Installation guide

SonoMeter 40

Ultrasonic energy meter

for heating and cooling applications

www.danfoss.com

This doc. is managed by 500B0577

1

of

2

Installation guide SonoMeter 40

EU DECLARATION OF CONFORMITY

Danfoss A/S

6430 Nordborg, Denmark | CVR nr.: 20 16 57 15 | Telephone: +45 7488 2222 | Fax: +45 7449 0949

declares under our sole responsibility that the

Product category: Energy Meters Type designation(s): SonoMeter 40

Covered by this declaration is in conformity with the following directive( s), standard(s) or other normative

document(s), provided that the product is used in accorda

[RED] – Radio Equipment Directive 2014/53/EU

Article 3.1a (LVD)

EN 61010-1:2010+A1:2019

EN 62368-1:2014

EN 62311: 2008

Article 3.1b (EMC)

EN 301 489-3 V2.1.1

EN 301 489-1 V1.9.2

Article 3.2 (Radio)

EN 300 220-1 V3.1.1

EN 300 220-2 V3.1.1

[EMC] – Electromagnetic Compatibility Directive 2014/30/EU

EN 55032:2015+A11:2020

[LVD] – Low Voltage Directive 2014/35/EU

EN 61010-1:2010+A1:2019

EN 62368-1:2014

EN 62311: 2008

[MID] – Measuring Instruments Directive 2014/32/EU

EN 1434-1:2015+A1:2018

EN 1434-2:2015+A1:2018

EN 1434-3:2015

EN 1434-4:2015+A1:2018

EN 1434-5:2015+A1:2019

EN 1434-6:2015+A1:2019

WELMEC 7.2:2015 - Software Guide

Noti�ied Body: Lithuanian Energy Institute, 1621, performed type approval and issued certi�icate LT-1621-MI004-047.

[RoHS] – Restriction of Hazardous Substances Directive 2011/65/EU+A:2015/863

EN IEC 63000:2018

Danfoss Energy Metering

nce with our instructions.

2

1

1, 3

4

1 For variants with Radio Module the declaration for EMC & LVD shall be ignor ed

2 For variants without Radio Module the declaration for RED shall be ignored.

3 For variants without Radio Module and without Mains power supply (24V AC /DC) the declaration for RED and LVD shall be ignored.

4 Not within MID – National Type Approval Certi�icate for cooling energy DE-21- M-PTB-0069 is issued by “Physikalisch-T

Date:

2021.09.22

Place of issue:

8811 Scheifling

Austria

Danfoss only vouches for the correctness of the English version of this declaration. In the event of the declaration being translated into any other

language, the translator concerned shall be liable for the correctness of the translation

ID No: 014R2944

Issued by Date:

Signature:

Name: Norbert Spreitzer

Title: Product Portfolio Manager

Revision No: 01

2021.09.22

Place of issue:

1210 Ljubljana,

Slovenia

Approved by

Signature:

Name: Gasper Benedik

Title: Energy Meters Director

echnische Bundesanstalt”.

Page

2 | © Danfoss | Energy Meters | 2021.10 AN384648824392en-010102

This doc. is managed by 500B0577

2

of

2

Installation guide SonoMeter 40

UK DECLARATION OF CONFORMITY

Danfoss A/S

6430 Nordborg, Denmark | CVR nr.: 20 16 57 15 | Telephone: +45 7488 2222 | Fax: +45 7449 0949

declares under our sole responsibility that the

Product category: Energy Meters Type designation(s): SonoMeter 40

Covered by this declaration is in conformity with the following directive( s), regulation(s), standard(s) or other

normative document(s), provided that the product

Radio Equipment Regulations 2017

Article 3.1a (LVD)

BS EN 61010-1:2010+A1:2019

BS EN 62368-1:2014

BS EN 62311:2008

Article 3.1b (EMC)

EN 301 489-3 V2.1.1

EN 301 489-1 V1.9.2

Article 3.2 (Radio)

EN 300 220-1 V3.1.1

EN 300 220-2 V3.1.1

Electromagnetic Compatibility Regulations 2016

BS EN 55032:2015+A11:2020

Electrical Equipment (Safety) Regulations 2016

BS EN 61010-1:2010+A1:2019

BS EN 62368-1:2014

BS EN 62311:2008

Danfoss Energy Metering

is used in accordance with our instructions.

2

1

1, 3

The Restriction of the Use of Certain Hazardous Substances in Electrical and Electronic Equipment Regulations 2012

(as amended)

BS EN IEC 63000:2018

Heat Metering and Billing Regulations 2014

Heat meter accuracy cl. 7.9:

Noti�ied Body: Lithuanian Energy Institute, 1621, performed type approval and issued certi�icate LT-1621-MI004-047.

1 For variants with Radio Module the declaration for EMC & LVD shall be ignor ed

2 For variants without Radio Module the declaration for RED shall be ignored.

3 For variants without Radio Module and without Mains power supply (24V AC /DC) the declaration for RED and LVD shal

Date:

2021.09.22

Place of issue:

8811 Scheifling

Austria

Danfoss only vouches for the correctness of the English version of this declaration. In the event of the declaration being translated into any other

language, the translator concerned shall be liable for the correctness of the translation

ID No: 014R2944

Issued by Date:

Signature:

Name: Norbert Spreitzer

Title: Product Portfolio Manager

Revision No: 01

2021.09.22

Place of issue:

1210 Ljubljana,

Slovenia

Approved by

Signature:

Name: Gasper Benedik

Title: Energy Meters Director

l be ignored.

Page

AN384648824392en-010102 © Danfoss | Energy Meters | 2021.10 | 3

Installation guide SonoMeter 40

1. Installation

1.1. Preparation

Only qualified personnel may install the equipment, following the requirements listed in this document.

More detailed instruction can be found on www.heating.danfoss.com.

Note! This product is approved for ambient temperature between 5-55° C, but to ensure optimal conditions for

battery it is recommended to install Calculator at max. 45° C. Avoid installation stress from pipes and fittings.

Flush the system.

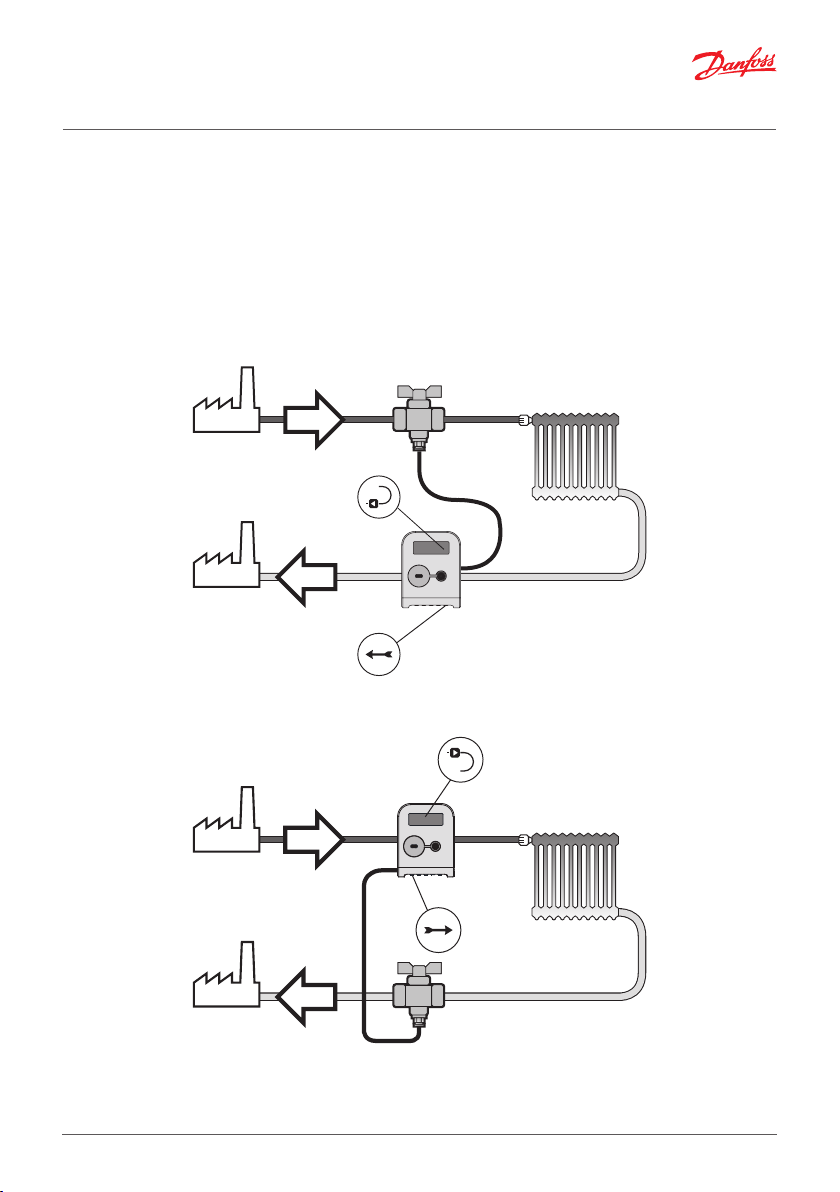

1.2. Identification of installation: Return/Supply pipe installation and flow direction

Flow direction

Return pipe installation

Flow direction

Supply pipe installation

AN384648824392en-010102 © Danfoss | Energy Meters | 2021.10 | 4

Installation guide SonoMeter 40

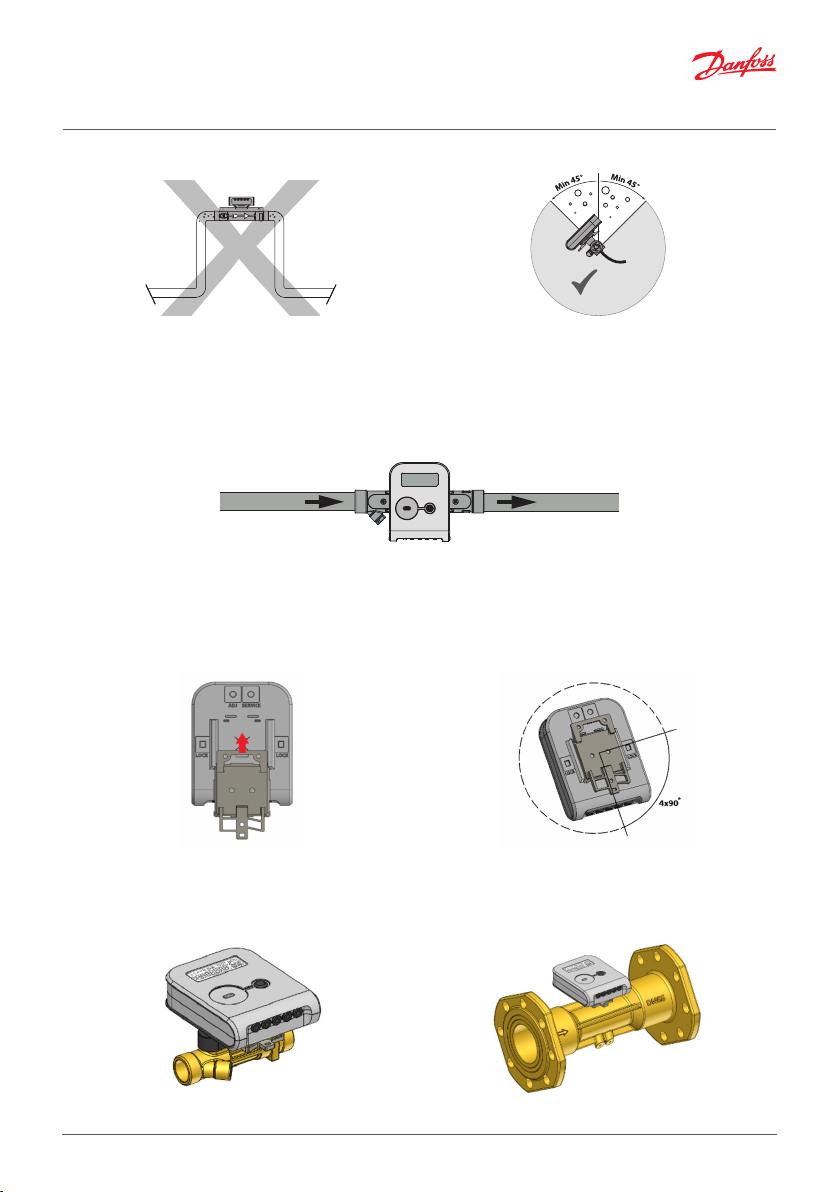

1.3. Mounting of flow sensor

Pipe position: No limitations but avoid positions

where air can be collected.

Rotation in pipe axis: Flow sensor should be angled

in 45 to 315° to avoid air collection in flow sensor.

Inlet/outlet conditions (only for DN 65-DN 100)

In order to maximize performance it is necessary to have straight inlet and outlet flow conditions before

and after the flow sensor: 5 × DN on inlet and 3 × DN on outlet of flow sensor.

5 x DN 3 x DN

flow

1.4. Mounting and sealing of calculator

Heat meter calculator may be installed in heated premises, working ambient temperature shall

be not more than 55 °C. It may not be exposed to direct sunlight.

The calculator is mounted on an auxiliary holder (it can be oriented in the required direction at an angle of

each 90 °:

The possible ways of the mounting of the calculator (auxiliary holder):

- Direct mounting on the housing of the flow sensor, by turning each 90o (only when the flow temperature

does not exceed 90oC):

5 | © Danfoss | Energy Meters | 2021.10 AN384648824392en-010102

Installation guide SonoMeter 40

- On the wall:

- Panel mounting on standard DIN-rail.

Important: It is prohibited to attach the electronic unit directly on the wall because there is a risk

that moisture may condense on the walls of the room or the temperature of the surface of the wall may

drop below 5 °C. In this case, it is recommended to mount the electronic unit so that to provide for an air

space of at least 5 cm between the unit and the wall surface.

Calculator seals

For design with permanently connected temperature sensors no additional sealing applies to the

electronic unit of a newly manufactured heat meter. Access to elements fixing the opening of the box,

configuration change activation contacts, and adjustment data change activation contacts is protected

by special easily breakable partitions.

a) b) c)

Access to elements fixing the opening of the box (a), configuration change activation contacts (b) and

adjustment data change activation contacts (c) (partitions easily breakable with a tool)

AN384648824392en-010102 © Danfoss | Energy Meters | 2021.10 | 6

Installation guide SonoMeter 40

Seal

Seal

After the opening of the box, change of the configuration, or adjustment of the meter (when the special

partitions were broken out for this purpose), the opened slots must be additionally sealed with sticker

seals:

- the two slots marked LOCK for access to the elements fixing the opening of the box are sealed with

test sticker seals (Fig. 4.1a),

- the slot marked SERVICE for access to the configuration change activation contacts is sealed with

the supplier’s sticker seal (Fig. 4.1b),

- the slot marked ADJ for access to the adjustment data change activation contacts is sealed with the

supplier’s sticker seal (Fig. 4.1c).

For design with changeable temperature sensors (IP65 protection class of the calculator only!) the

inspection seals /adhesive seals protect the access to protective cap mounting bolt and to adjustment data

change activation contacts ADJ, if breakable partition is broken out.

The inspection seals /adhesive seals protect the access to protective cap mounting bolt (1) and to

adjusment data change activation contacts (2) , if breakable partition is broken out.

1.5. Mounting and sealing of temperature sensors

Installation recommendations for

ball valve mounting and sealing

7 | © Danfoss | Energy Meters | 2021.10 AN384648824392en-010102

Installation recommendations for

direct short temperature sensors

Installation guide SonoMeter 40

Seal

ocket

Seal

Pocket

a) angled 45°

Installation recommendations for pocket temperature sensors with permanently connected signal leads.

b) perpendicular

P

2. Electrical wiring

2.1 Connection of a meter with permanently connected temperature sensors (IP 67/68)

The meter version with permanently connected temperature sensors is fully ready for installation,

complete with the necessary cables for connection (no need to open the meter).

If the meter is equipped with wired interfaces or a pulse input / output function, appropriate and marked

cables to connect the relevant external device are provided.

If the meter is intended to be powered by an external source of 230V AC or 24V AC / DC, the dedicated

and marked cable of the meter shall be connected to the appropriate source.

2.2 Connection of the meter with changeable temperature sensors (IP65)

If the meter is fully assembled (temperature sensors are connected, communication interface cables are

in place) - follow the installation procedure in p.5.3.1 (the meter does not need to be opened). Otherwise,

it is necessary to open the electronic unit box.

Opening of electronic unit box

Before opening the electronic box, make sure that the meter version is with changeable temperature

sensors:

Check!

IP65 = Openable Version (with exchangeable

temperature sensors)

IP67 = Not openable

IP68 = Not openable

8 | © Danfoss | Energy Meters | 2021.10 AN384648824392en-010102

Installation guide SonoMeter 40

Wiring diagram 1

Design with changeable

temperature sensors, Mbus1

interface. Meter power supply from

a battery.

Wiring diagram 2

Design with changeable

temperature sensors, additional

interface module

(additional interface module

mounting bracket under the

module). Meter power supply from

a battery.

9 | © Danfoss | Energy Meters | 2021.10 AN384648824392en-010102

Installation guide SonoMeter 40

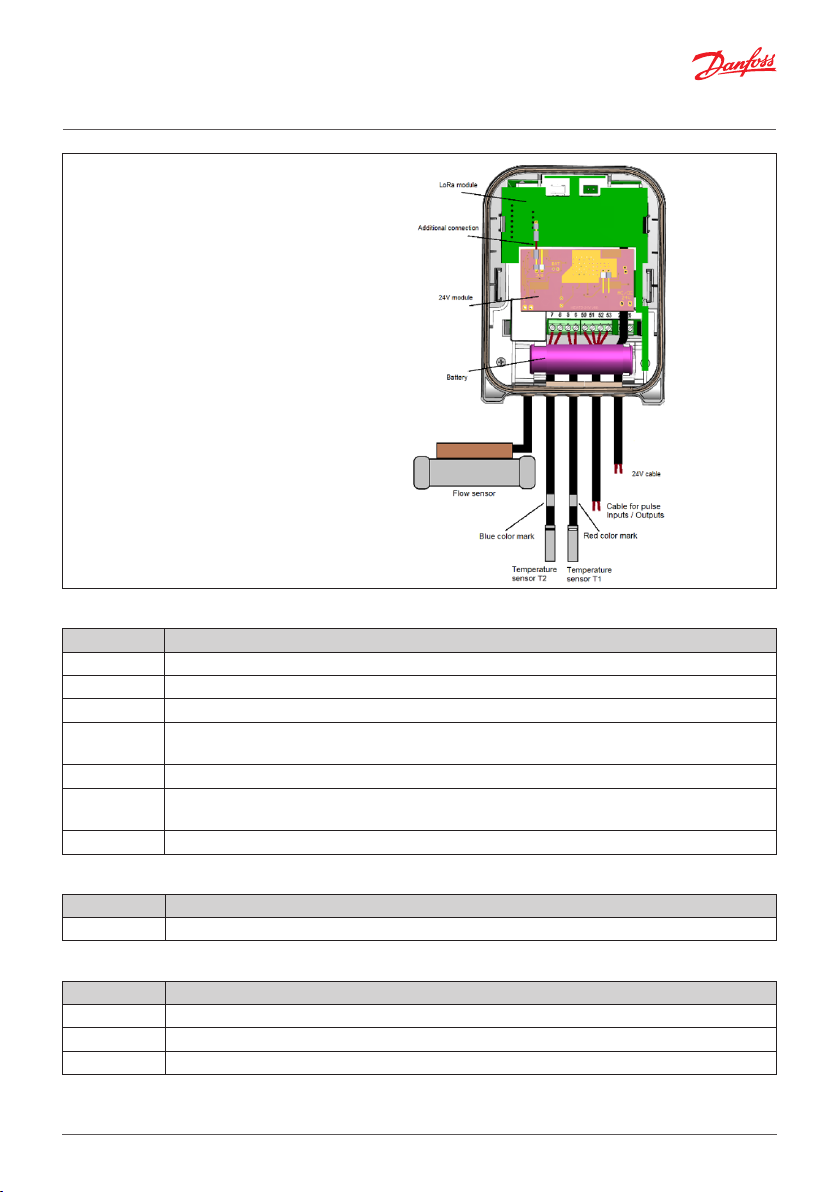

Wiring diagram 3

Design with changeable

temperature sensors, LoRa interface

and 24V power supply module.

The 24V power supply module is

mounted on the battery holder and

connected to the B1 connector of

the meter.

A backup battery is connected to

the BAT connector of the module.

The 24V power cable is connected

to the “24V” terminals of the

module (connections are made

before mounting the module, as

the connectors and terminals are

on the other side of the module).

The LoRa interface module is

connected to the 24V power supply

module connector by an additional

connection cable.

Numbering of calculator terminals

Terminal N. Description

5, 6 High temperature sensor (T1)

7, 8 Low temperature sensor (T2)

50 Common terminal for 2nd additional pulse input/output (GND)

51

52 Common terminal for 1st additional pulse input/output (GND)

53

24, 25 M-bus data lines (bipolar)

2nd additional pulse input/output (In/Out2)

(Volume output for TEST mode)

1st additional pulse input/output (In/Out1)

(Energy output for TEST mode)

Numbering of M-bus communication module terminals

Terminal N. Description

24, 25 M-bus module (bipolar)

Numbering of MODBUS and BACnet communication module terminals

Terminal N. Description

60, 61 12-24 V DC power supply voltage for MODBUS and BACnet (bipolar)

90 MODBUS or BACnet Line +

91 MODBUS or BACnet Line -

10 | © Danfoss | Energy Meters | 2021.10 AN384648824392en-010102

Installation guide SonoMeter 40

3. Commissioning

3.1. Bleeding

1. Bleed the system until the flow rate display is steady.

2. Make sure no error codes are displayed.

3. Check the display for a plausible indication of flow rate and temperatures.

3.2. IP class

Calculator IP65 (IP68 on special request)

Flow sensor IP68

4. Display function overview

4.1. Menu structure

INT

Integral parameters

BIL

Statistical data

INF

Informative parameters

1.1 1.2 1.3 1.4 1.51.6 1.7

2.1 2.2 2.3 2.4 2.52.6.1 2.7.12xx 2.15.1

3.1 3.2 3.3 3.4 3.5

3.6.13.7 3x 3.15

1.8

1.9

4.2. Display symbols

Explanation of special symbols:

flow is flowing forward (right direction)

flow is flowing backwards (wrong direction)

no arrow

no flow

Explanation of other symbols are described in detailed instruction on www.heating.danfoss.com.

4.3. Error codes

Long press

Shift down

Short press

Shift to the right

11 | © Danfoss | Energy Meters | 2021.10 AN384648824392en-010102

Installation guide SonoMeter 40

Errors are encoded by a 4-digit code.

Code Description

Status of calculator

Status of the return heat carrier temperature sensor (T2)

0 - normal operation

1 - battery service life has expired (or the meter was not power supplied –

if it is externally power supplied)

2 - temperature differential is higher than permissible limits

4 - temperature differential is lower than permissible limits

8 - electronic unit hardware failure *

0 - normal operation

4 - the sensor is short-circuited *

8 - the sensor is disconnected or short-circuited *

Status of the supply heat carrier temperature sensor (T1)

Status of flow sensor 0 - normal operation

* - only in case of these serious errors will be stopped the summation of energy and normal working time, the

error code will be displayed on the LCD first page, additionally the error date will be displayed.

Error codes sum up if there are more than one error. Then the summary indicated error code will be as

follows:

• 3 – corresponds to error codes 2 + 1

• 5 – corresponds to error codes 4 + 1

• 7 – corresponds to error codes 4 + 2 + 1

• 9 – corresponds to error codes 8 + 1

• A – corresponds to error codes 8 + 2

• B – corresponds to error codes 8 + 2 + 1

• C – corresponds to error codes 8 + 4

• D – corresponds to error codes 8 + 4 + 1

• E – corresponds to error codes 8 + 4 + 2

• F – corresponds to error codes 8 + 4 + 2 + 1

If at least one digit value of an error code is ≥8, the summing-up of energy, water quantity, and trouble-free

operation time is stopped.

In case of the flow sensor error 4, the time “when the flow q> 1.2∙qs” is recorded additionally.

0 - normal operation

4 - the sensor is short-circuited *

8 - the sensor is disconnected or short-circuited *

1 – no signal; the flow sensor is not filled with water

2 – reverse flow

4 – the flow is greater than 1.2∙qs (indicated q=1.2∙qs)

8 – hardware failure *

12 | © Danfoss | Energy Meters | 2021.10 AN384648824392en-010102

Installation guide SonoMeter 40

5. Disposal

This symbol on the product indicates that it may not be disposed of as household

waste.

It must be handed over to the applicable take-back scheme for the recycling of

electrical and electronic equipment.

• Dispose of the product through channels provided for this purpose.

• Comply with all local and currently applicable laws and regulations.

Item Material Disposal

Battery

PCBA with display

Cables Copper with PUR or PVC jackets Cable recovery

Flow sensor (incl. trans-

ducer and liner)

Transducer PZT, stainless steel, PEI Approved deposit for PZT

Other plastic parts PC, PPS, PEI, TPE Plastic recovery

AA-cell lithium/thionyl chloride 700 mg

lithium

Coppered epoxy laminate components

soldered on, PC, TPE

Brass, stainless steel, PPS Metal recovery

Approved deposit for lithium

batteries

Electronic waste

6. Local Importer name and address

For goods delivered to UK, importer name and address is:

Danfoss Ltd.

22 Wycombe End

HP9 1NB

GB

AN384648824392en-010102 © Danfoss | Energy Meters | 2021.10 | 13

Installation guide SonoMeter 40

14 | © Danfoss | Energy Meters | 2021.10 AN384648824392en-010102

Installation guide SonoMeter 40

15 | © Danfoss | Energy Meters | 2021.10 AN384648824392en-010102

16 | © Danfoss | Energy Meters | 2021.10 AN384648824392en-010102

Loading...

Loading...