Page 1

Data Sheet

Shut-off valve

Type SVA-S SS and SVA-L SS

Designed for highly demanding production environments,

where corrosion is a risk

In certain specic areas such as outdoor

applications and corrosive atmospheres, such

as coastal installations, there is a need for high

surface protection to prevent failure due to

corrosion.

Today's food safety standards often call for daily

treatment with detergents to protect against

bacteria growth, again producing a need for

high surface protection.

SVA-S/L SS are angleway and straightway

stainless steel shut-o valves, which are

designed to meet all industrial refrigeration

application requirements.

The valves are designed to give favourable ow

characteristics and are easy to dismantle and

repair when necessary. The valve cone is

designed to ensure perfect closing.

AI234986440234en-000801

Page 2

Shut-o valve, Type SVA-S SS and SVA-L SS

Features

• Applicable to HCFC, HFC, R717 (Ammonia), R744 (CO2) and all ammable refrigerants

• Optional accessories:

◦ Heavy duty industrial hand wheel for frequent operation

◦ Cap for infrequent operation

• Available in angleway and straightway versions with Standard neck or Long neck (DN 15 to DN 40) for insulated

systems

• Designed to give favourable ow conditions

• Internal backseating enables replacement of the spindle seal whilst the valve is active, i.e. under pressure

• Housing is made of stainless steel approved for low temperature operations

• Easy to disassemble for inspection and service

• SVA-S/L SS shut-o valves can accept ow in either direction

• Butt-weld DIN and ANSI connections

• Maximum allowable working pressure and temperature range:

◦ DN 15-65: 52 bar (754 psi) at -60 °C/+50 °C (-76 °F/+122 °F)

◦ DN 80-125: 50 bar (725 psi) at -60 °C/+50 °C (-76 °F/+122 °F) For SVA-S/L SS see the relation between PS and

temperature in the curve on page 2

• Temperature range: -60 °C/+150 °C (-76 °F +302 °F)

• Compact and light valves for easy handling and installation

• Classication: DNV, CRN, BV, EAC etc. To get an updated list of certication on the products please contact your

local Danfoss Sales Company

© Danfoss | Climate Solutions | 2021.02 AI234986440234en-000801 | 2

Page 3

Shut-o valve, Type SVA-S SS and SVA-L SS

Media

Refrigerants

Applicable to HCFC, HFC, R717 (Ammonia), R744 (CO2) and all ammable refrigerants. For further information please

contact your local Danfoss Sales Company.

New refrigerants

Danfoss products are continually evaluated for use with new refrigerants depending on market requirements.

When a refrigerant is approved for use by Danfoss, it is added to the relevant portfolio, and the R number of the

refrigerant (e.g. R513A) will be added to the technical data of the code number. Therefore, products for specic

refrigerants are best checked at store.danfoss.com/en/, or by contacting your local Danfoss representative.

© Danfoss | Climate Solutions | 2021.02 AI234986440234en-000801 | 3

Page 4

-70

Pressure

-50 -30 -10 10 30 50 70 90 110 130 150

Temperature

-94 -58 -22 14 50 86 122 158 194 230 266 302

˚C

˚F

0

73

145

218

290

363

435

508

580

653

725

798

psi

0

5

10

15

20

25

30

35

40

45

50

55

bar

SVA-S/L SS DN15-DN65

SVA-S SS DN80 - DN125

Description

Values

Temperature Range

-60 °C /+150 °C (-76 °F /+302 °F)

Pressure range

The valves are designed for max. working pressure 52 barg (754 psig)

P

S

5

0

/

7

2

5

p

s

i

g

S

T

O

P

V

A

L

V

E

S

V

A

-

S

S

S

D

N

8

0

/

3

@

–

6

0

°

C

\

–

7

6

°

F

–

1

5

0

°

C

\

3

0

2

°

F

Shut-o valve, Type SVA-S SS and SVA-L SS

Product specication

Pressure and temperature data

Figure 1: Pressure and temperature range

Table 1: Pressure and temperature range

Design

Housing

Made of stainless steel approved for low temperature operations.

Valve cone

The valve cone can be turned on the spindle, thus there will be no friction between the cone and the seat, when the

valve is opened and closed. A teon tightening ring provides perfect sealing at a minimum closing momentum.

Spindle

Made of polished stainless steel, ideal for O-ring sealing. Furthermore, parts of the spindle are heat treated to obtain

anti-abrasive/adhesive properties.

Packing gland

The stainless steel packing gland comprises a spring loaded seal packing gland which ensures a perfect tightness in

the range: -60 °C/+150 °C (-76 °F/+302 °F). The packing glands are equipped with a scraper ring to prevent

penetration of dirt and ice into the packing gland.

Figure 2: Example of Marking Ring

© Danfoss | Climate Solutions | 2021.02 AI234986440234en-000801 | 4

Page 5

ø

Size

ØDT15

mm

21.3

2.3½in.

0.839

0.09120mm

26.9

2.3

3

⁄4

in

1.059

0.09125mm

33.7

2.61in.

1.327

0.10332mm

42.4

2.6

1

1

⁄4

in.

1.669

0.10240mm

48.3

2.61½in.

1.902

0.10350mm

60.3

2.92in.

2.37

0.1165mm

76.1

2.92½in.30.1180mm

88.9

3.23in.

3.5

0.13

100

mm

114.3

3.64in.

4.5

0.14

125

mm

139.7

45in.

5.5

0.16

Size

ØDT15

mm

21.3

2.8½in.

0.839

0.1120mm

26.9

2.9

3

⁄4

in

1.06

0.1125mm

33.7

3.51in.

1.33

0.1432mm

42.4

3.6

Shut-o valve, Type SVA-S SS and SVA-L SS

Installation

It is recommended that the valves be installed in the direction of ow indicated by the arrow on the valve body. The

valve can be installed in the opposite direction but this slightly reduces the kv-value (Cv-value).

The valve is designed to withstand high internal pressure. However, the piping system in general should be

designed to avoid liquid traps and reduce the risk of hydraulic pressure caused by thermal expansion.

For further information refer to installation guide for SVA-S/L SS.

Connections

Available with the following connections:

• Butt-weld DIN (EN 10220)

◦ DN 15 - 125 (½ - 5 in.)

• Butt-weld ANSI (B 36.19M)

◦ DN 15 - 100 (½ - 4 in.)

Figure 3: DIN

Figure 4: ANSI

Table 2: Butt-weld DIN (EN 10220)

Table 3: Butt-weld ANSI (B 36.19M, SCHEDULE 40)

© Danfoss | Climate Solutions | 2021.02 AI234986440234en-000801 | 5

Page 6

Size

ØDT1

1

⁄4

in.

1.67

0.1440mm

48.3

3.7

1

1

⁄2

in.

1.9

0.15

Size

ØDT50

mm

60.3

2.82in.

2.37

0.1165mm733.12½in.

2.87

0.1280mm

88.9

3.13in.

3.5

0.12

100

mm

114.3

3.14in.

4.5

0.12

Danfoss

M148B0038_1

Danfoss

M148B0035_1

No.

Part

MaterialENISO

ASTM

1

Housing

Stainless steel

GX5CrNi19-1

EN10213-4

AISI 304

2

Bonnet, Flange

Stainless steel

X5CrNi18-10

EN10088

AISI 304

3

Bonnet, Insert

Stainless steel

X8CrNiS18-9

DIN 17440

AISI 303

4

Spindle

Stainless steel

X8CrNiS18-9

DIN 17440

Type 17

683/13

AISI 303

5

Cone

Steel

8

Packing gland

Stainless steel

X8CrNiS18-9

10088

Type 17

683/13

AISI 303

9

Packing washer

Aluminium

10

O-ring

Cloroprene (Neoprene)

Shut-o valve, Type SVA-S SS and SVA-L SS

Table 4: Butt-weld ANSI (B 36.19M, SCHEDULE 10)

Material specication

SVA-S SS 15-40 (½ - 1½ in.)

Figure 5: SVA-S SS 15-40 (½ - 1½ in.)

Table 5: SVA-S SS 15-40 (½ - 1½ in.)

© Danfoss | Climate Solutions | 2021.02 AI234986440234en-000801 | 6

Page 7

No.

Part

MaterialENISO

ASTM

11

Spring loaded Teon ring

PTFE12Bolts

Stainless steel

A2-70

A2-70

Type 308

13

Gasket

Fiber, Non-asbestos

14

Handwheel

Steel17Cap

Aluminium

18

Gasket for cap

Nylon

20

Identication ring

Stainless steel

21

Disk spring

Steel

Danfoss

M148B0040_1

Danfoss

M148B327_02-2017

No.

Part

MaterialENISO

ASTM

1

Housing

Stainless steel

GX5CrNi19-10

EN10213-4

AISI 304

2

Bonnet, Flange

Stainless steel

X5CrNi18-10

EN10088

AISI 304

3

Bonnet, Insert

Stainless steel

X8CrNiS18-9

DIN 17440

AISI 303

4

Spindle

Stainless steel

X8CrNiS18-9

DIN 17440

Type 17

683/13

AISI 303

5

Cone

Steel

8

Packing gland

Stainless steel

X8CrNiS18-9

10088

Type 17

683/13

AISI 303

9

Packing washer

Aluminium

10

O-ring

Cloroprene (Neoprene)

11

Spring loaded Teon ring

PTFE12Bolts

Stainless steel

A2-70

A2-70

Type 308

13

Gasket

Fiber, Non-asbestos

14

Handwheel

Steel17Cap

Aluminium

Shut-o valve, Type SVA-S SS and SVA-L SS

SVA-L SS 15 - 40 (½ - 1½ in.)

Figure 6: SVA-L SS 15 - 40 (½ - 1½ in.)

Table 6: SVA-L SS 15 - 40 (½ - 1½ in.)

© Danfoss | Climate Solutions | 2021.02 AI234986440234en-000801 | 7

Page 8

No.

Part

MaterialENISO

ASTM

18

Gasket for cap

Nylon

20

Identication ring

Stainless steel

21

Disk spring

Steel

Danfoss

M148B0039_1

Danfoss

M148B0036_1

No.

Part

MaterialENISO

ASTM

1

Housing

Stainless steel

GX5CrNi19-10

EN10213-4

AISI 304

3

Valve bonnet

Stainless steel

GX5CrNi19-10

EN10213-4

AISI 304

4

Spindle

Stainless steel

X8CrNiS18-9

DIN 17440

Type 17

683/13

AISI 303

5

Cone

Steel

8

Packing gland

Stainless steel

X8CrNiS18-9

10088

Type 17

683/13

AISI 303

9

Packing washer

Aluminium

10

O-ring

Cloroprene (Neoprene)

11

Spring loaded Teon ring

PTFE12Bolts

Stainless steel

A2-70

A2-70

Type 308

13

Gasket

Fiber, Non-asbestos

14

Handwheel

Steel17Cap

Aluminium

18

Gasket for cap

Nylon

19

Locking nut

Steel

20

Identication ring

Stainless steel

21

Disk spring

Steel

Shut-o valve, Type SVA-S SS and SVA-L SS

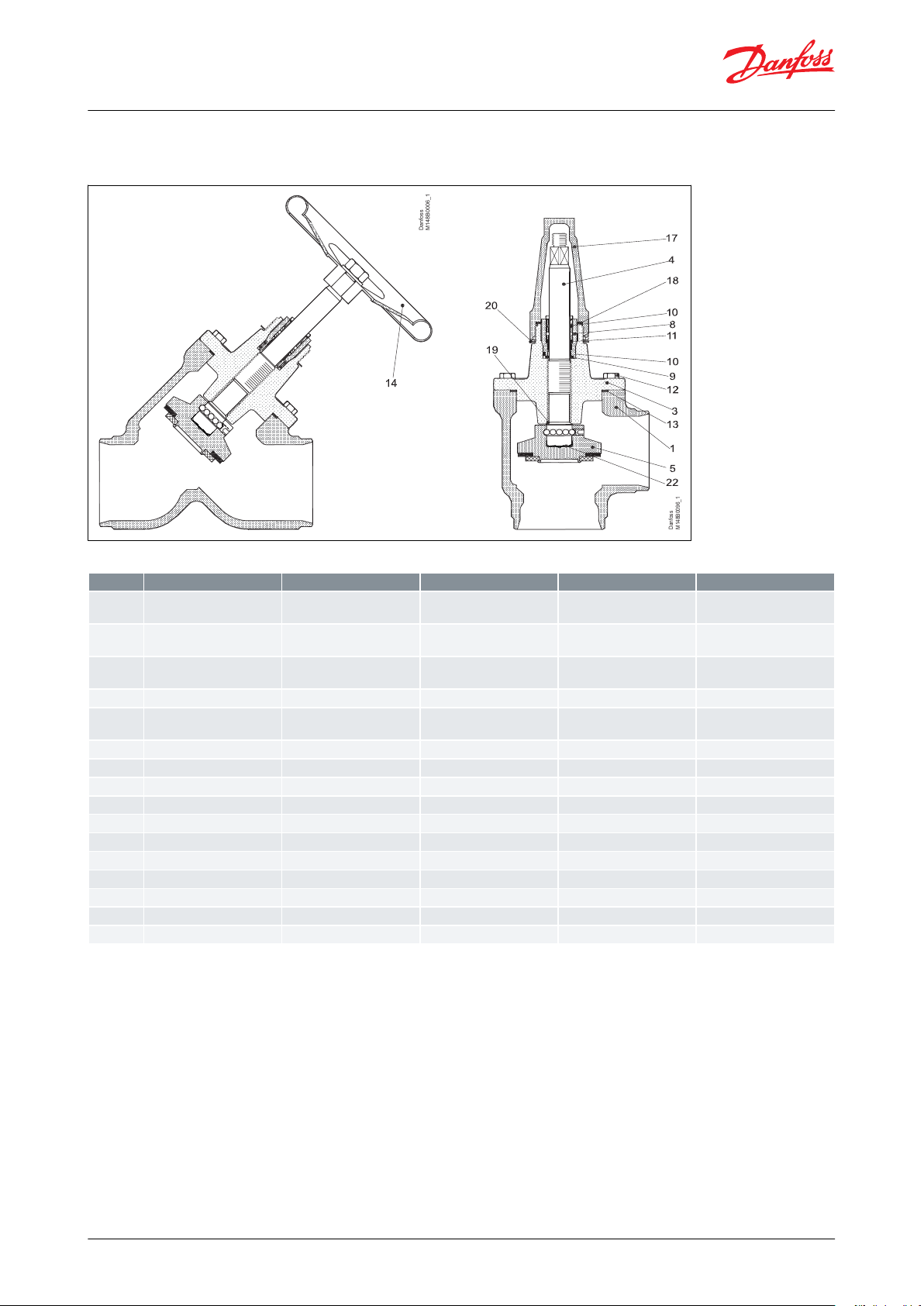

SVA-S SS 50-65 (2 - 2½ in.)

Figure 7: SVA-S SS 50-65 (2 - 2½ in.)

Table 7: SVA-S SS 50-65 (2 - 2½ in.)

© Danfoss | Climate Solutions | 2021.02 AI234986440234en-000801 | 8

Page 9

Danfoss

M148B0096_1

Danfoss

M148B0006_1

No.

Part

MaterialENISO

ASTM

1

Housing

Stainless steel

GX5CrNi19-10

EN10213-4

AISI 304

3

Valve bonnet

Stainless steel

GX5CrNiMo19-11-2

EN10213-4

AISI 304

4

Spindle

Stainless steel

X5CrNi18-10

DIN 17440

Type 17

683/13

AISI 303

5

Cone Cone seal

Steel Teon (PTFE)

8

Packing gland

Stainless steel

Type 17 R

683/13

AISI 303

9

Packing washer

Aluminium

10

O-ring

Cloroprene (Neoprene)

11

Spring loaded Teon ring

PTFE12Bolts

Stainless steel

A2-70

A2-70

Type 308

13

Gasket

Fiber, Non-asbestos

14

Hand wheel

Steel17Cap

Aluminium

18

Gasket for cap

Nylon (PA 6)

19

Soft backseat

Teon (PTFE)

20

Identication ring

Stainless steel

22

Disk spring

Steel

Shut-o valve, Type SVA-S SS and SVA-L SS

SVA-S SS 80 - 125 (3 - 5 in.)

Figure 8: SVA-S SS 80 - 125 (3 - 5 in.)

Table 8: SVA-S SS 80 - 125 (3 - 5 in.)

© Danfoss | Climate Solutions | 2021.02 AI234986440234en-000801 | 9

Page 10

SVA-xx x x ANG CAP

SVA-xx x x ANG H-WHEEL

Valve size

K

C

max .1Cmax .2

G

ØD1ØD

2

ØH

Weight

SVA-S SS 15-20

mm

4

178

18945603860

1.4 kg

SVA-S SS

1

⁄2 - 3⁄4"

in.

0.1677.44

1.77

2.36

1.5

2.36

3.1 lbs

SVA-S SS 25-40

mm

12

234

26855805070

2.4 kg

SVA-S SS 1 - 1⁄"

in.

0.47

9.21

10.55

2.17

3.15

1.97

2.76

5.3 lbs

SVA-xx x x STR CAP

SVA-xx x x STR H-WHEEL

Valve size

K

C

max.1Cmax.2Bmax.1Bmax.2

E

G

ØD1ØD

2

ØH

Weight

SVA-S SS 15 - 20

mm

4

146

141

160

156201206038602.0 kg

SVA-S SS (½ - ¾)

in.

0.16

5.74

5.55

6.3

6.14

0.79

4.72

2.36

1.5

2.36

4.4 lb

SVA-S SS 25 - 40

mm

12

199

208

212

222261558050703.0 kg

SVA-S SS (1 - 1½)

in.

0.47

7.83

8.19

8.35

8.74

1.02

6.1

3.15

1.97

2.76

6.6 lb

Shut-o valve, Type SVA-S SS and SVA-L SS

Dimensions and weight

SVA S SS 15 - 40 (½ - 1½ in. ) in angleway version with cap / hand wheel

Figure 9: SVA S SS 15 - 40 (½ - 1½ in. ) in angleway

version with cap / hand wheel

Table 9: SVA S SS 15 - 40 (½ - 1½ in. )

NOTE:

Specied weights are approximate values only.

SVA-S/L SS 15 - 40 (½ - 1½ in. ) straightway version with cap / hand wheel

Figure 10: SVA-S/L SS 15 - 40 (½ - 1½ in. ) straightway version with cap / hand wheel

Table 10: SVA-S SS 15 - 40 (½ - 1½ in. )

© Danfoss | Climate Solutions | 2021.02 AI234986440234en-000801 | 10

Page 11

Valve size

K

C

max.1Cmax.2Bmax.1Bmax.2

E

G

ØD1ØD

2

ØH

Weight

SVA-L SS 15 - 20

mm

63

188

184

202

198201206038602.0 kg

SVA-L SS (½ - ¾)

in.

2.48

7.4

7.24

7.95

7.8

0.79

4.72

2.36

1.5

2.36

4.4 lb

SVA-L SS 25 - 40

mm

74

243

252

256

265261558050703.0 kg

SVA-L SS (1 - 1½)

in.

2.91

9.57

9.92

10.08

10.43

1.02

6.1

3.15

1.97

2.76

6.6 lb

SVA-xx x x ANG CAP

SVA-xx x x ANG H-WHEEL

Valve size

K

C

max.1Cmax.2

G

ØD1ØD

2

ØH

Weight

SVA-S SS 50

mm

70

284

315601005077

3.2 kg

SVA-S SS (2)

in.

2.76

11.18

12.4

2.36

3.94

1.97

3.03

7.1 lb

SVA-S SS 65

mm

70

310

335701005090

4.8 kg

SVA-S SS (2½)

in.

2.76

12.2

13.19

2.76

3.94

1.97

3.54

10.6 lb

Shut-o valve, Type SVA-S SS and SVA-L SS

NOTE:

Specied weights are approximate values only.

Table 11: SVA-L SS 15 - 40 (½ - 1½ in. )

NOTE:

Specied weights are approximate values only.

SVA-S SS 50 - 65 (2 - 2½ in.) in angleway version with cap / hand wheel

Figure 11: SVA-S SS 50 - 65 (2 - 2½ in.) in angleway

version with cap / hand wheel

Table 12: SVA-S SS 50 - 65 (2 - 2½ in.)

NOTE:

Specied weights are approximate values only.

© Danfoss | Climate Solutions | 2021.02 AI234986440234en-000801 | 11

Page 12

SVA-xx x x STR CAP

SVA-xx x x STR H-WHEEL

Valve size

K

B

max.1Bmax.2Cmax.1Cmax.2

E

G

ØD1ØD

2

ØH

Weight

SVA-S SS 50

mm

70

259

259

257

25732148

1005077

4.2 kg

SVA-S SS (2)

in.

2.76

10.2

10.2

10.12

10.12

1.26

5.83

3.94

1.97

3.03

9.3 lb

SVA-S SS 65

mm

70

284

280

284

28040176

1005090

6.3 kg

SVA-S SS (2½)

in.

2.76

11.18

11.02

11.18

11.02

1.57

6.93

3.94

1.97

3.54

13.9 lb

Shut-o valve, Type SVA-S SS and SVA-L SS

SVA-S SS 50 - 65 (2 - 2½ in.) in straightway version with cap / hand wheel

Figure 12: SVA-S SS 50 - 65 (2 - 2½ in.) in straightway version with cap / hand wheel

Table 13: SVA-S SS 50 - 65 (2 - 2½ in.)

NOTE:

Specied weights are approximate values only.

© Danfoss | Climate Solutions | 2021.02 AI234986440234en-000801 | 12

Page 13

SVA-xx x x ANG CAP

Valve size

K

C

max.2

G

ØD1ØD

2

ØH

Weight

SVA-S SS 80

mm

76

3889020058129

9.7 kg

SVA-S SS (3)

in.

3

15.28

3.54

7.87

2.28

5.08

21.4 lb

SVA-S SS 100

mm

90

437

106

25058156

15.3 kg

SVA-S SS (4)

in.

3.54

17.2

4.17

9.84

2.28

6.14

33.7 lb

SVA-S SS 125

mm

90

533

128

31574193

28.1 kg

SVA-S SS (5)

in.

3.54

20.98

5.04

12.4

2.91

7.6

61.9 lb

Shut-o valve, Type SVA-S SS and SVA-L SS

SVA-S SS 80 - 125 (3 - 5 in.) angleway version with cap / hand wheel

Figure 13: SVA-S SS 80 - 125

(3 - 5 in.) angleway version

with cap / hand wheel

Table 14: SVA-S SS 80 - 125 (3 - 5 in.)

NOTE:

Specied weights are approximate values only.

© Danfoss | Climate Solutions | 2021.02 AI234986440234en-000801 | 13

Page 14

Valve type

SVA-S/L SS

Shut-o valve

Available connections

D

A

Nominal size in mm (valve

size measured on the

connection diameter)

15

DN 15 (½)

x

x

20

DN 20 (¾)

x

x

25

DN 25 (1)

x

x

32

DN 32 (1¼)

x

x

40

DN 40 (1½)

x

x

50

DN 50 (2)

x

x

65

DN 65 (2½)

x

x

80

DN 80 (3)

x

x

100

DN 100 (4)

x

x

125

DN 125 (5)

x

Connections

D

Butt-weld connection: DIN EN 10220

A

Butt-weld connection: ANSI B 36.19M

Valve housing

ANG

Angle ow

STR

Straight ow

Other equipment

H-WHEEL

Hand wheel

CAP

Cap

Size

Type

MWP

Code number

mm

in.

bar

psi

15

½

SVA-S SS 15 D ANG H-WHEEL

52

754

148B5289

15

½

SVA-S SS 15 D ANG CAP

52

754

148B5290

20

¾

SVA-S SS 20 D ANG H-WHEEL

52

754

148B5377

20

¾

SVA-S SS 20 D ANG CAP

52

754

148B5378

25

1

SVA-S SS 25 D ANG H-WHEEL

52

754

148B5486

25

1

SVA-S SS 25 D ANG CAP

52

754

148B5487

32

1¼

SVA-S SS 32 D ANG H-WHEEL

52

754

148B5566

32

1¼

SVA-S SS 32 D ANG CAP

52

754

148B5567

40

1½

SVA-S SS 40 D ANG H-WHEEL

52

754

148B5646

40

1½

SVA-S SS 40 D ANG CAP

52

754

148B5647

50

2

SVA-S SS 50 D ANG H-WHEEL

52

754

148B5753

50

2

SVA-S SS 50 D ANG CAP

52

754

148B5754

65

2½

SVA-S SS 65 D ANG H-WHEEL

52

754

148B5847

65

2½

SVA-S SS 65 D ANG CAP

52

754

148B5848

80

3

SVA-S SS 80 D ANG CAP

50

725

148B5928

100

4

SVA-S SS 100 D ANG CAP

50

725

148B6032

125

5

SVA-S SS 125 D ANG CAP

50

725

148B6126

Shut-o valve, Type SVA-S SS and SVA-L SS

Ordering

Please note that the type codes only serve to identify the valves, some of which may not form part of the standard

product range. For further information please contact your local Danfoss Sales Company.

Table 15: Type codes

NOTE:

Where products need to be certied according to specic certication societies or where higher pressures are

required, the relevant information should be included at the time of order.

Ordering SVA-S SS

SVA-S SS Angleway

Table 16: Butt-weld DIN (EN 10220)

© Danfoss | Climate Solutions | 2021.02 AI234986440234en-000801 | 14

Page 15

Size

Type

MWP

Code number

mm

in.

bar

psi

15

½

SVA-S SS 15 A40 ANG CAP

52

754

148B5396

20

¾

SVA-S SS 20 A40 ANG CAP

52

754

148B5395

25

1

SVA-S SS 25 A40 ANG CAP

52

754

148B6477

32

1¼

SVA-S SS 32 A40 ANG CAP

52

754

148B5595

40

1½

SVA-S SS 40 A40 ANG CAP

52

754

148B5683

Size

Type

MWP

Code number

mm

in.

bar

psi

50

2

SVA-S SS 50 D/A10 ANG CAP

52

754

148B5754

65

2½

SVA-S SS 65 A10 ANG CAP

52

754

148B6448

80

3

SVA-S SS 80 D/A10 ANG CAP

52

754

148B5928

100

4

SVA-S SS 100 A10 ANG CAP

52

754

148B6035

Size

Type

MWP

Code number

mm

in.

bar

psi

15

½

SVA-S SS 15 D STR H-WHEEL

52

754

148B5291

15

½

SVA-S SS 15 D STR CAP

52

754

148B5292

20

¾

SVA-S SS 20 D STR H-WHEEL

52

754

148B5379

20

¾

SVA-S SS 20 D STR CAP

52

754

148B5380

25

1

SVA-S SS 25 D STR H-WHEEL

52

754

148B5488

25

1

SVA-S SS 25 D STR CAP

52

754

148B5489

32

1¼

SVA-S SS 32 D STR H-WHEEL

52

754

148B5568

32

1¼

SVA-S SS 32 D STR CAP

52

754

148B5569

40

1½

SVA-S SS 40 D STR H-WHEEL

52

754

148B5648

40

1½

SVA-S SS 40 D STR CAP

52

754

148B5649

50

2

SVA-S SS 50 D STR H-WHEEL

52

754

148B5755

50

2

SVA-S SS 50 D STR CAP

52

754

148B5756

65

2½

SVA-S SS 65 D STR H-WHEEL

52

754

148B5849

65

2½

SVA-S SS 65 D STR CAP

52

754

148B5850

Size

Type

MWP

Code number

mm

in.

bar

psi

15

½

SVA-S SS 15 A40 STR CAP

52

754

148B5397

20

¾

SVA-S SS 20 A40 STR CAP

52

754

148B5398

25

1

SVA-S SS 25 A40 STR CAP

52

754

148B5399

32

1¼

SVA-S SS 32 A40 STR CAP

52

754

148B5596

40

1½

SVA-S SS 40 A40 STR CAP

52

754

148B5684

Size

Type

MWP

Code number

mm

in.

bar

psi

50

2

SVA-S SS 50 D/A10 STR CAP

52

754

148B5756

65

2½

SVA-S SS 65 A10 STR CAP

52

754

148B6449

Shut-o valve, Type SVA-S SS and SVA-L SS

Table 17: Butt-weld ANSI (B 36.19M SCHEDULE 40)

Table 18: Butt-weld ANSI (B 36.19M SCHEDULE 10)

SVA-S SS Straightway

Table 19: Butt-weld DIN (EN 10220)

Table 20: Butt-weld ANSI (B 36.19M SCHEDULE 40)

Table 21: Butt-weld ANSI (B 36.19M SCHEDULE 10)

ANG = Angleway

STR = Straightway

CAP = Cap

H-WHEEL = Hand wheel

Example:

SVA-S SS 20 DIN angleway with hand wheel = 148B5377

© Danfoss | Climate Solutions | 2021.02 AI234986440234en-000801 | 15

Page 16

Size

Type

MWP

Code number

mm

in.

bar

psi

15

½

SVA-L SS 15 D ANG H-WHEEL

52

754

148B6546

15

½

SVA-L SS 15 D ANG CAP

52

754

148B6547

20

¾

SVA-L SS 20 D ANG H-WHEEL

52

754

148B6550

20

¾

SVA-L SS 20 D ANG CAP

52

754

148B6551

25

1

SVA-L SS 25 D ANG H-WHEEL

52

754

148B6554

25

1

SVA-L SS 25 D ANG CAP

52

754

148B6555

32

1¼

SVA-L SS 32 D ANG H-WHEEL

52

754

148B6558

32

1¼

SVA-L SS 32 D ANG CAP

52

754

148B6559

40

1½

SVA-L SS 40 D ANG H-WHEEL

52

754

148B6562

40

1½

SVA-L SS 40 D ANG CAP

52

754

148B6563

Size

Type

MWP

Code number

mm

in.

bar

psi

15

½

SVA-L SS 15 D STR H-WHEEL

52

754

148B6548

15

½

SVA-L SS 15 D STR CAP

52

754

148B6549

20

¾

SVA-L SS 20 D STR H-WHEEL

52

754

148B6552

20

¾

SVA-L SS 20 D STR CAP

52

754

148B6553

25

1

SVA-L SS 25 D STR H-WHEEL

52

754

148B6556

25

1

SVA-L SS 25 D STR CAP

52

754

148B6557

32

1¼

SVA-L SS 32 D STR H-WHEEL

52

754

148B6560

32

1¼

SVA-L SS 32 D STR CAP

52

754

148B6561

40

1½

SVA-L SS 40 D STR H-WHEEL

52

754

148B6564

40

1½

SVA-L SS 40 D STR CAP

52

754

148B6565

Shut-o valve, Type SVA-S SS and SVA-L SS

NOTE:

Where products need to be certied according to specic certication societies or where higher pressures are

required, the relevant information should be included at the time of order.

Ordering SVA-L SS

SVA-L SS Angleway

Table 22: Butt-weld DIN (EN 10220)

SVA-L SS Straightway

Table 23: Butt-weld DIN (EN 10220)

ANG = Angleway

STR = Straightway

CAP = Cap

H-WHEEL = Hand wheel

© Danfoss | Climate Solutions | 2021.02 AI234986440234en-000801 | 16

Page 17

Type

File name

Document type

Document topic

Approval authority

SVA-SS

033F0686.AH

Manufacturers Declaration

PED

Danfoss

033F0453.AD

Manufacturers Declaration

ATEX

Danfoss

TSSA CRN.0C16578.523467890YTN

Pressure - Safety Certicate

CRN

TSSA

033F0691.AE

Manufacturers Declaration

RoHS

Danfoss

The stainless steel valves are approved and CE marked in accordance with the Pressure Equipment Directive - 97/23/EC.

SVA-S/L SS

Nominal bore

DN≤ 25 mm (1 in.)

DN32-80 mm (1¼ - 3 in.)

DN100 - 125 mm (4-5 in.)

Classied for

Fluid group I

Category

Article 3, paragraph 3

II

III

Shut-o valve, Type SVA-S SS and SVA-L SS

Certicates, declarations, and approvals

The list contains all certicates, declarations, and approvals for this product type. Individual code number may have

some or all of these approvals, and certain local approvals may not appear on the list.

Some approvals may change over time. You can check the most current status at danfoss.com or contact your local

Danfoss representative if you have any questions.

Table 24: Valid approvals

Table 25: Pressure Equipment Directive (PED)

Table 26: Compliance

© Danfoss | Climate Solutions | 2021.02 AI234986440234en-000801 | 17

Page 18

Online support

Danfoss oers a wide range of support along with our products, including digital product information, software,

mobile apps, and expert guidance. See the possibilities below.

The Danfoss Product Store

The Danfoss Product Store is your one-stop shop for everything product related—no matter where

you are in the world or what area of the cooling industry you work in. Get quick access to essential

information like product specs, code numbers, technical documentation, certications, accessories,

and more.

Start browsing at store.danfoss.com.

Find technical documentation

Find the technical documentation you need to get your project up and running. Get direct access to

our ocial collection of data sheets, certicates and declarations, manuals and guides, 3D models

and drawings, case stories, brochures, and much more.

Start searching now at www.danfoss.com/en/service-and-support/documentation.

Danfoss Learning

Danfoss Learning is a free online learning platform. It features courses and materials specically

designed to help engineers, installers, service technicians, and wholesalers better understand the

products, applications, industry topics, and trends that will help you do your job better.

Create your Danfoss Learning account for free at www.danfoss.com/en/service-and-support/learning.

Get local information and support

Local Danfoss websites are the main sources for help and information about our company and

products. Find product availability, get the latest regional news, or connect with a nearby expert—all

in your own language.

Find your local Danfoss website here: www.danfoss.com/en/choose-region.

Spare Parts

Get access to the Danfoss spare parts and service kit catalog right from your smartphone. The app

contains a wide range of components for air conditioning and refrigeration applications, such as

valves, strainers, pressure switches, and sensors.

Download the Spare Parts app for free at www.danfoss.com/en/service-and-support/downloads.

Coolselector®2 - nd the best components for you HVAC/R system

Coolselector®2 makes it easy for engineers, consultants, and designers to nd and order the best

components for refrigeration and air conditioning systems. Run calculations based on your operating

conditions and then choose the best setup for your system design.

Download Coolselector®2 for free at coolselector.danfoss.com.

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its

products without notice. This also applies to products already on order provided that such alterations can be made without subsequential

changes being necessary in specications already agreed. All trademarks in this material are property of the respective companies. Danfoss and

the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

© Danfoss | Climate Solutions | 2021.02 AI234986440234en-000801 | 18

Loading...

Loading...