Page 1

Data sheet

SonoMeter 31

Energy Meters

Description

MID examination cer tificate no.:

LT-1621- M I 00 4 - 0 23

The Danfoss SonoMeter 31 is a range of

ultrasonic, compact energy meters intended for

measuring energy consumption in heating and

cooling applications for billing purposes. The

meters are designed for remote meter read-out

(AMR).

SonoMeter 31 energy meters consist of

an ultrasonic flow sensor, a pair of Pt500

temperature sensors and a calculator

with integrated circuits for temperature

measurement, flow calculation and energy

calculation.

Features

• Available in nominal flow rates

qp 25, 40 and 60 m³/h

• DN 65, DN 80 and DN 100 housings with

flange connections

• MID approval for ultrasonic energy meter with

dynamic range of 1:100 (qi : qp) in class 2

• Optional MID approved dynamic range of

1:250 (qi : qp) in class 2

• Temperature range 5 –130 °C

• Short overload temperature up to 150 °C

• Operating pressure 25 bar as standard

• For 2 or 4 wire temperature sensors

• Glycol mixtures as option (not MID certified)

• Calculator with IP65 protection class as

standard

• Flow sensor with IP65 protection class as

standard (IP67 for combine heating and

cooling applications)

• Return or supply pipe installation, for vertical

or horizontal mounting

• Battery lifetime for at least 10 years

• Insensitive to dirt

• Remote reading via wired M-Bus, radio OMS

868 MHz, RS-485 Modbus RTU, pulse output,

analog output and optical interface

• Two pulse inputs as standard (passive or

active)

• Special option with 2 flow sensors, 2

pressure sensors and 3 temperature sensors

measurement

© Danfoss | 2019.04 VD.SH.V3.02 | 1

Page 2

Data sheet SonoMeter 31 - Energy Meters

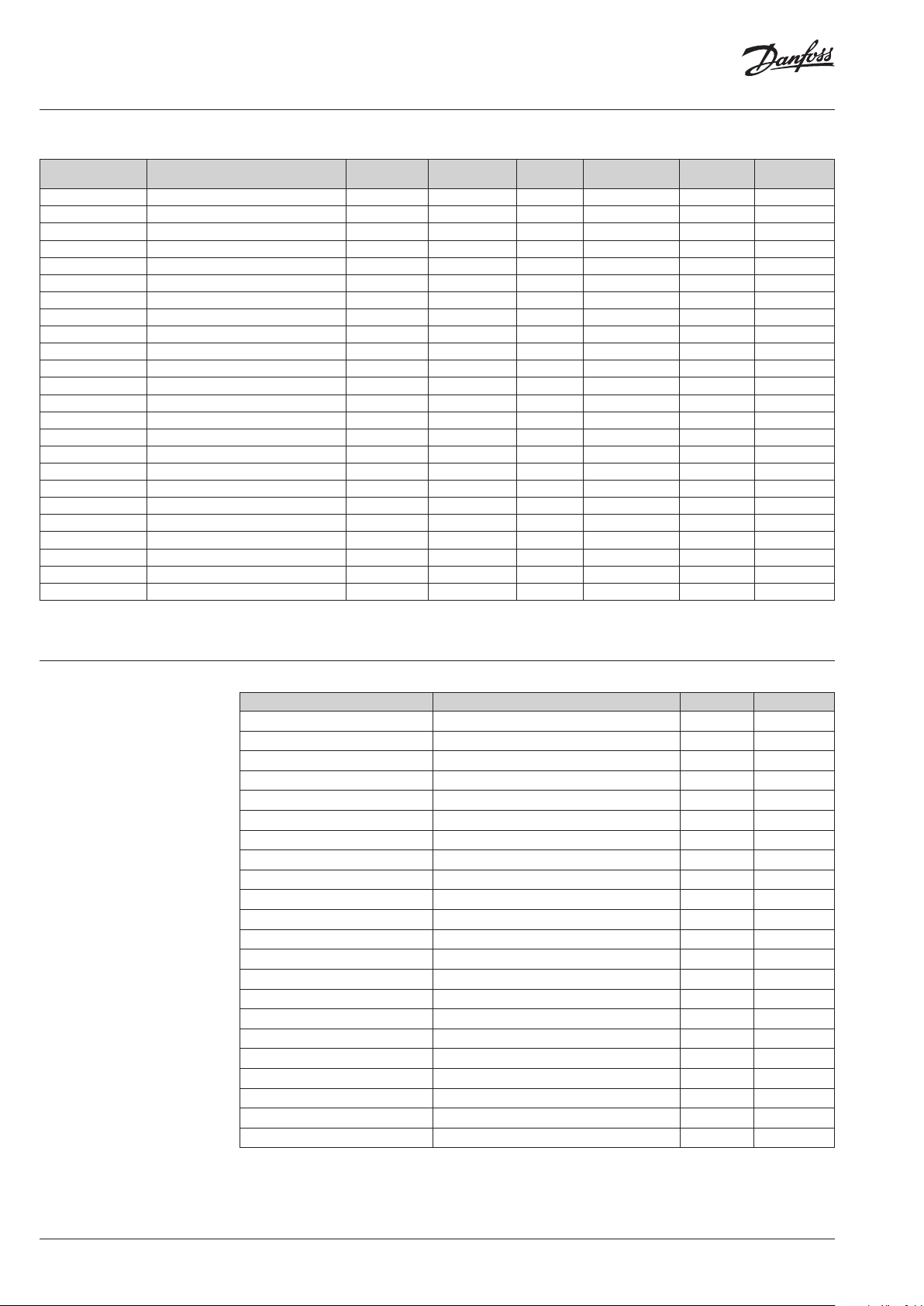

Ordering

Energy meter

application

Heating DN 65 / qp 25 m³/h / 300mm flange M-Bus MWh (2 dig.) Return batter y 3.6 V DC 25 bar 187F3300

Heating DN 65 / qp 25 m³/h / 300mm flange OMS 868.95 MWh (2 dig.) Return battery 3.6 V DC 25 bar 187F3301

Heating DN 65 / qp 25 m³/h / 300mm flange M-Bus MWh (2 dig.) Return mains 230 V AC 25 bar 187F3302

Heating DN 65 / qp 25 m³/h / 300mm flange OMS 868.95 MWh (2 dig.) Return mains 230 V AC 25 bar 187F3303

Heating / cooling DN 65 / qp 25 m³/h / 300mm flange M-Bus MWh (2 dig.) Return batter y 3.6 V DC 25 bar 187F3304

Heating / cooling DN 65 / qp 25 m³/h / 300mm flange OMS 868.95 MWh (2 dig.) Return battery 3.6 V DC 25 bar 187F3305

Heating / cooling DN 65 / qp 25 m³/h / 300mm flange M-Bus MWh (2 dig.) Return mains 230 V AC 25 bar 187F3306

Heating / cooling DN 65 / qp 25 m³/h / 300mm flange OMS 868.95 MWh (2 dig.) Return mains 230 V AC 25 bar 187F3307

Heating DN 80 / qp 40 m³/h / 350mm flange M-Bus MWh (2 dig.) Return battery 3.6 V DC 25 bar 187F3308

Heating DN 80 / qp 40 m³/h / 350mm flange OMS 868.95 MWh (2 dig.) Return battery 3.6 V DC 25 bar 187F3309

Heating DN 80 / qp 40 m³/h / 350mm flange M-Bus MWh (2 dig.) Return mains 230 V AC 25 bar 187F3310

Heating DN 80 / qp 40 m³/h / 350mm flange OMS 868.95 MWh (2 dig.) Return mains 230 V AC 25 bar 187F3311

Heating / cooling DN 80 / qp 40 m³/h / 350mm flange M-Bus MWh (2 dig.) Return battery 3.6 V DC 25 bar 187F3312

Heating / cooling DN 80 / qp 40 m³/h / 350mm flange OMS 868.95 MWh (2 dig.) Return battery 3.6 V DC 25 bar 187F3313

Heating / cooling DN 80 / qp 40 m³/h / 350mm flange M-Bus MWh (2 dig.) Return mains 230 V AC 25 bar 187F3314

Heating / cooling DN 80 / qp 40 m³/h / 350mm flange OMS 868.95 MWh (2 dig.) Return mains 230 V AC 25 bar 187F3315

Heating DN 100 / qp 60 m³/h / 350mm flange M-Bus MWh (2 dig.) Return batter y 3.6 V DC 25 bar 187F3316

Heating DN 100 / qp 60 m³/h / 350mm flange OMS 868.95 MWh (2 dig.) Return battery 3.6 V DC 25 bar 187F3317

Heating DN 100 / qp 60 m³/h / 350mm flange M-Bus MWh (2 dig.) Return mains 230 V AC 25 bar 187F3318

Heating DN 100 / qp 60 m³/h / 350mm flange OMS 868.95 MWh (2 dig.) Return mains 230 V AC 25 bar 187F3319

Heating / cooling DN 100 / qp 60 m³/h / 350mm flange M-Bus MWh (2 dig.) Return batter y 3.6 V DC 25 bar 187F3320

Heating / cooling DN 100 / qp 60 m³/h / 350mm flange OMS 868.95 MWh (2 dig.) Return battery 3.6 V DC 25 bar 187F3321

Heating / cooling DN 100 / qp 60 m³/h / 350mm flange M-Bus MWh (2 dig.) Return mains 230 V AC 25 bar 187F3322

Heating / cooling DN 100 / qp 60 m³/h / 350mm flange OMS 868.95 MWh (2 dig.) Return mains 230 V AC 25 bar 187F3323

Cable length of te mperature sensors is 3.0m .

Cable length b etween flow sensor an d energy calculator is 3.0m.

Nominal flow, size

and connection type

Comm.

module

Energy unit Installation

Power

supply

Operating

pressure

Code no.

Accessories

Product Designation Quantity Code no.

Power supply Battery 3.6 V DC (D cell) 1 pc. 187F3380

Power supply Mains unit 230 V AC 1 pc. 187F3381

Communication module M-Bus module 1 pc. 187F3382

Communication module Radio OMS 868.95 MHz 1 pc. 187F3383

Communication module RS-485 Modbus RTU 1 pc. 187F3384

Communication module RS-232 M-Bus 1 pc. 187F3385

Communication module RS-485 M-Bus

Communication module M-Bus, RS232 and two pulses outputs

Communication module M-Bus, RS232 and two 4-20mA outputs

1)

1)

1)

1 pc. 187F3386

1 pc. 187F3387

1 pc. 187F3388

Temperature sensor Pt 500 / f 5.2 mm / 1.5 m cable, MID 1 pair 187F312 5

Temperature sensor Pt 500 / f 5.2 mm / 2 m cable, MID 1 pair 187F312 6

Temperature sensor Pt 500 / f 5.2 mm / 3 m cable, MID 1 pair 187F3127

Temperature sensor Pt 500 / f 5.2 mm / 5 m cable, MID 1 pair 187F3390

Temperature sensor Pt 500 / f 5.2 mm / 10 m cable, MID 1 pair 187F3391

Sensor pockets Ø 5.2 mm, brass, 35 mm length 1 pair 087G6053

Sensor pockets Ø 5.2 mm, brass, 52 mm length 1 pair 087G6054

Sensor pockets Ø 5.2 mm, brass, 85 mm length 1 pair 087G6055

Sensor pockets Ø 5.2 mm, brass, 120 mm length 1 pair 087G6056

Sensor pockets Ø 5.2 mm, stainless steel, 85 mm length 1 pair 087G6057

Sensor pockets Ø 5.2 mm, stainless steel, 120 mm length 1 pair 087G6058

Sensor pockets Ø 5.2 mm, stainless steel, 155 mm length 1 pair 087G6059

Sensor pockets Ø 5.2 mm, stainless steel, 210 mm length 1 pair 087G6060

1) Only with mains suppl y 230 V AC

2 | VD.SH.V3.02 © Danfoss | 2019.04

Page 3

Data sheet SonoMeter 31 - Energy Meters

Technical specifications

Diameter D N 65 DN 80 DN 10 0

Connection type EN1092 flange

Overall length (mm) 300 350 350

Flow rate:

Nominal (m3/h) 25 40 60

Maximum (m3/h) 50 80 120

Standard min. (m3/h) 0.25 0.4 0.6

Star ting (m3/h) 0.10 0.16 0.24

Max. operating pressure 25 bar

Flow sensor temp. range 5 to 130 °C (short overload up to 150 °C)

Flow sensor cable length 3.0 m

Medium Water quality with pH 7 to 9.5

Pressure loss at qp, mbar 200 18 0 180

Measuring cycles Volume every 1 sec., energy, temperature sensors and display update every 10 sec.

Temperature sensors Pt 500 ø 5.2 mm with 2-wire leads

Temp. sensor cable length 3.0 m

Max. temp. diff. (∆θma x) 150 K

Min. temp. diff. (∆θmin) 3.0 K

Starting temp. diff. (∆θ) 0.15 K

Temp. measuring range 0 to 180 °C

Supply voltage 3.6 V DC Lithium-battery (D-cell) or Mains supply 230 V AC

Battery life time min. 10 years (including AMR communication)

Approval EN1434 class 2

Environmental class EN1434 class C

Ambient class class E2 + M1

Protection class Calculator: IP 65; Flow sensor: IP 65 (IP67 for heat and cooling meter)

Ambient operating temp. Calculator: 5 to 55 °C; Flow sensor: -30 to 55 °C

Ambient storage and

transportation temp.

Max. ambient humidity 93% rel. humidity

Display LCD, 8-digit

Display units MWh - kWh - GJ - Gcal - °C - m3 - m3/h

Display values Energy - volume - flow rate - power - temperatures

5 to 55 °C

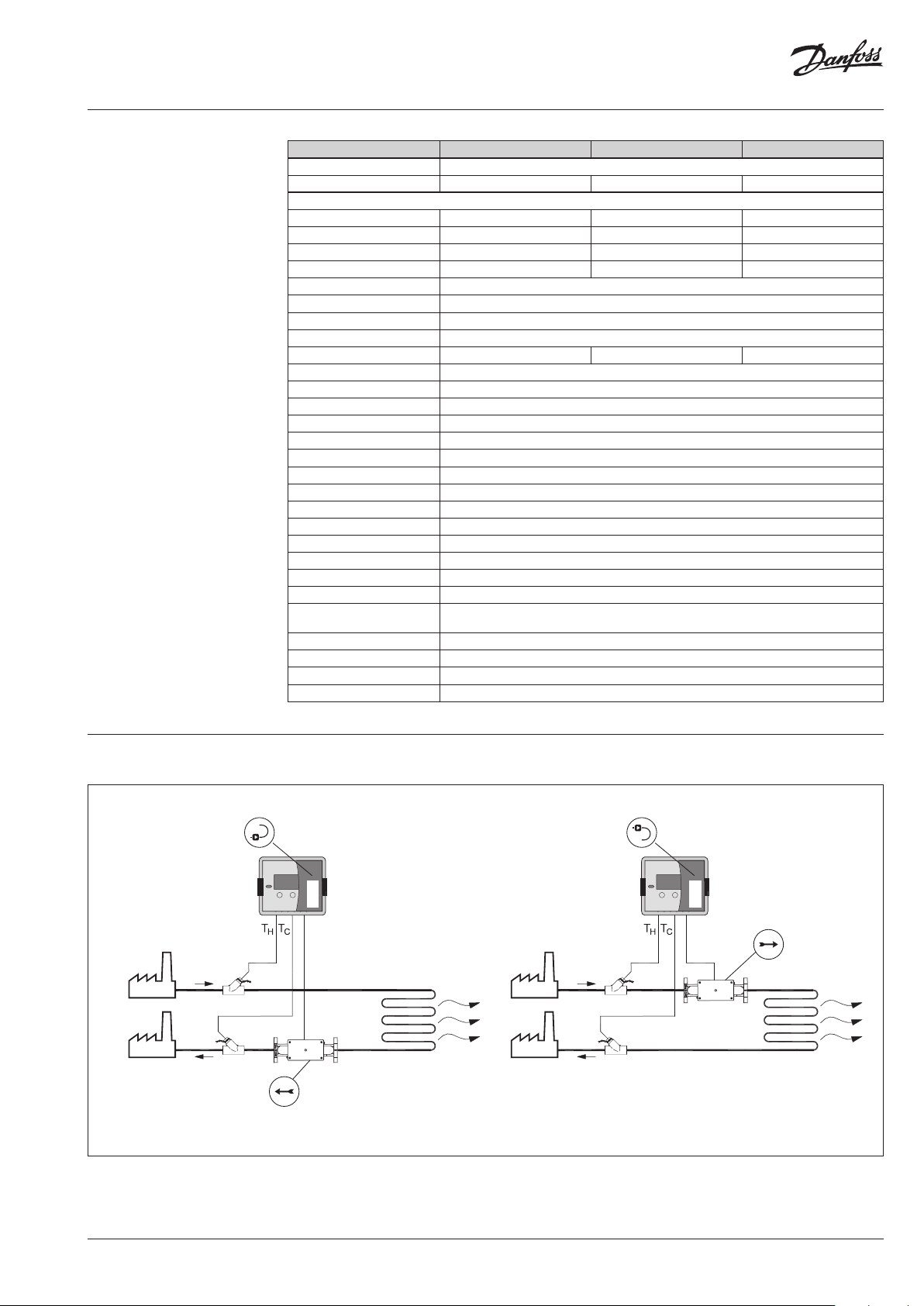

Application drawings

Return pipe installation Supply pipe installation

Flow direction

Flow direction

VD.SH.V3.02 | 3© Danfoss | 2019.04

Page 4

Data sheet SonoMeter 31 - Energy Meters

5

-1

-2

-3

-4

-5

Accuracy

4

3

2

1

0

Error [%]

Pressure loss

q

i

Measuring accuracy class 2

qpq

s

4 | VD.SH.V3.02 © Danfoss | 2019.04

Page 5

Data sheet SonoMeter 31 - Energy Meters

Design and function

Optical interface

Optical interface is integrated into the front panel of the calculator. It is designed for data reading via

M-bus protocol.

The optical interface is activated by pressing the control button and shuts automatically off 5 minutes

after the last pressing button or after completing data transmission via interface.

Wired M-Bus interface

The energy meter has 1 slot for an additional communication module. The internal M-Bus module

provides data reading possibility via M-Bus protocol:

• M-Bus protocol according to EN13757-3 standard

• 2-wire with polarity reversal protection

• Electrical isolation

• Maximum voltage 50 V DC

• Current drawn: one M-Bus load (1.5 mA)

• Primary or secondary addressing

• Baud rate 300/1200/2400/4800/9600 bps (default: 2400 baud rate)

• Battery lifetime min. 10 years (1 D cell)

• Fastest reading interval at battery supply: every 90 seconds (at 9600 b/s, internally protected)

• Fastest reading interval at mains supply: no limits (auto at order or manual if added later)

Radio OMS 868.95 MHz interface

The module can provide data reading via radio module:

• Wireless M-Bus protocol according to EN13757-4

• OMS (open metering system) compatible

• T1 mode (unidirectional)

• Sending interval every 90 seconds (suitable for ‘walk by’ readings)

Modbus RS-485 module

RS-485 module is Modbus RTU protocol and a serial interface for communication with external

devices.

Baud rate 1200, 2400, 4800, 9600 (default), 38400, 56000, 57600, 115200 bps

Polarity independent connection for power supply – connectors 60 and 61.

Power supply

Voltage 12-24 V AC/DC.

Maximum power consumption 2 W max.

Typical supply current 50 mA .

Pulse inputs

Data logger

Number of pulse inputs 2

Measurement units m

Pulse value configurable by control buttons

Min. pulse time 100 m s

Pulse type IB by LST EN1434-2

Max. frequency of input pulses 5 Hz

Max. voltage of input pulses 3.6 V

Data logger

3

Daily, weekly and monthly parameter values and

errors are recorded in heat meter memory:

Data logger capacity

up to 110 days (3,5 months) – for hourly records.

up to 1461 days (36 last months) - for daily and

monthly records.

Power supply Power supply (one of following depending on

meter configuration):

• 1 D-cell battery 3.6 V DC, 19 Ah (ER 34615)

lithium battery, life time at least 10 years.

• Mains power supply 230 V AC 50 (+/− 2) Hz .

Retention time of measured integrated

parameters even if device is disconnected from

power supply not more than 12 years.

VD.SH.V3.02 | 5© Danfoss | 2019.04

Page 6

Data sheet SonoMeter 31 - Energy Meters

Display symbols

description

Parameter and group numbers

Operation mode

Display menu structure

∑

1-2 3-4 5

Values

8:8:8.8.8.8.8.8

MAX

Group of parameters

Parameters shown Identification symbols

Integral values (L1)

Instantaneous parameters values (L2)

Set day parameters and archive data values (L3)

Printing reports by standard printer (L4)

Configuration settings parameters (L5)

Parametrization (configuration) mode (SET)

Test mode (TEST)

L1 L2 L3 L4 L5

HDM TEST SET

tm°/hkPa

°GJcal

MkWh

<R<MIN

L1 L2 L3 L4 L5

L1 L2 L3 L4 L5

L1 L2 L3 L4 L5

L1 L2 L3 L4 L5

L1 L2 L3 L4 L5

L1 L2 L3 L4 L5

L1 L2 L3 L4 L5

Measurement units

SET

TEST

Mounting

Pipe position: avoid position where air can

be collected.

Rotation in pipe axis

Inlet/outlet conditions In order to maximize performance it is necessary to have straight inlet and outlet flow conditions

before and after the flow sensor: 5 × DN on inlet and 3 × DN on outlet of flow sensor.

5 × DN 3 × DN

flow

6 | VD.SH.V3.02 © Danfoss | 2019.04

Page 7

Data sheet SonoMeter 31 - Energy Meters

Dimensions

Calculator

140

Flow sensor

sealing

159

142

80

119

~52

sealing

DN

65 / PN 16 300 185 185 145 200 4

65 / PN 25 300 185 185 145 200 8

80 350 200 200 160 215 8

100 350 220 220 180 235 8

L D H D1 B holes

mm

VD.SH.V3.02 | 7© Danfoss | 2019.04

Page 8

Danfos

produc

Al

Danfoss A/S

Heating Segment • heating

Data sheet SonoMeter 31 - Energy Meters

Dimensions (continuous)

Temperature sensors

Sensor pockets

Installation Typ e

Immersed (direct) or

in pocket (indirect)

Typ e Brass Stainless steel

Sensor

diameter

Length

(mm) ø 5.2 ø 5.2

L1

47 6 93 128 98 133 168 223

(mm)

L (mm) 35 52 85 12 85 12 155 21

Pt 5 ø 5.2 45

Diameter

D (mm)

Length

L (mm)

s can accept no responsibility for possible errors in catalogues, brochures and o ther printed material. Danfoss reserves the right to alter its products w ithout notice. This also applies to

ts already on order provided that such alterations can be m ade without subsequential changes being necessary in specications already agreed.

l trademarks in this material are p roperty of the respective companies. Danfoss and all Danfoss l ogotypes are trademarks of Danfoss A/S. All rights reserve d.

.danfoss.com • +45 7488 2222 • E-Mail: heating@danfoss.com

© Danfoss | DHS-SRMT/SI | 2019.048 | VD.SH.V3.02

Loading...

Loading...