Page 1

Data sheet STV Series

Balancing Valves

Applications/

Features:

Ordering

Information:

STV / STVL

Danfoss STV series of balancing valves provide

testing and balancing of circuit flow for hydronic

heating or cooling systems.

STV valves provide a high level of balancing

accuracy using an easy to set multi-turn setting

wheel and memory lock.

Valve Size

1/2” 1.2 (0.5) 4.1 065F8965 065F896501

3/4” 1.3 (0.6) 5.9 065F8966 065F896601

STV /

STVL

1” 1.7 (0.8) 10.2 065F8967 065F896701

1-1/4” 2.7 (1.2) 15.2 065F8968 065F896801

1-1/2” 3.3 (1.5) 22.6 065F8969 065F896901

2” 5.1 (2.3) 36.5 065F8970 065F897001

Weight

lbs. (kg)

STVA / STVC

Features:

Positive shut-off•

Built-in memory stop•

Multi-turn 360 hand wheel with vernier scale •

and digit readout

Offset pressure/ temperature ports•

Presetting and locking with Allen key•

Cv*

NPT (STV) F. Solder (STVL)

Connection

Valve Size

2-1/2” 31 (14) 110

3” 45 (20) 128 065F8972

STVA

STVC

*Cv= Flow rate in GPM with a pressure drop of 1 psi.

4” 58 (26) 222 065F8973

5” 90 (41) 350 065F8974

6” 112 (51) 495 065F8975

8” 275 (125) 696 065F8993

10” 490 (222) 1405 065F8994

12” 573 (260) 1764 065F8995

VDDNB122 © Danfoss 05/08

Weight

lbs. (kg)

Cv* Connection Code No.

065F8971

ANSI

class 125

Flanged

1

Page 2

Data sheet STV Series

Balancing Valves

Accessories:

Technical Specifications:

Part Description Code No.

Test Plug

Gauge Adapter Measuring

Needle

Replacement hand wheel

Max. static pressure:

Temperature range :

Connection:

Red Tag 065F8985

Blue Tag 065F8986

1/2” to 2” valves

(1/16” diameter, 1.75” length)

2-1/2” to 12” valves

(1/8” diameter, 1.75” length)

003Z40324

003Z0326

Hand wheel, 1/2” to 2” 900693

Hand wheel, 2-1/2” to 6” 900694

1/2” to 2” : 290 psi (20 bar)

2-1/2” to 12” : 232 psi (16 bar)

1/2” to 2”: -4° to 250°F (-20° to 120°C)

2-1/2” to 12”: 14° to 250°F (-10° to 120°C)

Female NPT and Female Solder (STV / STVL)

ANSI 125 Flanged (STVA / STVC)

Pressure tappings: P/T plugs

Allowable fluid Closed loop application, 100% water, max 50% glycol mixture

System Layout:

STVA / STVC

STV / STVL

STV / STVL

STV / STVL

STV / STVL

Copper Fin

Radiator

Fan Coil

Unit

STVA / STVC

Fan Coil

Unit

Fan Coil

Unit

STVA / STVC

M

M

M

M

M

STV / STVL

Chiller or

Boiler

VDDNB122 © Danfoss 05/08

2

Page 3

Data sheet STV Series

Balancing Valves

Installation:

Setting Flow Coefficient

values

(Cv value = gpm@1psi ∆P):

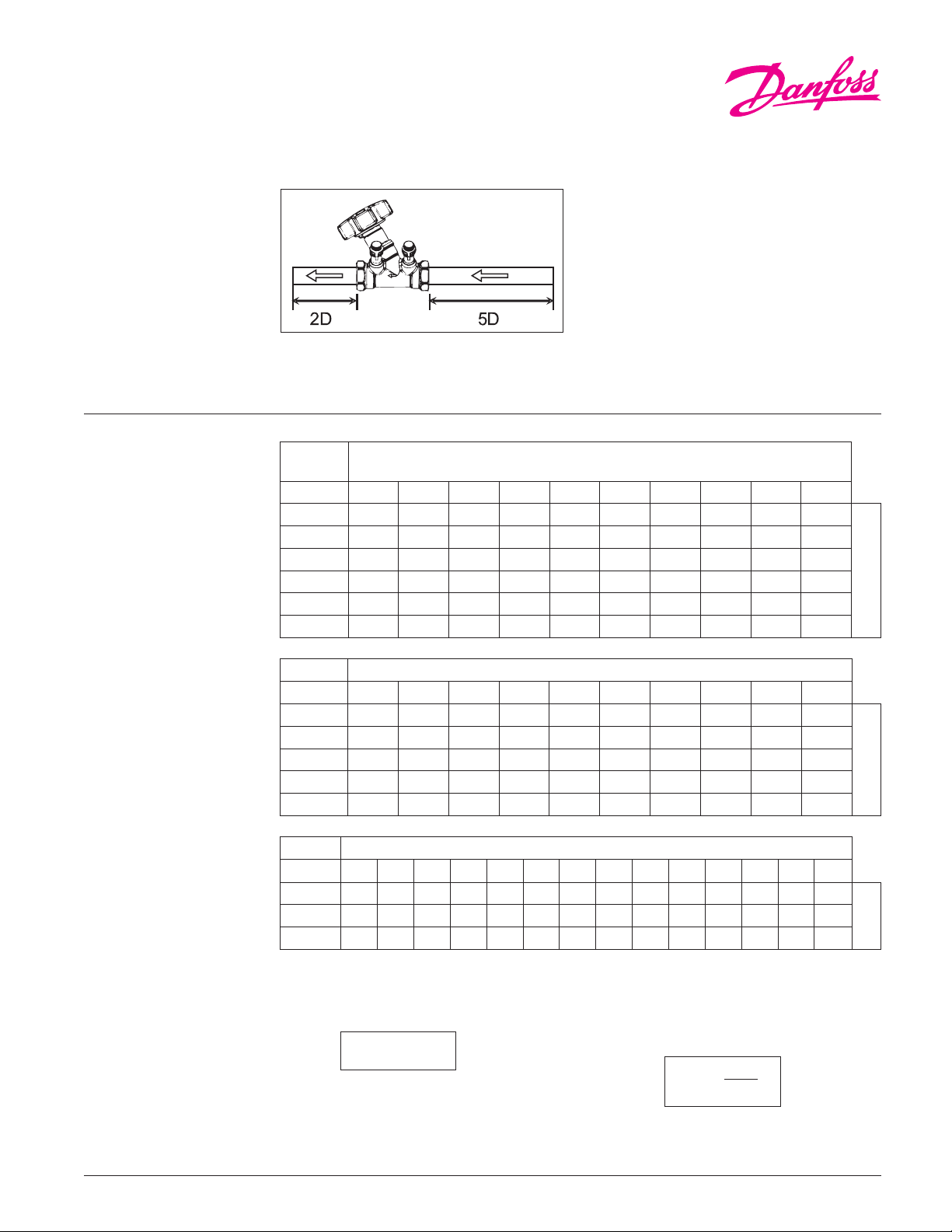

Install the balancing valve with the arrow on the

valve’s body pointing in the direction of the flow

in the system.

To ensure an accurate reading, a straight length

of 5 times the diameter of the pipe should be

piped prior to the valve and a straight length

of at least 2 times the pipe diameter should be

piped after the valve.

If a pump is installed near the valve, a straight

length of 10 times the diameter of the pipe

should be piped prior to the valve to reduce an

inaccurate measurement due to turbulence.

STV /

STVL

Size 1 2 3 4 5 6 7 8 9 10

1/2” 0.21 0.37 0.52 0.72 1.00 1.36 1.88 2.96 3.65 4.12

3/4” 0.39 0.70 0.96 1.31 1.80 2.44 3.36 4.47 5.22 5.92

1” 0.56 0.89 1.19 1.74 2.67 4.18 5.80 7.54 9.16 10.20

1-1/4” 0.92 1.53 2.09 3.13 4.76 6.84 9.05 11.30 13.30 15.20

1-1/2” 1.39 2.38 3.25 4.76 7.19 10.3 13.90 17.10 19.80 22.60

2” 2.32 4.18 6.03 8.82 13.80 19.4 24.60 29.00 33.20 36.50

Number of Turns

Cv Values

STVA Number of Turns

Size 1 2 3 4 5 6 7 8 9 10

2-1/2” 3.2 5.9 11.1 23.2 41.2 59.2 76.6 91.1 101.0 108.0

3” 6.4 11.0 15.7 21.5 34.2 56.8 79.5 98.6 114.0 128.0

4” 9.3 15.7 22.0 38.3 77.7 115.0 145.0 174.0 197.0 220.0

5” 11.6 25.5 38.3 73.1 123.0 174.0 225.0 274.0 317.0 349.0

6” 20.9 38.3 78.9 151.0 216.0 285.0 341.0 394.0 447.0 493.0

STVC Number of Turns

Size 2 3 4 5 6 7 8 9 10 11 12 14 16 18

8”

10”

12”

Based upon the flow or differential pressures

required within the system, the flow can be

determined by using the equation:

Q = flow

Cv= flow coefficient

∆p

= differential pressure

46 66

116 160

116 180

Q = C

v

84 139 215 290 365 452 545 638 696 - - -

204 349 494 689 884 1031 1177 1291 1405 - - -

244 396 546 708 869 1012 1153 1290 1427 1588 1668 1764

For correction of fluids other than water,

the following equation applies provided

the viscosity of the fluid is the same for

_____

.

∆p

√

water, which is the case for most glycol and

brine solutions:

Q

M

___

=

Q

R

√

Q

= real flow

R

Q

= measured flow

M

= specific density of fluid

Cv Values

Cv Values

VDDNB122 © Danfoss 05/08

3

Page 4

Data sheet STV Series

Balancing Valves

Flow Rate Graphs:

1 foot of head (FOH) = 0.434 psi

1. Plot the required flow rate

and pressure drop within the

columns and then draw a

line between these plotted

points.

2. Draw an additional

horizontal line from the

intersection of the Cv

column across the valve

sizes.

3. Based upon the intersection

of the horizontal line with

the valves sizes, select the

appropriate sized valve.

In selecting the valve, a margin

of allowance for adjustment

should be considered if during

commissioning the pressure

drop is lower than designed.

This reduced pressure drop may

result in an undersized valve.

STV/STVL Balancing Valves 1/2” - 2”

Flow Rate Cv / K

v

Number of Turns

Opened

Pressure Drop

The selection of a valve that has

a pre-set value above 3 turns

offers better accuracy when

setting.

Valve Size

Selection example:

Required- 8.73 GPM (0.55 l/s) at a pressure drop of 3.35 FOH (10kPa)

Potential sizes, 1”, 1-1/4” or 1-1/2”.

VDDNB122 © Danfoss 05/08

4

Page 5

Data sheet STV Series

Balancing Valves

Flow Rate Graphs:

1 foot of head (FOH) = 0.434 psi

1. Plot the required flow rate

and pressure drop within the

columns and then draw a

line between these plotted

points.

2. Draw an additional

horizontal line from the

intersection of the Cv

column across the valve

sizes.

3. Based upon the intersection

of the horizontal line with

the valves sizes, select the

appropriate sized valve.

In selecting the valve, a margin

of allowance for adjustment

should be considered if during

commissioning the pressure

drop is lower than designed.

This reduced pressure drop may

result in an undersized valve.

STVA Balancing Valves 2-1/2” - 6”

Flow Rate Cv / K

v

Number of Turns

Opened

Pressure Drop

The selection of a valve that has

a pre-set value above 3 turns

offers better accuracy when

setting.

Valve Size

Selection example:

Required- A flow rate of 222 GPM (14 l/s) and a pressure drop of 1.67 FOH (5 kPa)

The required balancing valve for this application is a 5” with a setting of 7.8 turns or a 6” with a

setting of 5.8 resulting in a Cv of 263 (Kv=225).

VDDNB122 © Danfoss 05/08

5

Page 6

Data sheet STV Series

Balancing Valves

Flow Rate Graphs:

1 foot of head (FOH) = 0.434 psi

1. Plot the required flow rate

and pressure drop within the

columns and then draw a

line between these plotted

points.

2. Draw an additional

horizontal line from the

intersection of the Cv

column across the valve

sizes.

3. Based upon the intersection

of the horizontal line with

the valves sizes, select the

appropriate sized valve.

In selecting the valve, a margin

of allowance for adjustment

should be considered if during

commissioning the pressure

drop is lower than designed.

This reduced pressure drop may

result in an undersized valve.

The selection of a valve that has

a pre-set value above 3 turns

offers better accuracy when

setting.

STVA Balancing Valves 8” - 12”

Flow Rate Cv / K

v

Number of Turns

Opened

Pressure Drop

Valve Size

Selection example:

Required- A flow rate of 1,316 GPM (83 l/s) and a pressure drop of 16.73 FOH (50 kPa)

The balancing valve for this application could be an 8” valve set for 9.5 turns, a 10” valve set for 6

turns or a 12” valve set for 5.8 turns resulting in a Cv of 502 (Kv=430).

VDDNB122 © Danfoss 05/08

6

Page 7

Data sheet STV Series

Balancing Valves

Dimensions and

Construction:

C

B

A

STV Valve STVL Valve

STV / STVL

Size

A

in (mm)

B

in (mm)

in (mm)

1/2” 3.4 (86.4) 3.7 (93.9) 1.6 (40.6)

3/4” 3.5 (88.9) 3.7 (93.9) 1.7 (43.2)

1” 4.0 (104.1) 3.8 (96.5) 1.7 (43.2)

1-1/4” 4.7 (119.4) 3.8 (96.5) 1.9 (45.7)

1-1/2” 5.2 (132.1) 4.3 (109.2) 1.9 (45.7)

2”

(1)

STVL F.Solder version,

(153.9/164.1)

6.1/6.5

(2)

P/T Tap offset

4.4 (111.7) 2.1 (53.1)

(1)

C

B

A

Body and parts

(2)

C

in contact

with liquid

Dezincification

resistant brass

Gaskets: EPDM

Seat Seal: EPDM

Handwheel:

Polyamide

Plastic

STVA / STVC

Size L1

in (mm)

STVA

2-1/2” 11.4 (290.1) 8.9 (227.1)

H1

in (mm)

3” 12.2 (309.9) 9.5 (241.3)

4” 13.8 (350.0) 10.2 (259.1)

5” 15.8 (400.1) 11.7 (297.9)

6” 18.9 (480.1) 12.1 (306.1)

STVC

8” 23.6 (599.4) 20.1 (510.5)

10” 28.7 (729.9) 20.9 (530.9)

12” 33.5 (850.9) 24.0 (609.6)

STVA / STVC

Body and bonnet: Cast iron

Seat seal: PTFE

Gaskets: EPDM

Other metal parts: Brass

Hand wheel,

STV / STVL / STVA

Ploymide

Plastic

VDDNB122 © Danfoss 05/08

7

Page 8

Data sheet STV Series

Balancing Valves

Typical specification:

The balancing valve shall be of a brass

construction and have female national pipe

thread (NPT) or female solder connections. The

valve shall be suitable for heating or cooling

closed loop circuits. The balancing valve shall be

capable of positive shut off and have P/T plug

connections for testing. The valve adjustment

shall be done via hand wheel hand wheel with

digit readout within the handle of the valve. The

balancing valve shall a hidden memory feature

stop to prevent unauthorized adjustment and

to ensure a return to the preset position. The

memory stop within the valve shall be set via

inner stem of the valve to prevent tampering.

The valve shall be an STV series balancing valve.

Danfoss can accept no responsibility for possible errors in printed materials and reserves the right to alter its products without notice.

All trademarks in this material are property of the respective companies. Danfoss and Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

Danfoss Inc.

6711 Mississauga Road, Suite 410

Mississauga, ON, L5N 2W3

Tel.: 905-285-2050, Fax: 905-285-2055

www.na.heating.danfoss.com

VDDNB122 © Danfoss 05/08

Danfoss Inc.

7941 Corporate Drive

Baltimore, MD 21236 USA

Tel.: 443-512-0266, Fax: 443-512-0270

www.na.heating.danfoss.com

Loading...

Loading...