Data Sheet

Shut-off valves

Type SVA-S and SVA-L

65 bar version for all industrial refrigeration and heat pump applications

The new 65 bar SVL range for Industrial

Refrigeration and Heat Pumps is based on the

successful modular Standard SVL platform. The

same exibility, simplicity and eciency are

features oered in this new series.

The SVA valves are designed to give favorable

ow characteristics and are easy to dismantle

and repair when necessary. The valve cone is

designed to ensure perfect closing and

withstand a high system pulsation and

vibration, which can be present specically in

the discharge line.

The valves are available from a parts program

consisting of:

• Valve housing with DIN or ANSI butt-weld

connections and DIN or ASME hard soldering

(brazing) connections in angle or straightway

and in a variety of sizes

• The function module in Standard neck (SVAS) and Long neck (SVA-L)

Further, SVA-S is available as complete valves

with ANSI butt-weld connection.

Function modules (Top Complete) for the SVA

Stop valves DN 50 to DN 100 are available in a

special high temperature version called

SVA-65BT.

AI377236007167en-000301

Shut-o valves, type SVA-S and SVA-L, 65 bar

Features

• Modular Concept:

◦ Each valve housing is available with DIN and ANSI butt weld connection and in several diferent sizes

◦ Possible to convert SVA-S or SVA-L to any other product in the FlexlineTM SVL family (regulating valve, check &

stop valve, check valve or strainer) just by replacing the complete top part

• Fast and easy valve overhaul service. It is easy to replace the top part and no welding is needed

• Optional accessories:

◦ Heavy duty industrial hand wheel for frequent operation

◦ Cap for infrequent operation

• Available in angleway and straightway versions with Standard neck or Long neck (DN 15 to DN 40) for insulated

systems

• Each valve type is clearly marked with type, size and performance range

• The valves and caps are prepared for sealing, to prevent operation by unauthorized persons, using a seal wire

• Internal metal backseating:

◦ DN 6 - 65 (¼ - 2

• Internal PTFE backseating:

◦ DN 80 - 200 (3 - 8 in)

• Can accept ow in both directions

• Housing and bonnet material is low temperature steel according to requirements of the Pressure Equipment

Directive and other international classication authorities

• Classication: DNV, CRN, BV, EAC etc. To get an updated list of certication on the products please contact your

local Danfoss Sales Company

1

⁄2 in)

© Danfoss | Climate Solutions | 2022.03 AI377236007167en-000301 | 2

Shut-o valves, type SVA-S and SVA-L, 65 bar

Media

Refrigerants

Applicable to HCFC, HFC, R717 (Ammonia) and R744 (CO2). For further information please see installation guide for

SVA.

New refrigerants

Danfoss products are continually evaluated for use with new refrigerants depending on market requirements.

When a refrigerant is approved for use by Danfoss, it is added to the relevant portfolio, and the R number of the

refrigerant (e.g. R513A) will be added to the technical data of the code number. Therefore, products for specic

refrigerants are best checked at store.danfoss.com/en/, or by contacting your local Danfoss representative.

© Danfoss | Climate Solutions | 2022.03 AI377236007167en-000301 | 3

Part

Temperature range

Max. working pressure

Housing DN50 -DN100

-60 °C to +190 °C (-76 °F to + 374 °F)

65 bar (943 psi)

Housing other than DN50 -DN100

-60 °C to +150 °C (-76 °F to +302 °F)

65 bar (943 psi)

Function module standard

-60 °C to +150 °C (-76 °F to +302 °F)

65 bar (943 psi)

Function module high temp SVA-65BT

0 °C to +190 °C (32 °F to + 374 °F)

65 bar (943 psi)

P

S

6

5

/

9

4

3

p

s

i

g

S

T

O

P

V

A

L

V

E

S

V

A

-

S

D

N

8

0

/

3

”

@

–

6

0

°

C

\

–

7

6

°

F

→

1

5

0

°

C

\

3

0

2

°

F

Shut-o valves, type SVA-S and SVA-L, 65 bar

Product specication

Design

Housing

Made of special, cold resistant steel

Valve cone

The valve cone can be turned on the spindle, thus there will be no friction between the cone and the seat when the

valve is opened and closed and the special design will avoid cone spin due to pulsation and vibration when the

valve is in open position. A teon tightening ring provides perfect sealing with minimum closing force.

Spindle

Made of polished stainless steel, ideal for leap seal sealing.

Packing gland

The low temperature packing gland ensures a perfect tightness. The packing glands are equipped with a scraper

ring to prevent penetration of dirt and ice into the packing gland.

Table 1: Technical data

Installation

Figure 1: Example of Marking Ring

The valve is designed to withstand high internal pressure. However, the piping system in general should be

designed to avoid liquid traps and reduce the risk of hydraulic pressure caused by thermal expansion.

It is recommended that the valves be installed in the direction of ow indicated by the arrow on the valve body. The

valve can be installed in the opposite direction but this slightly reduces the kv-value (Cv-value).

© Danfoss | Climate Solutions | 2022.03 AI377236007167en-000301 | 4

P1

P2

P1 P2

Valve size [DN]

Flow direction

Maximum opening and closing pressure

dierential

Maximum closing pressure dierential

Maximum opening pressure dierential

P1

→ P2

P2

→ P1

P2

→ P1

65(80)

60 bar / 870 psi

65 bar / 943 psi

60 bar / 870 psi

100

44 bar / 638 psi

65 bar / 943 psi

44 bar / 638 psi

125

33 bar / 478 psi

65 bar / 943 psi

33 bar / 478 psi

150

21 bar / 304 psi

65 bar / 943 psi

21 bar / 304 psi

200

14 bar / 203 psi

65 bar / 943 psi

14 bar / 203 psi

Shut-o valves, type SVA-S and SVA-L, 65 bar

Maximum opening and closing pressure dierential (for sizes 100 to 200)

Figure 2: Flow direction

The maximum opening pressure dierential is equal to the maximum pressure dierence between inlet and outlet

in the ow direction where the valve can be opened using normal hand force without damaging the valve.

The maximum closing pressure dierential is equal to the maximum pressure dierence between inlet and outlet in

the ow direction where the valve is sealing according to specications.

The maximum opening and closing pressure dierentials are as default equal to the maximum operating pressure

(PS or MWP) for valve sizes up to and including DN 50.

For valve sizes of DN 65(80) or larger than DN 65(80) the opening and closing pressure dierential depends on the

ow direction as shown below. Note that the default ow direction indicated by the ow arrow is P1 -> P2.

Table 2: Flow direction

© Danfoss | Climate Solutions | 2022.03 AI377236007167en-000301 | 5

SVA-S 6-10 (1/4 - 3/8 in.)

SVA-S 15-20 (1/2 - 3/4 in.)

10

8

11

9

3

19

20

13

9

4

25

5

1

Danfoss

M148B0100_1

Danfoss

M148B0004_1

17

18

No.

Part

MaterialENISO

ASTM

1

Housing

Steel

G20Mn5QT, 10213-3

LCC, A352

P285QH+QT, 10222-4

LF2, A350

2

Bonnet, Flange

Steel

G20Mn5QT, 10213-3

LCC, A352

P285QH+QT, 10222-4

LF2, A350

P275NL, 10028-3

3

Bonnet, Insert

Steel

11SMn30, 10087

Type 2 R, 683/9

AISI 1213

4

Spindle

Stainless steel

X8CrNiS18-9, 10088

Type 17, 683/13

AISI 3035Cone

Steel

11SMn30, 10087

Type 2 R, 683/9

AISI 1213

8

Packing gland

Stainless steel

X8CrNiS18-9, 10088

Type 17, 683/13

AISI 303

9

Packing washer

Aluminium

10

O-ring

Chloroprene

11

Spring loaded Teon ring

PTFE

12

Bolts

High temperature steel

42CrMo5, 10269

A193

13

Gasket

Fiber, Non-asbestos

17

Cap

Aluminium

18

Gasket for cap

Nylon

19

Locking nut

Steel20Screw

Steel

22

Disk spring

Steel

Shut-o valves, type SVA-S and SVA-L, 65 bar

Material specication

Table 3: SVA-S 6-10 & SVA-S 15-20

Table 4: SVA-S 6-10 & SVA-S 15-20

© Danfoss | Climate Solutions | 2022.03 AI377236007167en-000301 | 6

Danfoss

M148B0035_1

No.

Part

MaterialENISO

ASTM

1

Housing

Steel

G20Mn5QT, 10213-3

LCC, A352

P285QH+QT, 10222-4

LF2, A350

2

Bonnet, Flange

Steel

G20Mn5QT, 10213-3

LCC, A352

P285QH+QT, 10222-4

LF2, A350

P275NL, 10028-3

3

Bonnet, Insert

Steel

11SMn30, 10087

Type 2 R, 683/9

AISI 1213

4

Spindle

Stainless steel

X8CrNiS18-9, 10088

Type 17, 683/13

AISI 303

5

Cone

Steel

11SMn30, 10087

Type 2 R, 683/9

AISI 1213

8

Packing gland

Stainless steel

X8CrNiS18-9, 10088

Type 17, 683/13

AISI 303

9

Packing washer

Aluminium

10

O-ring

Chloroprene

11

Spring loaded Teon ring

PTFE

12

Bolts

High temperature steel

42CrMo5, 10269

A193

13

Gasket

Fiber, Non-asbestos

17

Cap

Aluminium

18

Gasket for cap

Nylon

20

Identication ring

Stainless steel

21

Disk spring

Steel

Shut-o valves, type SVA-S and SVA-L, 65 bar

Figure 3: SVA-S 25-40 (1 - 1½ in.)

Table 5: SVA-S 25-40 (1 - 1½ in.)

© Danfoss | Climate Solutions | 2022.03 AI377236007167en-000301 | 7

Danfoss

M148B0041_1

No.

Part

MaterialENISO

ASTM

1

Housing

Steel

G20Mn5QT, 10213-3

LCC, A352

P285QH+QT, 10222-4

LF2, A350

3

Valve bonnet

Steel

G20Mn5QT, 10213-3

LCC, A352

P285QH+QT, 10222-4

LF2, A350

4

Spindle

Stainless steel

X8CrNiS18-9, 10088

Type 17, 683/13

AISI 3035Cone

Steel

11SMn30, 10087

Type 2 R , 683/9

AISI 1213

8

Packing gland

Stainless steel

X8CrNiS18-9, 10088

Type 17, 683/13

AISI 303

9

Packing washer

Aluminium

10

O-ring

Chloroprene

11

Spring loaded Teon ring

PTFE

12

Bolts

High temperature steel

42CrMo5, 10269

A193

13

Gasket

Fiber, Non-asbestos

17

Cap

Aluminium

18

Gasket for cap

Nylon (PA6)

20

Identication ring

Stainless steel

21

Disk spring

Steel

Shut-o valves, type SVA-S and SVA-L, 65 bar

Figure 4: SVA-L 15 - 40 (½ - 1½ in.)

Table 6: SVA-L 15 - 40 (½ - 1½ in.)

© Danfoss | Climate Solutions | 2022.03 AI377236007167en-000301 | 8

Danfoss

M148B0036_1

22

No.

Part

MaterialENISO

ASTM

1

Housing

Steel

G20Mn5QT, 10213-3

LCC, A352

P285QH+QT, 10222-4

LF2, A350

3

Valve bonnet

Steel

G20Mn5QT, 10213-3

LCC, A352

P285QH+QT, 10222-4

LF2, A350

4

Spindle

Stainless steel

X8CrNiS18-9, 10088

Type 17, 683/13

AISI 3035Cone

Steel

11SMn30, 10087

Type 2 R, 683/9

AISI 1213

8

Packing gland

Stainless steel

(1)

(HL version) see pos. 8

X8CrNiS18-9, 10088

Type 17, 683/13

AISI 303

9

Packing washer

Aluminium

(1)

None

10

O-ring

Chloroprene

(1)

None

11

Spring loaded Teon ring

PTFE

(1)

None12Bolts

High temperature steel

42CrMo5, 10269

A193

13

Gasket

Fiber, Non-asbestos

(1)

Graphite

17

Cap

Aluminium

18

Gasket for cap

Nylon

(1)

PTFE (bre)

19

Locking nut

Steel

20

Identication ring

Stainless steel

21

Disk spring

Steel

22

Cone gasket

PTFE (bre)

(1)

PEEK (bre)

Shut-o valves, type SVA-S and SVA-L, 65 bar

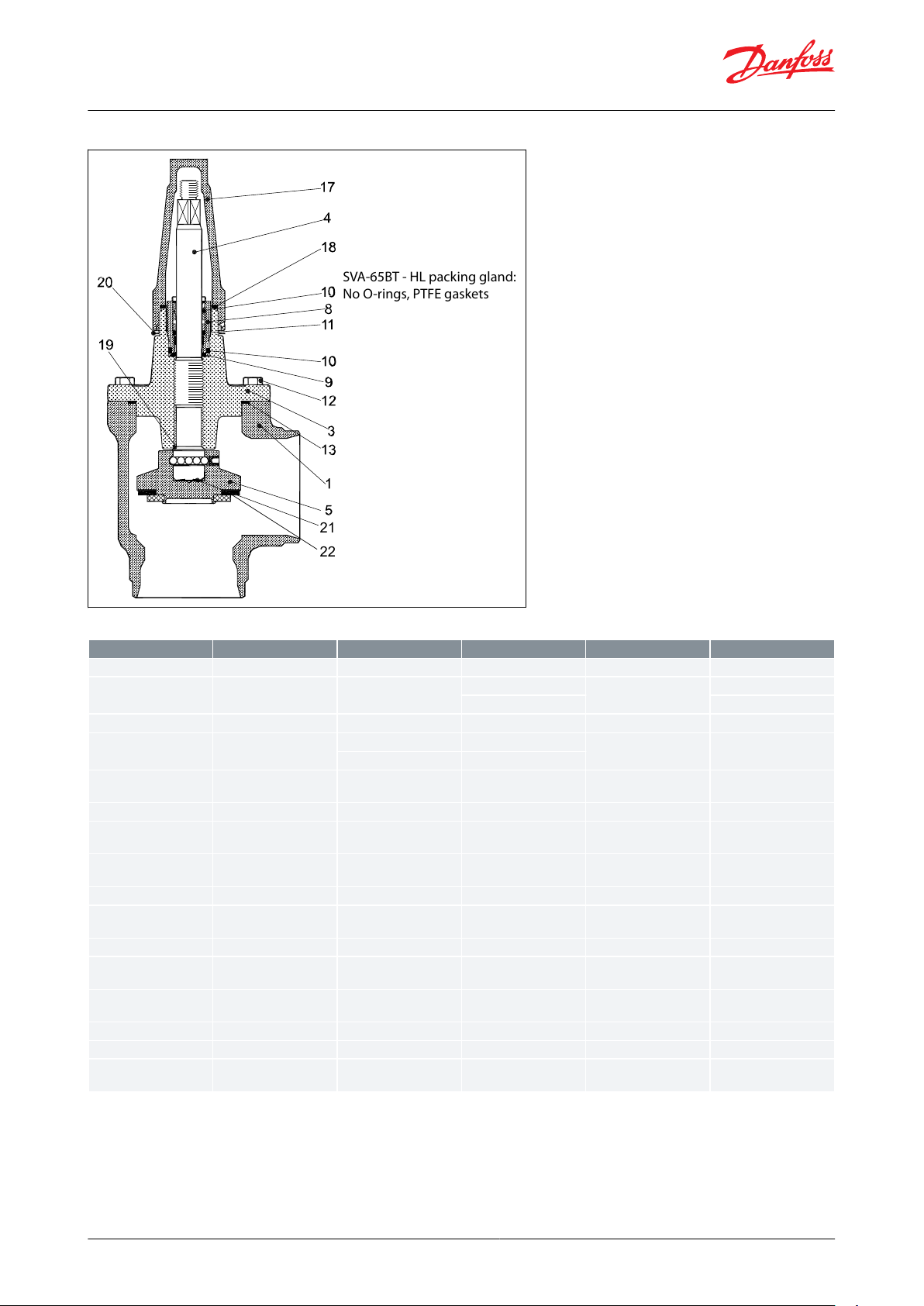

Figure 5: SVA-S 50-65 (2 - 2½ in.)

Table 7: SVA-S 50-65 (2 - 2½ in.)

(1)

(1)

SVA-65BT only

SVA-65BT only

© Danfoss | Climate Solutions | 2022.03 AI377236007167en-000301 | 9

SVA-65BT - HL packing gland:

No O-rings, PTFE gaskets

21

22

No.

Part

MaterialENISO

ASTM

1

Housing

Steel

G20Mn5QT, 10213-3

LCC, A352

3

Valve bonnet

Steel

G20Mn5QT, 10213-3

LCC, A352

P285QH+QT, 10222-4

LF2, A350

4

Spindle

Stainless steel

X5CrNi18-10, 10088

Type 11, R 683/13

AISI 304, A276

5

Cone

Cone seal

Steel

11SMn30, 10087

Type 2, R 683/9

AISI 1213

Teon (PTFE)

8

Packing gland

Stainless steel

(1)

(HL version) see pos. 8

X8CrNiS18-9, 10088

Type 17, R 683/13

AISI 303

9

Packing washer

Aluminium

10

O-ring

Chloroprene

(1)

None

11

Spring loaded Teon ring

PTFE

(1)

None12Bolts

High temperature steel

42CrMo5, 10269

A193

13

Gasket

Fiber, Non-asbestos

(1)

Graphite

17

Cap

Aluminium

18

Gasket for cap

Nylon

(1)

PTFE (bre)

19

Backseat

Teon (PTFE)

(1)

Steel

20

Identication ring

Stainless steel

21

Disk spring

Steel

22

Cone gasket

PTFE (bre)

(1)

PEEK (bre)

Shut-o valves, type SVA-S and SVA-L, 65 bar

Figure 6: SVA-S 80 - 150 (3 - 6 in.)

Table 8: SVA-S 80 - 150 (3 - 6 in.)

(1)

(1)

SVA-65BT only

SVA-65BT only

© Danfoss | Climate Solutions | 2022.03 AI377236007167en-000301 | 10

Danfoss

M148B0007_1

No.

Part

MaterialENISO

ASTM

1

Housing

Steel

G20Mn5QT, 10213-3

LCC, A352

3

Valve bonnet

Steel

G20Mn5QT, 10213-3

LCC, A352

P285QH+QT, 10222-4

LF2, A350

4

Spindle

Stainless steel

X5CrNi18-10, 10088

Type 11, R 683/13

AISI 304, A276

5

Cone

Cone seal

Steel

Teon (PTFE)

11SMn30, 10087

Type 2, R 683/9

AISI 1213

8

Packing gland

Stainless steel

X8CrNiS18-9, 10088

Type 17, R 683/13

AISI 303

9

O-ring

Chloroprene

10

Spring loaded Teon ring

PTFE11O-ring

Chloroprene

12

Bolts

High temperature steel

42CrMo5, 10269

A193

13

Gasket

Fiber, Non-asbestos

15

Washer

Stainless steel

16

Nut

Stainless steel

17

Cap

Aluminium

18

Gasket for cap

Nylon (PA 6)

19

Soft backseat

Teon (PTFE)

20

Identication ring

Stainless steel

21

Wear ring

Teon (PTFE)

22

Disk spring

Steel

23

O-ring

PTFE/Chloroprene

(Neoprene)

Shut-o valves, type SVA-S and SVA-L, 65 bar

Figure 7: SVA-S 200 (8 in.)

Table 9: SVA-S 200 (8 in.)

© Danfoss | Climate Solutions | 2022.03 AI377236007167en-000301 | 11

Size

ØDTØD

T

kv-angle

kv-straight

Cv-angle

Cv-straight

mm

in.mmmm

in.

in.

m3/h

m3/h

US

gal/minUSgal/min

6¼13.5

2.3

0.531

0.091

2.9

2.0

3.4

2.410⅜

17.2

2.3

0.677

0.091

4.5

3.2

5.2

3.615½

21.3

2.3

0.839

0.091

7.0

4.9

8.1

5.720¾

26.9

2.3

1.059

0.091

14.6

10.2

16.9

11.8251

33.7

2.6

1.327

0.103

24.8

17.4

28.8

20.2321¼

42.4

2.6

1.669

0.102

42.6

29.8

49.4

34.6401½

48.3

2.6

1.902

0.103

45.2

31.6

52.4

36.7502

60.3

2.9

2.37

0.1180659376652½

76.1

2.930.11

12097140

113803

88.9

3.2

3.50

0.13

182

152

211

176

1004114.3

3.6

4.50

0.14

313

278

363

323

1255139.7

4.0

5.50

0.16

514

470

596

545

1506168.3

4.5

6.63

0.18

785

597

911

693

2008219.1

6.3

8.63

0.25

1168

1024

1355

1188

Size

ØDTØD

T

k

v

-angle

k

v

-straight

C

v

-angle

C

v

-straight

mm

in.mmmm

in.

in.

m

3

/h

m

3

/h

US

gal/minUSgal/min

6¼13.5

3.0

0.531

0.118

2.9

2.03

3.4

2.410⅜

17.2

3.2

0.677

0.126

4.5

3.15

5.2

3.615½

21.3

3.7

0.839

0.146

7.0

4.9

8.1

5.720¾

26.9

4.0

1.059

0.158

14.6

10.2

16.9

11.8251

33.7

4.6

1.327

0.181

24.8

17.4

28.8

20.2321¼

42.4

4.9

1.669

0.193

42.6

29.8

49.4

34.6401½

48.3

5.1

1.902

0.201

45.2

31.6

52.4

36.7

Size

ØDTØD

T

k

v

-angle

k

v

-straight

C

v

-angle

C

v

-straight

mm

in.mmmm

in.

in.

m

3

/h

m

3

/h

US

gal/minUSgal/min

50260.3

3.9

2.37

0.1580659376652½

73.0

5.2

2.87

0.20

12097140

113803

88.9

5.5

3.50

0.22

182

152

211

176

1004114.3

6.0

4.50

0.24

313

278

363

323

Shut-o valves, type SVA-S and SVA-L, 65 bar

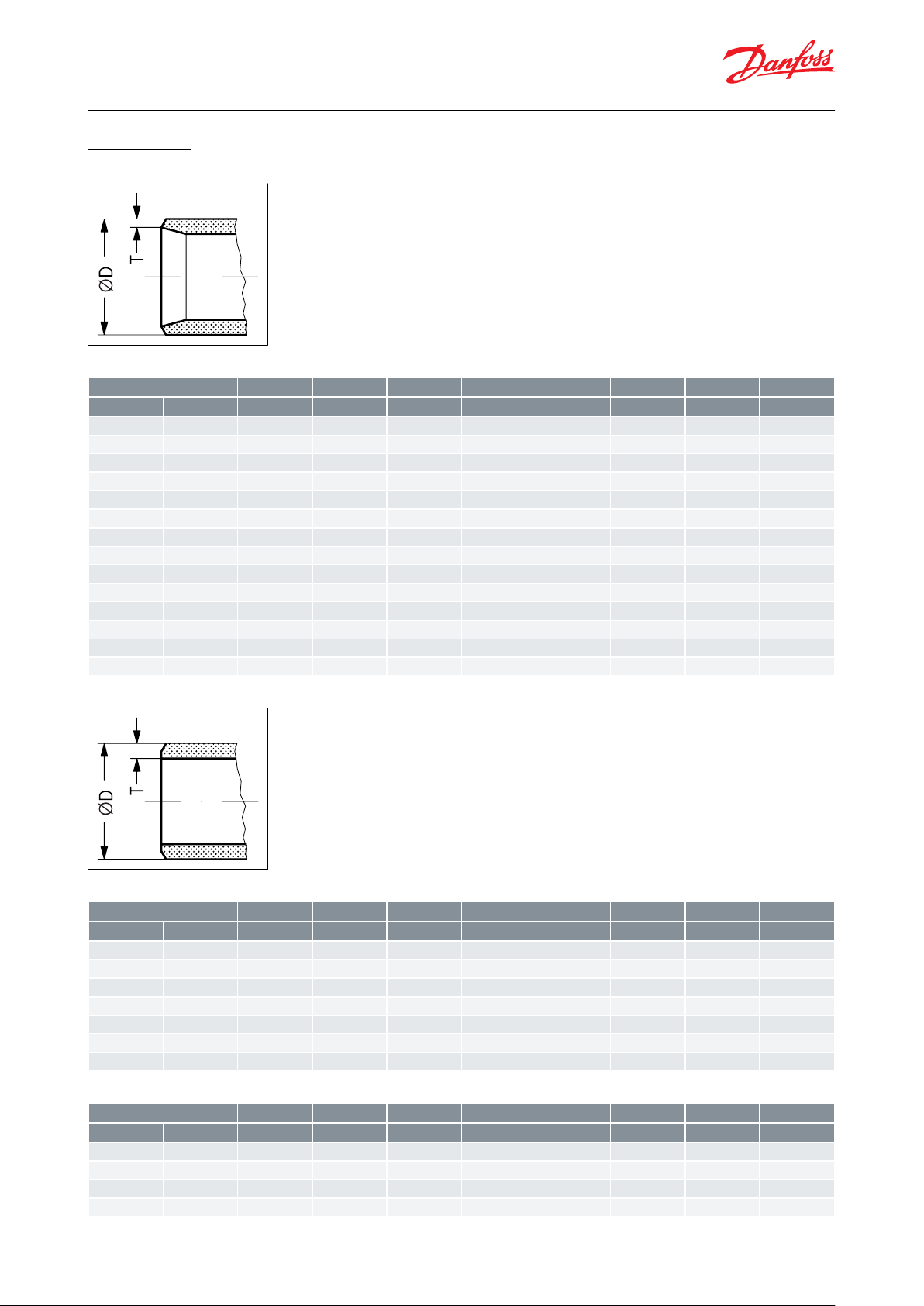

Connections

Figure 8: DIN

Table 10: Butt-weld DIN (EN 10220)

Figure 9: ANSI

Table 11: Butt-weld ANSI (B 36.10 Schedule 80)

Table 12: Butt-weld ANSI (B 36.10 Schedule 40)

© Danfoss | Climate Solutions | 2022.03 AI377236007167en-000301 | 12

Size

ØDTØD

T

kv-angle

kv-straight

Cv-angle

Cv-straight

mm

in.mmmm

in.

in.

m3/h

m3/h

US

gal/minUSgal/min

1255141.3

6.6

5.56

0.26

514

470

596

545

1506168.3

7.1

6.63

0.28

785

597

911

693

2008219.1

8.2

8.63

0.32

1168

1024

1355

1188

Size

IDLØD

T

kv-angle

kv-straight

Cv-angle

Cv-straight

mm

in.mmmmmmmm

m3/h

m3/h

US

gal/minUSgal/min

6¼6

7.7

12.7

3.35

2.9

2.0

3.4

2.410⅜108

15.88

2.94

4.5

3.2

5.2

3.615½168

21.3

2.65

7.0

4.9

8.1

5.720¾2211

26.9

2.45

14.6

10.2

16.9

11.82512811

33.7

2.85

24.8

17.4

28.8

20.2321¼3515

42.4

3.7

42.6

29.8

49.4

34.6401½4215

48.3

3.15

45.2

31.6

52.4

36.75025413.5

60.3

3.1580659376652½6413.5734.5

12097140

113803

76.11588.9

6.4

182

152

211

176

1004108

17.5

1185313

278

363

323

SizeIDLØDT

k

v

-angle

k

v

-straight

C

v

-angle

C

v

-straight

in.mmmmmmmm

m

3

/h

m

3

/h

US

gal/minUSgal/min

¼

6.35

7.7

12.7

3.18

2.9

2.0

3.4

2.4⅜9.53815.88

3.18

4.5

3.2

5.2

3.6⅝15.88821.3

2.71

7.0

4.9

8.1

5.7⅞22.231126.9

2.34

14.6

10.2

16.9

11.8

1⅛28.581133.7

2.56

24.8

17.4

28.8

20.2

1⅜34.931542.4

3.74

42.6

29.8

49.4

34.6

1⅝41.281548.3

3.51

45.2

31.6

52.4

36.7

2⅛54

13.5

60.3

3.1580659376

2⅝66.7

13.5

76.1

4.70

12097140

113

3⅛79.381588.9

4.76

182

152

211

176

4⅛104.78

17.5

114.3

4.76

313

278

363

323

Shut-o valves, type SVA-S and SVA-L, 65 bar

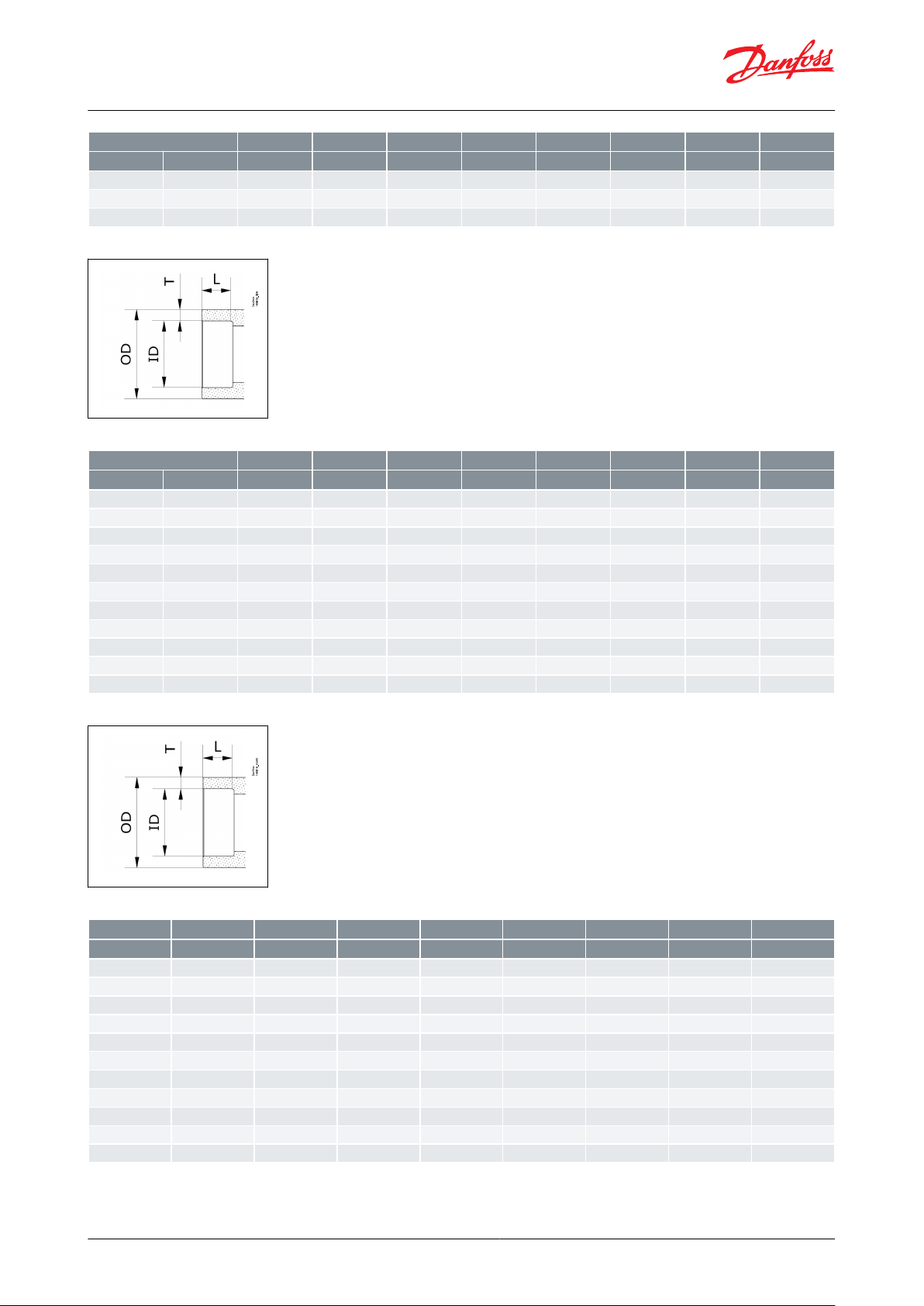

Figure 10: SD (DIN )

Table 13: Socket-Brazing DIN ( EN 1254-5)

Figure 11: SA (ASME)

Table 14: Socket-Brazing ASME (ASME B16.50)

© Danfoss | Climate Solutions | 2022.03 AI377236007167en-000301 | 13

SVA 6-10

ØD

G

C

G

H

Valve size

CGøDHWeight

SVA 6

mm

1393030

48

0.8 kg

in.

5.47

1.18

1.18

1.89

SVA 10

mm

1824538

60

1.4 kg

in.

7.17

1.77

1.5

2.36

øD

G

B

H

E

C

Shut-o valves, type SVA-S and SVA-L, 65 bar

Dimensions and weights

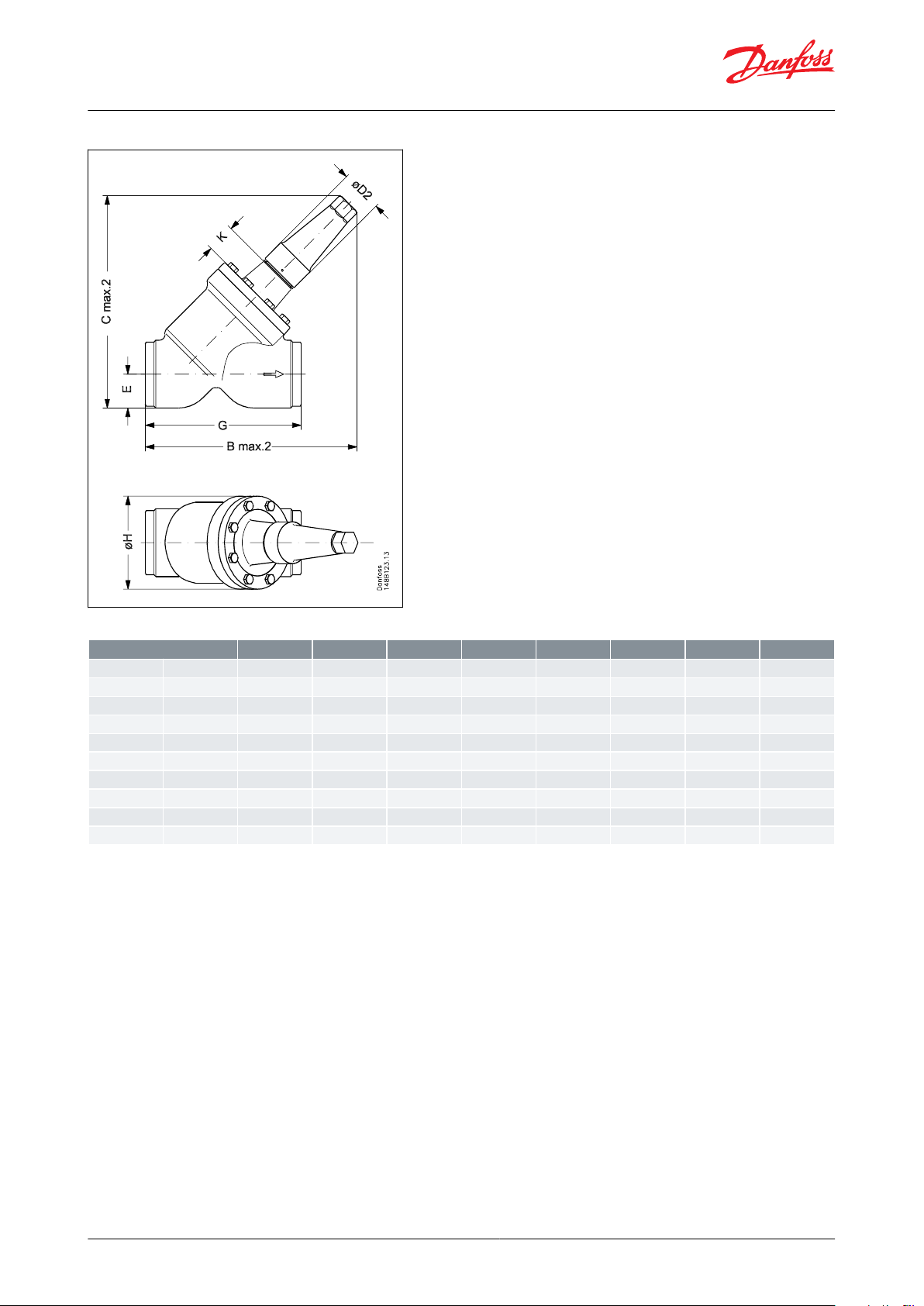

Figure 12: SVA 6 - 10 in angle execution with cap

Table 15: SVA 6-10

NOTE:

Specied weights are approximate values only.

Figure 13: SVA 6 - 10 in straight-way execution with cap

© Danfoss | Climate Solutions | 2022.03 AI377236007167en-000301 | 14

Valve size

CBEGøDHWeight

SVA 6

mm

110

12013703048

0.8 kg

in.

4.33

4.72

0.49

2.76

1.16

1.89

SVA 10

mm

145

155201203860

2.0 kg

in.

5.71

6.1

0.79

4.72

1.5

2.36

Valve size

K

C

max.2

G

øD

2

H

Weight

SVA 15 - 20mm63

2484538601.4 kg

SVA (½ - ¾)

in.

2.48

9.76

1.77

1.5

2.36

3.1 lb

SVA 25 - 40mm74

3305550702.4 kg

SVA (1 - 1½)

in.

2.91

12.99

2.17

1.97

2.76

5.3 lb

Valve size1K

C

max.2

G

øD2HWeight

SVA 15 - 20mm63

2484538601.4 kg

SVA (½ - ¾)

in.

2.48

9.76

1.77

1.5

2.36

3.1 lb

SVA 25 - 40mm74

3305550702.4 kg

SVA (1 - 1½)

in.

2.91

12.99

2.17

1.97

2.76

5.3 lb

Shut-o valves, type SVA-S and SVA-L, 65 bar

Table 16: SVA 6 - 10 in straight-way execution with cap

NOTE:

Specied weights are approximate values only.

Figure 14: SVA 15 - 40 (½ - 1½ in. ) in angleway version with cap

Table 17: SVA-S

Table 18: SVA-L

NOTE:

Specied weights are approximate values only.

© Danfoss | Climate Solutions | 2022.03 AI377236007167en-000301 | 15

B max.2

G

K

øD2

H

E

C max.2

Valve size

K

C

max.2Bmax.2

EGøD2HWeight

SVA 15 - 20mm4

141

156201203860

2.0 kg

SVA (½ - ¾)

in.

0.16

5.55

6.14

0.79

4.72

1.5

2.36

4.4 lb

SVA 25 - 40mm12

208

222261555070

3.0 kg

SVA (1 - 1½)

in.

0.47

8.19

8.74

1.02

6.1

1.97

2.76

6.6 lb

Valve size

K

Cmax.2

Bmax.2EG

øD2HWeight

SVA 15 - 20mm63

184

198201203860

2.0 kg

SVA (½ - ¾)

in.

2.48

7.24

7.8

0.79

4.72

1.5

2.36

4.4 lb

SVA 25 - 40mm74

252

265261555070

3.0 kg

SVA (1 - 1½)

in.

2.91

9.92

10.43

1.02

6.1

1.97

2.76

6.6 lb

Shut-o valves, type SVA-S and SVA-L, 65 bar

Figure 15: SVA 15 - 40 (½ - 1½ in. ) straightway version with cap

Table 19: SVA-S

Table 20: SVA-S

NOTE:

Specied weights are approximate values only.

© Danfoss | Climate Solutions | 2022.03 AI377236007167en-000301 | 16

Valve size

K

C

max.2

G

øD2HWeight

SVA 50mm70

3156050773.2 kg

SVA (2)

in.

2.76

12.4

2.36

1.97

3.03

7.1 lb

SVA 65mm70

3357050904.8 kg

SVA (2½)

in.

2.76

13.19

2.76

1.97

3.54

10.6 lb

Shut-o valves, type SVA-S and SVA-L, 65 bar

Figure 16: SVA 50 - 65 (2 - 2½ in.) in angleway version with cap

Table 21: SVA 50 - 65 (2 - 2½ in.) ANG CAP

NOTE:

Specied weights are approximate values only.

© Danfoss | Climate Solutions | 2022.03 AI377236007167en-000301 | 17

E

G

H

K

ØD2

B max.2

C max.2

Valve size

K

B

max.2Cmax.2

E

G

øD

2

H

Weight

SVA 50mm70

259

257321485077

4.2 kg

SVA (2)

in.

2.76

10.2

10.12

1.26

5.83

1.97

3.03

9.3 lb

SVA 65mm70

280

280401765090

6.3 kg

SVA (2½)

in.

2.76

11.02

11.02

1.57

6.93

1.97

3.54

13.9 lb

Shut-o valves, type SVA-S and SVA-L, 65 bar

Figure 17: SVA 50 - 65 (2 - 2½ in.) in straightway version with cap

Table 22: SVA-S

NOTE:

Specied weights are approximate values only.

© Danfoss | Climate Solutions | 2022.03 AI377236007167en-000301 | 18

Valve size

K

C

max.2

G

øD

2

øH

Weight

SVA 80mm76

3889058

129

9.7 kg

SVA (3)

in.315.28

3.54

2.28

5.08

21.4 lb

SVA 100mm90

437

10658156

15.3 kg

SVA (4)

in.

3.54

17.2

4.17

2.28

6.14

33.7 lb

SVA 125mm90

533

12874193

28.1 kg

SVA (5)

in.

3.54

20.98

5.04

2.91

7.6

61.9 lb

SVA 150mm90

568

14574219

39.7 kg

SVA (6)

in.

3.54

22.36

5.71

2.91

8.62

87.5 lb

SVA 200mm90

678

18086276

79.5 kg

SVA (8)

in.

3.54

26.69

7.09

3.39

10.87

175.3 lb

Shut-o valves, type SVA-S and SVA-L, 65 bar

Figure 18: SVA 80 - 200 (3 - 8 in.) angleway version with cap

Table 23: SVA-S

NOTE:

Specied weights are approximate values only.

© Danfoss | Climate Solutions | 2022.03 AI377236007167en-000301 | 19

Valve size

K

B

max.2Cmax.2

E

G

øD

2

øH

Weight

SVA 80mm76

321

3224821658129

10.9 kg

SVA (3)

in.312.64

12.72

1.89

8.5

2.28

5.08

24.0 lb

SVA 100mm90

367

3756026458156

18.2 kg

SVA (4)

in.

3.54

14.45

14.76

2.36

10.39

2.28

6.14

40.1 lb

SVA 125mm90

444

4567432274193

32.8 kg

SVA (5)

in.

3.54

17.48

17.95

2.91

12.68

2.91

7.6

72.3 lb

SVA 150mm90

483

5059137074219

60.0 kg

SVA (6)

in.

3.54

19.02

19.88

3.58

14.57

2.91

8.62

132.3 lb

SVA 200mm90

579

613

117

46486276

111.5 kg

SVA (8)

in.

3.54

22.8

24.13

4.61

18.27

3.39

10.87

245.8 lb

Shut-o valves, type SVA-S and SVA-L, 65 bar

Figure 19: SVA 80 - 200 (3 - 8 in.) straightway version with cap

Table 24: SVA-S

NOTE:

Specied weights are approximate values only.

© Danfoss | Climate Solutions | 2022.03 AI377236007167en-000301 | 20

Size

[DN]

Parts program

Housing

Top complete

ANG

STR

SVA-S

(cap)

SVA-L

(cap)

SVA- 65BT

DIN

ANSISDSA

DIN

ANSISDSA

6

148B6689

148B6687

148B6722

148B6711

148B6693

148B6691

148B6743

148B6732

148B6695

10

148B6690

148B6688

148B6723

148B6712

148B6694

148B6692

148B6744

148B6733

15

148B6622

148B6612

148B6724

148B6713

148B6642

148B6632

148B6745

148B6734

148B6652

148B6659

20

148B6623

148B6613

148B6725

148B6714

148B6643

148B6633

148B6746

148B6735

148B6652

148B6659

25

148B6624

148B6614

148B6726

148B6715

148B6644

148B6634

148B6747

148B6736

148B6653

148B6660

32

148B6625

148B6615

148B6727

148B6716

148B6645

148B6635

148B6748

148B6737

148B6653

148B6660

40

148B6626

148B6616

148B6728

148B6717

148B6646

148B6636

148B6749

148B6738

148B6653

148B6660

50

(1)

148B6627

148B6617

148B6718

148B6647

148B6637

148B6739

148B6654

148B6804

65

(1)

148B6628

148B6618

148B6729

148B6719

148B6648

148B6638

148B6750

148B6740

148B6655

148B6805

80

(1)

148B6629

148B6619

148B6730

148B6720

148B6649

148B6639

148B6751

148B6741

148B6656

148B6806

100

(1)

148B6630

148B6620

148B6731

148B6721

148B6650

148B6640

148B6752

148B6742

148B6657

148B6807

125

148B6631

148B6621

148B6651

148B6641

148B6658

150

200

Size

[DN]

Gasket

Complete valve

High temp for SVA-65BT

SVA (cap)

ANG

STR

DIN

ANSI

DIN

ANSI

6

148B5033

148B5053

10

148B5034

148B5054

15

148B5035

148B5055

20

148B5036

148B5056

25

148B5037

148B5057

32

148B5038

148B5058

40

148B5039

148B5059

50

148B6808

148B5040

148B5060

65

148B6809

148B5041

148B5061

80

148B6810

148B5042

148B5062

100

148B6811

148B5043

148B5063

125

148B5044

148B5064

150

148B6665

148B6667

148B6666

148B6668

200

148B6673

148B6675

148B6674

148B6676

Shut-o valves, type SVA-S and SVA-L, 65 bar

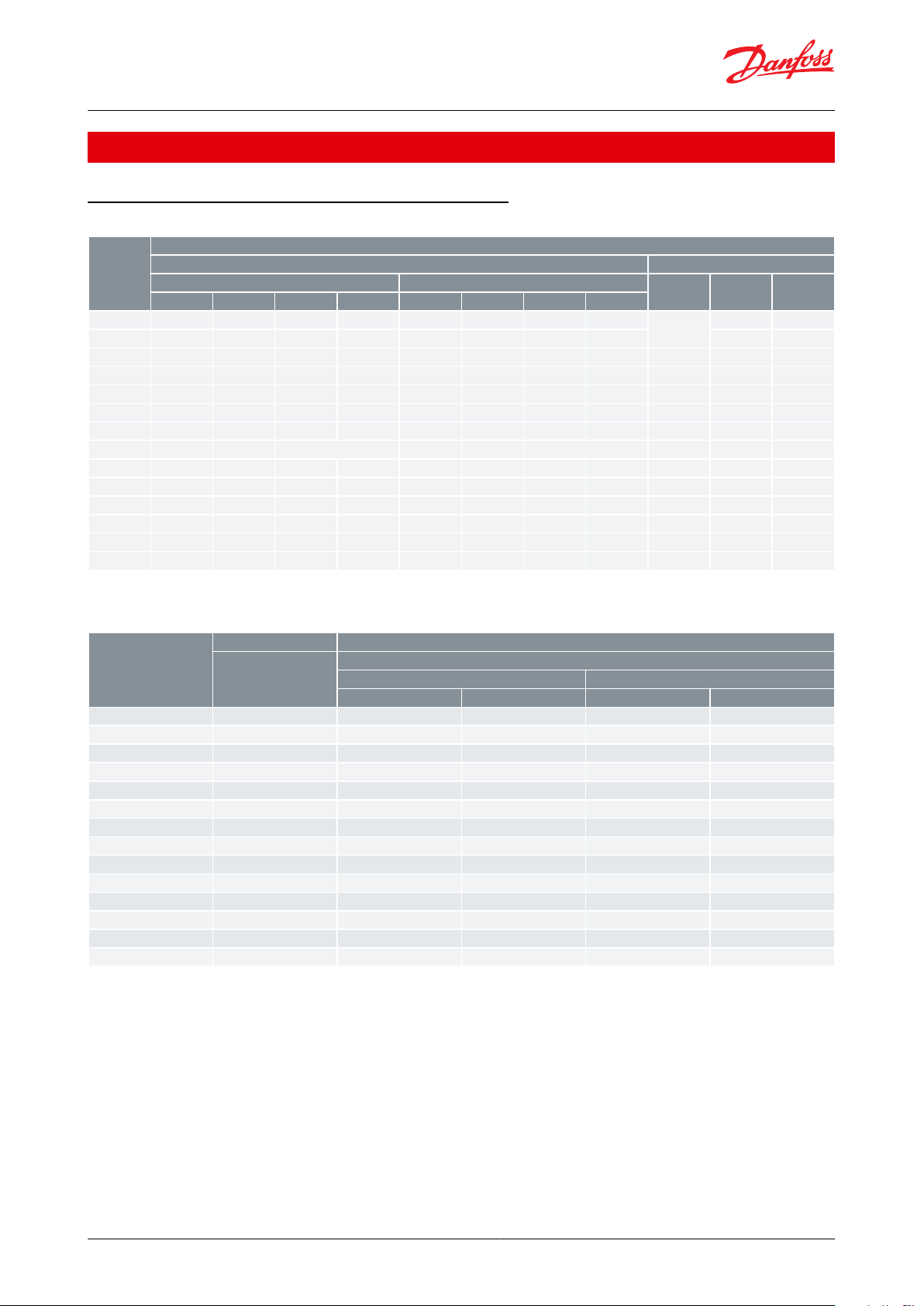

Ordering

Ordering from the entire SVL 65 bar (943 psi) series

Table 25: Ordering of SVL 65 bar (943 psi) series

(1)

(1)

Housings and Top complete SVA-65BT in these sizes: Max. temperature 190 °C (374 °F)

Housings and Top complete SVA-65BT in these sizes: Max. temperature 190 °C (374 °F)

Table 26: Gasket and complete valve

© Danfoss | Climate Solutions | 2022.03 AI377236007167en-000301 | 21

File name

Document type

Document topic

Approval authority

RU Д-DK.БЛ08.B.03634

EAC Declaration

Machinery & Equipment

EAC

0045 202 1204 Z 00354 19 D 001(00)

Pressure - Safety Certicate

TÜV

RU Д-DK.РА01.B.72064_20

EAC Declaration

PED

EAC

RU C-DK.БЛ08.B.01093_20

Pressure - Safety Certicate

PED

EAC

TS271067J-2023

Manufacturing Permission

TSG

AQSIQ

MD 033F0691.AE

Manufacturers Declaration

RoHS

Danfoss

MD 033F0686.AH

Manufacturers Declaration

PED

Danfoss

BV 03709-F0 BV

Marine - Safety Certicate

BV

TAP0000003 Rev. 1

Marine - Safety Certicate

DNV GL

EU 033F0685.AK

EU Declaration

EMCD/PED

Danfoss

033F0453.AD

Manufacturers Declaration

ATEX

Danfoss

19.10048.266

Marine - Safety Certicate

RMRS

SVL

Nominal bore

DN≤ 25 mm (1 in.)

DN32-80 mm (1¼ - 3 in.)

DN100 - 200 mm (4-8 in.)

Classied

for

Fluid group I

Category

Article 3, paragraph 3

II

III

Shut-o valves, type SVA-S and SVA-L, 65 bar

Certicates, declarations and approvals

The list contains all certicates, declarations, and approvals for this product type. Individual code number may have

some or all of these approvals, and certain local approvals may not appear on the list.

Some approvals may change over time. You can check the most current status at danfoss.com or contact your local

Danfoss representative if you have any questions.

Valid approvals

Pressure Equipment directive (PED)

SVA valves are approved according to the European standard specied in the Pressure Equipment Directive and are

CE marked. For further details / restrictions - see Installation Instruction.

Table 27: Pressure Equipment Directive (PED)

© Danfoss | Climate Solutions | 2022.03 AI377236007167en-000301 | 22

Online support

Danfoss oers a wide range of support along with our products, including digital product information, software,

mobile apps, and expert guidance. See the possibilities below.

The Danfoss Product Store

The Danfoss Product Store is your one-stop shop for everything product related—no matter where

you are in the world or what area of the cooling industry you work in. Get quick access to essential

information like product specs, code numbers, technical documentation, certications, accessories,

and more.

Start browsing at store.danfoss.com.

Find technical documentation

Find the technical documentation you need to get your project up and running. Get direct access to

our ocial collection of data sheets, certicates and declarations, manuals and guides, 3D models

and drawings, case stories, brochures, and much more.

Start searching now at www.danfoss.com/en/service-and-support/documentation.

Danfoss Learning

Danfoss Learning is a free online learning platform. It features courses and materials specically

designed to help engineers, installers, service technicians, and wholesalers better understand the

products, applications, industry topics, and trends that will help you do your job better.

Create your Danfoss Learning account for free at www.danfoss.com/en/service-and-support/learning.

Get local information and support

Local Danfoss websites are the main sources for help and information about our company and

products. Find product availability, get the latest regional news, or connect with a nearby expert—all

in your own language.

Find your local Danfoss website here: www.danfoss.com/en/choose-region.

Spare Parts

Get access to the Danfoss spare parts and service kit catalog right from your smartphone. The app

contains a wide range of components for air conditioning and refrigeration applications, such as

valves, strainers, pressure switches, and sensors.

Download the Spare Parts app for free at www.danfoss.com/en/service-and-support/downloads.

Coolselector®2 - nd the best components for you HVAC/R system

Coolselector®2 makes it easy for engineers, consultants, and designers to nd and order the best

components for refrigeration and air conditioning systems. Run calculations based on your operating

conditions and then choose the best setup for your system design.

Download Coolselector®2 for free at coolselector.danfoss.com.

Any information, including, but not limited to information on selection of product, its application or use, product design, weight, dimensions, capacity or any other

technical data in product manuals, catalogues descriptions, advertisements, etc. and whether made available in writing, orally, electronically, online or via download,

shall be considered informative, and is only binding if and to the extent, explicit reference is made in a quotation or order conrmation. Danfoss cannot accept any

responsibility for possible errors in catalogues, brochures, videos and other material. Danfoss reserves the right to alter its products without notice. This also applies to

products ordered but not delivered provided that such alterations can be made without changes to form, t or function of the product. All trademarks in this material

are property of Danfoss A/S or Danfoss group companies. Danfoss and the Danfoss logo are trademarks of Danfoss A/S. All rights reserved.

© Danfoss | Climate Solutions | 2022.03 AI377236007167en-000301 | 23

Loading...

Loading...