Page 1

Fitters notes Thermostatic expansion valves

Contents Page

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Superheat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Subcooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

External pressure equalization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Charges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Universal charge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

MOP charge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

MOP ballast charge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Thermostatic expansion valve selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Identication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Orice assembly replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Danfoss product range. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

expansion valves

Thermostatic

© Danfoss A/S (AC-DSL/MWA), 10 - 2006 DKRCC.PF.000.G1.02 / 520H1459 3

Page 2

Notes

4 DKRCC.PF.000.G1.02 / 520H1459 © Danfoss A/S (AC-DSL/MWA), 10 - 2006

Page 3

Fitters notes Thermostatic expansion valves

Introduction

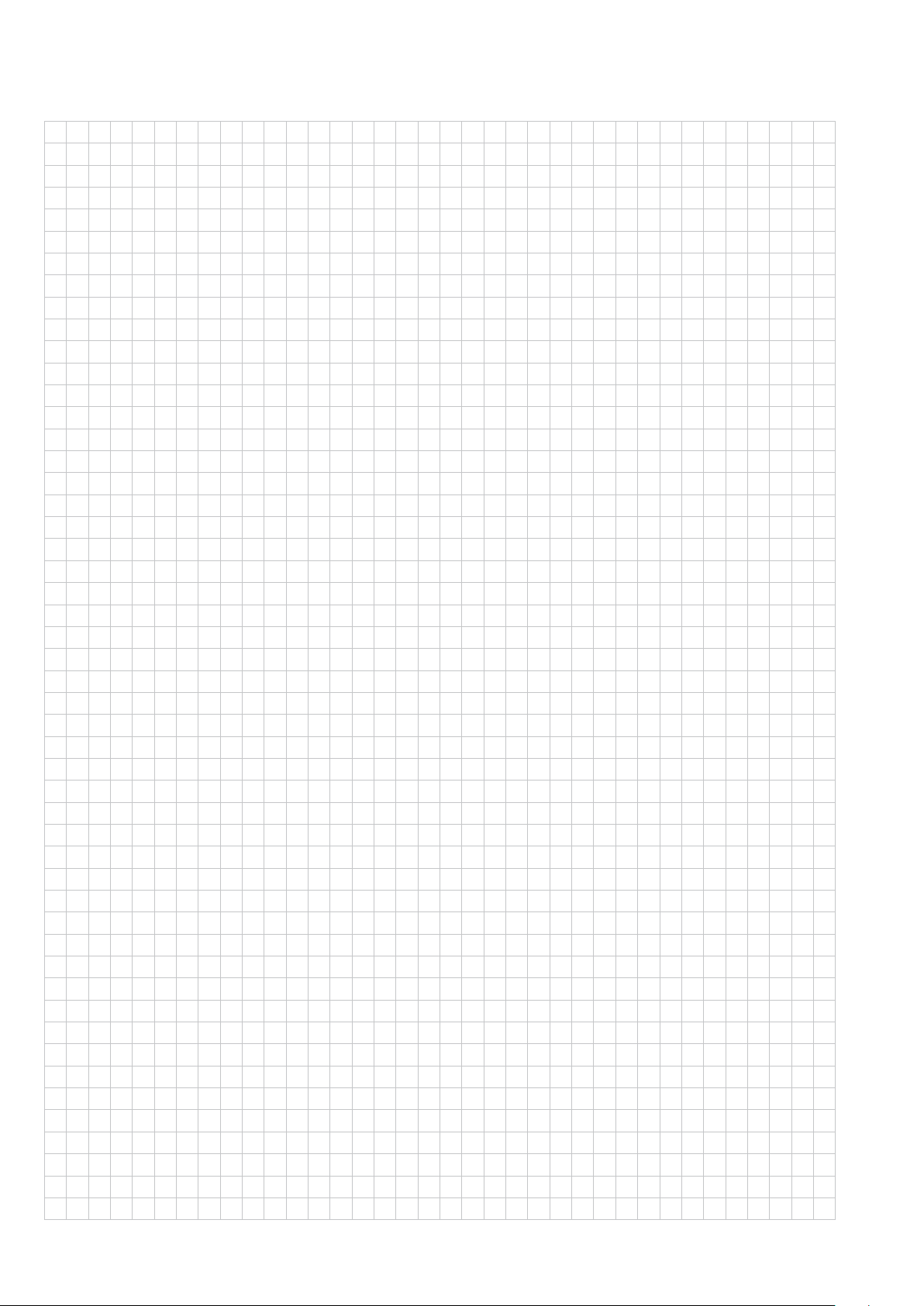

A thermostatic expansion valve is built up around

a thermostatic element (1) separated from the

valve body by a diaphragm.

A capillary tube connects the element to a bulb

(2) and a valve body with valve seat (3) and a

spring (4).

A thermostatic expansion valve works like this:

The function of a thermostatic expansion valve is

determined by three fundamental pressures:

P1: Bulb pressure which acts on the upper

surface of the diaphragm, in the valve

opening direction.

P2: Evaporating pressure which acts on the

underside of the diaphragm, in the valve

closing direction.

P3: Spring pressure which also acts on the

underside of the diaphragm, in the valve

closing direction.

When the expansion valve regulates, balance is

created between bulb pressure on one side of the

diaphragm and evaporating pressure plus spring

force on the other side.

The spring is used to set superheat.

expansion valves

Thermostatic

Superheat

Superheat is measured at the point where the

bulb is located on the suction line and is the

dierence between the temperature at the

bulb and the evaporating pressure/evaporating

temperature at the same point.

Superheat is measured in Kelvin (K) and is used as

a signal to regulate liquid injection through the

expansion valve.

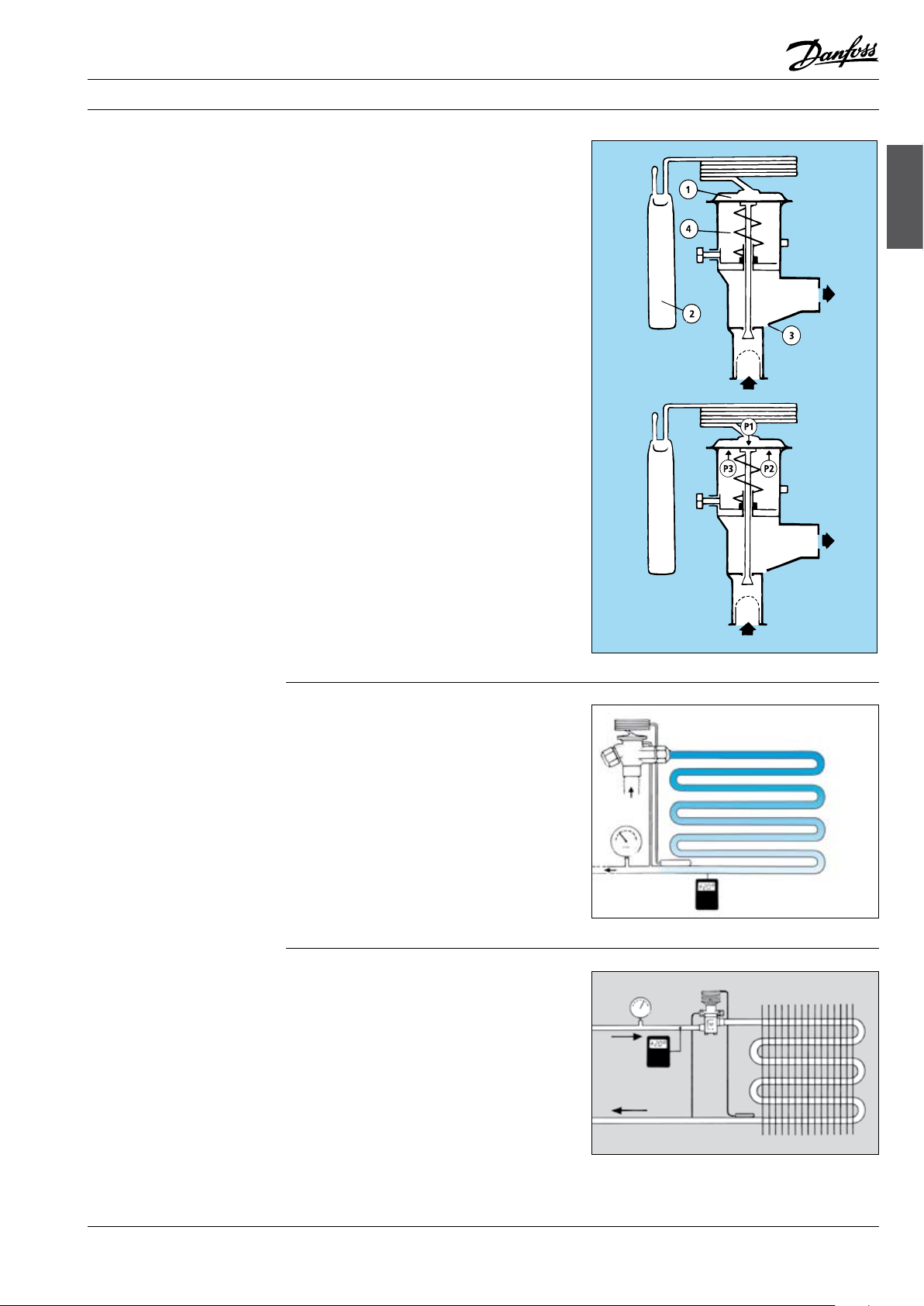

Subcooling Subcooling is dened as the dierence between

condensing pressure/temperature and liquid

temperature at the expansion valve inlet.

Subcooling is measured in Kelvin (K).

Subcooling of the refrigerant is necessary to

avoid vapour bubbles in the refrigerant ahead of

the expansion valve.

Vapour bubbles in the refrigerant reduce capacity

in the expansion valve and thereby reduce liquid

supply to the evaporator.

Subcooling of 4-5K is adequate in most cases.

Ad0-0001

Ad0-0012

Ad0-0015

© Danfoss A/S (AC-DSL/MWA), 10 - 2006 DKRCC.PF.000.G1.02 / 520H1459 5

Page 4

Fitters notes Thermostatic expansion valves

External pressure

equalization

Expansion valves with external pressure equalization must always be used if liquid distributors

are installed.

Typically, the use of distributors gives a pressure

drop of 1 bar across distributor and distribution

tubes.

Expansion valves with external pressure equalization should always be used in refrigeration

systems with heavy evaporators or plate

exchangers, where normally the pressure drop

will be greater than pressure corresponding to

2K.

Charges Thermostatic expansion valves can contain one

of three dierent types of charge:

1. Universal charge

2. MOP charge

3. MOP charge with ballast, standard for Danfoss

expansion valves with MOP.

Universal charge

Expansion valves with Universal charge are used

in most refrigeration systems where there is no

pressure limitation requirement and where the

bulb can be located warmer than the element

or at high evaporating temperature/evaporating

pressure.

Ad0-0016

MOP charge

Universal charge means that there is liquid

charge in the bulb. The amount of charge is so

large that charge remains in the bulb irrespective

of whether the element is colder or warmer than

the bulb.

Expansion valves with MOP charge are typically

used on factory-made units where suction

pressure limitation on starting is required, e.g.

in the transport sector and in air conditioning

systems.

All expansion valves with MOP have a very small

charge in the bulb.

This means that the valve or the element must be

located warmer than the bulb. If it is not, charge

can migrate from the bulb to the element and

prevent the expansion valve from functioning.

MOP charge means limited liquid charge in the

bulb.

“MOP” stands for Maximum Operating Pressure

and is the highest suction pressure/ evaporating

pressure permissible in the evaporator/suction

line.

The charge will have evaporated when the

temperature reaches the MOP point. Gradually,

as the suction pressure rises, the expansion valve

begins to close at approx. 0.3/0.4 bar below the

MOP point. It becomes completely closed when

the suction pressure is the same as the MOP

point.

Ad0-0017

Ad0-0018

MOP is often called “Motor Overload Protection”.

6 DKRCC.PF.000.G1.02 / 520H1459 © Danfoss A/S (AC-DSL/MWA), 10 - 2006

Page 5

Fitters notes Thermostatic expansion valves

MOP ballast charge

Thermostatic expansion

valve selection

Expansion valves with MOP ballast charges are

used mainly in refrigeration systems with “highdynamic” evaporators, e.g. in air conditioning

systems and plate heat exchangers with high

heat transfer.

With MOP ballast charge, up to 2 - 4 K less

superheat can be obtained than with other types

of charge.

The bulb in a thermostatic expansion valve

contains a material of high porosity and large

surface area in relation to weight.

MOP charge with ballast has a damping eect on

expansion valve regulation.

The valve opens slowly as bulb temperature rises

and closes quickly as bulb temperature fails.

The thermostatic expansion valve can be selected when the following are known:

Refrigerant

Evaporator capacity

Evaporating pressure

Condensing pressure

Ad0-0021

Subcooling

Pressure drop across valve

Internal or external pressure equalization

expansion valves

Thermostatic

Identication The thermostatic element is tted with a laser

engraving on top of the diaphragm.

The code refers to the refrigerant for which the

valve is designed:

L = R410A

N = R134a

S = R404A/ R507

X = R22

Z = R407C

This engraving gives valve type (with code

number), evaporating temperature range, MOP

point, refrigerant, and max. working pressure,

PS/MWP.

With TE 20 and TE 55 the rated capacity is

stamped on a band label fastened to the valve.

The orice assembly for T2 and TE2 is marked

with the orice size (e.g. 06) and week stamp +

last number in the year (e.g. 279).

The orice assembly number is also given on the

lid of its plastic container.

On TE 5 and TE 12 the upper stamp (TE 12)

indicates for which valve type the orice can be

used. The lower stamp (01) is the orice size.

On TE 20 and TE 55 the lower stamp (50/35 TR

N/B) indicates the rated capacity in the two

evaporating temperature ranges N and B, and the

refrigerant. (50/35 TR = 175 kW in range N and

123 kW in range B).

The upper stamp (TEX 55) refers to the valve type

for which the assembly can be used.

Ad0-0019

Ad0-0023

Ad0-0020

© Danfoss A/S (AC-DSL/MWA), 10 - 2006 DKRCC.PF.000.G1.02 / 520H1459 7

Page 6

Fitters notes Thermostatic expansion valves

Installation The expansion valve must be installed in the

liquid line, ahead of the evaporator, with its

bulb fastened to the suction line as close to the

evaporator as possible.

If there is external pressure equalization, the

equalizing line must be connected to the suction

line immediately after the bulb.

The bulb is best mounted on a horizontal suction

line tube and in a position corresponding to

between 1 o’clock and 4 o’clock.

Location depends on the outside diameter of the

tube.

Note:

The bulb must never be located at the bottom

of the suction line due to the possibility of oil

laying in the bottom of the pipe causing false

signals.

The bulb must be able to sense the temperature

of the superheated suction vapour and must

therefore not be located in a position that will

expose it to extraneous heat/cold.

If the bulb is exposed to a warm air current,

insulation of the bulb is recommended.

The Danfoss bulb strap allows a tight and secure

tting of the bulb to the tube, thereby securing

that the bulb has ultimate thermal contact to

the suction tube. The TORX design of the screw

makes it easy for the tter to transfer the torque

from the tool to the screw without having to

press the tool into the screw slot. Furthermore,

with the TORX slot design, there is no risk of

damaging the screw slot.

Ad0-0002

Ad0-0003

Ad0-0004

The bulb must not be installed after a heat

exchanger because in this position it will give

false signals to the expansion valve.

Ad0-0005

The bulb must not be installed close to components of large mass as this also will give rise to

false signals to the expansion valve

Ad0-0006

8 DKRCC.PF.000.G1.02 / 520H1459 © Danfoss A/S (AC-DSL/MWA), 10 - 2006

Page 7

Fitters notes Thermostatic expansion valves

Installation (cont.)

As previously mentioned, the bulb must be

installed to the horizontal part of the suction line

immediately after the evaporator. It must not be

installed to a collection tube or a riser after an oil

pocket.

The expansion valve bulb must always be

installed ahead of any liquid lock.

Ad0-0007

expansion valves

Thermostatic

Ad0-0008

Setting The expansion valve is supplied with a factory

setting suitable for most applications.

If necessary, readjustment can be made using the

setting spindle on the valve.

Turning the spindle clockwise increases the

expansion valve superheat and turning it

counterclock-wise reduces it.

For T /TE 2, one turn of the spindle produces a

change of approx. 4K in the superheat at 0°C

evaporating temperature.

Ad0-0009

© Danfoss A/S (AC-DSL/MWA), 10 - 2006 DKRCC.PF.000.G1.02 / 520H1459 9

Page 8

Fitters notes Thermostatic expansion valves

Setting (cont.)

For TE 5 and following sizes, one turn of the

spindle produces a change of approx. 0.5K in

the superheat at 0°C evaporating temperature.

For TUA and TUB, one turn of the spindle

produces a change of approx. 3K in the superheat at 0°C evaporating temperature.

Hunting in the evaporator can be eliminated by

the following procedure:

Increase the superheat by turning the expansion

valve setting spindle well to the right (clockwise)

so that hunting stops. Then turn the setting

spindle in counter-clockwise steps so that

hunting again occurs.

From this position, turn the spindle about once

clockwise (but only 1/4 turn for T /TE 2 valves).

On this setting the refrigeration system will not

hunt and the evaporator is fully utilized.

A variation of 1 K in superheat is not regarded as

hunting.

Ad0-0010

Ad0-0011

Orice assembly

replacement

If the superheat in the evaporator is too high, the

reason might be an inadequate supply of liquid

refrigerant.

The superheat can be reduced by turning the

expansion valve setting spindle counterclockwise

in steps until hunting is observed.

From this setting, the spindle must be turned

about once clockwise (but only 1/4 turn for T/TE

2). This setting fully utilizes the evaporator.

A variation of 1 K in superheat is not regarded as

hunting.

Ad0-0013

If the evaporator continues to hunt, regardless of

the superheat setting, the valve capacity might

be too high and the orice assembly, or the valve,

needs replacing with a smaller one.

If the evaporator superheat is too high the valve

capacity is too low and the orice assembly must

be replaced with a larger one.

TE, T2, TUA, TCAE valves are supplied with an

interchangeable orice.

Ad0-0014

10 DKRCC.PF.000.G1.02 / 520H1459 © Danfoss A/S (AC-DSL/MWA), 10 - 2006

Page 9

Fitters notes Thermostatic expansion valves

Danfoss product range

Thermostatic expansion

valves

Danfoss oers a comprehensive range of

thermostatic expansion valves with capacities

from 0.4 to 1083 kW (R134a).

T/TE 2 valves have a brass housing and are/

are or solder/are connections.

Rated capacity: 0.4 - 10.5 kW (R134a).

TUA, TUB, TUC valves have a stainless steel

housing and stainless steel/copper bimetal

solder connections.

Rated capacity: 0.5 - 12 kW (R134a).

The valves can be supplied with or without

external pressure equalization.

TUA has an interchangeable orice

assembly and adjustable superheat.

TUB has a xed orice and adjustable

superheat.

TUC has a xed orice and factory set

superheat.

TUB and TUC are primarily for OEM customers.

All TUB and TUC valves can be replaced by TUA

valves.

TCAE, TCBE, TCCE valves have a stainless steel

housing and stainless steel/copper bimetal

solder connections.

Rated capacity: 12 - 18 kW (R134a).

The valves are designed as the TU valves but with

a higher capacity.

TDE valves have a brass housing and copper

solder connections.

Rated capacity: 10.5 - 140 kW (R407C)

The valves are supplied with a xed orice and

adjustable superheat.

TE 5 - TE 55 valves have a brass housing.

The valves are supplied as a part programme

consisting of valve housing, orice and thermostatic element.

The valve housing is available in a straightway

or angleway version with solder, are and ange

connections.

Rated capacity: 12.9 - 220 kW (R134a).

The valves are supplied with external pressure

equalization.

PHT 85 - 300 valves are supplied as a part

programme consisting of valve housing, anges,

orice and thermostatic element.

Rated capacity: 55 - 1083 kW (R134a).

For further information consult the internet or

the catalogue material.

expansion valves

Thermostatic

The valves are supplied with external pressure

equalization.

TRE valves have a brass housing and stainless

steel/copper bimetal connections.

Rated capacity: 18 - 196 kW (R134a).

The valves are supplied with a xed orice and

adjustable superheat.

© Danfoss A/S (AC-DSL/MWA), 10 - 2006 DKRCC.PF.000.G1.02 / 520H1459 11

Page 10

Loading...

Loading...