Page 1

System Description

Subsystem Application

Anti Spin Control

powersolutions.danfoss.com

Page 2

System Description

ASC SSA

Revision history Table of revisions

Date Changed Rev

May 2016 Replaced screen images for system overview and vehicle geometry; Updated to Engineering

Tomorrow design

August 2014 Danfoss layout CA

August 2011 Updated wiring diagram BA

August 2011 Updated screen captures, added anti spin valve AB

July 2011 First edition AA

0301

2 | © Danfoss | May 2016 L1106431 | AB00000034en-US0301

Page 3

System Description

ASC SSA

Contents

Overview

Referenced documentation

Control system

Related products

About this document......................................................................................................................................................................4

OEM responsibility........................................................................................................................................................................... 4

Concept and function.....................................................................................................................................................................5

Benefits.................................................................................................................................................................................................5

System application wiring.............................................................................................................................................................6

PLUS+1® software development tools......................................................................................................................................7

Subsystem application................................................................................................................................................................... 7

Electronic product............................................................................................................................................................................7

Hydraulic product.............................................................................................................................................................................7

System development tools...........................................................................................................................................................9

Application hardware..................................................................................................................................................................... 9

Software details.................................................................................................................................................................................9

GUIDE-programmable...............................................................................................................................................................9

Application block........................................................................................................................................................................ 9

Plug-ins........................................................................................................................................................................................... 9

Downloading SSA software.................................................................................................................................................. 10

Application file ..........................................................................................................................................................................11

Vehicle Geometry screen.......................................................................................................................................................11

System Overview screen........................................................................................................................................................12

Electronic product details...........................................................................................................................................................13

PLUS+1® microcontrollers......................................................................................................................................................13

PLUS+1® expansion modules............................................................................................................................................... 13

DP200 and DP250 displays....................................................................................................................................................13

DP600 display............................................................................................................................................................................ 14

MBS pressure sensors..............................................................................................................................................................14

KPP pulse pickup speed sensors......................................................................................................................................... 14

Hydraulic product details............................................................................................................................................................15

H1 axial piston variable pumps........................................................................................................................................... 15

Series 90 high power axial variable piston pumps.......................................................................................................15

H1 medium power integral tandem axial piston pumps...........................................................................................15

S42 medium power variable pumps..................................................................................................................................16

H1B bent axis variable displacement motors.................................................................................................................16

Series 51 bent axis variable displacement motors....................................................................................................... 16

Series 90 high power axial piston motors........................................................................................................................16

L and K frame medium power motors..............................................................................................................................17

Series 40 medium power motors........................................................................................................................................17

Low speed high torque motors...........................................................................................................................................17

Anti spin control valve............................................................................................................................................................17

©

Danfoss | May 2016 L1106431 | AB00000034en-US0301 | 3

Page 4

System Description

ASC SSA

Overview

About this document

OEM responsibility

This document provides general information about the ASC SSA Subsystem Application (SSA) software

for use with Danfoss PLUS+1® microcontrollers and associated hydraulic and electronic products. In

addition, it is a reference tool for vehicle OEM design, engineering, and service personnel.

SSA software puts 40 years of Danfoss mobile machinery propel system experience at your fingertips. It is

a fully worked out application software example, enabling faster time-to-market and improved

performance and functionality for both new machine designs and model variants. PLUS+1® GUIDE

programmability allows developers to modify the SSA according to their individual vehicle requirements.

For control system developers programming in GUIDE, this document along with relevant software files,

user manuals, and other documents is included in the Application File posted on the Danfoss web site for

easy customer access and download.

This document is one of several sources of technical information for the control system. Additional

sources of technical information for the control system are listed under Referenced documentation on

page 7.

The OEM of a machine or vehicle in which Danfoss products are installed has the full responsibility for all

consequences that might occur. Danfoss has no responsibility for any consequences, direct or indirect,

caused by failures or malfunctions.

Danfoss has no responsibility for any accidents caused by incorrectly mounted or maintained

•

equipment.

Danfoss does not assume any responsibility for Danfoss products being incorrectly applied or the

•

system being programmed in a manner that jeopardizes safety.

All safety critical systems shall include an emergency stop to switch off the main supply voltage for

•

the outputs of the electronic control system. All safety critical components shall be installed in such a

way that the main supply voltage can be switched off at any time. The emergency stop must be easily

accessible to the operator.

4 | © Danfoss | May 2016 L1106431 | AB00000034en-US0301

Page 5

Application Block

Steering

Angle

Wheel

Speed

Wheel

Speed

Wheel

Speed

Wheel

Speed

Wheel

Speed

Limiter

Output

Driver

Offset

Reference

Speed

Calculations

Wheel

Spin

Calculator

Vehicle

Geometry

Turning

Circle

Offset

Mode

Speed

per

Wheel

P200076

System Description

ASC SSA

Overview

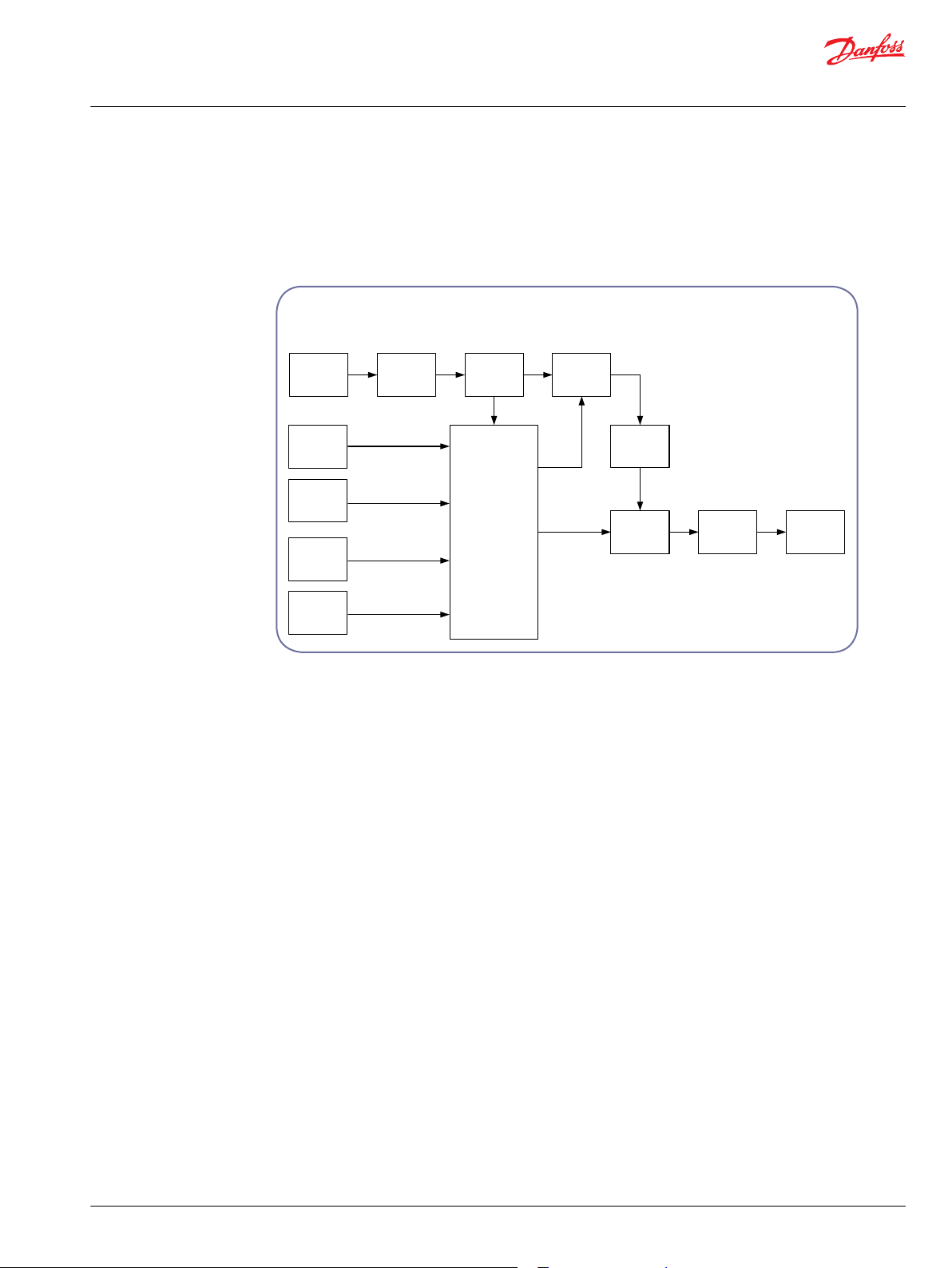

Concept and function

The Anti Spin Control Subsystem Application (ASC SSA) is designed for use with hydraulically propelled

vehicles incorporating single pump in conjunction with multiple motors. The subsystem application

software includes: an Application Block, Plug-in features, and a sample application.

User-programmable Anti Spin Control Subsystem Application

Benefits

The ASC SSA is a fully integrated, dual path control system solution that’s ready to be tailored to your

vehicle requirements. The software is made up of validated component software blocks that greatly

reduce vehicle testing time, provide responsive control and reduced project risk.

The graphical application code can be modified with GUIDE, using PLUS+1® Compliant products, such as

sensors, pumps and motors.

These PLUS+1® Compliant products are represented by functional software blocks. These blocks can be

dragged, dropped and connected to modify the ASC SSA to accommodate vehicle characteristics that are

different from those of the example application.

Compliance blocks that are pre-programmed for CAN communication between joysticks and PLUS+1

controllers are particularly easy to modify within the application.

Advanced control features and flexibility of plug-in design provide state of the art system performance.

Pre-configured service screens are provided to set up the software and adjust parameters.

®

©

Danfoss | May 2016 L1106431 | AB00000034en-US0301 | 5

Page 6

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

Battery (-)

Battery (+)

CAN 0 High

CAN 0 Low

Analog Input / CAN 0 Shield

Digital Input

Digital Input

5 V DC Sensor (+)

Digital Input

Digital Input

Digital Input

Digital Input

Digital Input / Analog Input

Sensor (-)

Digital Input / Analog Input

Digital Input / Analog Input

Digital Input / Analog Input / FreqIN

Digital Input / Analog Input / FreqIN

CAN 1 High

CAN 1 Low

Analog Input / CAN 1 Shield

Digital Input / Analog Input / FreqIN

Digital Input / Analog Input / FreqIN

Analog Input / Temp / Rheo

Digital Input / Analog Input

19

20

21

22

23

24

25

26

27

28

29

30

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

Digital Output

Digital Output

Digital Output / PVG Power 1

Digital Output / PVG Power 2

Digital Output / PVG Power 3

PWMOUT / Digital Out / PVG 1 OUT

PWMOUT / Digital Out / PVG 1 OUT

PWMOUT / Digital Out / PVG 1 OUT

PWMOUT / Digital Out / PVG 1 OUT

PWMOUT / Digital Out / PVG 2 OUT

PWMOUT / Digital Out / PVG 2 OUT

PWMOUT / Digital Out / PVG 2 OUT

PWMOUT / Digital Out / PVG 2 OUT

PWMOUT / Digital Out / PVG 3 OUT

Battery (+)

Battery (+)

Battery (+)

PWMOUT / Digital Out / PVG 3 OUT

Analog Input / Temp / Rheo

Analog Input / Temp / Rheo

Digital Input / Analog Input / FreqIN

Digital Input / Analog Input / FreqIN

Analog Input / Temp / Rheo

31

50

C1

Digital Output

Battery (+)

50 pins: Deutsch DRC connector

Batt.

12/24V

DC

+ -

S1

1

F1

C1: 09

C1: 08

Terminals

Sensor (+)

Terminals

Sensor (-)

Terminals

Batt. (-)

Terminals

Batt. (+)

C1: 01

C1: 02

C1: 27

C1: 23

C1: 17

C1: 16

C1: 47-50

C1: 15

C1: 31

Error LED

C1: 19

C1: 28

C1: 24

C1: 08

C1: 29

C1: 08

C1: 14

C1: 08

C1: 09

C1: 08

C1: 09

C1: 08

C1: 09

C1: 08

C1: 09

C1: 18

U

p

Pressure Sensor

PORT A

U

p

Pressure Sensor

PORT B

C1: 09

C1: 09

Rv

Rv

cw

Angle Sensor Front

C1: 08

C1: 09

C1: 30

Rv

Rv

cw

Angle Sensor Rear

C1: 08

C1: 09

PPU (left front)

4

2

3

5

PPU (right front)

4

2

3

5

PPU (left rear)

4

2

3

5

PPU (right rear)

4

2

3

5

2

2

2

P200075

System Description

ASC SSA

Overview

System application wiring

ASC SSA example application diagram

The ASC SSA example application has been designed to operate on the PLUS+1® MC050-012

microcontroller, but the ASC SSA can be modified to run on other PLUS+1® application hardware

modules.

6 | © Danfoss | May 2016 L1106431 | AB00000034en-US0301

Page 7

System Description

ASC SSA

Referenced documentation

Comprehensive technical literature online at powersolutions.danfoss.com

PLUS+1® software development tools

Subsystem application

Electronic product

PLUS+1® GUIDE Data Sheet

PLUS+1® GUIDE User Manual

PLUS+1® Service Tool User Manual

CG150 CAN/USB Gateway Interface Communicator Data Sheet

520L0708

10100824

520L0899

520L0945

The application software files are listed under Application file on page 11.

Anti spin Control Subsystem Application System Description

Anti spin Control Subsystem Application Data Sheet

Recommended Machine Electronic Control System Start Up Procedures

Subsystem Application Service Tool User Manual

Subsystem Application I/O Mapping User Manual

Application Block User Manual

Steering Plug-in GUIDE Programming User Manual

Machine State Plug-in User Manual

PLUS+1® microcontrollers and displays

PLUS+1® Controller Family Technical Information

DP2XX Graphical Display Family Technical Information

DP200 Series Graphical Terminals Technical Information

DP250 Series PLUS+1 Mobile Machine Displays Data Sheet

DP600 Series Graphical Terminals Technical Information

520L0719

L1026202

11023625

L1026137

520L0699

L1106431

L1106107

11010667

70055034

70054663

70047311

70047346

70047347

Sensors

MBS2250 Heavy Duty Pressure Transmitter (SAE Thread Version)

Data Sheet

MBS2250 Heavy-Duty Pressure Transmitter (DIN Thread Version)

Data Sheet

KPP Pulse Pickup (PPU) Technical Information

11005452

520L0801

11029257

Hydraulic product

High power axial piston pumps with electronic displacement control

H1 Axial Piston Pump, Size 078, Single Technical Information

H1 Axial Piston Pump, Size 089/100, Single Technical Information

H1 Axial Piston Pump, Size 115/130, Single Technical Information

H1 Axial Piston Pump, Size 147/165, Single Technical Information

©

Danfoss | May 2016 L1106431 | AB00000034en-US0301 | 7

11062169

11069970

11063346

11063347

Page 8

System Description

ASC SSA

Referenced documentation

High power axial piston pumps with electronic displacement control (continued)

H1 Axial Piston Pump, Size 115/130, 147/165, ISL Integrated Speed

Limitation Technical Information

Series 90 Axial Piston Pumps Technical Information

11053026

520L0603

High power variable displacement motors

H1B Bent Axis Variable Displacement Motors, Size 060/080/110

Technical Information

Series 51, Series 51-1 Bent Axis Variable Displacement Motors

Technical Information

Series 90 Axial Piston Motors Technical Information

11037153

520L0440

520L0604

Medium power variable axial piston pumps with electronic displacement control

H1 Axial Piston Pump, Size 045/053 Tandem Technical Information

H1 Axial Piston Pump, Size 045/053 Single Technical Information

H1 Axial Piston Pumps, Single and Tandem Basic Information

11063345

11063344

11062168

Medium power variable displacement motors

L and K Frame Variable Motors Technical Information

Series 40 Axial Piston Motors Technical Information

520L0627

520L0636

8 | © Danfoss | May 2016 L1106431 | AB00000034en-US0301

Page 9

System Description

ASC SSA

Control system

System development tools

PLUS+1® GUIDE (Graphical User Integrated Development Environment) is a desktop software

development tool used to create and customize application software to specific vehicle requirements.

GUIDE’s graphical editor allows easy development or modification of example applications by system

engineers without formal software development training.

Components and application blocks can be dragged from the component selector and dropped onto the

programming workspace for time-saving system design in the PLUS+1® GUIDE environment, generating

downloadable applications for all programmable PLUS+1® controllers and displays.

PLUS+1® Service Tool uses the CG150 Interface Communicator for programming PLUS+1® controllers via

CAN bus from a computer. Additionally, the PLUS+1® Service Tool features data logging capabilities with

oscilloscope and bar graph displays used for diagnostics and tuning. Graphical design features allow

development of specialized service screens to support applications created in PLUS+1® GUIDE.

The CG150 CAN/USB Gateway Interface Communicator serves as the interface between PLUS+1® modules

on the vehicle CAN network and a laptop USB port.

Application hardware

Software details

The SSA software may only be loaded onto keyed PLUS+1® application hardware. If the application

hardware key matches the Danfoss application software key the service tool permits the download to the

target application hardware.

Danfoss application key number is: 10106603

See product data sheet for controllers assembly part numbers.

GUIDE-programmable

PLUS+1® GUIDE programmable application software blocks. Graphical application code contained in the

PLUS+1® GUIDE programmable pages of the SSA can be modified by the user to tailor the application to

the specific needs of the vehicle or PLUS+1® controllers that are different from the example provided by

Danfoss.

Application block

The software application block assesses the wheel speed with consideration to vehicle geometry and

steer angle, wheel slip is identified and a corresponding output command signal is generated for

integration with the propel hardware and /or software configuration. The application block supports

manual enabling/disabling, operating tolerances for minimum motor speed, maximum motor speed and

steer angle.

Plug-ins

The Application Block accepts optional plug-in modules. Plug-ins provide design flexibility by allowing

enhanced features or performance. They may be used or deleted to conserve code space. Basic dual path

control functionality is preserved by replacing plug-ins with jumpers.

Plug-in Steering_PI Page

•

©

Danfoss | May 2016 L1106431 | AB00000034en-US0301 | 9

Page 10

System Description

ASC SSA

Control system

Steering plug-in converts vehicle geometry to values understood by the application block. Two

‒

and four wheel Ackerman steering geometry support is included, custom solutions may be

created and utilize socket.

Plug-in MachineState_PI Page

•

Machine State plug-in assesses command relative to propel conditions to establish an

‒

appropriate anti-spin operation. The plug-in utilizes pressure signals to determine slip wheel

relative to vehicle acceleration or deceleration.

I/O mapping

Input_Mapping page connects hardware input signals to appropriate software signals used within

•

the ASC application block and plug-ins.

Output_Mapping page connects the output command to physical hardware.

•

Parameters page applies configuration values for the anti spin operation.

•

Diagnostic page provides checkpoint visibility for the subsystem application.

•

Input mapping, output mapping, parameters, diagnostic

Downloading SSA software

PLUS+1® GUIDE license holders may visit the Danfoss web site, download the application file, and install

the enclosed software and documentation on their hard drive.

•

10 | © Danfoss | May 2016 L1106431 | AB00000034en-US0301

Page 11

System Description

ASC SSA

Control system

•

The application file contents are downloaded to your computer by clicking on the SSA exe.zip

link, clicking through the user acceptance agreement and installing the contents in the folder you

specify on your hard drive.

Application file

Application file for SSA software products contains all SSA graphical source code files, all required service

screens software files, and all software product documentation and user manuals associated with the

SSA. The software product documentation and user manuals (PDF) files are listed under Referenced

documentation on page 7: Subsystem application.

The Application file for the ASC SSA includes the following software files:

Software Installer Executable

Subsystem Application Software

Application Block Software

Steering Plug-in Software

Machine State Plug-in Software

Release Notes

.EXE 11081276_Vx

.P1P 11081276

.SCS 11096901

.SCS 11096922

.SCS 11096923

.HTML — —

Vehicle Geometry screen

Service Tool configurability. The Vehicle Geometry screen is used to configure the physical dimensions

and steering mechanism.

Vehicle Geometry screen and Diagnostic Navigator

©

Danfoss | May 2016 L1106431 | AB00000034en-US0301 | 11

Page 12

System Description

ASC SSA

Control system

System Overview screen

Service Tool configurability. The System Overview screen consolidates the most important about the

system, links provide access to additional detail.

System Overview screen and Diagnostic Navigator

12 | © Danfoss | May 2016 L1106431 | AB00000034en-US0301

Page 13

System Description

ASC SSA

Related products

Electronic product details

PLUS+1® microcontrollers

•

High speed DSP technology to process even the most complex applications

•

CAN-based communications for state-of-the art control performance

•

256K internal flash memory is recommended

PLUS+1® expansion modules

•

Expand control system capabilities with CAN-based Input/Output modules

•

12 and 24 pin housings with five possible configurations

•

Stackable design for optimum mounting flexibility

DP200 and DP250 displays

•

Cost effective alternative to existing analogue gauges

•

DP200 high-resolution monochrome displays fit every budget without compromising performance

•

DP250 high resolution color TFT (240x320 pixels, 15-bit color) displays are viewable in a wide range of

lighting conditions

•

Options featuring front USB 2.0 port for easy connection to PC-based service and diagnostic tools,

extended I/O for improved input design flexibility, real-time clock, and display heater

•

Customize the look and feel of engine monitoring and performance messages with Engine

Information Center (EIC) application software

Read and display engine operation and performance messages which are transmitted by the

‒

engine control module over a J1939 CANbus

Supports fifty engine and machine performance variables on up to four screens with up to four

‒

variables per screen

Soft keys at the front of the display provide the operator with easy navigation through diagnostic

‒

and engine information

©

Danfoss | May 2016 L1106431 | AB00000034en-US0301 | 13

Page 14

System Description

ASC SSA

Related products

DP600 display

•

Transflective TFT and DSTN, LCD display technologies, high resolution display, antiglare screen, and

sensor controlled backlighting

•

CAN, RS-232 and USB interfaces

•

Additional inputs for an external navigation button, which enables you to maneuver through all

terminal functions

MBS pressure sensors

•

Available in seven sizes ranging from to 2.5 bar to 600 bar [362 psi to 8,702 psi], load pressure is 10 to

20 times the measuring range

•

Temperature compensated, linearized, and laser calibrated

•

Available with DIN or UNF thread

KPP pulse pickup speed sensors

•

Outputs a digital pulse signal in response to the speed of a permanently magnetized speed ring on

the motor’s cylinder block or shaft

•

Ideal for low-speed measurement

•

For rugged outdoor, mobile, speed-sensing applications that do not allow contact with the rotating

shaft

14 | © Danfoss | May 2016 L1106431 | AB00000034en-US0301

Page 15

System Description

ASC SSA

Related products

Hydraulic product details

H1 axial piston variable pumps

•

Optimized for electrohydraulic control

•

Designed for improved operating efficiencies

•

Designed for short length and compact installation

Series 90 high power axial variable piston pumps

•

7 different displacements

•

Pressures up to 480 bar [6962 psi]

H1 medium power integral tandem axial piston pumps

•

2 integral tandem displacements

•

Optimized for electrohydraulic control

©

Danfoss | May 2016 L1106431 | AB00000034en-US0301 | 15

Page 16

System Description

ASC SSA

Related products

S42 medium power variable pumps

•

Pressures up to 415 bar [6019 psi]

•

Integral loop flushing

H1B bent axis variable displacement motors

•

Zero degree motor angle capability

•

Electric 2-position or electric proportional control

•

Higher corner HP/package size ratio

Series 51 bent axis variable displacement motors

•

Large displacement ratio (5:1)

•

Compact and lightweight

•

Pressures up to 480 bar [6962 psi]

Series 90 high power axial piston motors

•

Two-position motor

•

Short installed length

16 | © Danfoss | May 2016 L1106431 | AB00000034en-US0301

Page 17

System Description

ASC SSA

Related products

L and K frame medium power motors

•

Cartridge and SAE mounts available

•

Variable motor with 3.4:1 working displacement ratio

•

5 displacements in one compact package

Series 40 medium power motors

•

Short installed length

•

Pressures up to 345 bar [5000 psi]

Low speed high torque motors

•

High efficiency

•

Long life under extreme operating conditions

•

Smooth running over entire speed range

Anti spin control valve

•

Easy to service

•

Flexibility

©

Danfoss | May 2016 L1106431 | AB00000034en-US0301 | 17

Page 18

System Description

ASC SSA

18 | © Danfoss | May 2016 L1106431 | AB00000034en-US0301

Page 19

System Description

ASC SSA

©

Danfoss | May 2016 L1106431 | AB00000034en-US0301 | 19

Page 20

Danfoss

Power Solutions GmbH & Co. OHG

Krokamp 35

D-24539 Neumünster, Germany

Phone: +49 4321 871 0

Danfoss

Power Solutions ApS

Nordborgvej 81

DK-6430 Nordborg, Denmark

Phone: +45 7488 2222

Danfoss

Power Solutions (US) Company

2800 East 13th Street

Ames, IA 50010, USA

Phone: +1 515 239 6000

Danfoss

Power Solutions Trading

(Shanghai) Co., Ltd.

Building #22, No. 1000 Jin Hai Rd

Jin Qiao, Pudong New District

Shanghai, China 201206

Phone: +86 21 3418 5200

Products we offer:

Comatrol

www.comatrol.com

Schwarzmüller-Inverter

www.schwarzmuellerinverter.com

Turolla

www.turollaocg.com

Hydro-Gear

www.hydro-gear.com

Daikin-Sauer-Danfoss

www.daikin-sauer-danfoss.com

Bent Axis Motors

•

Closed Circuit Axial Piston

•

Pumps and Motors

Displays

•

Electrohydraulic Power

•

Steering

Electrohydraulics

•

Hydraulic Power Steering

•

Integrated Systems

•

Joysticks and Control

•

Handles

Microcontrollers and

•

Software

Open Circuit Axial Piston

•

Pumps

Orbital Motors

•

PLUS+1® GUIDE

•

Proportional Valves

•

Sensors

•

Steering

•

Transit Mixer Drives

•

Danfoss Power Solutions is a global manufacturer and supplier of high-quality hydraulic and

electronic components. We specialize in providing state-of-the-art technology and solutions

that excel in the harsh operating conditions of the mobile off-highway market. Building on

our extensive applications expertise, we work closely with our customers to ensure

exceptional performance for a broad range of off-highway vehicles.

We help OEMs around the world speed up system development, reduce costs and bring

vehicles to market faster.

Danfoss – Your Strongest Partner in Mobile Hydraulics.

Go to www.powersolutions.danfoss.com for further product information.

Wherever off-highway vehicles are at work, so is Danfoss. We offer expert worldwide support

for our customers, ensuring the best possible solutions for outstanding performance. And

with an extensive network of Global Service Partners, we also provide comprehensive global

service for all of our components.

Please contact the Danfoss Power Solution representative nearest you.

Local address:

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

already on order provided that such alterations can be made without changes being necessary in specifications already agreed.

All trademarks in this material are property of the respective companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

©

Danfoss | May 2016 L1106431 | AB00000034en-US0301

Loading...

Loading...