Installation guide

SonoMeter 30

Ultrasonic energy meter

for heating and cooling applications

www.danfoss.com

Date

Issued by

Place of issue

Date

Approved by

2018.04.26

Nordborg, DK

2018.04.26

Page 1 of 1

Danfoss A/S

DK

De

CVR nr.: 20 16 57 15

Teleph

Fax:

Installation guide SonoMeter 30

-6430 Nordborg

nmark

one: +45 7488 2222

+45 7449 0949

EU DECLARATION OF CONFORMITY

Danfoss A/S

declares under our sole responsibility that the

Product(s):

Energy Meters

Type(s):

SonoMeter 30

covered by this declaration is in conformity with the following directive(s), standard(s) or other normative

document(s), provided that the product is used in accordance with our instructions.

• MID Directive 2014/32/EU Measuring Instrument Dir ective

Module B +D

o EN1434-4:2015

Notified Body: Lithuanian Energy Institute , 1621, performed type approval and issued certificate

• EMC D irective 2014/30/EU Electromagnetic Compatibilit y

• RoHS Directive 2011/65/EU Restriction of Hazardous substances

• RED D irective 2014/53/EU Radio Equipment Directive

• LVD Directive 2014/35/EU L ow Voltage Directive

LT-1621-MI004-022

o EN 61000-6-1:2007

o EN 61000-6-3:2007/A1:2011

o EN 55022:2010

o EN 50581:2012

o EN 300 220-2 V3.1.1

o EN 301 489-1 V1.9.2:2011-09

o EN 301 489-3 V1.6.1:2013-06

o EN 62311:2008

o EN 61010-1:2010

o EN 60950-1:2006/A11:2009/A1:2010/A12:2011/AC:2011/A2:2013

o EN 62311:2008

o EN 61010-1:2010

o EN 60950-1:2006/A11:2009/A1:2010/A12:2011/AC:2011/A2:2013

• PED Directive 2017/68/EU

1

For variants with Radio Module the declaration for EMC & LVD shall be ignored

2

For variants without Radio Module the declaration for RED shall be ignored

Kim Jessen

Approval Engineer, Danfoss Ener gy Metering

Danfoss only vouches for the correctness of th e English version of this declaration. In the event of the declaration being t ranslated into any other

language, the translator concerned shall be li able for the correctness of the translation

ID No: VJSHO202 Revision No: 1

Danfoss Energy Metering

1

2

1

Jeppe Molleskov Blasbjerg

Energy Metering Category Manager

2 | © Danfoss | Energy Meters | 2020.11 BC200586470576en-020601

Installation guide SonoMeter 30

1. Installation

1.1. Preparation

Only qualified personnel may install the equipment, following the requirements listed in this document.

More detailed instruction can be found on www.heating.danfoss.com.

Note! This product is approved for ambient temperature between 5-55° C, but to ensure optimal conditions for

battery it is recommended to install Calculator at max. 45° C. Avoid installation stress from pipes and fittings.

Flush the system.

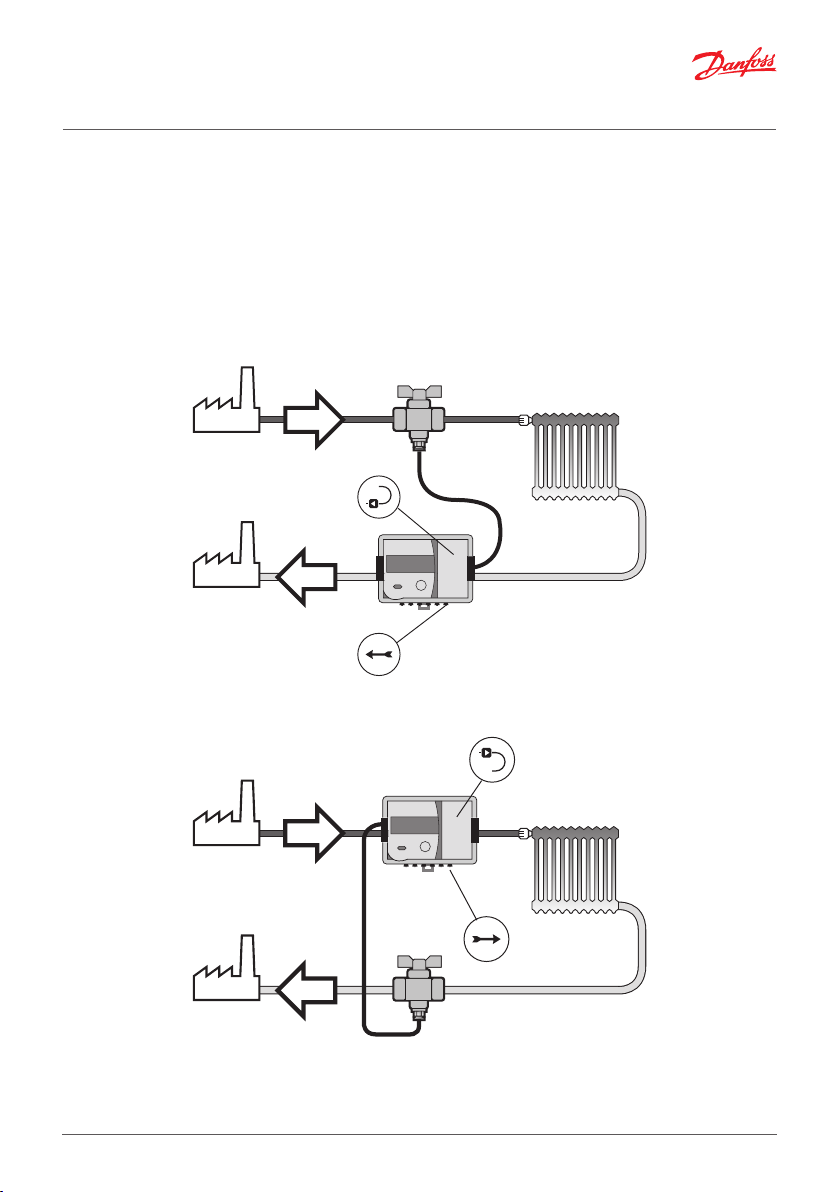

1.2. Identification of installation: Return/Supply pipe installation and flow direction

Flow direction

Return pipe installation

Flow direction

Supply pipe installation

BC200586470576en-020601 © Danfoss | Energy Meters | 2020.11 | 3

Installation guide SonoMeter 30

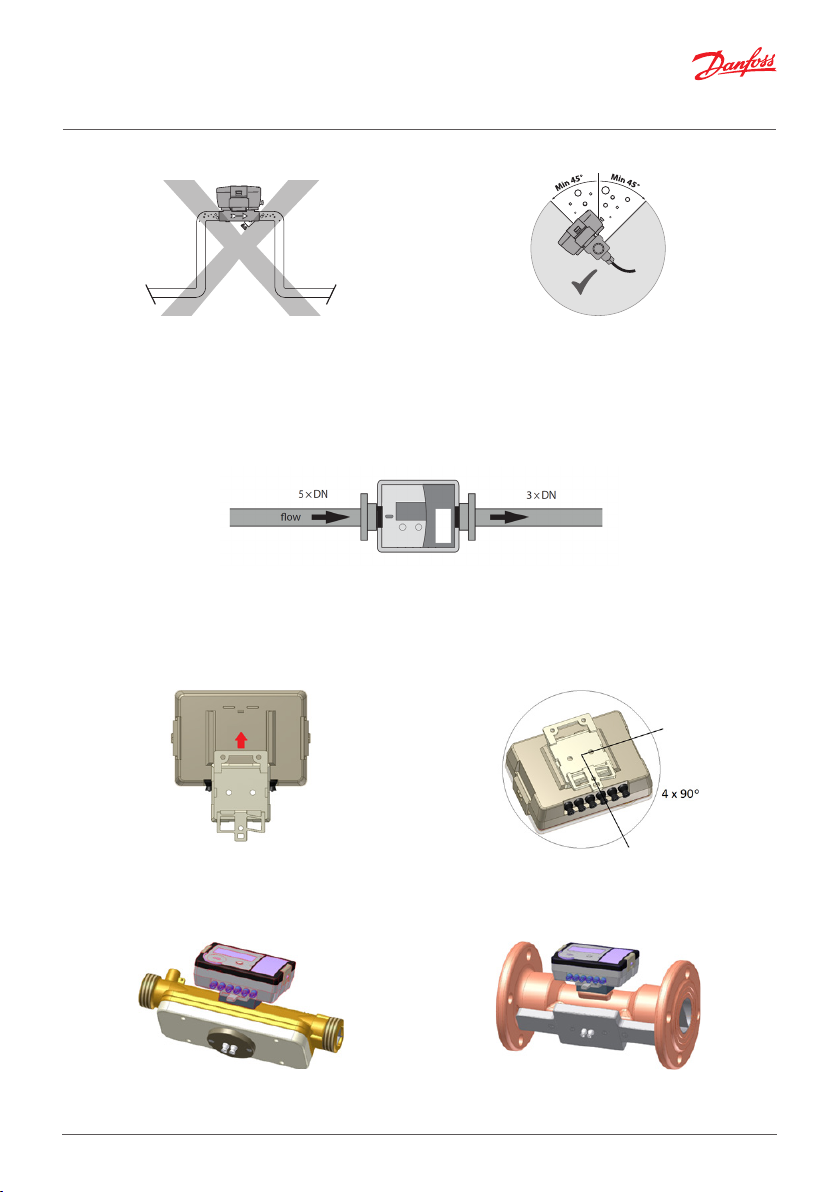

1.3. Mounting of flow sensor

Pipe position: No limitations but avoid positions

where air can be collected.

Inlet/outlet conditions (only for DN 65-DN 100)

In order to maximize performance it is necessary to have straight inlet and outlet flow conditions before

and after the flow sensor: 5 × DN on inlet and 3 × DN on outlet of flow sensor.

1.4. Mounting and sealing of calculator

Heat meter calculator may be installed in heated premises, working ambient temperature shall

be not more than 55 °C. It may not be exposed to direct sunlight.

The calculator is mounted on an auxiliary holder (it can be oriented in the required direction at an angle of

each 90 °:

The possible ways of the mounting of the calculator (auxiliary holder):

- Direct mounting on the housing of the flow sensor, by turning each 90o (only when the flow temperature

does not exceed 90oC):

Rotation in pipe axis: Flow sensor should be angled

in 45 to 315° to avoid air collection in flow sensor.

4 | © Danfoss | Energy Meters | 2020.11 BC200586470576en-020601

Installation guide SonoMeter 30

- On the wall:

- Panel mounting on standard DIN-rail.

- Adapter plate according to figure 8 of EN1434-2:2007 for wall mounting of calculator can be used (if the

aperture in the wall is too large for the calculator):

Important: It is forbidden to attach the calculator directly to a wall if there is a risk that on walls can

be condensed humidity or temperature of a surface of a wall can fall lower than 5°C. In this case, it is

recommended to attach the calculator so that between it and wall surfaces there was an air gap not

less than 5 cm.

BC200586470576en-020601 © Danfoss | Energy Meters | 2020.11 | 5

Installation guide SonoMeter 30

Seal

Seal

Seal

ocket

Calculator seals

1: Manufacturer adhesive seal-sticker on the access to the adjustment activation jumper -verification seal.

2: Manufacturer adhesive seal-sticker on the fixer of the cover protecting electronic module -manufacturer

security seal.

3: Mounting seal after installation.

1.5. Mounting and sealing of temperature sensors

Installation recommendations for

ball valve mounting and sealing

Seal

Pocket

a) angled 45°

Installation recommendations for pocket temperature sensors with permanently connected signal leads.

6 | © Danfoss | Energy Meters | 2020.11 BC200586470576en-020601

Installation recommendations for

direct short temperature sensors

P

b) perpendicular

Installation guide SonoMeter 30

1.6. Setting up the jumpers (J)

The connector J is on the calculator plate between the temperature sensors and pulse input / output connection terminals (see 6.3). Joining or leaving open the connector contacts, you can choose the normal or

verification (test) mode, activate the pulse inputs or outputs:

Jumper is not set

(contacts are opened)

NORMAL MODE VERIFICATION (TEST) MODE

The first pulse output V1 is active

(terminals 52,53).

Energy as default.

The second pulse output V2 is active

(terminals 50,51).

Volume as default.

Note: On delivery the heat meter is configured with two outputs.

2. Electrical wiring

Wiring diagram 1

Jumper settings:

1: Additional pulse input V2 is on.

2: Additional pulse input V1 is on.

Jumper is set

(contacts are connected)

The first pulse intput V1 is active

(terminals 52,53)

(Jumper must be removed when

operating in TEST mode)

The second pulse intput V2 is active

(terminals 50,51)

(Jumper must be removed when

operating in TEST mode)

T1: flow temperature sensor.

T2: return temperature sensor.

V1: additional pulse input/output 1.

V2: additional pulse input/output 2.

7 | © Danfoss | Energy Meters | 2020.11 BC200586470576en-020601

Installation guide SonoMeter 30

Wiring diagram 2

Connecting the meter to the mains

power supply, 24 V AC/DC.

230 V AC to 24 V AC transformer

must be used for connection to

230 V AC!

Calculator

Terminals Description

5 T1 supply temperature sensor

6 T1 supply temperature sensor

7 T2 return temperature sensor

8 T2 return temperature sensor

50 V2 additional pulse input/output GND

51 V2 additional pulse input/output (Volume output in TEST mode)

52 V1 additional pulse input/output GND

53 V1 additional pulse input/output (Energy output in TEST mode)

Communication modules

Terminals Description

24, 25 M-bus module (bipolar)

60, 61 12-24 V DC power supply voltage for Modbus and LON (bipolar)

90 RS-485 Modbus RTU module (+) or BACnet (+)

91 RS-485 Modbus RTU module (+) or BACnet (+)

96 LON module (line A)

97 LON module (line B)

8 | © Danfoss | Energy Meters | 2020.11 BC200586470576en-020601

Installation guide SonoMeter 30

External power supply module

Terminals Description

54 Mains supply 24 V AC/DC (bipolar)

55 Mains supply 24 V AC/DC (bipolar)

3. Commissioning

3.1. Bleeding

1. Bleed the system until the flow rate display is steady.

2. Make sure no error codes are displayed.

3. Check the display for a plausible indication of flow rate and temperatures.

3.2. IP class

Calculator IP65

Flow sensor IP65 for heat meter

IP67 for heat and cooling meter

4. Display function overview

4.1. Menu structure

L1

Integral parameters

L2

Statistical data

L3

Informative parameters

9 | © Danfoss | Energy Meters | 2020.11 BC200586470576en-020601

1.1 1.2 1.3 1.4 1.51.6 1.7

2.1 2.2 2.3 2.4 2.52.6.1 2.7.12xx 2.15.1

3.1 3.2 3.3 3.4 3.5

3.6.13.7 3x 3.15

1.8

1.9

Long press

Short press

Installation guide SonoMeter 30

4.2. Display symbols

Explanation of special symbols:

flow is flowing forward (right direction)

flow is flowing backwards (wrong direction)

no arrow

Explanation of other symbols are described in detailed instruction on www.heating.danfoss.com.

no flow

4.3. Error codes

Error codes may consist of up to 4 symbols.

Each symbol may have values 0…8

L1 L2 L3

Calculate errors

Temperature 2 errors

Temperature 1 errors

Flow errors

Code Description

Status of calculator 0 - no error, normal operation

1 - warning – ending battery life

2 - temperature difference is greater than the permitted limits

4 - temperature difference is less than the permitted limits

8 - electronics failure

Status of temperature

sensor 2 (return pipe)

0 - no error, normal operation

4 - short circuit

8 - sensor failure (open circuit or short circuit)

Status of temperature

sensor 1 (flow pipe)

0 - no error, normal operation

4 - short circuit

8 - sensor failure (open circuit or short circuit)

Status of flow sensor 0 - no error, normal operation

1 - no signal, flow sensor is empty

2 - flow flows in an reverse direction

4 - flow rate greater than 1.2∙qs (are displayed q = 1,2qs)

8 - electronics failure

Active error codes are added and simultaneously displayed, if more than one error is detected:

• 3 - corresponds errors 2 + 1

• 5 - corresponds errors 4 + 1

• 7 - corresponds errors 4 + 2 + 1

• 9 - corresponds errors 8 + 1

• A - corresponds errors 8 + 2

• B - corresponds errors 8 + 2 + 1

• C - corresponds errors 8+4

• D - corresponds errors 8 + 4 + 1

• E - corresponds errors 8 + 4 + 2

• F - corresponds errors 8 + 4 + 2 +1

10 | © Danfoss | Energy Meters | 2020.11 BC200586470576en-020601

Installation guide SonoMeter 30

5. Disposal

This symbol on the product indicates that it will not be treated as household waste.

It must be handed over to the applicable take-back scheme for the recycling of electrical and electronic equipment. For more detailed information about the recycling

of this product, please contact your local municipal office.

Item Material Disposal

Battery

PCBA with display

Cables Copper with PUR or PVC jackets Cable recovery

Flow sensor (incl. trans-

ducer and liner)

Transducer PZT, stainless steel, PEI Approved deposit for PZT

Other plastic parts PC, PPS, PEI, TPE Plastic recovery

AA-cell lithium/thionyl chloride 700 mg

lithium

Coppered epoxy laminate components

soldered on, PC, TPE

Brass, stainless steel, PPS Metal recovery

Approved deposit for lithium

batteries

Electronic waste

6. Local Importer name and address

For goods delivered to UK, importer name and address is:

Danfoss Ltd.

Oxford Road

UB9 4LH Denham

UK

11 | © Danfoss | Energy Meters | 2020.11 BC200586470576en-020601

12 | © Danfoss | Energy Meters | 2020.11 BC200586470576en-020601

Loading...

Loading...