Page 1

Application Note

Siemens S7 PLC and FC 300 Profibus

VLT® AutomationDrive FC 300

Page 2

Siemens S7 PLC and FC 300 Profibus

www.infoPLC.net

Introduction

This application note describes how to set

up a PROFIBUS system between a Danfoss

Drives FC 300 frequency converter and S7

PLC 315-2 from Siemens.

It is assumed that you are already familiar

with the Simatic S7 system.

Only the steps which are required in order

to establish communication between the FC

300 Profibus and the Simatic S7-315-2 DP

PLC are shown.

NOTE!:

The examples do not describe all the

functions needed for a real application, for

example error handling.

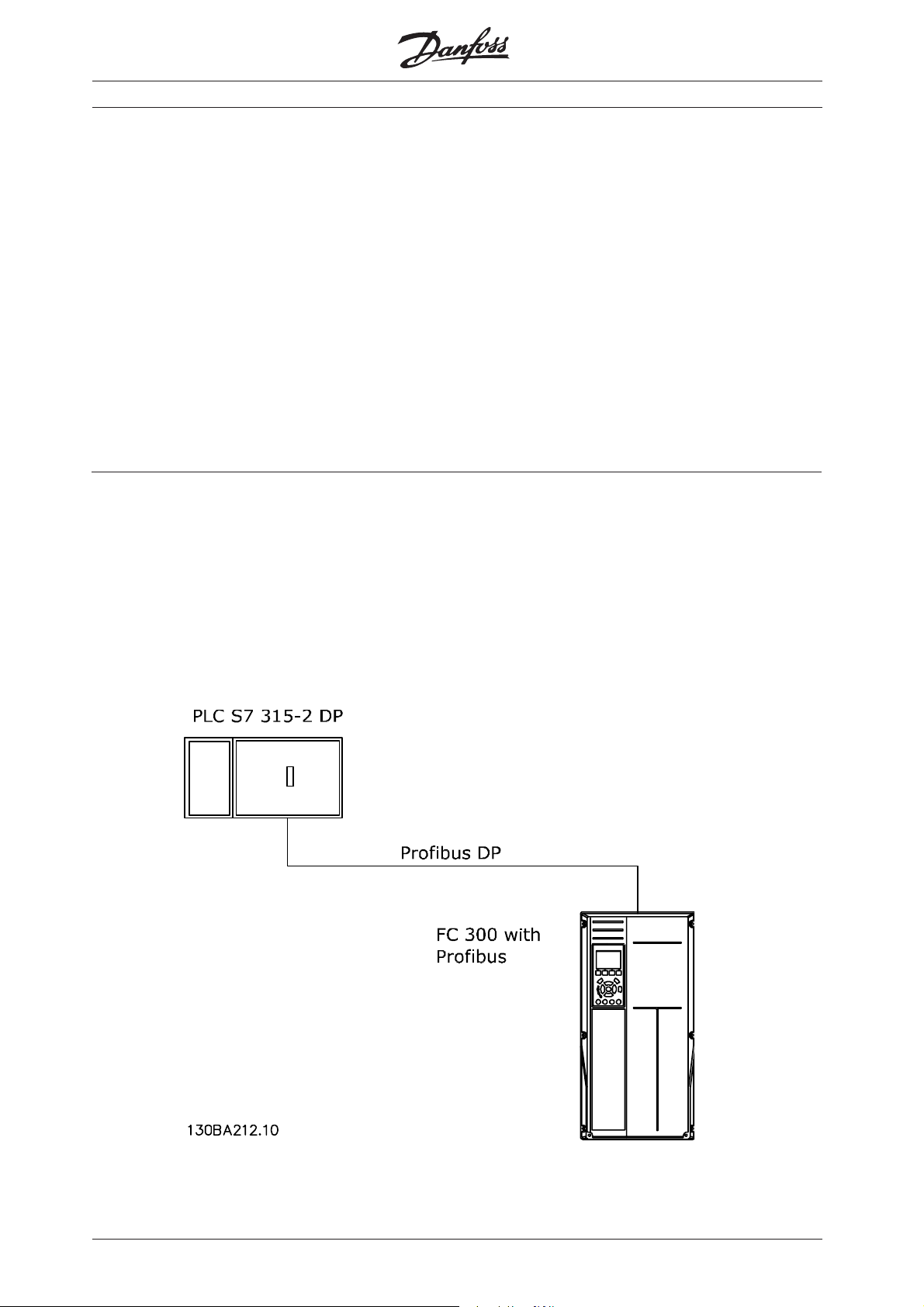

System description

The drawing shows the system in this

application note.

On the PROFIBUS network the stations are

programmed in the following way:

S7 PLC 315-2 DP: Address number 1.

FC 300: Address number 5 PPO Type 2

Module consistent.

This note describes:

System description

Configuring the Profibus network

Downloading and troubleshooting

Check of communication

Simatic project for download

Details of some of the components/

software:

FC 300 with PROFIBUS interface - sw.

version 2.xx.

FC 300 GSD version 2.00

PLC S7-315-2 DP (6ES7 315-2AG10-0AB0 /

V2.0)

SIMATIC Manager version 5.3 + SP1

MN.33.A1.02 - VLT is a registered Danfoss trademark

1

Page 3

Configuring the Profibus network

www.infoPLC.net

Start the SIMATIC Manager and create a

new project.

Open Hardware configuration in S7 Manager

to configure the system.

Siemens S7 PLC and FC 300 Profibus

In order to configure a PROFIBUS system,

the configuration tool needs a GSD file for

each type of slave on the network. The

GSD file is a PROFIBUS DP "standard" text

file containing the necessary communications setup data for a slave.

Download the necessary GSD files at

http://www.danfoss.com/BusinessAreas/

DrivesSolutions

The first step in configuration of the

PROFIBUS Master is to import the GSD file in

the configuration tool. The steps outlined

below show how to add a new GSD file to

the Simatic Manager software tool. For

each drive series, a GSD file is typically

imported once only, following the initial

installation of the software tool.

Using the browser for the GSD file, choose

to install the needed GSD files. Both the

GSD file and a bitmap for the device will be

imported into the Hardware catalogue.

2

MN.33.A1.02 - VLT is a registered Danfoss trademark

Page 4

Configuring the Profibus network

www.infoPLC.net

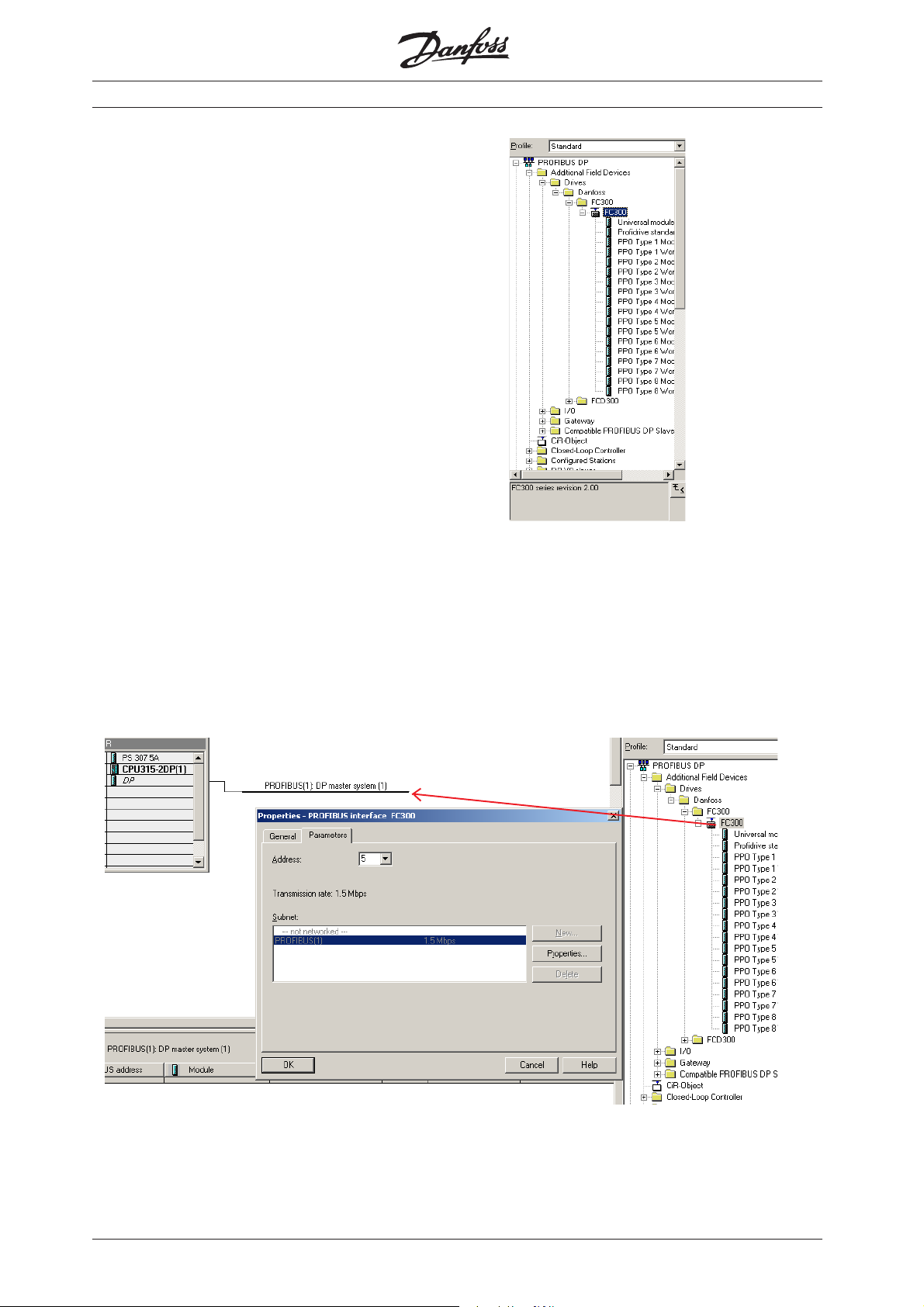

The GSD file is now imported and will be

accessible via the following path in the

Hardware catalogue.

Note that the GSD revision should display a

revision higher than 2.00.

Insert a Profibus network and add a

PROFIBUS Master system. Setup the

Profibus network to a baud rate from 9.6

kbaud to 12 Mbaud.

Select FC 300 from the Hardware catalogue

and drag and drop it to the PROFIBUS

network.

A window for the address of the FC 300

now appears. Select the address from the

scroll-down list. Note that this address

setting must match the address setting in

par. 9-18 Node address.

Siemens S7 PLC and FC 300 Profibus

MN.33.A1.02 - VLT is a registered Danfoss trademark

3

Page 5

Siemens S7 PLC and FC 300 Profibus

www.infoPLC.net

Configuring the Profibus network

The next step is to set up the peripheral

input and output data via a PPO type. In

the peripheral area data is transmitted

cyclically via PPO types. In the example

below, a PPO type 2 Module consistent is

dragged and dropped to the first slot.

The choice of PPO type is made in the

master configuration, and is then automatically recorded in the frequency converter.

No manual setting of PPO types in the FC

300 is required.

The current PPO type can be read in par.

9-22 Telegram selection.

In addition, all PPO types can be set up as

word consistent or module consistent.

For FC 300, the process data area can be

word or module consistent, whereas the

parameter channel must always be module

consistent. Module consistent data is

transmitted as sets of interrelated words

transferred simultaneously between the PLC

program and the Profibus master. Word

consistent data is transmitted as individual

independent words between the PLC and

the Profibus master.

4

MN.33.A1.02 - VLT is a registered Danfoss trademark

Page 6

Siemens S7 PLC and FC 300 Profibus

www.infoPLC.net

Configuring the Profibus network

The system is now set up to use the PPO

type 2 in the following peripheral I/O area:

Process data, i.e. write a Control word and

Parameter Characteristic (PCA), i.e. read

and write to parameters.

Master to Slave

Parameter channel (PCA) Process channel (PCD)

PCD 1 PCD 2 PCD 3 PCD 4 PCD 5 PCD 6

PCA Index High

PVA

PQW

256

PQW

258

PQW

260

Low

PVA

PQW

262

Control

word

PQW 264 PQW 266 PQW 268 PQW

Reference Torque

Reference and receiving a Status word and

Main Actual Value.

limit

Ramp 1

up time

270

Empty Empty

PQW

272

PQW

274

Slave to Master

Parameter channel (PCA) Process channel (PCD)

PCD 1 PCD 2 PCD 3 PCD 4 PCD 5 PCD 6

PCA Index High

PVA

PIW

256

PIW

258

PIW

260

Low

PVA

PIW

262

Status

word

PIW 264 PIW 266 PIW

Main Actual

Value

Motor

current

268

Frequency Digital

input

PIW 270 PIW

272

Empty

PIW

274

PQW means the data from the Master to

the Slave. By PCA the output data will

contain the request of a parameter read or

write. By Process data the first word of

output data is the Control word of the FC

300 and the next is the Reference. The rest

of the words can be freely configured to

transmit different kind of data to the FC

300 in parameter 915 PCD Write Configu-

ration.

PIW means the data from the Slave to the

Master. By PCA the input data will contain

the response of a parameter read or write.

By Process data the first word of input data

is the Status word of the FC 300 and the

next is the Main Actual Value. The rest of

the words can be freely configured to

transmit different kind of process data in

parameter 916 PCD Read Configuration. See

example on next page.

MN.33.A1.02 - VLT is a registered Danfoss trademark

5

Page 7

Configuring the Profibus network

www.infoPLC.net

Normally the setup of the PCD area is done

in parameter 915 PCD Write Configuration

and 916 PCD Read Configuration via the LCP

or the MCT 10 Setup Software. In FC 300 it

is possible to automatic configure the PCD

area in the PLC via the GSD file in Simatic

Manager. The configuration of parameter

915 and 916 is done when either the PLC or

the VLT is being power up via the

parameterise telegram.

Siemens S7 PLC and FC 300 Profibus

Note that to configure the PCD area via the

PLC the FC 300 and the GSD file need to

have a software version higher than 2.00.

Double click on the FC 300 and the click on

Parameter assignment:

By Device-specific parameters it is possible

to use the Scroll down list to setup the PCD

area. Remember to chose "Enable

Autoconfig" for automatic configuration of

PCD data.

P915/0 to P915/9 is process data written

from the PLC to the FC 300, PQW area.

P916/0 to P916/9 process data from the FC

300 to the PLC, PIW area.

6

MN.33.A1.02 - VLT is a registered Danfoss trademark

Page 8

Configuring the Profibus network

www.infoPLC.net

The Parameter channel can only be access

as consistent data and there for System

Function Call (SFC) are needed. In Simatic

you should use SFC 14 for reading data and

SFC 15 for writing data.

The Process channel can be access as

module or word consistent. In this example

module consistent is used and therefore

again SFC 14 / 15 is needed.

If a PPO type 2 Word consistent was

chosen the peripheral I/O area can be

access in each word.

Siemens S7 PLC and FC 300 Profibus

MN.33.A1.02 - VLT is a registered Danfoss trademark

7

Page 9

Siemens S7 PLC and FC 300 Profibus

www.infoPLC.net

Downloading and troubleshooting

Set the PLC in stop with the key on the PLC

processor and download the program.

Note that the FC 300 will show a Fieldbus

fault while the PLC is in Stop mode.

Before the PLC can be set in RUN mode

ensure that the node address in par. 918

match the corresponding address in the

program. Note that a change of parameter

918 is first active at next power up.

After the download of the PLC program the

LED marked as "NS" on the Profibus card

should be solid green when the key on the

S7 master is set in RUN. This indicate that

the master and slave is communicating.

The LED marked "MS" indicates the module

status, i.e. acyclical DP V1 communication

from either a PROFIBUS master class 1

(PLC) or a master class 2 (MCT 10, FDT

tool). When this light shows constant

green, then DP V1 communication from

master classes 1 and 2 is active.

If the "NS" LED on the FC 300 Profibus card

isn't solid green the fault could be:

- Wrong address setting in parameter 918

Node address according to the master.

- After changing the parameter 918 Node

address the power hasn’t been cycle.

- Wrong cable connection, check the cable

by the master and the FC 300.

62 = RxD/TxD-P Red cable

63 = RxD/TxD-N Green cable

- The termination of the Profibus network

isn't correct done.

- Wrong GSD file. Check that the used GSD

file is for FC 300.

Check of the communication

To easily check the communication between

a Master and the FC 300 in the Simatic

Manager a Variable Table (VAT) can be

created.

Go to S7 Programs and Blocks and create a

VAT table.

See the FC 300 Profibus Operating

Instruction for a more comprehensive

troubleshooting.

8

MN.33.A1.02 - VLT is a registered Danfoss trademark

Page 10

Check of the communication

www.infoPLC.net

Open the VAT table and insert a range of

variable from PIW 256 of 10 words and

range of variable from PQW 256 of 10

words.

Now the peripheral input data from PIW

256 – 274 can be monitored by clicking on

the glasses.

Siemens S7 PLC and FC 300 Profibus

In this example the peripheral input data will

show the following:

- PIW 256 shows the PCA response of a

parameter transfer double word

(parameter 351).

- PIW 262 shows the data of parameter

351 (300)

- PIW 264 shows the FC 300 Status word

- PIW 266 shows the Main actual Value

- PIW 268 shows the actual Motor current

(1.55 Amp)

- PIW 270 shows the frequency (12.6 Hz)

- PIW 272 shows the status of the digital

inputs (terminal 19 = 1)

MN.33.A1.02 - VLT is a registered Danfoss trademark

9

Page 11

Simatic project

www.infoPLC.net

A Simatic project is available for

downloading on

BusinessAreas/DrivesSolutions. This project

contains a Function Block 50 which can be

used to parameterise and control a FC 300

via PP0 type 2 Module consistent. Download

the zip file ???.

http://www.danfoss.com/

Siemens S7 PLC and FC 300 Profibus

10

MN.33.A1.02 - VLT is a registered Danfoss trademark

Page 12

www.danfoss.com/drives

175R1023 MN33A102

Rev. 2005-04-28

*MN33A102*

Loading...

Loading...