a distance from the terminal that you can fix it to

the frame with the grounding clamp. Strip the cable at a maximum length of 15

mm. Do not strip the aluminum cable shield!

5

Then connect the cable to its appropriate terminals on LonWorks Option Board

terminal block.

21 22 23

Data 1

Shield

Data 2

Fieldbus cable

24-hour support +358 (0)40 837 1150 • Email: vacon@vacon.com

4

vacon • 14 Layout, connections and installation

Using the cable clamp included in the delivery of the drive, ground the shield of

the LonWorks cable to the frame of the AC drive.

Cable clamp

6

If Vacon 100 is the last device on the bus, the bus termination must be set. To

assure a proper data transmission, termination of the network segments is

required. Depending on the type of network, either one or two terminations are

necessary. Free topology network segment requires only one termination

whereas a doubly terminated bus topology requires two.

The jumper X5 on the Vacon LonWorks board must be set accordingly.

• Use 94-ohm termination resistance when only one termination is needed

• 47-ohm termination resistance for two terminations

See also step 10 on page 17.

7

21

22

23

H3

H2

H1

X5

47

94

no termination

Ω

Ω

X5

4

Tel. +358 (0) 201 2121 • Fax +358 (0)201 212 205

Layout, connections and installation vacon • 15

Unless already done for the other control cables,

cut free the opening on the AC drive cover for the

fieldbus cable (protection class IP21).

NOTE: Cut the opening on the same side you

have installed the board in!

8

Remount the AC drive cover and run the cable as

shown in picture.

NOTE: When planning the cable runs, remember

to keep the distance between the fieldbus cable

and the motor cable at a minimum of 30 cm.

9

10

Fieldbus

cable

The bus termination must be set for the first and the last device of the fieldbus

line. See picture below. See also step 7 on page 16. We recommend that the first

device on the bus and, thus, terminated was the Master device.

Vacon 100 Vacon 100 Vacon 100 Vacon 100 Vacon 100

Terminat ion

activated

LonWorks cable

= Bus termination

Terminatio n

deactivated

Termination

activated

jum per X5

with

24-hour support +358 (0)40 837 1150 • Email: vacon@vacon.com

4

vacon • 16 Commissioning

5. COMMISSIONING

Please read first the commissioning chapter in Vacon 100 HVAC Installation manual (Download the latest version of the manual on www.vacon.com).

5.1 I/O and Hardware menu (M5)

The I/O and Hardware menu makes it possible for the user

1) to see what expander boards are connected to the control board and

2) to reach and edit the parameters associated with the expander board.

3) Software information

The navigation path to the fieldbus parameters may differ from application to application. The

exemplary paths below apply to the Vacon 100 HVAC drive.

1. Set fieldbus parameters (M5.x.3). See below.

Navigate: Main Menu > I/O and Hardware (M5) > OPTC4 (M5.x) > parame-

ters (M.x.3) > Select parameter > Edit

2. Select

OR

3. Choose source of reference.

‘Fieldbus control’ as the Remote Control Place.

Navigate: Main Menu > Quick Setup (M1) > Rem. Ctrl. Place (P1.15)

Navigate: Main Menu > Parameters (M3) > Start/Stop Setup (M3.2) > Rem.

Ctrl. Place (P3.2.1)

Navigate: Main Menu > Parameters (M3) > References (M3.3)

5.2 LonWorks board parameters

Code Parameter Min Max Unit Default ID Description

M5.x.3.1 Service Pin 0 1 0

Broadcasts a service pin

message to the network

5

Tel. +358 (0) 201 2121 • Fax +358 (0)201 212 205

LonWorks interface vacon • 17

6. LONWORKS INTERFACE

Features of the LonWorks interface:

• Direct control of Vacon 100 (e.g. Run, Stop, Direction, Speed reference, Fault reset)

• Full access to all Vacon 100 parameters

• Monitor Vacon 100 status (e.g. Output frequency, Output current, Fault code)

6.1 XIF file

XIF file tells network-management tools how to communicate and recognize a device. It can be

downloaded from www.vacon.com, and it is also included with the shipped Support CD. It contains Program ID, NVs, CPs, functional blocks, etc.

6.2 General

Node Object:0

nviRequest

nv1

SNVT_obj_request

Mandatory

nv oSta tus

Network

nv2

SNV T_o bj_s tatu s

Variables

Figure 3. The node object diagram

24-hour support +358 (0)40 837 1150 • Email: vacon@vacon.com

6

vacon • 18 LonWorks interface

Variable Speed Motor drive:

6010

nv iDrv Spee dStp t

nv1

SNV T_o bj_r equ est

nviDrvSpeedScale

nv2

SNVT _levP erce nt

nviRstFault

nv8

SNVT_switch

nviCrlCntr

nv9

SNVT_switch

nviProc essIN1

nv1 0

SNVT_lev_percent

nviProcessIN2

nv11

S NVT_ lev _per cent

nviProcessIN3

nv12

S NVT_ lev _per cent

nviProcessIN4

nv13

S NVT_ lev _per cent

nviProcessIN5

nv1 4

SNVT_lev_percent

nviProcessIN6

nv1 5

SNVT_lev_percent

nviProcessIN7

nv16

S NVT_l ev _per cent

nviProcessIN8

nv17

S NVT_l ev _per cent

nv18

nv19

nv20

nv21

nv22

nv23

nv2 4

nv25

nv26

nviDigitalIn1

SNVT_switch

nviDigitalIn2

SNVT_switch

nviDigitalIn3

SNVT_switch

nviDigitalIn4

SNVT_switch

nviDigitalIn5

SNVT_switch

nviDigitalIn6

SNVT_switch

nviDigitalIn7

SNV T_swi tch

nviDigitalIn8

SNVT_switch

nviParCmd

SNVT_reset

Mandatory

Network

Variables

Optional

Network

Variables

Configuration properties

nc50 nciMaxSpeed

nc53 nciMinSpeed

nc48 nciRcvHrtBt

nc49 nciSndHrtBt

nc52 nciMinOutTm

nc158 nciNmlSpeed

nc158 nciNmlFreq

nc160 nciRampUpTm

nc161 nciRampDownTm

nc162 nciDrvSpeedScal e

Manufacturer

Defined

Network

Variables

nvoDrvSpeed

nv4

SNVT_levPercent

nviRequest

nv1

SNVT_obj_request

nviRequest

nv1

SNVT_obj_request

nvi Req uest

nv1

SNVT _ob j_r eque st

nv2 7

nv2 8

nv2 9

nv oPro cess Out1

nv30

SNVT_lev_percent

nv oPro cess Out2

nv3 1

SNV T_l ev_ per cent

nvoProcessOut3

nv3 2

S NVT_l ev _per cent

nvoProcessOut4

nv3 3

S NVT_ lev _per cent

nvoProcessOut5

nv3 4

S NVT_l ev _per cent

nvoProcessOut6

nv3 5

S NVT_l ev _per cent

nvo Proc ess Out7

nv36

SNVT_lev_percent

nvo Proc ess Out8

nv37

SNVT_lev_percent

nvoDigitalOut1

nv3 8

SNVT_switch

nvoDigitalOut2

nv3 9

SNVT_switch

nvoDigitalOut3

nv40

SNVT_switch

nv oDi gita lOut 4

nv41

SNV T_swi tch

nvoDigitalOut5

nv42

SNVT_switch

nv oDi gita lOut 6

nv43

SNV T_swi tch

nvoDigitalOut7

nv44

SNVT_switch

nvo Dig italO ut8

nv4 5

SNVT_ swi tch

nv oPar Resp

nv46

SNVT_preset

nvo DrvSt atu s

SNVT_ sta te

nvoDrvStatus

SNVT_stat e

nvoActFault

SNVT_count

6

Figure 4. The Variable Speed Motor Drive object diagram

Tel. +358 (0) 201 2121 • Fax +358 (0)201 212 205

LonWorks interface vacon • 19

6.3 Input Network Variables

Function Variable Name SNVT Type Min. value

Node Object request nviRequest SNVT_obj_request

Driver speed setpoint nviDrvSpeedStpt SNVT_switch n / a n / a

Driver set point speed

scaling

Reset fault nviRstFault SNVT_switch n / a n / a

Clear kWh trip or Drive

total running hours trip

counters

Process In Data nviProcessIn1..8 SNVT_lev_percent 0 65535

Digital Inputs nviDigitalIn1..8 SNVT_switch 0 4

Parameter Set nviParCmd SNVT_preset n / a n / a

nviDrvSpeedScale SNVT_lev_percent -163.840% 163.830%

nviClrCntr SNVT_switch 1 2

Table 5. Input network variables

Max.

value

nviRequest

This input network variable provides the mechanism to request a particular mode for the Node

object or the Variable Speed Motor Drive object within a node. Supported requests are

RQ_NORMAL, RQ_UPDATE_STATUS, RQ_CLEAR_STATUS, RQ_REPORT_MASK,

RQ_DISABLED, RQ_ENABLE and RQ_CLEAR_ALARM.

nviDrvSpeedStpt

This input network variable provides control and a low resolution speed setpoint.

State Value Command

0NA Stop

10 0%

1 1 to 200 0.5 to 100%

1 201 to 255 100.0%

0xFF NA Auto

Table 6.

nviDrvSpeedScale

This input netork variable provides scaling for nviDrvSpeedStpt. Negative values indicate a motor direction in reverse. For example, if the nviDrvSpeedStpt value is 50% and nviDrvSpeedScale -150%, then the actual speed setpoint is -75%, or 0.75 times the nominal speed in

reverse direction. The valid range is -163,840% to 163,830. The value 0x7FFF (+163,835%) will

be handled as an invalid value. Default value is determined by nciDrvSpeedScale. This value

will be adopted at power-up and in case of not receiving an update within the specified Receive

Heartbeat time.

24-hour support +358 (0)40 837 1150 • Email: vacon@vacon.com

6

vacon • 20 LonWorks interface

nviRstFault

This input network variable provides a fault reset. Setting value 1 for State and a non-zero value for Value will reset an active fault in Vacon 100. Default value is 0; 0

State Value Command

0 any no action (0; 0)

1 0 no action (0; 1)

1 > 0 reset fault (200 ; 0)

-1(0xFF) any invalid (no action)

Table 7.

nviClrCntr

This input network variable provides a mechanism to clear the kWh trip counter or the Drive

total running hours trip counter.

1 = MWh trip counter

2 = Operation day trip counter

nviProcessIn1..8

These input network variables are sent directly to the application (see more detailed explanation in chapter 6.5 Process data) The valid range is 0 to 65535 (-163,840 to 163,835).

nviDigitalIn1..8

These input network variables are sent directly to the application (see more detailed explanation in chapter 6.5 Process data) Default value is 0; 0.

State Value Command

0 any off (0; 0)

1 0 off (0; 1)

1 > 0 on (200 ; 0)

-1(0xFF) any invalid (no action)

Table 8.

6

Tel. +358 (0) 201 2121 • Fax +358 (0)201 212 205

LonWorks interface vacon • 21

nviParCmd

This input network variable is used to read and write the parameters. The parameter addresses are determined in the application. Every parameter and actual value has been given an ID

number in the application. The ID numbering of the parameter as well as the parameter ranges

and steps can be found in the application manual in question. The parameter value must be given without decimals. Find the ID numbers of each parameter/actual value in the application

manual. The ID numbers are grouped as follows:

Parameter ID Group Description

0 Not used

1 … 98 Actual Values

37 Active Fault Code

100 Not used

101… 899 Parameter

900 … 999 Reserved

1000 Not used

1001…1999 Parameter

Reserved for LonWorks board

internal usage

Table 9.

Examples

Data format in examples is:

- learn selector <byte(3) byte(2) byte(1) byte(0)> day hour minute second millisecond

x = meaningless

Example1

Write to parameter number 102 (Max frequency "HVAC Application par. ID102") value 4500

(45Hz).

Write command to nviParSet

- LN_LEARN_CURRENT 102 <x x 11 94> x x x x

If the write command is successful then nvoParOut value is

- LN_LEARN_CURRENT 102 <0 0 11 94> 0 0 0 0

If the write command fails then nvoParOut value is

- LN_NUL 102 <0 0 11 94> 0 0 0 0

Example2

Read parameter number 112 (Nominal speed of the motor "HVAC Application par. ID112") default value 1440 (1440 rpm).

Read command to nviParSet

- LN_RECALL 112 <x x x x> x x x x

If the read command is successful then nvoParOut value is

- LN_RECALL 112 <0 0 5 A0> 0 0 0 0

If the read command fails then nvoParOut value is

- LN_ LN_NUL 112 <0 0 0 0> 0 0 0 0

24-hour support +358 (0)40 837 1150 • Email: vacon@vacon.com

6

vacon • 22 LonWorks interface

6.4 Output network variables

Function Variable Name SNVT Type Min. Value Max. Value

Node Object status nvoStatus SNVT_obj_status

Drive speed feedback nvoDrvSpeed SNVT_lev_percent -163.840% +163.830%

Actual motor current nvoDrvCurnt SNVT_amp 0.0A 3276.7A

Actual drive power nvoDrvPwr SNVT_power_kilo 0,0 kW 6553,5 kW

Drive total running

hours

Status word nvoDrvStatus SNVT_state n/a n/az

kWh trip counter nvoDrvEnrgy SNVT_elect_kwh 0kWh 65535kWh

Active fault code nvoActFault SNVT_count 0 41

Process Out nvoProcessOut1..8 SNVT_ lev_percent 0 65535

Digital Out nvoDigitalOut1..8 SNVT_switch 0 4

Parameter Out nvoParResp SNVT_preset

NvoStatus

This output network variable reports the status for Node object or Variable Speed Motor Drive

object

nvoDrvRunHours SNVT_time_hour 0 h 65535

Table 10. Output network variables

Field Description

object_id ID of object within node

invalid_id

invalid_request

disabled 1 means object disabled

1 means requested ID is not

implemented in this node

1 means request for unimplemented function

6

electrical_fault 1 means drive is faulted

in_alarm 1 means drive is in alarm

report_mask 1 means status is an event mask

Table 11.

nvoDrvSpeed

This output network variable provides the speed of the drive as a percentage of the nominal

speed.

nvoDrvCurnt

This output network variable provides the drive output current in amperes.

nvoDrvPwr

This output network variable provides the drive output power in kW.

Tel. +358 (0) 201 2121 • Fax +358 (0)201 212 205

LonWorks interface vacon • 23

nvoDrvRunHours

This output network variable provides the drive resettable operation time counter for the motor in running hours. The maximum value for used SNVT is 65535 h. On the frequency converter

the value can go much higher. If the counter exceeds the SNVT's maximum value, the network

variable stays at its maximum. In such cases the real value can be seen on Vacon 100 HVAC

operating keypad.

nvoDrvStatus

This output network variable provides the drive status.

Bit Description

Value = 0 Value = 1

0 Not Ready Ready

1 FC stopped Running

2 Clockwise Counterclockwise

3 No fault Fault active

4 No warning Warning active

5 Reference not Actual value Reference = Actual value

Table 12. Status word bit descriptions

nvoDrvEnrgy

This output network variable provides the drive resettable energy consumption counter. The

maximum value for used SNVT is 65535 kWh. On the frequency converter the value can go

much higher. If the counter exceeds the SNVT's maximum value, the network variable stays at

its maximum. In such cases the real value can be seen on Vacon 100 HVAC operating keypad.

nvoActFault

This output network variable provides the drive active fault code. If the value is 0 the frequency

converter has no fault. See the fault code list in Vacon 100 HVAC User's Manual for fault identification.

nvoProcessOut1..8

These output network variables are sent directly from the application (see more detailed explanation in chapter 6.5 Process data) The valid range is 0 to 65535 (-163,840 to 163,835)

nvoDigitalOut1..8

These output network variables are sent directly from the application (see more detailed explanation in chapter 6.5 Process data).

state value command

00off (0; 0)

1 200 (0xC8) on (200; 1)

-1 (0XfF) any invalid (NULL)

Table 13.

nvoParResp

explained in chapter nviParSet.

24-hour support +358 (0)40 837 1150 • Email: vacon@vacon.com

6

vacon • 24 LonWorks interface

6.5 Network configuration variables

Function Variable Name SNVT Type

Maximum motor speed nciMaxSpeed SCPTmaxSetpoint

Minimum motor speed nciMinSpeed SCPTminSetpoint

Receive heartbeat time nciRcvHrtBt SCPTmaxRcvTime

Send heartbeat time nciSndHrtBt SCPTmaxSndTime

Minimum output time nciMinOutTime SCPTminSndTime

Nominal motor speed in RPM nciNmlSpeed SCPTnomRPM

Nominal motor frequency nciNmlFreq SCPTnomFreq

Minimum ramp up time nciRampUpTm SCPTrampUpTm

Minimum ramp down time nciRampDownTm SCPTrampDownTm

Default value for nviDrvSpeedScale nciRampDownTm SCPTdefScale

Table 14. Network configuration variables

nciMaxSpeed

This configuration property is used to define the maximum speed of a motor. The value is entered as a percentage of nominal speed in RPM, as defined by the Nominal Speed (nciNmlSpeed) configuration value. The value of the maximum speed must be validated against the

value of the minimum speed as follows:

-163.840 < minimum speed < maximum speed < 163.830

nciMinSpeed

This configuration property is used to define the minimum speed of the motor. The value is entered as a percentage of nominal speed in RPM, as defined by the Nominal Speed (nciNmlSpeed) configuration value. The value of the minimum speed must be validated against the

value of the maximum speed as follows:

-163.840 < minimum speed < maximum speed < 163.830

nciRcvHrtBt

This configuration property is used to control the maximum time that elapses after the last update of the network variables nviDrvSpeedStpt or nviDrvSpeedScale before the VSD object

starts to use the default values.

nciSndHrtBt

This configuration property defines the maximum period that expires before the network variables nvoDrvSpeed, nvoDrvCurnt and nvoDrvPwr are automatically updated.

nciMinOutTime

This configuration property defines the minimum period of automatic network variable tansmission.

6

nciNmlSpeed

This configuration property is used to provide the nominal speed of the motor in RPM. This value is necessary to determine the minimum and maximum speeds for the motor, based on the

configuration properties nciMinSpeed, nciMaxSpeed (entered as a percentage of nominal

speed).

Tel. +358 (0) 201 2121 • Fax +358 (0)201 212 205

LonWorks interface vacon • 25

nciNmlFreq

This configuration property is used to provide the nominal frequency for the motor.

nciRampUpTm

Defines the acceleration time for Vacon 100 HVAC. The valid range is 0.0 to 6,553.4 sec (0.1 sec).

nciRampDownTm

Defines the deceleration time for Vacon 100 HVAC. The valid range is 0.0 to 6,553.4 sec (0.1

sec).

nciDrvSpeedScale

This configuration property is used as the default value for nviDrvSpeedScale. This value will

be adopted at power-up and in case no input variable within the specified Receive Heartbeat

time is received.

24-hour support +358 (0)40 837 1150 • Email: vacon@vacon.com

6

vacon • 26 Fault tracing

7. FAULT TRACING

When an unusual operating condition is detected by the AC drive control diagnostics, the drive

initiates a notification visible, for example, on the keypad. The keypad will show the ordinal

number of the fault, the fault code and a short fault description.

The fault can be reset with the Reset button on the control keypad or via the I/O terminal. The

faults are stored in the Fault history menu which can be browsed. The different fault codes you

will find in the table below. This fault table presents only the faults related to the fieldbus in

use.

The LonWorks option board status LEDs are described in more detail in Chapter 4.1.2

NOTE: When contacting distributor or factory because of a fault condition, always write down

all texts and codes on the keypad display and send a description of the problem together with

the

Drive Info File to fieldbus@vacon.com.

7.1 Typical fault conditions

Fault condition Possible cause Remedy

Termination

resistor

Cabling

Grounding Inadequate grounding.

Connections

Parameter

Missing or excessive termination resistor.

• Supply or motor cables are located

too close to the fieldbus cable

• Wrong type of fieldbus cable

• Too long cabling

Faulty connections.

• Excessive stripping of cables

• Conductors in wrong terminals

• Too loose connections of conductors

• Faulty address

• Overlapping slave addresses

• Wrong baud rate

• Wrong control place selected

Table 15. Typical fault conditions

Install termination resistors at both ends of the

fieldbus line.

Ensure grounding in all

points on the net

7

If you need to contact Vacon service in problems related to LonWorks, please send a description of the

problem together with the Drive Info File to fieldbus@vacon.com.

Tel. +358 (0) 201 2121 • Fax +358 (0)201 212 205

Quick Setup vacon • 27

8. QUICK SETUP

Frequency converter application

Choose Fieldbus (Bus/Comm) for the active control place (see Chapter 5.1).

Master software

1 = Write 100.0 1 to nviDrvSpeedStpt.

2 = Frequency converter status is RUN and output frequency is 1.00 * nviDrvSpeedScale

3 = Write 0.0 0 to nviDrvSpeedStpt

4 = Frequency converter status is STOP.

If nvoDrvStats bit 3 = 1 Status of frequency converter is FAULT.

24-hour support +358 (0)40 837 1150 • Email: vacon@vacon.com

8

Loading...

Loading...