Installation & User Guide

SonoMeter 31

Ultrasonic energy meter

for heating and cooling applications

www.danfoss.com

Installation & User Guide SonoMeter 31

2 | © Danfoss | DHS-SRMT / PL | 2018.08 VI.SH.O2.02

Installation & User Guide SonoMeter 31

1. Installation

1.1. Preparation

Only qualified personnel may install the equipment, following the requirements listed in this document.

More detailed instruction can be found on www.heating.danfoss.com.

Note! This product is approved for ambient temperature between 5-55° C, but to ensure optimal conditions for

battery it is recommended to install Calculator at max. 45° C. Avoid installation stress from pipes and fittings.

Flush the system.

1.2. Identification of installation: Return/Supply pipe installation and flow direction

Flow direction

Return pipe installation

Flow direction

Supply pipe installation

VI.SH.O2.02 © Danfoss | DHS-SRMT / PL | 2018.08 | 3

Installation & User Guide SonoMeter 31

1.3. Mounting of flow sensor

Pipe position: Avoid positions where

air can be collected.

Rotation in pipe axis: Flow sensor should be angled

in 45 to 315° to avoid air collection in flow sensor.

Inlet/outlet conditions

In order to maximize performance it is necessary to have straight inlet and outlet flow conditions before

and after the flow sensor: 5 × DN on inlet and 3 × DN on outlet of flow sensor.

5 × DN

flow

3 × DN

1.4. Mounting and sealing of calculator

On the wall: Panel mounting on standard DIN-rail:

4 | © Danfoss | DHS-SRMT / PL | 2018.08 VI.SH.O2.02

Installation & User Guide SonoMeter 31

Seal

ocket

1.5. Mounting and sealing of temperature sensors

Seal

Pocket

a) angled 45°

Installation recommendations for pocket temperature sensors with permanently connected signal leads.

b) perpendicular

P

2. Electrical wiring

Electrical wiring diagram with 2-wire temperature sensors for DN65, DN80 and DN100

V1…V2 – ultrasonic flow sensors

T1…T3 – temperature sensors

V3…V4 – water meters with pulse output

p1…p2 – pressure sensors

Remark: Only required for selected meter type is connected

VI.SH.O2.02 © Danfoss | DHS-SRMT / PL | 2018.08 | 5

Installation & User Guide SonoMeter 31

Electrical wiring diagram with 2-wire temperature sensors for smaller sizes (DN15 -DN50)

*

*

*

*

* optional*

V1…V2 – ultrasonic flow sensors

T1…T3 – temperature sensors

V3…V4 – water meters with pulse output

p1…p2 – pressure sensors

Remark: Only required for selected meter type is connected

6 | © Danfoss | DHS-SRMT / PL | 2018.08 VI.SH.O2.02

*

Installation & User Guide SonoMeter 31

Calculator

Terminals Marking Description

60 V1-1 (+) Output signal (OUT) from 1st flow sensor V1

61 V1-1(−) GND for output (OUT) of 1st flow sensor V1

62 V1-2 (+) Input signal (IN) from 1st flow sensor V1

63 V1-2 (−) GND for input (IN) of 1st flow sensor V1

64 V2-1 (+) Output signal (OUT) from 2nd flow sensor V2

65 V2-1 (−) GND for output (OUT) of 2nd flow sensor V2

66 V2-2 (+) Input signal (IN) from 2nd flow sensor V2

67 V2-2 (−) GND for input (IN) of 2nd flow sensor V2

1* T1 Current terminal for 1-st temperature sensor “+I”

5 T1 Voltage terminal for 1-st temperature sensor “+U”

6 T1 Voltage terminal for 1-st temperature sensor “−U”

2* T1 Current terminal for 1-st temperature sensor “−I”

50* GND for temperature sensors

3* T2 Current terminal for 2-nd temperature sensor “+I”

7 T2 Voltage terminal for 2-nd temperature sensor “+U”

8 T2 Voltage terminal for 2-nd temperature sensor “−U”

4* T2 Current terminal for 2-nd temperature sensor “−I”

9 + +3,6V power supply voltage for pulse inputs V3, V4

53 V3 Pulse input signal from 1-st input V3 (IN)

11 GND for V3 and V4 pulse inputs

54 V4 Pulse input signal from 2-nd input V4 (IN)

56* T3 Current terminal for 3-rd temperature sensor “+I”

57 T3 Voltage terminal for 3-rd temperature sensor “+U”

58 T3 Voltage terminal for 3-rd temperature sensor “−U”

59* T3 Current terminal for 3-rd temperature sensor “−I”

82 GND for pressure sensor р1

68 P1 Input signal from 1-st pressure sensor (IN)

51 + +18 V power supply voltage for pressure sensors p1, p2

83 GND for pressure sensor р2

69 P2 Input signal from 2-nd pressure sensor (IN)

7 | © Danfoss | DHS-SRMT / PL | 2018.08 VI.SH.O2.02

Installation & User Guide SonoMeter 31

REMARK: * – only for 4-wire connection method of temperature sensors (K)

Communication modules

Terminal

number

76 GND for currency outputs

77 Iout1 1st currency outputs (+)

78 Iout2 2nd currency outputs (+)

79 GND for pulse outputs

80 Puls 1 1st pulse outputs (+)

81 Puls 2 2nd pulse outputs (+)

24 (73) BUS M-bus line L1

25 (74) BUS M-bus line L2

75 BUS GND for communication interface RS-232

60 60 MODBUS module 12–24 V DC power terminal (bipolar)

61 61 MODBUS module 12–24 V DC power terminal (bipolar)

90 90 MODBUS module line (+)

91 91 MODBUS module line (−)

Power supply 230 V AC

Terminal

number

26 Main ground

27 N Neutral

28 L Mains supply 230 V AC

Marking Description

Marking Description

3. Commissioning

3.1. Bleeding

1. Bleed the system until the flow rate display is steady.

2. Make sure no error codes are displayed.

3. Check the display for a plausible indication of flow rate and temperatures.

3.2. IP class

Calculator IP65

Flow sensor

VI.SH.O2.02 © Danfoss | DHS-SRMT / PL | 2018.08 | 8

IP65 for heat meter

IP67 for heat and cooling meter

Installation & User Guide SonoMeter 31

4. Display function overview

4.1. Display symbols description

Parameter and group numbers Operation mode

Values

Group of parameters

4.2. Menu structure

Parameters shown Identification symbols

Integral values

Instantaneous parameters values (L2)

Set day parameters and archive data values (L3)

Printing reports by standard printer (L4)

Configuration settings parameters (L5)

Parametrization (configuration) mode (SET) SET

Test mode (TEST) TEST

L1 L2 L3 L4 L5

L1 L2 L3 L4 L5

L1 L2 L3 L4 L5

L1 L2 L3 L4 L5

L1 L2 L3 L4 L5

L1 L2 L3 L4 L5

L1 L2 L3 L4 L5

L1 L2 L3 L4 L5

Measurement units

9 | © Danfoss | DHS-SRMT / PL | 2018.08 VI.SH.O2.02

Installation & User Guide SonoMeter 31

4.3. Error codes

The meter continuously analyzes operational modes, diagnoses and informs of errors in system

Significant faults Er

If significant faults Er1 are detected in work of heating system, energy calculation is stopping and these

errors are displayed via 6 character error code:

1

Status of temperature sensor T1

Status of temperature sensor T2

Status of temperature sensor T3

Status of flow sensor V1

Status of flow sensor V2

Power supply voltage status (only for archive)

Detailed description of significant faults codes Er

1

Error display Error description

Er1: 000000 No error. Normal mode

Er1: 000001 Fault in temperature Θ1 measuring circuit*: temperature difference Θ1−Θ2 <

dΘmin (dΘmin – the minimum value of temperature difference)

Er1: 000002 Fault in temperature Θ1 measuring circuit: temperature Θ1< 0 °C

(or sensor has short circuit)

Er1: 000004 Fault in temperature Θ1 measuring circuit: temperature Θ1 > 180 °C

(or sensor has open circuit)

Er1: 000010 Fault in temperature Θ2 measuring circuit*: temperature difference Θ1−Θ2 <

dΘmin (dΘmin – the minimum value of temperature difference)

Er1: 000020 Fault in temperature Θ2 measuring circuit**: temperature Θ2 < 0 °C

(or sensor has short circuit)

Er1: 000040 Fault in temperature Θ2 measuring circuit**: temperature Θ2 > 180 °C

(or sensor has open circuit)

Er1: 000200 Fault in temperature Θ3 measuring circuit**: temperature Θ3 < 0 °C

(or sensor has short circuit)

Er1: 000400 Fault in temperature Θ3 measuring circuit**: temperature Θ3 > 180 °C

(or sensor has open circuit)

Er1: 002000 Fault in V1 measuring circuit*: flow rate q1< q1i

(qi – the minimum allowable value of flow rate)

Er1: 004000 Fault in V1 measuring circuit*: flow rate q1> q1s

(qs – the maximum allowable value of flow rate)

Er1: 008000 Fault in V1 measuring circuit: Fault in flow measuring channel

Er1: 020000 Fault in V2 measuring circuit*: flow rate q2 < q2i

(qi – the minimum allowable value of flow rate)

Er1: 040000 Fault in V2 measuring circuit *: flow rate q2 > q2s

(qs – the maximum allowable value of flow rate)

Er1: 080000 Fault in V2 measuring circuit: Fault in flow measuring channel

Er1: 100000 No supply voltage (only for data logger)

Note: * - only when non-standard energy calculation algorithm is applied

** - only in cases where the temperature sensors T2, T3 are used to calculate the thermal energy

Active error codes are added and simultaneously displayed

VI.SH.O2.02 © Danfoss | DHS-SRMT / PL | 2018.08 | 10

Installation & User Guide SonoMeter 31

Transistory fault Er

2

If transistory faults Er2 are detected in work of heating system, energy calculation do not stop and these

errors are displayed via 5 character error code:

Status of flow sensor V1

Status of flow sensor V2

Status of flow sensor V3

Status of flow sensor V4

Status of temperature sensor

Detailed description of transistory faults codes Er

2

Error display Error description

Er2: 00000 No error. Normal mode

Er2: 00001 Flow q1 flow in reverse direction

Er2: 00002 Flow value q1< q1i (the minimum allowable value of flow rate)

Er2: 00004 Flow value q1> q1s (the maximum allowable value of flow rate)

Er2: 00008 Flow sensor V1 is not filled by a liquid

Er2: 00010 Flow q2 flow in reverse direction*

Er2: 00020 Flow value q2< q2i (the minimum allowable value of flow rate)

Er2: 00040 Flow value q2> q2s (the maximum allowable value of flow rate)

Er2: 00080 Flow sensor V2 is not filled by a liquid

Er2: 00100 On input V3 more than 24 hours do not arrive pulses**

Er2: 00200 Flow value q3< q3i (the minimum allowable value of flow rate)

Er2: 00400 Flow value q3> q3s (the maximum allowable value of flow rate)

Er2: 00800 Short circuit V3***

Er2: 01000 On input V4 more than 24 hours do not arrive pulses**

Er2: 02000 Flow value q4< q4i (the minimum allowable value of flow rate)

Er2: 04000 Flow value q4> q4s (the maximum allowable value of flow rate)

Er2: 08000 Short circuit V4***

Er2:10000 Temperature difference Θ1−Θ2 < dΘmin

Er2:20000 Temperature difference Θ1-Θ2 < 0 °C

Er2:40000 Temperature Θ3 <−40 °C or sensor has short circuit****

Er2:80000 Temperature Θ3 > 180 °C or sensor has open circuit****

Er2:50000 At the same time there are two error: “10000” and “40000”

Er2:60000 At the same time there are two error: “20000” and “40000”

Er2:90000 At the same time there are two error: “10000” and “80000”

Er2:A0000 At the same time there are two error: “20000” and “80000”

Note: * - Are not shown, when the algorithm ‘winter / summer’ is applied

** - only when flow input type “L” is on (“24 hours pulse control”)

*** - only when flow input type “E” is on (“short circuit control”)

**** - only when temperature measurement chanell T3 is on

Active error codes are added and simultaneously displayed

VI.SH.O2.02 © Danfoss | DHS-SRMT / PL | 2018.08 | 11

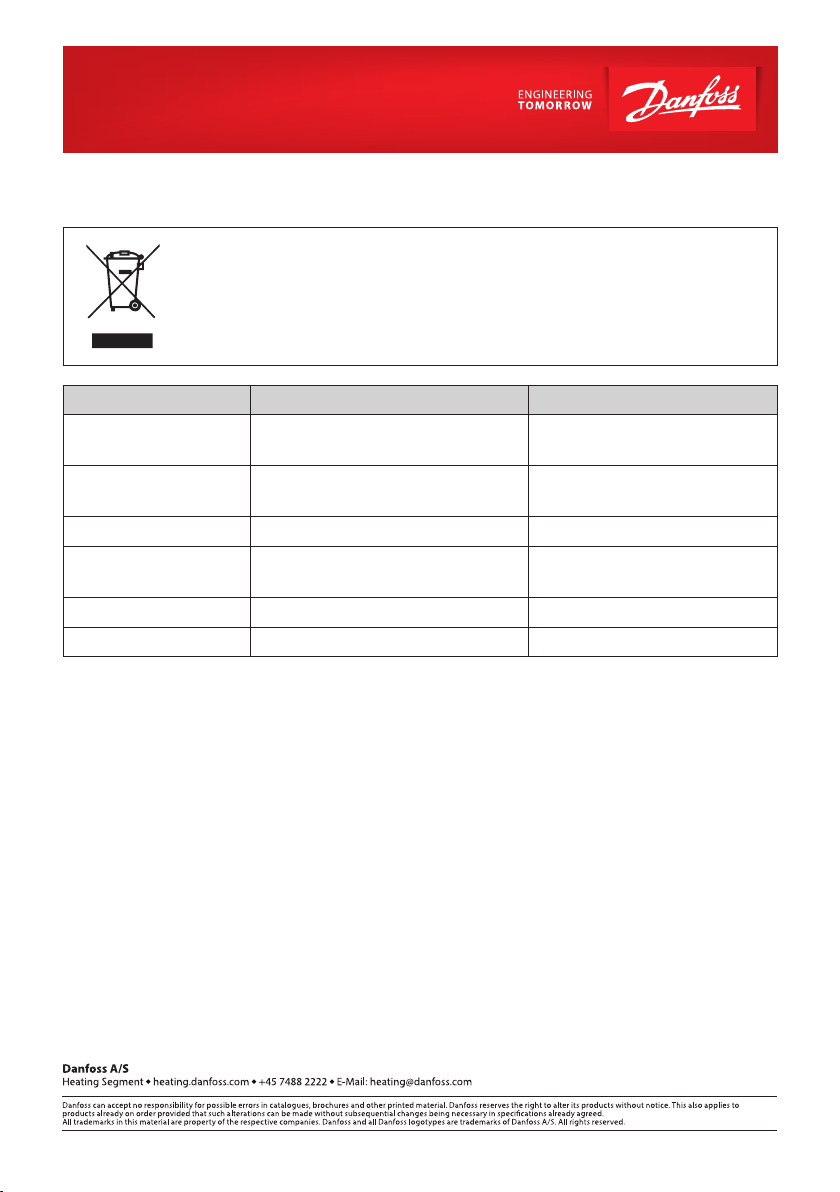

5. Disposal

This symbol on the product indicates that it will not be treated as household waste.

It must be handed over to the applicable take-back scheme for the recycling of electrical and electronic equipment. For more detailed information about the recycling

of this product, please contact your local municipal office.

Item Material Disposal

Battery

PCBA with display

D cell lithium/thionyl chloride

5,7 g lithium

Coppered epoxy laminate components soldered on, PC, TPE

Cables Copper with PUR or PVC jackets Cable recovery

Flow sensor (incl.

transducer and liner)

Brass, stainless steel, PPS Metal recovery

Transducer PZT, stainless steel, PEI Approved deposit for PZT

Other plastic parts PC, PPS, PEI, TPE Plastic recovery

Approved deposit for lithium

batteries

Electronic waste

12 | © Danfoss | DHS-SRMT / PL | 2018.08 VI.SH.O2.02

Loading...

Loading...