Page 1

MAKING MODERN LIVING POSSIBLE

SpeedUp™ Heating Systems

DANFOSS HEATING SOLUTIONS Handbook

Page 2

Handbook SpeedUp™ Heating Systems

2

VGCTA2302 © Danfoss 09/2009

Page 3

Handbook SpeedUp™ Heating Systems

Index

Page

Introduction SpeedUp™ and SpeedUp Eco™ . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Heating systems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

System variations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Advantages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Standards and guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Minimum thermal resistance of insulation

under floor heating systems from EN 1264, Part 4 . . . . . . . . . . . . . . 5

System parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Overview SpeedUp Panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

SpeedUp Eco Panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

To ol s . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Floor Construction Substrate requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Tolerance levels for evenness . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Levelling of sustrate (Danfoss recommends) . . . . . . . . . . . . . . . . . . 9

Separation of pipe from load bearing layer . . . . . . . . . . . . . . . . . . 10

Low surface weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Level free surface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Basic construction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Additional insulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Categories of loaded areas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Insulation values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Min. thermal resistance of insulating layers (m

2

K)/W

below the floor heating/cooling system . . . . . . . . . . . . . . . . . . . . 13

Sound impact . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

SpeedUp™ perimeter insulation . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Tanking for wet screed. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Sound impact insulation and wet screed . . . . . . . . . . . . . . . . . . . . 16

Danfoss composite pipes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Determine parts Danfoss lay-out pattern . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

for a system Determine number of SpeedUp™ system parts . . . . . . . . . . . . . . . . 18

Example: Calculation of SpeedUp™. . . . . . . . . . . . . . . . . . . . . . . . 18

Determine number of SpeedUp Eco™ system parts . . . . . . . . . . . . . 19

Example: Calculation of SpeedUp Eco™ . . . . . . . . . . . . . . . . . . . . . 19

Installation Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Check-list for installation of SpeedUp™ heating system. . . . . . . . . . . 20

Strongboard for tiles, check-list before and during installation . . . . . . 21

Installation time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Output tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

VGCTA302 © Danfoss 09/2009

3

Page 4

Handbook SpeedUp™ Heating Systems

- Introduction

SpeedUp™ and

SpeedUp Eco™

Heating systems

Dry installation and fast reacting wet screed

underfloor heating with low construction height

and weight, and quick response time.

Wherever a low construction floor is required to

save on headroom, or a screed floor is unsuitable,

the SpeedUp™ dry installation is a suitable

alternative. It also suitable for wet screed where

the floor level in heated rooms must stay the

same as in any adjoining unheated room.

SpeedUp™ solves individual heating problems.

The SpeedUp™ underfloor heating systems are

universal and optimum for all new and old

buildings. They are particularly suitable for

retrofitting in restoration work, extensions, and

for use in dry and timber installations.

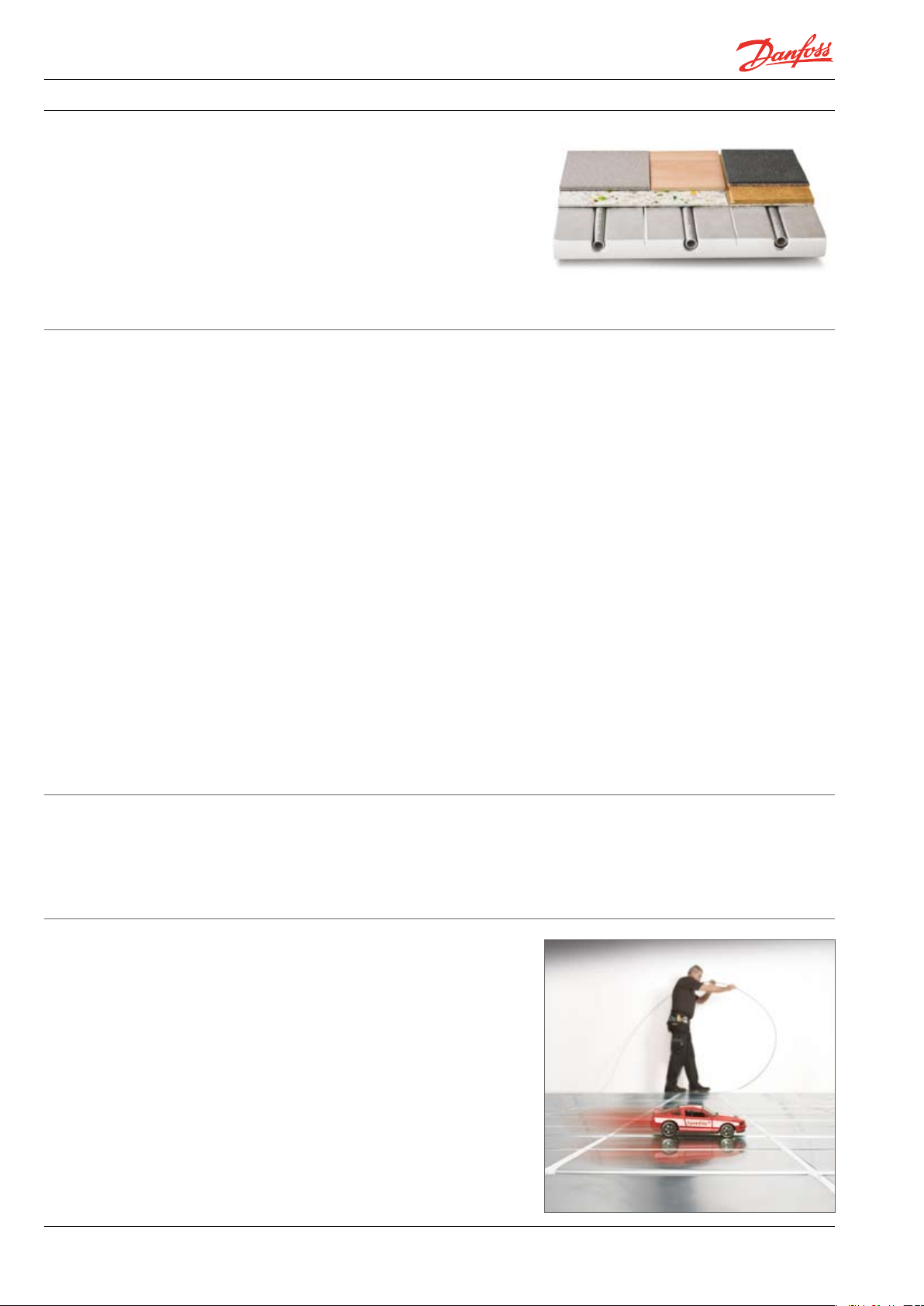

The individual heat panels are only 30 mm thick

and are prefabricated. In contrast to steel

(thermal conductivity 45 W/mK) the aluminium

covering all heat panels is a very good conductor

of heat (thermal conductivity 200 W/mK) so that

the heat is distributed equally and fast over the

entire area.

The pipes are 100% impervious to air so that over

the mid and long term the metal parts of the

heating system cannot suffer from corrosion.

Heat exchangers are not required.

Dry screed (20-25 mm) as well as engineered

flooring and laminates are suitable for load

bearing. Wherever floor height is a problem,

Danfoss Strongboard (5 mm) load bearing panels

offer the opportunity to lay tiles straight onto

SpeedUp™. In contrast to traditional underfloor

heating systems, a very thin layer of liquid screed

can be applied to SpeedUp™, saving mass, weight

and height.

The system is able to react very quickly to

temperature changes and is adjustable like light.

The whole system is available from one source.

Heat output is achieved quickly.

The extremely low flow temperatures are energy

efficient which makes the system ideally suited

for condensing boilers, heat pumps and solar

energy.

Via accessories (mixing shunts, RTB valves) the

system can be connected to existing heating

systems.

System variations

Advantages

4

Depending on the type of installation, system

panels are manufactured from different materials:

· SpeedUp™ with highly resilient insulation,

EPS 035 DEO 240 kPa.

Fast response time.•

Heat is only emitted when required.•

Prefabricated and easy to install system panels.•

Maintenance free and energy efficient.•

Clean and healthy warm air.•

Fast dry installation without residual moisture.•

VGCTA2302 © Danfoss 09/2009

· SpeedUp Eco™ with ecological wood fibre

insulation 140 kPa, which reduces impact

sound.

Page 5

Handbook SpeedUp™ Heating Systems

- Introduction

Standards and

guidelines

Minimum thermal

resistance of insulation

under floor heating

systems from EN 1264,

part4

System parts

For planning and construction legal requirements

and regulations have to be followed.

For dry underfloor heating EN 1264 is applicable.

Three Danfoss basic constructions are possible

under EN 13813 'Screed in the Building Industry'.

Construction Heated room

Thermal

resistance (R)

(m K/W)

* When ground water table is ≤ 5 m this value should be raised !

The Danfoss SpeedUp™ system parts are made of

compression resistant polystyrene EPS DEO 240

kPa or of wood fibre 140 kPa. The wood fibre load

bearing panels serve as thermal and sound

insulation.

To achieve optimum lateral heat transfer (edge/

outside wall much heat - inner area less heat) the

heat panels have pre-formed pipe channels with

two distances. The edge zone can be covered by

EZ-Panels with pipe distances of 12.5 cm and in

the comfort zone CZ-Panels with pipe distances

of 25cm are installed. Both systems are pre-channelled and are covered with heat conducting

aluminium sheet for optimum heat distribution.

The aluminium pipe channels are omega shaped

so that the pipes easily snap in when installed but

cannot ‘spring’ out afterwards. The channels are

beaded at the ends to avoid damage to the

composite pipe during and after installation.

The 1 m long and 0.5 m wide system panels are

pre-scored with the heating plates already cut in

the appropriate places so that the panels can be

snapped over the knee without tools, thus

avoiding unnecessary breaks (this does not apply

to SpeedUp Eco™ panels).

below

0.75 1.2 5 1.2 5 1.5 2

Unheated

room or

occasionally

heated room

below or

room on

ground floor *

They meet the minimum required insulation in

relation to use and position in the home.

For minimum thermal resistance of insulation

under underfloor heating see EN 1264, part 4.

Outside air temperature below construction

Design

outside

temperature

Td > 0° C

This way the system can be adapted to any room

dimensions, even the most awkward corners can

be fully covered.

Together with the two different panel types there

are matching 25 cm header panels, EZ and CZ, to

allow the pipe to return. The header panel CO

allows the cross over between 12.5 cm and 25 cm

pipe distances. Panels for flow and return pipes

CZ and EZ without aluminium plates make it

possible to take supply and returns through

unheated rooms and rooms with low temperature requirement without losing heat. Remaining

areas or areas in front of manifold require blank

panels BP. These are pre-scored as well.

Speedup Eco™ makes up the system with

additional 12.5 cm wide and 1 m long flow and

return panels with routed pipe channels and 90°

curve panels (to allow change of direction in the

flow and return area).

Support battens for stabilisation and sound

insulation as well as load bearing steel sheets

(stabilisation in front of manifold) and heating

aluminium plates (for header panels) complete

the system.

Design

outside

temperature

0° C > Td ≥ -5° C

Design

outside

temperature

-5° C > Td≥ -15°C

VGCTA302 © Danfoss 09/2009

5

Page 6

Handbook SpeedUp™ Heating Systems

SpeedUp Panels

- Overview

08 8X0100

SpeedUp Heat Panel

Comfort Zone CZ

088X0101

SpeedUp Heat Edge Zone

EZ

08 8X0102

SpeedUp Header Panel

Comfort Zone CZ

08 8X0103

SpeedUp Header Panel

Edge Zone EZ

0 88 X 0110

Heating plate

(aluminium)

0 88 X 0111

Load Bearing Sheet

(Steel)

08 8X013 4

Support Batten

088X0135

Threshold Support Batten

08 8X0104

SpeedUp Header Panel

Cross Over CO

08 8X0105

SpeedUp Blank Panel BP

08 8X0106

SpeedUp Flow and Return

Panel CZ

08 8X0107

SpeedUp Flow and Return

Panel EZ

08 8X0122

Perimeter insulation

088X0001

FH Composite pipe, 200 m,

16 x 2 mm

088X0003

FH Composite pipe, 500 m,

16 x 2 mm

6

VGCTA2302 © Danfoss 09/2009

Page 7

Handbook SpeedUp™ Heating Systems

SpeedUp Eco Panels

- Overview

088X0201

SpeedUp Eco Heat Panel

Comfort Zone CZ

088X0202

SpeedUp Eco Heat Panel

Edge Zone EZ

088X0203

SpeedUp Eco Header Panel

Comfort Zone CZ

088X0204

SpeedUp Eco Header Panel

Cross Over CO

088X0209

SpeedUp Eco Flow and

Return Panel CZ

08 8X0210

SpeedUp Eco Flow and

Return Panel EZ

08 8X013 4

Support Batten

088X0135

Threshold Support Batten

088X0205

SpeedUp Eco Header Panel

Edge Zone EZ

088X0206

SpeedUp Eco Blank Panel

BP

088X0207

SpeedUp Eco Flow and

Return Panel

088X0208

SpeedUp Eco 90° Curve

Panel

0 88 X 0110

Heating plate

(aluminium)

0 88 X 0111

Load Bearing Sheet

(Steel)

08 8X0123

Perimeter insulation

088X0001

FH Composite pipe, 200 m,

16 x 2 mm

088X0003

FH Composite pipe, 500 m,

16 x 2 mm

VGCTA302 © Danfoss 09/2009

7

Page 8

Handbook SpeedUp™ Heating Systems

- Overview

Tools

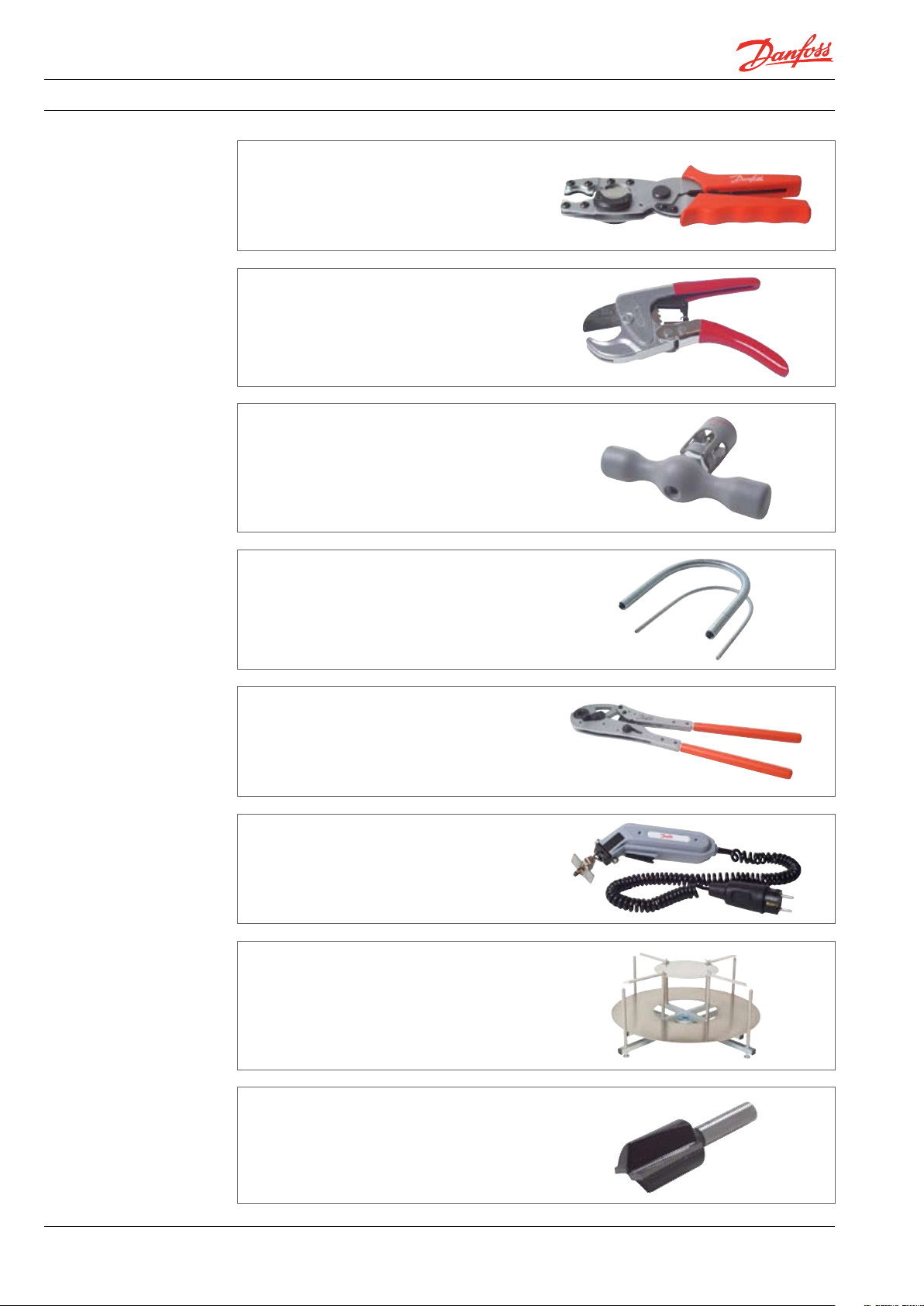

Pipe cutter

The Danfoss pipe cutter, incl. corrugate pipe

cutter for trimming of Danfoss composite pipes

16 x 2.00 mm / 20 x 2.25 mm and the Danfoss

corrugated protective pipe.

Pipe cutter

Danfoss universal pipe cutter for trimming of

Danfoss composite pipes up to 32 x 3 mm and

the Danfoss clip rail BasicRail

Bevelling tool

Danfoss bevelling tool for calibrating and

bevelling the Danfoss Composite Pipes. The

handle is removable so the tool can be attached

to rechargeable drills (< 500 U/min). Dimensions

of 16-20 mm allow inner and outer bevels which

facilitates installation.

Pipe bending springs

The Danfoss pipe bending springs are able to

form radiuses of up to 4 x D. It facilitates

installation and reduces strain on fittings.

Pressing tool

The Danfoss pressing tool is, together with the

inserts, suitable for pressing of Danfoss

composite pipe fittings with dimensions of

16-20 mm.

SpeedUp™ hot wire cutter

The Danfoss hot wire cutter, with its hot blade

and channel cutter, will cut pipe curves, pipe

channels and cleanly cut polystyrene panels.

Pipe dispensing wheel

The Danfoss pipe dispensing wheel is indispensable for one-man installations. It holds up to

200 m of coiled pipe, is compact and easy to

transport and will fit into narrow spaces.

An expansion kit for up to 500 m of coiled pipe

is available.

Ball nose routing bit

The Danfoss ball nose routing bit is used for

milling tracks in the SpeedUp Eco™ blank

panels.

8

VGCTA2302 © Danfoss 09/2009

Page 9

Handbook SpeedUp™ Heating Systems

- Floor Construction

Substrate requirements

Tolerance levels

for evenness

Levelling of substrate

(Danfoss recommends)

The following reqirements have to be met when

installing Danfoss SpeedUp™ heating systems:

The substrate must be dry and firm, it must be

Group Reference 0.1 m 1 m 4 m 10 m 15 m

Finished floors but subject to more stringent

4

requirements. e.g. self-levelling fillers

The system panels must lie fully flat on the

surface since load bearing steel plates in dry

installations cannot compensate for unevenness.

If the prerequisites are not met, levelling and

adjustments have to be undertaken dependent

on the deviation and surface (see table).

Correct minor

unevenness with

levelling products

typically from

builders merchants.Up to 10

mm levelling (e.g.

Maxit Floor 4010).

Up to 20 mm filler

(e.g. Maxit 4160 ).

Prime unfinished

floor (e.g.

Maxitfloor 4716).

For unevenness

over 20 mm use

levelling screed

(Maxit 446) , dry

compound if

moisture and

weight are not

important factors.

Prime unfinished

floor(e.g.

Maxitfloor 4716).

Level service

channels up to 50

mm level with

composite screed.

Depressions and

built-up height

over 30 mm are

levelled with dry

screed composite

panel Fermacell

2E31 (20 mm

gypsum fibre

board plus 10 mm

wood fibre

insulation).

Level minor

unevenness first.

rigid and free from cracks, as well as free from

cleaning agents and dirt.

Maximum deviation in mm, over distance in m

1 mm 3 mm 9 mm 12 mm 15 mm

Greater installation height with unevenness or

many pipe channels may require levelling and

build up of extra height with screed on insulation. The screed will achieve the necessary

evenness and will make further measures

unneccessary. It is also possible to add further

height using commercial insulation material.

Cover dry

levelling compound between

10-50 mm for

small objects with

load bearing

panel (10 mm

gypsum fibre).

Cover service

channels over 3

cm and construction over 11 cm

with screed on

insulation.

Unevenness of up to 3 mm is not a problem. Thin

wood fibre insulation or moisture barriers (e.g.

Gefitas/Firma Gefinex) eliminate this problem.

Unevenness of up to 10 mm can be eliminated

with self-leveling compound. Greater height

differences can be overcome with bonded dry

levelling compound (e.g. Danfoss dry levelling

compound). Before installing the compound on

the suspended floor the prepared area should be

lined to protect against any compound falling

through. As a rule the thickness of the levelling

compound is between a minimum of 10 mm and

a maximum of 60 mm. It is advisable to read the

manufacturer information. A finishing board is

used to make the compound safe to walk on. The

use of additional insulation with Danfoss dry

levelling compound makes the installation of the

board unnecessary. The additional insulation can

be installed directly on the leveling compound. It

is always advisable to follow the manufacturer

information when installing dry screed panels If

there is residual moisture in the building, a 0.2

mm PE foil will prevent the rising of the moisture

VGCTA302 © Danfoss 09/2009

into the building. Length of foil overlap by 20 cm,

at the edge up to floor level. Floors between

storeys don’t need a moisture seal since there is

no residual moisture. Suspended floors should

not have any lining since moisture could be

trapped and cause lasting damage. In accordance

with EN 13967 constructions on ground floors

must be protected against any moisture entering

the floor. In the absence of a lining, bitumen or

synthetic lining can be used; the floor will need

levelling afterwards. Such measures may have to

be decided by the builder.

For floors with greater exposure to humidity e.g.

bathrooms or entrance halls, dry screed panels

such as Fermacell will need a thick coating or a

sealing system before tiling. For shower rooms

and washrooms with floor drains in public and

commercial premises, Fermacell screed panels

are not suitable.

For wet areas, Fermacell Powerpanel SE can serve

as an alternative.

9

Page 10

Handbook SpeedUp™ Heating Systems

46

47

47

50

45

43

- Floor Construction

Separation of pipe from

load bearing layer

Low surface weight

Level free surface

SpeedUp™ is the Danfoss underfloor heating

system, where pipes are integrated into the

system panels and decoupled from the load

bearing layer.

The relatively light weight of dry screed makes

the whole construction light weight, which is an

advantage as well as essential in restoration of

older buildings, where floors are of lower load

bearing construction.

Danfoss Strongboards provide a unique solution

for level free floors.

With a thickness of only 5 mm the Strongboard

for Tiles and Laminates provides sufficient

stability as a load bearing layer to comply with

the demands of EN 1991 (Actions of structures).

The Strongboard for Carpet and Synthetics

provides the same stability, but with a thickness

of 10 mm.

Danfoss Strongboards are made of recycled

materials mixed with shreds of aluminium, which

ensure good heat transfer through the Strongboard to floor finish.

This means that the joints of the load bearing

panels do not have to be taken into consideration

when planning the heating circuit.

Where Strongboard for Tiles and Laminates does

not have a completely smooth surface, the

Strongboard for Carpet and Synthetics can serve

as a smooth surface for floor finishes like carpet,

linoleum, vinyl etc. A smooth surface can

therefore be achieved with only 10 mm instead of

the 20 mm or more that dry or wet screed

requires.

Danfoss Strongboards can be used as a replacement for the Fermacell 20 mm or 25 mm panels.

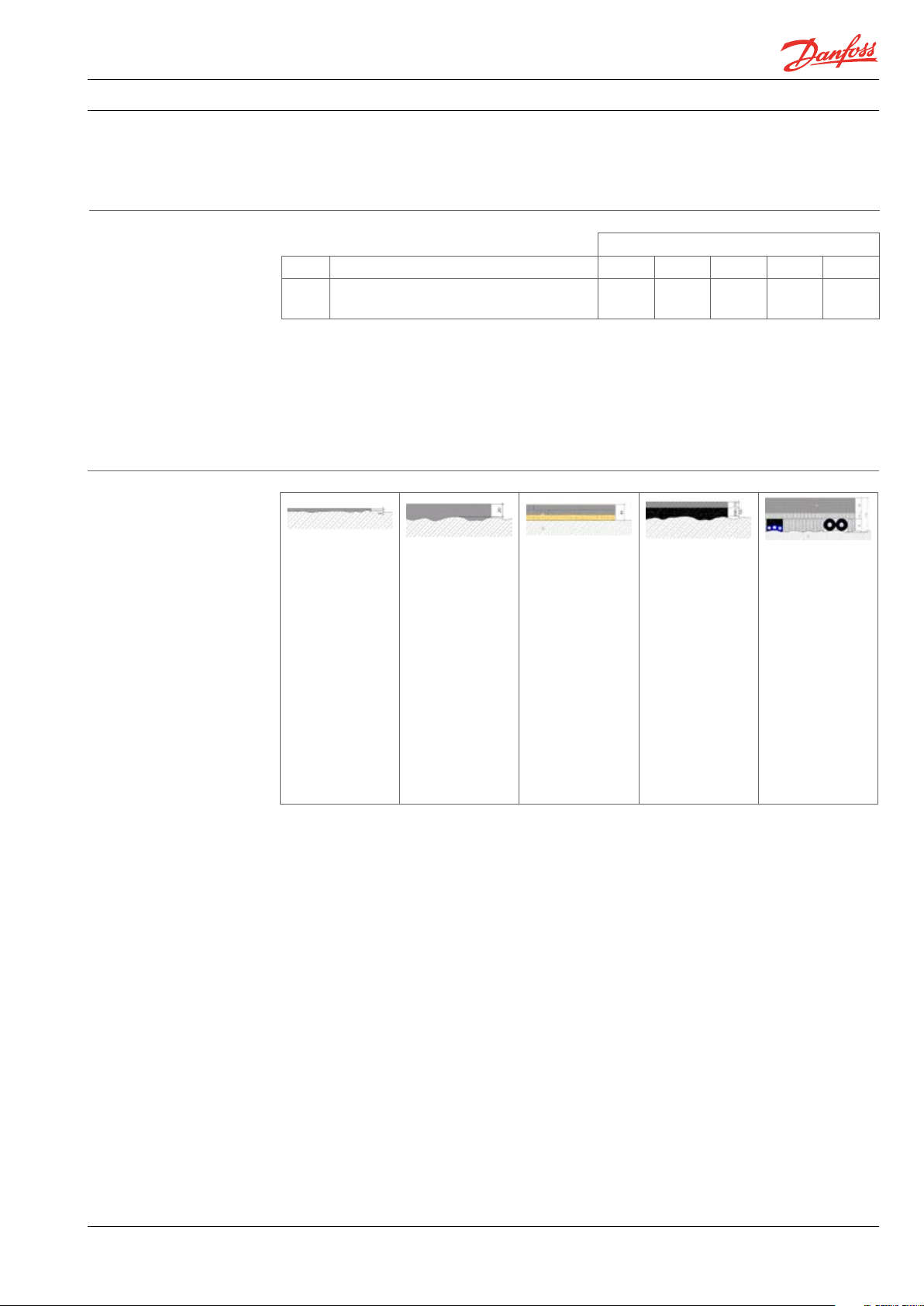

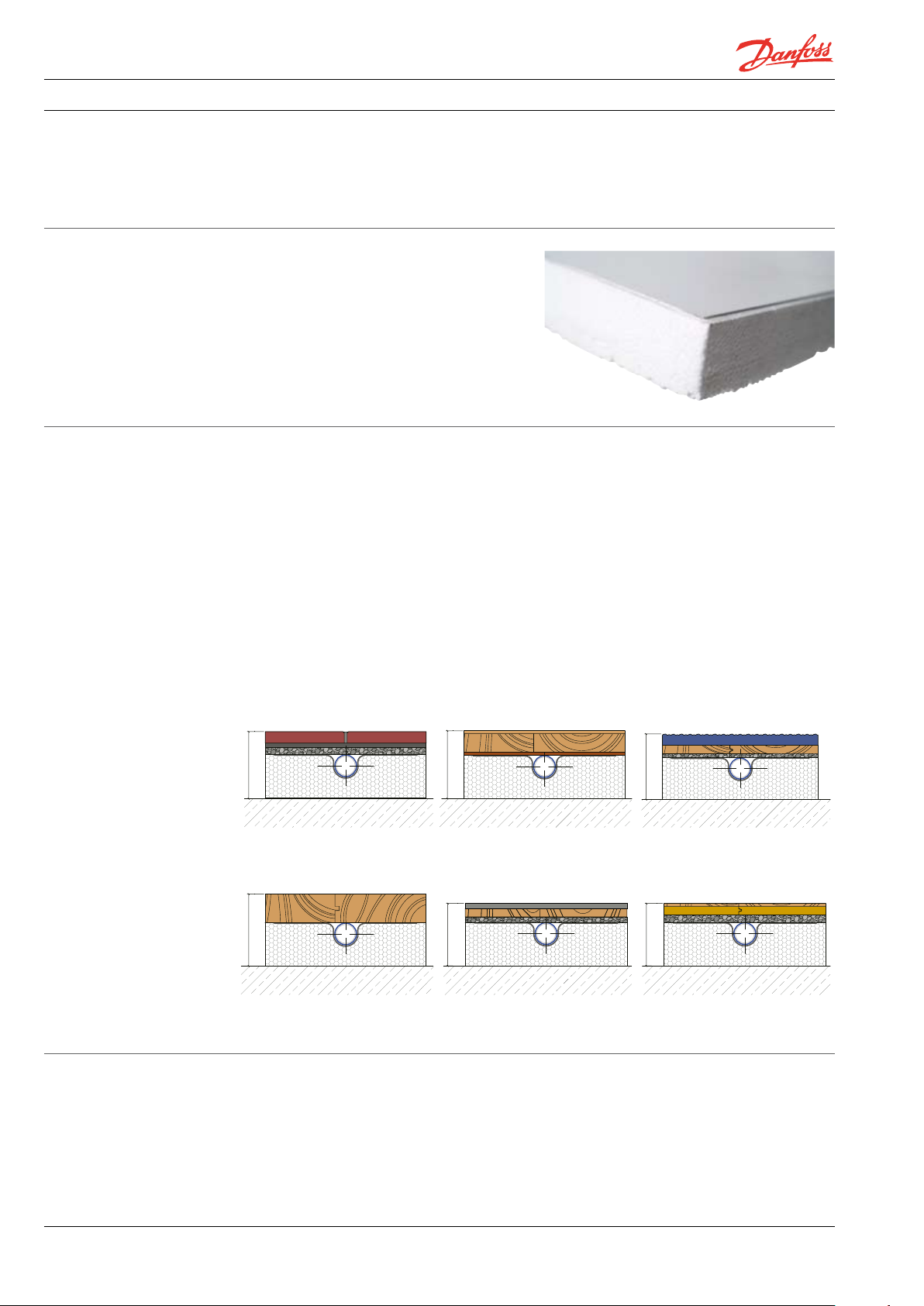

Basic construction

Danfoss Strongboards gives you the possibility to have almost level free floor surfaces

- no matter which floor finish you choose.

Strongboard for tiles and

laminates w/ tiles

Direct flooring

w/ wooden planks

Because of their constituent material and

construction, Strongboard, 20-35 mm dry screed

panels, engineered timber or laminates are used

in homes. For higher active loads the dry screed

Direct flooring

w/parquet

Strongboard for carpet and

synthetics w/ e.g. vinyl

in the house) extruded rigid foam and expanded

Polystyrene (200 kPa density) can be used.

If necessary, the load bearing panels have to be

reinforced (see table on page 11).

Strongboard for carpet and

synthetics w/ carpet

Strongboard for tiles and

laminates w/ laminate

is reinforced.

As an additional insulation under the heating

panels (thickness depending on use and position

10

VGCTA2302 © Danfoss 09/2009

Page 11

Handbook SpeedUp™ Heating Systems

- Floor Construction

Additional insulation

Maximum layers (number)

and thickness of insulation

SpeedUp™ Heating System

Applications Areas for domestic and residential activities (e.g. rooms in residential

Load bearing surface

Thickness (mm) 5 10 8 / 5 15 20 -22 20 25

EPS DEO 200 kPa WLG 035 (mm) max. 20 max. 20 max. 20 max. 20 max. 40 max. 50 max. 70

Maximum layers (pcs.) 1 1 1 1 1 1 2

XPS DEO 300 kPa WLG 035 (mm) max. 30 max. 30 max. 30 max. 30 max. 40 max. 50 max. 70

Maximum layers (pcs.) 1 1 1 1 1 2 2

XPS DEO 500 kPa WLG 035 (mm) max. 60 max. 60 max. 60 max. 60 max. 60 max. 70 max. 90

Maximum layers (pcs.) 1 1 1 1 2 1 2

Wood fibre insulation 150 kPa (mm) - max. 20 max. 20 max. 20 max. 20 - max. 40

Maximum layers + 12.5 mm

filler panel under SpeedUp (pcs.)

Levelling with Danfoss dry levelling

compound

* Point load: area at least 20 cm

aquariums, baths.

buildings and houses; bedrooms and wards in hospitals; bedrooms in hotels

and hostels; kitchens and toilets), office areas.

Point load: 2.0 KN*; Actual load: 2.0 kN/m

laminates

for tiles and

Strongboard

Not

possible

2

, maximum distor tion ≤ 3 mm; allowances to be made for particularly heavy items, e.g.

carpet

Strongboard

1 (essential) 1 1

+ 12.5 mm load bearing panel

Additional insulation > 30 mm or dry levelling compound >30 mm:

Reduce the maximum permitted additional insulation by the level

of the dry compound

Laminate

Engineered

timber floor

on battens

Solid timber

Fermacell

Fermacell

SpeedUp Eco™ Heating System

Applications Areas for domestic and residential activities (e.g. rooms in residential

Load bearing surface

Thickness (mm) 5 10 8 / 5 15 20-2 2 20 25

Wood fibre insulation 150 kPa (mm) max. 20 max. 20 max. 20 max. 20 max. 40 max. 20

Maximum layers

plus OSB-load bearing surface

under SpeedUp

Wood Fibre > 150 kPA (mm)

Pavatex Pavaboard 150 kPa

Gutex Thermowall - gf 200 kPa

Glunz Agepan THD 230

Maximum layers

plus OSB-load bearing surface

under SpeedUp

Levelling with

Danfoss dry levelling compound

* Point load: Load area min. 20 cm

aquariums, baths.

buildings and houses; bedrooms and wards in hospitals; bedrooms in hotels

and hostels; kitchens and toilets), office areas.

Point load: 2.0 KN*; Actual load: 2.0 kN/m

laminates

for tiles and

Strongboard

1

22 mm115 mm115 mm115 mm

max. 20 max. 20 max. 40 max. 40 max. 40 max. 20

1

22 mm118 mm118 mm115 mm

Not

possible

2

, maximum distor tion ≤ 3 mm; allowances to be made for particularly heavy items e.g.

carpet

Strongboard

Additional insulation > 30 mm or dry levelling compound > 30 mm:

Reduce the maximum permitted additional insulation by the level

of the dry compound

Laminate

Engineered

timber floor

on battens

Solid timber

1 1

1 1

Fermacell

Fermacell

VGCTA302 © Danfoss 09/2009

11

Page 12

Handbook SpeedUp™ Heating Systems

- Floor Construction

Categories of

loaded areas

The Danfoss construction sheets describe the

approved type of use. Depending on active and

constructions other than home and office

buildings.

point load, EN 1991 is also applicable for

qK

Category Use Examples

A1

Areas for

domestic and

A2 Stairs 2.0 - 4.0 2.0 - 4.0

residential

activities

A3 Balconies 2.5 - 4.0 2.0 - 3.0

B Office areas 2.0 - 3.0 1.5 - 4.5

C1

C2

Areas where

people may

congregate

(with the

C3

exception of

areas defined

under category

A, B, D)

C4

Floors 1.5 - 2.0 2.0 - 3.0

Areas with tables , e.g. areas in schools, cafés, restaurants,

dining halls, reading rooms, receptions

Areas with fixed seats, e.g. areas in churches, theatres or

cinemas, conference rooms, lecture halls, assembly halls,

waiting rooms, railway waiting rooms

Areas without obstacles for moving people, e.g. areas in

museums, exhibition rooms etc. and access areas in public

administration buildings, hotels, hospitals, railway station

forecour ts

Areas with possible physical activities, e.g. dance halls,

gymnastic rooms, stages

(Active

load)

kN/m

2.0 - 3.0 3.0 - 4.0

3.0 - 4.0

3.0 - 5.0 4.0 - 7.0

4.5 - 5.0 3.5 - 7. 0

QK

(Point

load)

kN

2.5 - 7.0

(note 3)

C5

D1

Shopping areas

D2 Areas in department stores 4.0 - 5.0 3.5 - 7. 0

Note 1: Depending on their anticipated uses, areas likely to be categorised as C2, C3, C4 may be categorised as C5 by

decision of the client and/or National annex.

Note 2: The National annex may provide sub categories to A, B, C1 to C5, D1 and D2.

Note 3: Recommended values are highlighted. For categories C2 and D1 the recommended value is 4.0.

Areas susceptible to large crowds, e.g. in buildings for

public events like concert halls, sports halls including

stands, terraces and access areas and railway platforms

Areas in general retail shops 4.0 - 5.0

5.0 - 7.5 3.5 - 4.5

3.5 - 7.0

(note 3)

12

VGCTA2302 © Danfoss 09/2009

Page 13

Handbook SpeedUp™ Heating Systems

- Floor Construction

Insulation values

EPS WLG 035 Wood Fibre

Thickness

10 mm 1.14 0.76 0.95 0.89 1.0 6 0. 81

20 mm 1.43 0.63 1.15 0. 76 1.26 0.70

30 mm 1.71 0.53 1.35 0.66 1.4 6 0. 61

40 mm 2.00 0.46 1.55 0.58 1.6 6 0.55

50 mm 2.28 0 .41

60 mm 2.57 0.36

70 mm 2.86 0.33

80 mm 3.14 0.30

90 mm 3.43 0.28

R-value incl.

SpeedUp

panel

m2K/W W/m2K m2k/W W/m2K m2K/W W/m2K

U-value incl.

SpeedUp

panel

R-value incl.

SpeedUp Eco

panel

U-value incl.

SpeedUp Eco

panel

R-value incl.

SpeedUp

panel

U-value incl.

SpeedUp

panel

Please note that the thickness of the additional insulation is based on the insulation being placed

between the loadbearing substrate and the SpeedUp panels, see tables on page 11 for load bearing

capabilities of the insulation.

Min. thermal resistance

of insulating layers

(m2K)/W below the floor

heating/cooling system

Unheated or

Heated room

below

Thermal

resistance

2

(m

K)/W

*) with ground water level ≤ 5 m below the supporting base, the value should be increased.

0.75 1.25 1. 25 1.5 0 2.00

intermittent

heated room

below or

directly on the

ground *)

External design

temperature

ϑd ≥ 0°C

External air temperature below

External design

temperature

0°C > ϑd ≥ -5°C

-5°C > ϑd ≥ -15°C

External design

temperature

When installing the insulating layer, the insulating panels shall be butted tightly together. Multiple

insulating layers shall be staggered or placed in such a way that the joints between panels of one layer

are out of line with the next layer.

VGCTA302 © Danfoss 09/2009

13

Page 14

Handbook SpeedUp™ Heating Systems

- Floor Construction

Sound impact

Sound impact improvement without raising the

floor level can be realised with the SpeedUp Eco™

heating system (sound insulation up to 28 dB).

Other measures, such as a suspended ceiling in

the room below, or the use of approved sound

insulating material, such as Silentboard, wood

fibre insulation or mineral wool, can also bring

improvement.

The 15 mm Silentboard is a particularly good

sound insulation for suspended floors. Soft

sound insulation panels are not permitted under

dry screed panels.

Calculations are always made of the whole floor.

Sound insulation approval for a one family home

is not required but the general regulations in

accordance with EN ISO 140-8 and DIN 4109

'Sound Insulation in the Building Industry' do

apply.

The following tables show the impact sound

behaviour of constructions using SpeedUp™.

Sound impact in different constructions - Table 1

Floor construction Height Sound

Unfinished floor: Reinforced concrete [mm] [dB] [dB] [dB] [m

Finished floor

20 mm Fermacell screed panel, 30 mm

SpeedUp heat panel, floor (120 mm),

suspended ceiling below *

Finished floor

25 mm Fermacell screed panel, 30 mm

SpeedUp heat panel, floor (120 mm)

Finished floor

25 mm Fermacell screed panel, 30 mm

SpeedUp heat panel, 20 mm mineral

wool SPT/G 22/20**, floor (120 mm),

suspended ceiling below*

Finished floor

20 mm Fermacell screed panel, 30 mm

SpeedUp Eco heat panel, floor (160 mm)

Finished floor

45 mm cement screed (CT F4), 30 mm

SpeedUp heat panel, 6 mm Danfoss

impact sound insulation, floor (120 mm)

15 mm easy assembly engineered

flooring, 2 mm impact sound insulation

(cork), 30 mm SpeedUp heat panel, 30 mm

Fermacell (with wood fibre insulation ),

20 mm additional insulation EPS DEO 200

kPa, floor (200 mm)

15 mm easy assembly engineered

flooring, 2 mm impact sound insulation

(cork), 30 mm SpeedUp Eco heat panel,

30 mm Fermacell (with wood fibre

insulation ), 20 mm additional insulation

EPS DEO 200 kPa, floor (200 mm)

15 mm easy assembly engineered

flooring, 2 mm impact sound insulation

(cork), 30 mm SpeedUp Eco heat panel,

15 mm Silentboard, 20 mm additional

insulation EPS DEO 200 kPa, floor (200 mm)

17 mm tiles and adhesive, 5 mm

Strongboard, 30 mm SpeedUp heat

panel, 30 mm Fermacell (with wood fibre

insulation), 20 mm additional insulation

XPS 200 kPa, floor (200 mm)

* Suspended ceiling : 350 mm suspended metal-UK with 50 mm mineral fibre , 2 x 10 mm Fermacell.

** Note: When laying the mineral wool do not walk on it since it will destroy the sound absorbing nature of the material.

50

55 83 14 69 0.86 33

75 70 29 41 1,3 30

50 79 28 51 0.75 34

81 78 27 51 0.87 93

97 76 28 48 1.69 40

97 72 26 46 1.5 8 45

82 71 21 50 1.4 38

102 75 32 43 1. 69 71

impact

level,

unfinished

floor

L’n , w, p

83 14 69

70 14 56

Sound

impact

improve-

ment

Measured

impact

sound

level, floor

L’n , w, p

R-value of

insulation

(top of

unfinished

floor )

2

0.86 27

Weight

K/W] [kg/m2]

14

VGCTA2302 © Danfoss 09/2009

Page 15

Handbook SpeedUp™ Heating Systems

Sound impact in different constructions - Table 2

- Floor Construction

Floor construction: Height Sound

Unfinished floor: Suspended timber floor [mm] [dB] [dB] [dB] [m

Finished floor

20 mm Fermacell screed panel, 30 mm

SpeedUp Eco heat panel, 28 mm

plywood, 80/ 200 mm suspended floor

Finished floor

20 mm Fermacell screed panel, 30 mm

SpeedUp heat panel, 10 mm Fermacell,

20 mm mineral wool SPT/G 22/20**, 28

mm chipboard, 100 / 200 mm suspended

floor with 60 mm mineral fibre, 30/ 50

mm battens, 10 mm Fermacell

Finished floor

20 mm Fermacell screed panel, 30 mm

SpeedUp heat panel, 28 mm chipboard,

100 / 200 mm suspended floor with 60

mm mineral fibre, 30/ 50 mm battens,

suspended 10 mm Fermacell

Finished floor

25 mm Fermacell screed panel, 30 mm

SpeedUp heat panel, 10 mm Fermacell,

20 mm floor rock GP (mineral fibre)**, 30

mm honeycomb/gravel filling, tongue

and groove joints, suspended floor with

100 mm mineral fibre, 50 mm resilient

bar, 10 mm Fermacell

Finished floor

25 mm Fermacell screed panel, 30 mm

SpeedUp heat panel, 10 mm Fermacell,

20 mm floor rock GP (mineral fibre)**, 30

mm honeycomb/gravel filling, tongue

and groove joints, suspended floor

Finished floor

25 mm Fermacell screed panel, 30 mm

SpeedUp heat panel, 10 mm Fermacell,

20 mm floor rock GP (mineral fibre)**,

tongue and Groove joints, suspended

floor

** Note : When laying the mineral wool do not walk on it since it will destroy the sound absorbing nature of the material.

108 72 11 61 1. 34 47

78 72 9 63 0.86 27

115 65 20 45 1.51 98

115 94 37 57 1.4 98

85 94 23 71 1. 37 52.5

impact

level,

unfinished

floor

L’n , w, p

78 80 15 65 0.75 34

Sound

impact

improve-

ment

Measured

impact

sound

level, floor

L’n , w, p

R-value of

insulation

(top of

unfinished

floor )

2

Weight

K/W] [kg/m2]

VGCTA302 © Danfoss 09/2009

15

Page 16

Handbook SpeedUp™ Heating Systems

- Floor Construction

SpeedUp™

perimeter insulation

Tanking for wet screed

Sound impact insulation

and wet screed

Active load and height of

screed

The SpeedUp™ perimeter insulation consists of 8 mm

PE-Foam and is 100 mm high. The double-sided

adhesive strip allows it to be easily attached to

Both types of perimeter insulation conform to

EN 1264. They can be pressed together 5 mm and

prevent thermal and sound bridges.

the wall.

The SpeedUp Eco™ perimeter insulation consists

of waxed corrugated cardboard and is 140 mm

high.

When installing wet screed the heat panels have

to be covered with system foil. Instead of

SpeedUp™ perimeter insulation the Basic

perimeter insulation will have to be installed.

The constituent material of the heat panels is just

for thermal insulation (EPS 035 DEO 240 kPa). If

Using the self -adhesive strip, fix down the flap

attached to the perimeter insulation to the sytem

foil. This now forms the tank for the screed. For

liquid screed overlap system foil and tape up.

This insulation should only be used in combina-

tion with wet screed.

additional sound insulation is required, the 6 mm

Danfoss sound impact insulation would achieve

an improvement of up to 27 dB.

Both in the Basic and in the SpeedUp™ heating

systems the thickness of the screed depends on

the use and load bearing requirements of the

floor.

Nominal thickness in mm for load capacity, SpeedUp™ heating systems

< 2 kN/m

2

< 3 kN/m

Point load up

to 2 kN/m

2

Point load up

2

to 3 kN/m

4 kN/m

2

Point load up

2

5 kN/m

to 4 kN/m

CT F4 with "Screed Additive Normal" 45 65* 70* 75*

CAF F4 40 50* 60* 65*

CT F5 with "Screed Additive Special" 40* 55* 60* 65*

CAF F5 30** 45* 50* 55*

* For insulation < 40 mm the screed depth can be reduced by 5 mm.

** For stone and ceramic finishes the nominal thickness of the screed is 40 mm, in accordance with EN 13813.

However, many manufacturers offer screed that fulfils these requirements with a minimum thickness of 35 mm.

2

2

Danfoss composite pipes

16

The grey Danfoss composite pipe is 100 % impervious to air, temperature resistant, and highly

flexible. It consists of an aluminium pipe which is

covered inside and out with a Polyethylene layer.

All layers are permanently bonded with each

other through a layer of adhesive.

Unlinked Polyethylene with its Raised Temperature Resistance (PE-RT) is used, in accordance

with EN ISO 22391.

The octen side chains of the molecular structure

of the PE-RT (Polyethylene Raised Temperature

resistance) give it a similar effect to that of the

linked PE.

A minimum performance over a time of 50 years

has to be proved for the Danfoss composite

pipes.

VGCTA2302 © Danfoss 09/2009

1. Water carrying inner pipe of Polyethylene (PE-RT)

2. Bonding adhesive

3. Aluminium pipe

4. Protective outer Polyethylene pipe (PE-RT)

Page 17

Handbook SpeedUp™ Heating Systems

Manifold

- Determine parts for a system

Danfoss lay-out pattern

As with the BasicRail heating system the pipes are

laid in meander form. Edge zones EZ and comfort

zones CZ are combined. The supply and return

pipes take the heating water to the edge zone

and are installed with a distance of up to 1 m. Via

a header panel cross over zone CO, the change to

the wider pipe distances is achieved and the

cooler water is taken to the comfort zone.

It should be noted that dry screed panels must

only be installed under maximum 50° C supply

temperatures. It is important not to exceed the

maximum surface temperature as recommended

by the manufacturer of the floor finish.

VGCTA302 © Danfoss 09/2009

17

Page 18

Handbook SpeedUp™ Heating Systems

- Determine parts for a system

Determine number of

SpeedUp™ system parts

Edge and comfort zone (mixed)

System part Quantity / m

2

Heat panel edge zone EZ 0,30

Heat panel comfort zone CZ 1,2 6

Header panel EZ (1/5), CZ (4/5) 0,24

Blank panel BP 0,15

Supply and return panel EZ 0,05

Header panel cross-over CO = Number of heating circuits (minus number of header panel EZ)

Composite pipe 5,00

Perimeter insulation 1,0 0

Support batten 1,2 0

Threshold support batten 2 per threshold and heating cicuit

Comfort zone (pipe distance 25 cm)

System part Quantity / m

2

Heat panel edge zone EZ Heat panel comfort zone CZ 1,4 6

Header panel CZ 0,24

Blank panel BP 0,25

Supply and return panel CZ 0,05

Composite pipe 4,00

Perimeter insulation 1,0 0

Support batten 1,2 0

Threshold support batten 2 per threshold and heating cicuit

Example:

Calculation

of SpeedUp™

Edge zone (pipe distance 12,5 cm)

System part Quantity / m

2

Heat panel edge zone EZ 1,4 6

Heat panel comfort zone CZ Header panel EZ 0,24

Blank panel BP 0,25

Supply and return panel EZ 0,05

Composite pipe 8,00

Perimeter insulation 1,0 0

Support batten 1,2 0

Threshold support batten 2 per threshold and heating cicuit

2

Calculation for 100 m

underfloor heating with comfort zone - and edge zone (Mix):

EZ 100 m2 x 0.3 panels/m2 = 30 panels

CZ 100 m2 x 1.26 panels/m2 = 126 panels

H/EZ / H/CZ 100 m2 x 0.24 panels/m2 = 24 panels

Unit /EZ: 5 panels

Unit /CZ: 19 panels

BP 100 m2 x 0.2 panels/m2 = 20 panels

6 combined heating circuits (with EZ und CZ):

6 individual pieces CO -> They are deducted from the unit H/EZ

(With the SpeedUp Header Panels one panel consists of four individual pieces)

6 individual pieces correspond to 1 unit K/CO: 1.5 panels

New unit H/EZ: 3.5 panels

Important!

18

All calculations are based on average experience

per m2 and also included unheated areas

VGCTA2302 © Danfoss 09/2009

e.g. in front of the manifold. All values are based

on calculation without waste.

Page 19

Handbook SpeedUp™ Heating Systems

- Determine parts for a system

Determine number

of SpeedUp Eco™

system parts

Edge and comfort zone (mixed)

System part Quantity / m

2

Heat panel edge zone EZ, C-C = 125 mm 0,30

Heat panel comfort zone CZ, C-C = 250 mm 1, 26

Header panel EZ (1/5), CZ (4/5) 0,96

Blank panel BP 0,15

Supply and return panel EZ 0,20

Header panel cross-over CO = Number of heating circuits (minus number of header panel EZ)

90° curve panel 0,40

Composite pipe 5,00

Perimeter insulation 1,0 0

Support batten 1,2 0

Threshold support batten 2 per threshold and heating cicuit

Comfort zone (pipe distance 250 mm)

System part Quantity / m

2

Heat panel edge zone EZ, C-C = 125 mm Heat panel comfort zone CZ, C-C = 250 mm 1,46

Header panel EZ (1/5), CZ (4/5) 0,96

Blank panel BP 0,25

Supply and return panel CZ 0,20

90° curve panel 0,20

Composite pipe 4,00

Perimeter insulation 1,0 0

Support batten 1,2 0

Threshold support batten 2 per threshold and heating cicuit

Example:

Calculation of

SpeedUp Eco™

Edge zone (pipe distance 125 mm)

System part Quantity / m

2

Heat panel edge zone EZ, C-C = 125 mm 1,4 6

Heat panel comfort zone CZ, C-C = 250 mm Header panel EZ (1/5), CZ (4/5) 0,96

Blank panel BP 0,25

Supply and return panel EZ 0,20

90° curve panel 0,10

Composite pipe 8,00

Perimeter insulation 1,0 0

Support batten 1,2 0

Threshold support batten 2 per threshold and heating cicuit

Calculation for 100 m2 underfloor heating with comfort- and edge zone:

EZ: 100 m2 x 0.3 piece/m2 = 30 panels

CZ 100 m2 x 1.26 piece/m2 = 126 panels

H/EZ / H/CZ 100 m2 x 0.96 piece/m2 = 96 individual pieces:

Unit H/EZ: 20 individual pieces

Unit H/CZ: 76 individual pieces

BP 100 m

100 m

2

x 0.15 panels/m2 = 15 panels

2

x 0.2 piece = 20 pieces

100 m2 x 0.2 piece = 20 pieces

6 combined heating circuits (with EZ and CZ):

6 individual pieces CO -> They are deducted from the unit H/EZ H/EZ

New unit H/EZ: 14 individual pieces

Important!

All calculations are based on average experience

2

and also included unheated areas

per m

VGCTA302 © Danfoss 09/2009

e.g. in front of the manifold. All values are based

on calculation without waste.

19

Page 20

Handbook SpeedUp™ Heating Systems

- Installation

Installation

Check-list for installation

of SpeedUp™ heating

system

Prerequisite for installation is an even and load

bearing substrate.

Before installation the SpeedUp™ heating systems

checklist should be consulted.

The following illustrations show the chronological

sequence of how to achieve an even substrate up

A. Interior finish

A1 The building is plastered and boarded, all

breaking work for recesses, e.g. manifold,

have been done, open floors have been

closed.

A2 The building has been sealed against

moisture and water in accordance with

standards in effect at the time.

A3 Supply and return from heat source to mani-

fold has been installed, manifold is correctly

positioned.

A4 Fence off open areas and overhangs for

stairs to retain screed.

A5 Clearly mark position of stair base on the

sub-floor.

A6 Position for shower trays and baths without

side panels are fixed with timber batten to

the lower edge of SpeedUp and screwed

down.

A7 Measuring base points on all floors.

A8 Changes in flooring have been agreed by

installer and been included in the floor plan.

A9 The floor has been fully prepared: the

substrate is dry and able to support a load

and is ready for installation of the heating

system. For solid floors with a possibility of

residual moisture a moisture barrier should

be laid.

A10 The load bearing substrate should be

prepared within the tolerance (maximum

height difference of 3 mm per 1 m) as

follows:

•Even,roughconcreteoor/suspended

floor.

•Screedoninsulation.

•Compositescreed.

•Dryscreedwithapprovedsubstructure.

•Danfossdrylevellingcompoundupto50

mm with 10 mm gypsum fibre board or

equivalent, covered (pipe channels - in

the additional insulation - with a width of

more than 10 cm must be covered with a

metal plate (min. 1 mm). If the pipe

channels have a width of more than 15 cm

a special load bearing plate (min. 18 mm)

must be used.

•Connectedlevellinginsulationasload

bearing base , approved for dry installations

and smoothed (minimum strength:

0.5 N / mm

2

).

to installing the load bearing panels. Depending

on the unevenness of the floor and the existing

built-up height different variations are possible

(see table; Levelling of substrate).

A11 Approved additional insulation (maximum

height and suitable insulation material see

construction leaflets).

•Installedonsite.

•Isdeliveredandinstalled.

A12 The installation of load bearing panels:

Strongboard for tiles or carpet, engineered

timber floor, laminates: All dry and decorating work is completed. There is no more

installation work requiring heavy equipment.

B. Building Site Conditions

B1 Water and electricty are connected.

B2 Storage facilties are assured.

B3 On -site disposal of building waste, e.g.

packing material, bricks, etc., is assured.

B4 During the installation no other work

should be done in the room and all areas

should be cleared and freely accessible.

B5 After installation, the heating surface

should not be walked upon until the

finished floor/load bearing panels are laid.

C. Technical Information

C1 The electrical supply 230 V / 50 Hz is

installed in manifold cabinet.

C2 Room thermostats:

•Wirelesscontrol.

•Hardwiredcontrol:

cabelling (5 core x 1,5 mm

2

) between

room thermostat and manifold are

installed.

•Isolatingswitchforturningothe

underfloor heating is installed.

20

VGCTA2302 © Danfoss 09/2009

Page 21

Handbook SpeedUp™ Heating Systems

- Installation

Strongboard for tiles,

check-list before and

during installation

A. Substrate

A1 Perimeter insulation is installed all round

and visible at least 5 cm.

A2 Support batten installed all round and fixed

down in door threshold.

A3 SpeedUp heat panels are optically well

installed, lie firmly and without give on the

substrate.

A4 Header and fitted blank panels (e.g. in

thresholds) as well as available and

approved additional insulation are fixed to

the substrate.

A5 The Danfoss pipe layout is installed free of

sharp corners and fixed down. Raised pipe

curves are adjusted and lie flush.

A6 The existing floor construction is conform

with Danfoss and the heat panels are

installed in accordance with tolerance levels

for evenness (maximum 3 mm per 1 m).

A7 Movement gap strips (maximum size of area

2

; ratio to sides < 1:2) have been agreed

60 m

by installer and underpinned with support

battens.

Note: Until the finished floor is laid, it is advisable

that only qualified personnel walk on the heat

panels.

B2 It is important to store material safely and

outside the area to be installed. Strongboard should be stored flat and not leant

against a wall (risk of deformation).

B3 During the installation no other work

should be done in the room and all areas

should be cleared and freely accessible.

C. Notes

It is important continually to inspect the

Strongboard installation. If a Strongboard seems

to give, it is an indication of unevenness of the

base which needs to be checked: Determine the

give by placing a straight edge on the installed

board, put on load and measure the drop with a

measuring wedge.

C1 Advice for maximum unevenness up to 3

mm (on 1 m):

Strongboard slightly warped and pipe curves

are slightly proud, install tile lightly:

•ifthetileonlylightlypushesdownthe

Strongboard no action is necessary

•ifthetileistoolight,applyactionC2.

C2 For unevenness of below 5 mm:

The installer will decide. However, in this

case the Strongboard will have to be fully

fixed down with MAPEI ECO-FIX onto the

SpeedUp.

Installation time

B. Building Site Conditions

B1 It is advisable to lay load bearing plates (e.g.

15 mm OSB or 50 mm XPS) in order to avoid

damage from pedestrian traffic.

Installation time for SpeedUp™ heating systems*

Article/ Unit Min. per unit Unit

Manifold without cabinet 55.00 piece

Manifold with cabinet 75.00 piece

Additional insulation without perimeter insulation - per layer 2.50 m

C-C = 125/250 mm installation - SpeedUp™ 10.00 m

C-C = 125 mm installation - SpeedUp™ 12 .0 0 m

C-C = 250 mm installation - SpeedUp™ 8.00 m

C-C = 125/250 mm installation - SpeedUp Eco™ 14. 00 m

C-C = 125 mm installation - SpeedUp Eco™ 16.00 m

C-C = 250 mm installation - SpeedUp Eco™ 12 .0 0 m

Strongboard for tiles 10.00 m

Strongboard for carpet 15.00 m

* Date 06/2004 - Values based on many years of practical experience.

VGCTA302 © Danfoss 09/2009

21

Page 22

Handbook SpeedUp™ Heating Systems

- Output tables

Output table,

Danfoss SpeedUp™

heating system

Differential temperature (δ K) 5.

Heat output based on EN 1264.

Strongboard

5 mm

EZ 12.5 cm

water temperature

Mean central heating

θ

m

Room temperature

θ

i

tiles on Strongboard

Surface temperature

θ

F

°C °C W/m °C W/m °C W/m °C W/m °C

30 15 100 .6 24.0 75.5 22.0 56.2 20.3 44.4 19. 3

30 18 80.1 25.4 6 0.1 23.7 44.7 22.3 35.4 21.5

30 20 66.3 26.2 49.7 24.8 3 7. 0 23.6 29.3 22.9

30 22 52.4 2 7. 0 39. 3 25.8 29.2 24.9 23 .1 24.4

30 24 38.2 2 7. 7 28.6 26.9 21. 3 26.2 16 .8 25.8

35 15 13 4.7 26.8 101.1 24 .1 75.2 21.9 59.5 20.6

35 18 114 . 3 28.2 85.7 25.8 63.8 24.0 50.5 22.8

35 20 100. 6 29.0 75.5 2 7. 0 56.2 25.3 44.4 24. 3

35 22 86.9 29.9 65.2 2 8.1 48.5 26.7 38.4 25.8

35 24 73.2 30.8 54.9 29. 2 40.9 28.0 32.3 2 7. 2

40 15 168 .7 29. 5 126 .6 26 .1 94.2 23.5 74 .5 21. 9

40 18 14 8. 3 30.9 111. 3 2 7. 9 82.8 25.6 65.5 24 .1

40 20 13 4. 7 31.8 101.1 2 9.1 75.2 26.9 59.5 25.6

40 22 121 .1 32.7 90.9 30.2 6 7. 6 28.3 53.5 2 7.1

40 24 1 07. 5 33.6 80.6 31. 4 60.0 29.7 4 7.4 28.6

45 15 202.7 32.1 152 .1 28.2 113 .1 25 .1 89. 5 23 .1

45 18 182 .3 33.5 136. 8 30.0 101.8 27. 1 80.5 25.4

45 20 168 .7 34.5 126 .6 31.1 94.2 28.5 74 .5 26.9

45 22 15 5.1 35.4 116 . 4 32.3 86.6 29.9 68.5 28.4

45 24 141. 5 36.3 106 .2 33.5 79.0 31. 3 62.5 29.9

50 15 236.6 34.7 17 7.5 30.2 132.1 26.6 104. 5 24.4

50 18 216. 2 3 6.1 162. 2 32.0 120. 7 28.7 95.5 26.6

50 20 202.7 3 7.1 152 .1 33.2 113 .1 30 .1 89.5 28 .1

50 22 18 9.1 38 .1 141.9 34.4 10 5.6 31.5 83.5 29.6

50 24 17 5. 5 39.0 131.7 35.6 98.0 32.8 7 7. 5 31.1

55 15 270.5 37. 2 202.9 32.1 151.0 28 .1 119 .4 25.6

55 18 250.2 38.7 187. 7 33.9 139. 6 30.2 11 0 . 5 2 7.8

55 20 236.6 39.7 1 77. 5 35. 2 132 .1 31. 6 104. 5 29.4

55 22 223.0 40.7 16 7. 3 36.4 124 .5 33.0 98.5 30.9

55 24 209. 5 41. 6 15 7.1 37. 6 116 . 9 34.4 92.5 32. 4

5 mm

CZ 25 cm

tiles on Strongboard

Surface temperature

θ

F

10 mm

EZ 12.5 cm

carpet on Strongboard

Surface temperature

θ

F

CZ 25 cm

carpet on Strongboard

10 mm

Surface temperature

θ

F

22

Maximum floor surface temperature in accordance

with EN 1264:

Edge Zone 1.00 m . . . . . . . . . 35° C

Comfort Zone. . . . . . . . . . . . 29° C

Bathrooms. . . . . . . . . . . . . . 33° C

VGCTA2302 © Danfoss 09/2009

Page 23

Handbook SpeedUp™ Heating Systems

- Output tables

Output table,

Danfoss SpeedUp™

heating system

Differential temperature (δ K) 5.

Heat output based on EN 1264.

Cork panels 2 mm for sound insulation included

in output figures.

Engineered timber & laminate

timber

14 mm

EZ 12.5 cm

water temperature

Mean central heating

θ

m

Room temperature

θ

i

Surface temperature

θ

F

timber

14 mm

CZ 25 cm

Surface temperature

θ

F

°C °C W/m °C W/m °C W/m °C W/m °C

30 15 50.5 19. 8 40.3 18. 9 63.5 21.0 49.9 19. 8

30 18 40.2 21.9 32.0 21. 2 50.5 22.8 39.7 21.9

30 20 33.3 23.3 26. 5 22.7 41. 8 24 .1 32.9 23.3

30 22 26.3 24.7 21. 0 24.2 33.0 25.3 26.0 24.6

30 24 19. 2 26.0 15 .3 25.6 24 .1 26.5 18 .9 26.0

35 15 67. 6 21. 3 53.9 2 0.1 85.0 22.8 66.8 21.2

35 18 5 7. 4 23.4 45.7 22.4 7 2.1 24.7 56.7 23.4

35 20 50.5 24.8 40.3 23.9 63.5 26.0 49.9 24.8

35 22 43.6 26.2 34.8 25.4 54.8 2 7. 2 4 3.1 26.2

35 24 36.7 27. 6 29.3 26.9 4 6.1 28.5 36.3 2 7.6

40 15 84.7 22.7 6 7. 5 21. 3 10 6.4 24.5 83.7 22.7

40 18 74. 5 24.9 59.4 23.6 93.5 26.5 73.6 24.8

40 20 6 7. 6 26.3 53.9 2 5.1 85.0 27. 8 66.8 26.2

40 22 60.8 2 7. 7 48.5 26.7 76.4 29.0 60 .1 27. 7

40 24 54.0 29.1 43.0 28.2 67. 8 30.3 53. 3 29.1

45 15 101. 8 2 4.1 81.1 22.4 127. 8 26.2 100. 6 24.0

45 18 91. 5 26.3 73.0 24.8 115 . 0 28.2 90.5 26. 2

45 20 84.7 2 7.7 67. 5 26.3 106 .4 29.5 83.7 27. 7

45 22 7 7.9 29.2 6 2.1 2 7. 8 9 7.8 30.8 7 7.0 2 9.1

45 24 7 1.1 30.6 56.6 29.4 89.2 32 .1 70.2 30.5

50 15 11 8 . 8 25.5 94.7 23.6 149. 2 27.9 117. 4 25.4

50 18 10 8.6 2 7.7 86.5 25.9 136 .4 29.9 107. 3 2 7.6

50 20 101. 8 29.1 81.1 2 7. 4 12 7. 8 31. 2 10 0.6 29.0

50 22 94.9 30.6 75.7 29.0 119 . 2 32.6 93.8 30.5

50 24 88 .1 32.0 70.2 30.5 110 .7 33.9 8 7.1 31.9

55 15 135 .8 26.9 10 8.3 24.7 170. 6 29.6 134. 2 26.8

55 18 125 .6 2 9.1 100 .1 27. 0 15 7.7 31. 6 124.1 29.0

55 20 118 . 8 30.5 94.7 28.6 14 9.2 32.9 117. 4 30.4

55 22 112 . 0 32.0 89.3 3 0.1 140 .6 34.3 11 0 .7 31.9

55 24 105 .2 33.4 83.8 31. 7 132 .1 35.6 103.9 33.3

8 mm

EZ 12.5 cm

CZ 25 cm

Surface temperature

laminate with Strongboard

θ

F

laminate with Strongboard

8 mm

Surface temperature

θ

F

Maximum floor surface temperature in accordance

with EN 1264:

Edge Zone 1.00 m . . . . . . . . . 35° C

Comfort Zone. . . . . . . . . . . . 29° C

Bathrooms. . . . . . . . . . . . . . 33° C

VGCTA302 © Danfoss 09/2009

23

Page 24

Handbook SpeedUp™ Heating Systems

- Output tables

Output table,

Danfoss SpeedUp™

heating system

Thermal resistance of finished floor surface:

Rλ,B m2 K/W 0,00 (e.g. tiles)

Differential temperature (δ K) 5.

Heat output based on EN 1264.

Fermacell

20 mm

Fermacell

EZ 12.5 cm

water temperature

Mean central heating

θ

m

Room temperature

θ

i

Surface temperature

θ

F

°C °C W/m °C W/m °C W/m °C W/m °C

30 15 74 .6 21.9 5 7.7 20.5 6 7. 5 21. 3 52.6 20.0

30 18 59.4 23.6 45.9 22.4 53.7 23 .1 41. 9 22 .1

30 20 4 9.1 24.7 38.0 23.7 44.4 24.3 34.6 23.4

30 22 38.8 25.8 30.0 25.0 35 .1 25.5 2 7. 4 24. 8

30 24 28.3 26.9 21.9 26.3 25.6 26.6 19. 9 26 .1

35 15 99.9 24.0 7 7. 2 2 2.1 90.3 23.2 70.4 21.5

35 18 84.7 25.7 65.5 24 .1 76 .6 2 5.1 59.7 23.6

35 20 74. 6 26.9 57. 7 25.5 6 7.5 26.3 52.6 25.0

35 22 64.4 28.0 49.8 26.8 58.3 2 7. 5 45.4 26.4

35 24 54.3 29.2 41.9 28 .1 49 .1 28.7 38.3 27. 8

40 15 12 5.1 26.0 96.7 23.7 113 .1 2 5.1 88.2 23.0

40 18 110 . 0 2 7. 8 85.0 25.8 99.4 2 7.0 7 7. 5 25 .1

40 20 99.9 29.0 7 7. 2 2 7.1 90.3 28.2 70.4 26.5

40 22 89.8 30.2 69.4 28.5 81. 2 29.4 63.3 2 7.9

40 24 79.7 31.3 61. 6 29. 8 72.0 30.7 56.2 29.3

45 15 150 .3 28.0 116 .1 25.3 13 5.9 26.9 106. 0 24.5

45 18 135 .2 29.8 104. 5 2 7. 4 122 .2 28.8 95.3 26.6

45 20 12 5.1 31.0 96.7 28.7 113 .1 30 .1 88.2 28.0

45 22 11 5. 0 32.2 88.9 30 .1 10 4.0 31.3 81 .1 29.4

45 24 10 4.9 33.4 81.1 31. 4 94.9 32.6 74 .0 30.8

50 15 17 5. 4 30.0 135 .6 26.9 15 8. 6 28.7 123 .7 25.9

50 18 16 0.3 31. 8 12 3. 9 28.9 145.0 30.6 113. 0 28 .1

50 20 150 .3 33.0 11 6. 1 30.3 135.9 31.9 106 .0 29. 5

50 22 14 0. 2 34.2 108. 4 31.7 12 6. 8 33.2 98.9 30.9

50 24 130 .1 35.4 10 0.6 33.0 117. 7 34.4 91.8 32.3

55 15 200.5 31.9 155. 0 28.4 181. 4 30.5 141.4 27. 3

55 18 18 5.5 33.8 143. 3 30.5 16 7.7 32 .4 130 .8 29.5

55 20 175 .4 35.0 135 .6 31.9 15 8.6 33.7 123 .7 30.9

55 22 165 .3 36.2 127. 8 33.2 14 9.5 35.0 116 . 6 32.3

55 24 155 .3 3 7. 4 120 .0 34.6 14 0.4 36.3 109. 5 33.8

20 mm

CZ 25 cm

Fermacell

Surface temperature

θ

F

25 mm

Fermacell

EZ 1.,5 cm

CZ 25 cm

Fermacell

Surface temperature

θ

F

25 mm

Surface temperature

θ

F

Maximum floor surface temperature in accordance

with EN 1264:

Edge Zone 1.00 m . . . . . . . . . 35° C

Comfort Zone. . . . . . . . . . . . 29° C

Bathrooms. . . . . . . . . . . . . . 33° C

24

VGCTA2302 © Danfoss 09/2009

Page 25

Handbook SpeedUp™ Heating Systems

- Output tables

Output table,

Danfoss SpeedUp™

heating system

Thermal resistance of finished floor surface:

Rλ,B m2 K/W 0,05 (e.g. tiles).

Differential temperature (δ K) 5.

Heat output based on EN 1264.

Fermacell

20 mm

Fermacell

EZ 12.5 cm

water temperature

Mean central heating

θ

m

Room temperature

θ

i

Surface temperature

θ

F

°C °C W/m °C W/m °C W/m °C W/m °C

30 15 57. 7 20.5 46.5 19. 5 53.2 2 0.1 43 .1 19. 2

30 18 45.9 22.4 3 7. 0 21. 6 42.3 22 .1 34.3 21.4

30 20 38.0 23.7 30.6 2 3.1 35.0 23.5 28.4 22.9

30 22 30.0 25.0 24.2 24.5 27. 7 24.8 22.4 24. 3

30 24 21.9 26. 3 17. 6 25.9 20.2 2 6.1 16. 3 25.7

35 15 7 7. 2 22 .1 62.3 20.8 71. 2 21.6 5 7.7 20.5

35 18 65.5 24 .1 52. 8 23.0 60.4 23.7 48.9 22.7

35 20 5 7.7 25.5 46.5 24 .5 53.2 2 5.1 43 .1 24.2

35 22 49. 8 26.8 40.2 25.9 46.0 26.4 3 7. 2 25.7

35 24 41. 9 28 .1 33.8 2 7.4 38.7 2 7. 8 31. 3 2 7.1

40 15 96.7 23.7 78.0 22.2 89.2 2 3.1 72.3 21.7

40 18 85.0 25.8 68.6 24.4 78.4 25.2 63.5 24.0

40 20 7 7. 2 2 7.1 62.3 25.8 71. 2 26.6 57. 7 25.5

40 22 69.4 28.5 56.0 2 7.3 64.0 28.0 51.9 2 7.0

40 24 61 .6 29.8 49.7 28.8 56.8 29.4 46.0 28.4

45 15 11 6 .1 25.3 93.7 23.5 107. 2 24. 6 86.8 22.9

45 18 104 .5 27. 4 84.3 25.7 96.4 26.7 78 .1 25.2

45 20 96.7 28.7 78.0 2 7. 2 89.2 2 8.1 72.3 26.7

45 22 88.9 3 0.1 71. 7 28.6 82.0 29.5 66.4 28.2

45 24 8 1.1 31. 4 65.4 30 .1 74. 8 30.9 60.6 29.7

50 15 13 5.6 26.9 109.4 24.8 125 .1 26.0 101.3 24 .1

50 18 12 3.9 28.9 100.0 27. 0 11 4. 3 28.2 92.6 26.4

50 20 116 .1 30.3 93.7 28.5 107. 2 29.6 86.8 2 7.9

50 22 10 8.4 31.7 8 7.4 30.0 100.0 31. 0 81. 0 29.4

50 24 10 0.6 33.0 81.1 31. 4 92.8 32. 4 75.2 30.9

55 15 155 .0 28.4 12 5. 0 26.0 143 .0 27. 5 115 . 8 25.3

55 18 14 3.3 30.5 115. 6 28.3 13 2. 3 29.6 10 7.1 2 7.6

55 20 13 5. 6 31.9 109.4 29.8 12 5.1 31. 0 101.3 29.1

55 22 12 7.8 33.2 103 .1 31.2 117. 9 32 .5 95.5 30.6

55 24 12 0. 0 34.6 96.8 32.7 110 . 7 33.9 89.7 32.2

20 mm

CZ 25 cm

Fermacell

Surface temperature

θ

F

25 mm

Fermacell

EZ 12.5 cm

CZ 25 cm

Fermacell

Surface temperature

θ

F

25 mm

Surface temperature

θ

F

Maximum floor surface temperature in accordance

with EN 1264:

Edge Zone 1.00 m . . . . . . . . . 35° C

Comfort Zone. . . . . . . . . . . . 29° C

Bathrooms. . . . . . . . . . . . . . 33° C

VGCTA302 © Danfoss 09/2009

25

Page 26

Handbook SpeedUp™ Heating Systems

- Output tables

Output table,

Danfoss SpeedUp™

heating system

Thermal resistance of finished floor surface:

2

R

λ,B m

K/W 0.10

Differential temperature (δ K) 5.

Heat output based on EN 1264.

Fermacell

20 mm

Fermacell

EZ 12.5 cm

water temperature

Mean central heating

θ

m

Room temperature

θ

i

Surface temperature

θ

F

°C °C W/m °C W/m °C W/m °C W/m °C

30 15 47. 0 19. 5 38.9 18 .8 44.0 19. 3 36.6 18. 6

30 18 3 7. 4 21.7 31.0 2 1.1 35.0 21. 5 2 9.1 20.9

30 20 30.9 2 3.1 25.6 22.6 29.0 22.9 2 4.1 22.5

30 22 24.4 24. 5 20.3 2 4.1 22.9 24.4 19. 0 24.0

30 24 17. 8 25.9 14 .8 25.6 16 .7 25.8 13 .9 25.5

35 15 62.9 20.9 52 .1 20.0 58.9 20.6 48.9 19 .7

35 18 53.3 2 3.1 44.2 22.3 50.0 22.8 41. 5 22.0

35 20 4 7.0 24. 5 38.9 23.8 44.0 24.3 36.6 23.6

35 22 40.6 26.0 33.6 25.3 38.0 25.7 31. 6 25.2

35 24 34.2 2 7. 4 28.3 26.9 32.0 2 7.2 26.6 26.7

40 15 78.7 22.2 65.3 21 .1 73.8 21. 8 61. 3 20.8

40 18 69.2 24.4 5 7. 4 23.4 64.8 24 .1 53.9 23 .1

40 20 62.9 25.9 52 .1 25.0 58.9 25.6 48.9 24.7

40 22 56.5 2 7. 4 46.9 26.5 52.9 2 7. 0 44.0 26.3

40 24 5 0.1 28.8 41. 6 2 8.1 47. 0 28.5 39.0 2 7. 8

45 15 94.6 23.6 78.4 22.2 88.6 2 3.1 73.6 21.8

45 18 8 5.1 25.8 70.5 24.6 79.7 25.3 66.2 24. 2

45 20 78.7 27. 2 65.3 26 .1 73.8 26.8 61. 3 25.8

45 22 72.4 28.7 60.0 27. 7 6 7. 8 28.3 56.4 2 7. 3

45 24 66.0 30.2 54.8 29.2 61.9 29.8 51.4 28.9

50 15 11 0 .4 24.8 91. 5 23.3 103.4 24.3 86.0 22.8

50 18 100 .9 27.1 83.7 25.7 94.5 26.5 78.6 25.2

50 20 94.6 28.6 78.4 27. 2 88.6 2 8.1 73.6 26.8

50 22 88.2 30.0 73.2 28.8 82.7 29.6 68.7 28.4

50 24 81.9 31. 5 67. 9 30.3 76. 7 31 .1 63.8 30.0

55 15 126 . 2 2 6.1 104.7 24.4 118 . 2 25.5 98.3 23.9

55 18 11 6. 7 28.4 96.8 26.7 10 9.4 27. 8 90.9 26.2

55 20 110 . 4 29.8 91. 5 28.3 103.4 29.3 86.0 2 7.8

55 22 10 4.1 31. 3 86.3 29.9 97. 5 30.8 81.0 29.4

55 24 9 7.7 32. 8 81.0 31.4 91.6 32.3 76 .1 31. 0

20 mm

CZ 25 cm

Fermacell

Surface temperature

θ

F

25 mm

Fermacell

EZ 12.5 cm

CZ 25 cm

Fermacell

Surface temperature

θ

F

25 mm

Surface temperature

θ

F

26

Maximum floor surface temperature in accordance

with EN 1264:

Edge Zone 1.00 m . . . . . . . . . 35° C

Comfort Zone. . . . . . . . . . . . 29° C

Bathrooms. . . . . . . . . . . . . . 33° C

VGCTA2302 © Danfoss 09/2009

Page 27

Handbook SpeedUp™ Heating Systems

- Output tables

Output table,

Danfoss SpeedUp™

heating system

Thermal resistance of finished floor surface:

2

R

λ,B m

K/W 0.15

Differential temperature (δ K) 5.

Heat output based on EN 1264.

Fermacell

20 mm

Fermacell

EZ 12.5 cm

water temperature

Mean central heating

θ

m

Room temperature

θ

i

Surface temperature

θ

F

°C °C W/m °C W/m °C W/m °C W/m °C

30 15 39.7 18. 9 33.4 18. 3 37. 6 18 .7 31.7 18 .2

30 18 31. 6 21.2 26.6 20.7 29.9 21. 0 25.2 20.6

30 20 2 6.1 22.7 22.0 22.3 24.8 22.5 20.8 22.2

30 22 20.6 24 .1 17. 4 23.8 19.6 24.0 16. 5 23.7

30 24 15. 0 25.6 12 .7 25.4 14 .3 25.5 12 .0 25.3

35 15 5 3.1 2 0.1 44.8 19. 3 50.3 19 .8 42.4 19.1

35 18 4 5.1 22.4 38.0 21. 7 0.0 18 .0 35.9 21.5

35 20 39.7 23.9 33.4 23.3 3 7. 6 23.7 31.7 23.2

35 22 34.3 25.4 28.9 24.9 32.5 25.2 27. 3 24.8

35 24 28.9 26.9 24. 3 26.5 27. 3 26.8 23.0 26.4

40 15 66.5 21. 2 5 6.1 20.3 63.0 20.9 53 .1 20 .1

40 18 58.5 23.5 49. 3 22.7 0.0 18. 0 46.7 22.5

40 20 53 .1 2 5.1 44.8 24.3 50.3 24. 8 42 .4 2 4.1

40 22 4 7.7 26.6 40.2 25.9 45.2 26.4 38 .1 25.7

40 24 42.4 28 .1 35.7 2 7.5 4 0.1 27. 9 33.8 2 7. 4

45 15 79.9 22.3 6 7. 3 21. 3 75.7 22.0 63.8 21.0

45 18 7 1.9 24.7 60.6 23.7 0.0 18. 0 5 7. 3 23.4

45 20 66.5 26.2 5 6.1 25.3 63.0 25.9 53 .1 25 .1

45 22 61. 2 2 7. 8 51. 5 26.9 58.0 2 7. 5 48.8 26.7

45 24 55.8 29.3 47. 0 28.5 52.9 29.0 44.5 28.3

50 15 93.3 23.4 78.6 22.2 88.4 23.0 74 .4 21.9

50 18 85.3 25.8 71.9 24.7 0.0 18 .0 68.0 24. 3

50 20 79.9 2 7. 3 67. 3 26.3 75.7 27. 0 63.8 26.0

50 22 74 .6 28.9 62.8 2 7.9 70.7 28.6 59.5 2 7. 6

50 24 69.2 30.4 58.3 29. 5 65.6 3 0.1 55. 2 29.2

55 15 106 .7 24. 5 89.9 23.2 101.1 24.1 85 .1 22.8

55 18 98.6 26.9 83 .1 25.6 0.0 18. 0 78.7 25.2

55 20 93. 3 28.4 78.6 27. 2 88.4 28.0 74. 4 26.9

55 22 8 7.9 30.0 74 .1 28.9 83.3 29.6 70.2 28.5

55 24 82.6 31.6 69.6 30.5 78.3 31. 2 65.9 30.2

20 mm

CZ 25 cm

Fermacell

Surface temperature

θ

F

25 mm

Fermacell

EZ 12.5 cm

CZ 25 cm

Fermacell

Surface temperature

θ

F

25 mm

Surface temperature

θ

F

Maximum floor surface temperature in accordance

with EN 1264:

Edge Zone 1.00 m . . . . . . . . . 35° C

Comfort Zone. . . . . . . . . . . . 29° C

Bathrooms. . . . . . . . . . . . . . 33° C

VGCTA302 © Danfoss 09/2009

27

Page 28

Handbook SpeedUp™ Heating Systems

- Output tables

Output table,

Danfoss SpeedUp™

heating system

Thermal resistance of finished floor surface:

2

R

λ,B m

K/W 0.00 (e.g. tiles)

Differential temperature (δ K) 5.

Heat output based on EN 1264.

Cement - & liquid screed

45 mm

EZ 12.5 cm

water temperature

Mean central heating

θ

m

Room temperature

θ

i

cement screed

Surface temperature

θ

F

45 mm

CZ 25 cm

cement screed

Surface temperature

θ

F

°C °C W/m °C W/m °C W/m °C W/m °C

30 15 96.6 23.7 74. 6 21.9 11 0 .7 24.9 85 .1 22.8

30 18 76.9 2 5.1 59.4 23.6 8 8.1 26.0 6 7. 8 24. 3

30 20 63.6 26.0 49 .1 24.7 72.9 26.8 5 6.1 25.3

30 22 50.3 26.8 38.8 25.8 5 7. 6 2 7.4 44.3 26.3

30 24 36.6 2 7. 6 28.3 26.9 42.0 28 .1 32.3 2 7. 2

35 15 12 9.3 26.4 99.9 24.0 148 .2 27. 9 11 4 .0 25 .1

35 18 10 9.7 27. 8 84.7 25.7 125 .7 29 .1 96.7 26.7

35 20 96.6 28.7 74. 6 26.9 110 .7 29.9 8 5.1 2 7. 8

35 22 83.4 29.6 64.4 28.0 95.6 30.6 73.6 28.8

35 24 70.3 30.5 54.3 29. 2 80.5 31.4 61. 9 29.8

40 15 162.0 28.9 125.1 26.0 18 5.6 30.8 142 .8 27. 4

40 18 14 2.4 30.4 110. 0 27. 8 16 3.2 32.0 125. 5 29.1

40 20 129 .3 31. 4 99.9 29.0 148. 2 32.9 114 . 0 30 .1

40 22 116 . 2 32. 3 89. 8 30.2 133 .2 33.7 102. 5 31. 2

40 24 10 3.1 33.3 79.7 31. 3 118 . 2 34.5 90.9 32. 3

45 15 19 4. 5 31. 5 150. 3 28.0 223.0 33.7 171. 5 29.7

45 18 17 5. 0 33.0 13 5.2 29.8 200.6 34.9 154. 3 31.3

45 20 162 .0 33.9 125.1 31.0 185 .6 35.8 142. 8 32.4

45 22 14 8.9 34.9 115. 0 32.2 170 .7 36.6 13 1.3 33.5

45 24 135 .9 35.9 10 4.9 33.4 155. 7 37. 5 11 9. 8 34.6

50 15 22 7.1 34.0 175. 4 30.0 260.3 36.5 200.2 31.9

50 18 2 07. 6 35.5 16 0.3 31.8 2 3 7.9 37. 8 18 3.0 33.6

50 20 194 .5 36.5 150 .3 33.0 223.0 38.7 17 1.5 34.7

50 22 181. 5 37. 5 140 .2 34.2 208.0 39.5 160. 0 35.8

50 24 168. 5 38.5 130.1 35.4 193.1 40.4 14 8. 5 36.9

55 15 259.7 36.4 200.5 31.9 2 97. 6 39.2 228.9 3 4.1

55 18 24 0.1 38.0 185. 5 33. 8 275.2 40.6 2 11. 7 35. 8

55 20 2 27. 1 39.0 175 .4 35.0 260.3 41 .5 200.2 36.9

55 22 214.1 40.0 165.3 36.2 245.4 42 .3 18 8.7 38.0

55 24 201 .1 41.0 155 .3 3 7.4 230.4 43.2 17 7. 2 39 .1

35 mm

EZ 12.5 cm

liquid screed

CZ 25 cm

liquid screed

Surface temperature

θ

F

35 mm

Surface temperature

θ

F

28

Maximum floor surface temperature in accordance

with EN 1264:

Edge Zone 1.00 m . . . . . . . . . 35° C

Comfort Zone. . . . . . . . . . . . 29° C

Bathrooms. . . . . . . . . . . . . . 33° C

VGCTA2302 © Danfoss 09/2009

Page 29

Handbook SpeedUp™ Heating Systems

- Output tables

Output table,

Danfoss SpeedUp™

heating system

Thermal resistance of finished floor surface:

2

R

λ,B m

K/W 0,05 (e.g. tiles)

Differential temperature (δ K) 5.

Heat output based on EN 1264.

Cement- & liquid screed

45 mm

EZ 12.5 cm

water temperature

Mean central heating

θ

m

Room temperature

θ

i

cement screed

Surface temperature

θ

F

45 mm

CZ 25 cm

cement screed

Surface temperature

θ

F

°C °C W/m °C W/m °C W/m °C W/m °C

30 15 69. 8 21.5 56.8 20.4 76. 8 2 2.1 62.6 20.9

30 18 55.6 23.3 45.2 22.4 61.1 23.8 49.8 22.8

30 20 46.0 24.4 37. 4 23.7 50.6 24.8 41. 2 24.0

30 22 36.3 25.6 29.5 25.0 40.0 25.9 32.6 25.2

30 24 26. 5 26.7 21. 5 26.2 2 9.1 26.9 23.7 26.4

35 15 93.5 23.5 76 .0 22.0 10 2.9 24.2 83.8 22.7

35 18 79.3 25.3 64.5 24.0 8 7. 3 25.9 7 1.1 24.6

35 20 69.8 26.5 56.8 25.4 76 .8 2 7.1 62.6 25.9

35 22 60.3 2 7.7 49.0 26.7 66.4 28.2 54.0 2 7.1

35 24 50.8 28.9 41. 3 28.0 55.9 29.3 45.5 28.4

40 15 117.1 25.4 95.2 23.6 12 8. 8 26. 3 104.9 24.4

40 18 10 3.0 27. 2 83.7 25.7 113 . 2 2 8.1 92.2 26.4

40 20 93.5 28.5 76.0 2 7. 0 102. 9 29.2 83.8 2 7.7

40 22 8 4.1 29.7 68.3 28.4 92.5 30.4 75. 3 29.0

40 24 74 .6 30.9 60.6 29.7 82.0 31. 5 66.8 30.2

45 15 140 .7 27. 3 114 . 3 25.2 15 4. 7 28.4 126 .0 26 .1

45 18 126 . 5 29.1 102. 8 2 7. 2 139 .2 30.2 113. 3 2 8.1

45 20 11 7.1 30.4 95.2 28.6 12 8. 8 31.3 104 .9 29.4

45 22 1 07. 7 31.6 8 7. 5 30.0 118 .4 32.5 96.4 30.7

45 24 98.2 32.9 79.8 31. 3 108 .1 33.7 88.0 32.0

50 15 164 .2 29.1 133 .5 26.7 180. 6 30.4 147. 1 27. 8

50 18 15 0.1 31. 0 12 2. 0 28.8 165.1 32.2 13 4. 4 29. 8

50 20 14 0.7 32.3 114 . 3 30.2 15 4.7 33.4 126 .0 31.1

50 22 131 .2 33.5 106. 7 31. 5 14 4.4 34.6 117.6 32.4

50 24 121. 8 34.8 99.0 32.9 134 .0 35.7 109.1 33.7

55 15 1 87. 8 31.0 152.6 28.2 206.5 32 .4 168 .2 29.4

55 18 173 .6 32.9 141.1 30.3 191.0 34.2 15 5. 5 31.4

55 20 16 4.2 34 .1 13 3. 5 31.7 180. 6 35.4 1 47.1 32.8

55 22 15 4. 8 35.4 125 .8 33 .1 170. 3 36.6 13 8. 7 3 4.1

55 24 14 5.4 36.6 11 8. 2 34.5 159. 9 37. 8 130 .2 35.4

35 mm

EZ 12.5 cm

liquid screed

CZ 25 cm

liquid screed

Surface temperature

θ

F

35 mm

Surface temperature

θ

F

Maximum floor surface temperature in accordance

with EN 1264:

Edge Zone 1.00 m . . . . . . . . . 35° C

Comfort Zone. . . . . . . . . . . . 29° C

Bathrooms. . . . . . . . . . . . . . 33° C

VGCTA302 © Danfoss 09/2009

29

Page 30

Handbook SpeedUp™ Heating Systems

- Output tables

Output table,

Danfoss SpeedUp™

heating system

Thermal resistance of finished floor surface:

2

R

λ,B m

K/W 0,10

Differential temperature (δ K) 5.

Heat output based on EN 1264.

Cement- & liquid screed

45 mm

EZ 12.5 cm

water temperature

Mean central heating

θ

m

Room temperature

θ

i

cement screed

Surface temperature

θ

F

45 mm

CZ 25 cm

cement screed

Surface temperature

θ

F

°C °C W/m °C W/m °C W/m °C W/m °C

30 15 54.8 20.2 45.8 19. 4 59. 0 20.6 49.5 19. 7

30 18 43.6 22.2 36.4 21.6 46.9 22.5 39.4 21.9

30 20 3 6.1 23.6 3 0.1 23.0 38.9 23.8 32.6 23.2

30 22 28.5 24.9 23.8 24.4 30.7 25 .1 25.7 24.6

30 24 20.8 26.2 1 7.4 25.8 22.4 26.3 18 .8 26.0

35 15 73.4 21.8 61. 3 20.8 79.0 22.3 66.3 21. 2

35 18 62.3 23.8 52.0 23.0 67. 0 24.3 56.2 23.3

35 20 54.8 25.2 45.8 24.4 59.0 25.6 49.5 24.7

35 22 47. 4 26.6 39.5 25.9 51.0 26.9 42 .8 26.2

35 24 39.9 27. 9 33.3 2 7. 3 42.9 28.2 36.0 27. 6

40 15 91. 9 23.3 76 .7 2 2.1 98.9 23.9 83.0 22.6

40 18 80.8 25.4 67. 5 24.3 87. 0 25.9 72.9 24.8

40 20 73.4 26.8 61. 3 25.8 79.0 27. 3 66.3 26.2

40 22 66.0 28.2 5 5.1 2 7. 2 7 1.0 28.6 59.6 2 7. 6

40 24 58.6 29.5 48.9 28.7 63.0 29.9 52.8 29.0

45 15 11 0. 4 24.8 92.2 23.4 11 8 . 8 25.5 99.7 24.0

45 18 99. 3 26.9 82.9 25.6 10 6.9 27. 6 89.7 2 6.1

45 20 91.9 28.3 76.7 2 7.1 98.9 28.9 83.0 27. 6

45 22 84.5 29.7 70.6 28.6 90.9 30.3 76. 3 29.0

45 24 7 7.1 31.1 64.4 30.0 83.0 31. 6 69.6 30.5

50 15 12 8. 9 26.3 107. 6 24.6 138 .7 2 7.1 116 . 4 25.3

50 18 117. 8 28.4 98.4 26.9 126. 8 29.2 10 6.3 27. 5

50 20 11 0 .4 29.8 92.2 28.4 118 .8 30.5 99.7 29.0

50 22 103. 0 31. 2 86.0 29.8 110 . 9 31. 9 93.0 30.4

50 24 95.6 32.6 79.8 31. 3 102.9 33.2 86.3 31.9

55 15 14 7.4 2 7. 8 123 .0 25.9 158. 6 28.7 133. 0 26.7

55 18 13 6. 3 29.9 113. 8 28 .1 14 6. 7 30.7 12 3. 0 28.9

55 20 12 8. 9 31.3 1 07. 6 29.6 13 8. 7 32.1 11 6. 4 30.3

55 22 12 1.5 32.7 101.4 31.1 130 .8 33.5 109.7 31. 8

55 24 114 .1 3 4.1 95.3 32.6 12 2. 8 34.8 103 .0 33. 2

35 mm

EZ 12.5 cm

liquid screed

CZ 25 cm

liquid screed

Surface temperature

θ

F

35 mm

Surface temperature

θ

F

30

Maximum floor surface temperature in accordance

with EN 1264:

Edge Zone 1.00 m . . . . . . . . . 35° C

Comfort Zone. . . . . . . . . . . . 29° C

Bathrooms. . . . . . . . . . . . . . 33° C

VGCTA2302 © Danfoss 09/2009

Page 31

Handbook SpeedUp™ Heating Systems

- Output tables

Output table,

Danfoss SpeedUp™

heating system

Thermal resistance of finished floor surface:

2

R

λ,B m

K/W 0.15

Differential temperature (δ K) 5.

Heat output based on EN 1264.

Cement- & liquid screed

45 mm

EZ 12.5 cm

water temperature

Mean central heating

θ

m

Room temperature

θ

i

cement screed

Surface temperature

θ

F

45 mm

CZ 25 cm

cement screed

Surface temperature

θ

F

°C °C W/m °C W/m °C W/m °C W/m °C

30 15 45.2 19 .4 38.5 18 .8 48.0 19. 6 41 .0 19. 0

30 18 35.9 21. 5 30.6 21.1 38.2 21. 8 32.6 21. 3

30 20 29.8 23.0 25.4 22.6 31. 6 23.2 2 7. 0 22.7

30 22 23.5 24. 4 20.0 2 4.1 25.0 24. 5 21.3 24.2

30 24 17.1 25.8 14. 6 25.6 18. 2 25.9 15 .6 25.7

35 15 60.5 20.7 51. 5 19. 9 64.3 21.0 54.9 20.2

35 18 51. 3 22.9 43.7 22.2 54.5 23.2 46.6 22.5

35 20 45.2 24. 4 38.5 23.8 48.0 24.6 41 .0 24.0

35 22 39.0 25.8 33.3 25.3 41. 5 26.0 35.4 25.5

35 24 32.9 2 7. 3 28.0 26.8 34.9 27. 5 29.8 27. 0

40 15 75.7 22.0 64.5 21.0 80.5 22.4 68.8 21.4