Page 1

Technical Information

shhark® Low Noise Gear Pumps

Group 2

www.danfoss.com

Page 2

Technical Information

shhark® Low Noise Aluminum Gear Pumps, Group 2

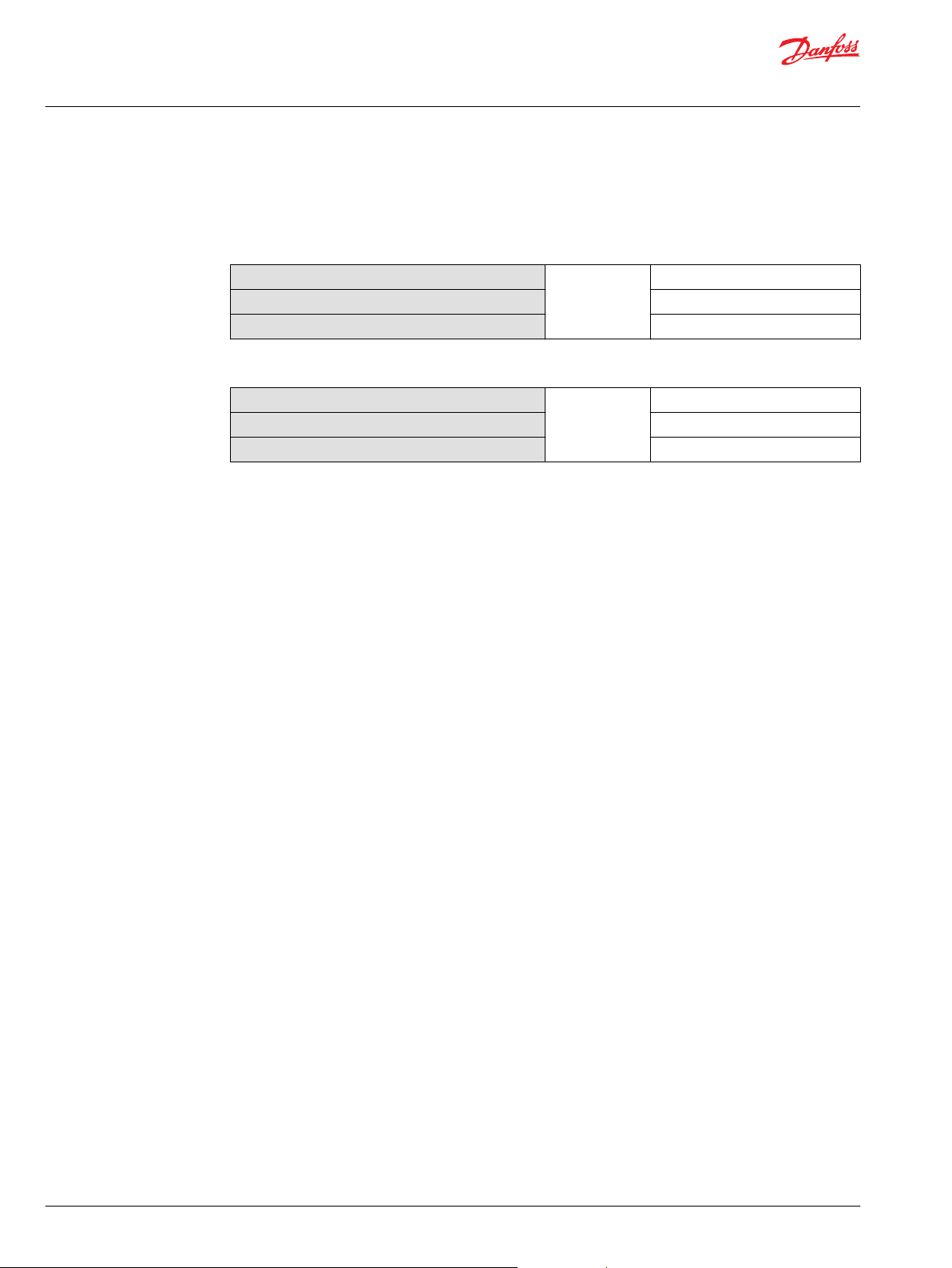

Revision history Table of revisions

Date Changed Rev

July 2021 Sound level graphs added 0201

February 2020 Added frame size 025 sound levels graphs 0105

November 2019 Minor edits to text, tables and the diagrams in "Dimensions and Data" 0104

October 2019 Features text change on page 6. 0103

October 2019 New images replacement. 0102

September 2019 First edition. 0101

2 | © Danfoss | July 2021 BC315962412551en-000201

Page 3

Technical Information

shhark® Low Noise Aluminum Gear Pumps, Group 2

Contents

General information

The shhark® Low Noise Technology.......................................................................................................................................... 4

Features and Benefits......................................................................................................................................................................5

shhark® Gear Pumps Representatives.......................................................................................................................................5

Advantages of the shhark® technology versus the “dual contact flank” technology..............................................6

shhark® Pump Design..................................................................................................................................................................... 6

shhark® Technical Data...................................................................................................................................................................7

Determination of Nominal Pump Sizes....................................................................................................................................8

Master Model Code

Model Code for Single Gear Pumps........................................................................................................................................ 11

Model Code for Tandem Gear Pumps.................................................................................................................................... 12

Model Code for Tandem Gear Pumps.................................................................................................................................... 14

System Requirements

Inlet Pressure................................................................................................................................................................................... 16

Speed..................................................................................................................................................................................................17

Hydraulic Fluids.............................................................................................................................................................................. 17

Temperature and viscosity......................................................................................................................................................... 17

Filtration............................................................................................................................................................................................ 19

Filters.............................................................................................................................................................................................19

Selecting a filter.........................................................................................................................................................................19

Reservoir...................................................................................................................................................................................... 19

Line sizing......................................................................................................................................................................................... 19

Pump Drive.......................................................................................................................................................................................20

Pump Life..........................................................................................................................................................................................20

Sound Level......................................................................................................................................................................................21

Sound Level Graph

Pump Performance Graphs

Performance Graphs for Frame Size 8,0 and 011................................................................................................................23

Performance Graphs for Frame Size 014 and 017..............................................................................................................23

Performance Graphs for Frame Size 019, 022 and 025.....................................................................................................24

Product Options

Standard Flange, Shaft and Ports Configuration Overview............................................................................................25

Shaft Options...................................................................................................................................................................................26

Pumps with integral relief valve • internally and externally drained...........................................................................27

Integral relief valve covers E10 or I10..................................................................................................................................... 28

Model Codes for Integral Relief Valve.....................................................................................................................................29

Dimensions and Data

SHP2 with E10-T80 flange-drive gear combination.......................................................................................................... 30

SHP2 with B10-T50 flange-drive gear combination..........................................................................................................31

SHP2 with D10-I10 flange-drive gear combination...........................................................................................................32

SHP2 with B20/B22 - T50 flange-drive gear combination...............................................................................................33

SHP2 with SA1 - S09/S11/PS1 flange-drive gear combination......................................................................................34

©

Danfoss | July 2021 BC315962412551en-000201 | 3

Page 4

Technical Information

shhark® Low Noise Aluminum Gear Pumps, Group 2

General information

The shhark® Low Noise Technology

The standard technology currently used in low noise gear pumps is based on double-flank contact. This

solution reduces the peak-to-peak flow pulsation by 75% compared to a single-flank contact gear pumps

with the same number of teeth.

The Danfoss shhark® achieves the same reduction of flow pulsation, but in a totally different way. As

illustrated below, for the same outer diameter, shhark® gears feature almost twice the number of teeth of

a standard gear pump, thanks to a revolutionary asymmetric tooth profile design. Moreover, the shhark®

teeth are also slightly helical; the small helix angle does not generate any additional radial and axial load

but makes the flow characteristic smoother, further reducing the flow pulsation.

Standard gear pump (11-teeth) versus shhark® (17-teeth) technology

The comparison between the flow characteristic of Danfoss SKP2 (11-teeth) and shhark® (17-teeth) is

illustrated in the plot below: the reduction of peak-to-peak flow pulsation is 78%. In addition, the average

flow per unit width of shhark® is approximately 2.7% higher than SKP2; this means that for the exact same

pump dimensions, shhark® delivers more flow.

Flow characteristics of shhark® vs SKP2 standard

4 | © Danfoss | July 2021 BC315962412551en-000201

Page 5

Technical Information

shhark® Low Noise Aluminum Gear Pumps, Group 2

General information

Features and Benefits

•

Noise level emissions reduced up to 10 dB(A)

•

Low noise performance guaranteed throughout the whole life of the pump

•

Low vibration, flow pulsation reduced by a stunning 78% compared to a standard gear pump

•

Higher volumetric efficiency than a standard gear pump by 2%

•

Noise emitted at low frequency, resulting in high sound quality

•

Wide range of displacements from 6.18 to 29 cm3/rev

•

Rated pressure up to 250 bar

•

Operating speed up to 4000 rpm

•

SAE, DIN and European standard mounting flanges and shafts

•

Available with integral relief valve

•

Interchangeable with all standard gear pumps

•

Multiple pump configurations, available also in compact configuration

•

Compact and lightweight

•

Internal spline available, which means compactness and availability of big displacements working at

high pressure simultaneously (maximum 120 Nm at the intermediate coupling)

•

Helps to meet legal NVH requirements

•

Innovative solution (Danfoss Patents US 20150330387 (A1) and WO2017064046 (A1)

•

Ideal for hybrid and full electric machines for which the hydraulic pump is the most important source

of noise together with fan drive

•

Cost and space saving due to elimination of end-of-line noise reduction measures

shhark® Gear Pumps Representatives

Many combinations of the gear pumps are available as multiple units made to fit any need.

SHP2 - SA1-S09 SHP2 - D10-I10 SHP2 - E10-T80

©

Danfoss | July 2021 BC315962412551en-000201 | 5

Page 6

Technical Information

shhark® Low Noise Aluminum Gear Pumps, Group 2

General information

Advantages of the shhark® technology versus the “dual contact flank” technology

The effectiveness of dual contact flank is very likely to decrease throughout the pump’s life, because

external gear units often work at high pressure with high level of contaminants in the hydraulic fluid.

In such conditions, the critical components of the rotating kit slowly wear out, with a progressive loss of

the double-flank contact condition and with it, the low noise performance.

shhark®pumps are able to keep low noise performance even after thousands of hours of heavy duty

operation in the field and it even slightly improve, due to the tribologic adaptation of components, while

in the same conditions the dual contact flank pump starts emitting noise due to gears wearing. In

addition, shhark® emits noise at lower frequency than the dual contact flank technology, resulting in a

better sound quality.

shhark® Pump Design

In terms of rated operating range (speed, pressure and temperature), overall dimensions and available

configurations, the shhark® has been designed to be essentially a low noise version of SKP2 pump.

The 20 mm shaft can accommodate any type of drive end, such as:

S09 (SAE 9-teeth 16/32)

•

S11 (SAE 11-teeth 16/32)

•

S13 (SAE 13-teeth 16/32)

•

T50 (Taper 1:5)

•

T80 (Taper 1:8)

•

PS1(Parallel SAE Ø15.875)

•

I10 (Tang 8x17.8)

•

As for SKP2, the hydrostatic compensation system is on the bearing blocks to ensure high efficiency,

more compact tandem combinations and higher flexibility to distributors.

SHP2 - SA1-S11 cutaway view

6 | © Danfoss | July 2021 BC315962412551en-000201

Page 7

C

Technical Information

shhark® Low Noise Aluminum Gear Pumps, Group 2

General information

shhark® Technical Data

The table below details the technical data for shhark® gear pumps based on the model and displacement

configuration.

Technical data for SHP2

Feature Unit Frame size

6.0 8.0 011 014 017 019 022 025 028

Displacement

Peak pressure

Rated pressure

Minimum speed at

0-100 bar

Minimum speed at

100-180 bar

Minimum speed at 180

bar to rated pressure

Maximum speed

Weight

Moment of inertia of

rotating components

Theoretical flow at

maximum speed

cm3/rev

[in3/rev]

bar

[psi]

min-1(rpm) 600 600 500 500 500 500 500 500 500

min-1(rpm) 1200 1000 800 750 750 700 700 700 600

min-1(rpm) 1400 1400 1200 1000 1000 1000 800 800 700

kg [lb] 2.4 [5.3] 2.5 [5.5] 2.7 [5.5] 2.9 [6.3] 3.0 [6.5] 3.1 [6.7] 3.2 [7.0] 3.4 [7.5] 3.4 [7.5]

x 10

kg•m

[-6 lb•ft2]

l/min [US

gal/min]

6.18 [0.37]

280

[4060]

250

[3625]

4000 4000 4000 3500 3000 3000 3000 3000 2500

-6

27.6 [629]

2

24.72 [6.4]

8.7

[0.53]

280

[4060]

250

[3625]

32.4

[769]

34.8

[9.2]

11.1

[0.68]

280

[4060]

250

[3625]

38.4

[911]

44.4

[11.7]

14.8

[0.90]

280

[4060]

250

[3625]

47.3

[1122]

51.8

[13.7]

17.3

[1.06]

280

[4060]

250

[3625]

53.3

[1265]

51.9

[13.7]

19.8

[1.21]

260

[3770]

240

[3480]

59.2

[1405]

59.4

[15.7]

23.5

[1.43]

230

[3335]

210

[3045]

68.1

[1616]

70.5

[18.6]

25.94

[1.58]

200

[2900]

190

[2755]

71.1

[1687]

77.8

[20.6]

29 [1.75]

190 [2755]

180 [2610]

77.6

[1827]

116.36

[30.2]

1 kg•m2 = 23.68 lb•ft

2

Caution

The rated and peak pressure mentioned in the table are for pumps with flanged ports only. When

threaded ports are required a de-rated performance has to be considered. To verify the compliance of a

high pressure application with a threaded ports pump apply to a Danfoss representative.

©

Danfoss | July 2021 BC315962412551en-000201 | 7

Page 8

Qe =

1000

Vg • n • η

v

(l/min)

Qe =

231

(US gal/min)

Vg • n • η

v

Me =

20 • π • η

m

Vg • ∆p

(N•m)

Me =

2 • π • η

m

Vg • ∆p

(lbf•in)

P

e

=

30 000

η

t

• n • p

=

600 •

Qe • ∆p

M

e

(kW)

P

e

=

198 000

η

t

• n • p

=

1714 •

Qe • ∆p

M

e

(hp)

Technical Information

shhark® Low Noise Aluminum Gear Pumps, Group 2

General information

Determination of Nominal Pump Sizes

Generally, the sizing process is initiated by an evaluation of the machine system to perform the necessary

work function. The following formulae can be used to determine the nominal pump size for a specific

application.

Metric System Inch System

Output flow

Input torque

Input power

Variables:

Vg = Displacement per rev.

pHP = High pressure

pNP = Low pressure

∆p = pHP – p

n = Input speed

ηv = Volumetric efficiency

ηm = Mechanical (torque) efficiency

ηt = Overall efficiency (ηv • ηm)

NP

SI units [US units]:

cm3/rev [in3/rev]

bar [psi]

bar [psi]

bar [psi]

min-1 (rpm)

8 | © Danfoss | July 2021 BC315962412551en-000201

Page 9

Technical Information

shhark® Low Noise Aluminum Gear Pumps, Group 2

Master Model Code

Model Code for Single Gear Pumps

A B C D E F G H I J K L M N O

SHP2•• • •

A – Family

SHP2

B – Frame size and Displacement

6,0

8,0

011

014

017

019

022

025

*

Frame size 028 is available upon a request.

Low-noise Group 2 gear pump

3*

6.18 cm

3

8.7 cm

3

11.1 cm

3

14.8 cm

3

17.3 cm

3

19.8 cm

3

23.5 cm

3

25.94cm

C – Direction of Rotation

L

R

Left hand (Counter-clockwise)

Right hand (Clockwise)

D – Mounting flange

B10

B20

B21

B22

D10

E10

SA1

SA2

SB1

Pilot Ø80 mm; 4 holes

Pilot Ø50 mm; 2 holes through body

Pilot Ø50 mm; 2 holes through body; Seal on pilot

Pilot Ø50 mm; 2 holes through body

Pilot Ø52 mm; O-ring; 4 holes through body

Pilot Ø36.5 mm; 4 holes

SAE A pilot Ø82.55 mm; 2 holes

SAE A pilot Ø82.55 mm; 2 holes; Seal on pilot

SAE B pilot Ø101.6 mm; 2 holes

©

Danfoss | July 2021 BC315962412551en-000201 | 9

Page 10

Technical Information

shhark® Low Noise Aluminum Gear Pumps, Group 2

Master Model Code

Model Code for Single Gear Pumps

A B C D E F G H I J K L M N O

SHP2 • • • •

E – Shaft type

T50

T80

I10

PS1

S09

S11

S13

F – Inlet and G – Outlet ports dimensions

Taper 1:5; M12x1.25 with Key 3

Taper 1:8; M12x1.25 with Key 4

Tang 8 x Ø17.8 x 6.5

Parallel SAE Ø15.875 x 23.8; Key 4x18

Spline SAE J498-9T-16/32DP

Spline SAE J498-11T-16/32DP

Spline SAE J498-13T-16/32DP

F – Inlet and G – Outlet ports dimensions

Code Dimensions Ports Code Thread Dimensions

B5 15x35xM6 D5 M18x1.5

B6 15x40xM6 D7 M22x1.5

B7 20x40xM6 E4 3/4-16UNF

C3 13.5x30xM6 E5 7/8-14UNF

C5 13.5x40xM8 E6 11/16-12UN

C7 20x40xM8 F3 3/8 Gas

MB 12 x 38.1 x 17.48 x M8 (=) F4 1/2 Gas

MC 18.5 x 47.63 x 22.23 x M6 (=) F5 3/4 Gas

MD 18.5 x 47.63 x 22.23 x M8 (=) F6 1 Gas

ME 18.5 x 47.63 x 22.23 x M10 (=) H5 M18 x 1.5 per ISO6149

MG 25/20 x 52.37 x 26.19 x M10 (=) H7 M22 x 1.5 per ISO6149

NN Without outlet port

To be used with rear ported units only.

H8 M27 x 2 per ISO6149

H9 M33 x 2 per ISO6149

H - Rear cover

P10

I10

E10

Standard cover for pump

Rear cover for pump with relief valve with internal drain

Rear cover for pump with relief valve with external drain 3/8 Gas

10 | © Danfoss | July 2021 BC315962412551en-000201

Page 11

Technical Information

shhark® Low Noise Aluminum Gear Pumps, Group 2

Master Model Code

Model Code for Single Gear Pumps

A B C D E F G H I J K L M N O

SHP2 • • • • • • •

I – Shaft seal

V

J – Sealing

N

K – Screws

N

A

B

Viton

NBR

Standard burnished screws

Zinc plated screws

Geomet screws

L – Valve setting

NNN

V**

No valve

Integral relief valve pressure setting

M – Marking type

N

A

Z

Standard Danfoss marking

Standard Danfoss marking + Customer code

No marking

N – Mark position

N

A

Standard marking on the top

Special marking position at the bottom

O – Special features

0000

No special features

©

Danfoss | July 2021 BC315962412551en-000201 | 11

Page 12

Technical Information

shhark® Low Noise Aluminum Gear Pumps, Group 2

Master Model Code

Model Code for Tandem Gear Pumps

A1 B1 A2 B2 C D E F1 G1 H F2 G2 I J K L M N O P

• • • • •

A1 – First stage family and A2 - Second stage family

SHP2 Low-noise Group 2 gear pumps

SKP2 Standard Group 2 gear pump

B1 – Pump 1st frame size and B2 – Pump 2nd frame size displacement

3*

6,0

8,0

011

014

017

019

022

025

*

Frame size 028 is available upon a request.

**

Frame size 025 is available for B1 only.

6.18 cm

3

8.7 cm

11.1 cm

14.8 cm

17.3 cm

19.8 cm

23.5 cm

25.94 cm

3

3

3

3

3

3**

C – Direction of Rotation

L

R

Left hand (Counter-clockwise)

Right hand (Clockwise)

12 | © Danfoss | July 2021 BC315962412551en-000201

Page 13

Technical Information

shhark® Low Noise Aluminum Gear Pumps, Group 2

Master Model Code

Model Code for Tandem Gear Pumps

A1 B1 A2 B2 C D E F1 G1 H F2 G2 I J K L M N O P

• •

D – Mounting flange

B10

B20

B21

B22

E10

SA1

SA2

SB1

E – Shaft type

T50

T80

S09

S11

S13

Pilot Ø80 mm; 4 holes

Pilot Ø50 mm; 2 holes through body

Pilot Ø50 mm; 2 holes through body; Seal on pilot

Pilot Ø50 mm; 2 holes through body

Pilot Ø36.5 mm; 4 holes

SAE A pilot Ø82.55 mm; 2 holes

SAE A pilot Ø82.55 mm; 2 holes; Seal on pilot

SAE B pilot Ø101.6 mm; 2 holes

Taper 1:5; M12x1.25 with Key 3

Taper 1:8; M12x1.25 with Key 4

Spline SAE J498-9T-16/32DP

Spline SAE J498-11T-16/32DP

Spline SAE J498-13T-16/32DP

©

Danfoss | July 2021 BC315962412551en-000201 | 13

Page 14

Technical Information

shhark® Low Noise Aluminum Gear Pumps, Group 2

Master Model Code

Model Code for Tandem Gear Pumps

A1 B1 A2 B2 C D E F1 G1 H F2 G2 I J K L M N O P

F1/F2 – Inlet and G1/G2 – Outlet ports dimensions

F – Inlet and G – Outlet ports dimensions

Code Dimensions Ports Code Thread Dimensions

B5 15x35xM6 D5 M18x1.5

B6 15x40xM6 D7 M22x1.5

B7 20x40xM6 E4 3/4-16UNF

C3 13.5x30xM6 E5 7/8-14UNF

C5 13.5x40xM8 E6 11/16-12UN

C7 20x40xM8 F3 3/8 Gas

• • • • •

MB 12 x 38.1 x 17.48 x M8 (=) F4 1/2 Gas

MC 18.5 x 47.63 x 22.23 x M6 (=) F5 3/4 Gas

MD 18.5 x 47.63 x 22.23 x M8 (=) F6 1 Gas

ME 18.5 x 47.63 x 22.23 x M10 (=) H5 M18 x 1.5 per ISO6149

MG 25/20 x 52.37 x 26.19 x M10 (=) H7 M22 x 1.5 per ISO6149

NN Without outlet port

To be used with rear ported units only.

H8 M27 x 2 per ISO6149

H9 M33 x 2 per ISO6149

H – Intermediate section

CC

Standard compact intermediate flange

I – Cover

E10

I10

P10

Rear cover for pump with relief valve with external drain 3/8 Gas

Rear cover for pump with relief valve with internal drain

Standard cover for pump

14 | © Danfoss | July 2021 BC315962412551en-000201

Page 15

Technical Information

shhark® Low Noise Aluminum Gear Pumps, Group 2

Master Model Code

Model Code for Tandem Gear Pumps

A1 B1 A2 B2 C D E F1 G1 H F2 G2 I J K L M N O P

J – Shaft seal

V

K – Sealing

N

L – Screws

N

A

B

Viton

NBR

Standard burnished screws

Zinc plated screws

Geomet screws

• • • • • • •

M – Valve setting

NNN

V**

No valve

Integral relief valve pressure setting

N – Marking type

N

A

Z

Standard Danfoss marking

Standard Danfoss marking + Customer code

No marking

O – Mark position

N

A

Standard marking on the top

Special marking position at the bottom

P – Special features

0000

No special features

©

Danfoss | July 2021 BC315962412551en-000201 | 15

Page 16

Peak pressure

Rated pressure

Reaction time (100 ms max)

Time

Pressure

Technical Information

shhark® Low Noise Aluminum Gear Pumps, Group 2

System Requirements

Inlet Pressure

Peak pressure is the highest intermittent pressure allowed at the pump's outlet. Peak pressure depends

on the relief valve over shoot (reaction time).

Rated pressure is the maximum continuous operating pressure. The maximum machine load demand

determines rated pressure.

Inlet Vacuum must be controlled in order to preserve pump's expected life and performance.

The system design must meet inlet pressure requirements during all operation modes. Expected lower

inlet pressures during cold start will be improved as soon as the fluid warms up.

Max. continuous vacuum Max. intermittent vacuum Max. inlet pressure

0.8 bar absolute [20.7in. Hg] 0.6 bar absolute [17.7in. Hg] 4.0 bar absolute [118.1in. Hg]

The illustration below shows peak pressure in relation to rated pressure and reaction time (100 ms

maximum).

16 | © Danfoss | July 2021 BC315962412551en-000201

Page 17

Pr

essure

0

Speed

Max

Operating

Envelope

N

1

0

N

2

N

3

P

1

P

2

Rated pressure

C

Technical Information

shhark® Low Noise Aluminum Gear Pumps, Group 2

System Requirements

Speed

Maximum speed is the limit recommended by Danfoss for a particular gear pump when operating at

rated pressure. It is the highest speed at which normal life can be expected.

Minimum speed is the lowest operating speed limit at which normal life can be expected. The minimum

speed increases according to operating pressure increase.

When operating at higher pressures, a higher minimum speed must be maintained, see below:

Hydraulic Fluids

Speed versus pressure

Operating envelope legend:

N1Minimum speed at 100 bar

N2Minimum speed at 180 bar

N3Minimum speed at rated pressure

Ratings and data for shhark® gear pumps are guaranteed when the hydraulic system operates with

premium hydraulic fluids without containing oxidation, rust, or foam inhibitors.

These fluids have to work with good thermal and hydrolytic stability to prevent wear, erosion, or

corrosion of internal components. They include:

•

Hydraulic fluids following DIN 51524, part 2 (HLP) and part 3 (HVLP) specifications

•

API CD engine oils conforming to SAE J183

•

M2C33F or G automatic transmission fluids

•

Certain agricultural tractor fluids

Caution

Use only clean fluid in the gear pumps and hydraulic circuit. Never mix hydraulic fluids.

Temperature and viscosity

Temperature and viscosity requirements must be concurrently satisfied. Use petroleum / mineral-based

fluids.

High temperature limits apply at the inlet port to the pump. The pump should run at or below the

maximum continuous temperature. The peak temperature is based on material properties. Don’t exceed

it.

Cold oil, generally, doesn’t affect the durability of pump components. It may affect the ability of oil to

flow and transmit power. For this reason, keep the temperature at 16 °C [60 °F] above the pour point of

the hydraulic fluid.

Minimum (cold start) temperature relates to the physical properties of component materials.

Minimum viscosity occurs only during brief occasions of maximum ambient temperature and severe

duty cycle operation. You will encounter maximum viscosity only at cold start. During this condition, limit

©

Danfoss | July 2021 BC315962412551en-000201 | 17

Page 18

Technical Information

shhark® Low Noise Aluminum Gear Pumps, Group 2

System Requirements

speeds until the system warms up. Size heat exchangers to keep the fluid within these limits. Test

regularly to verify that these temperatures and viscosity limits aren’t exceeded. For maximum unit

efficiency and bearing life, keep the fluid viscosity in the recommended

Fluid viscosity

Maximum (cold start)

Recommended range

Minimum

Temperature (with standard NBR seals)

Minimum (cold start)

Maximum continuous

Peak (intermittent)

mm2/s [SUS]

°C [°F]

1600 [7273]

12-100 [66-456]

10 [60]

-20 [-4]

80 [176]

90 [194]

18 | © Danfoss | July 2021 BC315962412551en-000201

Page 19

Technical Information

shhark® Low Noise Aluminum Gear Pumps, Group 2

System Requirements

Filtration

Filters

Use a filter that conforms to Class 22/18/13 of ISO 4406 (or better). It may be on the motor outlet

(discharge filtration) or inlet (pressure filtration).

Selecting a filter

When selecting a filter, please consider:

•

Contaminant ingression rate (determined by factors such as the number of actuators used in the

system)

•

Generation of contaminants in the system

•

Required fluid cleanliness

•

Desired maintenance interval

•

Filtration requirements of other system components

Measure filter efficiency with a Beta ratio (βX). βx ratio is a measure of filter efficiency defined by ISO 4572.

It is the ratio of the number of particles greater than a given diameter (in microns) upstream of the filter

to the number of these particles downstream of the filter.

•

For discharge filtration with controlled reservoir ingression, use a β

•

For pressure filtration, use a filtration with an efficiency of β10 = 75

35-45

= 75 filter

The filtration requirements for each system are unique. Evaluate filtration system capacity by monitoring

and testing prototypes.

Fluid cleanliness level and βX ratio

Fluid cleanliness level (per ISO 4406)

βX ratio (discharge filtration)

βX ratio (pressure or return filtration)

Recommended inlet screen size

Reservoir

The reservoir provides clean fluid, dissipates heat, removes entrained air, and allows fluid volume

changes associated with fluid expansion and cylinder differential volumes. A correctly sized reservoir

accommodates maximum volume changes during all system operating modes. It promotes de-aeration

of the fluid as it passes through, and accommodates a fluid dwell-time between 60 and 180 seconds,

allowing entrained air to escape.

Minimum reservoir capacity depends on the volume required to cool and hold the oil from all retracted

cylinders, allowing for expansion due to temperature changes. A fluid volume of 1 to 3 times the pump

output flow (per minute) is satisfactory. The minimum reservoir capacity is 125% of the fluid volume.

Install the suction line above the bottom of the reservoir to take advantage of gravity separation and

prevent large foreign particles from entering the line. Cover the line with a 100-125 micron screen. The

pump should be below the lowest expected fluid level.

Put the return-line below the lowest expected fluid level to allow discharge into the reservoir for

maximum dwell and efficient deaeration. A baffle (or baffles) between the return and suction lines

promotes deaeration and reduces fluid surges.

Class 22/18/13 or better

β

= 75 and β10 = 2

35-45

β10 = 75

100 – 125 μm [0.004 – 0.005 in]

Line sizing

Choose pipe sizes that accommodate minimum fluid velocity to reduce system noise, pressure drops, and

overheating. This maximizes system life and performance.

Design inlet piping that maintains continuous pump inlet pressure above 0.8 bar absolute during normal

operation. The line velocity should not exceed the values in this table:

©

Danfoss | July 2021 BC315962412551en-000201 | 19

Page 20

Pilot cavity

Ø 0.1[0.004]

Mating spline

C

Technical Information

shhark® Low Noise Aluminum Gear Pumps, Group 2

System Requirements

Maximum line velocity

Inlet

Outlet

Return

Most systems use hydraulic oil containing 10% dissolved air by volume. Under high inlet vacuum

conditions the oil releases bubbles. They collapse when subjected to pressure, resulting in cavitation,

causing adjacent metal surfaces to erode. Over-aeration is the result of air leaks on the inlet side of the

pump, and flow-line restrictions. These include inadequate pipe sizes, sharp bends, or elbow fittings,

causing a reduction of flow line cross sectional area. This problem will not occur if inlet vacuum and rated

speed requirements are maintained, and reservoir size and location are adequate.

Pump Drive

Shaft options for shhark® Group 2 gear pump include tapered, tang, splined, or parallel shafts. They are

suitable for a wide range of direct and indirect drive applications for radial and thrust loads.

Plug-in drives, acceptable only with a splined shaft, can impose severe radial loads when the mating

spline is rigidly supported. Increasing spline clearance does not alleviate this condition. Use plug-in drives

if the concentricity between the mating spline and pilot diameter is within 0.1 mm [0.004 in]. Lubricate

the drive by flooding it with oil. A 3-piece coupling minimizes radial or thrust shaft loads.

Pilot cavity

m/s [ft/sec]

2.5 [8.2]

5.0 [16.4]

3.0 [9.8]

Caution

In order to avoid spline shaft damages it is recommended to use carburized and hardened steel

couplings with 80-82 HRA surface hardness.

Allowable radial shaft loads are a function of the load position, load orientation, and operating pressure

of the hydraulic pump. All external shaft loads have an effect on bearing life, and may affect pump

performance.

In applications where external shaft loads can’t be avoided, minimize the impact on the pump by

optimizing the orientation and magnitude of the load. Use a tapered input shaft; don’t use splined shafts

for belt or gear drive applications. A spring-loaded belt tension-device is recommended for belt drive

applications to avoid excessive tension. Avoid thrust loads in either direction. Contact Danfoss if

continuously applied external radial or thrust loads occur.

Pump Life

Pump life is a function of speed, system pressure, and other system parameters (such as fluid quality and

cleanliness).

All Danfoss gear pumps use hydrodynamic journal bearings that have an oil film maintained between the

gear/shaft and bearing surfaces at all times. If the oil film is sufficiently sustained through proper system

maintenance and operating within recommended limits, long life can be expected.

20 | © Danfoss | July 2021 BC315962412551en-000201

Page 21

Technical Information

shhark® Low Noise Aluminum Gear Pumps, Group 2

System Requirements

B10 life expectancy number is generally associated with rolling element bearings. It does not exist for

hydrodynamic bearings.

High pressure, resulting from high loads, impacts pump life. When submitting an application for review,

provide machine duty cycle data that includes percentages of time at various loads and speeds. We

strongly recommend a prototype testing program to verify operating parameters and their impact on life

expectancy before finalizing any system design.

Sound Level

Fluid power systems are inherent generators of noise. As with many high power density devices, noise is

an unwanted side effect.

However, there are many techniques available to minimize noise associated with fluid power systems. To

apply these methods effectively, it is necessary to understand how the noise is generated and how it

reaches the listener. The noise energy can be transmitted away from its source as either fluid borne noise

(pressure ripple) or as structure borne noise.

Fluid borne noise (pressure ripple) is the result of the number of pumping elements (gear teeth)

delivering oil to the outlet and the pump’s ability to gradually change the volume of each pumping

element from high to low pressure. In addition, the pressure ripple is affected by the compressibility of

the oil as each pumping element discharges into the outlet of the pump. Pressure pulsations will travel

along the hydraulic lines at the speed of sound (about 1400 m/s in oil) until affected by a change in the

system such as an elbow fitting. Thus the pressure pulsation amplitude varies with overall line length and

position.

Structure borne noise may be transmitted wherever the pump casing is connected to the rest of the

system. The response of one circuit component to excitation depends on its size, form, and manner in

which it is mounted or supported. Because of this excitation, a system line may actually have a greater

noise level than the pump. To reduce this excitation, use flexible hoses in place of steel plumbing. If steel

plumbing must be used, clamping of lines is recommended. To minimize other structure borne noise, use

flexible (rubber) mounts.

Contact your Danfoss representative for assistance with system noise control.

©

Danfoss | July 2021 BC315962412551en-000201 | 21

Page 22

Technical Information

shhark® Low Noise Aluminum Gear Pumps, Group 2

Sound Level Graph

The sound level graph below shows comparative sound pressure levels for shhark® and standard pumps

(with SAE A flange and spline shaft) expressed in dB(A) at 1 m [3.28 ft] from the unit.

Data were taken using ISO VG46 petroleum /mineral based fluid at 50°C (viscosity at 28 mm2/s [cSt]).

For more details about shhark® noise performance contact your Danfoss Sales Representative.

22 | © Danfoss | July 2021 BC315962412551en-000201

Page 23

0

2

[2.7]

6

[8.0]

4

[5.4]

8

[10.7]

10

[13.4]

12

[16.1]

14

[18.8]

16

[21.5]

18

[24.1]

0

5

[1.3]

10 bar

250 bar

10 bar

250 bar

[2.6]

15

10

[3.9]

20

[5.3]

25

[6.6]

30

[7.9]

35

[9.2]

40

[10.6]

0 1000 2000 3000 4000

Speed rpm

Input power kW [hp]

Input power kW [hp]

20

[26.8]

0

5

[6.7]

10

[13.4]

15

[20.1]

20

[26.8]

25

[33.5]

30

[40.2]

35

[46.9]

0

50

[13.2]

0 1000 2000 3000 4000

Speed rpm

100 bar

150 bar

250 bar

100 bar

150 bar

250 bar

Flow l/min [ US gal/min]

40

[53.6]

8,0

011

5

[1.3]

[2.6]

15

10

[3.9]

20

[5.3]

25

[6.6]

30

[7.9]

35

[9.2]

40

[10.6]

45

[11.8]

Flow l/min [ US gal/min]

10 bar

250 bar

Input power kW [hp]

0

5

[6.7]

10

[13.4]

15

[20.1]

20

[26.8]

25

[33.5]

30

[40.2]

35

[46.9]

0

50

[13.2]

60

[15.9]

0 1000 2000

3000

Speed rpm

100 bar

150 bar

250 bar

40

[53.6]

017

[2.6]

10

20

[5.3]

30

[7.9]

40

[10.6]

Flow l/min [ US gal/min]

10 bar

250 bar

Input power kW [hp]

0

5

[6.7]

10

[13.4]

15

[20.1]

20

[26.8]

25

[33.5]

30

[40.2]

35

[46.9]

0

50

[13.2]

0 1000

2000

3000

Speed rpm

100 bar

150 bar

250 bar

40

[53.6]

014

5

[1.3]

[2.6]

15

10

[3.9]

20

[5.3]

25

[6.6]

30

[7.9]

35

[9.2]

40

[10.6]

45

[11.8]

Flow l/min [ US gal/min]

Technical Information

shhark® Low Noise Aluminum Gear Pumps, Group 2

Pump Performance Graphs

The graphs on the next pages provide typical output flow and input power for shhark® pumps at various

working pressures.

Data were taken using ISO VG46 petroleum /mineral based fluid at 50°C (viscosity at 28 mm2/s [cSt]).

Performance Graphs for Frame Size 8,0 and 011

Performance Graphs for Frame Size 014 and 017

©

Danfoss | July 2021 BC315962412551en-000201 | 23

Page 24

10 bar

210 bar

Input power kW [hp]

0

5

[6.7]

10

[13.4]

15

[20.1]

20

[26.8]

25

[33.5]

30

[40.2]

35

[46.9]

0

50

[13.2]

70

[18.5]

80

[21.1]

60

[15.9]

0 1000 2000

3000

Speed rpm

100 bar

150 bar

210 bar

40

[53.6]

022

[2.6]

10

20

40

[10.6]

[5.3]

30

[7.9]

Flow l/min [ US gal/min]

10 bar

240 bar

Input power kW [hp]

0

5

[6.7]

10

[13.4]

15

[20.1]

20

[26.8]

25

[33.5]

30

[40.2]

35

[46.9]

0

0 1000

2000

3000

Speed rpm

100 bar

150 bar

240 bar

40

[53.6]

019

Flow l/min [ US gal/min]

50

[13.2]

70

[18.5]

60

[15.9]

[2.6]

10

20

40

[10.6]

[5.3]

30

[7.9]

7 bar

190 bar

Input power kW [hp]

0

10

[13.4]

20

[26.8]

30

[40.2]

0

50

[13.2]

70

[18.5]

80

[21.1]

60

[15.9]

0 1000 2000

3000

Speed rpm

100 bar

150 bar

190 bar

40

[53.6]

025

[2.6]

10

20

40

[10.6]

[5.3]

30

[7.9]

Flow l/min [ US gal/min]

Technical Information

shhark® Low Noise Aluminum Gear Pumps, Group 2

Pump Performance Graphs

Performance Graphs for Frame Size 019, 022 and 025

24 | © Danfoss | July 2021 BC315962412551en-000201

Page 25

Technical Information

shhark® Low Noise Aluminum Gear Pumps, Group 2

Product Options

Standard Flange, Shaft and Ports Configuration Overview

Code (single) Flange Shaft Ports

E10-T80

Pilot Ø36.5 mm; 4

holes

Taper 1:8; M12x1.25

with Key 4

European 01, +

pattern

B10-T50

D10-I10

B20-T50

B22-T50

SA1-PS1

Pilot Ø80 mm; 4

holes

German PTO

Danfoss D10

Pilot Ø50 mm; 2

holes through body

German PTO

Pilot Ø50 mm; 2

holes through body

German PTO

SAE A pilot Ø82.55

mm; 2 holes

Taper 1:5; M12x1.25

with Key 3

Danfoss tang German standard, ×

Taper 1:5; M12x1.25

with Key 3

Taper 1:5; M12x1.25

with Key 3

Ø15.875 mm [0.625

in]

parallel SAE

German standard, ×

pattern

pattern

German standard, ×

pattern

German standard, ×

pattern

Threaded SAE; O-

Ring boss

SA1-S09

SA1-S11

SB1-S13

SAE A pilot Ø82.55

mm; 2 holes

SAE A pilot Ø82.55

mm; 2 holes

SAE B 2 bolts pilot

Ø101,6

Spline SAE

J498-9T-16/32DP

Spline SAE

J498-11T-16/32DP

Spline SAE J498 - 13

T

Threaded SAE; O-

Ring boss

Threaded SAE; O-

Ring boss

Threaded SAE; O-

Ring boss

Other combinations are available upon request.

©

Danfoss | July 2021 BC315962412551en-000201 | 25

Page 26

C

Technical Information

shhark® Low Noise Aluminum Gear Pumps, Group 2

Product Options

Shaft Options

Direction is viewed facing the shaft. Group 2 pumps are available with a variety of tang, splined, parallel,

and tapered shaft ends. Not all shaft styles are available with all flange styles.

Model code section H

A B C D E F G H I J K L M N O

Shaft versus flange availability and torque capability

Shaft Mounting flange code with maximum torque in N•m [lbf•in]

Description Code 01 02 03 04 05 06

Taper 1:5; M12x1.25

with Key 3

Taper 1:8; M12x1.25

with Key 4

Spline SAE

J498-9T-16/32DP

Spline SAE

J498-11T-16/32DP

Spline SAE

Parallel SAE Ø15.875

(5/8")

Parallel SAE Ø19.05 (¾") PS2 – – – – – 150 [1328]

T50 – 140 [1239] – 140 [1239] 140 [1239] –

T80 150 [1328] – – – – –

S09 – – – – – 90 [796]

S11 – – – – – 150 [1328]

PS1 – – – – – 80 [708]

•

Other shaft options may exist. Contact your Danfoss representative for availability.

Caution

Shaft torque capability may limit allowable pressure. Torque ratings assume no external radial loading.

Applied torque must not exceed these limits, regardless of stated pressure parameters. Maximum torque

ratings are based on shaft torsional fatigue strength.

The second section torque limit is equal to 120 N•m. Other configuration with higher rated torque are

available upon request.

26 | © Danfoss | July 2021 BC315962412551en-000201

Page 27

bar

With mineral oil @ 26 cSt

0

1000

2000

3000

4000

5000

psi

0 4 8 l/min

0

1 2

3 4 5 US gal/min

0

100

200

300

400

Minimum valve setting

12

16

20

1

2

C

Technical Information

shhark® Low Noise Aluminum Gear Pumps, Group 2

Product Options

Pumps with integral relief valve • internally and externally drained

Group 2 pumps are offered with an optional integral relief valve in the rear cover . This valve can have

an internal (I10 cover option) or external drain (E10 cover option).

This valve opens directing all flow from the pump outlet to the internal or external drain when the

pressure at the outlet reaches the valve setting. This valve can be ordered preset to the pressures shown

in the table below. Valve performance curve, rear cover cross-section and schematics are shown below.

Integral relief valve performance graph

Integral relief valve cross-section

1. Inlet

2. Drain

Caution

When the relief valve is operating in bypass condition, rapid heat generation occurs. If this bypass

condition continues, the pump prematurely fails. The reason for this is that it is a rule, not an exception.

When frequent operation is required, external drain option must be used.

Danfoss | July 2021 BC315962412551en-000201 | 27

©

Page 28

I

O

I

O

D

15.7

±0.5

[0.618

±0.02

]

B ±1.5 [±0.06]

115.5 ma

x

[4.547 max]

93 max

[3.66 max]

Technical Information

shhark® Low Noise Aluminum Gear Pumps, Group 2

Product Options

Integral relief valve schematics

Integral relief valve with drain: internal (left) / external (right)

I – inlet

O – outlet

D – external drain

Integral relief valve covers E10 or I10

Dimensions (with SAE flange); mm [in]

SHP2 with E10 o I10 cover dimensions

Frame size 8,0 011 014 017 019 022

B

117.5 [4.63] 121.5 [4.78] 127.5 [5.02] 131.5 [5.18] 135.5 [5.33] 141.5 [5.57]

28 | © Danfoss | July 2021 BC315962412551en-000201

Page 29

C

Technical Information

shhark® Low Noise Aluminum Gear Pumps, Group 2

Product Options

Model Codes for Integral Relief Valve

The tables below detail the various codes for ordering integral relief valves in M section of the model

code:

A B C D E F G H I J K L M N O

SHP2 I10 • VGN •

SHP2 -017 -R -SA1 -S11 -B7 -B5 -P10 -V -N -B -V00 -N -N 0000

N1 – integral relief valves variant codes

V

N2 – Pump speed codes

Code Pump speed for RV setting Code Pump speed for RV setting

A Not defined

C 500 min-1 (rpm) I 2250 min-1 (rpm)

E 1000 min-1 (rpm) L 2500 min-1 (rpm)

F 1250 min-1 (rpm) M 2800 min-1 (rpm)

G 1500 min-1 (rpm) N 3000 min-1 (rpm)

K 2000 min-1 (rpm) O 3250 min-1 (rpm)

With integral relief valve variant

N3 – Pressure setting codes

Code Pressure setting Code Pressure setting

A No setting

B No valve P 100 bar [1450 psi]

C 18 bar [261 psi] Q 110 bar [1595 psi]

D 25 bar [363 psi] R 120 bar [1740 psi]

E 30 bar [435 psi] S 130 bar [1885 psi]

F 35 bar [508 psi] T 140 bar [2030 psi]

G 40 bar [580 psi] U 160 bar [2320 psi]

K 50 bar [725 psi] V 170 bar [2465 psi]

L 60 bar [870 psi] W 180 bar [2611 psi]

M 70 bar [1015 psi] X 210 bar [3046 psi]

N 80 bar [1160 psi] Y 240 bar [3480 psi]

O 90 bar [1305 psi] Z 250 bar [3626 psi]

Caution

For pressures higher than 210 bar or lower than 40 bar apply to your Danfoss representative.

©

Danfoss | July 2021 BC315962412551en-000201 | 29

Page 30

Technical Information

shhark® Low Noise Aluminum Gear Pumps, Group 2

Dimensions and Data

SHP2 with E10-T80 flange-drive gear combination

Standard porting for E10-T80; mm [in]

1. Nut and washer supplied with pump; recommended tightening torque 45-55 N•m.

SHP2 - E10-T80 dimensions

Frame size 6,0 8,0 011 014 017 019 022 025

Dimensi

on

Inlet

Outlet

A 45 [1.772] 45

[1.772]

B 93 [3.681] 97.5

[3.839]

C 13.5 [0.531] 20 [0.787]

D 30 [1.181] 40 [1.575]

E M6 M8

c 13.5 [0.531]

d 30 [1.181]

e M6

49 [1.929] 52 [2.047] 52 [2.047] 56 [2.205] 59

101.5

[3.996]

107.5

[4.232]

111.5

[4.390]

115.5

[4.574]

[2.323]

121.5

[4.783]

59 [2.323]

125.5

[4.941]

Model code example, maximum shaft torque

Flange/drive gear Model code example Maximum shaft torque

E10-T80 SHP2-014-R-E10-T80-C7-C3-P10-V-N-N-N00-N-N-0000 150 N•m [1328 lbf•in]

For further details on ordering, see the Model Code section.

30 | © Danfoss | July 2021 BC315962412551en-000201

Page 31

Technical Information

shhark® Low Noise Aluminum Gear Pumps, Group 2

Dimensions and Data

SHP2 with B10-T50 flange-drive gear combination

Standard porting for B10-T50; mm [in]

1. Nut and washer supplied with pump; recommended tightening torque 45-55 N•m.

SHP2 - B10-T50 dimensions

Frame size 6,0 8,0 011 014 017 019 022 025

Dimensi

on

Inlet

Outlet

A 41.1 [1.618] 43.1

[1.697]

B 96 [3.780] 100

[3.937]

C 20 [0.787]

D 40 [1.575]

E M6

c 15 [0.591]

d 35 [1.378]

e M6

47.5

[1.870]

104

[4.094]

47.5 [1.870] 47.5 [1.870] 47.5 [1.870] 55 [2.165] 94.5 [2.539]

110 [4.331] 114 [4.488] 118 [4.646] 124 [4.882] 128 [5.039]

Model code example, maximum shaft torque

Flange/drive gear Model code example Maximum shaft torque

B10-T50 SHP2-8,0-L-B10-T50-B7-B5-P10-V-N-N-N00-N-N-0000 140 N•m [1239 lbf•in]

For further details on ordering, see the Model Code section.

©

Danfoss | July 2021 BC315962412551en-000201 | 31

Page 32

Technical Information

shhark® Low Noise Aluminum Gear Pumps, Group 2

Dimensions and Data

SHP2 with D10-I10 flange-drive gear combination

Standard porting for D10-I10; mm [in]

1. Coupling supplied with pump

SHP2 - D10-I10 dimensions

Frame size 6,0 8,0 011 014 017 019 022 025

Dimensi

on

Inlet

Outlet

A 38.6 [1.520] 40.6

B 85 [3.364] 89

C 20 [0.787]

D 40 [1.575]

E M6

c 15 [0.591]

d 35 [1.378]

e M6

[1.598]

93 [3.661] 99 [3.897] 103 [4.055] 107 [4.212] 113

[3.503]

45 [1.772] 52.5

[2.067]

[4.448]

62 [2.441]

117 [4.606]

Model code example, maximum shaft torque

Flange/drive gear Model code example Maximum shaft torque

D10-I10 SHP2-017-R-D10-I10-B7-B5-P10-V-N-N-N00-N-N-0000 70 N•m [620 lbf•in]

For further details on ordering, see the Model Code section.

32 | © Danfoss | July 2021 BC315962412551en-000201

Page 33

Technical Information

shhark® Low Noise Aluminum Gear Pumps, Group 2

Dimensions and Data

SHP2 with B20/B22 - T50 flange-drive gear combination

Standard porting for B20/B22-T50; mm [in]

1. Nut and washer supplied with pump; recommended tightening torque 45-55 N•m.

SHP2 – B20/B22-T50 dimensions

Frame size 6,0 8,0 011 014 017 019 022 025

Dimensi

on

Inlet

Outlet

A 38.6 [1.520] 40.6

B 85 [3.364] 89

C 20 [0.787]

D 40 [1.575]

E M6

c 15 [0.591]

d 35 [1.378]

e M6

[1.598]

93 [3.661] 99 [3.897] 103 [4.055] 107 [4.212] 113

[3.503]

45 [1.772] 52.5

[2.067]

[4.448]

62 [2.441]

117 [4.606]

Model code example, maximum shaft torque

Flange/drive gear Model code example Maximum shaft torque

B20-T50 SHP2-8,0-L-B20-T50-B7-B5-P10-N-N-N-N00-N-N-0000

B22-T50 SHP2-014-R-B22-T50-B7-B5-P10-N-N-N-N00-N-N-0000

140 N•m [1239 lbf•in]

For further details on ordering, see the Model Code section.

©

Danfoss | July 2021 BC315962412551en-000201 | 33

Page 34

Technical Information

shhark® Low Noise Aluminum Gear Pumps, Group 2

Dimensions and Data

SHP2 with SA1 - S09/S11/PS1 flange-drive gear combination

Standard porting for SA1 - S09/S11/PS1; mm [in]

1. Splined: SAE J498-9T-16/32DP; Flat root side fit (circular tooth thickness 0.127 mm [0.005] less than standard class 1 fit)

2. Splined: SAE J498-11T-16/32DP; Flat root side fit (circular tooth thickness 0.127 mm [0.005] less than standard class 1 fit)

SHP2 – SA1 - S09/S11/PS1 dimensions

Frame size 6,0 8,0 011 014 017 019 022 025

Dimensi

on

Inlet C 11/16–12UNF–2B, 18.0 [0.709] deep

Outlet c

A 45 [1.772] 47 [1.85] 49 [1.92] 52 [2.047] 54 [2.126] 56 [2.205] 59 [2.323] 61 [2.402]

B 93.5 [3.681] 97.5

[3.839]

101.5

[3.996]

107.5

[4.232]

7

/8–14UNF–2B, 16.7 [0.658] deep

111.5

[4.390]

115.5

[4.547]

121.5

[4.783]

Model code examples, maximum shaft torques

Flange/drive gear Model code example Maximum shaft torque

SA1-PS1 SHP2-6,0-R-SA1-PS1-E6-E5-P10-N-N-N-N00-N-N-0000 80 N•m [708 lbf•in]

SA1-S09 SHP2-011-L-SA1-S09-E6-E5-P10-N-N-N-N00-N-N-0000 90 N•m [796 lbf•in]

SA1-S11 SHP2-022-R-SA1-S11-E6-E5-P10-N-N-N-N00-N-N-0000 150 N•m [1328 lbf•in]

For further details on ordering, see the Model Code section.

125.5

[4.941]

34 | © Danfoss | July 2021 BC315962412551en-000201

Page 35

Danfoss

Power Solutions GmbH & Co. OHG

Krokamp 35

D-24539 Neumünster, Germany

Phone: +49 4321 871 0

Danfoss

Power Solutions ApS

Nordborgvej 81

DK-6430 Nordborg, Denmark

Phone: +45 7488 2222

Danfoss

Power Solutions (US) Company

2800 East 13th Street

Ames, IA 50010, USA

Phone: +1 515 239 6000

Danfoss

Power Solutions Trading

(Shanghai) Co., Ltd.

Building #22, No. 1000 Jin Hai Rd

Jin Qiao, Pudong New District

Shanghai, China 201206

Phone: +86 21 2080 6201

Products we offer:

Hydro-Gear

www.hydro-gear.com

Daikin-Sauer-Danfoss

www.daikin-sauer-danfoss.com

Cartridge valves

•

DCV directional control

•

valves

Electric converters

•

Electric machines

•

Electric motors

•

Gear motors

•

Gear pumps

•

Hydraulic integrated

•

circuits (HICs)

Hydrostatic motors

•

Hydrostatic pumps

•

Orbital motors

•

PLUS+1® controllers

•

PLUS+1® displays

•

PLUS+1® joysticks and

•

pedals

PLUS+1® operator

•

interfaces

PLUS+1® sensors

•

PLUS+1® software

•

PLUS+1® software services,

•

support and training

Position controls and

•

sensors

PVG proportional valves

•

Steering components and

•

systems

Telematics

•

Danfoss Power Solutions is a global manufacturer and supplier of high-quality hydraulic and

electric components. We specialize in providing state-of-the-art technology and solutions

that excel in the harsh operating conditions of the mobile off-highway market as well as the

marine sector. Building on our extensive applications expertise, we work closely with you to

ensure exceptional performance for a broad range of applications. We help you and other

customers around the world speed up system development, reduce costs and bring vehicles

and vessels to market faster.

Danfoss Power Solutions – your strongest partner in mobile hydraulics and mobile

electrification.

Go to www.danfoss.com for further product information.

We offer you expert worldwide support for ensuring the best possible solutions for

outstanding performance. And with an extensive network of Global Service Partners, we also

provide you with comprehensive global service for all of our components.

Local address:

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

already on order provided that such alterations can be made without subsequent changes being necessary in specifications already agreed.

All trademarks in this material are property of the respective companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

©

Danfoss | July 2021 BC315962412551en-000201

Loading...

Loading...