Page 1

Data Sheet

Float valve

Type SV 1 and SV 3

For industrial refrigeration liquid level regulation

Several oat valves are available for Industrial

refrigeration liquid level control in the product

group “Liquid level regulating valves”, such as

HFI and SV series. The SV series contains the

following types: SV 1, SV 3, SV 4, SV 5 and SV 6,

some of which can be delivered as dedicated

“E” versions for hydrocarbon application.

The SV 1 and SV 3 can be used separately as a

modulating liquid level regulator in

refrigerating, freezing and air conditioning

systems for ammonia or uorinated

refrigerants.However, in most cases, the SV is

used as a oat pilot valve for the main

expansion valve type PMFH.

The SV 1 and SV 3 are used as liquid level

regulators in either low pressure applications or

in high pressure applications. Adaptation to the

specic application is done by the orientation

of the valve and thereby the oat functions

AI221686430747en-001001

Page 2

Description

Values

Refrigerants

R134a, R22, R401A, R402A, R404A, R407A, R407B, R407C, R407F, R409A, R410A,

R421A, R502, R507, R717

Application

High Pressure Liquid Level Control System (HP LLRS)

Low Pressure Liquid Level Control System (LP LLRS)

Design versions

Media temperature range

-50 °C – 65 °C

P-band [mm]

35 mm

MWP [bar]

28 bar

K

v

value [m3/h]

0.06 for SV 1

0.14 for SV 3

Rated capacity (kW)

SV1: 25

SV3: 64

(R717 +5/32 °C, Tl = 28 °C)

Float valve, Type SV 1 and SV 3

Portfolio overview

The SV 1 and SV 3 can be used separately as a modulating liquid level regulator in refrigerating, freezing and air

conditioning systems for ammonia or uorinated refrigerants.

However, in most cases, the SV is used as a oat pilot valve for the main expansion valve type PMFH.

Several oat valves are available for Industrial refrigeration liquid level control in the product group “Liquid level

regulating valves”, such as HFI and SV series. The SV series contains the following types: SV 1, SV 3, SV 4, SV 5 and SV

6, some of which can be delivered as dedicated “E” versions for hydrocarbon application.

Figure 1: Float valve SV 1 and SV 3

Table 1: Portfolio overview

© Danfoss | Climate Solutions | 2021.02 AI221686430747en-001001 | 2

Page 3

Float valve, Type SV 1 and SV 3

Applications

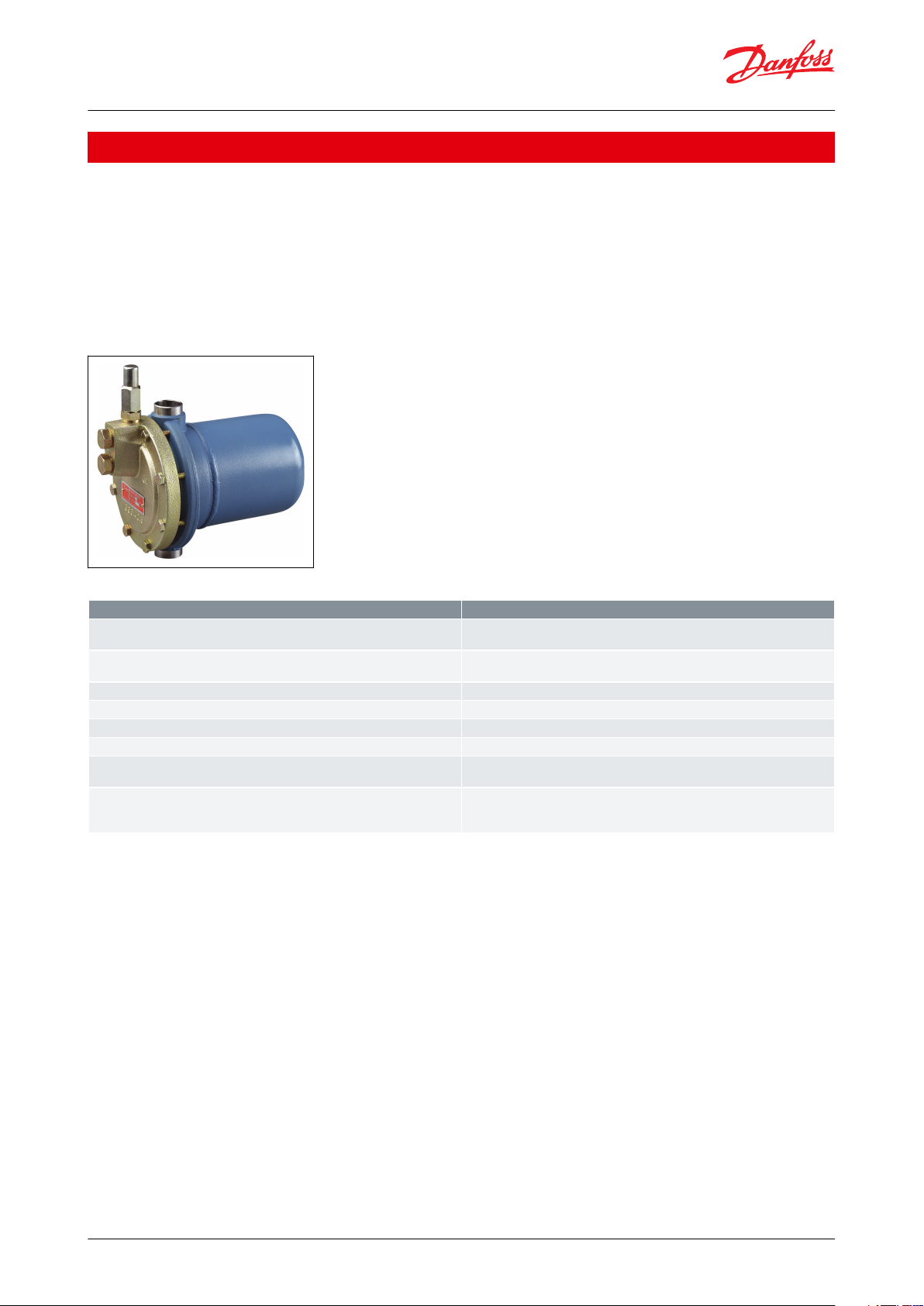

SV (L), low-pressure function

SV (L), low-pressure function

SV (L) is used for small, ooded evaporators, where only slight variations in the liquid level can be accepted.

When the liquid level falls, the oat pos. (2) moves downwards. This draws the needle pos. (15) away from the orice

and the amount of liquid injected is increased.

The liquid inlet line, which is mounted on the nipple pos. (C), should be dimensioned in such a way that acceptable

liquid velocities and pressure drops are obtained.

This is particularly important when the liquid is only slightly subcooled, since valve capacity is reduced considerably

if ashgas occurs in the liquid ahead of the orice and wear is strongly increased.

See the suggested dimensions for the liquid line in "Pipe dimensions". Refer section Dimensions and weights

The ashgas quantity which occurs on expansion is removed through the balance pipe from pos. (D). On

refrigeration plant using uorinated refrigerants, slight subcooling and a large pressure drop can give a ashgas

quantity of approx. 50% of the injected liquid quantity. Therefore the pressure drop in this balance pipe must be

kept at a minimum, since there will otherwise be a risk that the liquid level in the evaporator will vary to an

unacceptable degree as a function of evaporator load the absolute dierence between the liquid level of the

evaporator and the SV valve will be too large.

See the suggested dimensions for the balance pipe in "Pipe dimensions". Refer section Dimensions and weights

Figure 2: SV (L), low-pressure function

SV (H), high-pressure function

SV (H), high-pressure function

When the liquid level rises, the oat pos. (2) moves upwards. This draws the needle pos. (15) away from the orice

and the excess liquid is drawn away.

On refrigeration plant using uorinated refrigerants slight subcooling and a large pressure drop can, as already

mentioned, cause the formation of a large amount of ashgas.

This mixture of liquid and vapour has to pass through the nipple pos. (C) and out into the liquidline.

If the dimensions of the line are too small, a pressure drop will occur which can reduce the capacity of the SV (H)

valve considerably. This will mean a risk of inadvertent liquid accumulation in the condenser or receiver.

© Danfoss | Climate Solutions | 2021.02 AI221686430747en-001001 | 3

Page 4

SV(L)

10 32 22

P-connection

SV(L)

10 32 22

S-connection

Float valve, Type SV 1 and SV 3

See the suggested dimensions for the liquid line in "Pipe dimensions". Refer section Dimensions and weights

Figure 3: SV (H), high-pressure function

The connection nipple (C) can be mounted either in P or in S

Figure 4: P-connection (= parallel)

NOTE:

With P-connection an SV with closed oat orice will have a capacity which corresponds to the degree of opening of

the adjustable throttle valve 10.

Figure 5: S-connection (= series)

NOTE:

With S-connection the throttle valve 10 will function as a pre-orice on SV (L) and as a post orice on SV (H)

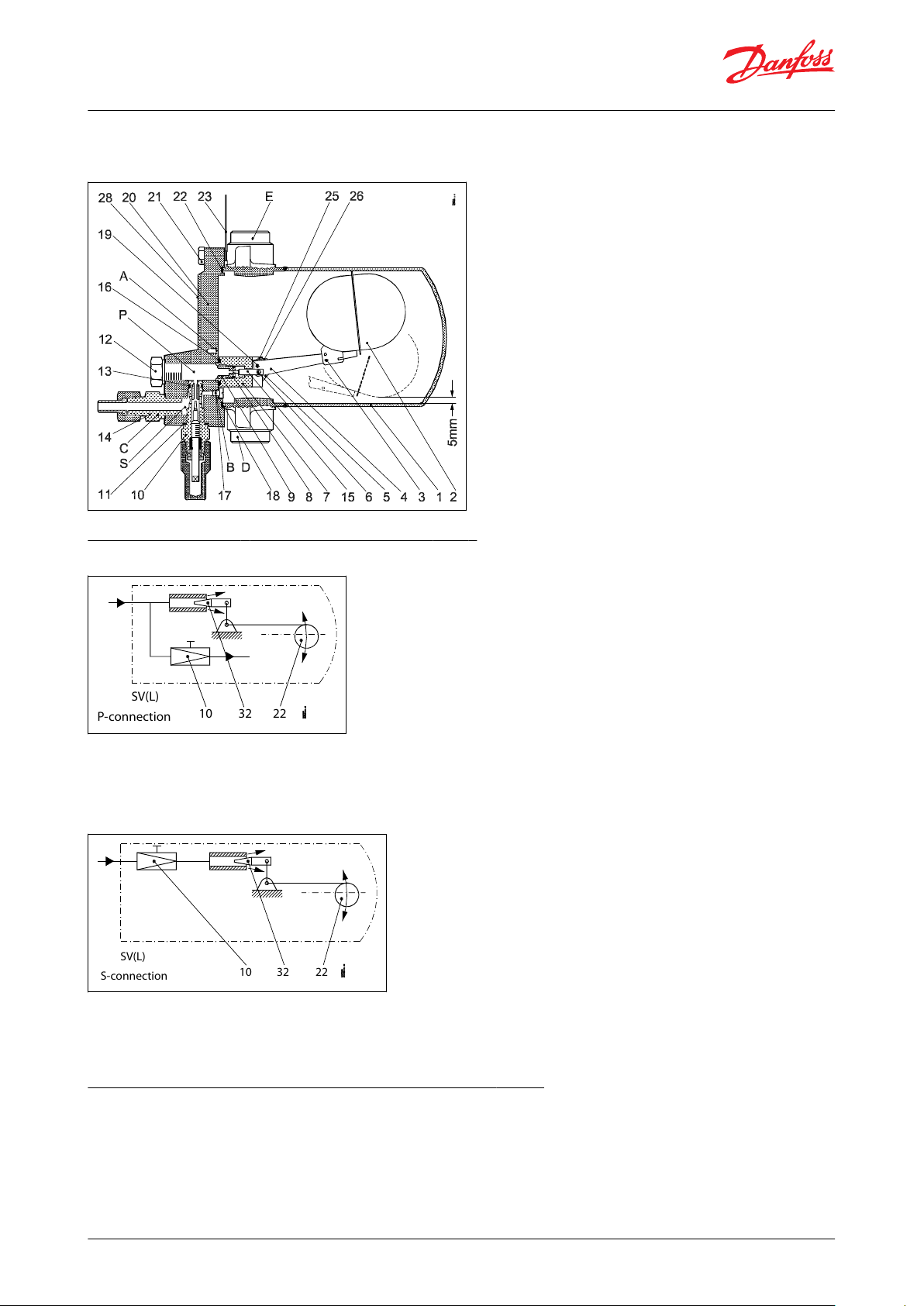

SV 1 - 3 used as a high pressure defrost drain oat valve

SV 1 - SV 3 can be used as a defrost drain oat valve, when one balance pipe is sealed o and the liquid level

regulator

is mounted with a special kit (code no. 027B2054) consisting of:

• Special orice and orice needle with a larger kv-value of 0.28 m3/h.

• Gas drain pipe

© Danfoss | Climate Solutions | 2021.02 AI221686430747en-001001 | 4

Page 5

Liquid out to

wet suction

Condensed liquid in

from evaporator

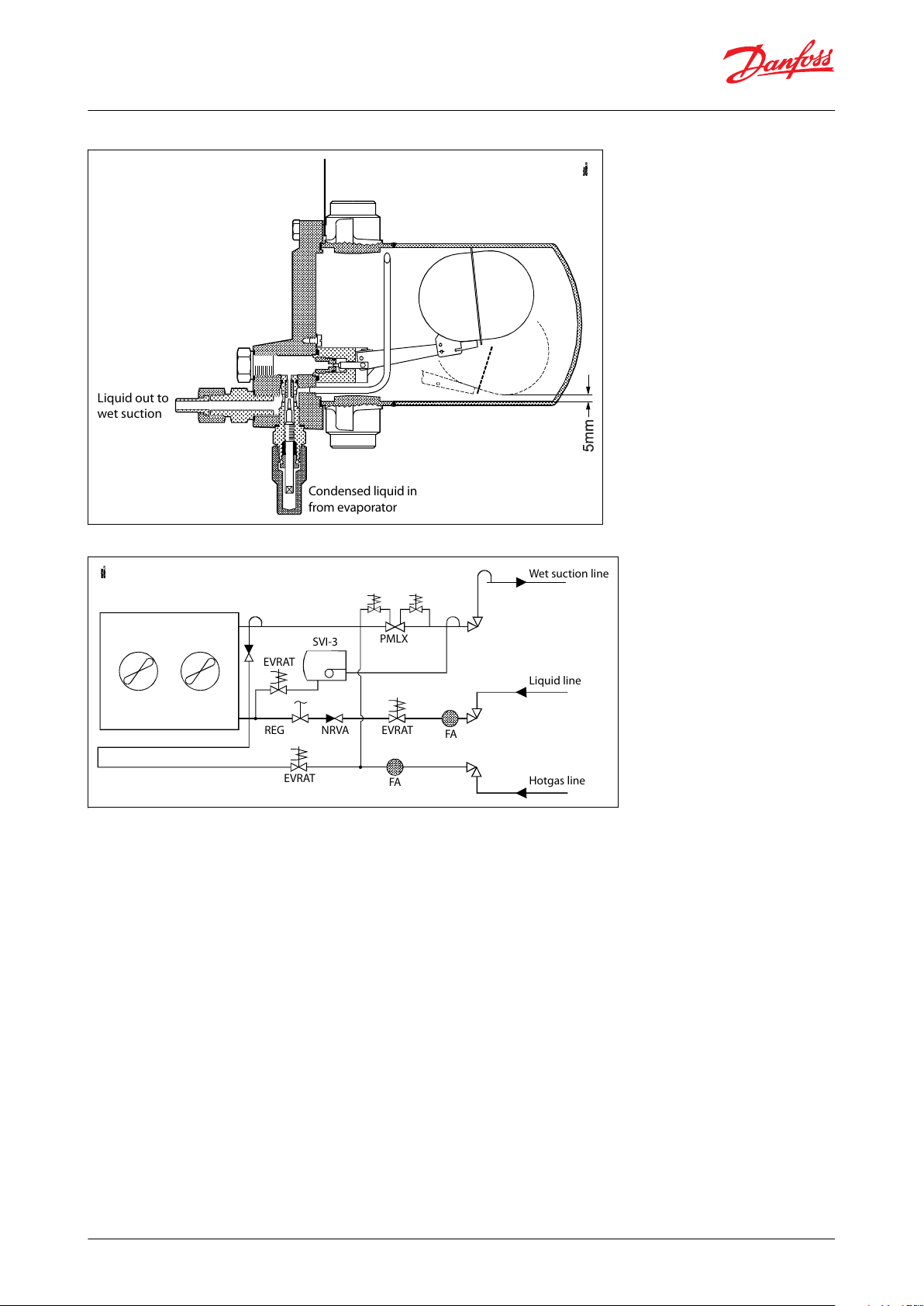

Wet suction line

Liquid line

PMLX

SVI-3

EVRAT

EVRAT

REG

NRVA

Hotgas line

EVRAT

FA

FA

Float valve, Type SV 1 and SV 3

Figure 6: SV 1 - 3 tted with the special kit (code no. 027B2054)

Figure 7: Application example

NOTE:

SV 1 - 3 with special kit mounted as defrost drain foat valve on a fooded evaporator with hotgas defrost.

© Danfoss | Climate Solutions | 2021.02 AI221686430747en-001001 | 5

Page 6

Float valve, Type SV 1 and SV 3

Media

Refrigerants

The SV 1 and SV 3 can be used separately as a modulating liquid level regulator in refrigerating, freezing and air

conditioning systems for ammonia or uorinated refrigerants.

SV oat valves are currently authorized by Danfoss for use with several R numbers HCFC, non-ammable HFC,

Ammonia, CO2 and hydrocarbons. New refrigerants are added frequently to the list of Danfoss approved refrigerants

and added to the product types.

For an exhaustive and updated list, look up a code number in https://store.danfoss.com/en/.

New refrigerants

Danfoss products are continually evaluated for use with new refrigerants depending on market requirements.

When a refrigerant is approved for use by Danfoss, it is added to the relevant portfolio, and the R number of the

refrigerant (e.g. R513A) will be added to the technical data of the code number. Therefore, products for specic

refrigerants are best checked at store.danfoss.com/en/, or by contacting your local Danfoss representative.

© Danfoss | Climate Solutions | 2021.02 AI221686430747en-001001 | 6

Page 7

C

D

P

S

Nipple

Connection for balance pipe

Parallel connection of pos. C (screw 17 in pos.

A)

Series connection of pos. C (screw 17 in pos. B)

Description

Values

P band

35 mm

Temperature of medium

-50 °C – 65 °C

Max. working pressure

PS = 28 bar

Max. test pressure

p' = 36 bar

kv value for oat orice

SV 1 = 0.06 m3/h

SV 3 = 0.14 m3/h

No.

Part

Material

DIN / EN

1

Float housing

Stainless steel

Low temperature, steel

X5CrNi18-10, DIN 17440

P285QH, EN 10222-4

2

Float

Stainless steel

3

Split pin

Steel4Float arm

Stainless steel

5

Link

Steel6Pin

Stainless steel

7

Valve housing

Steel8O-ring

Cloroprene (Neoprene)

9

Float orice

Plastic10Manual regulation unit. Throttle valve

Steel11Gasket

Non asbestos

12

Plug

Steel13O-ring

Cloroprene (Neoprene)

14

Pilot connection (spare part)

Steel15Orice needle

Plastic

Float valve, Type SV 1 and SV 3

Product specication

Pressure and temperature data

Table 2: Pressure and temperature data

NOTE:

The highest kv value for the built-in throttle valve is 0.18 m3/h. The throttle valve can be used both in parallel and in

series with the oat orice.

Material specication

SV with low-pressure function

Figure 8: SV with low-pressure function

Table 3: SV with low-pressure function

© Danfoss | Climate Solutions | 2021.02 AI221686430747en-001001 | 7

Page 8

C

D

P

S

Nipple

Connection for balance pipe

Parallel connection of pos. C (screw 17 in pos.

A)

Series connection of pos. C (screw 17 in pos. B)

No.

Part

Material

DIN / EN

16

O-ring

Cloroprene (Neoprene)

17

Screw

Steel18Gasket

Non asbestos

19

Pin

Steel

20

Cover

Low temperature, cast iron

(spherical)

EN-GJS-400-18-LT

EN 1563

21

Screw

Stainless steel

A2-7022Gasket

Non asbestos

23

Label

Cardboard

25

Screw

Steel26Spring washer

Steel28Sign

Aluminium

No.

Part

Material

DIN / EN

1

Float housing

Stainless steel

Low temperature, steel

X5CrNi18-10, DIN 17440

P285QH, EN 10222-4

2

Float

Stainless steel

3

Split pin

Steel4Float arm

Stainless steel

5

Link

Steel6Pin

Stainless steel

7

Valve housing

Steel8O-ring

Cloroprene (Neoprene)

9

Float orice

Plastic10Manual regulation unit. Throttle valve

Steel11Gasket

Non asbestos

12

Plug

Steel13O-ring

Cloroprene (Neoprene)

14

Pilot connection (spare part)

Steel15Orice needle

Plastic16O-ring

Cloroprene (Neoprene)

17

Screw

Steel18Gasket

Non asbestos

19

Pin

Steel

20

Cover

Low temperature, cast iron

(spherical)

EN-GJS-400-18-LT

EN 1563

Float valve, Type SV 1 and SV 3

SV with high-pressure function

Figure 9: SV with high-pressure function

Table 4: SV with high-pressure function

© Danfoss | Climate Solutions | 2021.02 AI221686430747en-001001 | 8

Page 9

No.

Part

Material

DIN / EN

21

Screw

Stainless steel

A2-7022Gasket

Non asbestos

23

Label

cardboard

25

Screw

Steel26Spring washer

Steel28Sign

Aluminium

DANFOSS

27F691_01-2017

M16 × 1.5

AF 19

G 3/8 A

AF 22

∅ 6.5 / ∅ 10

Type

Evaporating tempera‐

ture te °C

Capacity in kW at pressure drop across valve ∆p bar

0.8

1.2

1.624812

16

SV 1

10

9.511131520273009.912141520273133-10

1012141521273133-20

1112141521273033-30

1112141520263033-40

1113141520262932-50

11121315202629

32

SV 3

10

2531353952717702632364052697883-10

2632364052687783-20

2631353952677682-30

2530343850667582-40

2429333649657380-50

23273135476471

79

Type

Evaporating tempera‐

ture te °C

Capacity in kW at pressure drop across valve ∆p bar

0.8

1.2

1.624812

16

SV 1

10

2.2

2.633.2

4.2

4.8

5.7

5.702.3

2.7

3.1

3.4

4.4

4.9

5.8

5.8

-10

2.4

2.8

3.2

3.5

4.555.8

5.9

-20

2.4

2.9

3.3

3.6

4.655.8

5.8

−30

2.5

2.9

3.3

3.6

4.555.7

5.7

-40

2.5

2.9

3.3

3.6

4.4

4.9

5.6

5.6

-50

2.6

2.9

3.3

3.5

4.3

4.8

5.4

5.4

Float valve, Type SV 1 and SV 3

Connections

Table 5: Pilot connection (weld / solder)

Capacity tables

The values in the capacity tables are based on a subcooling of 4 K just ahead of the SV valve.

If the subcooling is more or less than 4 K, refer to the correction factors provided after the capacity tables.

Table 6: R717 (ammonia)

Table 7: R22

© Danfoss | Climate Solutions | 2021.02 AI221686430747en-001001 | 9

Page 10

Type

Evaporating tempera‐

ture te °C

Capacity in kW at pressure drop across valve ∆p bar

0.8

1.2

1.624812

16

SV 3

10

5.6

6.8

7.7

8.51113151505.878

8.811131515

-10

6

7.3

8.2912131515-20

6.1

7.3

8.3

8.911131415

-30

6.2

7.3

8.1

8.811121414

-40

6.1

7.1

7.9

8.511121414

-50

5.9

6.9

7.6

8.211121314

∆t K

24101520253035404550k1.0110.98

0.96

0.94

0.92

0.91

0.89

0.87

0.86

0.85

∆t K

24101520253035404550k1.0110.96

0.93

0.9

0.87

0.85

0.83

0.8

0.78

0.77

74.5

106

132

170.5

92

92

5+2

122.6

155

141.5

ID 28

ID 28

ID 6.8

OD 9.8

Danfoss

27B326.12

Type

Weight

SV 1

5.7 kg

SV 3

5.7 kg

Float valve, Type SV 1 and SV 3

Correction factors

When dimensioning, multiply the evaporator capacity by a correction factor k dependent on the subcooling Δt

just ahead of the valve. The corrected capacity can then be found in the capacity table.

Table 8: R717 (ammonia)

Table 9: R22

sub

Dimensions and weights

Figure 10: SV1 and SV3

Table 10: SV 1 and SV 3 Dimensions and weights

Pipe dimensions

Liquid line

© Danfoss | Climate Solutions | 2021.02 AI221686430747en-001001 | 10

Page 11

Type

Dimensions

0.8 bar < ∆psv < 4 bar

4 bar < ∆psv < 16 bar

Steel tube

Steel tube

SV 1

3

⁄8 in.3⁄8 in.

SV 3

3

⁄8 in.1⁄2 in.

Type

Dimensions

0.8 bar < ∆psv < 4 bar

4 bar < ∆psv < 16 bar

Steel tube

Copper tube

Steel tube

Copper tube

SV 1

3

⁄8 in.3⁄8 in.3⁄8 in.1⁄2 in.

SV 3

3

⁄8 in.5⁄8 in.1⁄2 in.3⁄4 in.

Type

Dimensions

SV (L) 1

1 in.

SV (L) 3

1

1

⁄2 in.

Float valve, Type SV 1 and SV 3

The following suggested dimensions for the liquid line, which is connected to the nipple pos. C are based on a

maximum velocity in a line with subcooled ammonia of approx. 1 m/s and a maximuM velocity in a line with

subcooled uorinated refrigerant of approx. 0.5 m/s.

Table 11: R717 (ammonia)

Table 12: R22, R134a, R404A

Table 13: Upper balance pipe (connect to pos. D on SV (L)

© Danfoss | Climate Solutions | 2021.02 AI221686430747en-001001 | 11

Page 12

Valve type

Rated capacity in kW

Packing format

Qty./pack

Code no.

R717

R22

R134a

R404A

R12

R502

SV 1

25

4.7

3.9

3.7

3.1

3.4

Single pack

1 pc

027B2021

SV 3

641310

9.7

7.9

8.8

Single pack

1 pc

027B2023

Float valve, Type SV 1 and SV 3

Ordering

Table 14: SV 1 - SV 3 Ordering

NOTE:

The code nos. stated apply to oat valves, types SV 1 and SV 3 incl. ∅ 6.5 / ∅ 10 mm weld connection

line.

Balance tube connection (liquid/vapour): 1 in. weld / 1

1

⁄8 in. solder.

The rated capacity refers to the valve capacity at evaporating temperature te = +5 °C, condensing temp. tc = +32 °C

and liquid temperature tl = +28 °C.

(1)

for the pilot

1

3

⁄8 in. are connection can be supplied under code no. 027B2033.

© Danfoss | Climate Solutions | 2021.02 AI221686430747en-001001 | 12

Page 13

File name

Document type

Document topic

Approval authority

Д-DK.БЛ08.В.00191_18

EAC Declaration

Machinery & Equipment

EAC RU

0045 202 1204 Z 00354 19 D 001(00)

Pressure - Safety Certicate

TÜV

Д-DK.РА01.B.72054_20

EAC Declaration

PED

EAC RU

EU 033F0685.AK

EU Declaration

EMCD/PED

Danfoss

033F0691.AD

Manufacturers Declaration

RoHS

Danfoss

033F0473.AD

Manufacturers Declaration

ATEX

Danfoss

Д-DK.БЛ08.В.01592

EAC Declaration

EMC

EAC RU

Д-DK.МХ24.В.00273

EAC Declaration

Machinery & Equipment

EAC RU

Д-DK.БЛ08.B.01120_19

EAC Declaration

EMC

EAC RU

UL SA7200

Mechanical - Safety Certicate

UL

UA.1O146.D.00069-19

UA Declaration

PED

LLC CDC EURO-TYSK

UA.TR-089.1112.01-19

Pressure - Safety Certicate

PED

LLC CDC EURO-TYSK

Type

SV 1 and SV 3

Classied for

Fluid group I

Category

I

Pressure Equipment Directive (PED)

SV 1 and SV 3 are approved in accordance with the European standard specied in the Pressure Equipment Directive and are CE

marked.

For further details / restrictions - see Installation guide.

Float valve, Type SV 1 and SV 3

Certicates, declarations, and approvals

The list contains all certicates, declarations, and approvals for this product type. Individual code number may have

some or all of these approvals, and certain local approvals may not appear on the list.

Some approvals may change over time. You can check the most current status at danfoss.com or contact your local

Danfoss representative if you have any questions.

Table 15: Valid Approvals

Table 16: Compliance table

Table 17: Conformity Approvals

© Danfoss | Climate Solutions | 2021.02 AI221686430747en-001001 | 13

Page 14

Online support

Danfoss oers a wide range of support along with our products, including digital product information, software,

mobile apps, and expert guidance. See the possibilities below.

The Danfoss Product Store

The Danfoss Product Store is your one-stop shop for everything product related—no matter where

you are in the world or what area of the cooling industry you work in. Get quick access to essential

information like product specs, code numbers, technical documentation, certications, accessories,

and more.

Start browsing at store.danfoss.com.

Find technical documentation

Find the technical documentation you need to get your project up and running. Get direct access to

our ocial collection of data sheets, certicates and declarations, manuals and guides, 3D models

and drawings, case stories, brochures, and much more.

Start searching now at www.danfoss.com/en/service-and-support/documentation.

Danfoss Learning

Danfoss Learning is a free online learning platform. It features courses and materials specically

designed to help engineers, installers, service technicians, and wholesalers better understand the

products, applications, industry topics, and trends that will help you do your job better.

Create your Danfoss Learning account for free at www.danfoss.com/en/service-and-support/learning.

Get local information and support

Local Danfoss websites are the main sources for help and information about our company and

products. Find product availability, get the latest regional news, or connect with a nearby expert—all

in your own language.

Find your local Danfoss website here: www.danfoss.com/en/choose-region.

Spare Parts

Get access to the Danfoss spare parts and service kit catalog right from your smartphone. The app

contains a wide range of components for air conditioning and refrigeration applications, such as

valves, strainers, pressure switches, and sensors.

Download the Spare Parts app for free at www.danfoss.com/en/service-and-support/downloads.

Coolselector®2 - nd the best components for you HVAC/R system

Coolselector®2 makes it easy for engineers, consultants, and designers to nd and order the best

components for refrigeration and air conditioning systems. Run calculations based on your operating

conditions and then choose the best setup for your system design.

Download Coolselector®2 for free at coolselector.danfoss.com.

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its

products without notice. This also applies to products already on order provided that such alterations can be made without subsequential

changes being necessary in specications already agreed. All trademarks in this material are property of the respective companies. Danfoss and

the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

© Danfoss | Climate Solutions | 2021.02 AI221686430747en-001001 | 14

Loading...

Loading...