Page 1

Classified as Business

Page 2

Classified as Business

Table of Contents

1 Notes and conventions ........................................................................................................................................... 6

1.1 About this document ................................................................................................................... 6

1.2 Legal basis ....................................................................................................................................... 6

Copyright protection ................................................................................................................... 6

Personnel qualification ................................................................................................................ 6

Intended use ................................................................................................................................... 6

1.3 Symbols ............................................................................................................................................ 6

1.4 Font conventions .......................................................................................................................... 6

1.5 Number notation ........................................................................................................................... 7

1.6 Safety guidelines ........................................................................................................................... 7

1.7 Scope ................................................................................................................................................. 7

1.8 Abbreviations ................................................................................................................................. 7

2 Presentation of the device ..................................................................................................................................... 9

2.1 Delivery variants ............................................................................................................................ 9

2.2 Connectors ...................................................................................................................................... 9

2.3 Status LEDs ................................................................................................................................... 10

2.4 First steps ...................................................................................................................................... 10

Power supply ............................................................................................................................... 10

Network configuration and first access .............................................................................. 11

2.5 Specific troubleshooting SonoCollect 112 ........................................................................ 12

All LEDs remain dark, the device does not respond. ...................................................... 12

The Power LED flashes green. ................................................................................................ 12

2.6 Typical application scenarios ................................................................................................. 12

Local application without control system ......................................................................... 13

Remote monitoring without control system .................................................................... 13

Remote monitoring with email dispatch ........................................................................... 13

Remote monitoring with FTP upload .................................................................................. 13

Remote monitoring with SFTP upload ................................................................................ 13

Remote monitoring with TCP/HTTP transmission .......................................................... 14

2.7 Technical data ............................................................................................................................. 14

General properties ..................................................................................................................... 14

Electrical properties ................................................................................................................... 14

Further characteristics .............................................................................................................. 15

3 Netdiscover tool ..................................................................................................................................................... 16

3.1 Locating and accessing devices ............................................................................................ 16

3.2 Network configuration ............................................................................................................. 17

3.3 Access to the web-based front end via HTTP ................................................................... 18

3.4 Access to the file system via FTP ........................................................................................... 18

3.5 Access to the command line via SSH ................................................................................... 20

3.6 Mass management .................................................................................................................... 20

3.7 Import of a device list................................................................................................................ 22

4 Web-based front end ............................................................................................................................................ 23

4.1 Access via HTTPS ........................................................................................................................ 23

4.2 General tab ................................................................................................................................... 24

4.3 Meter tab ....................................................................................................................................... 25

AQ332837053242en-010201 © Danfoss | 2021.03 | 2

Page 3

Classified as Business

System meter ............................................................................................................................... 27

4.4 Configuration tab ....................................................................................................................... 28

4.5 WAN tab ........................................................................................................................................ 30

4.6 Server tab ...................................................................................................................................... 32

4.7 Security tab................................................................................................................................... 34

4.8 User tab .......................................................................................................................................... 34

4.9 Log tab ........................................................................................................................................... 36

4.10 Service tab .................................................................................................................................... 37

4.11 Print page ...................................................................................................................................... 39

4.12 Supplied manual ........................................................................................................................ 41

4.13 Front-end troubleshooting ..................................................................................................... 41

Website or front end cannot be accessed ......................................................................... 41

Login on website not possible ............................................................................................... 41

All input fields or buttons are greyed out. ......................................................................... 41

Not all tabs are visible ............................................................................................................... 41

Export of the log data of one/several meters is empty ................................................. 42

The log is empty ......................................................................................................................... 42

5 Reading meters via M-Bus ................................................................................................................................... 43

5.1 Signalling on the M-Bus ........................................................................................................... 43

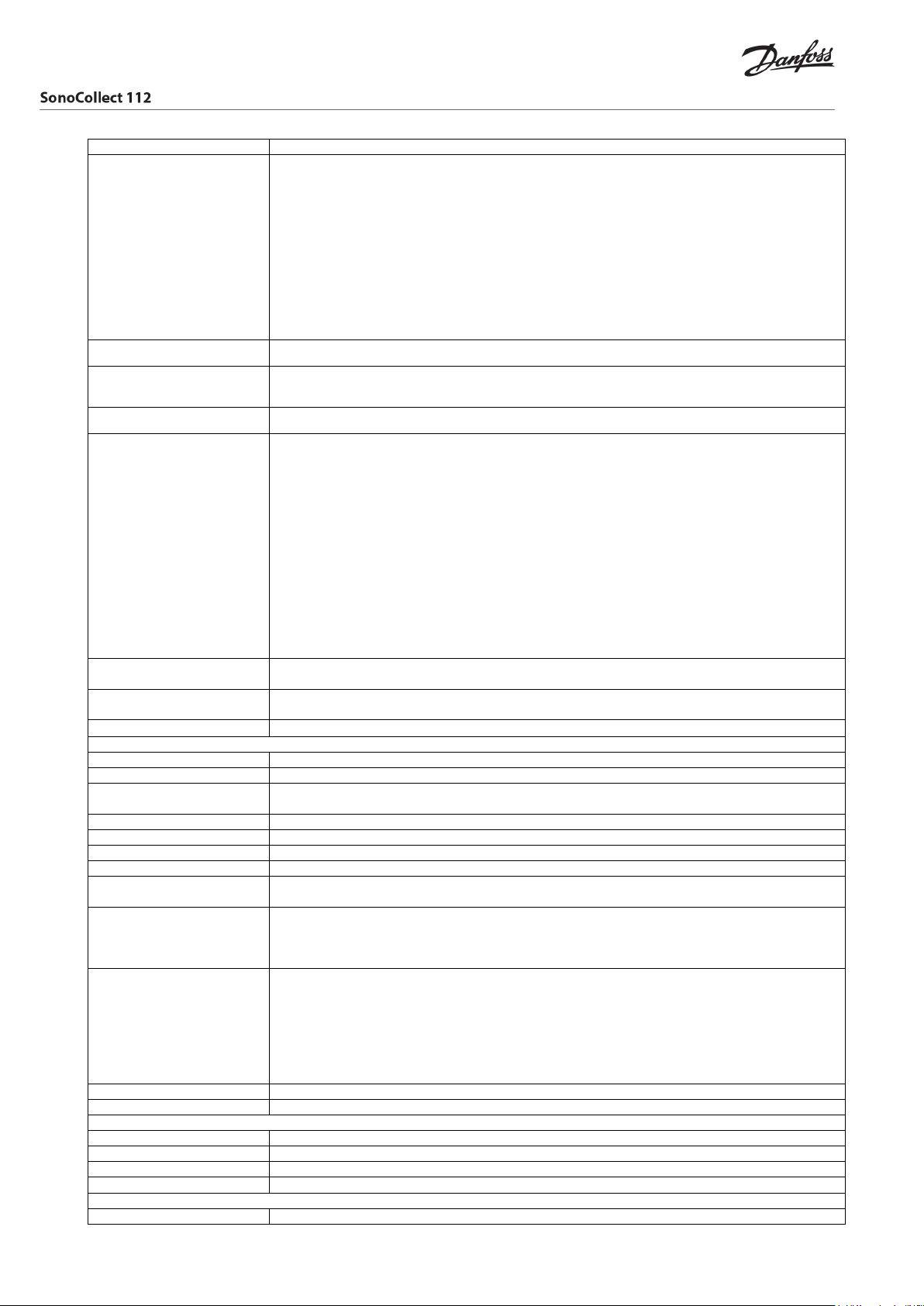

5.2 Setup of the interface in the web front end ...................................................................... 44

M-Bus mode ................................................................................................................................. 44

Addressing, search and search range .................................................................................. 45

M-Bus baud rate .......................................................................................................................... 47

M-Bus timeouts ........................................................................................................................... 47

M-Bus request mode ................................................................................................................. 47

M-Bus reset mode ...................................................................................................................... 47

M-Bus multipaging .................................................................................................................... 48

5.3 M-Bus troubleshooting ............................................................................................................ 48

Physical troubleshooting ......................................................................................................... 48

M-Bus meters are not found ................................................................................................... 49

M-Bus meters are found, but do not show any data ...................................................... 49

The search takes a long time .................................................................................................. 50

Device restarts during search ................................................................................................. 50

6 Reading meters via wM bus ................................................................................................................................ 51

6.1 Signalling via wM bus ............................................................................................................... 51

6.2 Troubleshooting the wM bus ................................................................................................. 51

wM-Bus meters are not found ............................................................................................... 51

wM-Bus mounters are found but show no data .............................................................. 52

7 Reading meters via pulse interface ................................................................................................................... 53

7.1 Setup of a meter in the web front end ................................................................................ 53

7.2 Troubleshooting the pulse interface ................................................................................... 55

The meter does not increment .............................................................................................. 55

8 Reading meters via serial interface ................................................................................................................... 56

8.1 Setup of the interface in the web front end ...................................................................... 56

Serial mode ................................................................................................................................... 56

DLDE baud rate, data bits, stop bits and parity ................................................................ 56

DLDE mode................................................................................................................................... 57

DLDE timeouts ............................................................................................................................ 57

AQ332837053242en-010201 © Danfoss | 2021.03 | 3

Page 4

Classified as Business

8.2 Setup of the meter in the web front end ........................................................................... 57

8.3 Troubleshooting the serial interface.................................................................................... 59

Meters are not read out ............................................................................................................ 59

9 Transmission of meter data ................................................................................................................................ 60

9.1 Instances and database ............................................................................................................ 60

9.2 General settings .......................................................................................................................... 60

9.3 Preset data or file formats ....................................................................................................... 60

XML format ................................................................................................................................... 60

CSV format .................................................................................................................................... 62

JSON format ................................................................................................................................. 63

User format ................................................................................................................................... 64

9.4 Data transmission via TCP ....................................................................................................... 65

9.5 Data transmission via TLS ........................................................................................................ 65

9.6 Sending files via FTP .................................................................................................................. 67

Sending files via SFTP or FTPS ................................................................................................ 67

9.7 Sending e-mails via SMTP ........................................................................................................ 68

Report as content of the e-mail ............................................................................................. 68

Report as attachment to an e-mail ....................................................................................... 68

SMTP with STARTLS ................................................................................................................... 68

9.8 Data transmission via MQTT ................................................................................................... 69

Example Azure Cloud ................................................................................................................ 69

Example AWS Cloud .................................................................................................................. 70

9.9 Local file storage ......................................................................................................................... 71

9.10 Script-based report .................................................................................................................... 72

9.11 Specific troubleshooting ......................................................................................................... 72

10 Advanced configuration options ...................................................................................................................... 73

10.1 Linux operating system ............................................................................................................ 73

User rights ..................................................................................................................................... 73

Command line ............................................................................................................................. 73

Standard commands ................................................................................................................. 73

10.2 Update ........................................................................................................................................... 74

10.3 Configuration file chip.ini ........................................................................................................ 75

10.4 Configuration file Device\_Handle.cfg ................................................................................ 84

10.5 OpenVPN Client .......................................................................................................................... 85

Configuration of the device .................................................................................................... 85

10.6 Preconfiguration of the meter list ........................................................................................ 85

10.7 Scripting ........................................................................................................................................ 86

XSLT parser ................................................................................................................................... 86

Report script ................................................................................................................................. 86

System meter script ................................................................................................................... 87

10.8 Media types, measurement types and units ..................................................................... 88

11 Access to meter data via Modbus TCP ............................................................................................................. 92

11.1 General information .................................................................................................................. 92

11.2 Function codes and addressing ............................................................................................ 92

11.3 Data display .................................................................................................................................. 93

11.4 Configuration via web front end ........................................................................................... 95

Modbus mode and Modbus port .......................................................................................... 95

Modbus test ................................................................................................................................. 95

AQ332837053242en-010201 © Danfoss | 2021.03 | 4

Page 5

Classified as Business

Modbus swap .............................................................................................................................. 96

Modbus float only ...................................................................................................................... 96

Modbus multi slave ................................................................................................................... 97

11.5 Instructions for use .................................................................................................................... 97

How often is the data updated? ............................................................................................ 97

How can you detect if the meter is read or the value is current? ............................... 97

Which data type must be used? ............................................................................................ 98

What is the unit of value? ........................................................................................................ 98

How many Modbus masters can call data simultaneously? ........................................ 98

How can the data be automatically assigned? ................................................................. 98

11.6 Specific troubleshooting ......................................................................................................... 99

Why does the value in the Modbus differ from the value on the website? ............ 99

Why does the device/the Modbus server not respond? ............................................... 99

12 Access to meter data via BACnet IP ................................................................................................................ 100

12.1 General information ................................................................................................................ 100

Implemented services ............................................................................................................ 100

Supported BACnet Interoperability Building Blocks (Annex K) ................................ 100

12.2 Configuration via web front end ......................................................................................... 100

BACnet active ............................................................................................................................ 100

BACnet config network, BACnet IP, BACnet netmask und BACnet broadcast .... 100

BACnet BBMD ............................................................................................................................ 100

BACnet port ................................................................................................................................ 101

BACnet device ID, BACnet device name and BACnet location ................................. 101

Change of Value ........................................................................................................................ 101

Export of an EDE file ................................................................................................................ 101

12.3 Data display ................................................................................................................................ 101

Meter values ............................................................................................................................... 101

BACnet Device object ............................................................................................................. 102

12.4 Specific troubleshooting ....................................................................................................... 103

AQ332837053242en-010201 © Danfoss | 2021.03 | 5

Page 6

Classified as Business

1 Notes and conventions

1.1 About this document

This manual provides guidance and procedures for a fast and efficient installation and start-up of the units

described in this manual. It is imperative to read and carefully follow the safety guidelines.

1.2 Legal basis

Copyright protection

This documentation, including all illustrations contained therein, is protected by copyright. The author is

Danfoss A/S, Nordborg. The exploitation rights are also held by Danfoss A/S. Any further use that deviates

from the copyright regulations is not allowed. Reproduction, translation into other languages, as well as

electronic and phototechnical archiving and modification require the written permission of Danfoss A/S.

Violations will result in a claim for damages.

Danfoss A/Sreserves the right to provide for any alterations or modifications that serve to increase the effi-

ciency of technical progress. All rights in the event of the granting of a patent or the protection of a utility

model are reserved by Danfoss A/S. Third-party products are always mentioned without reference to patent rights. The existence of such rights can therefore not be excluded.

Personnel qualification

The product use described in this documentation is intended exclusively for electronics specialists or persons instructed by electronics specialists. They must all have good knowledge in the following areas:

Applicable standards

Use of electronic devices

The solidus GmbH accepts no liability for faulty actions and damage to the described devices and thirdparty products caused by disregarding the information in this manual.

Intended use

If necessary, the components or assemblies are delivered ex works with a fixed hardware and software configuration for the respective application. Modifications are only permitted within the scope of the possibilities shown in the documentation. All other changes to the hardware or software as well as the non-intended use of the components result in the exclusion of liability on the part of Danfoss A/S.

Please send any requests for a modified or new hardware or software configuration to Danfoss A/S.

1.3 Symbols

Caution: It is essential to observe this information in order to prevent damage to the device.

Notice: Boundary conditions that must always be observed to ensure smooth and efficient opera-

tion.

ESD (Electrostatic Discharge): Warning of danger to components due to electrostatic discharge.

Observe precautionary measures when handling components at risk of electrostatic discharge.

Note: Routines or advice for efficient equipment use.

Further information: References to additional literature, manuals, data sheets and internet pages.

1.4 Font conventions

Names of paths and files are marked in italics. According to the system the notation is done by slash or

backslash.

e. g.: D:\Data

Menu items or tabs are marked in bold italics.

AQ332837053242en-010201 © Danfoss | 2021.03 | 6

Page 7

Classified as Business

Number system

Example

Comments

Decimal

100

Normal notation

Hexadecimal

0x64

C notation

Binary

'100'

in quotation marks

Abbreviation

Meaning

2G

Mobile radio standard, synonym for GSM or GPRS

e. g.:

Save

An arrow between two menu items or tabs indicates the selection of a sub-menu item from a menu or a

navigation history in the web browser.

e. g.:

File → New

Buttons and input fields are shown in bold letters.

e. g.: Input

Key labels are enclosed in angle brackets and shown in bold with capital letters.

e. g.: <F5>

Program codes are printed in Courier font.

e. g.: ENDVAR

Variable names, identifiers and parameter entries are marked in italics in the text.

e. g.: Measured value

1.5 Number notation

Numbers a noted according to this table:

'0110.0100'

Table 1: Number systems

nibbles separated by dot

1.6 Safety guidelines

The power supply must be switched off before replacing components and modules.

If the contacts are deformed, the affected module or connector must be replaced, as the function is not

guaranteed in the long term. The components are not resistant to substances that have creeping and insulating properties. These include e.g. aerosols, silicones, triglycerides (ingredient of some hand creams). If

the presence of these substances in the vicinity of the components cannot be excluded, additional

measures must be taken. Install the components in an appropriate casing. Handle components with clean

tools and materials only.

Only use a soft, wet cloth for cleaning. Soapy water is allowed. Pay attention to ESD.

Do not use solvents like alcohol, acetone etc. for cleaning.

Do not use a contact spray, because in an extreme case the function of the contact point is im-

paired and may lead to short circuits.

Assemblies, especially OEM modules, are designed for installation in electronic housings. Do not

touch the assembly when it is live. In each case, the valid standards and directives applicable to the

construction of control cabinets must be observed.

The components are populated with electronic elements which can be destroyed by an electro-

static discharge. When handling the components, ensure that everything in the vicinity is well

earthed (personnel, workplace and packaging). Do not touch electrically conductive components,

e.g. data contacts.

1.7 Scope

This documentation describes the devices made by Danfoss A/S, Nordborg stated in the title.

1.8 Abbreviations

AQ332837053242en-010201 © Danfoss | 2021.03 | 7

Page 8

Classified as Business

Abbreviation

Meaning

3G

Mobile radio standard, synonym for UMTS

4G

Mobile radio standard, synonym for LTE

BACnet

Building Automation and Control networks

BBMD

BACnet Broadcast Management Device

CA

Certification Authority

CHAP

Challenge Handshake Authentication Protocol

COSEM

COmpanion Specification for Energy Metering

CSV

Character-Separated Values

DNS

Domain Name System

DE, DI

Digital Input, Digital Input Terminal

DA, DO

Digital Output, Digital Output Terminal

DIN

German Institute for Standardization

DLDE

Direct Local Data Exchange (EN 62056-21, IEC 1107)

DLMS

Device Language Message Specification

I/O

Input / output

ESD

ElectroStatic Discharge

FNN

Forum Network Technology/Network Operation

FTP

File Transfer Protocol

GPRS

General Packet Radio Service

GSM

Global System for Mobile Communications

HTTP

Hypertext Transfer Protocol

I/O

Input/Output

ICMP

Internet Control Message Protocol

ID

Identification, identifier, unique marking

IoT

Internet of Things

IP

Internet Protocol or IP address

JSON

JavaScript Object Notation

LED

Light-Emitting Diode

LSB

Least significant byte

LSW

Least significant word

LTE

Long Term Evolution

M-Bus

Meter bus (EN 13757, part 2 - 3)

MAC

Medium Access Control or MAC address

MEI

Modbus Encapsulated Interface

MQTT

Message Queuing Telemetry Transport

MSB

Most Significant Byte

MSW

Most Significant Word

MUC

Multi Utility Communication, MUC-Controller

NBIoT

Narrow Band Internet of Things

OEM

Original Equipment Manufacturer

OMS

Open Metering System

PAP

Password Authentication Protocol

PEM

Privacy Enhanced Mail

PPP

Point-to-Point Protocol

PPPoE

Point-to-Point Protocol over Ethernet

RFC

Requests For Comments

RSSI

Received Signal Strength Indicator

RTC

Real Time Clock

RTOS

Real-Time Operating System

S0

S0 interface (pulse interface, EN 62053-31)

SIM

Subscriber Identity Module

SML

Smart Message Language

SMTP

Simple Mail Transfer Protocol

SNTP

Simple Network Time Protocol

SSL

Secure Socket Layer

TCP

Transmission Control Protocol

UDP

User Datagram Protocol

UMTS

Universal Mobile Telecommunications System

UTC

Universal Time Coordinated

VDE

Association of Electrical, Electronic & Information Technologies e.V.

WAN

Wide Area Network

wM-Bus

Wireless Meter Bus (EN 13757, part 3 - 4)

XML

eXtensible Markup Language

XSLT

eXtensible Stylesheet Language Transformation

DLDERS DLDE communication via RS-232 or RS-485

TLS Transport Layer Security

AQ332837053242en-010201 © Danfoss | 2021.03 | 8

Table 2: Abbreviations

Page 9

Classified as Business

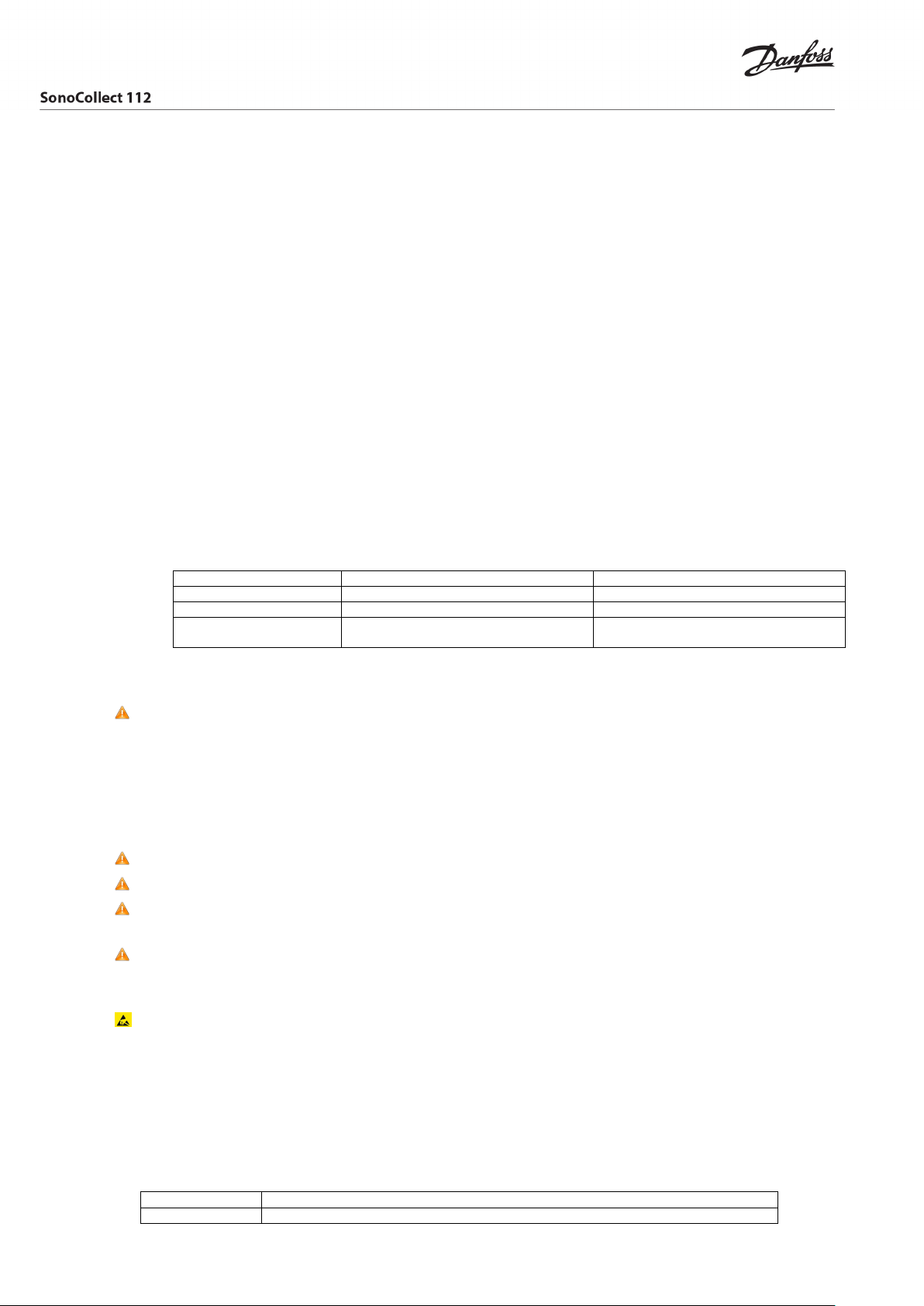

Variant Order number

Meter interfaces

Communication interfaces

Outputs

M-Bus

wM-Bus

S0

Ethernet

WAN

RS-485

Digital 24 V

SonoCollect 112 E-WM-80

014U1603

X X 3 X - X 1

SonoCollect 112 G-WM-80

014U1605

X X 3 X X (LTE) X 1

SonoCollect 112 EB-WM-80*

014U1609

X X 3 X - X 1

SonoCollect 112 GB-WM-80*

014U1612

X X 3 X X (LTE) X 1

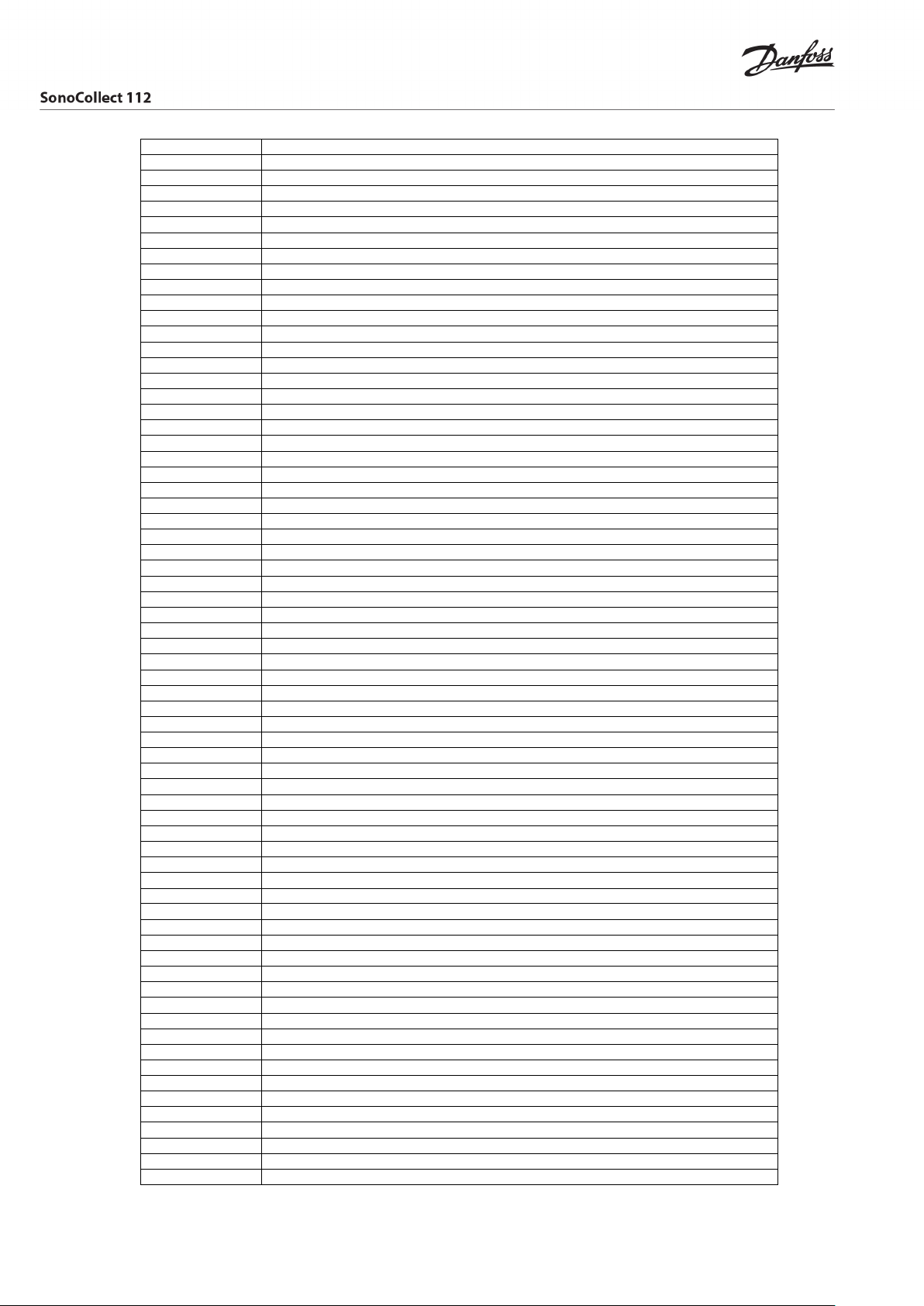

Connector

Designation

Pinning

Comments

Power supply

N, L

N: neutral conductor

230 VAC (90-260 VAC), 50 Hz

Connection cable 2.5 mm²

Ethernet connection

Ethernet

1: TX+

according to EIA/TIA 568A/B

2 Presentation of the device

SonoCollect stands for a communication module, which automatically records customer's consumption

data within the scope of Smart Metering. This is sent via a wide area network (WAN) to the measuring service provider or measuring point provider and, via a local interface, it can also be displayed on a customer

PC.

The so-called SonoCollect 112 is a variant of such a communication module. This is separate from the meter, and acts as the data transport interface. The SonoCollect is the central device for the implementation of

Smart Metering. Its advantage is that the measuring equipment and short-lived wide area communication

are installed in separate devices, and so can be installed or exchanged independently of each other.

The SonoCollect 112 is a modular controller. The device comes in a 4U enclosure (modules) and is intended

for DIN rail mounting (DIN rail 35 mm).

2.1 Delivery variants

The SonoCollect 112 is offered in a range of versions, and so can easily be adapted to the requirements of

the particular property.

Table 3: Abbreviations

*The Variants “EB-WM-80” and “GB-WM-80” includes the BACnet IP communication protocol.

The RS485 interface can be used both for communication (e.g. with a display (optional) and for reading

meters.

2.2 Connectors

The various interfaces of the SonoCollect 112 are on different sides of the device.

The following figure shows the device variants:

Figure 1 SonoCollect 112 E-WM-80 SonoCollect 112 G-WM-80

The following connectors are available at SonoCollect 112:

AQ332837053242en-010201 © Danfoss | 2021.03 | 9

L: Phase conductor

2: TX3: RX+

4:

5:

6: RX7:

Screw clamp

Page 10

Classified as Business

8:

RS-485

RS+, RS-

RS+: positive bus line

Screw clamp

WAN antenna

WAN

Inner: RF

Outer: Reference ground

SMA

with 4G variant only

wireless M-Bus antenna

OMS

Inner: RF

SMA

S0 inputs

Sx+, Sx

Sx+: Pulse input

Screw clamp

No galvanic isolation

Digital output

DO+, DO-

DO+: Output

Screw clamp

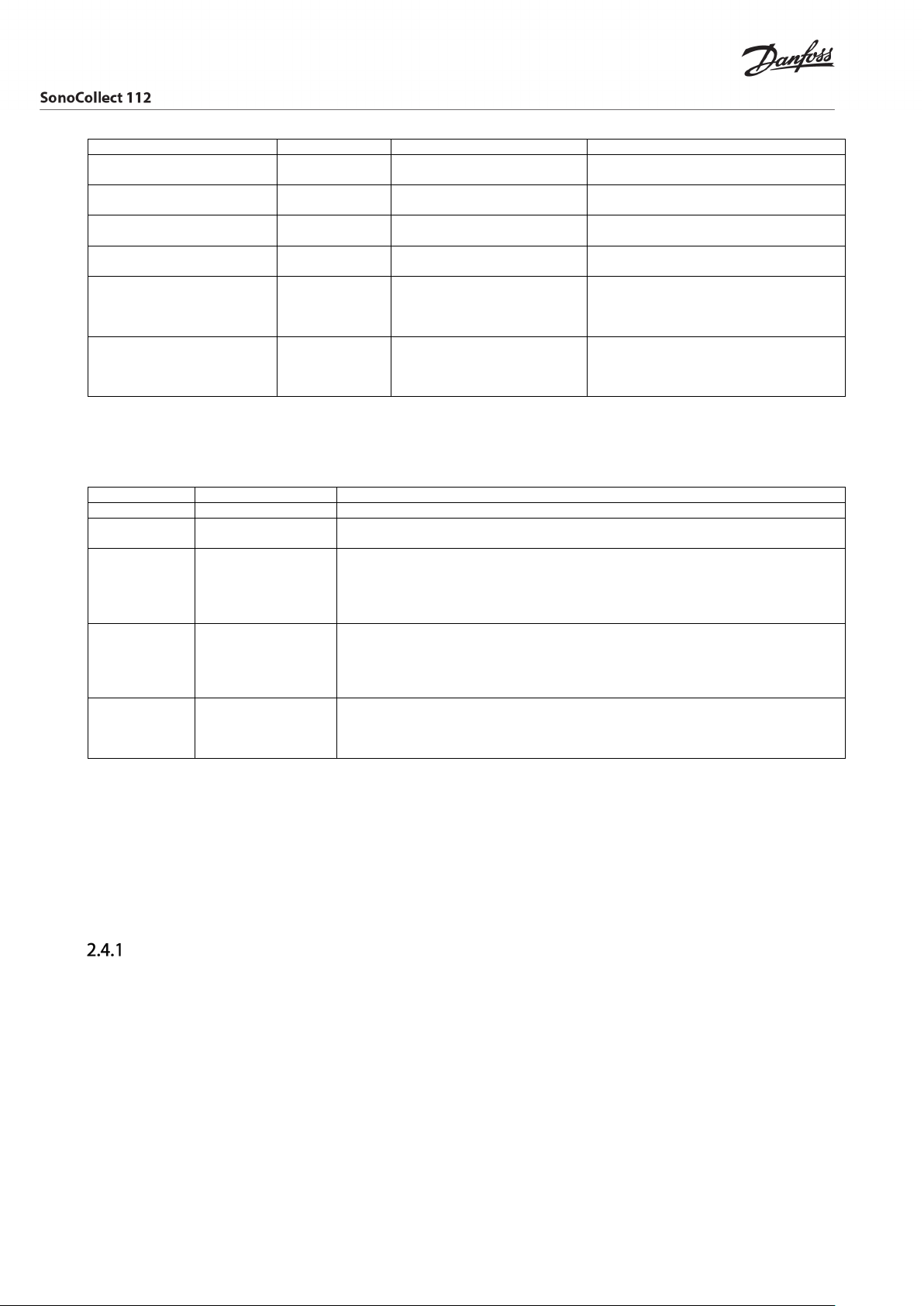

LED

Colour

Meaning

Power

green

Power supply active

Active (ACT)

Off

inactive, waiting state

State (STA)

Off

red

Software is not started

Error

Mode*

off

No connection

Link*

Off

WAN module switched off

RS-: negative bus line

Outer: Reference ground

M-Bus connection MB+, MB- MB+: positive bus line

(x = 1..3)

MB-: negative bus line

Sx-: Reference ground

DO-: Reference ground

Connection cable 2.5 mm²

Screw clamp

Connection cable 2.5 mm²

Connection cable 2.5 mm²

Voltage range 24 VDC

Connection cable 2.5 mm²

24 VDC, 100 mA

No galvanic isolation

Table 4: Pin assignments

2.3 Status LEDs

Depending on the version, the SonoCollect 112 has up to 5 status LEDs. These indicate the following states:

green

green

orange (flashing)

orange

Meter reading

Main program is running

Scanning meters

Initialization is running

red (flashing)

red

yellow

green

green

yellow

white

Data connection setup

Low received field strength

Average received field strength

Good received field strength

WAN module switched on (no data connection)

WAN module switched on + data connection (no data traffic)

WAN module switched on + data connection (active data traffic)

*only available in variant with WAN

Table 5: Status LEDs (all models)

In the operating state, the State LED is green and the active LED flashes green briefly during the readout.

The Mode LED indicates the reception field strength when the WAN connection is active at and the Link

LED lights up yellow or white when the WAN connection is active.

2.4 First steps

Power supply

The SonoCollect 112 has an integrated power supply unit and is supplied with 230 VAC (wide input voltage

range). Therefore, initially only the supply of the device must be ensured. The SonoCollect 112 starts automatically after connection to the supply voltage.

By default, following calls are made on system startup:

Configuration of the network interface (Ethernet) via DHCP or static configuration

Initial generation of SSL device keys (needs some time at first startup)

Obtaining the system time via SNTP

Starting the system services

Start of the main program

AQ332837053242en-010201 © Danfoss | 2021.03 | 10

Page 11

Classified as Business

The main program then provides the entire functionality, including the web interface of the SonoCollect

112.

Network configuration and first access

The SonoCollect 112 can be completely configured via the network interface. This must therefore be configured according to your network. If necessary, ask your administrator.

SonoCollect 112 is set by default to the static IP address 192.168.1.101 (subnet mask: 255.255.255.0,

gateway: 192.168.1.254).

For intuitive operation, a configuration website is available on the device, which can be accessed via

website on the SonoCollect 112, e.g.: http://192.168.1.101

when handling multiple devices under one IP (e.g. commissioning) or different software versions

(e.g. update), you should always empty the cache of the browser (e.g. Ctrl+F5) to prevent an inconsistent display of the website.

The following site opens in the browser:

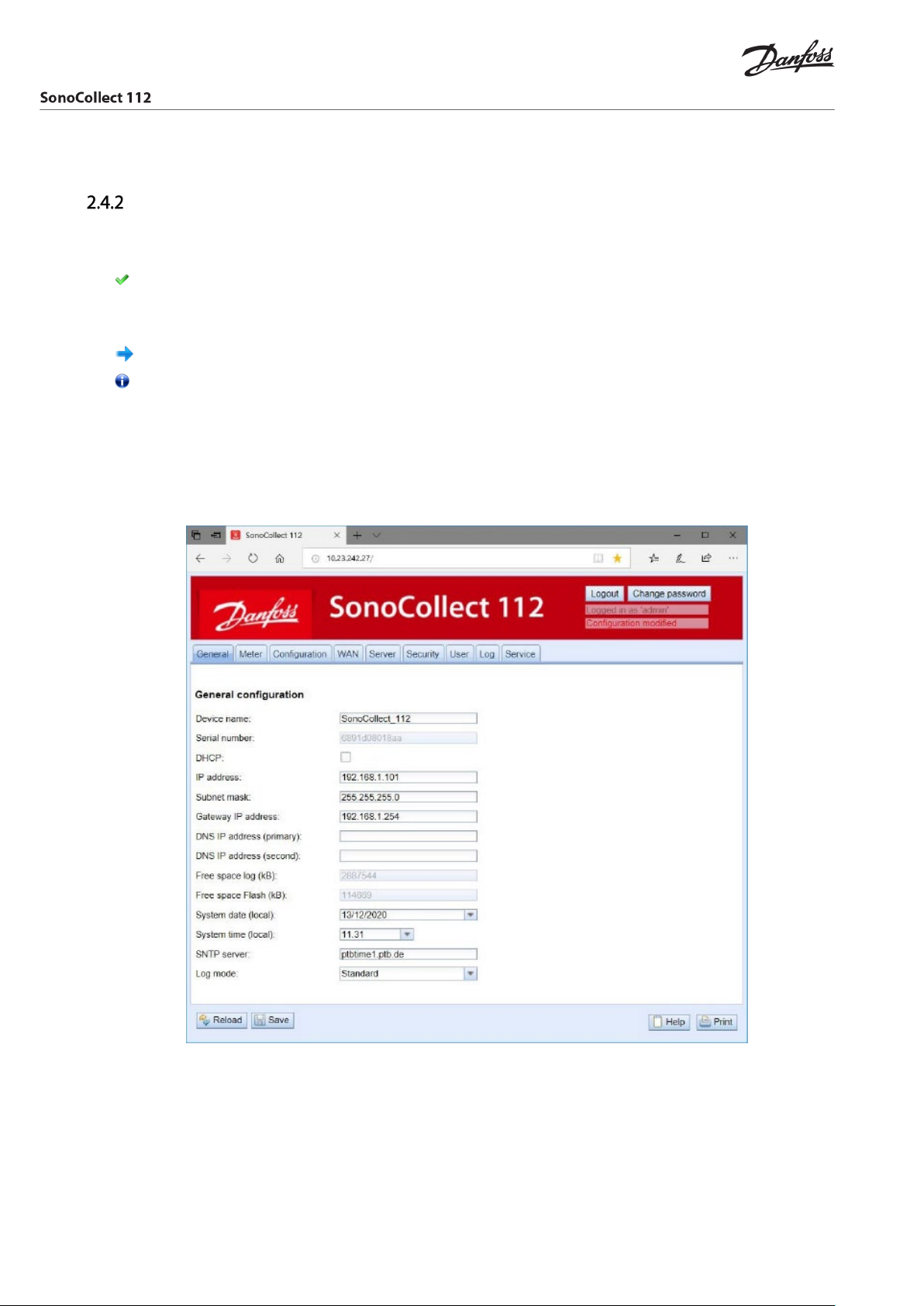

Figure 2 Website of the SonoCollect 112

The web frontend is described separately in chapter 4. There you will find a detailed overview of the functionalities of the web-based frontend.

In addition, access via SFTP, SCP, FTPS (file transfer) or via SSH (console) is also possible by default:

AQ332837053242en-010201 © Danfoss | 2021.03 | 11

Page 12

Classified as Business

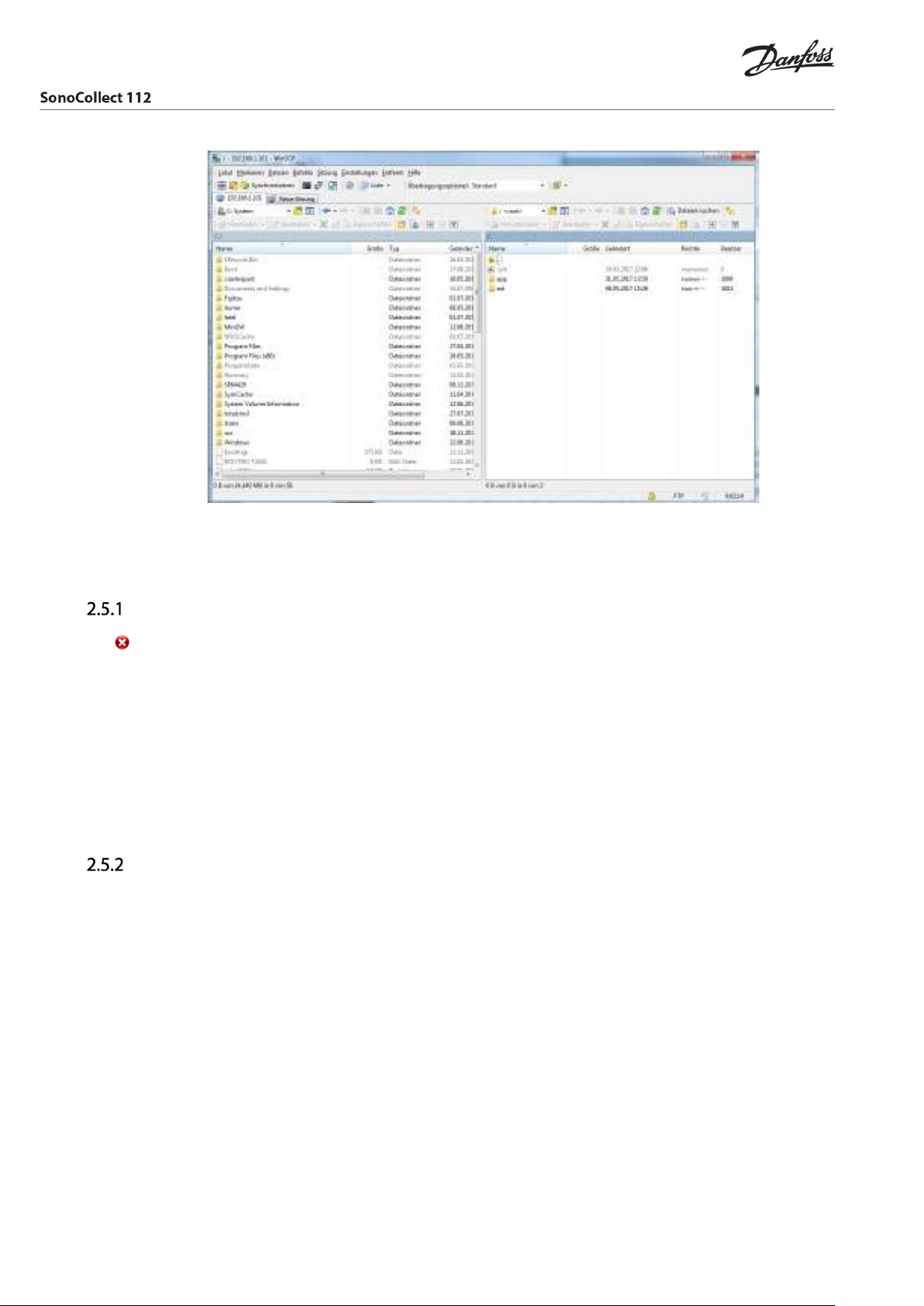

Figure 3 WinSCP main window after connection establishment

2.5 Specific troubleshooting SonoCollect 112

All LEDs remain dark, the device does not respond.

CAUTION LIFE HAZARD: The testing of the power supply may only be carried out by trained person-

nel.

Switch off the power supply. Remove all cables and antennas except the power supply. Now switch on the

power supply and check the voltage level from 90 to 260 VAC.

Ensure that no faults are caused by the infrastructure, circuit breakers or circuit breakers of the power supply. Test the SonoCollect 112 under laboratory conditions if necessary.

If errors could not be rectified, please contact your local Danfoss customer support.

The Power LED flashes green.

Switch off the power supply. Remove all cables and antennas except the power supply. Now switch on the

power supply and check whether the power LED is now permanently lit.

Now reconnect all cables and antennas one by one and check after each step whether the power LED remains permanently lit.

If the fault actually occurs on the connection of a specific cable, check it more thoroughly. There may be a

fault in the external circuitry, e.g. short-circuit or overload. If necessary, replace faulty cables.

If errors could not be rectified, please contact your local Danfoss customer support.

2.6 Typical application scenarios

The following are examples of how the SonoCollect 112 can be used.

To use the SonoCollect 112, the network and meter interfaces must be parameterized according to your

application and your plant (see chapter 4).

AQ332837053242en-010201 © Danfoss | 2021.03 | 12

Page 13

Classified as Business

Local application without control system

The SonoCollect 112 can be used for local meter reading.

No control system is required to collect and store meter data. Server services can therefore be deactivated

(Server tab ). Only the local storage of CSV files has to be set up.

The SonoCollect 112 is accessed in this application via a PC that is located in the same network. The current

meter values can thus be monitored via the website in the Meters tab. The CSV files can be accessed via

FTP access, provided logging is active. To do this, connect to the SonoCollect 112 with an FTP client (see

chapter: 6.2.2).

Users can be configured in the user management with the corresponding access rights to allow read access to the meter list (see chapter 4.7).

Remote monitoring without control system

This application case is largely equivalent to the example in section 2.6.1. The only difference is the network infrastructure that is set up between a PC and the SonoCollect 112 (Internet). The PC and the SonoCollect 112 are not located in a physical but in a logical network.

As a rule, routers and firewalls must be parameterized here to allow access from an external net-

work (PC in the Internet) to the SonoCollect 112 in the internal system network. Please ask your administrator about setting up routings, port forwarding, packet filters and firewalls for the individual

services of the product, such as FTP, HTTP and SSH.

If the network is parameterized correctly, you can access the SonoCollect 112 in the same way as in the local application.

Remote monitoring with email dispatch

The SonoCollect 112 can send the meter data as e-mails to any e-mail address. The meter data is stored in

XML format and can be processed as required (see section 9.7).

In order to send emails, the internal system network has to be set up correspondingly (e.g. firewall,

router). Ask your administrator about this.

Remote monitoring with FTP upload

The SonoCollect 112 can also actively upload this data to an FTP server instead of manually downloading

the CSV data. This makes it possible to access and process the files automatically.

For the FTP Upload, on the one hand the internal system network (e.g. firewall, router) and on the

other hand the receiving FTP server must be correctly configured. Ask your administrator about

this.

Remote monitoring with SFTP upload

The transfer of files to a server can also be secured via encrypted communication. For example, it is possible to encrypt the data using Secure Shell (SSH).

The following configuration must be made in the device to use the so-called SFTP.

The SSH and thus the SFTP use the asymmetric encryption and are secured by certificates. Both remote sta-

tions have both a private and a public key. A PKI (Public Key Infrastructure) is used to check the authenticity. This is usually associated with administrative work. Therefore, the authenticity can also be confirmed by

the user.

For this purpose, a finger print is exchanged during the initial connection, which uniquely identifies the

remote station. The finger print is the public key of the remote station. Now the user can manually check

and trust this. If this remote station is a trusted host, its fingerprint must be entered in the file

app/ssh/known_hosts. This is done by adding such a line to the file:

192.168.2.34 ecdsa-sha2-nistp256 AAAAE2VjZHNhLXNoYTItbmlzdHAyNTYAAAAIbmlzdHAy[...]

AQ332837053242en-010201 © Danfoss | 2021.03 | 13

Page 14

Classified as Business

Therefore, the corresponding finger print of the server must first be called in order to be entered into this

file. There are two possibilities:

The finger print is called directly from the server and manually entered into the file

app/ssh/known_hosts.

The server is accessed via SSH from the device and its finger print is accepted. Then the finger print is

automatically written to the file app/ssh/known_hosts.

It can be done directly from the device via the SSH console:

> ssh admin@192.168.2.34 <ENTER>

The authenticity of host '192.168.2.34 (192.168.2.34)' can't be established. ECDSA key fingerprint is

SHA256:HtAa1pkvafJSmAiMJmi1ZvJi6spgf5i0yt/A2rJ/OnY. Are you sure you want to continue connecting

(yes/no/[fingerprint])?

yes <ENTER>

Warning: Permanently added '192.168.2.13' (ECDSA) to the list of known hosts.

Subsequently, an encrypted cyclic upload of meter data can be performed via SFTP.

Remote monitoring with TCP/HTTP transmission

The transmission of XML data per TCP or HTTP is suitable for the direct connection of database systems.

The database servers can thus receive the data directly (XML format see chapter: 6.3.3).

For TCP/HTTP dispatch, on the one hand the internal system network (e.g. firewall, router) and on

the other hand the database server must be correctly configured. Ask your administrator about

this.

2.7 Technical data

General properties

Dimensions/Weight

The casing has the following dimensions (without antenna):

Width: 72 mm

Height: 91 mm

Depth: 62 mm (without antenna sockets)

Weight: approx. 210 or 220 g

Assembly

The device is intended for control cabinet mounting:

Temperature range: -20-70 °C

Air humidity: 0-95 \% relH

Type of protection: IP20

Top hat rail mounting (DIN rail 35 mm)

Electrical properties

Power supply

The device has an internal power supply unit (for pin assignment, see section 2.2):

Voltage: 90-260 V(AC), 50-60 Hz, screw clamps (≤2.5 mm²)

Power consumption: 2 W (idle), max. 10 W

Safety: Overvoltage category 3, protection class 1

AQ332837053242en-010201 © Danfoss | 2021.03 | 14

Page 15

Classified as Business

Peak inrush-current: <40 A

Galvanic isolation between interfaces and mains: >3 kV

Meter interfaces

The device has various meter interfaces (for pin assignment, see section 2.2):

M-Bus: compliant with to EN 13757-2, max. 80 standard loads (UL), Uspace = 36 V, Umark = 24 V, screw

clamps (≤2.5 mm²).

wM-Bus: compliant with EN 13757-4, 169/433/868 MHz, S, T or C mode, SMA antenna connector for ex-

ternal antenna

S0: compliant with EN 62053-31, U = 24 V, screw terminals (≤2.5 mm²)

DLDERS: compliant with EN 62056-21, mode and UART settings, see section: 4.4, EIA-485, screw clamps

(≤2.5 mm²)

The meter interfaces are not galvanically isolated from each other.

Communication interfaces

The device has an Ethernet communication interface (for pin assignment, see section 2.2):

Ethernet: compliant with IEEE 802.3, 10/100 base-TX, RJ45 connector incl. status LEDs, no Auto-MDIX

Mobile communication: 4G modem, LTE Cat1, Band 2,8,9, SMA antenna connector for external antenna

Further characteristics

Galvanic isolation

The Ethernet communication interface is separated from the meter interface and supply:

Galvanic isolation: 1000 V

Processing unit

The central unit is a microprocessor system:

CPU: ARM9™ architecture, 454 MHz clock frequency

Memory: 128 MB RAM, 4 GB internal eMMC flash memory

Operating System : Linux

Integrated RTC: Power reserve for up to 7 days

AQ332837053242en-010201 © Danfoss | 2021.03 | 15

Page 16

Classified as Business

3 Netdiscover tool

Danfoss provides its customers with the Netdiscover tool for easier management of products in the customer network. This tool allows you to find SonoCollect devices in the local network and to manage them.

The installation integrates two additional programs. The Putty and WinSCP programs are installed utilities

for SSH and (S) FTP access. The integration into the Netdiscover tool enables the easy access to the devices

from a central location.

3.1 Locating and accessing devices

When the tool started, it uses UDP broadcast via UDP port 8001 to determine all SonoCollect devices accessible in the local network and displays them in the main window.

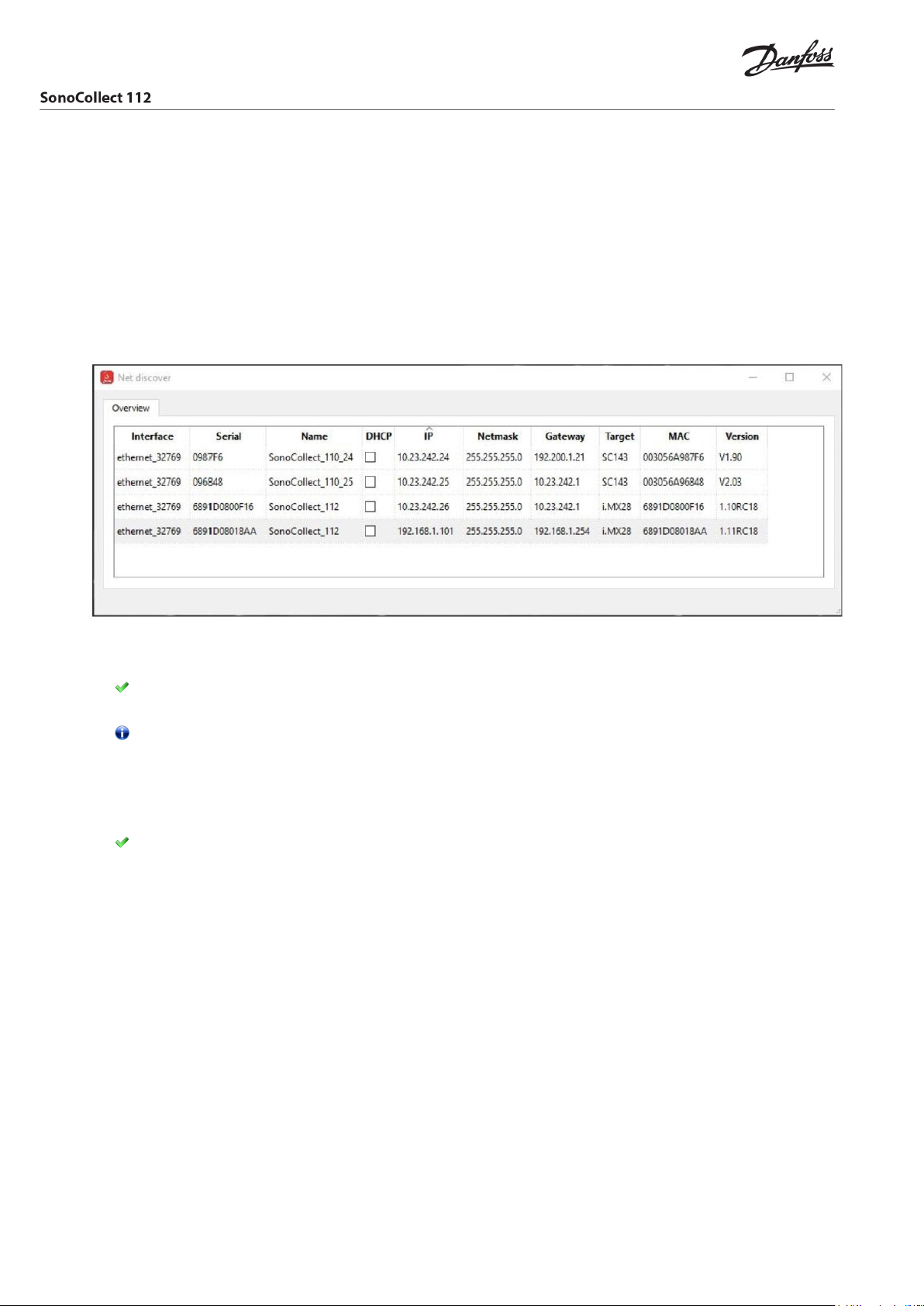

Figure 4 Main window of the Netdiscover tool

The UDP broadcast finds all devices on the local network, regardless of IP settings and subnet

masks. Therefore, this function is initially recommended.

The UDP broadcast is usually not forwarded by routers. Therefore, this tool will only find all devices

on the local network in front of the router.

In addition to the MAC address of the devices and their network configuration, the names of the devices

and also the version of the operating system can be viewed. Thus, all devices to be managed can be clearly

identified and assigned.

The name of the devices corresponds to the Device name entry in the General tab (see section 4.2).

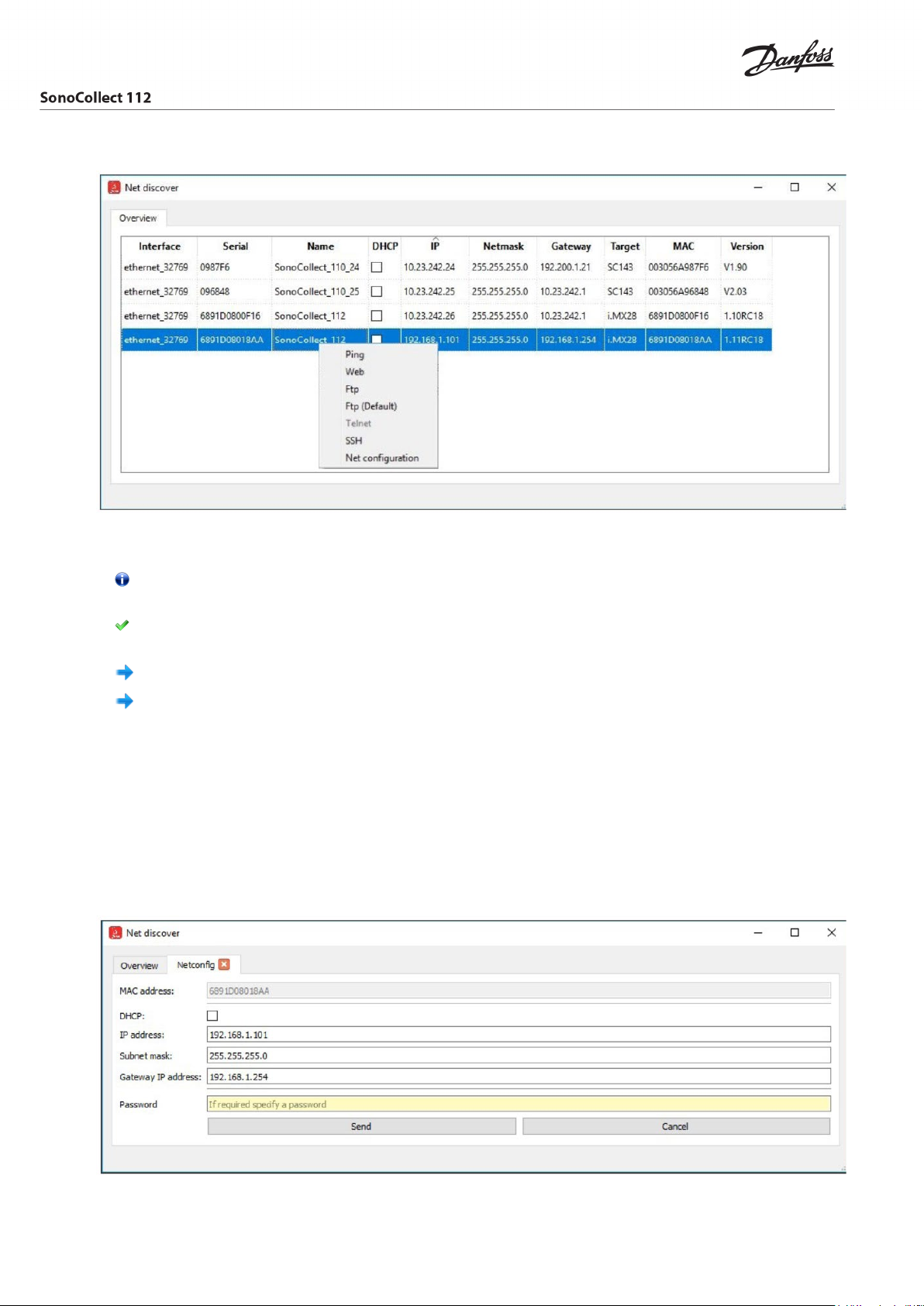

Various functions can be called up in the context menu that appears by right-clicking on one of the devices:

Ping:

Starts the ping via ICMP to the device in a separate tab. So testing of connectivity via TCP is possi-

ble.

Web:

Opens the default browser with the IP of the device. The web-based frontend should open (see

chapter 4).

FTP:

Starts WinSCP with the IP of the device or in general. The login data or also its IP must be entered

before connecting to the FTP/SFTP server of the device.

FTP (default):

the admin-user.

SSH:

sole.

Deploy:

Import device list:

Net configuration:

broadcast.

Starts WinSCP with the IP of the device and connects an SFTP with default access data of

Starts Putty with the IP of the device. The login data must be entered to connect to the SSH con-

Starts the mass management of the devices in a separate tab.

Imports a device list into the main window.

Starts in a separate tab for changing the network configuration of the devices via UDP

AQ332837053242en-010201 © Danfoss | 2021.03 | 16

Page 17

Classified as Business

Version:

Version information about the Netdiscover tool.

Figure 5 Context menu in the Netdiscover tool

Depending on the network settings of your PC or your general network infrastructure, the UDP

port 8001 may be blocked. Then calls of the tool are blocked and the main window remains empty.

When a firewall in your network (also directly on the PC) is used, it is to create an appropriate fire-

wall rule. It releases this port to be able to list the devices.

Ask your administrator about the firewall and network configuration.

If access via UDP broadcast is not possible, a list can be imported with the Import device list func-

tion in order to still be able to use all other functions via TCP.

Some important functions are described in more detail in the following subsections.

3.2 Network configuration

It is often necessary to adjust the network settings of the device for further work with the devices, especially when commissioning devices.

The command

network configuration. Thus, IP address, subnet mask or gateway address can be changed statically or

DHCP can be activated to obtain these settings automatically from a DHCP server.

Net configuration from the context menu in the Netdiscover tool opens another tab for the

Figure 6 Network configuration via the Netdiscover tool

AQ332837053242en-010201 © Danfoss | 2021.03 | 17

Page 18

Classified as Business

Modifications are only accepted with the password of the admin user.

3.3 Access to the web-based front end via HTTP

A web server is integrated on the SonoCollect devices. This enables the configuration of the devices via an

integrated, web-based front end (see chapter 4).

Use the command

default browser.

Web

from the context menu in the Netdiscover tool to quickly and easily call it from the

If the web-based front end does not open, please follow the instructions in section 4.13.

3.4 Access to the file system via FTP

The SonoCollect devices can be accessed via FTP to work directly on the file system level. Updates, special

configurations and function extensions can be carried out (see chapter 10). The integrated FTP server of

the devices supports both FTP and SFTP.

If access via FTP or SFTP is not possible, check especially the IP settings and the port release of port

21 for FTP and 22 for SFTP.

In case of access problems, ask your administrator.

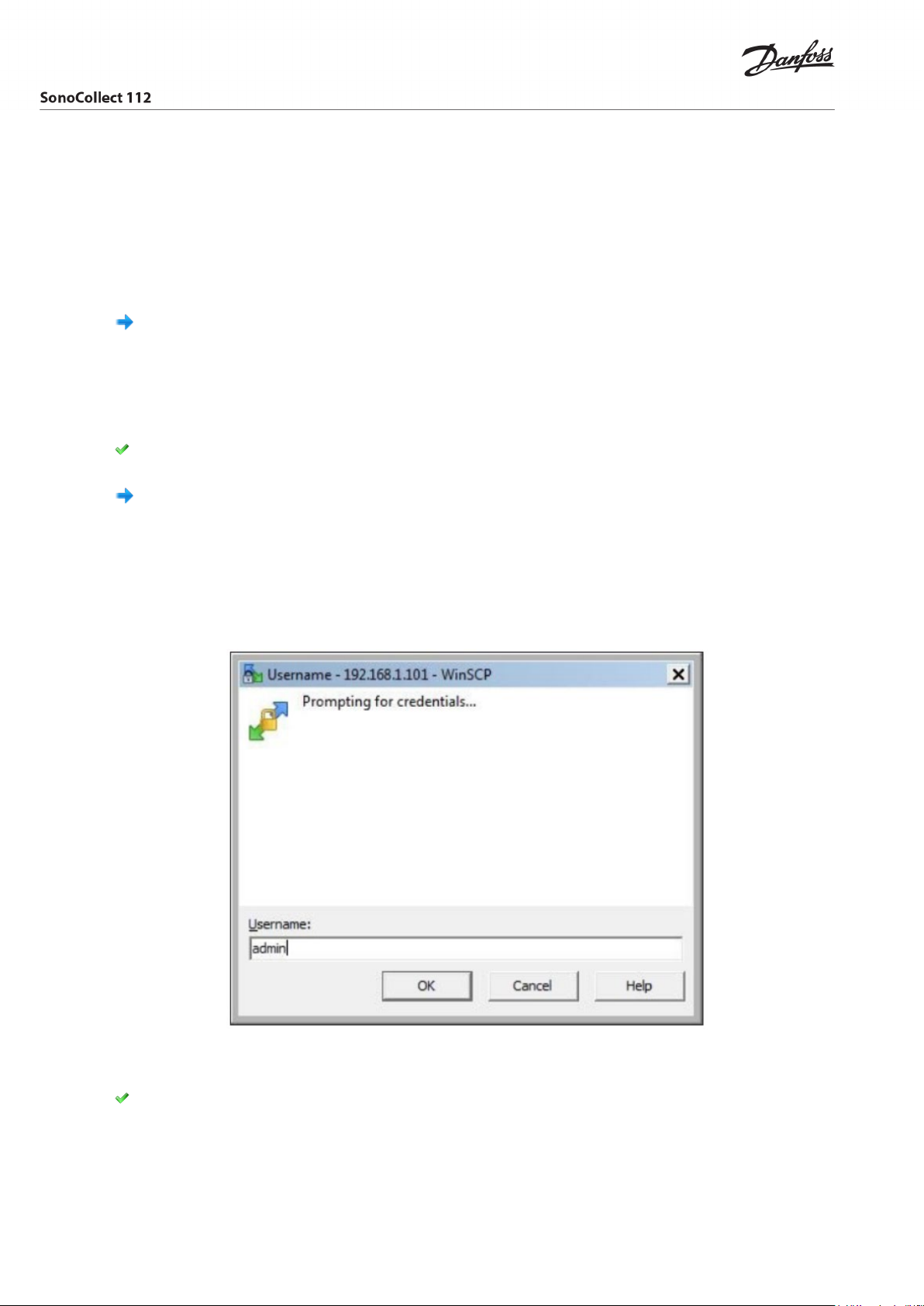

The commands

gram and use the IP address of the selected device. Always use the selected device to have access via FTP.

To use a secure SFTP, the context menu must be called without a selected device, then only the command

FTP

is available. Now select in the WinSCP window whether FTP, SFTP or SCP should be used.

The mode

any access data can be entered.

FTP

and

FTP (default)

FTP (default)

tries to log in with the default access data of the admin user, while in the mode

from the context menu in the Netdiscover tool start the WinSCP pro-

FTP

Figure 7 Entering user data when logging in via SFTP

If the access data of the admin user is modified, the use of FTP (default) is not possible.

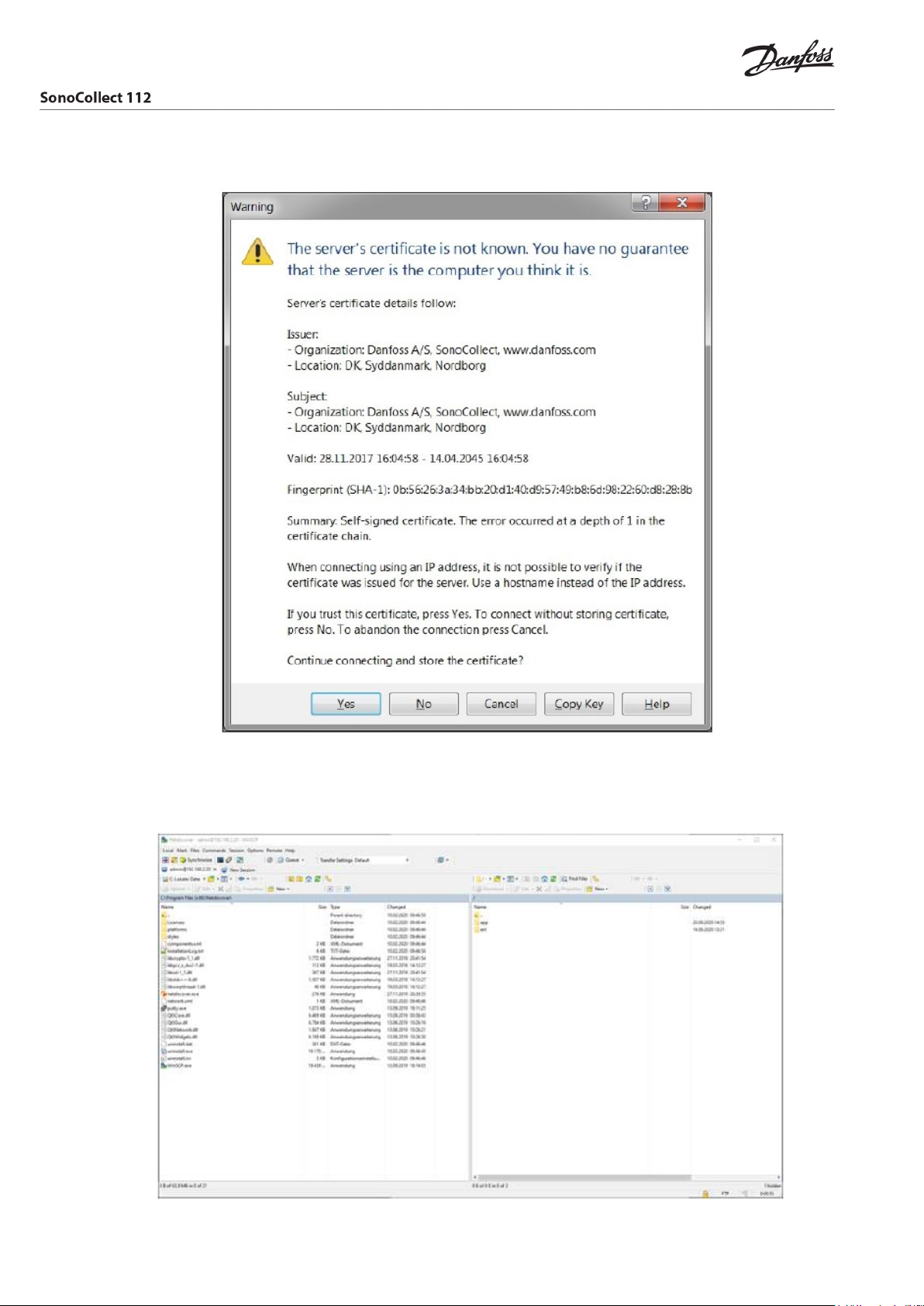

WinSCP now establishes a secure SFTP or unsecure FTP connection. When a connection is established to a

specific device with SFTP, its authenticity is checked using stored certificates. Normally, the SonoCollect

devices receive an individual, self-signed certificate upon delivery. This certificate is usually classified as untrusted by your PC. Therefore, a security prompt with information about the device's certificate is

AQ332837053242en-010201 © Danfoss | 2021.03 | 18

Page 19

Classified as Business

displayed. The user must actively trust this certificate for the connection to be established. The confirmed

certificate is stored in the PC for future connections.

Figure 8 Safety query for the certificate of the device

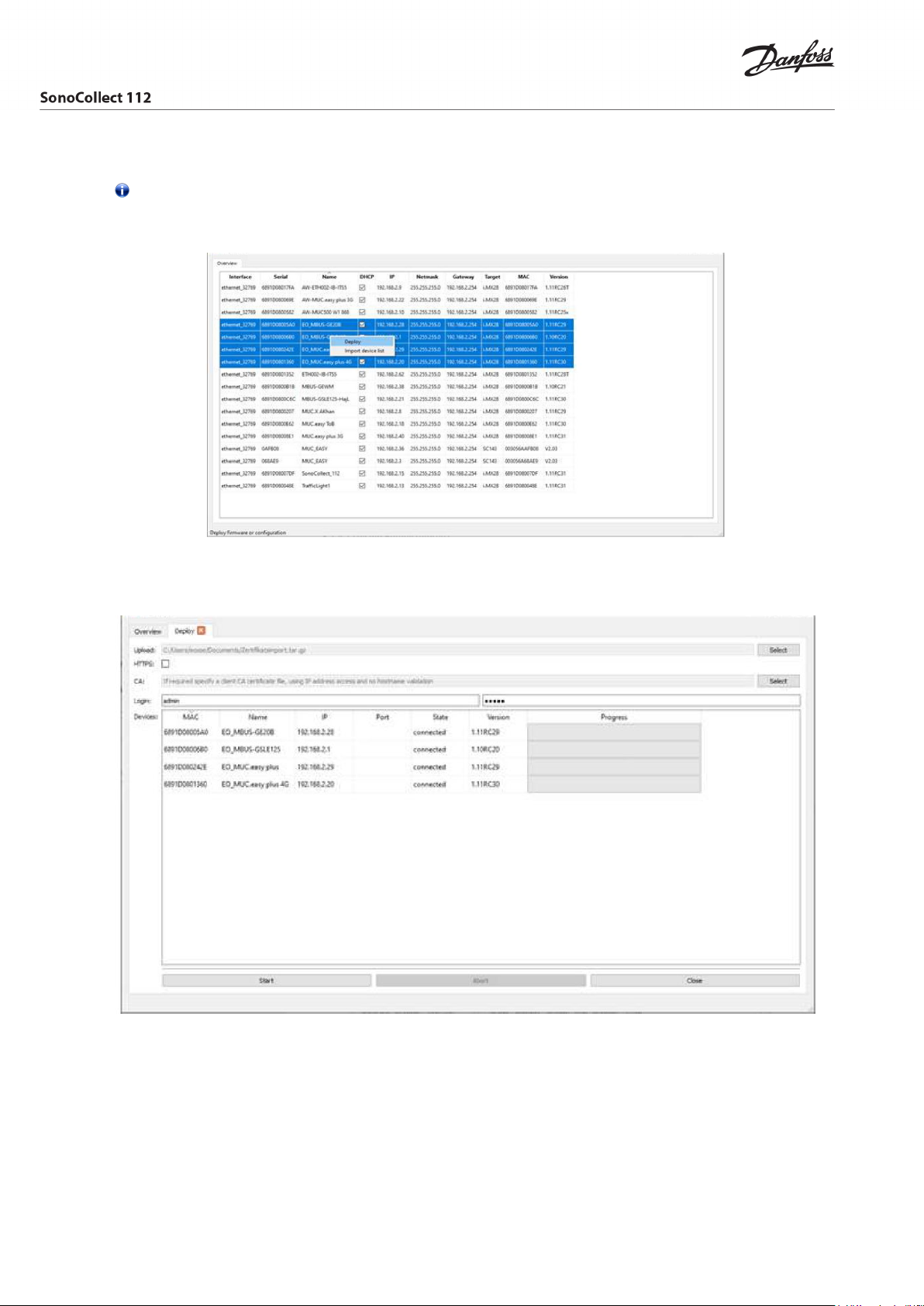

WinSCP presents a two-part file browser view after successful login. This allows files to be uploaded to or

downloaded from the device. File commands can be executed via a context menu (e.g. copying, renaming

or editing. Drag&Drop for uploading and downloading is also supported.

Figure 9 File Browser View in WinSCP

AQ332837053242en-010201 © Danfoss | 2021.03 | 19

Page 20

Classified as Business

Changes to the files or the file system can limit the functionality of the system.

The standard access data in the delivery state are contained in the section 4.8.

3.5 Access to the command line via SSH

Access to the command line interface (CLI) of the device is suitable for maintenance purposes.

The command

establishes a connection to the device.

When a connection is established to a specific device with SSH, its authenticity is checked using stored cer-

tificates. Normally, the SonoCollect devices receive an individual, self-signed certificate upon delivery. This

certificate is usually classified as untrusted by your PC. Therefore, a security prompt with information about

the device's certificate is displayed. The user must actively trust this certificate for the connection to be established. The confirmed certificate is stored in the PC for future connections.

SSH

from the context menu in the Netdiscover tool opens the integrated Putty client and

Figure 10 Safety query for the certificate of the device

Now the Putty client opens where the SSH access data of the admin user must first be entered. Then. the

command line is ready for input via SSH.

Figure 11 Command line in the Putty client

Inputs on the command line can restrict the functionality of the system.

The standard access data in the delivery state are contained in the section 4.8.

3.6 Mass management

Using this function it is possible to perform certain device configurations or firmware updates in parallel for

all devices displayed in Netdiscover. This makes it possible, for example, to import an exported device configuration to other devices at the same time. Another example would be importing certificate files needed

AQ332837053242en-010201 © Danfoss | 2021.03 | 20

Page 21

Classified as Business

on multiple devices to export meter data. A third and final example would be updating the application

software on multiple devices in parallel.

The configuration or update should only be carried out explicitly for similar devices.

In this case mark the devices in Netdiscover on which you want to perform a parallel configuration or firmware update.

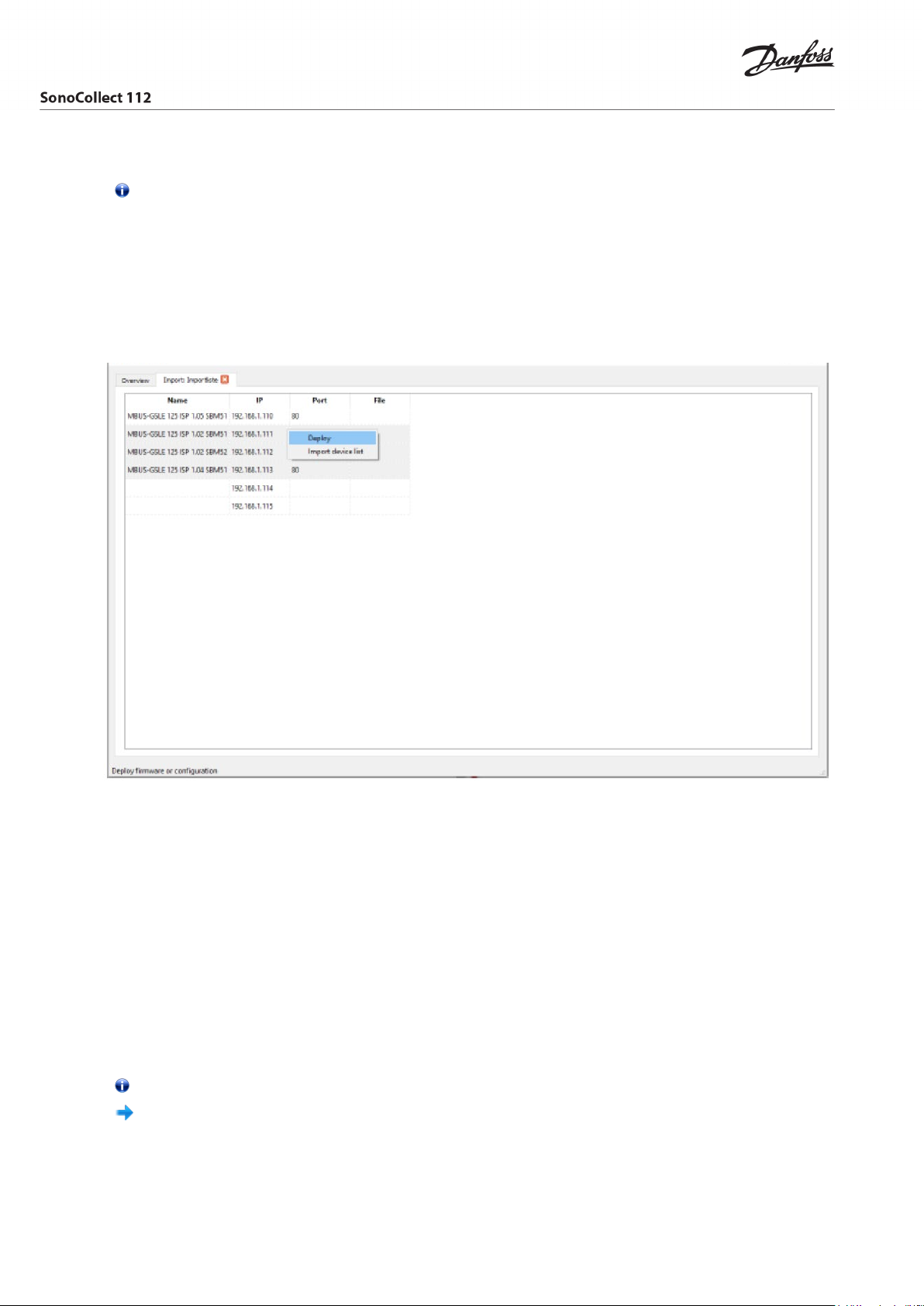

Figure 12 Selection and call of the mass management

The

Deploy

ment.

command from the context menu in the Netdiscover tool opens another tab for mass manage-

Figure 13 Mass management via the Netdiscover tool

The following input fields and buttons are available here:

Upload: The configuration or update to be uploaded.

HTTPS: Selection field whether HTTP or HTTPS should be used.

CA: The CA certificate to verify the client certificate of the devices for HTTPS-based work.

Login: User name and password for the admin user.

Start: Starts the process.

Abort: Cancels the process.

Close: Closes the mass management tab.

AQ332837053242en-010201 © Danfoss | 2021.03 | 21

Page 22

Classified as Business

In the central part, there is a list view with information about the devices and the status/progress of the operation.

Only *.tar.gz archives are intended for uploading to the device.

The file is unpacked on the device after the upload, and processed, the device is then restarted.

3.7 Import of a device list

Devices cannot always be found automatically. Firewalls, routing settings or also the deactivation of the

function

A device list can be imported in order to still be able to manage devices via the Netdiscover tool.

Network discovery active in the

Security

tab (see section 4.7) are possible causes.

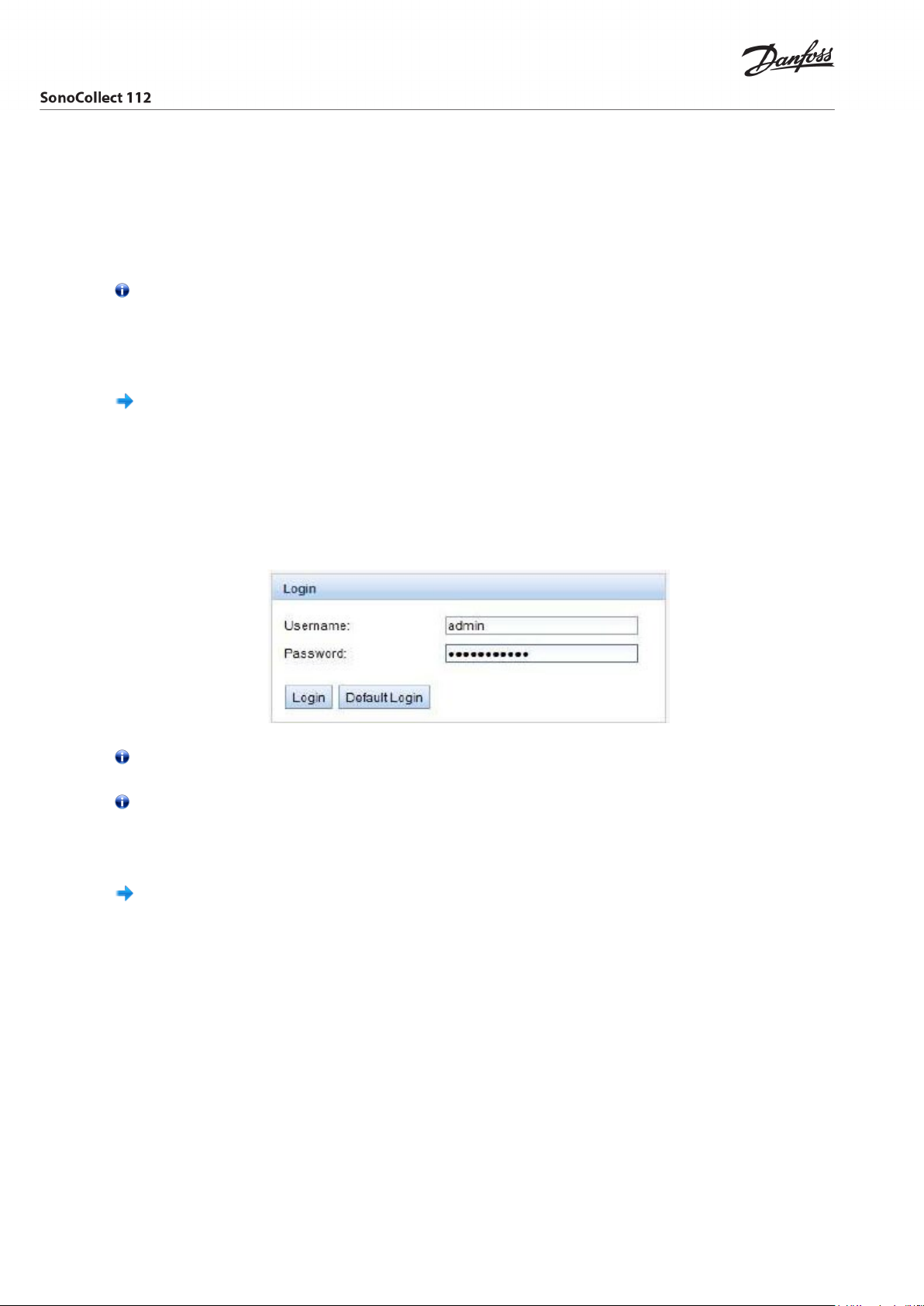

Figure 14 Viewing and using an imported list in the Netdiscover tool

A suitable CSV file must first be created before the actual import. A comma or semicolon can be used as a

separator in the CSV file. The device data is entered here according to the following example to obtain the

above list in the Netdiscover tool:

Port;Name;Password;Username;IP;File

80;MBUS-GSLE 125 ISP 1.05 SBM51;admin;admin;192.168.1.110;

80;MBUS-GSLE 125 ISP 1.02 SBM51;admin;admin;192.168.1.111;

80;MBUS-GSLE 125 ISP 1.02 SBM52;admin;admin;192.168.1.112;

80;MBUS-GSLE 125 ISP 1.04 SBM51;admin;admin;192.168.1.113;

;;admin;;192.168.1.114;

;;;;192.168.1.115;

The header of the CSV file must be identical to the one above.

Only the IP column is mandatory. The other columns can be left empty and are set to default for

special functions (port: 80, password: admin, user name: admin).

AQ332837053242en-010201 © Danfoss | 2021.03 | 22

Page 23

Classified as Business

4 Web-based front end

Many products of Danfoss A/S, especially data concentrators and gateways for smart metering, have an

integrated web server and provide a website for the configuration. The devices can be configured easily

and in a user-friendly manner via this website. Device parameters, meter configuration as well as service

services can be displayed or changed on this website.

This chapter contains an overview of the operating options via the web front end.

The use of some functions listed below depends on the product. A gateway for example does not

have a report interface for data push or a cellular modem. This is indicated at the relevant point.

The web front end can be easily opened in the browser by entering the device IP address. Alternatively,

right-click on the device in our Netdiscover tool (see chapter 3

text menu to call the browser.

) and select the

We test the web front end in different browsers. We recommend the use of the Chrome and Firefox

browsers for optimal viewing.

In the delivery state, the browser automatically logs the user into the website using the standard access

data. The user "`web"' with the password "`web"' is stored ex works for this purpose. This user has full access to the website. This facilitates the initial commissioning.

If the default user "`web"' has been changed in the configuration via the tab

the password, the correct access data must be entered in order to log in. Then, the automatic login will not

take place. A login window will then always appear:

Web

command in the con-

User

, for example by changing

Figure 15 Login window

To change an already logged-in user (or default user), the Logout button in the top right can be

selected.

The standard access data in the delivery state are contained in the chapter 4.7.

If the logged-in user has write access, the user must be logged out after the configuration has finished. If

the connection remains active, no other work computers have write access to the web front end. Only one

session with write access is possible at a time.

If a session is terminated without prior logout, e.g. by closing the browser window, it remains ac-

tive for approx. 1 min. Afterwards it is automatically closed and write access is possible again.

The functions are subdivided into different tabs on the website of the device. So the clarity can be maintained despite the large number of parameters. All modifications in one of the tabs must be saved before

changing tabs, otherwise the modifications will be lost. The functions and parameters of the individual

tabs are described below.

4.1 Access via HTTPS

Normally the web front end is accessible via HTTP (port 80) as well as via HTTPS (port 443). Depending on

the requirements, one of the services can be deactivated (see section 4.10).

Compared to HTTP, HTTPS offers both encryption and authentication methods and thus enables secure

access to the devices in insecure networks.

The SonoCollect devices are delivered with certificates and keys in preparation for HTTPS access:

app/keys/http_host_cert. : Self-generated certificate of the device to verify the identity of the de-

vice, server-side authentication

app/keys/http_host_key. : Private key of the device

AQ332837053242en-010201 © Danfoss | 2021.03 | 23

Page 24

Classified as Business

Field name

Description

Device name

Name of the device (assignment in Netdiscover)

Serial number

Serial number of the device (MAC address), not editable

DHCP

Enable automatic network configuration

IP address

IP address of the device, not editable with DHCP

Subnet mask

Subnet mask of the device, not editable with DHCP

Gateway IP address

IP address of the default gateway, not editable with DHCP

DNS IP address (primary)

IP address of the primary DNS server, not editable with DHCP

DNS IP address (secondary)

IP address of the secondary DNS server, not editable with DHCP

VPN

Activates the OpenVPN client functionality

Free space log (kB)

Free space on the log area, not editable

Free space Flash (kB)

Free space on the application area, not editable

System date (local)

Current, local system date

System time (local)

Current, local system time

Log mode

Detail depth of the log entries of the application

The user can upload another certificate to the device to fully secure the communication and for mutual authentication.

app/keys/http_host_ca. : Root certificate to check the client certificate of the browser and thus the

identity of the client, client-side authentication

Based on these files, a protected identification and authentication of the communication partners takes

place and a symmetric session key is negotiated.

Access to the web front end via HTTPS can be blocked by installing incorrect or invalid certificates.

Deactivating HTTPS or HTTP is only possible via the other access to the web front end.

Optionally, customer-specific certificates can be uploaded before delivery.

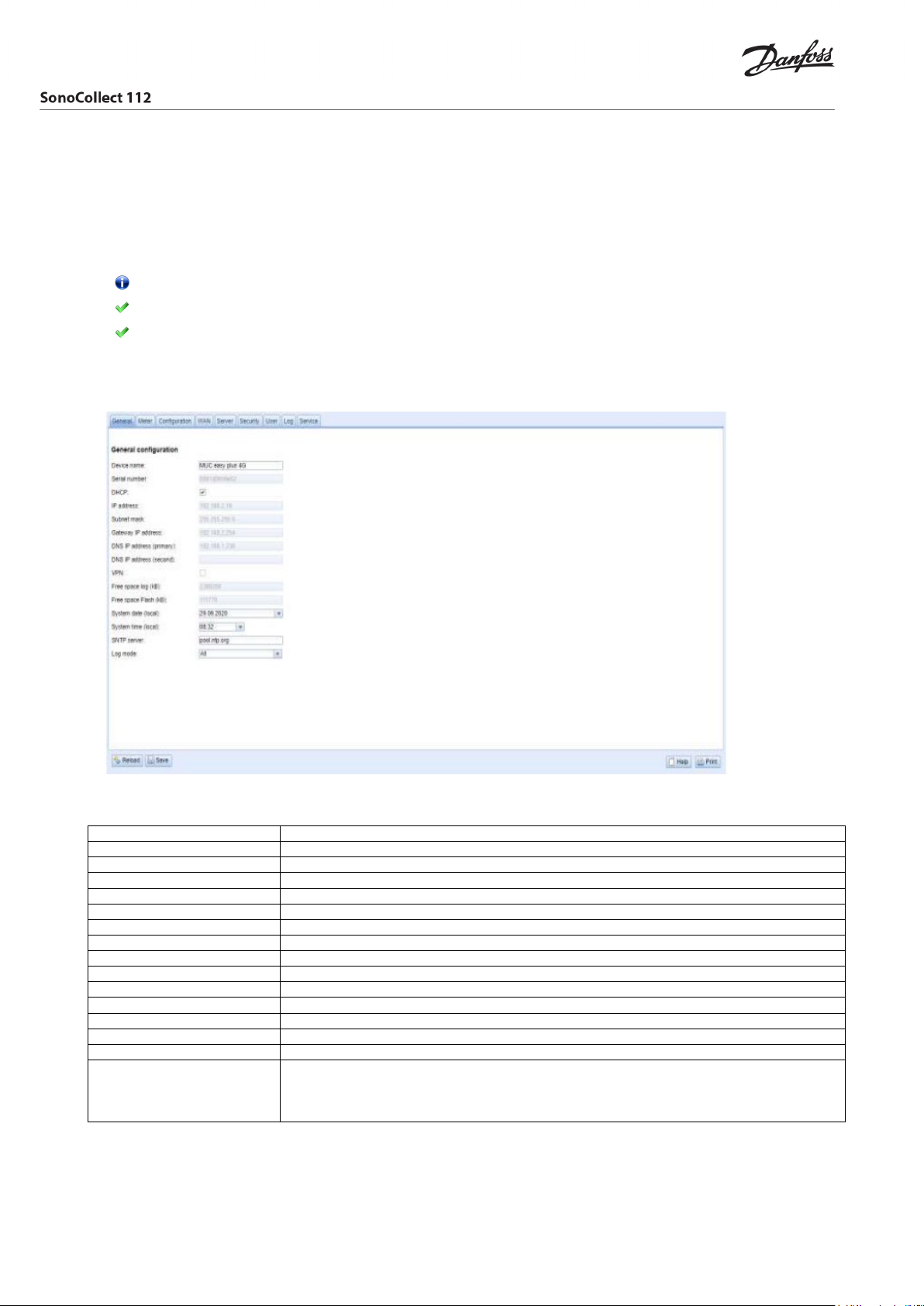

4.2 General tab

The General tab displays general properties of the device and its network configuration.

Figure 16 General tab

The following values can be viewed or changed here:

SNTP server Address of the time server

None: The application does not generate log entries

Standard: The application generates log entries for errors and warnings.

All: The application generates log entries for all events

Table 6: Fields in the General tab

The Save button is used to save the configuration. The Reload command loads the last saved values and

resets the current changes.

AQ332837053242en-010201 © Danfoss | 2021.03 | 24

Page 25

Classified as Business

Field name

Description

Interface

Interface to the meter

System: Monitoring of internal measured values of the device

S (Status)

Shows the status of the meter or the meter value

Serial

Serial number of the meter (meter number, secondary ID)

MAN

Manufacturer of the meter (abbreviation), DLMS Flag-ID

Medium

Meter medium, see second column in Table 25

Version

Version number of the meter

Link

Primary address of a meter (M-Bus) or reception field strength (RSSI) for wM-Bus

Value

Meter reading or measured value (unscaled)

Scale

Scaling factor (scientific notation)

Unit

Unit, see second column in Table 27

OBIS-ID

OBIS code in the format X-X:X.X*X (X=0..255)

If the network configuration is changed, the device is available under the new IP after the save process. All

existing connections will be disconnected or logged in users will be logged out automatically.

Changing the network parameters of the device can restrict the accessibility. If the network param-

eters have already been set correctly by an administrator, they should not be changed.

The device is automatically reinitialized by setting the parameters via the SAVE button.

Date and time are always processed as UTC time (without time zone shift). When displayed on the

website, the browser converts it according to the locally set time zone of the computer. In Central

Europe, for example, this is Central European Time or Central European Summer Time. If a different

time zone is set here, the time on the website will also be displayed accordingly.

The use of OpenVPN is described in the section 10.5.

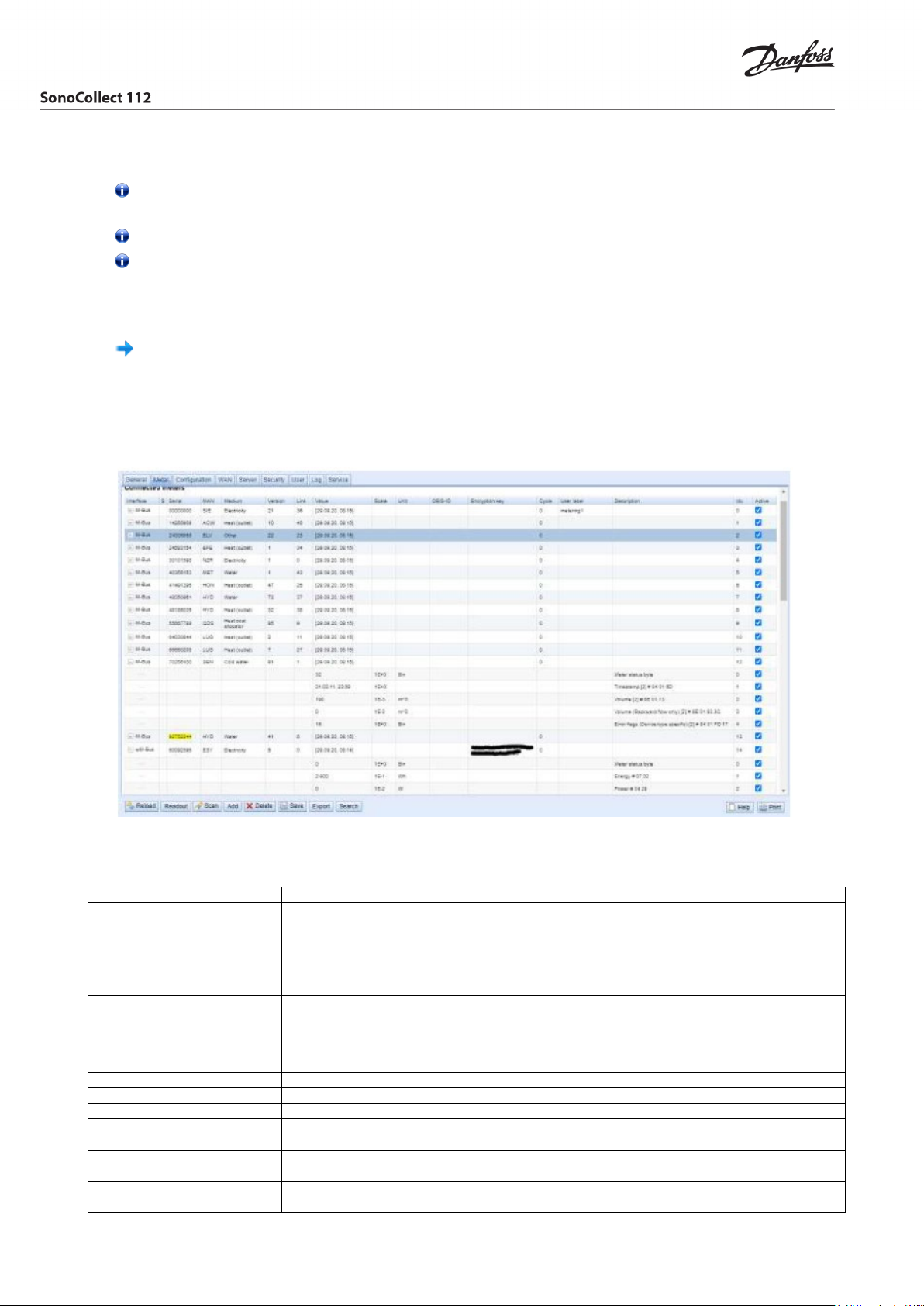

4.3 Meter tab

The Meter tab displays an overview of the connected meters, and gives the user the possibilities of automatically searching for meters, adding meters manually, and configuring meters that are already present.

The meter list can additionally be exported in this way.

The meter list is displayed in tabular form. Meter entries and the corresponding meter value entries are displayed one below the other. The individual columns have the following meaning:

AQ332837053242en-010201 © Danfoss | 2021.03 | 25

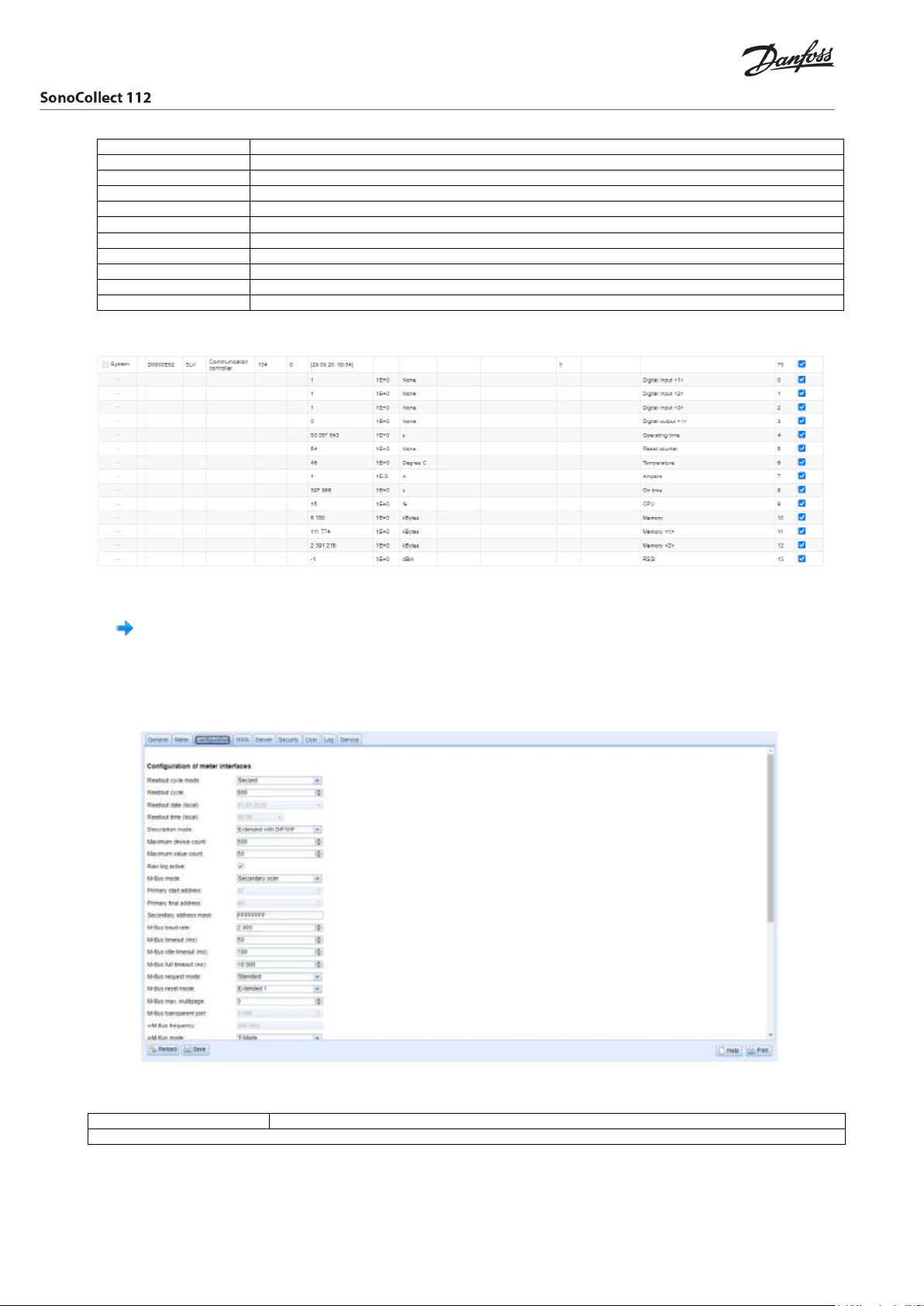

Figure 17 General tab

M-Bus: wired M-Bus according to EN 13757-2/-3/-7 and OMS

wM-Bus: wireless M-Bus according to EN 13757-4/-3/-7 and OMS

DLDE: wired serial interface according to IEC 62056-21 or IEC 1107/61107

S0: wired meter/pulse interface according to IEC 62053-31 or for simple contactors

!: Meter or not all meter values can be read, meter value not current

E: Meter/meter value edited

A: Meter/meter value added

*: Meter value list limited (see Maximum value parameter count in Configuration tab)

Page 26

Classified as Business

Encryption key Key for encrypted wM-Bus meters

Cycle

Readout interval in seconds (at 0 the general readout cycle is used, see Configuration tab)

User label

User defined description of the meter value, this allows an application specific assignment.

Description

Description of the meter value according to the second column in Table 26. The display of memory

Configuration tab.

Idx

Index/position of meter/meter value in the meter list

Register

Offset of the register set to the value when using the Modbus server

BACnet

Object number of the value when using the BACnet server

Active

Activates a meter or meter value for transmission to the server or logging.

Allowed characters are: A-Z, a-z, 0-9, !,§,\$,\%,\ ,/,(,),=,?,+ and *. A comma is also allowed.

Inadmissible are: $\langle$, $\rangle$ and ".

When using the CSV format, the semicolon (or the corresponding separator) should not be used.

number, tariff, value type and raw data can be configured via the Description mode parameter in the

Table 7: Columns in the Meter tab

The meter configuration can be changed with the buttons in the lower area or through the context menu.

Individual meters or meter values can be automatically searched for, created, deleted or changed according to the limitation of the interface used (M-Bus, wM-Bus etc.).

The meters or meter values in the list can be selected by a simple mouse click. A range can be selected with

SHIFT> key held down, or multiple meters can be selected with the <STRG> key held down.

the <

Duplicates of the serial number are marked in yellow for easier checking of the meters created. With the

Search button the complete meter list can be searched for a search text. Hidden entries are also searched

(meter values of closed maters).

Reload loads the last saved values, resets current changes, and correspondingly updates the meter values.

In the delivery state, the device has an empty meter list. If meters are connected via the external interfaces

of the device, the

Configuration

Scan button can start an M-Bus scan. The scan mode "M-Bus mode" is configured in the

tab. More information on this can be found in chapter 6.1.1.

Depending on the mode and the number of connected meters, this may take a very long time.

The process can be interrupted with the Cancel button, whereby the meters already found are saved in the

meter configuration. After the scan, the meter configuration is immediately accepted, and only has to be

saved again after further changes. The scan can add meters to the existing meter list but no already configured meters are deleted or changed. Newly found M-Bus meters and their values are automatically activated after the scan or are assigned a Modbus address or BACnet number. The scan also permanently adds

newly received wM-Bus meters to the configuration, provided that the parameter wM-Bus listen in the

figuration

tab is activated. Since wM-Bus meters are not necessarily your own, they are not automatically

Con-

activated, unlike the M-Bus. The list mode initially only lists all received meters without permanently saving

their configuration.

The meter values of M-Bus and wM-Bus meters are arranged in the same order as the data in the M-

Bus or wM-Bus protocol. This means that the meanings of the values can be directly compared with

the data sheet of the relevant meter. Alternatively, the arrangement can be via the raw data of the

meter values (see Description mode parameter in the

Configuration

tab in chapter 4.3).

The time stamps transmitted in the M-Bus or wM-Bus protocol are automatically assigned to the

individual measured values, and therefore not listed in the meter list by default. The explicit representation of all time stamps can be manually activated via the configuration parameter

MUC_SHOWTIMESTAMPENTRIES (chip.ini) (see chapter 8.4.1).

Newly received wM-Bus meters are deactivated by default, and have to be manually activated and

saved in order to be transmitted in the server communication and log data. Non-saved wM-Bus

meters are deleted after a restart.

Meters not found and meters not connected via interfaces which do not allow an automated search, can

be added manually with the

can be found in chapter 6.1.3.

Add button or with

Add meter

in the context menu. More information on this

To configure individual meters or meter values, double click an entry or call the Editing window with the

Edit

context menu item

Individual fields are activated or deactivated according to the interface.

. The field descriptions correspond to the columns of the meter list (see Table 7).

AQ332837053242en-010201 © Danfoss | 2021.03 | 26

Page 27

Classified as Business

Field name

Description

Digital Input <x>

State of the digital input, channel x

Among other things, User label can be assigned to all entries here, so the meter or meter value can be as-

signed to a specific application. The (specific) read out interval of the meters can also be set via the parameter Cycle. The key required for decoding can also be set for wM-Bus meters in the Meter editing window.

S0 meters are internally processed with the number of pulses. The representation on the website in

the value column is nevertheless scaled to provide better readability. The Scale column contains

the pulse value and, in contrast to other meter interfaces, does not have to be additionally multiplied. If a value of 280.09 and a scaling of 1e-4 is displayed in the Meter tab, 2800900 pulses are recorded internally. However, this unscaled meter value appears analogously to those of other meters

in the report data, such as the CSV of the XML.

With S0 meter values, the meter value itself can only be set in the Add or Edit window if the Set

Value checkbox set is activated. The Set Value checkbox must be deactivated if a configuration does

not change or overwrite the current meter value (e.g.: change of the user label). The input of a meter value is scaled.

Before an S0 meter value is saved, the input value is calculated back to the pulse value and

rounded to whole pulses. Inaccuracies can result from the floating point data types.

The configuration can be finished with the Ok button or cancelled with the Cancel button.

For transmission and logging, individual meters and meter values can be directly activated or deactivated

with the checkbox in the Active column. The meter values are automatically activated or deactivated by the

configuration of a meter corresponding to the hierarchy. In the same way, an inactive meter is automatically activated if one of its meter values is activated. Multiple selected meters or meter values can be set

with the context menu items

Activate

and

Deactivate

.

All selected meters and meter values can be deleted with the Delete button or the context menu item with

the same name. Deleted wM-Bus meters are then created again if the wM-Bus lists parameter in the Config-

uration tab is activated.

Individual meter values of an M-Bus or wM-Bus meter cannot be deleted.

The meter list is saved with the Save button.

Saving causes all the meter log data on the clipboard which have not yet been transmitted via the

WAN interface to be lost. This also deletes the CSV log data of the current day because the column

assignment it contains may have changed.

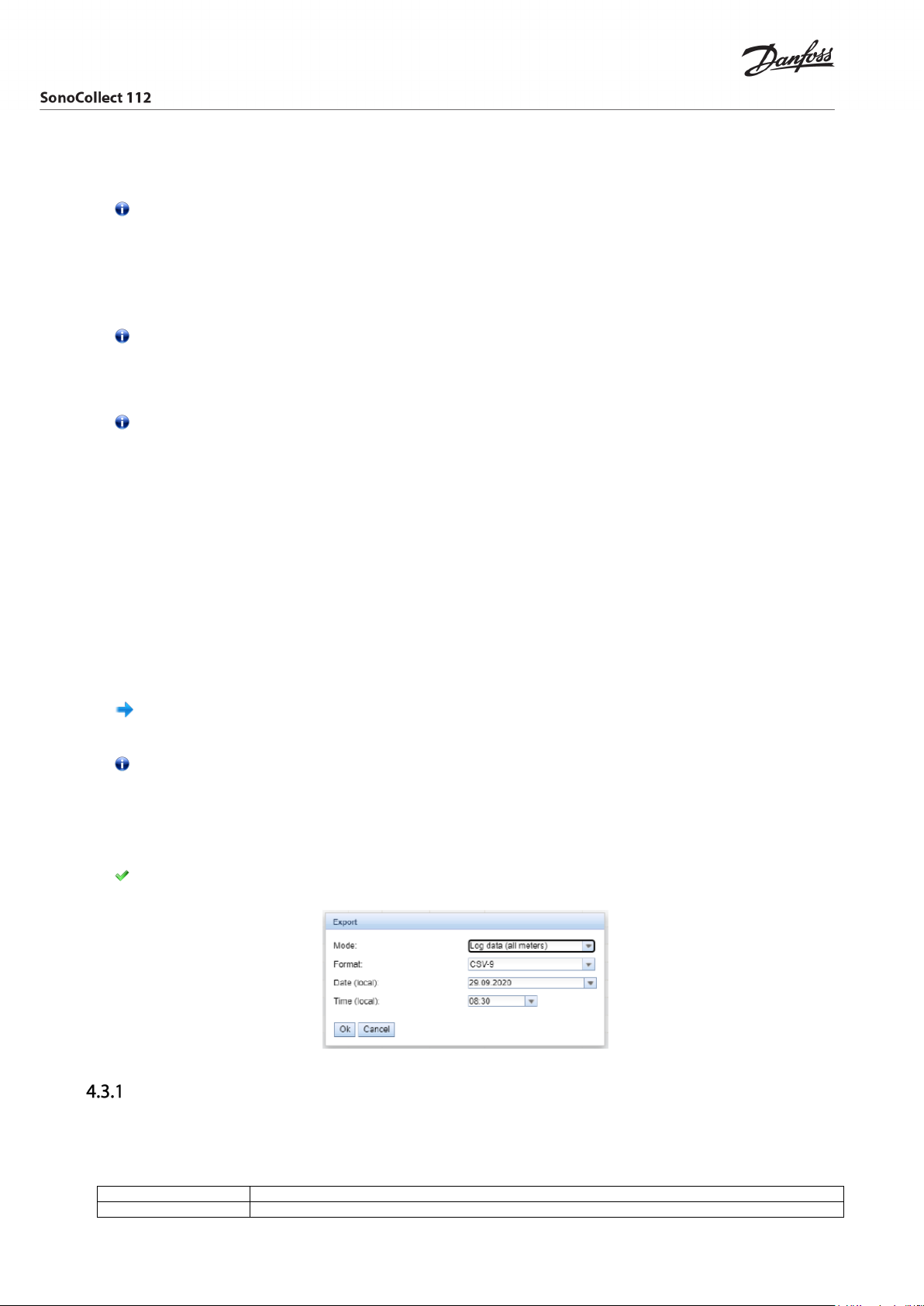

The

Export

of an active report at a certain point in time as a CSV or XML file.

The system meter is a special function for providing device-specific operating parameters. These parameters are displayed via the system meter like normal meter values and can thus be monitored and evaluated.

These default values are available depending on the device: