Page 1

SONO 3500 CT

Ultrasonic Flowmeter

Operating Instructions

Edition

11/2020

Classified as Business

Page 2

Classified as Business

Page 3

11/2020

Introduction

1

Safety notes

2

Description

3

Installing/Mounting

4

Electrical connection

5

Commissioning

6

Functions

7

Service and maintenance

8

Troubleshooting/FAQs

9

Technical data

10

Parameter lists

A

Settings

B

Ultrasonic Flowmeter SONO 3500 CT

Operating Instructions

AQ237286479555en-010402

Classified as Business

Page 4

Legal information

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

indicates that minor personal injury can result if proper precautions are not taken.

NOTICE

indicates that property damage can result if proper precautions are not taken.

WARNING

Danfoss products may only be used for the applications described in the catalog and in the relevant technical

ambient conditions must be complied with. The information in the relevant documentation must be observed.

Warning notice system

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

Qualified Personnel

The product/system described in this documentation may be operated only by personnel qualified for the specific

task in accordance with the relevant documentation, in particular its warning notices and safety instructions.

Qualified personnel are those who, based on their training and experience, are capable of identifying risks and

avoiding potential hazards when working with these products/systems.

Proper use of Danfoss products

Trademarks

Note the following:

documentation. If products and components from other manufacturers are used, these must be recommended

or approved by Danfoss. Proper transport, storage, installation, assembly, commissioning, operation and

maintenance are required to ensure that the products operate safely and without any problems. The permissible

All names identified by ® are registered trademarks of Danfoss A/S. The remaining trademarks in this publication

may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

Disclaimer of Liability

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

Local Importer name and address

For goods delivered to UK, importer name and address is:

Danfoss Ltd.

Oxford Road

UB9 4LH Denham

UK

SONO 3500 CT

Operating Instructions, 11/2020, AQ237286479555en-010402

Page 5

5

SONO 3500

Legal information

Table of contents

1

Introduction ............................................................................................................................................. 9

1.1

1.2

1.3

1.4

1.5

2

Safety notes .......................................................................................................................................... 14

2.1

2.2

2.3

2.4

2.5

3

Description ............................................................................................................................................ 17

3.1

3.2

3.3

3.4

3.5

Items supplied ........................................................................................................................... 9

Checking the consignment ..................................................................................................... 10

Device identification ................................................................................................................ 10

Further Information ................................................................................................................. 12

Transportation and storage ..................................................................................................... 13

General safety instructions ..................................................................................................... 14

Manufacturer's design and safety statement ......................................................................... 14

Conformity with European directives ..................................................................................... 15

Lithium batteries...................................................................................................................... 15

Installation in hazardous area ................................................................................................. 16

Overview ................................................................................................................................. 17

System components ............................................................................................................... 17

Design ..................................................................................................................................... 17

Features .................................................................................................................................. 18

Principle of operation .............................................................................................................. 19

4

5

Operating Instructions, 11/2020, AQ237286479555en-010402

Installing/Mounting ................................................................................................................................ 21

4.1

4.2

4.2.1

4.2.2

4.2.3

4.3

4.3.1

Flowmeter installation ............................................................................................................. 21

Sensor installation .................................................................................................................. 21

Inlet/Outlet conditions ............................................................................................................. 21

Reduction ................................................................................................................................ 25

Insulation ................................................................................................................................. 26

Transmitter installation (compact/remote versions) ................................................................ 26

Installation wall mounting kit (remote transmitter) .................................................................. 27

Electrical connection ............................................................................................................................. 28

5.1

5.2

Backup battery ........................................................................................................................ 28

Connecting battery (battery-powered versions and mains-powered versions with back-up

battery) .................................................................................................................................... 28

5.3

5.4

5.4.1

5.4.2

Connecting sensor link cable .................................................................................................. 29

Connecting power supply cable (main-powered systems only) ............................................. 30

Connecting pulse output signal cable(s) ................................................................................. 31

Finishing connection ............................................................................................................... 32

CT

Classified as Business

Page 6

Legal information

SONO 3500 CT

010402

6

5.4.2.1 Connecting battery (battery-powered versions and mains-powered versions with back-up

battery) ................................................................................................................................. 33

5.5

Compact and remote transmitters: Connecting output and power supply ............................. 33

5.6

5.6.1

5.6.2

5.6.3

5.7

5.8

5.8.1

5.8.2

6

Commissioning ...................................................................................................................................... 39

6.1

6.2

6.3

6.4

6.5

6.5.1

6.5.2

6.5.3

6.5.4

6.5.5

6.5.6

6.5.7

6.5.8

7

Functions ............................................................................................................................................... 50

Optional current output module .............................................................................................. 35

Finishing connection ............................................................................................................... 36

Connecting .............................................................................................................................. 37

Finishing connection ............................................................................................................... 37

Wiring energy calculator type INFOCAL 9 ............................................................................. 38

Sealing of SONO 3500 CT .................................................................................................... 38

User sealing ............................................................................................................................ 38

Verification sealing .................................................................................................................. 38

Introduction ............................................................................................................................. 39

Operating the local display ..................................................................................................... 39

Navigating the menu structure ................................................................................................ 40

Start-up routine ....................................................................................................................... 41

Commissioning via PDM......................................................................................................... 42

Installing and connecting the IrDA interface adapter .............................................................. 43

Installing EDD files .................................................................................................................. 43

Adding the device to the network ........................................................................................... 44

Configuring the device ............................................................................................................ 44

Optimizing the system ............................................................................................................ 46

Output A, terminals 56/57: ...................................................................................................... 47

Output B, terminals 66/67: ...................................................................................................... 48

Checking the operation readiness .......................................................................................... 48

7.1

7.2

7.3

7.4

8

Service and maintenance ....................................................................................................................... 53

8.1

8.2

8.3

8.4

8.5

8.6

8.7

8.8

Unit selection .......................................................................................................................... 50

Number of decimal digits ........................................................................................................ 50

Password-protected data ........................................................................................................ 51

Hardware key .......................................................................................................................... 51

Maintenance ........................................................................................................................... 53

Battery replacement ................................................................................................................ 53

Service menu .......................................................................................................................... 56

Technical support ................................................................................................................... 57

Application-specific data - Qualification certificate ................................................................. 57

Qualification certificate............................................................................................................ 59

Return procedures .................................................................................................................. 61

Battery disposal ...................................................................................................................... 62

Operating Instructions, 11/2020, AQ237286479555en-

Classified as Business

Page 7

7

SONO 3500

Legal information

9

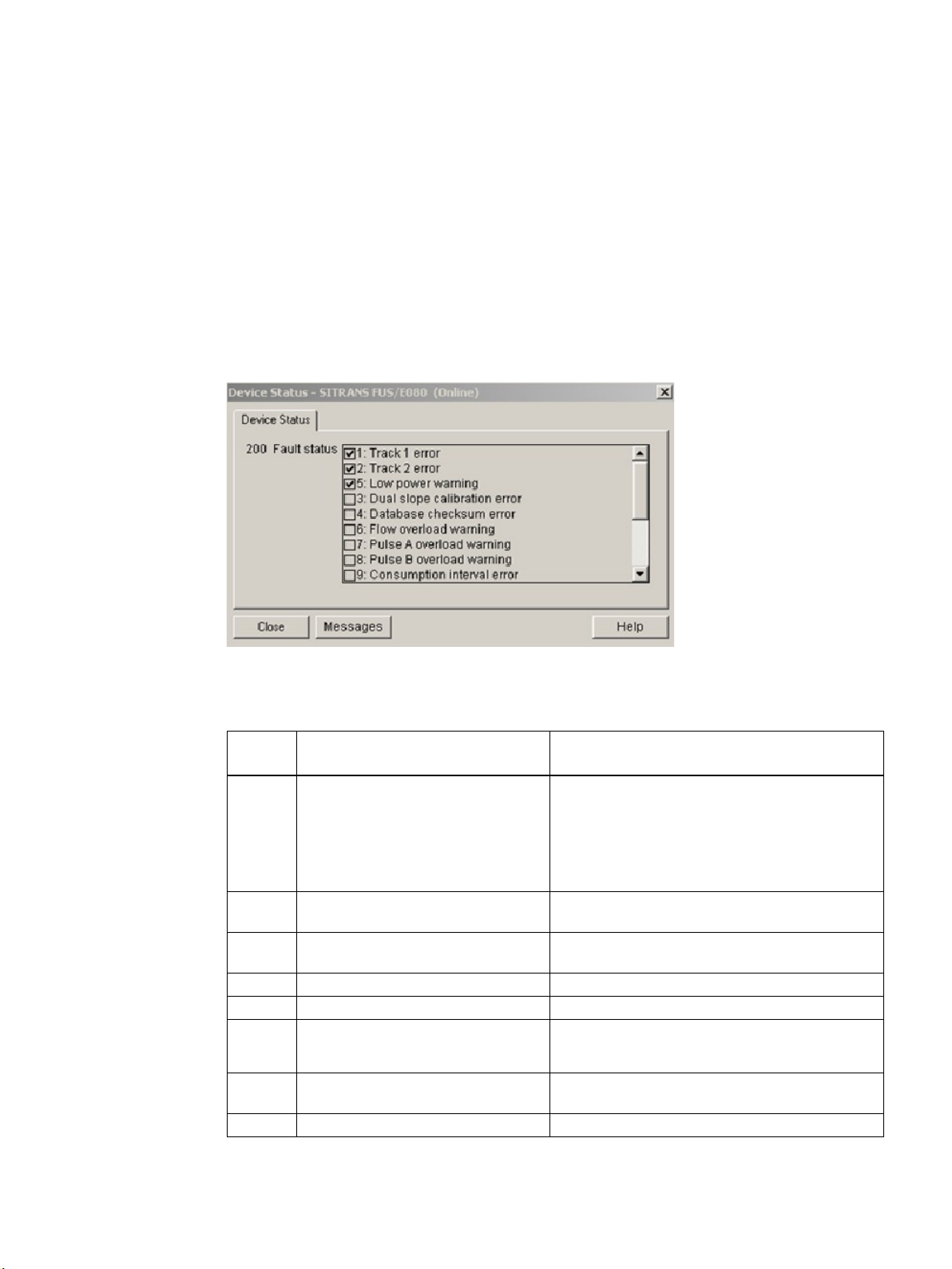

Troubleshooting/FAQs ........................................................................................................................... 63

9.1

9.2

10 Technical data ....................................................................................................................................... 68

10.1 SONO 3500 CT ...................................................................................................................... 68

10.2

10.3

10.4

10.5

A

Parameter lists ...................................................................................................................................... 73

A.1

A.2

A.3

A.4

A.5

A.6

B

Settings ................................................................................................................................................ 85

B.1

Error codes ............................................................................................................................. 63

Diagnosing with PDM ............................................................................................................. 64

Battery .................................................................................................................................... 69

Sensor for SONO 3500 CT ..................................................................................................... 70

Dimensional drawings for SONO 3500 CT ............................................................................. 71

Pipe dimensions for SONO 3500 CT ...................................................................................... 71

Identification ............................................................................................................................... 73

Output ......................................................................................................................................... 74

Diagnostic ................................................................................................................................... 76

Meter setup ................................................................................................................................ 81

Human Interface ......................................................................................................................... 83

Unit conversion table .................................................................................................................. 83

Factory settings .......................................................................................................................... 85

B.2

Factory settings for Modbus communication ............................................................................. 86

Operating Instructions, 11/2020, AQ237286479555en-010402

CT

Classified as Business

Page 8

Legal information

SONO 3500 CT

010402

8

Classified as Business

Operating Instructions, 11/2020, AQ237286479555en-

Page 9

SONO 3500 CT

Operating Instructions, 11/2020,

9

Introduction

1.1 Items supplied

Compact system

1

These instructions contain all information required to commission and use the device. It is

your responsibility to read the instructions carefully prior to installation and commissioning. In

order to use the device correctly, first review its principle of operation.

The instructions are aimed at persons mechanically installing the device, connecting it

electronically, configuring the parameters and commissioning it, as well as service and

maintenance engineers.

The device can be delivered as either a compact or a remote system.

• Sensor

• Transmitter

• Connection PCB

• DVD with documentation and cerificates

• Safety note

• Calibration report

• Sensor link cable

• Connection accessories

AQ237286479555en-010402

Classified as Business

Page 10

10

CT

010402

Remote system

• Sensor

• Transmitter

• Connection PCB

• DVD with documentation and cerificates

• Safety note

• Calibration report

• Mounting kit with bracket and terminal box

• Sensor link cable

• Connection accessories

Note

Scope of delivery may vary, depending on version and add-ons. Make sure the scope of

delivery and the information on the nameplate correspond to your order and the delivery

note.

1.2 Checking the consignment

1.

Check the packaging and the device for visible damage caused by inappropriate handling

during shipping.

2.

Report any claims for damages immediately to the shipping company.

3.

Retain damaged parts for clarification.

4.

Check the scope of delivery by comparing your order to the shipping documents for

correctness and completeness.

1.3 Device identification

The SONO 3500 CT flowmeter is delivered with different labels (nameplates) on the

transmitter and sensor. The transmitter and sensor are matched paired.

The transmitter has two nameplates. One (silver) is placed on the front of the transmitter.

The transmitter system nameplate (white) is placed on the right side of the transmitter. Both

provide valuable information about the device and system. The sensor system nameplate

(white) is placed on middle of the sensor.

Note Identification

Identify your device by comparing your ordering data with the information on the product and

specification nameplates.

Operating Instructions, 11/2020, AQ237286479555en-

Classified as Business

SONO 3500

Page 11

SONO

Operating Instructions, 11/2020,

11

①

System number (order code identifying selected options and system serial number)

②

Transmitter production code and serial number

③

Sensor production code and serial number

④

Maximum flow value (qs), Nominal flow value (qp), Minimum flow value (qi)

⑤

Pulse value (output A)

⑥

Pulse width (output A)

⑦

⑧

⑨

⑩

⑪

⑫

⑬

Transmitter system nameplate

Cable length (one transducer cable); Software version

Calibration factor; Production year

Ambient temperature range

Type approval number

Accuracy class

Environmental class

Verification markings

Figure 1-1 Transmitter system nameplate

3500 CT

AQ237286479555en-010402

Page 12

CT

010402

12

①

②

③

④

⑤

⑥

⑦

⑧

Water temperature range

⑨

Production year

⑩

System number (order code identifying selected options and system serial number)

⑪

⑫

Accuracy class

⑬

Environmental class

⑭

Verification markings

⑮

PED marking

Sensor system nameplate

Sensor production code and serial number

Dimension (nominal size ordered)

Pressure rating (nominal pressure rate ordered)

Maximum flow value (qs), Nominal flow value (qp), Minimum flow value (qi)

Cable length (one transducer cable)

Calibration factor

Ambient temperature range

Type approval number

Figure 1-2 Sensor system nameplate

Note

The matched paired transmitter and sensor shall be mounted together

Please check that the system nameplates of transmitter and sensor have the same system

serial number.

1.4

Product information on the Internet

Further Information

The Operating Instructions are available on the Danfoss homepage, where further

information on the range of Danfoss flowmeters may also be found: Product information

(https://www.danfoss.com/en/products/energy-metering/dhs/energy-metering/)

SONO 3500

Operating Instructions, 11/2020, AQ237286479555en-

Page 13

SONO 3500

13

NOTICE

● Provide additional packaging as necessary.

1.5

1.3.1 Keep the original packaging for subsequent transportation.

1.3.2 Devices/replacement parts should be returned in their original packaging.

1.3.3 If the original packaging is no longer available, ensure that all shipments are properly

Transportation and storage

To guarantee sufficient protection during transport and storage, observe the following:

packaged to provide sufficient protection during transport. Danfoss cannot assume liability

for any costs associated with transportation damages.

Insufficient protection during storage

The packaging only provides limited protection against moisture and

infiltration.

Operating Instructions, 11/2020, AQ237286479555en-010402

CT

Page 14

CT

010402

14

Safety notes

2

CAUTION

Correct, reliable operation of the product requires proper transport, storage, positioning and

assembly as well as careful operation and maintenance.

Note

Alterations to the product, including opening or improper modifications of the product are not

permitted.

If this requirement is not observed, the CE mark and the manufacturer's warranty will expire.

2.1 General safety instructions

Only qualified personnel should install or operate this instrument.

2.2 Manufacturer's design and safety statement

● Responsibility for the choice of flowmeter pipe material as regards abrasion and corrosion

resistance lies with the purchaser. The effect of any change in process medium during

operation of the meter should be taken into account. Incorrect selection of flowmeter pipe

material could lead to failure of the flowmeter.

● Stresses and loading caused by earthquakes, traffic, high winds and fire damage are not

taken into account during flowmeter design.

● Do not install the flowmeter such that it acts as a focus for pipeline stresses. External

loading is not taken into account during flowmeter design.

● Please be aware of the risk of installing the sensor in a highly vibrating environment.

Parts may shake loose and the complete system must be monitored in that case.

● Flanges and joints as well as related pressure/temperature (p/t) classification has been

described in EN 1092-1. See ferrite steel group 1E1: table 15.

● During operation do not exceed the pressure and/or temperature ratings indicated on the

data label or in these operating instructions.

● It is recommended that all installations include an appropriate safety valve and adequate

means for draining.

● Under the „Pressure Equipment Directive" (PED), this product is a pressure accessory

and not approved for use as a safety accessory, as defined by the PED.

Environmental conditions according MID (Directive 2014/32/EU)

● Environment class: E2 (electromagnetic), M1 (mechanical)

● Climatic class: -10°C - +55°C, condensing, closed

Operating Instructions, 11/2020, AQ237286479555en-

SONO 3500

Page 15

15

WARNING

Potential hazard

–

Do not expose contents to water.

2.3 Conformity with European directives

The CE marking on the device symbolizes the conformity with the following European directives:

Electromagnetic compatibility EMC 2014/30/EU

Directive of the European Parliament and of the Council on the harmonization of the laws of the

Member States relating to electromagnetic compatibility

Low voltage directive LVD 2014/35/EU

Directive of the European Parliament and of the Council on the harmonization of the laws of the

Member States relating to the making available on the market of electrical equipment designed

for use within certain voltage limits

Pressure equipment directive PED EMC 2014/68/EU

Directive of the European Parliament and of the Council on the harmonization of the laws of the

Member States relating to electromagnetic compatibility

Radio equipment directive RED 2014/53/EU

Directive of the European Parliament and of the Council on the harmonization of the laws of the

Member States relating to the making available on the market of radio equipment and repealing

Directive 1999/5/EC

2.4 Lithium batteries

Measuring instruments directive MID 2014/32/EU

Directive of the European Parliament and the Council on the harmonization of the laws of the

Member States relating to the making available on the market of measuring instruments

Restriction of Hazardous Substances RoHS 2011/65/EU

Directive of the European Parliament and the Council on the restriction of the use of certain

hazardous substances in electrical and electronic equipment

The applicable directives can be found in the EU declaration of conformity of the specific device.

Lithium batteries are primary power sources with high energy content designed to represent

the highest possible degree of safety.

Lithium batteries may present a potential hazard if they are abused electrically or

mechanically.

• Observe the following precautions when handling and using lithium batteries:

–

Do not short-circuit, recharge or connect with false polarity.

–

Do not expose to temperature beyond the specified temperature range or incinerate

the battery.

–

Do not crush, puncture or open cells or disassemble battery packs.

–

Do not weld or solder to the battery’s body.

SONO 3500 CT

Operating Instructions, 11/2020, AQ237286479555en-010402

Page 16

CT

010402

16

WARNING

NOT allowed for use in hazardous areas!

2.5 Installation in hazardous area

Equipment used in hazardous areas must be Ex-approved and marked accordingly!

This device is NOT approved for use in hazardous areas!

SONO 3500

Operating Instructions, 11/2020, AQ237286479555en-

Page 17

17

Description

3

Sensor type

Transmitter

Flowmeter system

DN 100 to DN 1200

SONO 3500 CT transmitter

3.1 Overview

The SONO 3500 CT ultrasonic flowmeter systems consist of a sensor and a transmitter. The

transmitter is type-approved with the custody transfer (CT) approval for use in energy

metering systems. The transmitter is designed to measure flow water applications.

The ultrasonic flowmeter transmitter comes as a mains-powered version with battery backup.

The following table shows the ultrasonic flowmeter systems with these transmitter types:

SONO 3500 CT (2-path)

3.2 System components

The flowmeter system includes:

●

Mains-powered transmitter with battery backup

●

The sensor is a 2-path sensor with flanges and inline transducers wet-calibrated from

factory together with the transmitter (DN 100 (4") to DN 1200 (48"))

3.3 Design

The transmitter is designed with fiberglass reinforced polyamide enclosure for remote or

compact installation in normal areas. The remote versions are available with up to 30 meter

distance from flowmeter to transmitter. When ordered as a compact version in the series

SONO 3500 CT the transducer cables are pre-mounted at the sensor.

incl SONO 3500 CT

SONO 3500 CT

Operating Instructions, 11/2020, AQ237286479555en-010402

SONO 3500 CT display

The transmitter is available in an IP67/NEMA 4X/6 enclosure.

For spare part cases the transmitter is always ordered as part of a complete flowmeter

system.

The transmitter can be ordered preprogrammed with the given sensor data (system serial

number).

Page 18

CT

010402

18

3.4 Features

The following features are available:

●

Mains-powered transmitter

●

Battery backup with 3.6 V Lithium single D-cell battery

●

Suitable for sensor pipe diameters from DN 100 (4") up to DN 1200 (48")

●

IP67 (NEMA 4X/6) rated polyamide transmitter enclosure

●

Factory preset to the nominal dimensions of pipe type and pipe size

●

Programming via SIMATIC PDM

●

Local control panel with single push button, 8-digit display and IrDA optical interface for

communication with SIMATIC PDM

●

Display showing accumulated volume as well as instantaneous flow rate. The displayed

units are m

●

Two digital outputs for volume pulse or alarm

3

/h and m

3

●

4-20mA output (optional)

Applications

The main application for the type-approved SONO 3500 CT flowmeters is measurement of

water flow in district heating plants, local networks, boiler stations, substations, chiller plants,

irrigations plants, and other general water applications.

Integration

The flowmeter pulse output is often used as input for an energy meter or as input for digital

systems for remote reading. The transmitter has two pulse outputs, with functions that can

be individually selected, and integrated IRDA (optical eye) communication interface (Modbus

RTU).

The settings of the transmitter, for example flow and pulse output rate, are defined when

ordering the complete flowmeter. If the flowmeter forms part of an energy meter system for

custody transfer, no further approvals are needed, except possible local approvals.

Transmitter communication solutions

The transmitter supports Modbus RTU communication via the optical IrDA interface at the

display, enabling the change of different transmitter settings using the SIMATIC PDM

software tool.

The transmitter is configured in a combination of hardware (HW) and firmware (FW). For the

communication and parametrization via SIMATIC PDM a firmware-specific device

description (EDD) is needed.

Operating Instructions, 11/2020, AQ237286479555en-

SONO 3500

Page 19

19

3.5 Principle of operation

Physical principle

Figure 3-1 Velocity distribution along sound path

A sound wave travelling in the same direction as the liquid flow arrives at point B from point

A in a shorter time than the sound wave travelling against the flow direction (from point B to

A).

SONO 3500 CT flowmeters

The difference in sound transit time indicates the flow velocity in the pipe.

Since delay time is measured at short intervals both in and against flow direction,

temperature has no influence on measurement accuracy.

In SONO 3500 CT flowmeters the ultrasonic transducers are placed at an angle θ in relation

to the pipe axis. The transducers function as transmitters and receivers of the ultrasonic

signals. Measurement is performed by determining the time the ultrasonic signal takes to

travel with and against the flow. The principle can be expressed as follows:

v = K × (t

B,A

A,B

) / (t

A,B

× t

B,A

) = K × Δt/t²

– t

where

v = Average flow velocity

t = Transit time

K = Proportional flow factor

This measuring principle offers the advantage that it is independent of variations in the actual

sound velocity of the liquid, i.e. independent of the temperature.

The mechanical/geometrical pipe data is transducer angle (θ), distance between sensors (L)

and pipe dimension (D

and Du) shown in the figure below.

i

SONO 3500 CT

Operating Instructions, 11/2020, AQ237286479555en-010402

Page 20

CT

010402

20

Figure 3-2 Measuring principle

The ultrasonic signal is sent directly between the transducers. The advantage gained

sending signals from point to point is an extremely good signal strength.

Operating Instructions, 11/2020, AQ237286479555en-

SONO 3500

Page 21

21

Installing/Mounting

4

CAUTION

Direct sunlight

4.1 Flowmeter installation

The flowmeter installation is done in two steps:

1.

Sensor installation

2.

Transmitter installation

Environment

SONO 3500 CT flowmeters are suitable for indoor and outdoor installations.

●

Make sure that temperature and ambient specifications indicated on the device type

plate/label are not exceeded.

Device damage.

The device can overheat or materials become brittle due to UV exposure.

Protect the device from direct sunlight.

Make sure that the maximum permissible ambient temperature is not exceeded.

Refer to the information in Technical data (Page 68).

Ambient temperature for transmitter:

●

-10 °C to +55 °C (14 to 131 °F)

●

Non-MID versions -10 to +60°C (14 to 140°F)

●

The enclosure rating of the transmitter is IP67 (NEMA 4X/6) or better.

4.2 Sensor installation

4.2.1

SONO 3500 CT

Operating Instructions, 11/2020, AQ237286479555en-010402

Inlet/Outlet conditions

Requirement for straight inlet before flowmeter

In order to maximize performance it is necessary to have straight inlet and outlet flow

conditions before and after the flowmeter.

Furthermore, a minimum distance between flowmeter and pumps and valves must be

respected.

It is also important to centre the flowmeter in relation to flanges and gaskets.

Page 22

CT

010402

22

Make sure that flowmeter is positioned as low as possible to prevent air from being trapped

in flowmeter at transducers.

Find a position on the pipeline where inlet pipe to flowmeter has a straight length as

specified below.

Single bend

1 x 90° bend

L2: Min. 10 x pipe diameter

L1: 3 x pipe diameter

Operating Instructions, 11/2020, AQ237286479555en-

SONO 3500

Page 23

23

Dual bend

2 x 90° bends in the same plane

L2: Min. 10 x pipe diameter

L1: 3 x pipe diameter

Triple bend

3 x 90° bends in two planes

L2: Min. 20 x pipe diameter

L1: 3 x pipe diameter

SONO 3500 CT

Operating Instructions, 11/2020, AQ237286479555en-010402

Page 24

CT

010402

24

Valves and pumps

Orienting the sensor

Valves

L2: Min. 10 x pipe diameter, fully open valve

L1: 3 x pipe diameter

Pumps:

L2: Min. 20 x pipe diameter

L1: 3 x pipe diameter

Horizontal orientation, terminal box upwards or downwards

Precautions

In horizontal installation avoid any upward/downward position of the transducers.

Avoid installation at the highest point in the system because air bubbles will be trapped in

flowmeter.

Avoid installation at a point where there is a free outlet after flowmeter.

Operating Instructions, 11/2020, AQ237286479555en-

SONO 3500

Page 25

25

Note

To obtain maximum battery lifetime with the Lithium Thionyl Chloride battery pack. it is

Flowmeter pipe section may be installed in either a horizontal or vertical position.

recommended to install the flowmeter transmitter in an upright position.

4.2.2

Reduction

SONO 3500 CT

Operating Instructions, 11/2020, AQ237286479555en-010402

Page 26

CT

010402

26

4.2.3

Installation in large pipes

The flowmeter can be installed between two reducers as shown. At 8° reducing angles the

below pressure drop curve applies.

Delta-P example:

A water flow velocity of 3 m/s (V) in a sensor with a diameter reduction from DN 200 to DN

100 (D

= 0.5) gives a pressure drop of 9 mbar.

1/D2

L2: Min. 10 x pipe diameter

Insulation

Both versions can be insulated.

We always recommend insulation of sensor in the compact or remote version. For compact

versions the insulation can prevent heat transfer to transmitter.

4.3 Transmitter installation (compact/remote versions)

The transmitter is packed separately - ready for plug-in into base part.

There are two mounting versions of the transmitter (as shown in figures below):

●

remote transmitter

●

compact transmitter

Remote transmitter Compact transmitter

Note

The matched paired transmitter and sensor shall be mounted together. At installation, please

check that the system nameplates of transmitter and sensor have the same system serial

number.

Operating Instructions, 11/2020, AQ237286479555en-

SONO 3500

Page 27

27

4.3.1 Installation wall mounting kit (remote transmitter)

Mount wall/pipe mounting bracket in an appropriate place.

Wall mounting

Pipe mounting

Note

Take coaxial cable length into consideration and allow adequate space for cable inlets

underneath and on both sides.

SONO 3500 CT

Operating Instructions, 11/2020, AQ237286479555en-010402

Page 28

010402

28

Electrical connection

5

WARNING

Skills

WARNING

Danger of electric shock!

The transmitter is mains-powered with battery backup

Important:

On compact versions, all transducer cables are pre-mounted from factory.

Mounting of output pulse cables is identical for compact and remote versions.

Only qualified personnel may carry out work on the electrical connections.

Never install the device with the mains voltage switched on!

5.1 Backup battery

The mains-powered transmitter is supplied with a single backup lithium battery.

In the event of power failure battery will take over power supply of unit.

The battery is not of a rechargeable type and must be replaced latest after 6 years.

Note

Male battery plug is not connected to plug female socket connection upon delivery. This

connection must be made to enable backup battery power supply.

5.2 Connecting battery (battery-powered versions and mains-powered

versions with back-up battery)

Plug in male battery plug. Ensure that the wire is inserted into the small channel leading

from plug to battery.

SONO 3500 CT

Operating Instructions, 11/2020, AQ237286479555en-

Page 29

29

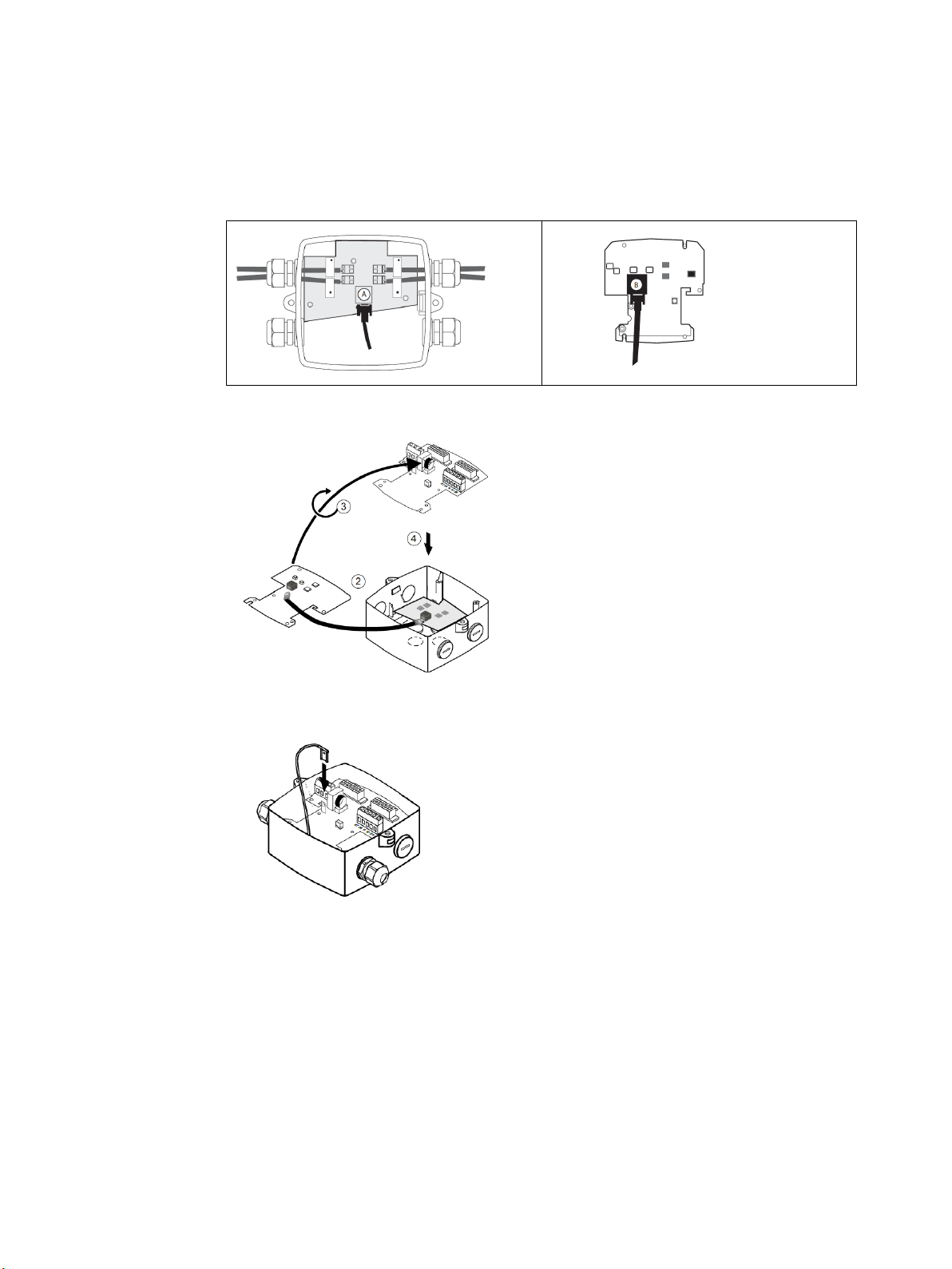

5.3 Connecting sensor link cable

1. Remove the plastic lid from the terminal box.

2. Click the sensor link cable onto sensor connection board (A) and onto transmitter

connection board (B).

3. Turn the transmitter connection board so that the connection cable is facing

downwards.

4. Click the transmitter connection board into the terminal box.

5. Connect protective earth wire.

SONO 3500 CT

Operating Instructions, 11/2020, AQ237286479555en-010402

Page 30

010402

30

WARNING

Power supply requirements

WARNING

Wire insulation

National Installation Code

the flowmeters are installed is met.

Note

Conductor terminal

The wire size for the output

.

5.4 Connecting power supply cable (main-powered systems only)

Make sure the power supply requirements stated on the nameplates are met!

The insulation between the connected mains supply and the low voltage supply for the

flowmeter must be rated with at least double or reinforced insulation at mains voltage.

For field wiring installation: Ensure that the

of the country in which

terminals are AWG24 to AWG16 or 0.205 mm2 to 1.500 mm²

1. Replace blind plug with cable gland.

2. Push power supply cable through open gland.

3. Connect power supply to L1, N and protective earth (PE) and tighten cable strap (C).

5.

Tighten cable gland for power supply cable (approx. 20 Nm).

SONO 3500 CT

Operating Instructions, 11/2020, AQ237286479555en-

Page 31

31

CAUTION

Pulse output

isolation.

Note

Cables with voltage

Keep the output signal cable(s) separated from cables with voltages > 60 V.

Note

Ingress protection

To guarantee the IP67 (NEMA 4X/6) degree of protection, use

specifications.

Note

Protected terminal

Keep the output signal cable(s) separated from cables with voltages > 60 V.

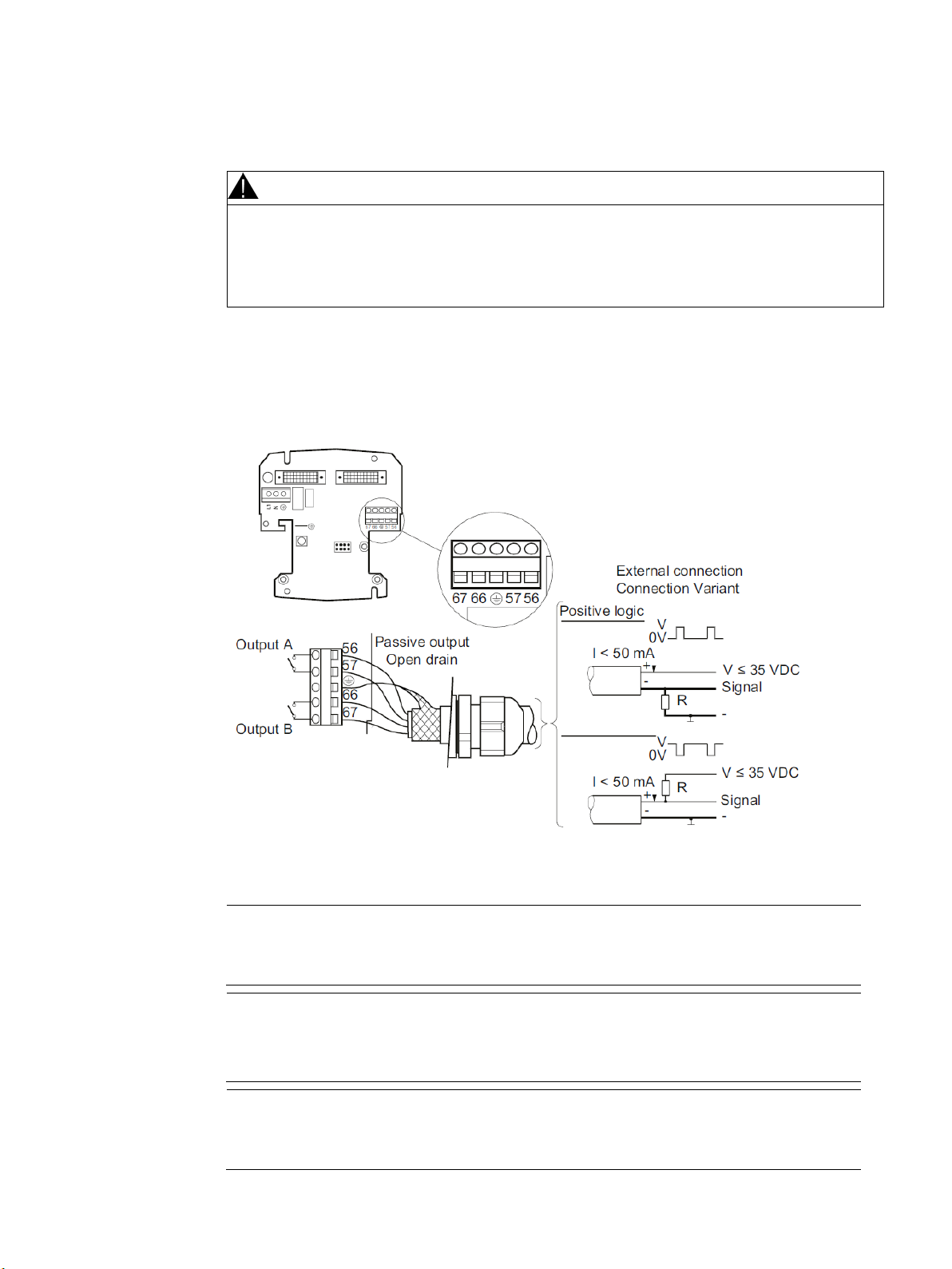

5.4.1 Connecting pulse output signal cable(s)

If no output signals are needed, proceed with "Finishing connection".

The pulse output must be connected to equipment complying with Low-Voltage Directive in

order to be considered safe. The isolation within FUS080 pulse output is only a functional

1. Replace blind plug with cable gland (if two output signals are required, use a double

entry cable gland).

2. Push output cable(s) through open gland.

3. Connect output cable(s).

SONO 3500 CT

Operating Instructions, 11/2020, AQ237286479555en-010402

4. Tighten cable gland for output cable(s) (approx. 20 Nm).

cables with the required

Page 32

010402

32

Note

EMC performance

Incorrect fixing of the output cable shield will affect the EMC performance.

Note

Optional current output module

If you want to install the optional current output module, proceed with chapter Installing

and connecting optional current output module (Page 35) before mounting the transmitter.

Note

Grounding

To ensure identical potential for sensor and transmitter, a direct grounding of transmitter

and sensor is recommended.

Note

Aligning the gasket

Please ensure that the gasket between terminal box and transmitter is well

tightening the screw (Min. torque 0.5 Nm).

5.4.2 Finishing connection

Mount the transmitter.

aligned before

Operating Instructions, 11/2020, AQ237286479555en-

SONO 3500 CT

Page 33

33

WARNING

Power supply requirements

5.4.2.1 Connecting battery (battery-powered versions and mains-powered versions with

back-up battery)

Plug in male battery plug. Ensure that the wire is inserted into the small channel leading from

plug to battery.

5.5 Compact and remote transmitters: Connecting output and power supply

The wiring of output and power supply is done in three steps:

1.

Wiring power supply

2.

Wiring pulse output (if relevant)

3.

Mounting transmitter

Step 1: Wiring power supply

Make sure the power supply requirements stated on the nameplates are met!

SONO 3500 CT

Operating Instructions, 11/2020, AQ237286479555en-010402

Page 34

CT

010402

34

Note

Cable straps

It is recommended to use cable straps.

Note

Sensor grounding

To ensure identical potential for sensor and transmitter, a direct grounding of transmitter and

sensor is recommended.

CAUTION

Pulse output

functional isolation.

1.

Connect power supply to L1, N and protective earth (PE).

Figure 5-2 Output and power supply connection

2.

Fix the power supply cable to the terminal housing with the clamp.

3.

Ground transmitter and sensor.

Step 2: Wiring pulse output

The pulse output must be connected to equipment complying with Low Voltage Directive in

order to be considered safe. The isolation within the transmitter pulse output is only a

1.

Prepare the cable ends as shown in the figure above.

2.

Connect output cables to terminals 56 and 57 (Output A) and to 66 and 67 (Output B)

according to use.

The output functions are used as shown in the figure above.

3.

Ground the cable shielding by fixing it with the clamp.

Operating Instructions, 11/2020, AQ237286479555en-

SONO 3500

Page 35

connection

5.4 Wiring energy calculator type INFOCAL 9

Operating Instructions, 11/2020,

35

Note

Current output range during start up

bled (default setting) the output is 3.6 mA during start

up. When the current output module is disabled the output is fixed to 4 mA.

Note

Restricted use of the optional current output module

signal is not approved for custody transfer use.

Electrical

CAUTION

EMC performance

Incorrect fixing of the cable shield will affect the EMC performance!

Step 3: Mounting Transmitter

1.

Tighten the power supply and pulse output cable glands.

2.

Mount the transmitter.

Figure 5-3 Mounting transmitter on terminal box

5.6 Optional current output module

The optional current output module converts the flow signal into a 4-20 mA output signal. The

4 mA always equals 0 flow rate and the 20 mA equals the Qp value selected via the order code.

The default Qp can be found on the transmitter nameplate.

The current output module is passive and therefore needs an external power supply.

When the current output module is ena

The module can be used with all mains-powered SONO3500 CT versions, but the output

SONO 3500 CT

Page 36

CT

Operating Instructions, 11/2020, AQ237286479555en-010402

36

WARNING

Danger of electric shock!

CAUTION

EMC performance

affect the EMC performance!

Note

Power supply

power supply.

Note

Current output module

(Page 85).

CAUTION

Protective earth

5.6.1 Finishing connection

Never install the device with the mains voltage switched on!

Current output cable shield must be connected. Incorrect fixing of the cable shield may

Installing

The current output module is a passive module and should only be used with external

To support the function with current output module the default communication settings for

the transmitter is recommended. See Factory settings for Modbus communication

1.

Remove transmitter/terminal box lid.

2.

Carefully mount current output module on the eight pins.

3.

Fasten module to transmitter connection board by use of a M3x5 screw (0.5 Nm).

The M3x5 screw also functions as earth conductor (EMC).

See also

Optional current output module (Page 35)

SONO 3500

Page 37

37

Note

Grounding

and sensor is recommended.

Note

Aligning the gasket

tightening the screw (Min. torque 0.5 Nm).

5.6.2 Connecting

The output terminals are marked 31 and 32 with corresponding polarity + and - on the

terminal strip. The connector is for shielding.

The requirements for the current output cable, for example max. load can be found in

AUTOHOTSPOT.

1. Replace blind plug with cable gland (if two output signals are required, use a double entry

cable gland).

2. Push output cable through open gland.

3. Connect output cable to terminals 31, 32 and .

4.

Tighten cable gland for current output cable (approx. 20 Nm).

5.6.3 Finishing connection

Mount the transmitter.

To ensure identical potential for sensor and transmitter, a direct grounding of transmitter

Please ensure that the gasket between terminal box and transmitter is well aligned before

SONO 3500 CT

Operating Instructions, 11/2020, AQ237286479555en-010402

Page 38

CT

Operating Instructions, 11/2020, AQ237286479555en-010402

38

SONO 3500 CT in supply pipe

Infocal 9 terminal

57 (ground)

11 (q1-)

56 (flow pulse)

52 (q2+)

Transmitter

Sensor

Remote version

Under transmitter display frame

On bottom of transmitter

On sensor body

On side of transmitter

5.7 Wiring energy calculator type INFOCAL 9

Energy calculator is typically connected via the pulse output A of the transmitter.

Wiring to flow meter SONO 3500 CT:

56 (flow pulse) 10 (q1+)

SONO 3500 CT in return pipe Infocal 9 terminal

57 (ground) 11 (q2-)

5.8 Sealing of SONO 3500 CT

5.8.1 User sealing

After finishing the installation and electrical connection, it is recommended to seal the

flowmeter as shown. Drill through marked drilling holes in terminal box and

transmitter/lid. Seal the transmitter on both sides with either one or two wires.

5.8.2 Verification sealing

This illustration shows how the device is verification sealed.

Note

For type-approved and verified SONO3500 CT flowmeters

The HW key is located behind the display and is thereby protected by the display sealing.

The verification sealing may only be broken with the acceptance of the local authorities.

SONO 3500

Page 39

39

Commissioning

6

Symbol

Description

6.1 Introduction

Commissioning the device includes the following steps:

1.

2.

3.

It is recommended to read the basic guide to the local display and the menu structure in

Operating the local display (Page 39) and Navigating the menu structure (Page 40) before

commissioning the device.

Resetting the battery lifetime (see Start-up routine (Page 41)).

Checking values in the service menu.

Configuring the device via SIMATIC PDM (see Commissioning via PDM (Page 42)).

6.2 Operating the local display

The local display is divided into 3 areas:

1.

Top area with symbols for status information

2.

Mid area with actual readings

3.

Lower area with index number of the shown menu

Activate the push button to go the next index menu and related information.

Figure 6-1 Operating the local display

Table 6-1 Status information symbols

SONO 3500 CT

Operating Instructions, 11/2020, AQ237286479555en-010402

Mains power supply connected

Battery charge status

Warning

Service menu

Page 40

CT

010402

40

Symbol

Description

Menu

Parameter

Display example

Comments

Battery status

There are two symbols for battery charge status:

4.

"Battery full" indicates battery charge above the warning level (6-year hour counter).

5.

"Battery low" indicates battery charge below the warning level and that the battery should

be replaced.

Note

"Battery low" only indicates that battery charge is below a pre-set level, not that charge is

zero.

Flow measurement continues uninterrupted until the battery is completely drained.

Table 6- 2 Battery status information symbols

6.3 Navigating the menu structure

Use the push button to navigate between the following menu items:

Table 6- 3 Menu items

Menu 1 Flow volume totalizer 1

Menu 2 Flow volume totalizer 2

Battery status, full

Battery status, low

Factory preset is forward

volume flow.

The battery symbol shows

full.

Factory preset for reverse

flow.

Negative values indicate

reverse flow calculation.

Menu 3 Actual flow rate

Menu 4 Alarm codes

Menu 5 Display test

Negative values indicate

reverse flow calculation.

Each code refers to a specific alarm.

Check of all segments. Display toggles between all

segments on/off.

SONO 3500

Operating Instructions, 11/2020, AQ237286479555en-

Page 41

41

Menu

Parameter

Display example

Comments

Service menu (Page 56).

Table 6-4 Service menu

Service menu

6.4 Start-up routine

1.

Power-up device.

2.

Reset battery status indicator as described below.

Resetting the battery counter

Note

The reset can also be carried out via SIMATIC PDM.

When a new battery is installed and the plug is connected, the transmitter start-up

routine begins. The display shows the active software version, e.g. 2.04.

The service menu is

accessible from all menus by

pressing push button for

minimum 2 seconds. For

more information on the

complete service menu, see

After ten seconds the message "reset.bat" will appear.

1.

Press push button within six seconds to reset the internal battery counter. The message

"accept" will appear.

2.

Press push button again within six seconds in order to reset the internal battery counter.

The battery indicator now shows full. If the push button is not pressed again, the battery

indicator will show "Low".

Figure 6-2 Reset internal battery counter

* Firmware version, here version 2.03

SONO 3500 CT

Operating Instructions, 11/2020, AQ237286479555en-010402

Page 42

CT

42

Note

For instructions on installation and operation of SIMATIC PDM, refer to the SIMATIC PDM

Getting Started (included in the documentation package that comes with PDM).

Note

PDM version

Note

Default password

Any data change in PDM requires a password. The default password is 1000. For further

information, see Password-protected data (Page 51).

Note

For type-approved and verified SONO 3500 CT flowmeter the settings are HW key protected

and

verification

sealing. The

local authorities.

6.5 Commissioning via PDM

SIMATIC PDM (Process Device Manager) is a software package for configuring,

parameterizing, commissioning, and maintaining field devices (for example transducers).

Among other features, SIMATIC PDM contains a simple process for monitoring process

values, interrupts and status/diagnosis signals of a field device.

required is SIMATIC PDM V6.1

can only be read, but not changed via PDM. This HW key is protected via the

verification sealing can only be broken by the user with the acceptance of the

In the following it is described how the device is commissioned using SIMATC PDM.

The commissioning is divided into the following steps:

1.

Installing and connecting the IrDA interface adapter (Page 43)

2.

Installing EDD files (Page 43)

3.

Adding the device to the network (Page 44)

4.

Configuring the device (Page 44)

5.

Optimizing the system (Page 46)

6.

Checking the operation readiness (Page 48)

Operating Instructions, 11/2020, AQ237286479555en-010402

SONO 3500

Page 43

SONO 3500 CT

Operating Instructions, 11/2020,

43

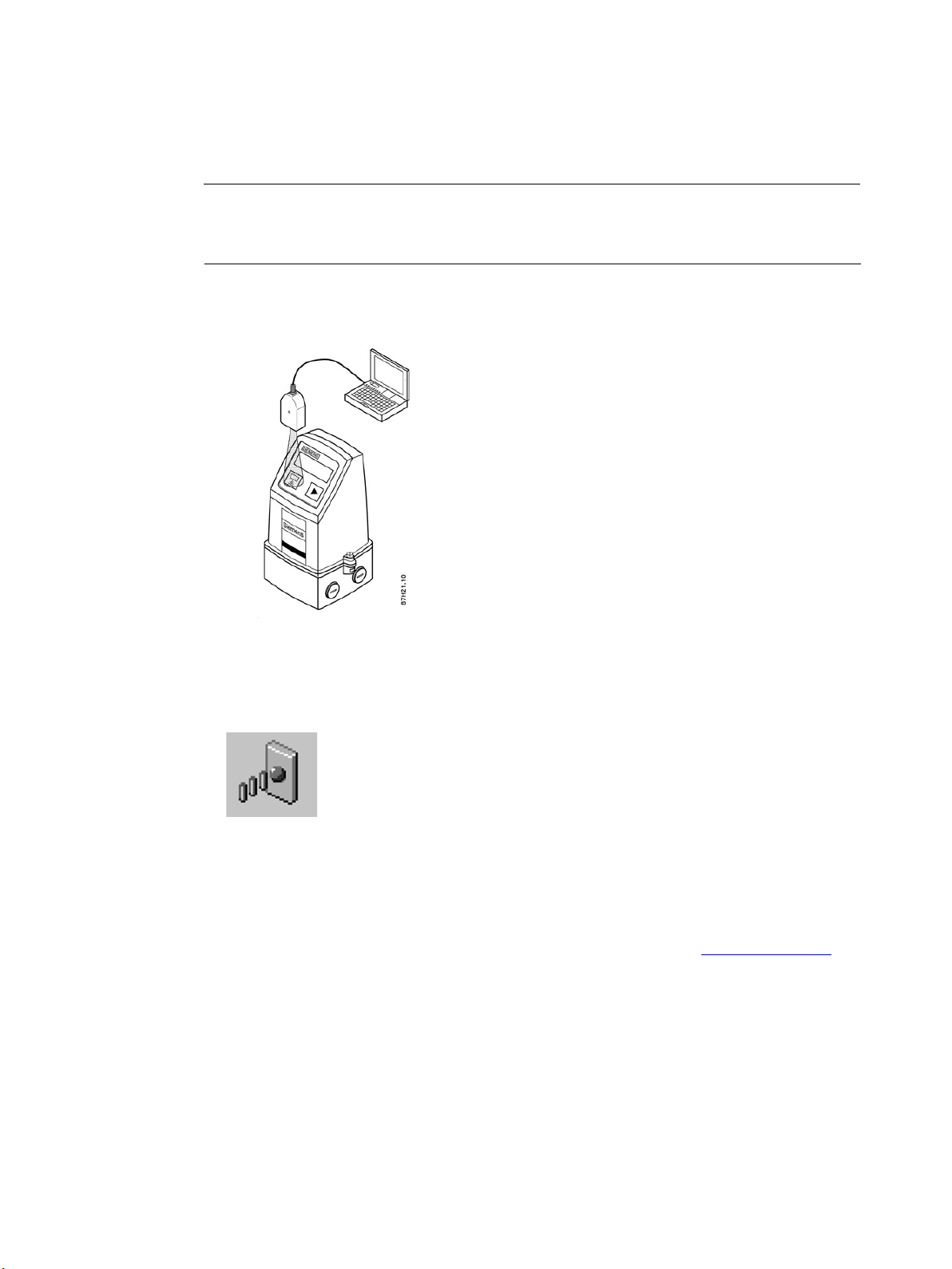

6.5.1 Installing and connecting the IrDA interface adapter

Note

IrDA driver installation

For installation of the IrDA driver, refer to the instructions delivered with the adapter.

1.

Connect IrDA adapter to PC

2.

Mount adapter on the transmitter

When the IrDA adapter is connected correctly, a small icon appears on the taskbar of your

PC. When the mouse is placed on this icon, the device information will be shown (e.g.

"SN1033 is in range").

6.5.2 Installing EDD files

Install the PDM device driver as follows:

1. Download update from the Internet on http://www.danfoss.com. (www.danfoss.com

Check that the EDD (electronic device descriptions) is the version valid for the device.

2. Open "Manage Device Catalog" from Start → SIMATIC → SIMATIC PDM.

3. Navigate to PDM device driver, select device and click "OK". The driver is installed on

the PC.

)

AQ237286479555en-010402

Page 44

CT

010402

44

6.5.3 Adding the device to the network

It is recommended to configure the project in PDM before setting the parameters.

Add device to SIMATIC Modbus network:

1. Select [File → New]

Type in a project name, e.g. SONO 3500 CT

2. Right click on your new project, select [Insert New Object → Networks].

3. Right click on your Networks, select [Insert New Object → Communication Network].

4. Click on [Assign Device Type] and select Networks → MODBUS → MODBUS networks

→ MODBUS network.

5. Click [OK] and click [OK] again.

6. Right click on MODBUS network and select [Insert New Object → Object]

7. Click on [Assign Device Type] and assign the MODBUS device to SITRANS

FUS/E080 [Devices → MODBUS → Sensors → Flow → Ultrasonic → SIEMENS AG →

SITRANS FUS/ E080] and click [OK].

Name device according to application requirements (max. 32 characters) and click [OK].

Set up communication parameters for SIMATIC MODBUS network.

8. Select Networks → MODBUS network.

9. Right click on Modbus network and select Object Properties.

10. On the Communication tab, select MODBUS communication to activate IrDA.

6.5.4 Configuring the device

In the following it is described how to configure the device by defining all sensor specific

parameters.

Note

Measurement accuracy

A correct flowmeter installation is required to ensure optimum measurement accuracy.

SONO 3500

Operating Instructions, 11/2020, AQ237286479555en-

Page 45

45

Read all parameters

Read, write device data

Before any parameterization is done it is necessary to read all parameters from the device

into the offline table of SIMATIC PDM. The offline table merely contains default data.

1. Open PDM device driver.

2. Select "Upload to PC/PG .." Select "Execute even if the device TAG does not match the

project data TAG.", and click "OK" to read all parameters to the offline table.

After closing the dialog box, all loaded parameters should show "Loaded" in the status of

the PDM table. For a complete parameter list, see Parameter lists (Page 73).

3. Store factory set default values on your local PC ("File" → "Export") in order to be able to

retrieve default settings.

Note Status field

• "Changed" indicates off-line data not yet stored in the device.

Only parameters (data) shown with white background can be changed.

• "Loaded" indicates actual device data.

To view possible settings, right-click and select "Help".

SONO 3500 CT

Operating Instructions, 11/2020, AQ237286479555en-010402

Page 46

CT

010402

46

SONO 3500 CT

Preset: Alarm

Pulse width

Preset: 5 ms

6.5.5 Optimizing the system

After storage of the settings, the parameters can be set according to use.

The following shows how to set Pulse Output A and Qmax. For other parameters, refer to

"Parameter list" in the appendix.

Setting Pulse Output and Maximum Flow (Q

1. In SIMATIC PDM navigate to menu "Device" → "Pulse guide"

The "guide" calculates the pulse-frequency at the max flow condition and tells you how

close you are on over-speeding the pulse-output.

The volume per pulse is freely scalable from 0.000001 to 10000 units per pulse. It also

calculates the minimum volume per pulse you can choose to avoid pulse over-speeding.

The maximum output frequency depends on the pulse selected; e.g. maximum output

frequency at 5 ms is 100 Hz. Increasing the pulse width lowers the maximum output

frequency.

2. Select maximum flow rate (never to be exceeded).

3. Select an appropriate pulse width, e.g. 5 ms.

4. Enter a value in "Amount per pulse A", e.g. 100, to define the volume/pulse with respect

to the "Minimum amount per pulse value".

5. Press "Apply Change of Pulse" to apply the settings.

6. If needed, proceed with setting Pulse Output B according to application specific

requirements (Default setting = Alarm).

Output A and B setting

For SONO 3500 CT, output A and B settings depend on the ordering: Recommended

settings, see the following table. The SONO 3500 CT settings cannot be changed according

approval requirements, and are therefore read only.

) via SIMATIC PDM

max

Output A

Output B

Pulse value A & B

(depending on DN value)

Forward or reverse pulses

Preset: Forward

Forward or reverse pulses, alarm, call-up

Preset: See scheme for SONO 3500 CT or the

following settings for INFOCAL 9 energy calculator.

Note

For type-approved and verified SONO 3500 CT flowmeter the settings are HW key protected

and therefore read only. This HW key is protected via the verification sealing. The verification

sealing can only be broken by the user with the acceptance of the local authorities.

SONO 3500

Operating Instructions, 11/2020, AQ237286479555en-

Page 47

47

DN

Pulse setting (liter/pulse)

100

2.5

125

2.5

150

2.5

250

10

350

10

500

50

600

100

700

100

800

100

1000

100

6.5.6 Output A, terminals 56/57:

Pulse rate can be seen on transmitter side label (system nameplate).

The settings are depending on the ordering. The following table shows the recommended

pulse output settings (pulse width 5 ms), which can be adapted to heat calculator INFOCAL 9.

200 10

300 10

400 50

900 100

1200 100

Note

For use with a energy calculator the pulse value must correspond to pulse setting of energy

calculator.

SONO 3500 CT

Operating Instructions, 11/2020, AQ237286479555en-010402

Page 48

CT

010402

48

6.5.7 Output B, terminals 66/67:

The output B setting must be selected according to application specific requirements (Default

setting = Alarm).

Preset to alarm indication:

Example: If track 1 is not measuring, a "triangle" alert appears on display. Failure code "F1"

appears in display menu 4, and relay output terminals switch to "off".

Call up indication:

When output B is configured as "call-up", the output is activated by an alarm condition and

remains on until it is manually reset via communication interface and the PDM program (or

via manually power down of the device).

A new alarm will not activate a "call-up" function if the "call-up" function is still active from a

previous alarm.

6.5.8 Checking the operation readiness

All parameters are now set and defined according to the application.

1. Select: "Device" → "Download to device..." to download the parameters to the device.

Note

Before downloading the parameters, check that all listed data are loaded or changed and

in accordance with the application requirements.

2. Select "Execute even if the device TAG does not match the project data TAG." and click

"OK" to download all changes from the table to the device.

Operating Instructions, 11/2020, AQ237286479555en-

SONO 3500

Page 49

49

View process values

The system is now ready for normal operation.

1.

Select "View" → "Display" to see all measured process values.

2.

Verify that the fields show the expected values.

Store settings on the PC

Note

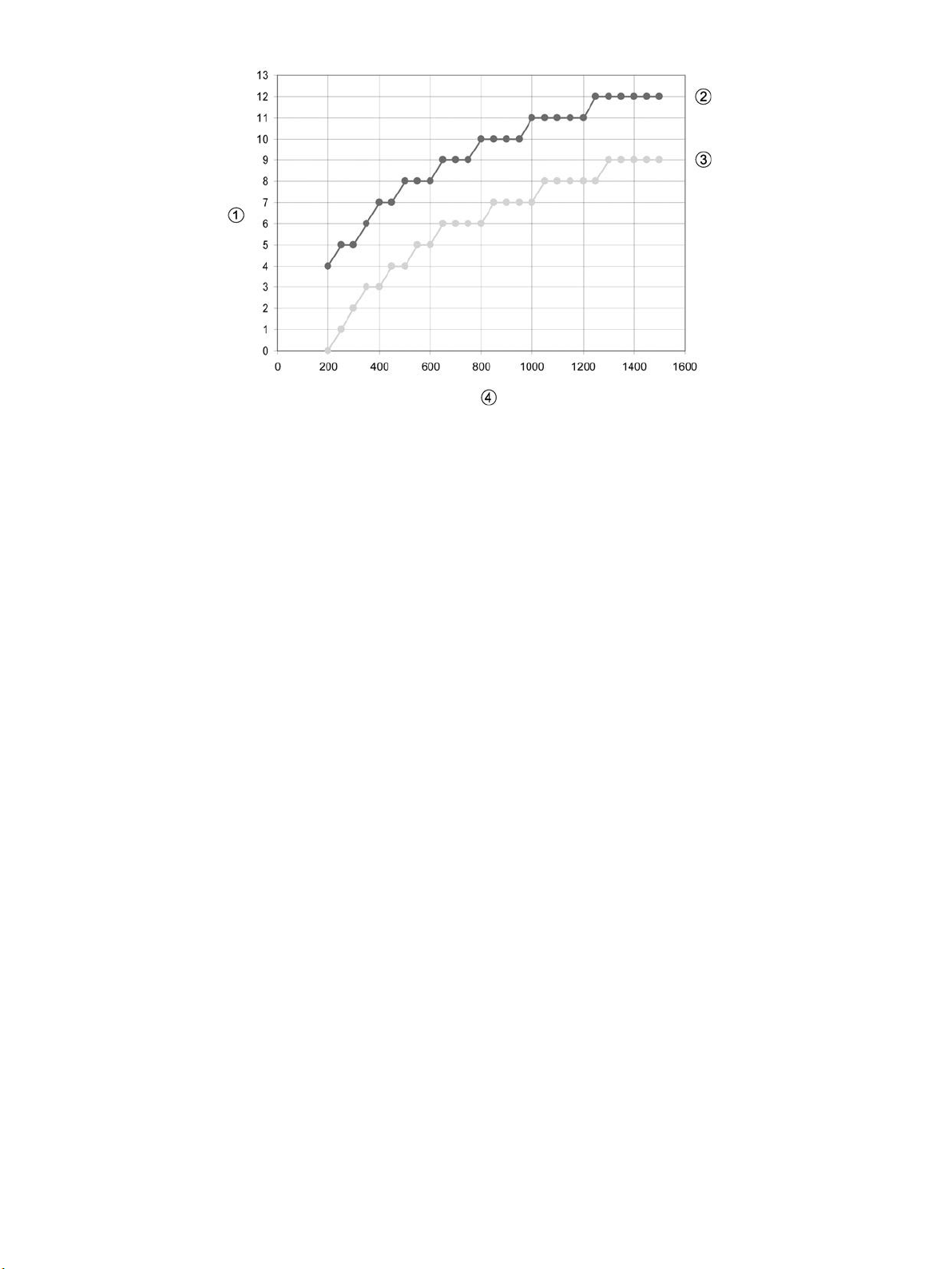

Measured Track Values

The "Measured Track Values" should show stable values within the normal range, i.e. the

gains should be stable values between 3 and 12 (smaller sizes low values and larger sizes

high values) and the actual velocities for the paths should be stable, constant and smoothly

changing values between 0 and 10 m/s.

Store the device settings after verifying the values.

●

Choose: "Read" → "Upload to PC" to get all the settings.

●

Store the complete settings on your PC via "File" → "Export".

SONO 3500 CT

Operating Instructions, 11/2020, AQ237286479555en-010402

Page 50

CT

010402

50

Functions

7

7.1 Unit selection

The device is delivered with totalizer and flow rate units in m and m3/h, respectively, as

standard. However, it is possible to manually configure the device to operate with other units.

Changing the units

Go via PDM menu "Device" → "Unit guide". Select the new unit from the list and click on

"Apply Change of Units". The change should be stored into the transmitter via "Device" →

"Download to Device" afterwards

.

7.2 Number of decimal digits

Figure 7-1 Unit selection

Note

The display is only able to show m3 and m3/h

If the units are changed to units other than m3 and m3/h, the display will not show any unit

indication after the measured value on the display. To show the new customer unit on the

display, a sticker can be used to show units. This sticker should be affixed to the transmitter

display.

For the display values (totalizers in menu 1 and 2 and flow in menu 3) "Auto adjust decimal

point" is the default setting. This means that the number of digits after the decimal point

automatically will be reduced with increasing number of digits before the decimal point.

SONO 3500

Operating Instructions, 11/2020, AQ237286479555en-

Page 51

51

7.3 Password-protected data

In the MODBUS communication via SIMATIC PDM, the flowmeter information is protected

by a password. The default password is "1000" and it can be changed after gaining access

to the flowmeter or via the PDM menu "Device" → "Change Password". The password can be

changed without the use of the HW key.

Figure 7-2 Change password

Click "Write new password to the device" and "Close"

7.4 Hardware key

To gain access to protected parameters of the transmitter, a hard-ware jumper (HW key)

must be installed as shown below. The HW key place is located internally on the right top

part of PCB behind the display as shown.

Note

For type-approved and verified SONO 3500 CT flowmeter the HW key is protected by a

verification sealing on the display frame (see Sealing of SONO 3500 CT (Page 38)). The

verification sealing can only be broken by the user with the acceptance of local authorities.

SONO 3500 CT

Operating Instructions, 11/2020, AQ237286479555en-010402

Page 52

CT

010402

52

Figure 7-3 HW key behind the display (placed on the right pins)

Note

Important

In this mode, with the HW key installed, many parameters in PDM are opened. If these

parameters are changed, it can seriously affect the meter accuracy and operation. Be careful

when writing new parameters.

Changing the HW-protected parameters

1.

Disconnect power supply to transmitter, i.e. battery plug and the mains power supply

2.

Remove frame and display from transmitter.

3.

Insert HW key vertically on right pins as shown in figure above.

4.

Remount display and frame on transmitter.

5.

Restart device.

6.

Make parameter changes via PDM.

7.

Download parameter changes to device.

8.

Remove HW key by following the steps above.

Operating Instructions, 11/2020, AQ237286479555en-

SONO 3500

Page 53

53

Service and maintenance

8

NOTICE

Repair and service

Note

The flow sensors are defined as non-repairable products.

NOTICE

Battery replacement interval

8.1 Maintenance

The device is maintenance-free. However, a periodic inspection according to pertinent

directives and regulations must be carried out.

An inspection can include check of:

●

Ambient conditions

●

Seal integrity of the process connections, cable entries, and cover screws

●

Reliability of power supply, lightning protection, and grounds

Repair and service must be carried out by Danfoss authorized personnel only.

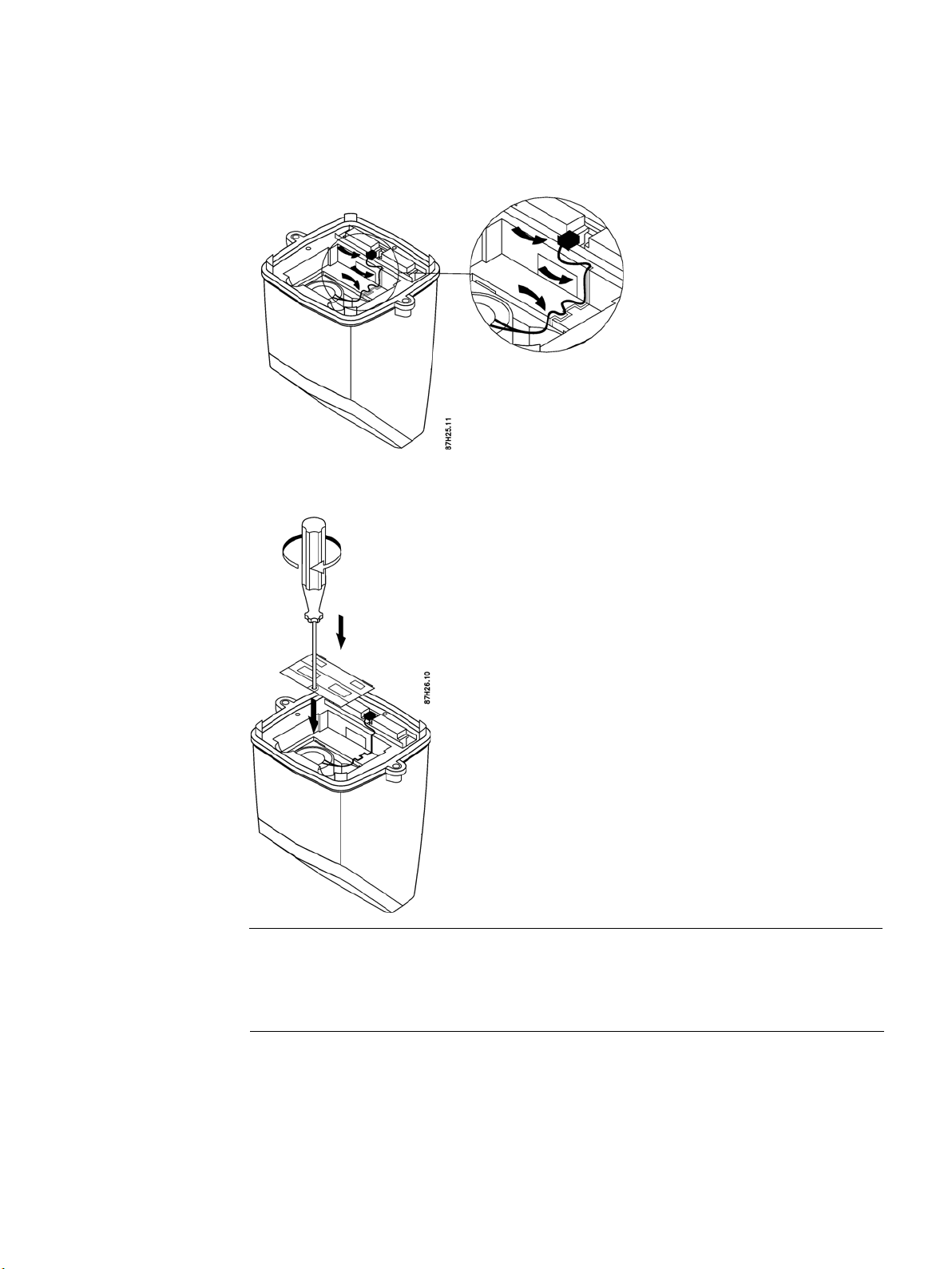

8.2 Battery replacement

It is recommended to replace the battery pack at the latest after 6 years.

SONO 3500 CT

Operating Instructions, 11/2020, AQ237286479555en-010402

Page 54

CT

010402

54

Battery lifetime

The battery lifetime depends on the frequency of mains supply failure. Under normal

temperature and working conditions a battery can have an operation lifetime up to 6 years.

1.

Unscrew battery cover and remove old battery pack.

2.

Fit new battery pack in transmitter.

Operating Instructions, 11/2020, AQ237286479555en-

SONO 3500

Page 55

SONO 3500 CT

Operating Instructions, 11/2020,

55

3.

Connect battery.

Ensure that wire is inserted into small channel leading from plug to battery.

4.

Remount battery cover.

Note

Every time a battery is fitted and connected, the unit runs a start-up routine.

A battery replacement does not influence the transmitter settings and accumulated

process values.

AQ237286479555en-010402

Page 56

CT

010402

56

Menu

Parameter

Display example

Comments

Sensor distance (Page 66).

Resetting the internal battery counter

After replacing the batteries, reset the internal battery counter in order to indicate the power

capacity correctly.

Note

Battery capacity

The transmitter setting for the battery capacity is pre-configured by the ordered version. To

ensure the correct battery status calculation the replacement battery shall be the same type

and have the specific capacity. The capacity setting can be controlled via SIMATIC PDM.

8.3 Service menu

The service menu ( ) is accessible from all menus by pressing the push button for minimum

2 seconds. To return back to the main menu you need to press the push button for a minimum

of 2 seconds again. If no action is taken you will be taken back to the main menu after 10 min

if back-up battery powered or after 2 min if mains-powered.

Table 8-1 Service menu

1 Gain path 1 and path 2

2 Signal level AB and BA of path 1

3 Signal level AB and BA of path 2

4 Transition time (μs) AB of path 1

5 Transition time (μs) AB of path 2

Gain for path 1 and path 2 ranging

from 0 to 15. The optimal gain values

are explained in Figure 9-2 SI‐ TRANS

FUS080 Gain step vs.

Signal level for Downstream and

Upstream Sensor for path 1 typically

between 230 and 380

Signal level for Downstream and

Upstream Sensor for path 2 typically

between 230 and 380

Time of Flight Downstream, from Sensor A

to B for path 1

Time of Flight Downstream, from Sensor

A to B for path 2

6 Transition time (μs) BA of path 1

Time of Flight Upstream ,from Sen‐ sor B

to A for path 1

SONO 3500

Operating Instructions, 11/2020, AQ237286479555en-

Page 57

SONO 3500 CT

Operating Instructions, 11/2020,

57

Menu

Parameter

Display example

Comments

7 Transition time (μs) BA of path 2

8 Delta time (ns) of path 1

9 Delta time (ns) of path 2

10 Velocity (m/s) path 1

11 Velocity (m/s) path 2

Time of Flight Upstream from Sensor B

to A for path 2

Delta Time Of Flight for path 1,

difference between Down and upstream TOF

Positive value equals positive flow

Delta Time Of Flight for path 2,

difference between Down and upstream TOF

Positive value equals positive flow

Measured flow velocity for path 1

Measured flow velocity for path 2

See also

Optional current output module (Page 35)

8.4 Technical support

Additional Support

Contact your local Danfoss representative and offices if you have additional questions about

the device.

Find your local contact partner at: www.danfoss.com (www.danfoss.com

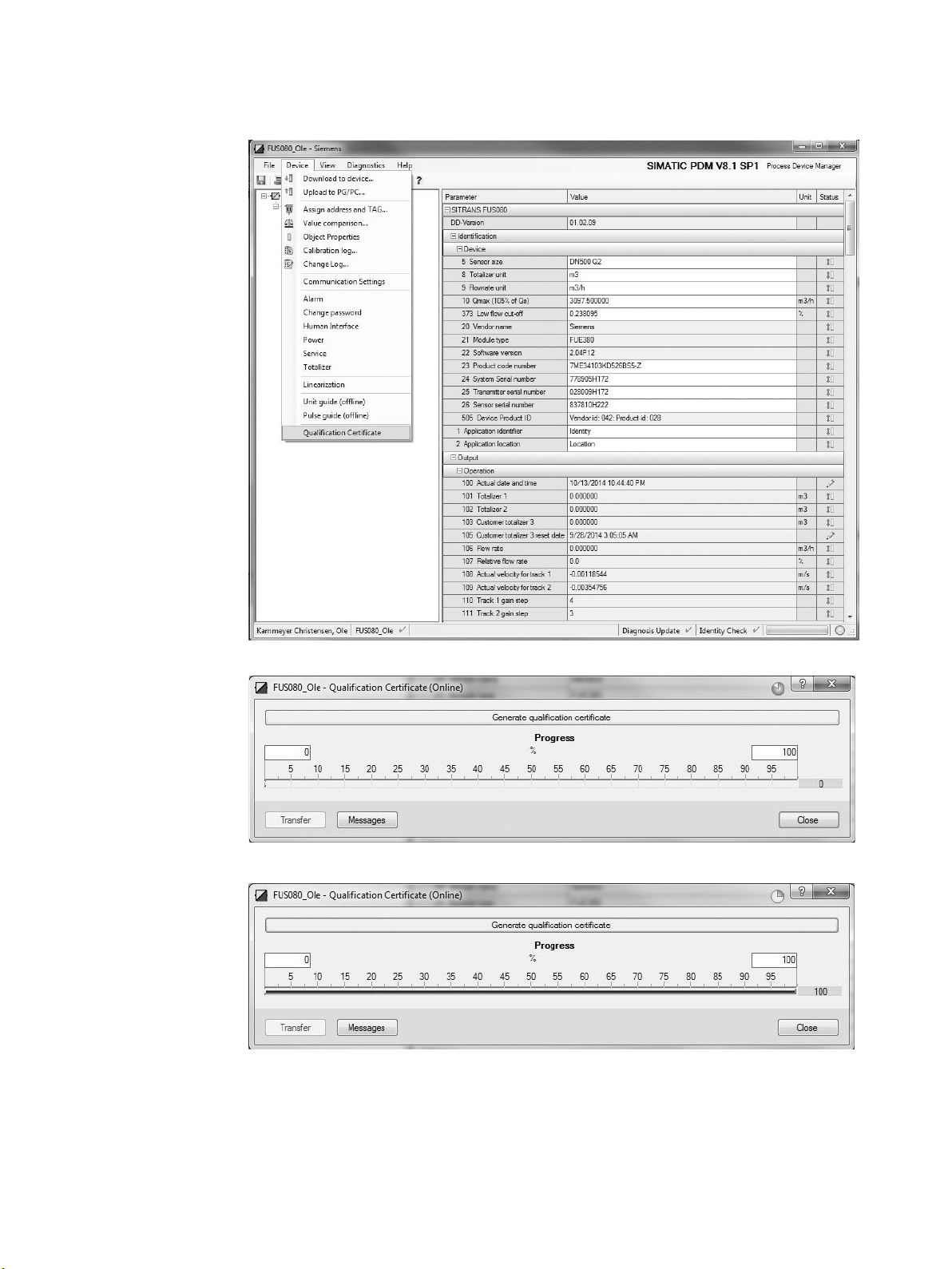

8.5 Application-specific data - Qualification certificate

In case the device needs service, the technical support team will typically request

information about the application and the flowmeter.

)

●

Prepare a sketch of the installation/application.

●

For your convenience you may create a qualification certificate via SIMATIC PDM

AQ237286479555en-010402

Page 58

CT

010402

58

1.

In PDM click on "Device" → "Qualification Certificate".

2.

Click on "Generate qualification certificate".

3.

Click on "Close".

The Qualification Certificate is now available via Microsoft Word. In it add the required

application information (see Figure 8-1 Qualification certificate - page 1 (Page 59), Figure 8-

2 Qualification certificate - page 2 (Page 60) and Figure 8-3 Qualification certificate - page 3

(Page 61).

Operating Instructions, 11/2020, AQ237286479555en-

SONO 3500

Page 59

59

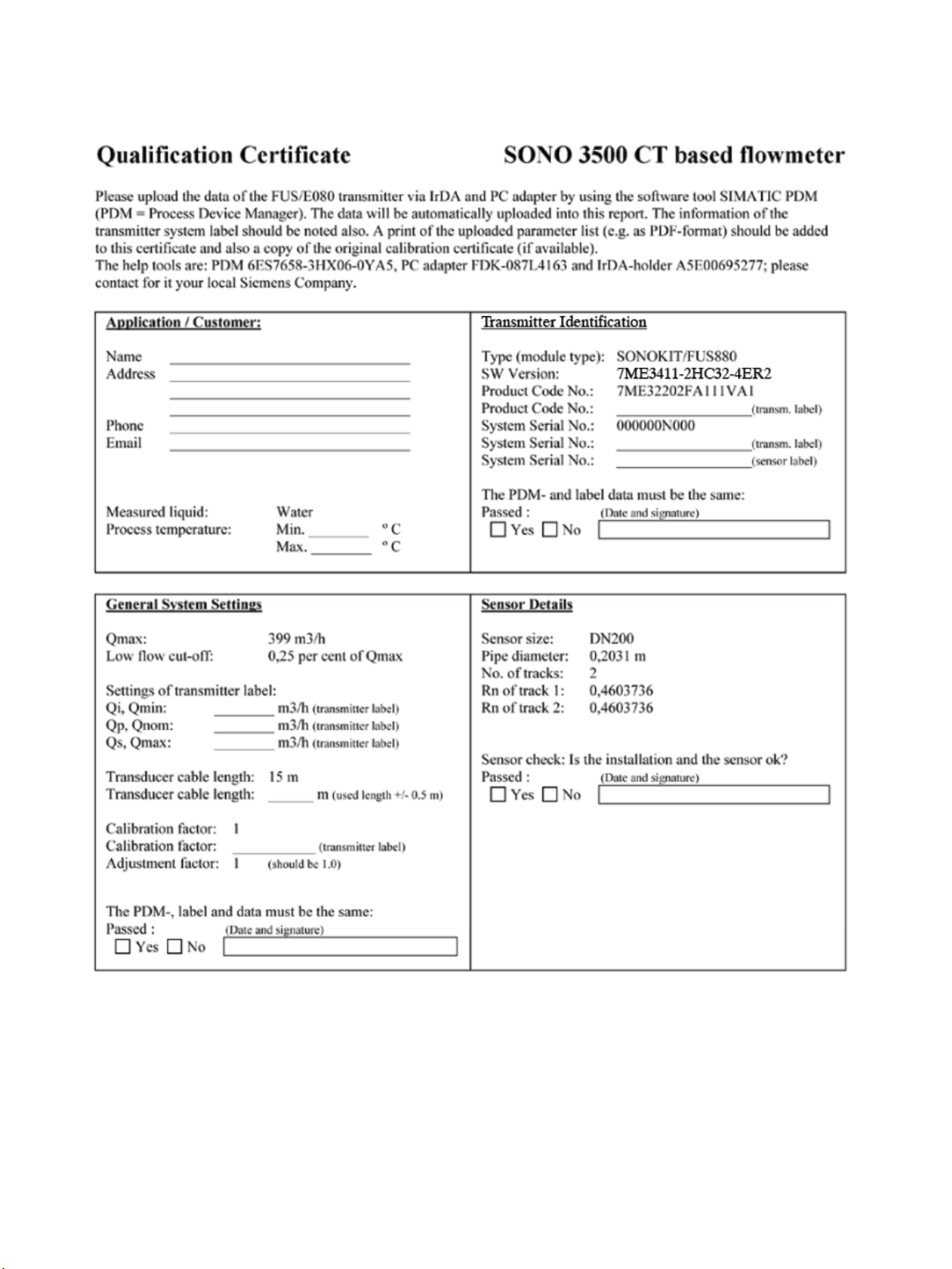

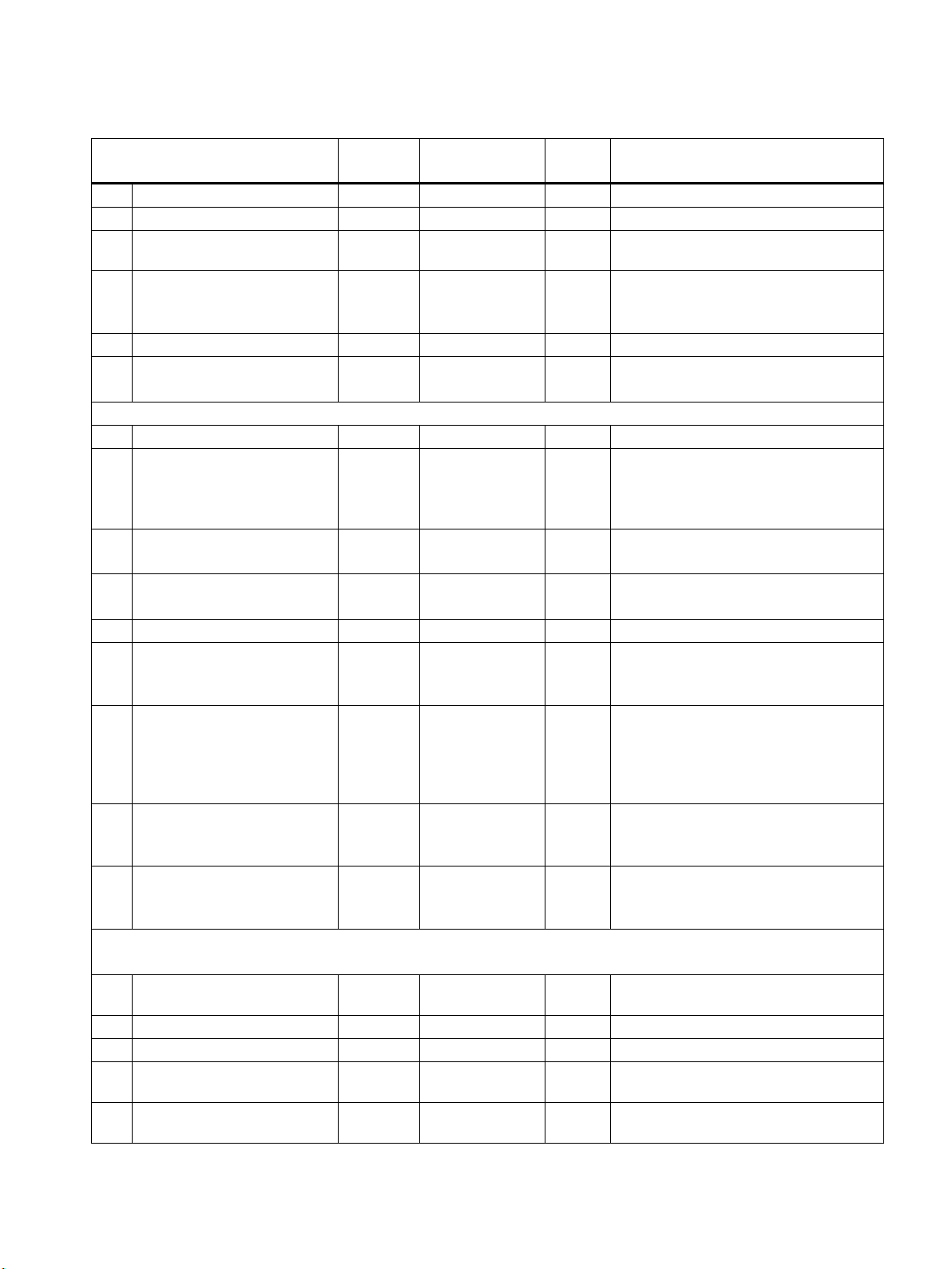

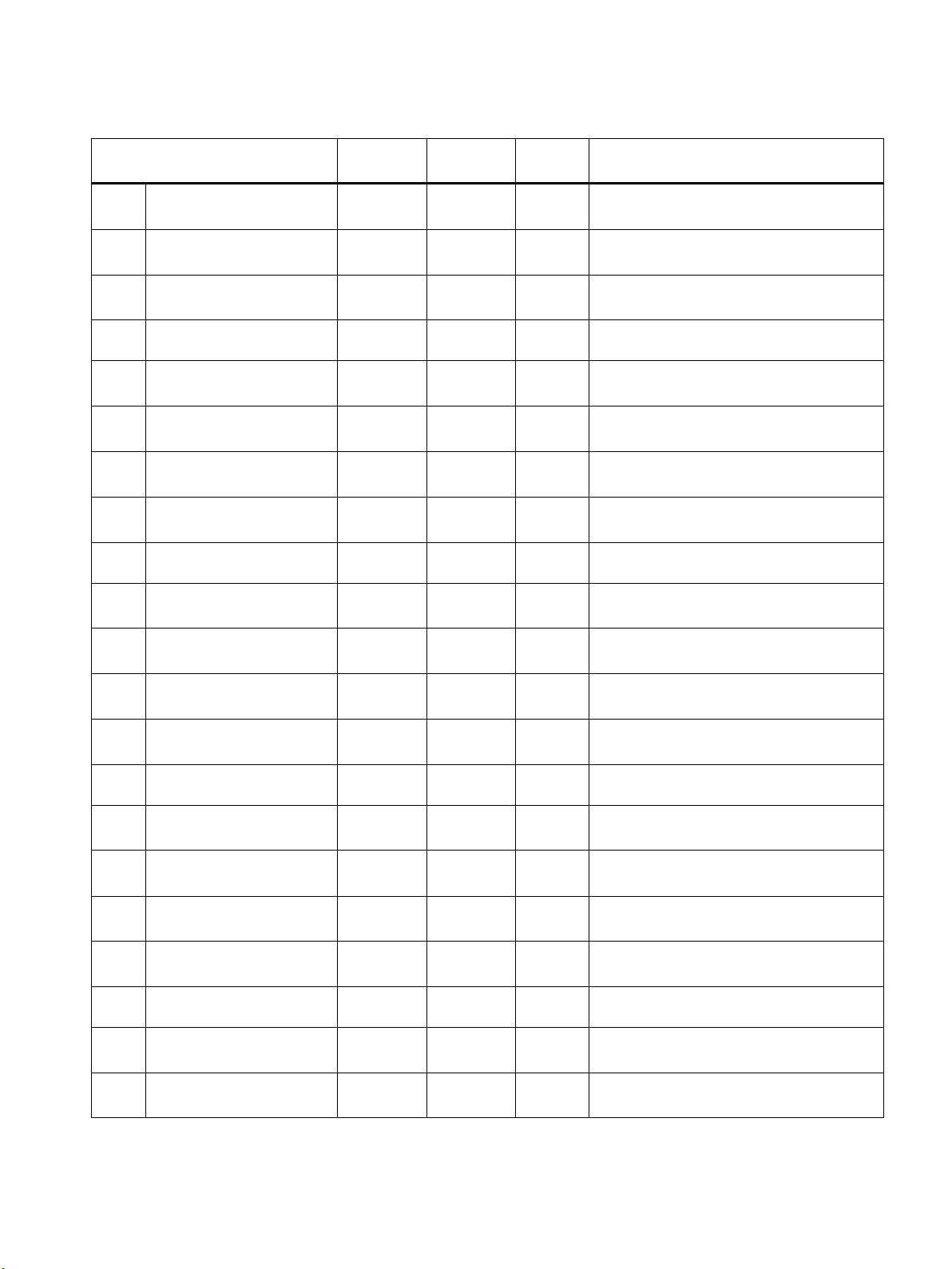

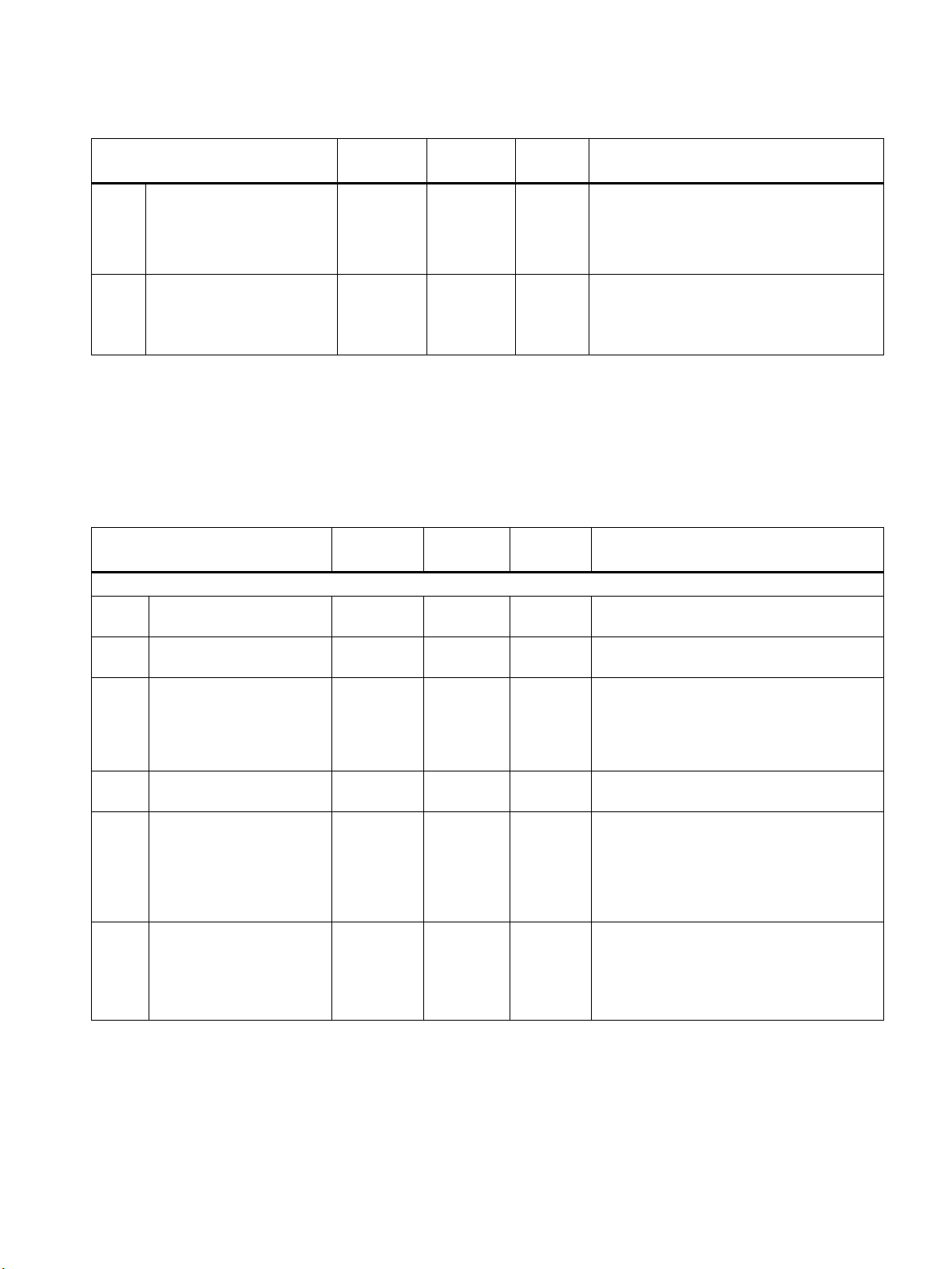

8.6 Qualification certificate

Figure 8-1 Qualification certificate - page 1

SONO 3500 CT

Operating Instructions, 11/2020, AQ237286479555en-010402

Page 60

CT

010402

60

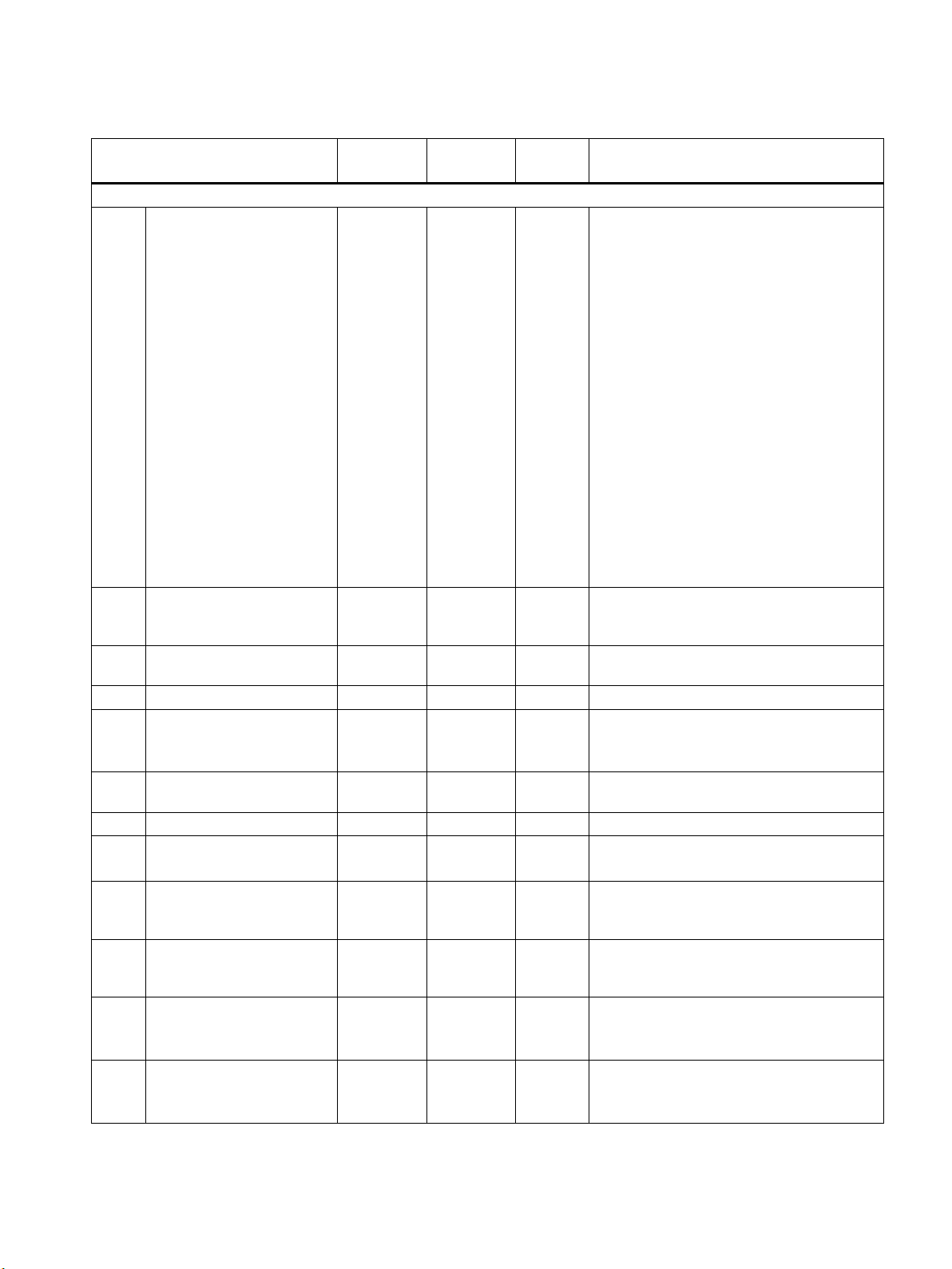

Figure 8-2 Qualification certificate - page 2

SONO 3500

Operating Instructions, 11/2020, AQ237286479555en-

Page 61

61

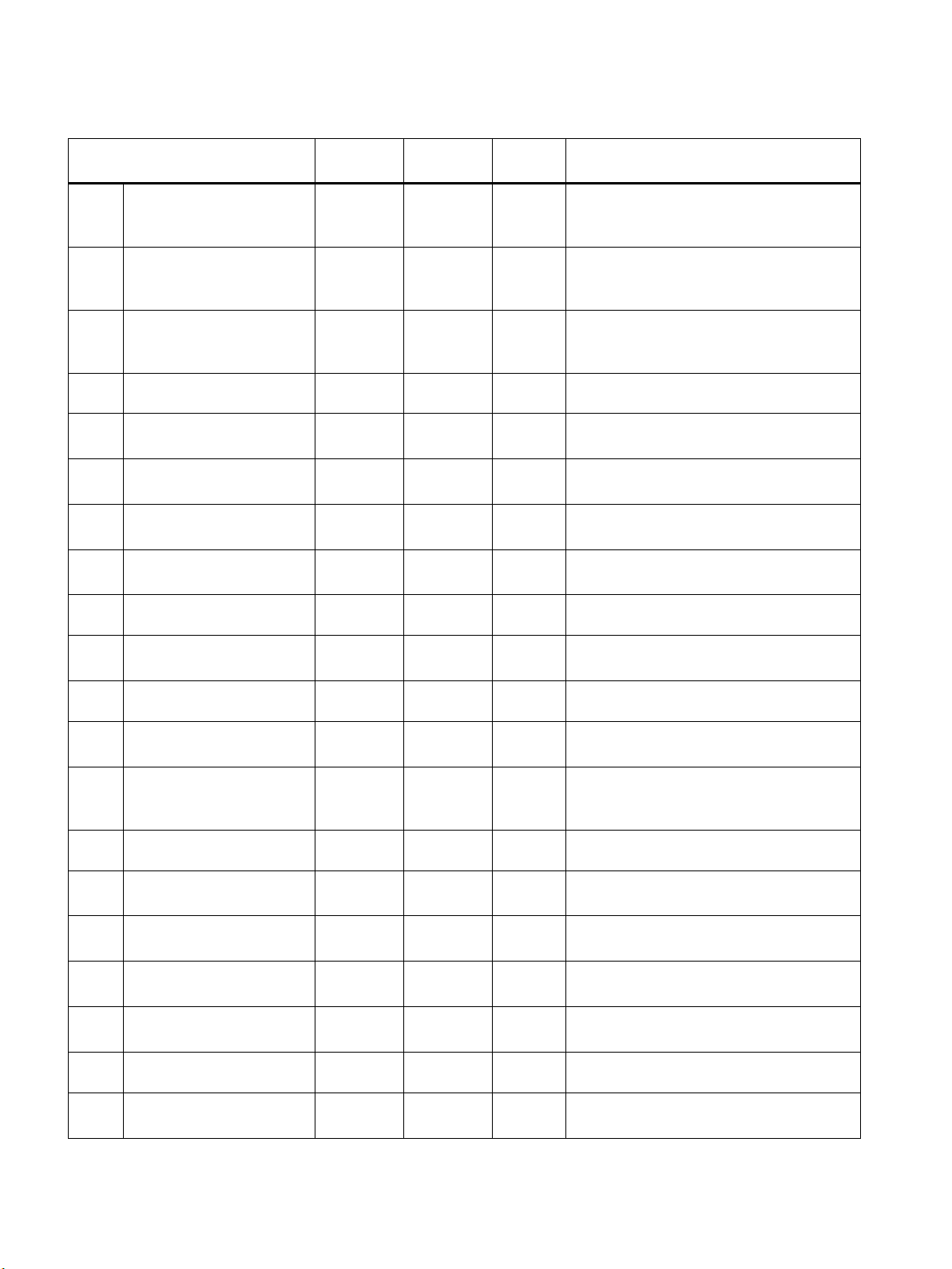

Figure 8-3 Qualification certificate - page 3

8.7 Return procedures

Enclose the delivery note, the cover note for return delivery together with the declaration of

decontamination form on the outside of the package in a well-fastened clear document

pouch.

SONO 3500 CT

Operating Instructions, 11/2020, AQ237286479555en-010402

Page 62

CT

010402

62

Required forms

●

Delivery Note

●

Cover Note for Return Delivery with the following information

–

product (ordering number)

–

number of devices or spare parts returned

–

reason for the return

●

Declaration of Decontamination

With this declaration you certify

carefully cleaned and are free from any residues.

If the device has been operated together with toxic, caustic, flammable or waterdamaging products, clean the device before return by rinsing or neutralizing. Ensure that

all cavities are free from dangerous substances. Then, double-check the device to ensure

the cleaning is completed.

We will not service a device or spare part unless the declaration of decontamination

confirms proper decontamination of the device or spare part. Shipments without a

declaration of decontamination will be cleaned professionally at your expense before

further proceeding.

You can find the forms on the Internet.

Note

Return of products with Lithium batteries