Page 1

Data Sheet

Float valve

Type SV 4, SV 5 and SV 6

Liquid level regulators in refrigeration, freezing

and air conditioning systems

SV 4, SV 5 and SV 6 are for use on the low

pressure side as modulating liquid level

regulators in refrigeration, freezing and air

conditioning systems with ammonia and other

common types of refrigerants.

Features:

• Reliable function

• Stable regulation, even during momentary

load change

• Liquid injection into the oat housing or

directly into the evaporator through external

pipe connection

• Orice assembly and lter can be replaced

without evacuating the oat housing

• Can be supplied without oat housing for

direct installation in the system (special order

only)

• Can be used as pilot oat for PMLF if

mounted with special orice (diameter Ø2.5

mm)

• Classication: DNV, CRN, BV, EAC etc. To get

an updated list of certication on the

products please contact your local Danfoss

Sales Company.

AI175286419654en-000601

Page 2

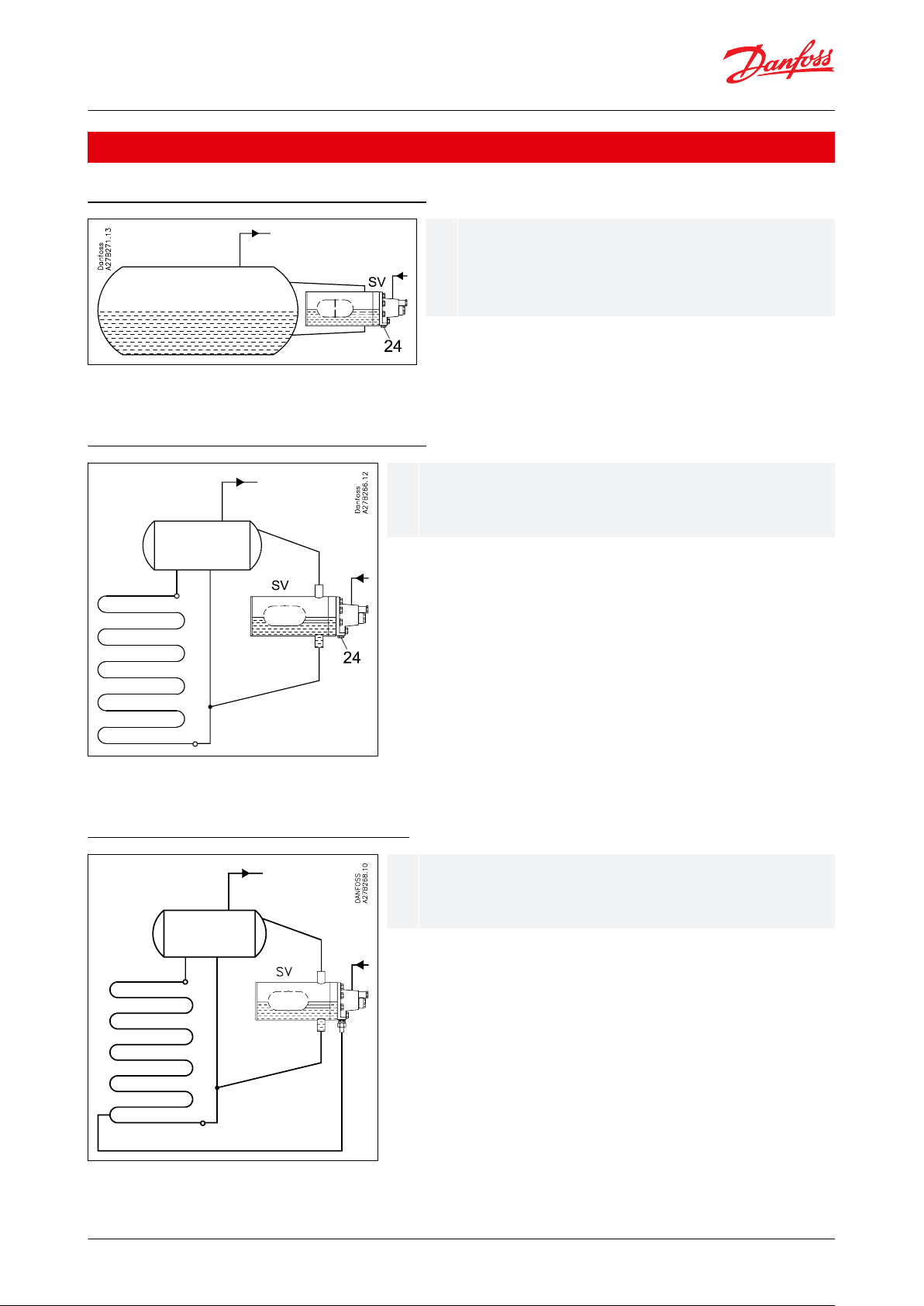

Direct liquid injection into the oat housing 4 pcs. M6

screws (pos. 23) are removed, and pos. 24 remains

blanked o. This leaves four holes through which liquid

expands directly.

4 pcs. M6 screws (pos. 23) are removed, and pos. 24 remains

blanked o. This leaves four holes through which liquid

expands directly.

Used in large evaporators with long pipe lines.

pos. 24 is removed and weld connection is mounted

pos. 23 remains screwed

Float valve, Type SV 4, SV 5 and SV 6

Applications

The liquid expands into the oat housing

NOTE:

If the capacity is too high, only remove two or three screws. Pos. 23 and 24, see .Table 7

The liquid expands into the oat housing

NOTE:

If the capacity is too high, only remove two or three screws. Pos. 23 and 24, see Table 7

The liquid expands into the evaporator

NOTE:

Pos. 23 and 24, see Table 7

© Danfoss | Climate Solutions | 2021.02 AI175286419654en-000601 | 2

Page 3

4 pcs. M6 screws (pos. 23) are removed, and pos. 24 remains

blanked o. This leaves four holes through which liquid

expands directly.

Float valve, Type SV 4, SV 5 and SV 6

The liquid expands directly into the surge drum

NOTE:

If the capacity is too high, only remove two or three screws. Pos. 23 and 24, see Table 7

Media

Refrigerants

Applicable to HCFC, HFC and R717 (Ammonia). Use with ammable hydrocarbons cannot be recommended; please

contact Danfoss.

New refrigerants

Danfoss products are continually evaluated for use with new refrigerants depending on market requirements.

When a refrigerant is approved for use by Danfoss, it is added to the relevant portfolio, and the R number of the

refrigerant (e.g. R513A) will be added to the technical data of the code number. Therefore, products for specic

refrigerants are best checked at store.danfoss.com/en/, or by contacting your local Danfoss representative.

© Danfoss | Climate Solutions | 2021.02 AI175286419654en-000601 | 3

Page 4

Description

Values

P band

Approx. 35 mm

Max. working pressure

MWP = 28 bar

Max. Δp

SV 4 = 23 bar

SV 5 = 21 bar

SV 6 = 19 bar

Media temperature

-50 °C to 120 °C

Max. test pressure

MTP = 32 bar

kv value and diameter for orice

SV 4: kv = 0.23 m3/h D = 3.0 mm

SV 5: kv = 0.31 m3/h D = 3.5 mm

SV 6: kv = 0.43 m3/h D = 4.0 mm

Description

Values

Refrigerant

R717 (NH

3

)

Evaporating capacity

Q

e

= 145 kW

Evaporating temperature

t

e

= -10 °C (~ pe = 2.9 bar abs.)

Condensing temperature

t

c

= +30 °C (~ pc = 11.7 bar abs.)

Liquid temperature ahead of SV

t

l

= +20 °C

Subcooling

Δtsub = t

c

− tl = 30 °C − 20 °C = 10 K

Pressure drop in SV

Δp = p

c

− pe = 11.7 − 2.9 = 8.8 bar

Correction factor k for 10 K subcooling

= 0.98

Corrected capacity

145 × 0.98 = 142 kW

Float valve, Type SV 4, SV 5 and SV 6

Product specication

Pressure and temperature data

Table 1: Pressure and temperature data

Identication

Figure 1: Identication

Materials

• Gaskets are non asbestos

• Valve housing made of lowtemperature cast iron, spherical (EN-GJS-400-18-LT)

• Float housing: ST 35.8 DIN 17175 W. no. 1.0305

Dimensioning example for SV

Table 2:

NOTE:

At te = -10 °C and Δp = 8 bar SV 5 yields 147 kW and can therefore be used.

Capacity

The values in the capacity tables are based on a subcooling of 4 K just ahead of the SV valve. If the subcooling is

more or less than 4 K, refer to the following correction factors.

© Danfoss | Climate Solutions | 2021.02 AI175286419654en-000601 | 4

Page 5

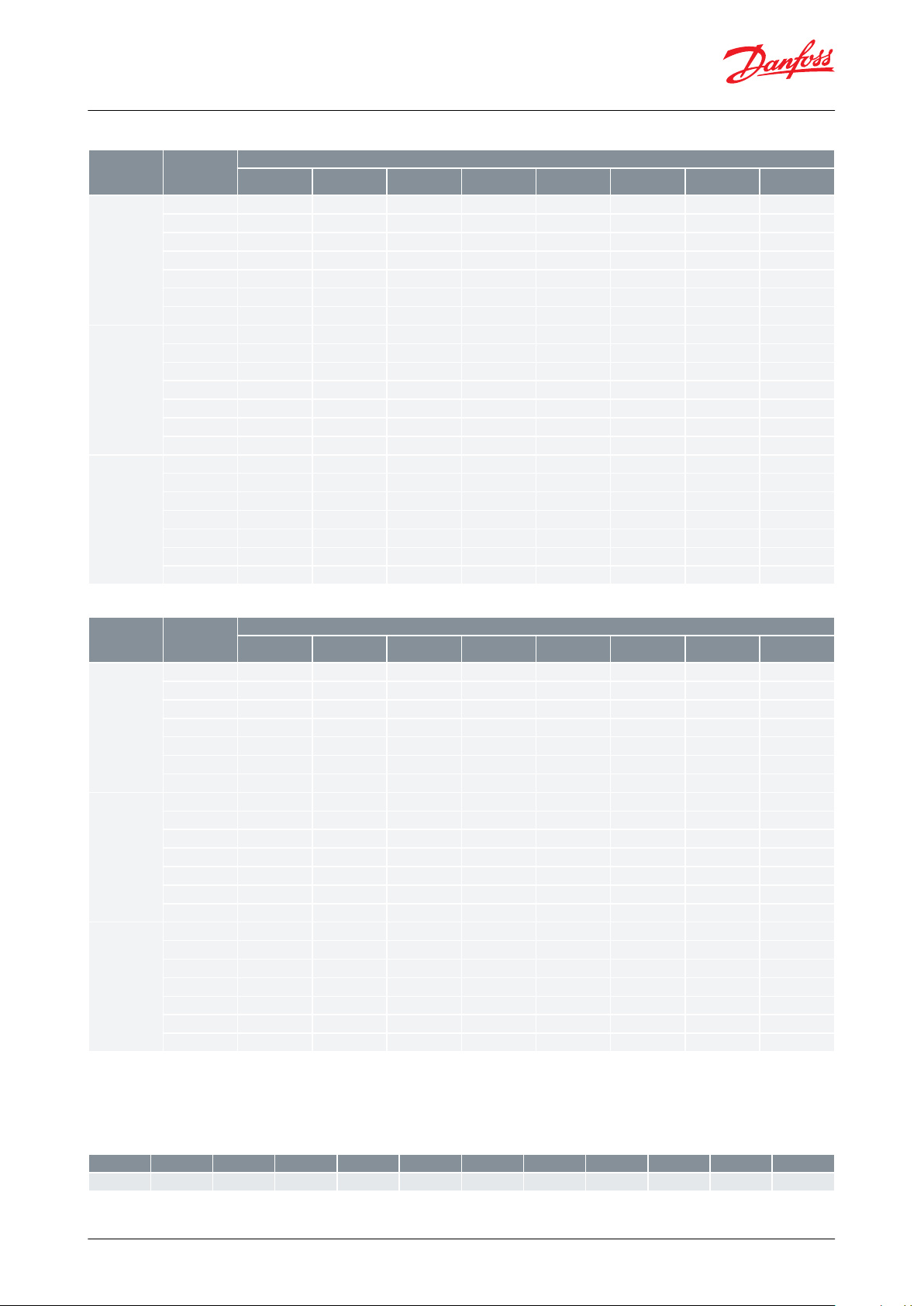

Type

Evaporating

temperature

te [°C]

Capacity in kW at pressure drop across valve ∆p bar

0.8

1.2

1.624812

16

SV 4

103745525879105

122

13403947545981

107

124

136

-104048556182108

125

137

-204149566283109

125

137

-304250576384109

125

136

-404251586384108

124

135

-504351586383107

122

133

SV 5

1051627178

107

143

166

183053647381110

145

168

185

-1054667583

112

147

170

1862056677684113

148

170

186

-3057687885

114

148

170

185

-4058697886

114

147

168

184

-5058697886

113

146

167

182

SV 6

10688395105

144

191

222

2450718698

108

147

195

226

248

-107388

101

111

150

197

227

250

-207590

103

113

152

198

228

250

-307692

104

115

153

198

227

248

-407793

105

115

153

197

226

246

-507893

105

115

152

196

223

243

Type

Evaporating

temperature

te [°C]

Capacity in kW at pressure drop across valve ∆p bar

0.8

1.2

1.624812

16

SV 4

10

8.5

10.3

11.7

12.9

17.2

21.8

24.1

25.108.9

10.7

12.2

13.5

17.8

22.4

24.6

25.7

-10

9.3

11.2

12.71418.3

22.82525.9

-20

9.7

11.6

13.1

14.4

18.7

23.1

25.1

25.9

-30

9.9

11.8

13.4

14.6

18.9

23.12525.7

-40

10.1

12.1

13.6

14.8

18.9

22.9

24.7

25.3

-50

10.3

12.1

13.6

14.8

18.8

22.6

24.2

24.8

SV 5

10

11.61415.9

17.6

23.4

29.6

32.7

34.2012.1

14.6

16.7

18.4

24.3

30.5

33.5

34.9

-10

12.7

15.2

17.31924.9

31.13435.3

-20

13.1

15.7

17.8

19.6

25.4

31.4

34.1

35.3

-30

13.5

16.1

18.2

19.9

25.7

31.43435

-40

13.8

16.4

18.4

20.1

25.7

31.2

33.6

34.5

-501416.5

18.5

20.2

25.6

30.73333.7

SV 6

10

15.5

18.7

21.3

23.6

31.4

39.7

43.9

45.8016.3

19.6

22.3

24.6

32.6

40.94546.8

-101720.4

23.2

25.5

33.5

41.7

45.6

47.3

-20

17.6

21.1

23.9

26.2

34.1

42.1

45.8

47.3

-30

18.1

21.6

24.4

26.7

34.5

42.1

45.647-40

18.52224.72734.5

41.84546.2

-50

18.7

22.2

24.82734.3

41.2

44.2

45.2

∆t K241015202530354045

50

k

1.0110.98

0.96

0.94

0.92

0.91

0.89

0.87

0.86

0.85

Float valve, Type SV 4, SV 5 and SV 6

Table 3: R717 (NH3)

Table 4: R22

Correction factors

When dimensioning, multiply the evaporating capacity by the correction factor k, dependent on the subcooling

Δtsub just ahead of the valve. The corrected capacity can then be found in the capacity table.

Table 5: R717 (NH3)

© Danfoss | Climate Solutions | 2021.02 AI175286419654en-000601 | 5

Page 6

∆t K241015202530354045

50

k

1.0110.96

0.93

0.9

0.87

0.85

0.83

0.8

0.78

0.77

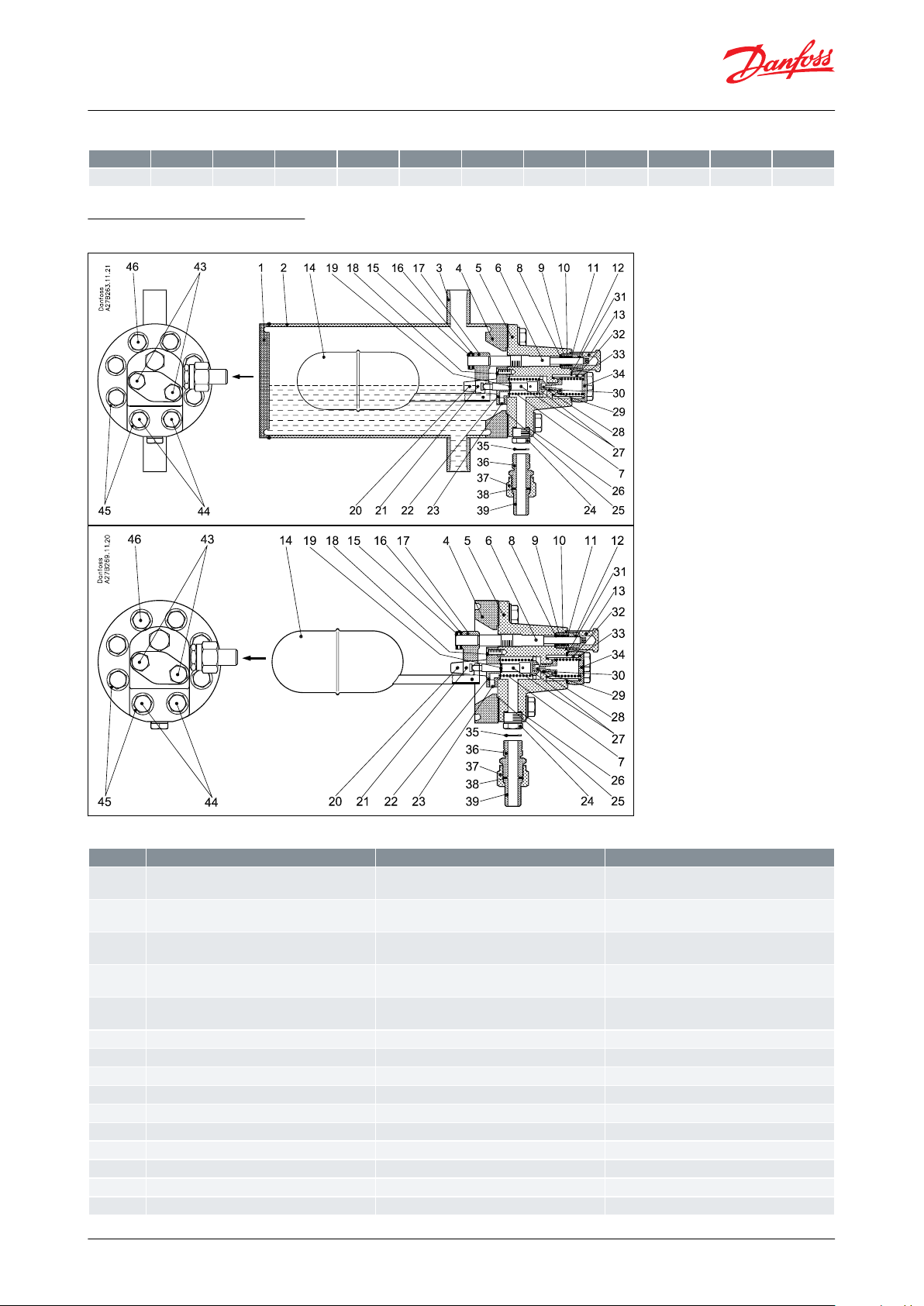

No.

Part

Material

DIN / EN

1

Bottom ange for oat valve

Steel

P275NL1

EN10028-3

2

Tube for valve body

Steel

TTST35N

DIN17173

3

Connection for oat house

Steel

TTST35N

DIN17173

4

Top cover for oat valve

Steel

P275NL1

EN10028-3

5

Valve housing

Low temperature, cast iron

(spherical)

EN-GJS-400-18LT

EN1563

6

Spindle

Stainless steel

7

Spring

Steel

8

Sealing ring

Nylon (PA 6)

9

O-ring

Cloroprene (Neoprene)

10

Distance ring

Nylon (PA 6)

11

Packing ring

Nylon (PA 6)

12

Packing box

Steel13Cap

Steel14Float

Stainless steel

15

Adjusting ring

Steel

Float valve, Type SV 4, SV 5 and SV 6

Table 6: R22

Construction and function

Figure 2: Construction and function

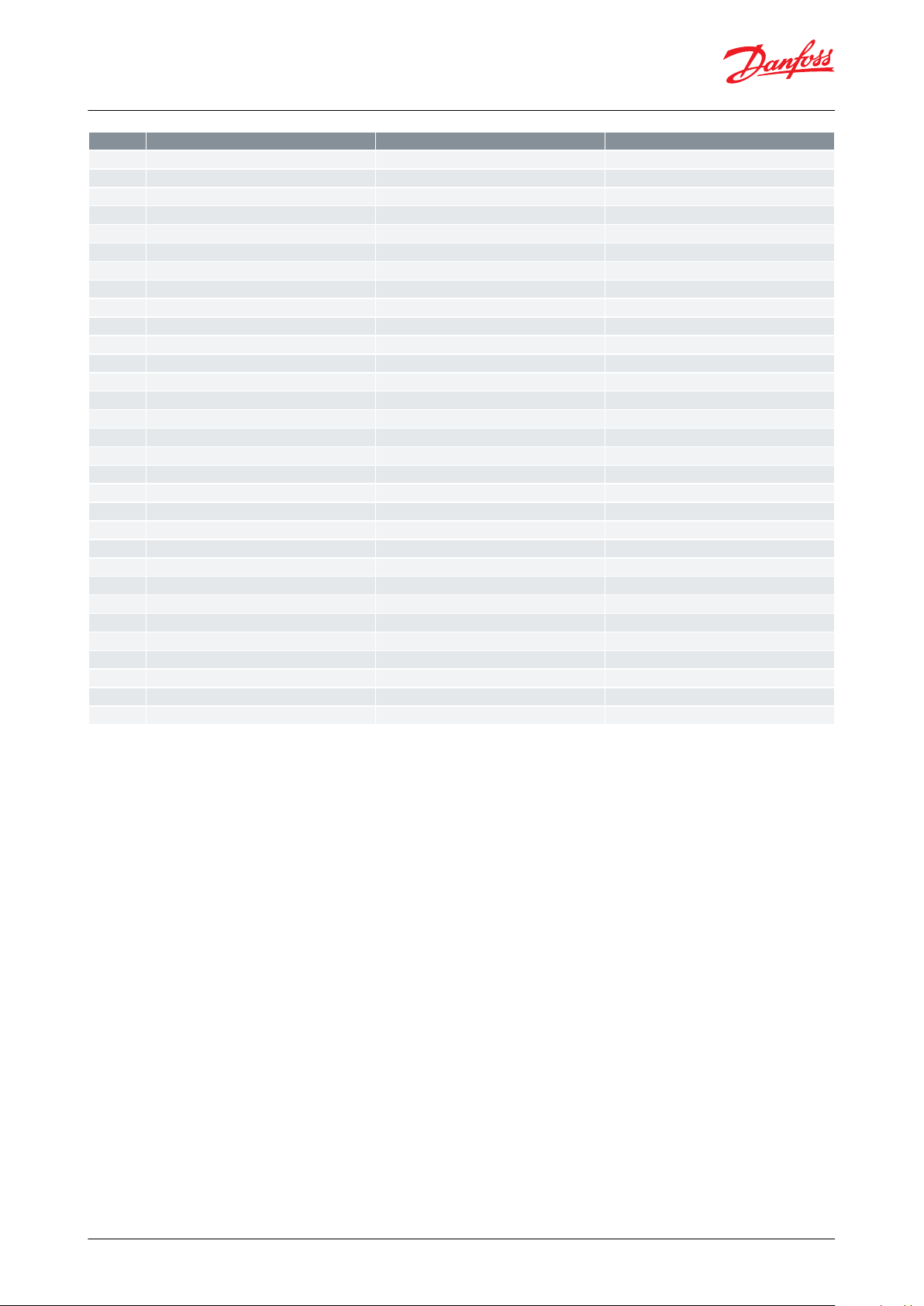

Table 7: Construction and function

© Danfoss | Climate Solutions | 2021.02 AI175286419654en-000601 | 6

Page 7

No.

Part

Material

DIN / EN

16

Pin

Steel

17

Fork for spindle

Steel18Screw

Steel

19

Locking ring

Steel20Pin

Steel21Pin

Steel

22

Cover with guide

Steel23Screw

Steel24Plug

Steel25Gasket

Non asbestos

26

Gasket

Aluminium

27

Valve cone (guide) with pin

Steel / Nylon (PA6)

28

Valve cone

Teon (PTFE)

29

O-ring

Cloroprene (Neoprene)

30

Nozzle

Teon (PTFE)

31

Gasket

Non asbestos

32

Filter

Steel / Stainless steel

33

Spring

Steel

34

Cover for lter

Steel35Gasket

Aluminium

36

Nipple

Steel

37

Union nut

Steel38Gasket

Aluminium

39

Welding nipple

Steel

40

Locking ring

Steel41Ring

Nylon (PA6)

42

Pin

Steel43Screw

Stainless steel

A2-7044Screw

Stainless steel

A2-7045Washer

Steel46Screw

Stainless steel

A2-70

Float valve, Type SV 4, SV 5 and SV 6

SV 4-6 oat valves are for low pressure operation only. They are used for ooded evaporators, where only slight

variations in the liquid level can be accepted. When the liquid level decreases, the oat moves downwards. This

opens the orice (pos. 7) and the amount of liquid injected is increased.

The liquid inlet line should be dimensioned in such a way that acceptable liquid velocities and pressure drops are

obtained. This is particularly important when the liquid is only slightly subcooled, since valve capacity is reduced

considerably if ashgas occurs in the liquid ahead of the orice.

The ashgas quantity which occurs on expansion is removed through the balance pipe. On refrigeration plant using

uorinated refrigerants, slight subcooling and a large pressure drop can result in a ashgas quantity of approx. 50%

of the injected liquid quantity.

Therefore the pressure drop in this balance pipe must be kept at a minimum, otherwise there is a risk that:

• the liquid level in the evaporator will vary to an unacceptable degree as a function of evaporator load

• the absolute dierence between the liquid level of the evaporator and the SV valve

If too large amounts of ash gas are created it is recommended to use the external injection connection or let the

liquid expand directly into the surge drum. See application drawings 3 and 4.

See instruction for SV 4-6 for:

• Cleaning of strainer

• Change of orice

• Change of valve plate

© Danfoss | Climate Solutions | 2021.02 AI175286419654en-000601 | 7

Page 8

Float valve, Type SV 4, SV 5 and SV 6

Dimensions and weight

NOTE:

Weight: 19.6 kg

NOTE:

Weight: 9.7 kg

NOTE:

Weight: 3.1 kg

© Danfoss | Climate Solutions | 2021.02 AI175286419654en-000601 | 8

Page 9

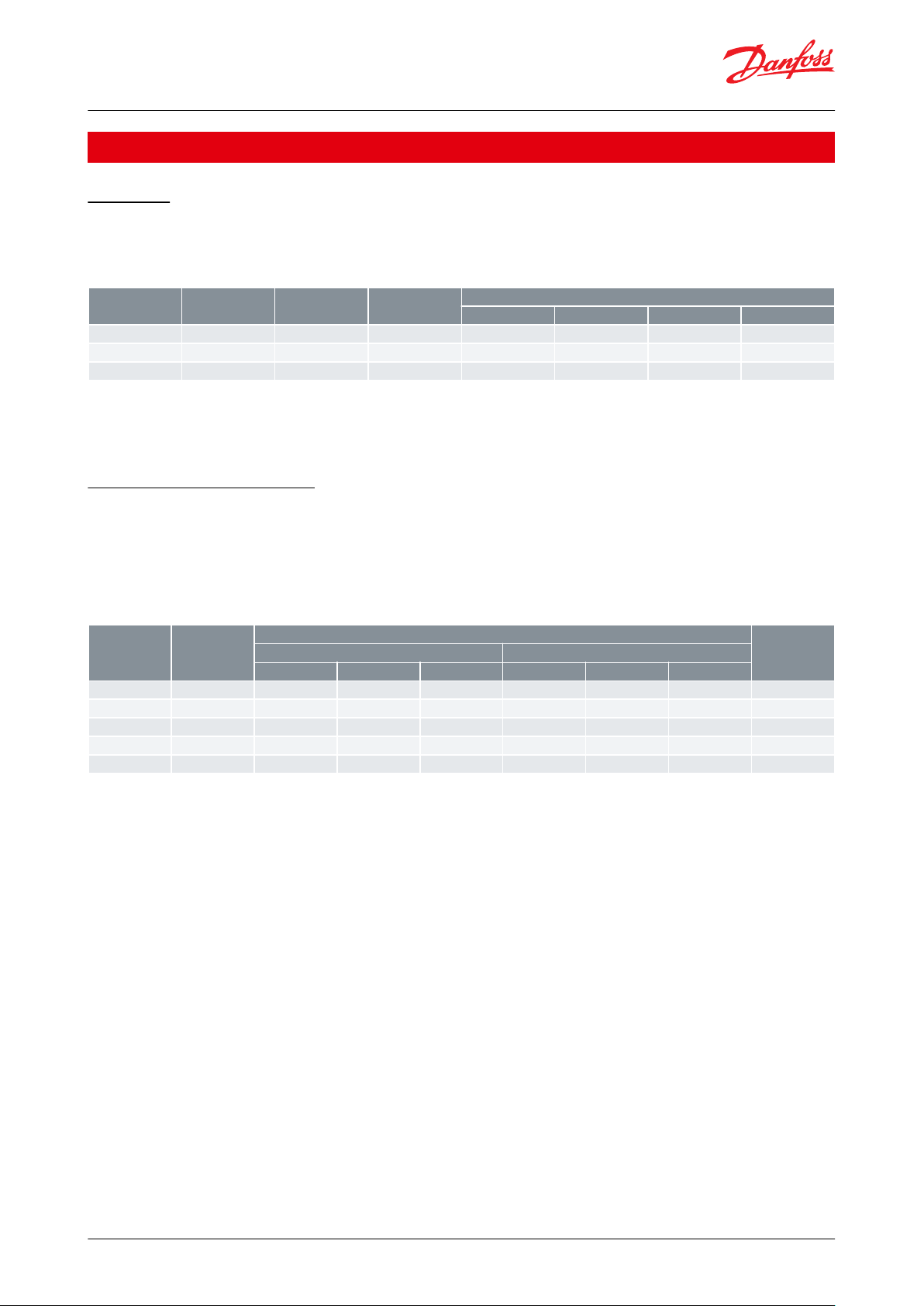

Valve type

Orice diameter

Code no.

Code no. without

housing

(1)

Rated capacity in kW

(2)

R717

R22

R134a

R404A

SV 4

∅ 3.0 mm

027B2024

027B2014

1022116.4

15.4

SV 5

∅ 3.5 mm

027B2025

027B2015

138

28.6

22.3

21

SV 6

∅ 4.0 mm

027B2026

027B2016

186

38.3

29.9

28.1

Orice

diameter

k

v

Capacities at -10°C evaporating temperature at pressure drop across valve ∆P bar

Code no.

(1)

R717

R22

471047

10

∅

1.0 mm

0.026912

13.5

1.6

2.2

2.4

027B2080

∅

1.5 mm

0.062127293.8

4.9

5.2

027B2081

∅

2.0 mm

0.13546506.3

8.3

9

027B2082

∅

2.5 mm

0.16567081101315

027B2083

∅

2.8 mm

0.27087.5

1011216

18

027B2084

Float valve, Type SV 4, SV 5 and SV 6

Ordering

Regulator

The code nos. stated apply to oat valves types SV 4, 5 and 6 with two 1" weld connections for balance tubes and

two ½" weld joints for liquid and evaporator connections respectively.

Table 8: Ordering

(1)

(1)

Flange for mounting without housing Code no. 027B2027

Flange for mounting without housing Code no. 027B2027

(2)

(2)

The rated capacity refers to the valve capacity at evaporating temperature tc = +5 °C, condensing temp. tc = +32 °C and liquid temperature tl =

The rated capacity refers to the valve capacity at evaporating temperature tc = +5 °C, condensing temp. tc = +32 °C and liquid temperature tl =

+28 °C

+28 °C

Spare parts and accessories

Smaller orices for the SV 4 - 6 are available as spare parts and can be mounted in the SV 4 - 6 if smaller capacities

are required.

• Seal kit: 027B2070

• Other spare parts: See spare parts catalogue

Table 9: Special orice code no. and rated capacities for SV 4 - 6

(1)

(1)

The code no. includes

The code no. includes

orice and all necessary gaskets

orice and all necessary gaskets

NOTE:

The SV 4 - 6 mounted with special orice diameter ∅2.5 mm is recommended as pilot oat valve for the servooperated level regulators type PMFL for higher capacities.

© Danfoss | Climate Solutions | 2021.02 AI175286419654en-000601 | 9

Page 10

Type

File name

Document type

Document topic

Approval authority

SV 4

19.10327.266

Marine - Safety Certicate

RMRS

SV 5

SV 6

SV 4, SV 5 and SV 6

Classied for

Fluid group I

Category

II

SV 4, SV 5 and SV 6 are approved in accordance with the European standard specied in the Pressure Equipment Directive

and are CE marked. For further details / restrictions - see Installation guide.

Float valve, Type SV 4, SV 5 and SV 6

Certicates, declarations, and approvals

The list contains all certicates, declarations, and approvals for this product type. Individual code number may have

some or all of these approvals, and certain local approvals may not appear on the list.

Some approvals may change over time. You can check the most current status at danfoss.com or contact your local

Danfoss representative if you have any questions.

Table 10: Valid approvals

Table 11: Compliance

Table 12: Pressure Equipment Directive (PED)

© Danfoss | Climate Solutions | 2021.02 AI175286419654en-000601 | 10

Page 11

Online support

Danfoss oers a wide range of support along with our products, including digital product information, software,

mobile apps, and expert guidance. See the possibilities below.

The Danfoss Product Store

The Danfoss Product Store is your one-stop shop for everything product related—no matter where

you are in the world or what area of the cooling industry you work in. Get quick access to essential

information like product specs, code numbers, technical documentation, certications, accessories,

and more.

Start browsing at store.danfoss.com.

Find technical documentation

Find the technical documentation you need to get your project up and running. Get direct access to

our ocial collection of data sheets, certicates and declarations, manuals and guides, 3D models

and drawings, case stories, brochures, and much more.

Start searching now at www.danfoss.com/en/service-and-support/documentation.

Danfoss Learning

Danfoss Learning is a free online learning platform. It features courses and materials specically

designed to help engineers, installers, service technicians, and wholesalers better understand the

products, applications, industry topics, and trends that will help you do your job better.

Create your Danfoss Learning account for free at www.danfoss.com/en/service-and-support/learning.

Get local information and support

Local Danfoss websites are the main sources for help and information about our company and

products. Find product availability, get the latest regional news, or connect with a nearby expert—all

in your own language.

Find your local Danfoss website here: www.danfoss.com/en/choose-region.

Spare Parts

Get access to the Danfoss spare parts and service kit catalog right from your smartphone. The app

contains a wide range of components for air conditioning and refrigeration applications, such as

valves, strainers, pressure switches, and sensors.

Download the Spare Parts app for free at www.danfoss.com/en/service-and-support/downloads.

Coolselector®2 - nd the best components for you HVAC/R system

Coolselector®2 makes it easy for engineers, consultants, and designers to nd and order the best

components for refrigeration and air conditioning systems. Run calculations based on your operating

conditions and then choose the best setup for your system design.

Download Coolselector®2 for free at coolselector.danfoss.com.

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its

products without notice. This also applies to products already on order provided that such alterations can be made without subsequential

changes being necessary in specications already agreed. All trademarks in this material are property of the respective companies. Danfoss and

the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

© Danfoss | Climate Solutions | 2021.02 AI175286419654en-000601 | 11

Loading...

Loading...