Page 1

Data Sheet

Shut-off valve

Type SVA DH and

SVA DL 250 – 300

Designed to meet all industrial refrigeration application requirements

SVA-DL and SVA-DH are angleway shut-o

valves designed to meet all industrial

refrigeration application requirements.

SVA-DL (Delta pressure Low)

is designed with a restriction in the opening

function. High dierential pressure can be

applied from the side port and reduced

pressure can be applied from bottom port.

SVADL is a twostep valve for pressure relief.

SVA-DH (Delta pressure High)

is designed without restriction in the opening

function. As a result of its balanced design this

valve is able to open at

all dierential pressures with limited torque.

The angleway shut-o valves are carefully

designed to give favourable ow

conditions. Easy to dismantle for inspection

and repair.

Both SVA-DL & SVA-DH shut-o valves have

internal backseating enabling the spindle seal

to be replaced with the valve still under

pressure.

The valves are designed to give favourable ow

characteristics and are easy to dismantle for

servicing. The valve cone is designed to ensure

perfect closing.

AI177086432445en-000801

Page 2

Description

Features

Valve body/connection material

Steel

Equipment

Handwheel/Cap

Connection standard

EN 10220

ASME B 36.10M SCHEDULE 40/STD

DIN 2448

Connection type

Butt weld

Max. temperature range

-60 °C – 150 °C (-76 °F – +302 °F)

Max. working pressure [bar/psig]

40 bar (580 psig) at -60 °C – +60 °C (-76 °F – +140 °F)

36 bar (522 psig) at +60 °C – +80 °C (+140 °F – +176 °F)

32 bar (464 psig) at +80 °C – +120 °C (+176 °F – +248 °F)

28 bar (406 psig) at +120 °C – +150 °C (+248 °F – +302 °F)

Packing format

Single pack

Shut-o valves, Type SVA DH and SVA DL 250 – 300

Features

• Applicable to HCFC, HFC, R717 (Ammonia) and R744 (CO2) and all ammable refrigerants

• Optional accessories:

◦ Heavy duty industrial handwheel for frequent operation

◦ Vented cap for infrequent operation

• Available in angleway version with extended bonnet for insulated systems

• The valve caps can be wire-sealed, to prevent operation by unauthorised persons

• Internal PTFE backseating

• The bonnet is suitable for installation in insulated low temperature applications

• The housing and bonnet are made from low temperature steel in accordance with the requirements of the

Pressure Equipment Directive and other international classication authorities

• Classication: DNV, CRN, BV, EAC etc.

Portfolio overview

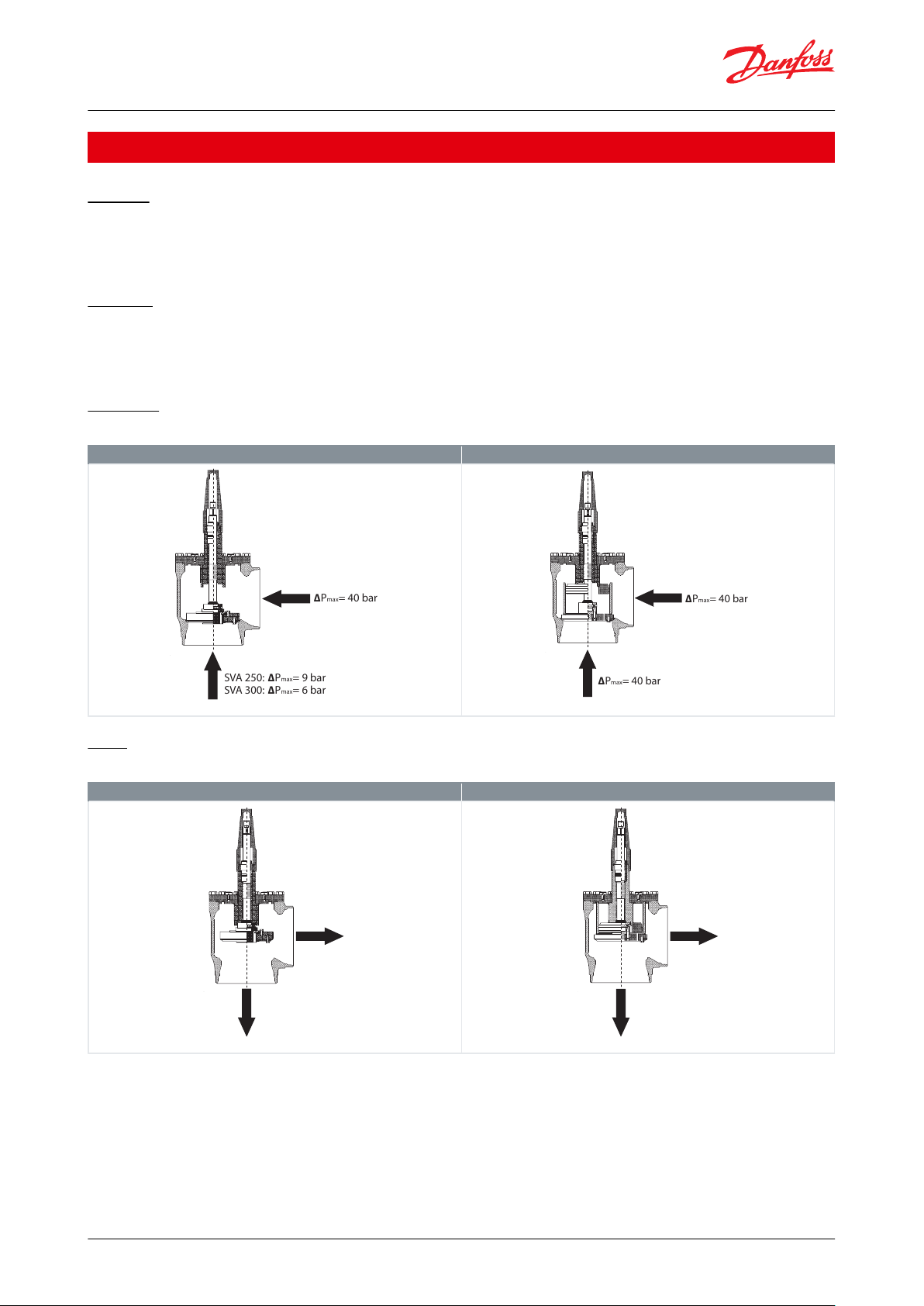

Figure 1: SVA-DL &

SVA-DH

Table 1: Portfolio overview

© Danfoss | Climate Solutions | 2021.02 AI177086432445en-000801 | 2

Page 3

SVA-DL

SVA-DH

SVA 250: ∆Pmax= 9 bar

SVA 300: ∆Pmax= 6 bar

∆Pmax= 40 bar

∆Pmax= 40 bar

∆Pmax= 40 bar

SVA-DL

SVA-DH

Shut-o valves, Type SVA DH and SVA DL 250 – 300

Functions

SVA-DL

The SVA-DL shut-o valve is designed with a restriction in the ow direction (dierential pressure). To ensure the

most favourable valve performance the ow must be directed from the side port towards the valve cone. Operation

of the valve with ow in this direction is made possible by the two-step opening valve cone as illustrated below.

SVA-DH

The SVA-DH shut-o valve is designed without restrictions in either ow direction or dierential pressure. Due to

the balanced valve cone design the torque required to operate the valve is minimized and the valve can be opened

and closed against high pressure with ow in any direction.

Pressure

Table 2: Pressure SVA-DL and SVA-DH

Flow

Table 3: Flow SVA-DL and SVA-DH

NOTE:

Above pressures indicates the maximum pressures at which the the valve can be operated manually and tightness

can be achieved.

© Danfoss | Climate Solutions | 2021.02 AI177086432445en-000801 | 3

Page 4

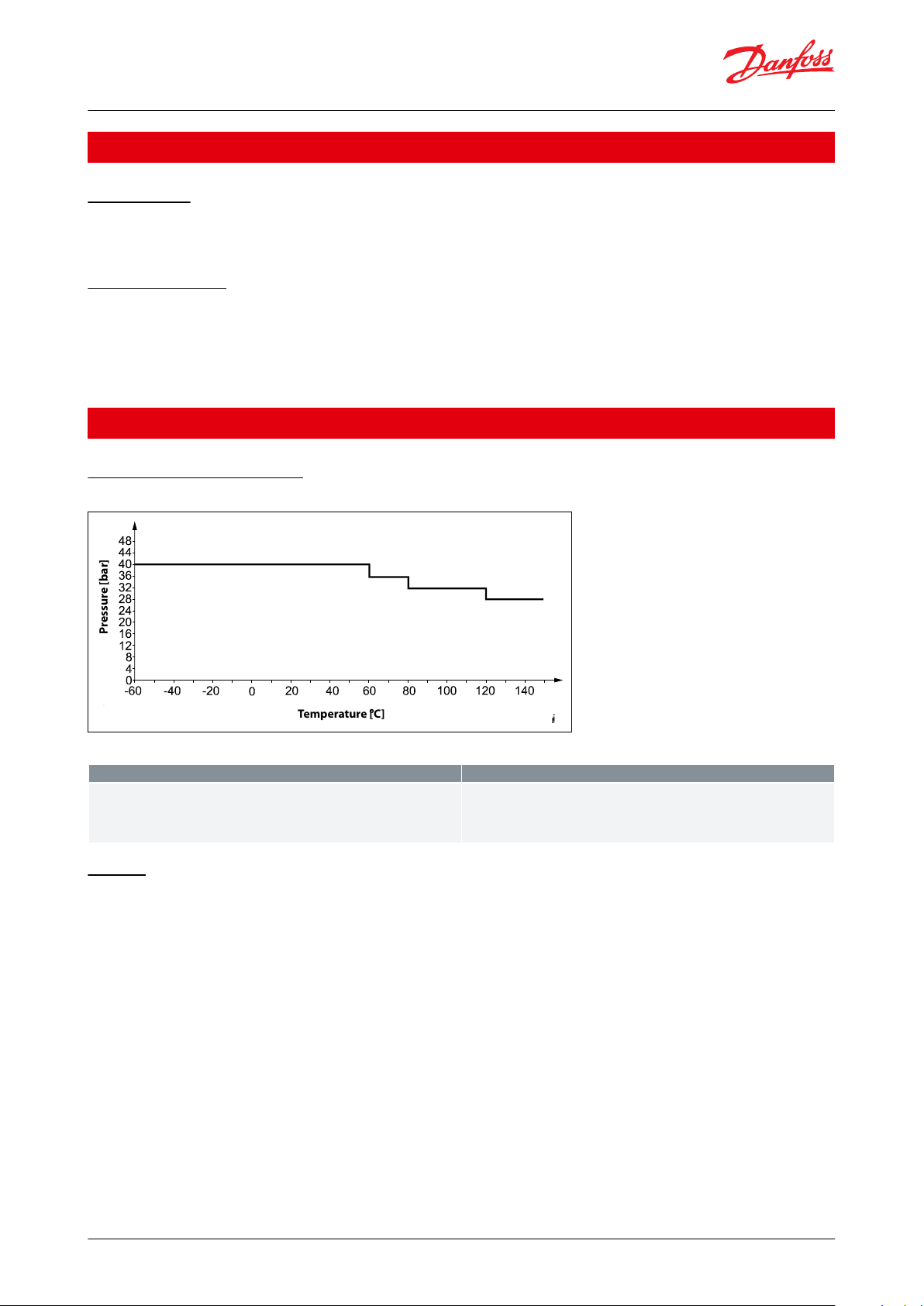

Pressure [bar]

Temperature [ºC]

Temperature range

Max Working Pressure @ specic temperature range

-60 °C – +150 °C (-76 °F – +302 °F)

40 bar (580 psig) at -60 °C – +60 °C (-76 °F – +140 °F)

36 bar (522 psig) at +60 °C – +80 °C (+140 °F – +176 °F)

32 bar (464 psig) at +80 °C – +120 °C (+176 °F – +248 °F)

28 bar (406 psig) at +120 °C – +150 °C (+248 °F – +302 °F)

Shut-o valves, Type SVA DH and SVA DL 250 – 300

Media

Refrigerants

Applicable to HC, HCFC, HFC, R717 (Ammonia) and R744 (CO2). For further information please see installation guide

for SVA-DL and SVA-DH.

New refrigerants

Danfoss products are continually evaluated for use with new refrigerants depending on market requirements.

When a refrigerant is approved for use by Danfoss, it is added to the relevant portfolio, and the R number of the

refrigerant (e.g. R513A) will be added to the technical data of the code number. Therefore, products for specic

refrigerants are best checked at store.danfoss.com/en/, or by contacting your local Danfoss representative.

Product specication

Pressure and temperature

Figure 2: Pressure and temperature graph

Table 4: Pressure and temperature

Design

Housing and bonnet

Made from special, cold-resistant steel approved for low temperature operations.

Bolts

Stainless steel, Quality A2-70.

Valve cone assembly

The valve cone assembly is turnable on the spindle, thus there is no friction between cone and seat when the valve

is opened and closed. A Teon tightening ring provides perfect sealing at a minimum closing torque.

Spindle

Made of polished stainless steel, ideal for O-ring sealing.

Packing gland

The packing gland comprises a spring loaded seal packing which ensures perfect tightness in the range: -60 °C –

150 °C (-76 °F – 302 °F). Furthermore, the packing glands incorporate a scraper ring to prevent the penetration of

dirt and ice.

© Danfoss | Climate Solutions | 2021.02 AI177086432445en-000801 | 4

Page 5

Danfoss

M148B0072_1

No.

Part

Material

EN

ASTM

1

Housing

Steel

G20Mn5 QT, EN 10213-3

LCC, A352

3

Bonnet

Steel

P275NL1, EN 10028-3

G20Mn5QT EN 10213-3

Grade A, A662

LCC, A352

4

Spindle

Steel

X5CrNi18-10, EN10088

AISI 304

5

Cone

Steel

P275NL1, EN 10028-3

Grade A, A662

6

Set screw

Steel

Quality 8.8

Grade 5

7

Balls

Stainless steel

8

Packing Gland

Stainless steel

X8CrNiS18-9

10088

AISI 303

9

O-ring

Cloroprene (Neoprene)

10

Spring loaded Teon ring

PTFE11O-ring

Cloroprene (Neoprene)

12

Bolts

Stainless steel

A2-70

Type 308

13

Gasket

Fiber, Non-asbestos

14

Handwheel

Steel15Washer

Stainless steel

16

Lock nut

Stainless steel+nylon

Shut-o valves, Type SVA DH and SVA DL 250 – 300

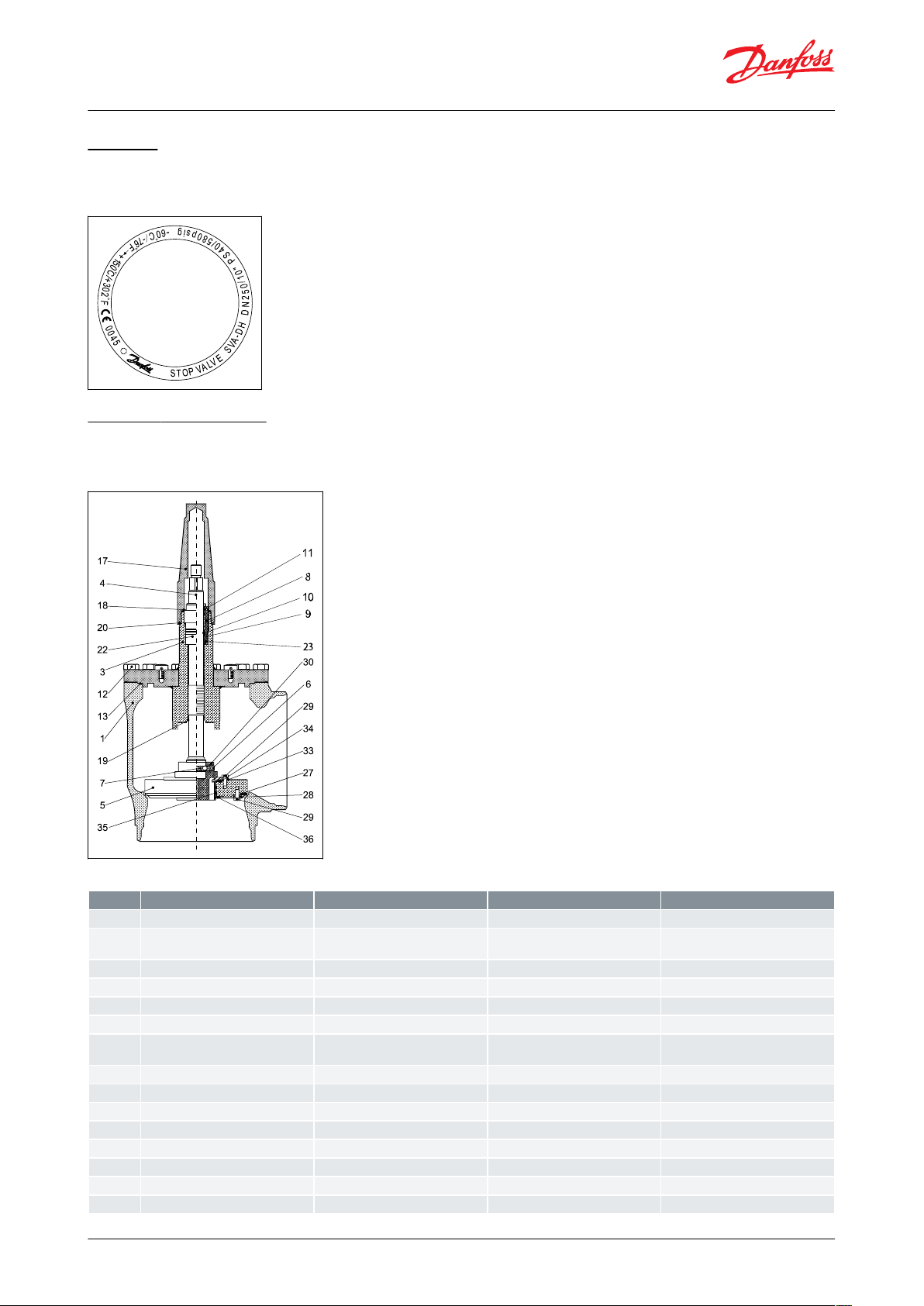

Marking

Each valve type is clearly marked with type, size and performance range

Figure 3: Example of marking ring, SVA-DH

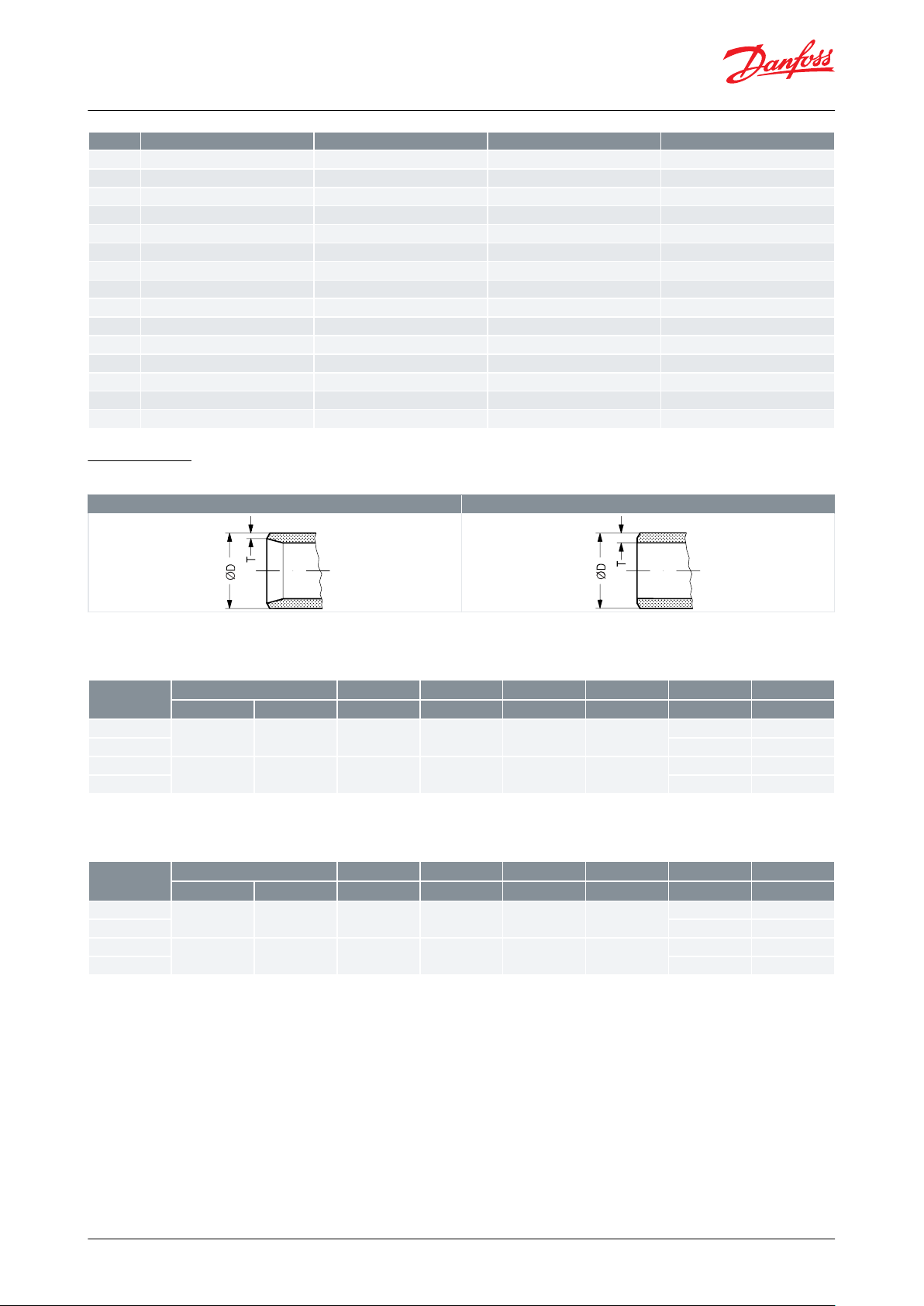

Material specication

SVA-DL 250-300

Figure 4: SVA-DL 250-300

Table 5: SVA-DL 250 - 300

© Danfoss | Climate Solutions | 2021.02 AI177086432445en-000801 | 5

Page 6

No.

Part

Material

EN

ASTM

17

Cap

Aluminium

AlMgSi1

18

Gasket for cap

Nylon (PA 6)

19

Soft backseat

Teon (PTFE)

20

Identication ring

Stainless steel

22

Guide for spindle

Steel

11SMn30

Grade1213, A29

23

O-ring

PTFE/FKM

27

Gasket

Teon (PTFE)

28

Front for valve cone

Steel

S235JRG2, EN10025

Grade C, A283

29

Bolts

Steel

Quality 8.8

Grade 5

30

Insert, valve cone

Spheroidal graphite cast iron

EN-GJS-250

Class 40B

31

Lifting eye bolts

Steel33Backing for valve cone

Steel

S235JRG2, EN10025

Grade C, A283

34

Gasket

Teon (PTFE)

35

Wear ring

Teon (PTFE)

36

Retaining ring

Spring steel

Danfoss

M148B0073_1

No.

Part

Material

EN

ASTM

1

Housing

Steel

G20Mn5 QT, EN 10213-3

LCC, A352

3

Bonnet

Steel

P275NL1, EN 10028-3

G20Mn5QT EN 10213-3

Grade A, A662

LCC, A352

4

Spindle

Steel

X5CrNi18-10 DIN 17440

5

Cone

Steel

P275NL1, EN 10028-3

Grade A, A662

6

Set screw

Steel

Quality 8.8

Grade 5

7

Balls

Stainless steel

8

Packing Gland

Stainless steel

X8CrNiS18-9

10088

AISI 303

9

O-ring

Cloroprene (Neoprene)

10

Spring loaded Teon ring

PTFE11O-ring

Cloroprene (Neoprene)

12

Bolts

Stainless steel

A2-70

Type 308

13

Gasket

Fiber, Non-asbestos

14

Handwheel

Steel15Washer

Stainless steel

16

Lock nut

Stainless steel+nylon

Shut-o valves, Type SVA DH and SVA DL 250 – 300

SVA-DH 250 - 300

Figure 5: SVA-DH 250-300

Table 6: SVA-DH 250 - 300

© Danfoss | Climate Solutions | 2021.02 AI177086432445en-000801 | 6

Page 7

No.

Part

Material

EN

ASTM

17

Cap

Aluminium

AlMgSi1

18

Gasket for cap

Nylon (PA 6)

19

Soft backseat

Teon (PTFE)

20

Identication ring

Stainless steel

22

Guide for spindle

Steel

11SMn30

Grade1213, A29

23

Bolts

Steel24Washer

Steel25U-sleeve sealing

Teon (PTFE) +Stainless steel

26

Wear ring

Teon (PTFE)

27

Gasket

Teon (PTFE)

28

Front for valve cone

Steel

S235JRG2, EN10025

Grade C, A283

29

Bolts

Steel

Quality 8.8

Grade 5

30

Insert, valve cone

Spheroidal graphite cast iron

EN-GJS-250

Class 40B

31

Lifting eye bolts

Steel32O-ring

PTFE/FKM

DIN

ANSI

ø

Type

Size

øDTøD

T

KVCVmm

in.mmmm

in.

in.

m

3

/h

Us

gal

/min

SVA-DH

25010273

6.3

10.75

0.25

1405

1630

SVA-DL

1610

1868

SVA-DH

30012323.9

7.1

12.75

0.28

1870

2169

SVA-DL

2082

2415

Type

Size

øDTøD

T

KVCVmm

in.mmmm

in.

in.

m

3

/h

Us

gal

/min

SVA-DH

25010273

9.3

10.75

0.25

1405

1630

SVA-DL

1610

1868

SVA-DH

30012323.9

9.5

12.75

0.28

1870

2169

SVA-DL

2082

2415

Shut-o valves, Type SVA DH and SVA DL 250 – 300

Connections

Table 7: Available connections

Welding DIN (2448)

Table 8: Welding DIN (2448)

Welding ANSI (B 36.10)

Table 9: Welding ANSI (B 36.10)

© Danfoss | Climate Solutions | 2021.02 AI177086432445en-000801 | 7

Page 8

With handwheel

With vented cap

Valve sizeKC

max. 1Cmax. 2

G

øD1øD2øH

Weight

SVA-DL / SVA-DH

SVA 250

mm

102

745

782

210

40086334

130 kg

SVA (10)

in.

4

29.33

30.79

8.27

15.75

3.39

13.14

287 lb

SVA 300

mm

102

852

842

240

50086384

190 kg

SVA (12)

in.

4

33.54

33.14

9.45

19.69

3.39

15.12

419 lb

Shut-o valves, Type SVA DH and SVA DL 250 – 300

Dimensions and weights

Table 10: Dimensions and weights

Table 11: SVA-DH, SVA-DL 250 -300, angleway version

NOTE:

Specied weights are nominal, and may dier depending on actual conguration of the code number.

© Danfoss | Climate Solutions | 2021.02 AI177086432445en-000801 | 8

Page 9

Valve type

Nominal size in mm

SVA-DL

SVA-DH

Shut-o valve

(Δp Low)

(Δp High)

Available connections

D

A

(Valve size measured on the

connection diameter)

250

DN250XX

300

DN300XX

Connections

D

Butt weld connection: DIN 2448

A

Butt weld connections: ANSI B 36.10 DN250: Schedule 40and DN300: STD

Other euipment

CAP

Aluminum cap

H-WHEEL

Steel handweel

Type

Size

Code number

mm

in.

SVA-DL 250 D CAP

250

10

148B3760

SVA-DL 250 D H-WHEEL

250

10

148B3761

SVA-DL 250 A CAP

250

10

148B3762

SVA-DL 250 A H-WHEEL

250

10

148B3763

SVA-DH 250 D CAP

250

10

148B3764

SVA-DH 250 D H-WHEEL

250

10

148B3765

SVA-DH 250 A CAP

250

10

148B3766

SVA-DH 250 A H-WHEEL

250

10

148B3767

SVA-DL 300 D CAP

300

12

148B3770

SVA-DL 300 D H-WHEEL

300

12

148B3771

SVA-DL 300 A CAP

300

12

148B3772

SVA-DL 300 A H-WHEEL

300

12

148B3773

SVA-DH 300 D CAP

300

12

148B3774

SVA-DH 300 D H-WHEEL

300

12

148B3775

SVA-DH 300 A CAP

300

12

148B3776

SVA-DH 300 A H-WHEEL

300

12

148B3777

Shut-o valves, Type SVA DH and SVA DL 250 – 300

Ordering

The table below can be used to identify the valve required.

Please note that the type codes only serve to identify the valves, some of which may not form part of the standard

product range.

For further information please contact your local Danfoss Sales Company.

Table 12: Identify the valve

NOTE:

Where products need to be certied according to specic certication societies or where higher pressures are

required, contact your local Danfoss Sales Company .

Table 13: Ordering

A = ANSI butt-weld

D = DIN butt-weld

H-WHEEL: Handwheel

CAP: Vented cap

© Danfoss | Climate Solutions | 2021.02 AI177086432445en-000801 | 9

Page 10

Type

File name

Document type

Document topic

Approval authority

SVA-DL 250

CRN.0C16578.523467890YTN

Pressure - Safety Certicate

CRN

TSSA

SVA-DL 300

0045 202 1201 Z 00423 19 D 001(00)

Pressure - Safety Certicate

PED

TÜV

CRN.0C16578.523467890YTN

CRN

TSSA

SVA-DH 250

CRN.0C16578.523467890YTN

Pressure - Safety Certicate

CRN

TSSA

SVA-DH 300

0045 202 1201 Z 00423 19 D 001(00)

Pressure - Safety Certicate

PED

TÜV

CRN.0C16578.523467890YTN

CRN

TSSA

Nominal bore

DN 250 mm (10 in.)

DN 300 (12 in.)

Classied for

Fluid group I

Category

III

IV

SVA-DL and SVA-DH valves are approved and CE marked in accordance with the Pressure Equipment Directive - 97/23/EC.

For further details / restrictions - see Installation guide.

Shut-o valves, Type SVA DH and SVA DL 250 – 300

Certicates, declarations, and approvals

The list contains all certicates, declarations, and approvals for this product type. Individual code number may have

some or all of these approvals, and certain local approvals may not appear on the list.

Some approvals may change over time. You can check the most current status at danfoss.com or contact your local

Danfoss representative if you have any questions.

Table 14: Valid Approvals

Table 15: Compliance

Table 16: Pressure Equipment Directive (PED)

© Danfoss | Climate Solutions | 2021.02 AI177086432445en-000801 | 10

Page 11

Online support

Danfoss oers a wide range of support along with our products, including digital product information, software,

mobile apps, and expert guidance. See the possibilities below.

The Danfoss Product Store

The Danfoss Product Store is your one-stop shop for everything product related—no matter where

you are in the world or what area of the cooling industry you work in. Get quick access to essential

information like product specs, code numbers, technical documentation, certications, accessories,

and more.

Start browsing at store.danfoss.com.

Find technical documentation

Find the technical documentation you need to get your project up and running. Get direct access to

our ocial collection of data sheets, certicates and declarations, manuals and guides, 3D models

and drawings, case stories, brochures, and much more.

Start searching now at www.danfoss.com/en/service-and-support/documentation.

Danfoss Learning

Danfoss Learning is a free online learning platform. It features courses and materials specically

designed to help engineers, installers, service technicians, and wholesalers better understand the

products, applications, industry topics, and trends that will help you do your job better.

Create your Danfoss Learning account for free at www.danfoss.com/en/service-and-support/learning.

Get local information and support

Local Danfoss websites are the main sources for help and information about our company and

products. Find product availability, get the latest regional news, or connect with a nearby expert—all

in your own language.

Find your local Danfoss website here: www.danfoss.com/en/choose-region.

Spare Parts

Get access to the Danfoss spare parts and service kit catalog right from your smartphone. The app

contains a wide range of components for air conditioning and refrigeration applications, such as

valves, strainers, pressure switches, and sensors.

Download the Spare Parts app for free at www.danfoss.com/en/service-and-support/downloads.

Coolselector®2 - nd the best components for you HVAC/R system

Coolselector®2 makes it easy for engineers, consultants, and designers to nd and order the best

components for refrigeration and air conditioning systems. Run calculations based on your operating

conditions and then choose the best setup for your system design.

Download Coolselector®2 for free at coolselector.danfoss.com.

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its

products without notice. This also applies to products already on order provided that such alterations can be made without subsequential

changes being necessary in specications already agreed. All trademarks in this material are property of the respective companies. Danfoss and

the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

© Danfoss | Climate Solutions | 2021.02 AI177086432445en-000801 | 11

Loading...

Loading...