Page 1

Installation Guide

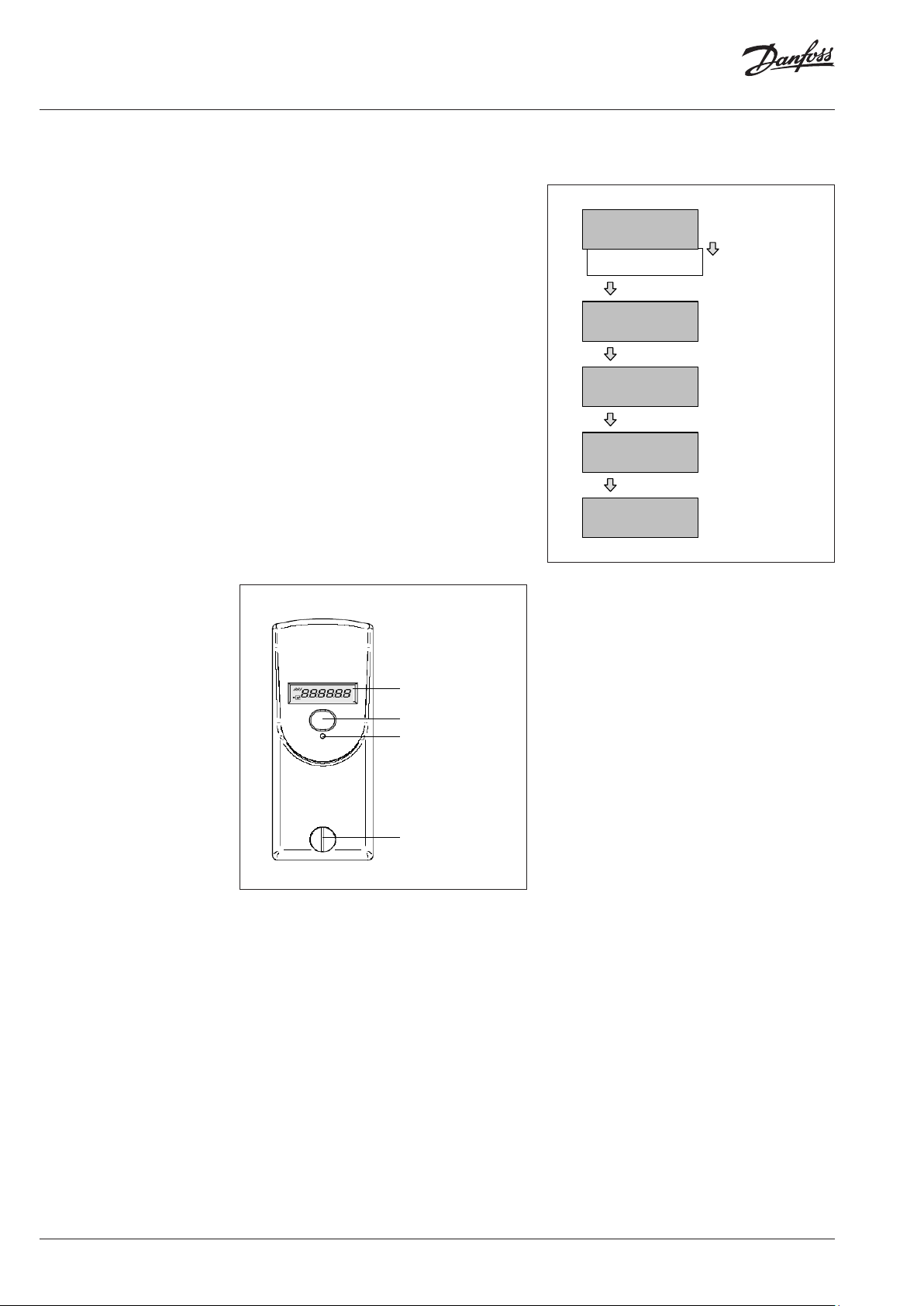

LC-Display

Optical Interface

Push Button

Seal

Electronic Heat Cost Allocator

SonoHCA

1 Specification

1.1 General Description

1.1.1 Type

1.1.2 Design

The heat cost allocator consists of a

microprocessor, a lithium battery, two

temperature sensors, a heat conducting

aluminium back plate, a multi-functional display

and a plastic housing.

The measuring circuit consists of the

temperature sensors, the analogue-digital

The electronic heat cost allocators SonoHCA

operate with the double sensor principle. The

device has been developed and approved

in accordance with the European Standard

EN 834 :2013.

conversion, the reference resistance for

standardising the measuring transformation and

the microprocessor for accessing the radiator

heat output. During each measuring the circuit

tolerances are eliminated with a reference

resistance and the heat cost allocator carries out

an automatic self-test.

Standard aluminium back plate

for nearly all existing bolts with

common dimensions and mounting

possibilities – thus easy installation

© Danfoss | 2019.05 VI.SH.R1.02 | 1

Snap-on blind to cover

colour shadows for

increased aesthetics

Page 2

Installation Guide SonoHCA

1.1.3 Characteristics

1.1.4 Display

• Measuring by two temperature sensors,

radiator and ambient temperature sensor

(NTC-resistor).

• Unit scale or product scale.

• Recording of cumulated heat consumption on

the annual set day.

• Recording of 144 monthly values and 18

half monthly values for cumulated heat

consumption.

• Recording of 18 monthly values for the

maximum radiator temperature.

• Optical interface for the readout of the data

and programming

• The radio module comprises a unidirectional

radio transmitter.

Two telegrams: short telegram, OMS

compliant and long telegram for Walk-by

reading.

• User-friendly operation by push button.

• 6-digit and high-contrast LCD display.

• Automatic commissioning during the

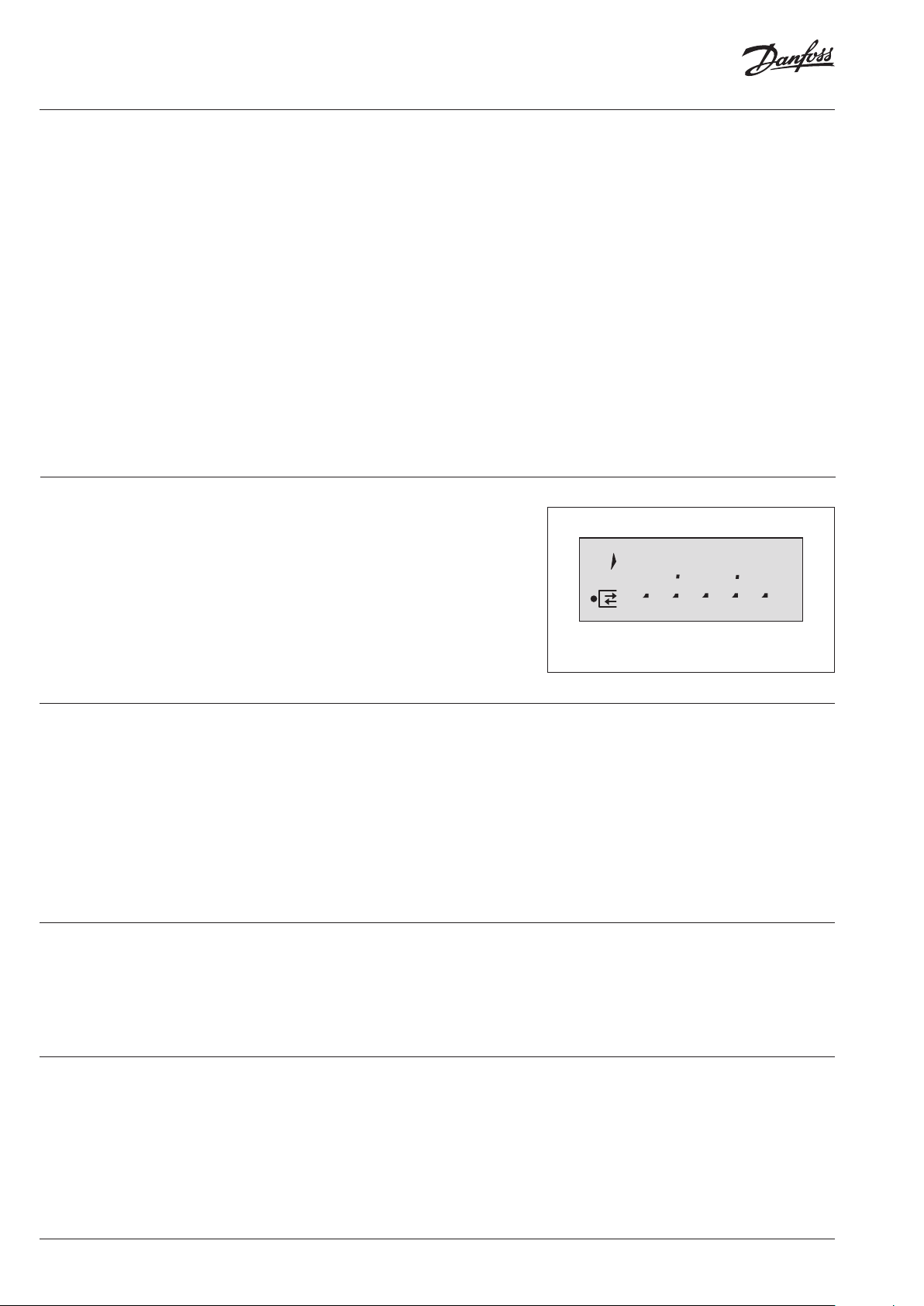

The heat cost allocator has a LCD-display with 6

large main digits on the right and 2 smaller digits

on the left as well as two special symbols and

one communication indicator. The main digits

are separated by four decimal points. Please find

the display segments:

mounting on the aluminium back plate

(available when ordering).

• Check code for postcard mail-in method

• Possibility to connect a remote sensor on each

version of heat cost allocator. The remote

sensor will be automatically detected by the

heat cost allocator.

• Remote sensor version with 2 m cable.

• Standard aluminium back plate for nearly

all existing bolts with common dimensions

and installation possibilities – thus easy

installation (no cutting and welding of bolts

necessar y).

• Snap-on blind to cover colour shadows for

increased aesthetics.

• Safe operation and fraud/manipulation

detection.

• Lithium battery with a capacity of up to 10+1

year.

• Meets EN 834:2013.

88

888888

1.1.5 E lec tronics

1.1.6 Optical Interface

Normally, the heat cost allocators are supplied

with switched-off LCD-display. On request, the

heat cost allocators can also be supplied with

permanent LCD- display.

The device has an electrical circuitry with

an 8-Bit-CMOS-micro controller of the latest

generation STM8L with extremely low current

consumption operating at a voltage as from

1.8 V.

The temperature measuring circuit with

automatic self-calibration measures the

discharging time of a capacitor. The accuracy

of the measuring circuit is independent of the

supply voltage.

With a standardised optical probe the

consumption and configuration values can

be transferred directly to a computer. All

consumption values can be readout over the

optical interface and over radio. The data are

Display with all active segments

For SonoHCA it is possible to plug the connector

of the remote sensor to an interface inside the

heat cost allocator. Refer to chapter 2.3 Mounting

the Remote Sensor.

Once equipped with a remote sensor, the heat

cost allocator will only work for an application

with remote sensor.

Remote sensor version with 2 m cable.

transmitted in M-bus-format acc. to EN136757-3.

Authorised personnel can alter the configuration

of the device over the optical interface with an

optical probe.

1.1.7 Radio Transmission

wM-Bus

2 | VI.SH.R1.02 © Danfoss | 2019.05

The radio heat cost allocator features a

transmitter circuit in the 868 MHz band with

integrated antenna.

This radio module comprises a unidirectional

radio transmitter which is used to transfer data

according to the wM-Bus (EN 13757-4) radio

communication protocol and in compliance with

the OMS (Open Metering System) Release V3.0.1.

• Please refer to chapter 1.7.4 Operation Mode

for Radio wM-Bus (SonoHCA) for the radio

reading range.

Page 3

Installation Guide SonoHCA

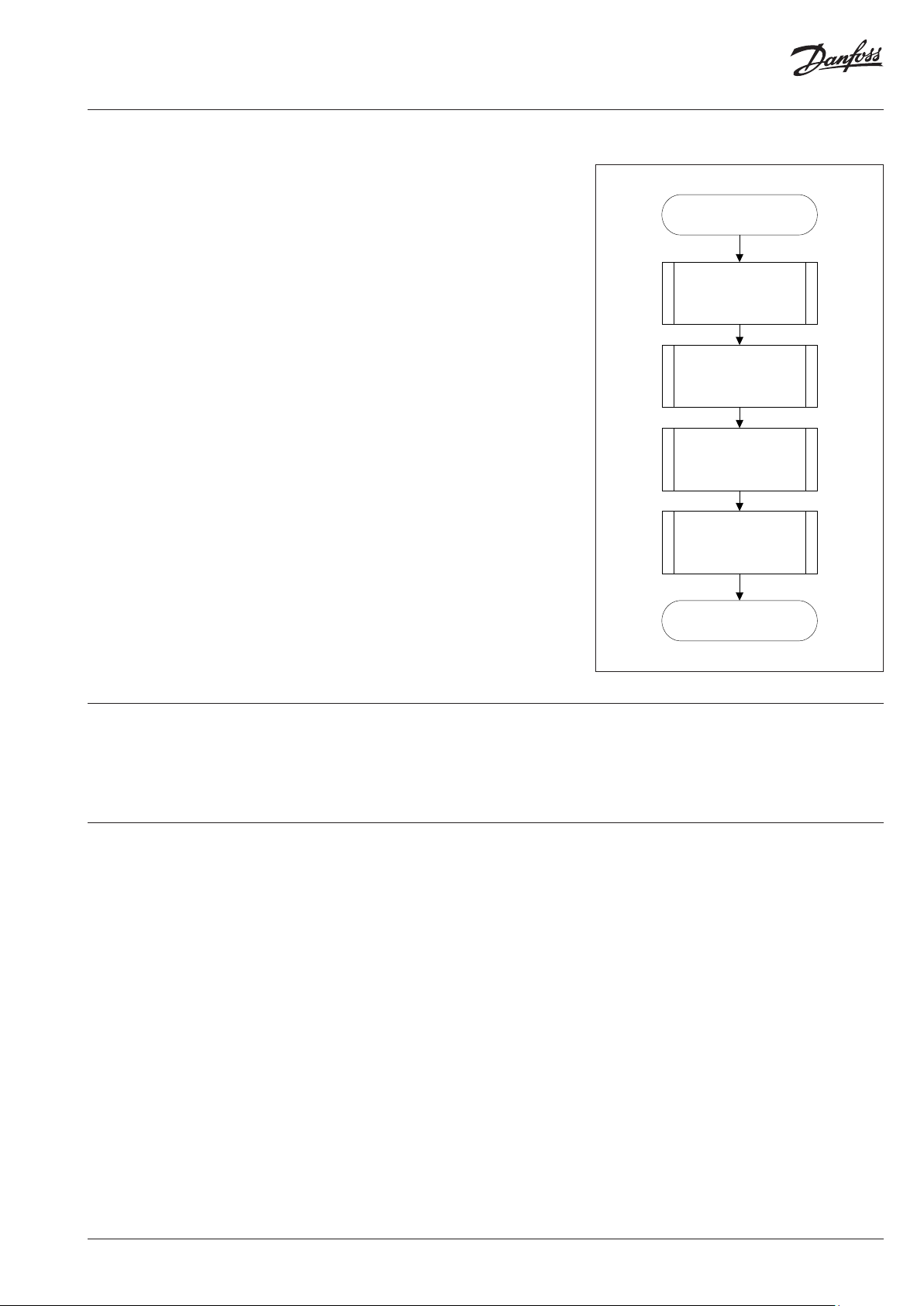

Start of cylce

Measuring and

calculation of the

temperature

Calculation of the

new consumption

value

Update time and

date

End of cycle

Update display

1.2 Operating mode

1.2.1 Cycle Time

SonoHCA operate in a cycle of 4 minutes. Most

of the time, the device is in sleeping mode. Every

4 minutes the device is set into operation and

operates according to the adjoining diagram.

The clock-pulse generator is a counter which is

completely independent from the rest of the

program. This counter is designed in a way so

that it is impossible to stall the cycle or to skip

one or more cycles.

Each cycle follows the adjoining diagram.

The measuring and calculating processes are

explained in detail later.

The tasks carried out during one cycle are taking

approx. 100 ms. This means that the device is in

sleeping mode more than 99.8 % of the time. It

can be set into operation between two cycles

over the optical probe or by pushing the button.

In this case it carries out the requested task and

then returns to sleeping mode.

In case an optical probe is connected or the

button is pushed during the course of the cycle,

the respective value is readout at the end of the

cycle.

The button can be pushed for an indefinite

period of time and the optical probe can be

left in its position since the normal function of

the device is not impaired by an influence from

outside.

1.2.2 Double Sensor real temperature, measured by the ambient

1.2.2.1 Heat Accumulation

Mode

For the double sensor version basically the

same specifications apply as for the single

sensor version with start sensor. However,

for calculating the room temperature the

In order to avoid faulty measuring due to heat

accumulation (e.g. in case the radiator is hidden

by panels), the device switches from a defined

ambient temperature (e.g. 28 °C) to the one

temperature sensor (corrected via the

corresponding radiator-dependent „K

is used as the basis.

sensor mode and calculates with an ambient

temperature of 20 °C.

-value“),

air

VI.SH.R1.02 | 3© Danfoss | 2019.05

Page 4

Installation Guide SonoHCA

NTC

1.2.3 Comparison of the

Measuring Principles

1.2.4 Temperature

Measurement and

Calculation

1.2.4.1 Measuring of a

Resistor, Principle

Double sensor measuring principle

For heating systems with tm

≥ 35 °C

min

The heat cost allocator calculates with a variable

reference temperature T

air temperature

Application:

Double sensor devices are used in areas where

precise measuring of the ambient temperature

is necessary and/or in low temperature heating

systems.

Radiators which are covered or blocked by

fixtures are detected automatically by the

double sensor system which then switches over

internally to the single sensor mode.

The temperature is measured with an NTC –

resistor. For the resistance measurement the

discharging time of the capacitor is measured.

The measurement is carried out as follows:

1. Charging of the capacitor

2. Discharging of the capacitor through the

resistance which is to be measured. At the

same time a 16+1 bit-timer starts with the

discharge to measure the discharging time

3. As soon as the voltage on the capacitor

terminals reaches a certain value, an interrupt

is induced and the timer stops. At the same

time the discharging of the capacitor is

stopped as well.

Within one billing unit, only one measuring

principle (either single sensor measuring

principle with start sensor or double sensor

measuring principle) can be used. Mixed

fitments or the use of different types of

devices in the same billing unit is therefore

also not allowed.

The processes for determining the K-value for

the single sensor device with start sensor and the

double sensor device are identical. It is only the

measuring principle that is different.

After the three mentioned stages, the timer

provides a 16-bit-value which corresponds to the

discharging time of the capacitor through the

resistance which is to be measured. In case the

resistance is known (reference resistance), the

constant ratio between discharging time and

resistance can be assessed.

1.2.4.2 Calculation of

the Value of an Unknown

Resistance (e.g. sensor

resistance)

1.2.4.3 Measuring of

the Radiator and Ambient

Temperature

The capacitor C is loaded at constant current. The

interrupt at the end of the discharge is triggered

by the same threshold voltage (a fraction of the

discharge voltage). If these two conditions are

met, the dis-charge time is directly proportional

to the resistance. With a reference resistance R

whose exact value is known, it is now possible to

ref

calculate the unknown resistance value Rx with

The following measurements are carried out

during one cycle:

1. Measuring of the reference resistance R

2. Measuring of the ambient temperature

sensor NTC

3. Measuring of the radiator temperature

sensor NTC

A

R

ref

The measuring values are calculated with the

following formula:

t

NTC

A R

R TC

= ⋅ = ⋅ N

A

t

ref

ref R

t

NTC

R

ref

t

ref

the following equation:

tRt

ref

= ⇒ = ⋅

R

refXX

From this equation the self-calibration of the

converter can be derived, which is given by

t

X

R

R

X

ref

t

ref

measuring the discharging time through the

reference resistance.

The reference resistance value is defined ex

works with a tolerance of 0.5% with 50 ppm.

The reference resistance features an excellent

temperature and long-term stability.

The capacitor value and the threshold voltage

have to remain stable over the whole cycle.

However, they can vary at the medium- or long

term without causing any failures because the

self-calibration of the con-verter is repeated

in every cycle while measuring the reference

resistance.

4 | VI.SH.R1.02 © Danfoss | 2019.05

Page 5

Installation Guide SonoHCA

= ∗∫ (

−

60

)

1.33

1.2.5 Calculation of the

Displayed Consumption

Value

1.2.6 Start of Counting

The value displayed on the heat cost allocator is

calculated as follows:

Double sensor device

Explanation: TH Temperature of the radiator surface in [°C]

TA Ambient temperature in [°C]

Q Displayed consumption value, without unit

Kc Factor that carries back the ΔT measured at a normalized value

Kq Factor Kq is a numerical value of the nominal power of the radiator

stated in [kW].

Unit scale: Kc = 1 and Kq=1.

Product scale: Kc <> 1 and Kq <> 1

The updating (increment) of the consumption

value is carried out under the following

conditions:

During winter period (heating period):

(TR ≥ 25 °C)

Or

(TR ≥ 20 °C ) E (TR - TA ≥ ΔT

MIN

)

During summer period (off heating period):

(TR ≥ 35 °C)

Or

(TR ≥ 20 °C ) E (TR - TA ≥ ΔT

MIN

)

Explanation:

TR Radiator temperature

TA Ambient temperature

ΔT

Minimum temperature difference

MIN

between radiator and room

3K for standard device (winter heating

period standard setting)

4K for remote sensor device (summer

heating period standard setting)

Note:

The thresholds of starting (25°C et 35°C) are

indicative values. These temperatures of starting are

adjust-ed according to the needs and specificities of

the customer.

VI.SH.R1.02 | 5© Danfoss | 2019.05

Page 6

Installation Guide SonoHCA

LC-Display

Optical Interface

Push Button

Seal

1.3 Display and

Additional Functions

1.3.1 The Menu

Sequences of the Digital

Display

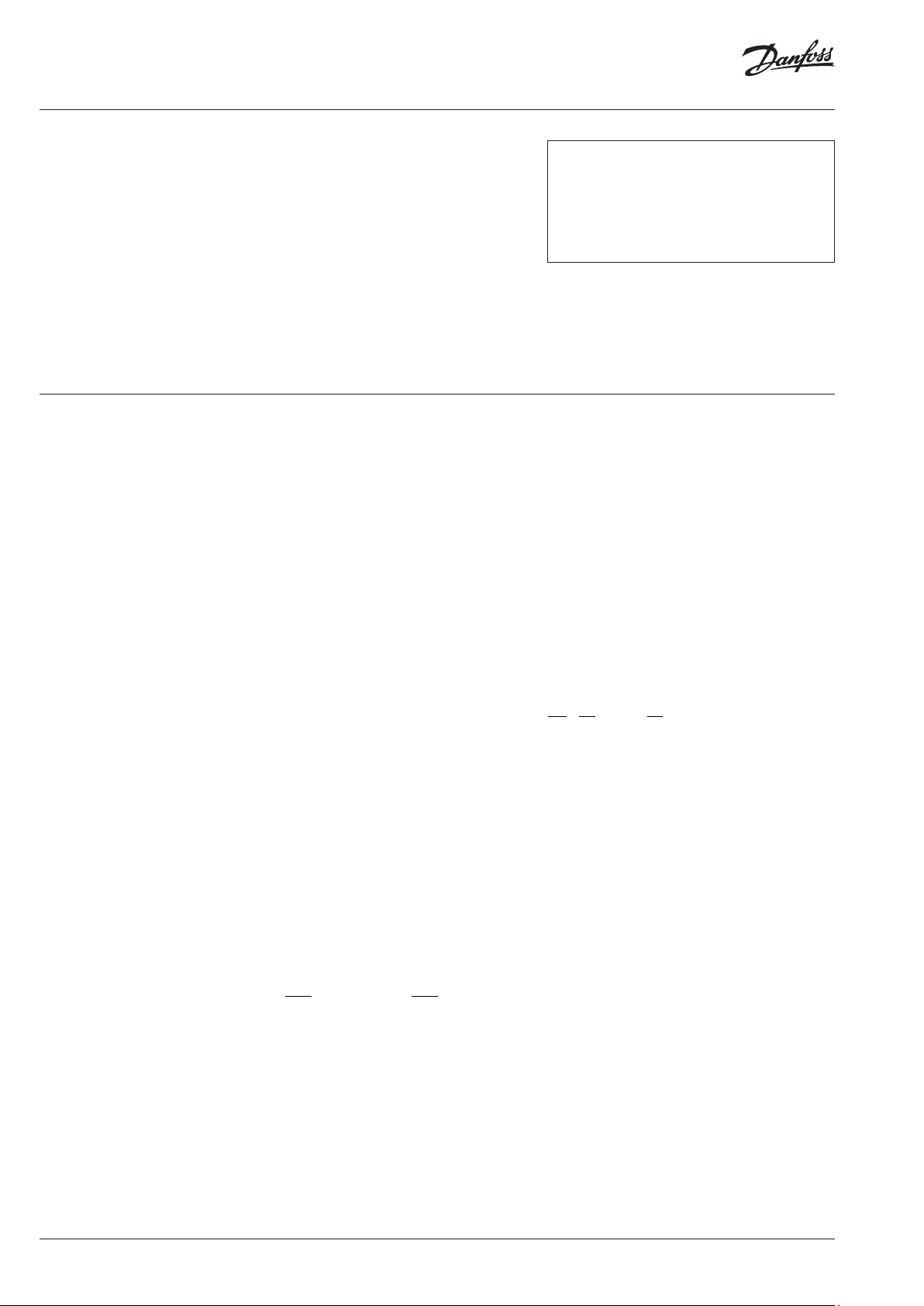

The menu sequences

Ex factory all menu sequences are activated.

With a software the order of the menu

sequences 1 - 15 can be changed in any order.

However the order within the individual menu

sequences 1 – 15 cannot be changed. It is also

possible to hide individual menu sequences so

that they are not visible to the end-user.

When reading out over the optical interface

or via radio the complete set of data is always

readout and transferred.

Operation of the Push Button

When pushing the button briefly the digital

display always goes to the next menu sequence.

When pushing the button in one menu sequence

for 2 seconds the individual values within the

selected menu sequence can be accessed. When

the last value within one menu sequence has

been displayed, the 1st position will be displayed

by pushing the button again.

If the button is not pushed for 2 minutes,

the digital display returns to the cumulated

consumption value.

Consumption value

36 Monthly Values

Short key press

Current time

Short key press

Current date

Short key press

Set Day value

Short key press

Radiator temperature

Display position 1

Long key press

Display position 2

Display position 3

Display position 4

Display position 5

6 | VI.SH.R1.02 © Danfoss | 2019.05

Page 7

Installation Guide SonoHCA

002345

000000

54321

290515

1.3.2 The Digital

Displays

During normal operation the display is

deactivated and can be activated by pushing the

button.

If the button is not pushed, the display will be

active for 2 minutes only.

On request, the heat cost allocator is also

available with permanent display 24h/24h or

with a rolling menu displayed.

Consumption Value Unit Scale

u

002345

Consumption Value Product Scale

Display in Euro

Eu

43725

On the display of the heat cost allocator with

unit scale an index u for unit is shown on the left

side. If the index u is not displayed, the heat cost

allocator is equipped with the product scale.

When commissioning the device this value is

000000. When reaching the value 999999, the

counting restarts automatically at 000000.

The heat cost allocators have the option to

display the heating cost in Euro.

The cost in Euro indicated on the display is only

approximate and is based on historical values

from the previous year.

The displayed cost does not necessarily

represent the charges to be paid.

Manufacturer and supplier decline any claims

concerning the use and interpretation of the

indicated values.

This option can be activated via a software.

Set day Value

Sd

002345

Sd

Check code

CC

Time

14h27

Date

With the index Sd the consumption value

recorded at midnight of the set day is displayed.

The consumption value recorded can be in unit

scale or in product scale. It’s depending of the

unit setting.

If a new device has not yet reached the

programmed set day, 000000 is displayed.

With the index CC the check code for the

plausibility check of the manual readout is

displayed.

The current time (always winter time).

The current date of the heat cost allocator.

VI.SH.R1.02 | 7© Danfoss | 2019.05

Page 8

Installation Guide SonoHCA

2905--

020615

1568

32

002345

002345

158

123456

1.3.2 The Digital

Displays (continuous)

Set Day

Sd

Date of Opening of the Device

od

290515

Data messa in funzione

Cd

Cumulated Duration of the Opening of the

Device

du

It is possible to program an annual set day on

which the cumulated consumption value as

well as the maximal radiator temperature are

recorded.

With the index Sd the programmed annual set

day is displayed.

Each heat cost allocator is equipped with a

manipulation protection which detects an

unauthorised opening of the device after

installation to the radiator. The date of the last

opening of the device is recorded and displayed

with the index od.

With the index Cd the commissioning date is

displayed, i.e. the date on which the device has

been activated by pushing the button or during

the mounting of the aluminium back plate if the

function automatic commissioning is set.

With the index du, the cumulated duration in

minutes during which the device was opened

is detected. This display turns up only after

commissioning in case the heat cost allocator

was opened or removed.

Fraud Counter

fc

Identification Number

15

Running Hours

rh

Monthly Values

01

36

This value indicates how many times the fraud /

manipulation was activated.

With the index an 8 digit identification number

is displayed. Ex factory the serial number is

identical with the identification number. The

first two digits of the identification number are

the two small digits on the left upper side of the

digital display.

With the index rh, the running hours is displayed.

This value can be compared to the battery use

duration.

The cumulated consumption values are recorded

automatically at midnight on the last day of each

month.

Number of monthly values: 36

The small digits on the upper left side show

the number of previous monthly values. Digit

01 stands for the recent full month and digit 36

stands for the least recent month. All monthly

values are set to 000000 when the device is

commissioned.

Note:

Short telegram, OMS compliant: no monthly values transmitted via radio telegram.

Long telegram for Walk-by reading, the first 18 monthly values transmitted via radio telegram.

8 | VI.SH.R1.02 © Danfoss | 2019.05

Page 9

Installation Guide SonoHCA

002345

002345

359 'c

359 'c

Fir003

1.3.2 The Digital

Displays (continuous)

Half Monthly Values The cumulated consumption values are recorded

41

58

Note:

Short telegram , OMS compliant and long

telegram for Walk-by reading: no half monthly

values transmitted via radio telegram.

Radiator Temperature

tr

automatically at midnight on the 16th of each

month.

Number of monthly values: 18

The small digits on the upper left side indicate

the number of half monthly values. Digit 41

stands for the recent half monthly value and digit

58 for the least recent half monthly value. All

half monthly values are set to 000000 when the

device is commissioned.

With the index tr the current radiator

temperature is displayed.

689 'c

Ambient Temperature

tA

With the index tA the current ambient

temperature is displayed.

257 'c

Maximum Radiator Temperature of the

Current Heating Period

With the index ΠΨ the maximum radiator

temperature of the current heating period (since

the Set Day) is displayed.

Maximum Radiator Temperature of the

Previous Heating Period

Sd

Monthly Value for Maximum Radiator

Temperature

327 'c

01

327 'c

18

327 'c

Software Version

With the index Sd the maximum radiator

temperature of the previous heating period

(before the Set Day) is displayed.

With the index ΠΠ the maximum radiator

temperature of the currently month is displayed.

Number of monthly values: 18

Recording of 18 monthly values for the maximum

radiator temperature.

The small digits on the upper left side show

the number of previous monthly values. Digit

01 stands for the recent full month and digit 18

stands for the least recent month.

All monthly values are set to 000000 when the

device is commissioned.

On the right side the software version x.x.x of the

heat cost alloca-tor is displayed.

Measuring Principle The index -- or FF indicates the type of the

--

radiator sensor:

-- = Standard device, compact sensor.

FF = Remote sensor device, remote sensor.

2 SENS = double sensor device.

VI.SH.R1.02 | 9© Danfoss | 2019.05

Page 10

Installation Guide SonoHCA

Short

1.3.2 The Digital

Displays (continuous)

1.3.3 Rolling Digital

Display

Segment Test

88

888888

Error Message

err 2

wM-Bus mode

lon6

SonoHCA also feature the possibility of a rolling

display 24h/24h.

With a software, it is possible to individualize the

rolling display.

Up to 15 parameters can be chosen optionally

from the list below. These parameters can be

combined in any order and are then shown on

the rolling display.

• Consumption value

• Time

• Date

• Set Day

• Set Day value

• 36 monthly values for cumulated

consumption

• 18 half monthly values for cumulated

consumption

• Radiator temperature

• Ambient temperature

• Identification number

• Maximum radiator temperature of the

previous heating period

• Maximum radiator temperature of the

current heating period

• 18 monthly values for the maximum radiator

temperature

• Error code

• Manipulation protection: storing of the

duration of the last manipulation with

date and the accumulated duration of all

manipulations in minutes

• Fraud Counter

• Segment test

• Software version

• Running hours

• Commissioning date

• Measuring principle, single sensor device

with start sensor or double sensor device

• Short or long telegram for radio wM-Bus

Segment test of the display.

If an error is detected, Err is displayed in the first

display sequence with the corresponding error

message.

Telegram defined into heat cost allocator.

Type of telegram must be defined when

ordering.

Short telegram (Short) used.

Long telegram (LonG) used.

The duration of the display of the values can be

chosen individually between 1 - 30 seconds.

Example:

Order and duration of display

• Pos. 0 : Error (parameter ex factory, cannot

be changed) [5 s]

(only displayed in case of an error message)

• Pos. 1 : Time [1 s]

• Pos. 2 : Segment test [5 s]

• Pos. 3 : Consumption value [10 s]

• Pos. 4 : Set Day [1 s]

• Pos. 5 : Set Day value [8 s]

• Pos. 6 : Monthly value [5 s]

• Pos. 7 : Blank (therefore no display).

• Pos. 8 – Pos 15 : Blank (therefore no display. It

is not necessary to occupy all positions)

The rolling display can also be deactivated by a

software, i.e. the device operates as in standard

menu mode except that only these values and

the values of the corresponding sub-menus that

have been defined in the rolling menu can be

displayed by pushing the button. After 2 minutes

during which the button has not been pushed,

the display goes out.

10 | VI.SH.R1.02 © Danfoss | 2019.05

Page 11

Installation Guide SonoHCA

1.3.4 Communication

Indicator and Measuring

Indicator •

1.3.5 Real Time Clock

and Calendar

The communication indicator displays if the heat

cost allocator is currently making a calculation

and/or if it communicates internally or externally

over the optical.

u

123456

u

123456

u

123456

u

123456

The device has a 24 h real time clock and a

calendar. However, the change from summer

to winter time is not taken into account. The

calendar is programmed until December 31

If the current date and time have to be updated over the optical inter face or via radio, it is necessary

to check the date of the computer first. Date and time of the device aim at those of the computer. If

the reading/programming device (computer/PDA/ Smart Phone) has a wrong time, this time will be

programmed into the heat cost allocator and suddenly no longer be reached at the usual time, because

the time of the heat cost allocator possibly is shifted by several hours.

If the arrow of the communication indicator

points inwardly internal communication takes

place over the optical.

If the arrow of the communication indicator

points outwards external communication takes

place over the optical.

If the frame of the communication indicator

appears the heat cost allocator has detected a

wake-up signal.

If the point indicator appears the heat cost

allocator is carrying out a measuring or a

calculation.

2099, including all leap years. The real time clock

as well as the date of the heat cost allocator can

be readout over the optical interface or via radio

and if necessary be updated.

1.3.6 Readout

The current and monthly values recorded by

the heat cost allocator as well as several other

parameters can be readout over the optical

interface or also over radio.

The following parameters are transmitted:

Optical Interface:

• Identification number (information in

header)

• Date and time

• Consumption value

• Set Day

• Set Day value

• Maximum radiator temperature of previous

heating period

• 36 monthly values and 18 half monthly

values for cumulated consumption

• 18 monthly values for the maximum radiator

temperature

• Rating factor K

• Rating factor K

C

Q

• Current radiator temperature

• Current ambient temperature

• Maximum radiator temperature of the

current heating period

• Manipulation protection:

- Duration of the manipulations

- Date of the last manipulation

- Manipulation counter

• Error code

• Firmware version

• Commissioning date

• State of parameters

• 36 half monthly values for the average

ambient temperature

VI.SH.R1.02 | 11© Danfoss | 2019.05

Page 12

Installation Guide SonoHCA

1.3.6 Readout

(continuous)

1.3.7 Check Code

The following parameters are transmitted by

SonoHCA via 868MHz Radio (wM-Bus):

Short telegram, OMS compliant:

• Identification number (information in

header)

• Date and time

• Consumption value

• Set Day

• Set Day value

• Error code

• Current radiator temperature

• Current ambient temperature

• State of parameters

Long telegram for Walk-by reading:

• Identification number (information in

header)

• Date and time

• Consumption value

• Set Day

• Set Day value

• 18 monthly values for the cumulated

consumption

A special additional feature of the electronic heat

cost allocator is the check code function for the

postcard mail-in method.

With especially developed algorithms a 5 digit

check code is generated out of several device

data. With this check code the values stated on

the postcards mailed-in by tenants can be cross

checked.

• Rating factor K

• Rating factor K

• Current radiator temperature

C

Q

• Current ambient temperature

• Maximum radiator temperature of the

current heating period

• Maximum radiator temperature of the

previous heating period

• Manipulation protection:

- Duration of the manipulations

- Date of the last manipulation

- Manipulation counter

• Error code

• Firmware version

• Commissioning date

• State of parameters

AES 128 bits encryption is available for all

versions.

For this check, the following parameters are

required:

• Identification number

• The date

• The current consumption value

• The check code

For the verification of the check code SonoHCA

places all necessary tools (programs, formulas) at

the disposal of the authorized personnel.

1.3.8 Change of Battery

The battery of the heat cost allocator is soldered.

The lithium battery is not rechargeable. A change

of battery is not planned. Therefore the heat cost

allocators have to be replaced after 10 years.

Disposal

It is mandatory to dispose of the heat cost

allocator environmentally friendly or to return

it after use to the manufacturer for appropriate

disposal to ensure that the components are

recycled in accordance with the battery and

electronic scrap regulations. Should you do the

disposal yourself please get information from

your local authority on the recycling possibilities

12 | VI.SH.R1.02 © Danfoss | 2019.05

Page 13

Installation Guide SonoHCA

1.3.9 Protection against

Outside Influences

1.3.9.1 Seal

The heat cost allocator is closed with a seal which

cannot be removed without damaging it. Thus it

is impossible to open the device unnoticed.

After installation, the electronic part of the

device is no longer accessible. The digital display,

the push button and the optical interface are

covered by a sight glass. It is impossible to access

the inside of the device through these openings

without damaging the sight glass.

1.3.9.2 Electronic Detector

in Case of an Opening of the

Device

1.4 Special Functions

1.4.1 Suppression of

Summer Counting

1.4.2 Annual Reset of the

Consumption Value

1.4.3 Unit Scale and

Product Scale

The electronic detector detects unauthorised

opening, removing and closing of the heat cost

allocator. As soon as the housing of the heat

cost allocator is opened and/or removed, the

electronic detector triggers an error message.

The period during which summer counting is

suppressed can be programmed by the software.

If the heat cost allocator is in the period of

summer counting suppression, consumption

The function of the annual reset of the

cumulated consumption value can be

programmed by the software over the optical

interface. One of the following options can be

chosen for the reset:

• Set Day

• Never

For the heat cost allocators SonoHCA, distinction

is made between the unit scale and the product

scale.

If heat cost allocators are used with the same

scale on all radiators, this scale is called unit

scale. The display values are the same on the

different radiators if the heat cost allocators are

The duration of each opening is counted,

cumulated and only the last date of opening

recorded.

measuring is deactivated. If an automatic

readout is carried out during this period the

temperatures can be read anyway since the

temperature measuring is still active.

Please note that only the cumulated

consumption value is reset. All other values are

not reset.

exposed to the same temperature for the same

period of time.

The evaluation of the display values is carried

out arithmetically with the rating factors of

the calculation software to receive the final

consumption values.

1.4.3.1 Advantages of the

Unit Scale

• Easy and quick installation of the heat cost

allocator, no programming necessary

• Possible errors by doing the scaling on site

are avoided due to allocation by experts

on site. The overall rating factor total (K

calculated directly in the heat cost allocator

and thus the consumption value is displayed

immediately.

Tota l

) is

With the product scale, the radiator rating data

are programmed in the heat cost allocator

1.4.3.2 Advantages of the

Product Scale

• The actual consumption of each consuming

point within one billing unit can be

compared easily and quickly on site

1.5 Parameterization ‘’installer’’ password ex-factory of the heat cost

A software allows the parameterization over the

optical interface.

To protect heat cost allocator against fraud, a

allocator is ''56781234'', and may be changed by

the user.

password has been integrated into the products,

therefore also in the software. The default

VI.SH.R1.02 | 13© Danfoss | 2019.05

Page 14

Installation Guide SonoHCA

1.6 Error

1.6.1 List of Errors

1.7 Radio Standby –

SonoHCA

The heat cost allocator displays an error message

with the 3 letters “ Err. ” and a code. If several

errors occur at the same time, the different codes

are added together.

The error is displayed in the first position of the

display menu. It will still be possible to select

all the other display menus by pressing the

• Err. 1 Manipulation (fraud)

• Err. 2 Measuring error

• Err. 32 Push button constantly pushed

• Err. 64 Measured temperature not within

temperature range (0...105°C; 0...120°C

remote sensor)

In order to achieve a user-friendly and powersaving radio standby, the radio heat cost

allocator features the following different

operating modes:

navigation button. If the navigation button is

no longer pressed for a period of 2 minutes, the

error code will automatically appear again in the

first position of a display menu.

Display of an error automatically disappears

when the error is no longer present.

* : SLEEP information w ill be displayed by

pushing the push bu tton.

Transition from sleeping mode to installation mode is achieved by two different ways:

1. Pushing the push button once the heat cost allocator is mounted on the aluminium back plate.

2. An automatic detection during the mounting on the aluminium back plate. This function must be

specified at the order.

1.7.1 Sleeping Mode Transition from sleeping to installation mode is

Ex factory the radio heat cost allocator is in

sleeping mode, but the internal clock and the

date are running.

Current consumption is reduced to a minimum

since no measuring and no calculations are

carried out. Only the optical communication

achieved by pushing the button once the heat

cost allocator is mounted on the aluminium back

plate or by an automatic commissioning during

the mounting on the aluminium back plate (must

be specified when ordering).

interface is available.

14 | VI.SH.R1.02 © Danfoss | 2019.05

Page 15

Installation Guide SonoHCA

1.7.2 Installation Mode

1.7.3 Operation Mode

for Radio wM-Bus (SonoHCA

868MHz Radio)

1.7.3.1 Readout over

the short telegram

(OMS compliant)

u

123456

The • symbol indicates that the heat cost

allocator is in installation mode.

During the installation mode all functions of the

radio heat cost allocator are carried out.

• For heat cost allocator, an installation

telegram is activated during the installation

phase. Data are transmitted each 30 seconds

(short and long telegram) till at the end of

the second day at midnight.

If heat cost allocator is removed from the aluminium back plate during the installation mode, the heat cost

allocator switches to the sleeping mode.

With this operating mode, the heat cost allocator

SonoHCA transmits data:

• Transmission interval each 120 seconds

(minimum)

• Radio reading, 24h/24h

The radio heat cost allocator switches

automatically into operating mode at the end of

the second day at midnight.

1.7.3.2 Readout over the

long telegram for Walk-by

reading

1.7.4 Short Telegram or

Long Telegram for Radio

wM-Bus (868)

2. Installation

2.1 Introduction

With this operating mode, the heat cost allocator

SonoHCA transmits data:

• Transmission interval each 120 seconds

(minimum)

• Radio reading and periods, 12h per day

(programmable), 5days/7days

Type of telegram must be defined when

ordering. There is no possibility to select the type

of telegram directly on the heat cost allocator.

To guarantee the proper functioning of the heat

cost allocator, it is of great importance that it is

installed by an expert. On one hand, a constant

heat transfer between radiator and heat cost

allocator has to be guaranteed. On the other

hand, the installation of the heat cost allocators

on a large variety of radiator types should be as

easy as possible.

The installation can be carried out in two

different ways.

• The standard device is installed directly on

the radiator.

• For the wall-mounted version the remote

sensor is installed on the radiator and the

heat cost allocator is wall-mounted.

For the installation of the heat cost allocators,

special fastening-parts kits are available. To

avoid faulty installation, we also recommend

reading the Kc-data in the data base prior to the

installation.

The heat cost allocator is an electronic device

which – like all other similar devices – has to

be handled with care. It is sensible to electric

discharge and contacting certain areas of the

PCB. Electric discharge can destroy the device

or – even worse - damage it in a way that it fails

after an indefinite period of time.

For this reason it is essential in any case to

avoid contact with the PCB.

VI.SH.R1.02 | 15© Danfoss | 2019.05

Page 16

Installation Guide SonoHCA

2.2 DIN Standard

Requirements for the

Installation

2.3 Mounting the

Remote Sensor

• Heat cost allocators can be installed

in heating systems where the mean

temperature is between the upper

operating temperature limit t

lower operating temperature limit t

and t

are stated in the technical data, see

min

chapter 4 Technical Data)

and the

max

min

(t

• The installation of the devices has to be

durable and avoid manipulations.

• The devices have to be installed in a place

where sufficient correlation between the

displayed value and the heat output of the

radiator is given over a maximum operating

range.

• Within a billing unit (in case of predistribution of the energy consumption:

within a users’ group) only heat cost

allocators of the same manufacturer and

For each version of heat cost allocator, it is

possible to plug the connector of the remote

sensor into an interface inside the heat cost

allocator.

The remote sensor will be automatically

detected by the heat cost allocator.

max

the same type with identical rating systems

may be used. Each device type has to be

identifiable as such.

• Combinations of radiators and heat cost

allocators with a measured value of c > 0.3

in basic condition are not permitted. In

exceptional cases c-values of up to 0.4

are permitted within a billing unit if the

concerned heating surface does not exceed

25 % of the overall heated surface or if the

mean ambient temperature is above 80 °C.

Heat cost allocators may only be installed to

radiators where the c-value is known at the

time of billing.

Once equipped with a remote sensor, the heat

cost allocator will only work for an application

with remote sensor.

Remote sensor version with 2 m cable. The cable

includes a stopper-knot.

Insert the remote sensor cable into the groove

Return the heat cost allocator and plug the connector of the

remote sensor into the interface inside the heat cost allocator.

Proceed to the commissioning of the heat cost

allocator on the aluminium back plate. Take care

not to stick the cable.

Respect the color code of the radiator sensor and

the remote sensor:

• Heat cost allocator SonoHCA: the

radiator sensor and the remote sensor are

manufactured with a white color.

provided up to the slot of housing.

Place the stopper-knot inside the housing. The

knot will avoid any traction on the connector.

During the commissioning of the heat cost

allocator on the aluminium back plate, there are

2 possibilities to turn on the heat cost allocator:

1. By an automatic commissioning during the

mounting on the aluminium back plate.

See chapter 3.1 Automatic commissioning

during the installation

2. By pushing the push button.

See chapter 3.2 Commissioning by pressing

push button.

Once equipped with a remote sensor, the heat cost allocator will only work for an application with remote sensor.

If the remote sensor is disconnected from the heat cost allocator, an error message will be displayed.

16 | VI.SH.R1.02 © Danfoss | 2019.05

Page 17

Installation Guide SonoHCA

2.4 General

Restrictions

2.5 Operating Range

2.6 Mounting and

Sealing

Electronic heat cost allocators cannot be used

with steam heating, floor heating, ceiling radiant

heaters, flap-controlled radiators and electrical

radiator.

In case of combined valve- and flap-controlled

radiators, the installation of an electronic heat

cost allocator is only permitted if the flap control

is dismounted or maintained in position „open“.

The SonoHCA heat cost allocators can be used

in heating systems with the following mean

heating medi-um temperatures:

For double sensor devices:

• 35°C…105° C for standard heat cost

allocators

• 55°C…120°C for wall-mounted heat cost

allocators (remote sensor)

After installation of the respective fasteningparts kit to the radiator, the heat cost allocator

can be mounted and sealed by the installer as

described below:

Convector heaters where the performance can

be altered by an electric blower as well as heat

towel racks with an electric heating cartridge

may only be equipped with an electronic

heat cost allocator if the additional electric

attachments are dismounted or shut down.

A heat cost allocator can be used in heating

systems where the suitability of the system is in

line with the operating conditions for which the

heat cost allocator has been approved.

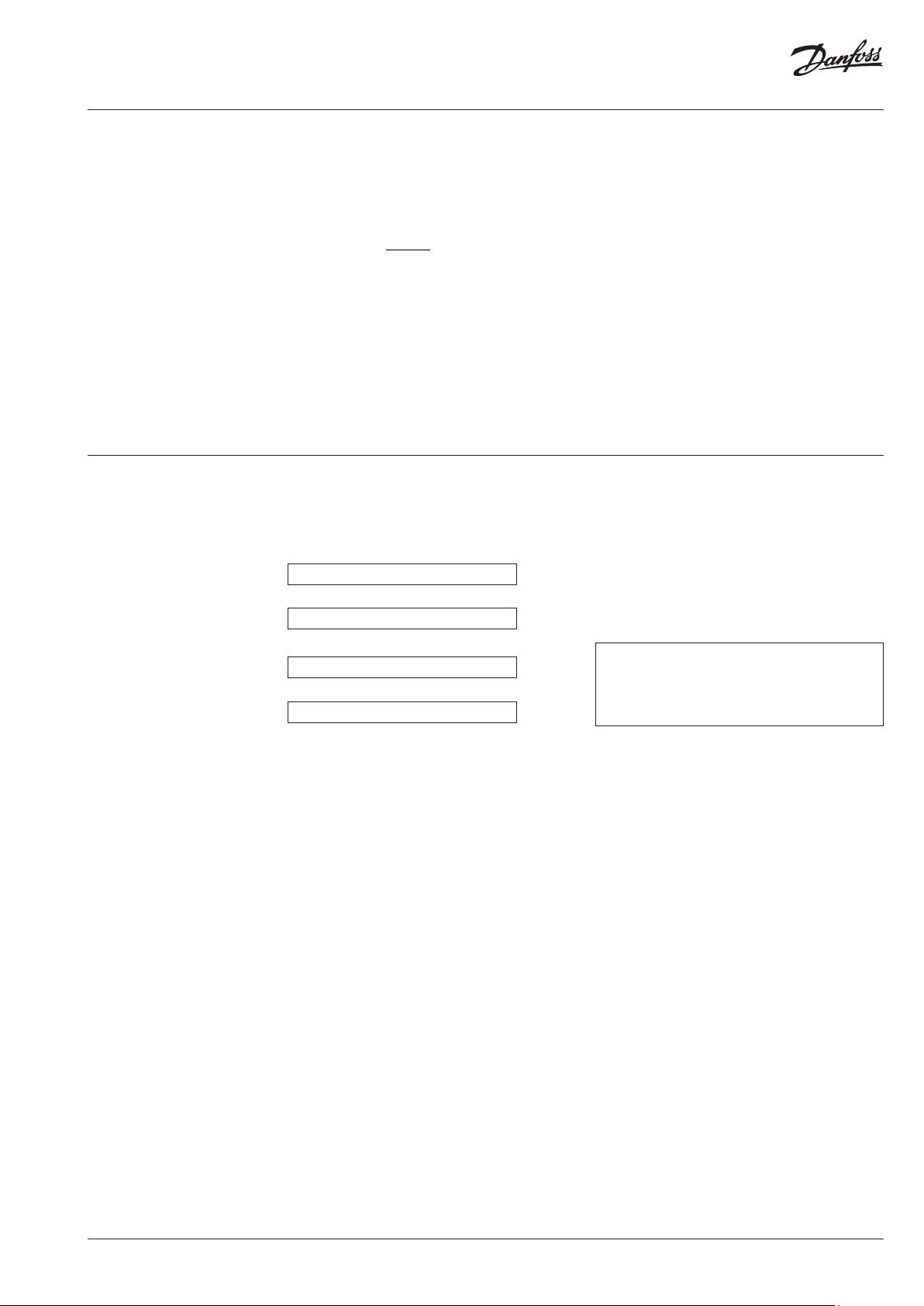

The heat cost allocator is

placed at the upper end

of the aluminium back

plate. Move the heat cost

allocator down so that

the hooks in the housing

fit in the aluminium back

plate.

The heat cost allocator is

placed on the aluminium

back plate in the

direction of the arrow.

Push the seal preinstalled

by SonoHCA in the slot

of the housing, then

press until the seal click s

into the aluminium back

plate.

Now the heat cost

allocator can only be

opened by destroying

the seal.

VI.SH.R1.02 | 17© Danfoss | 2019.05

Page 18

Installation Guide SonoHCA

Automatic change

Pushing the push

SLEEP

3. Commissioning

3.1 Automatic

commissioning during the

installation

Ex factory the heat cost allocators are in the socalled sleeping mode. In this mode no measuring

is carried out and thus no consumption values

are calculated. Furthermore the digital display,

the radio communication options as well as the

device opening detection are deactivated. Only

Transition from sleeping to installation mode is

achieved by pushing the button once when the

heat cost allocator is mounted on the aluminium

back plate or by an automatic commissioning

during the mounting on the aluminium back

plate.

the optical communication interface is available.

The date and time are running in the

background.

After the commissioning and before leaving a new site, we recommend to per form a radio read out test and to

create an installation protocol, to ensure that all the radio communication between the heat cost allocators and

the radio central or radio modem was successful.

Once heat cost allocator is fixed with/against the

aluminium back plate, the LCD-display will show

Transition from sleeping to installation mode is

achieved automatically after 5 seconds:

the following message:

FF

SLEEP

The index FF indicates that the heat cost

allocator has recognized the remote sensor.

If the remote sensor is not detected by the

device, the index -- will be displayed.

FF

after 5 sec

SLEEP

The • symbol indicates that the heat cost

allocator is in installation mode.

u

123456

Installation ModeSleeping Mode

The index -- indicates also a standard device with

a compact sensor.

This message will be displayed during 5 seconds

and after that, the transition from sleeping mode

to installation mode will be done automatically.

Once installed on the back plate or the wall, the

heat cost allocator switches automatically from

the installation mode into the operating mode at

the second transition of midnight.

3.2 Commissioning by

pressing push button

Once heat cost allocator is fixed with/against the

aluminium back plate, the LCD-display will show

the following message:

FF

The index FF indicates that the heat cost

allocator has recognized the remote sensor.

If the remote sensor is not detected by the

device, the index -- will be displayed.

The index -- indicates also a standard device with

a compact sensor.

This message will be displayed during 2 minutes

before the LCD-display will switch off.

Transition from sleeping to installation mode

is achieved by pushing the push button during

3 seconds:

FF

button (3sec)

SLEEP

u

123456

Installation ModeSleeping Mode

The • symbol indicates that the heat cost

allocator is in installation mode.

Once installed on the back plate or the wall,

the heat cost allocator switches automatically

into operating mode at the second transition of

midnight.

18 | VI.SH.R1.02 © Danfoss | 2019.05

Page 19

Installation Guide SonoHCA

4. Technical Data

Measuring systems

For heating systems with tm

Calculation with variable ref. temperature T-air sensor

≥ 35 °C

min

Necessar y rating factors: KQ, KC, (KA, K T)

Optional scales Unit scale or product scale

Current supply 3 V-Lithium-battery

Life-span with 1 battery > 10 years

Display Liquid crystal display (LCD-display)

No. of displayed digits 6 digits (000000 ... 999999)

Sensor temperature range: 0 °C ... 120 °C

Exponent n = 1.33

Radiator – performance range 4 Watt ... 16.000 Watt

Design temperature range

(tm

… tm

min

)

max

Double sensor system

35 °C ... 105°C / 120 °C (compact- / remote sensor)

KC-values Rating fac tors see digital KC-data base

Models Compact device or remote sensor device

Set day Freely programmable

144 monthly values and 18 half monthly values for cumulated heat consumption, 18

Data storage:

monthly values for the maximum radiator temperature. Maximum temperature of

the current and previous year, all relevant consumption values

Self-test Before every measuring

Start of counting

Heating period 25°C – 4 0°C (programmable)

Off-heating period 25°C – 4 0°C (programmable)

Standard version Acc. to EN 834

Homologation acc. to H KV O: A1.0 2.20 15

DIN registry No. 291/08 E

Conformity CE

At 75% of the overall height of the radiator.

Standard mounting height

If the height of the radiator is less than (<) 470 mm, the heat cost allocator must

be installed at 50% BH. (in case of deviating mounting heights, please refer to this

manual and the digital KC-data base.

VI.SH.R1.02 | 19© Danfoss | 2019.05

Page 20

Danfoss S.r.l.

Heating Segment

Danf

Ciò vale anche per i prodotti già ordinati, a condizione che tali modiche possano essere appor

citati nel presente materiale sono di proprietà delle rispettive società. Danf

Installation Guide SonoHCA

•

heating.danfoss.it • +39 011 3000 511 • E-mail: info@danfoss.it

oss declina ogni responsabilità per eventuali errori contenuti in cataloghi, brochure o altra documentazione cartacea. Danfoss si riserva il diritto di modicare i propri prodotti senza preav viso.

oss e il logo Danfoss sono marchi registrati di Danfoss A/S. Tutti i diritti sono riservati.

tate senza rendere necessarie successive variazioni alle speciche già concordate. Tutti i marchi registrati

© Danfoss | DHS-SRMT/SI | 2019.0520 | VI.SH.R1.02

Loading...

Loading...