Page 1

Application guidelines

Danfoss scroll for refrigeration

LLZ for parallel applications

50 - 60 Hz - R404A - R507

http://cc.danfoss.com

Page 2

Page 3

Application Guidelines

Content

General overview .................................................................................................................................4

Scope .............................................................................................................................................................................................................. 4

Benets .......................................................................................................................................................................................................... 4

Oil management concept ....................................................................................................................5

Active systems............................................................................................................................................................................................. 5

Passive systems ........................................................................................................................................................................................... 6

Operating conditions ..........................................................................................................................8

Power supply ............................................................................................................................................................................................... 8

Compressor ambient temperature ..................................................................................................................................................... 8

Operating envelope .................................................................................................................................................................................. 8

Refrigerants and lubricants .................................................................................................................................................................... 8

Discharge temperature protection ..................................................................................................................................................... 8

High and low pressure protection ...................................................................................................................................................... 8

Cycle rate limit ............................................................................................................................................................................................. 8

System design recommendations ......................................................................................................9

Essential piping design considerations ............................................................................................................................................. 9

Expansion device ..................................................................................................................................................................................... 10

Suction accumulator............................................................................................................................................................................... 10

Suction header .......................................................................................................................................................................................... 10

Oil level regulator .................................................................................................................................................................................... 11

Oil separator / oil reservoir ................................................................................................................................................................... 12

Oil separator / Oil reservoir for active system ............................................................................................................................... 12

Economizer for parallel vapour injection compressors ...........................................................................................................14

Refrigerant charge limits....................................................................................................................................................................... 14

Installation and service .....................................................................................................................15

Piping design ............................................................................................................................................................................................. 15

Wiring and rotation direction ............................................................................................................................................................. 15

Failure analysis .......................................................................................................................................................................................... 15

Sound and vibration management ..................................................................................................16

Running sound level ............................................................................................................................................................................... 16

Ordering information ........................................................................................................................17

Parallel units LLZ013-15-18-24 ..........................................................................................................18

Composition of LLZ013-024 uneven tandem/trio/quadro ......................................................................................................18

Composition of LLZ013-024 even tandem ..................................................................................................................................... 18

Compressor mounting ........................................................................................................................................................................... 19

Suction and discharge connection ................................................................................................................................................... 20

Oil equalisation connection................................................................................................................................................................. 20

3FRCC.PC.032.A4.02

Page 4

Application Guidelines

General overview

Scope

Benets

The application guidelines describe the operating

characteristics, design features and application

requirements for LLZ parallel compressors in

low temperature refrigeration applications.

They apply to both standard and economized

compressors.

To ensure proper parallel installation and running

conditions, the following recommendations must

be followed:

Parallel compressor installation' refers to a system

of interconnected compressors with a common

suction line and common discharge line. The

technique of mounting compressors in parallel

is also referred to as manifolding. In a system

with only two compressors, this is referred to as a

tandem conguration.

The main reason for manifolding is reduced

operating cost through greater control of

capacity and power consumption. This is

achieved by staggering the compressor switchon sequences that allow the parallel system to

match its power with the capacity needed.

• It is essential to follow all the instructions

given in these guidelines, the instruction

leaet delivered with each compressor and the

Selection & Application Guidelines for single

compressors.

• For additional system components related to

specic application requirements, the supplier's

recommendations must always be followed.

A second reason for manifolding is improved

part load eciency. In a parallel installation the

individual compressor(s) can be switched o

while the other compressor(s) keep operating at

100% load. Therefore the part load eciency is

very near the full load eciency. Conventional

xed-speed compressor unloading methods

impose a serious penalty on part load eciency,

mainly at low load conditions.

4 FRCC.PC.032.A4.02

Page 5

Application Guidelines

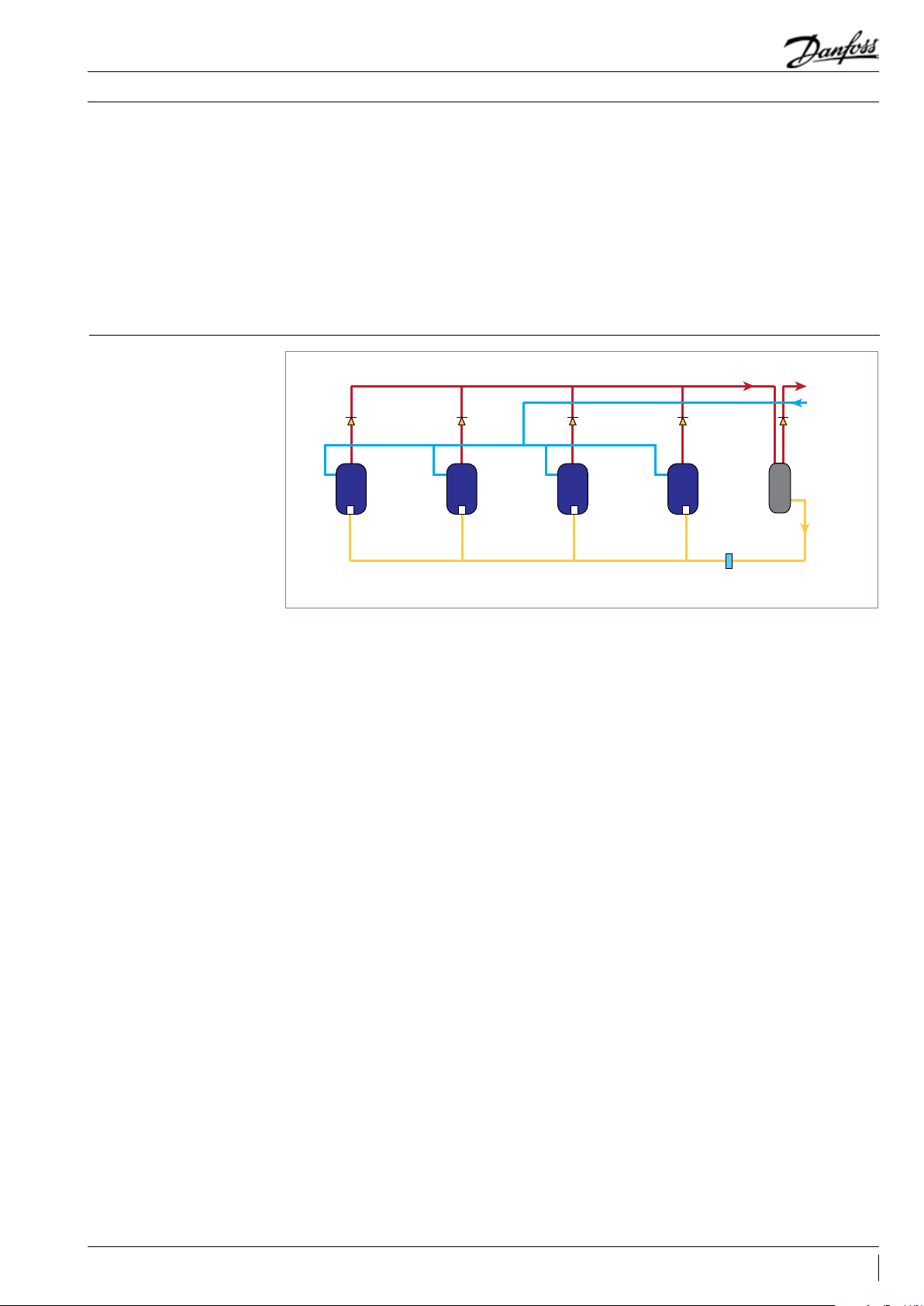

Oil management concept

Active systems

Suction gas in a hermetic scroll compressor

ows via the oil sump,which makes it more

dicult to maintain equal pressure in the sumps

of parallel compressors. Since oil equalisation

usually depends on equal sump pressures, this is

a point of special attention. Danfoss Commercial

Compressors have developed specially adapted

oil management systems which ensure proper

Suction

header

Non return

valve

Compressor 1

Oil level regulator Oil level regulator Oil level regulator Oil level regulator

Non return

valve

Compressor 2 Compressor 3 Compressor 4

oil balancing between the compressors, but it is

always recommended to carry out some tests to

validate oil balancing in the system.

To ensure suitable oil distribution, both passive

and active types of systems are introduced into

LLZ compressors.

High pressure

Low pressure

Non return

valve

Non return

valve

Oil lter

Non return

valve

Combined oil

separator/reservoir

An active system can oer more exible

and ecient oil management. It is highly

recommended for manifolding since this

positive system increases the reliability of the

manifolding conguration. Oil management

will be secured mainly by the oil level regulator

and the oil separator, which can supply the

oil when required. The active system can thus

accommodate itself to various oil conditions.

Danfoss has qualied tandem / trio / quadro

composition for active systems.

For manifolding with more than two

compressors, it is always suggested to use a

suction header. Each compressor will equip

the oil level regulator to facilitate the oil level

balance.

To avoid refrigerant back ow from high pressure,

it is always recommended to have a non-return

valve on the discharge line of each compressor,

as well as one non-return valve on the outlet

of the oil separator in the system to prevent

refrigerant migration.

For more details on the oil separator/reservoir

and oil level regulator please refer to the “System

design recommendation” in this guideline.

5FRCC.PC.032.A4.02

Page 6

Application Guidelines

Oil management concept

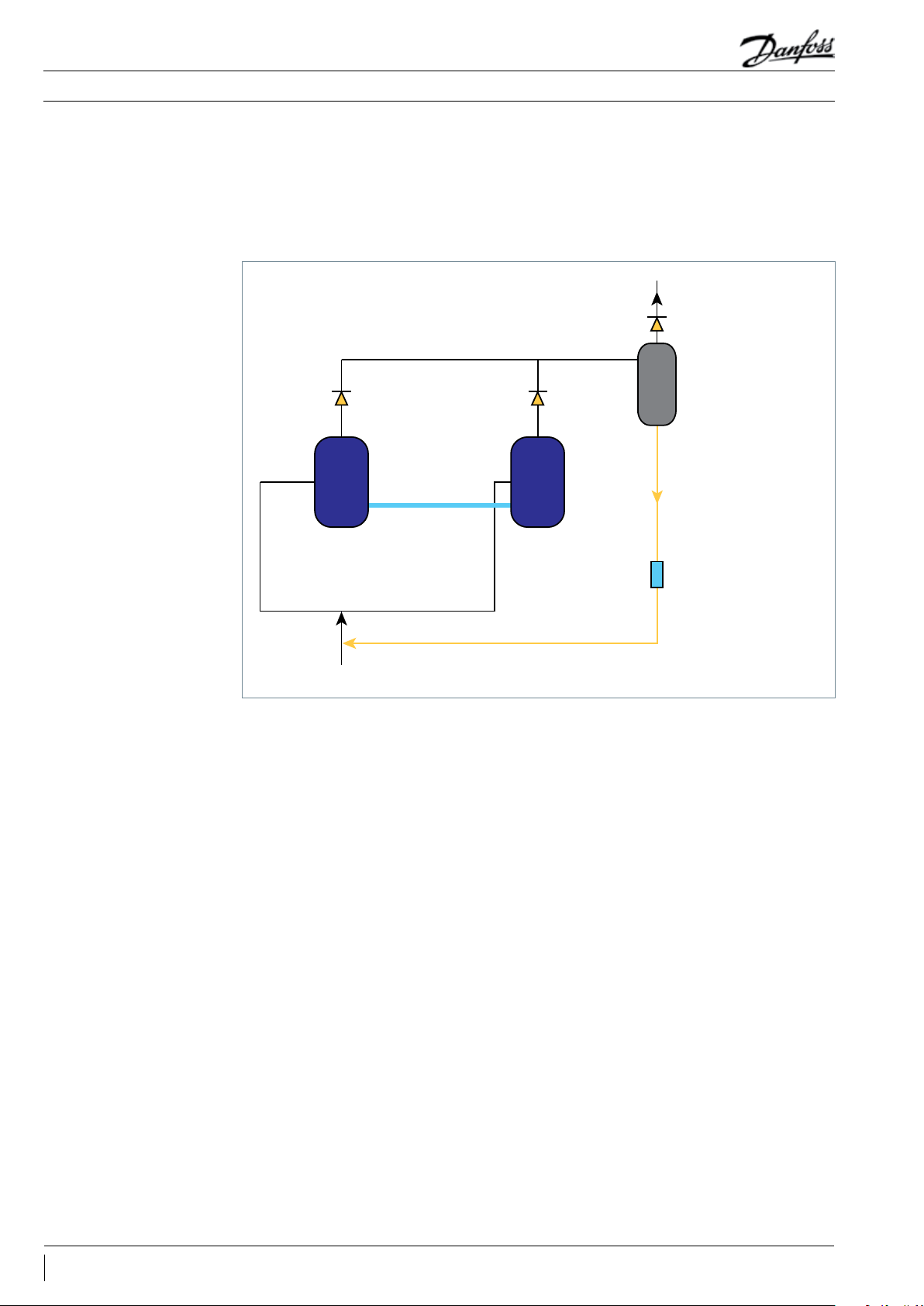

Passive systems

A passive system is an oil management system

without any measurement or control devices

such as oil level regulators and oil controllers.

By contrast, a solution equipped with such

measurement or control devices is called an

active system.

Non return valve

Oil equalization

line

Compressor 1 Compressor 2

Suction header

Danfoss has qualied only the even tandem

(two same compressors) for passive solutions.

To condenser

Non return valve

Oil separator with

oating-ball valve

Oil lter

From evaporator

6 FRCC.PC.032.A4.02

Page 7

Application Guidelines

Oil management concept

This is one of the simplest and cheapest ways of

manifolding compressors. It is very popular in airconditioning applications, but in refrigeration this

kind of system needs to be paid special attention

due to severe operating conditions.

Danfoss has qualied only the even tandem

(two same compressors) for passive solutions.

Compressor sumps and low-pressure shells are

interconnected. An interconnecting pipe on the

lower part of the compressor (installed on the

existing oil sight glass) ensures oil balancing.

The suction header design is critical, as it

ensures a pressure drop balancing and an equal

distribution of oil returning from the system

when both compressors are running.

The success of such a system relies very much

on the sizing and design of the pipe work, as

small dierences in sump pressure can result in

signicant oil level variations. This system needs

perfect suction tube balancing.

For an LLZ even tandem, oil return can be

secured by an oil separator with oat ball valve,

which will return the oil to the main suction

line. The oil equalisation line goes through the

oil sight glass with an adaptor on the standard

compressor. To avoid refrigerant back ow from

high pressure, it is always recommended to have

a non-return valve on the discharge line of each

compressor, as well as one non-return valve on

the outlet of the oil separator in the system to

prevent refrigerant migration.

The following are recommendations from

Danfoss application engineering for connecting

low temperature compressors using an oil

equalisation line system without active control:

• An adequately (generously) sized suction

header is needed to provide for equal

distribution of returning refrigerant gas and oil

to each individual compressor; also the suction

header should be installed horizontally.

• To secure sucient oil return to the compressor,

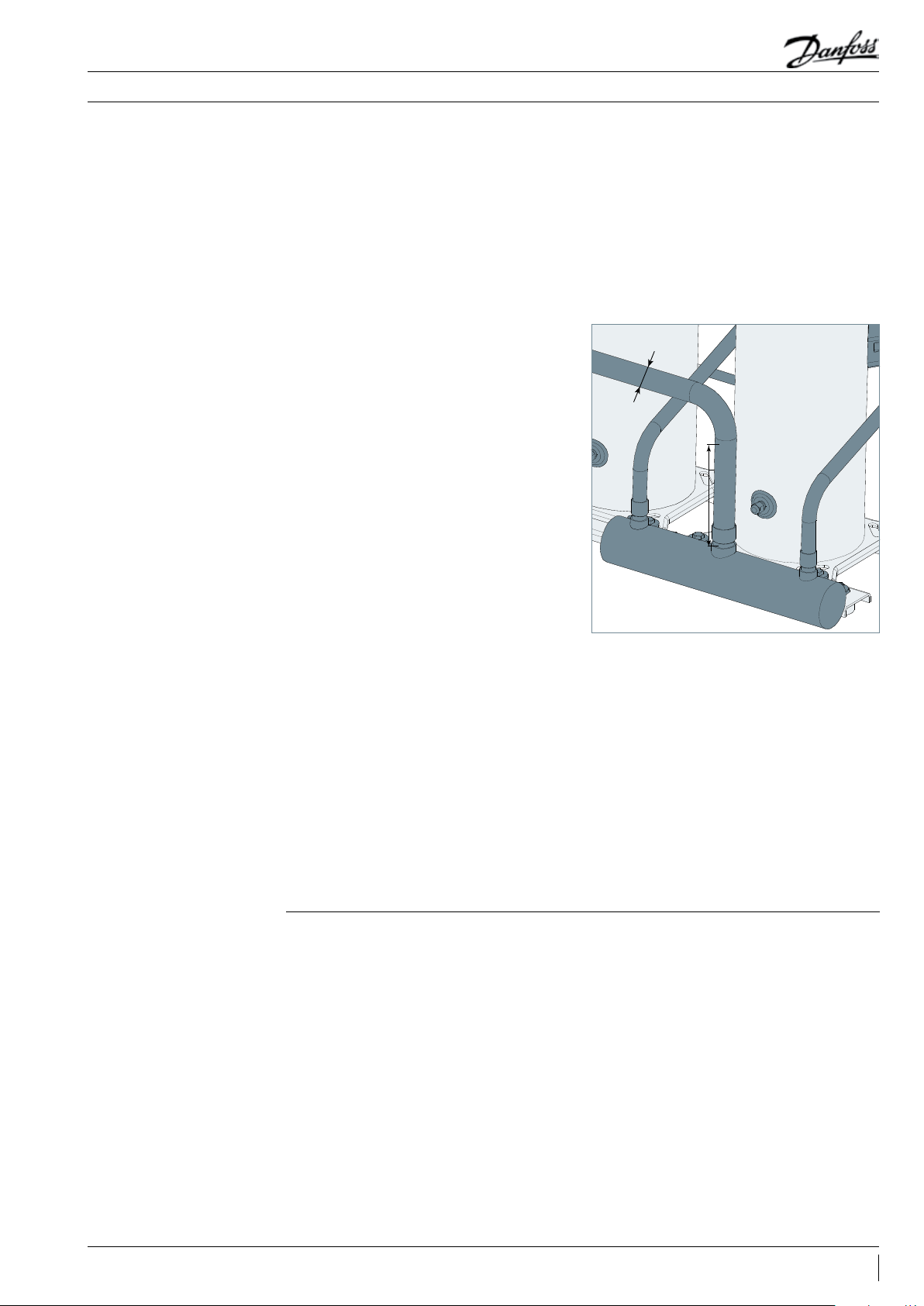

Danfoss suggests below dimension requirement

of the suction header: H>5D.

D

Main suction

line

Height

• The oil equalization tube is recommended to

have an outer diameter of ½’’.

• If the unit runs in a very cold situation, both

compressors need to be switched on after a

period of single running for better oil circulation,

especially in low load conditions.

• Care must be taken to mount all the

compressors on the same horizontal level and

also to provide adequate liquid ood back

protection when using this method.

Danfoss could provide piping drawings for even

tandem passive system, please contact Danfoss

for more information.

7FRCC.PC.032.A4.02

Page 8

Application Guidelines

Operating conditions

Power supply

Compressor ambient

temperature

Operating envelope

LLZ compressors can be operated at nominal

voltages as indicated below. Under-voltage

and over-voltage operation is allowed within

the indicated voltage ranges. In case of risk of

Motor voltage

code 2

Nominal voltage 50 Hz 200-220 V - 3 ph 380-415 V - 3 ph - -

Voltage range 50 Hz 180 - 242 V 342 - 456 V - -

Nominal voltage 60 Hz 208-230 V - 3 ph 460 V - 3 ph 575 V - 3 ph 380 V - 3 ph

Voltage range 60 Hz 187 - 253 V 414 - 506 V 517 - 632 V 342 - 418 V

LLZ scroll compressors can be applied from -35°C

to 50°C ambient temperature. The compressors

are designed as 100% suction gas cooled without

the need for additional fan cooling.

The recommended parallel assemblies design

from Danfoss Commercial Compressors have

been qualied to ensure there is no impact on

the compressor operating envelope.

undervoltage operation, special attention must

be paid to current draw.

LLZ scroll compressors are available in four

dierent motor voltages.

Motor voltage

code 4

Ambient temperature has very little eect on the

compressor performance.

For detailed information please refer to “the "LLZ

application guidelines”.

More details can be found in the “LLZ application

guidelines”.

Motor voltage

code 7

Motor voltage

code 9

Refrigerants and

lubricants

Discharge temperature

protection

High and low pressure

protection

Approved refrigerants and lubricants for LLZ

single compressors are also allowed for parallel

The discharge gas temperature of each

compressor must not exceed 135°C.

DGT protection is required if the high and

low-pressure switch settings do not protect

The pump-down pressure switch must have a set

point slightly higher than the lowest compressor

safety pressure switch set point. The compressor

switch must never be bypassed and shall stop

all the compressors. The high-pressure safety

pressure switch shall stop all the compressors.

Whenever possible (i.e. PLC control) it is

recommended to limit the possibility of

Cycle rate limit The system must be designed in a way that

guarantees a minimum compressor running time

of two minutes so as to provide for sucient

motor cooling after start-up along with proper oil

return. Note that the oil return may vary since it

depends upon system design.

assemblies. For more details, please refer to the

"LLZ application guidelines".

the compressor against operations beyond its

specic application envelope.

More details can be found in the “LLZ application

guidelines”.

compressor auto-restart caused by LP safety

switch settings to fewer than 3 to 5 times during

a 12-hour period.

Please refer to the “LLZ application guidelines” for

recommended settings.

of the motor-compressor unit. If necessary, place

an anti-short-cycle timer in the control circuit,

then connect as shown in the wiring diagram

in the Danfoss Scroll compressor application

guidelines. A three-minute (180-second) time-out

is recommended.

8 FRCC.PC.032.A4.02

There must be no more than 12 starts per hour (6

when a resistor soft-start accessory is introduced);

a number higher than 12 reduces the service life

Danfoss recommends a restart delay timer to

limit compressor cycling.

Page 9

max. 4 m

max. 4 m

Application Guidelines

System design recommendations

Essential piping design

considerations

Proper piping practices should be employed to

ensure adequate oil return, even under minimum

load conditions, with special consideration

given to the size and slope of the tubing coming

from the evaporator. Tubing returns from the

evaporator should be designed so as not to trap

oil and to prevent oil and refrigerant migration

back to the compressor during o-cycles.

If the evaporator lies above the compressor,

the addition of a pump-down cycle is strongly

recommended. If a pump-down cycle were to

be omitted, the suction line must have a loop at

the evaporator outlet to prevent refrigerant from

draining into the compressor during o-cycles.

If the evaporator is situated below the

compressor, the suction riser must be trapped to

ensure the oil return to the compressor (see g.1).

When the condenser is mounted at a higher

position than the compressor, a suitably sized

“U”-shaped trap close to the compressor is

necessary to prevent oil leaving the compressor

from draining back to the discharge side of the

compressor during o-cycle. The upper loop also

helps avoid condensed liquid refrigerant from

draining back to the compressor when stopped

(see g. 2). The maximum elevation dierence

between the indoor and outdoor section cannot

exceed 8 m. System manufacturers should specify

precautions for any applications that exceed

these limits to ensure compressor reliability.

Economiser heat exchanger piping shall be

arranged in a counter ow of gas and liquid to

assure optimum heat transfer and therefore best

subcooling eect.

Piping should be designed with adequate threedimensional exibility (gure 2). It should not

be in contact with the surrounding structure,

unless a proper tubing mount has been installed.

This protection proves necessary to avoid

excess vibration, which can ultimately result

in connection or tube failure due to fatigue

or wear from abrasion. Aside from tubing and

connection damage, excess vibration may be

transmitted to the surrounding structure and

generate an unacceptable sound level within that

structure as well (for more information on sound

and vibration, see the section on “Sound and

vibration management”).

<15 m/s

0.5% >

>3.6 m/s

HP

LP

U-trap

>7.6 m/s

>3.6m/s

Evaporator

To ensure proper refrigerant and oil circulation,

the speed limits in all pipes are generally

recommended as follows:

• For horizontal/vertical discharge gas velocity: no

more than 15m/s;

• For vertical suction gas velocity: no less than

7.6m/s;

Condenser

HP

LP

• For horizontal suction gas velocity: no less than

3.6m/s;

• For horizontal/vertical liquid velocity: around

1.5m/s;

• For suction header gas velocity: no more than

4m/s.

9FRCC.PC.032.A4.02

Page 10

Application Guidelines

System design recommendations

Expansion device When the parallel installation is serving a single

evaporator system, the dimensioning of the

expansion device (thermostatic or electronic)

becomes critical and must be made in relation

to both minimum and maximum capacity.

This will ensure correct superheat control in all

situations, with a minimum of 5K superheat at

the compressor suction. The expansion device

should be sized to ensure proper control of

the refrigerant ow into the evaporator. An

oversized valve may result in erratic control.

Proper selection could imply a slightly undersized

expansion valve at full load. This consideration

is especially important in manifolded units

Suction accumulator

The refrigeration compressor is designed to

compress vapour only. A suction line accumulator

prevents compressor damage from a sudden

surge of liquid refrigerant and oil that could enter

the compressor from the suction line. For low

temperature application, suction accumulator

is a must unless approved by careful tests under

dierent operating conditions.

Selection of a suction line accumulator should

be made on the basis of the following three

capabilities:

1. The accumulator should have an adequate

liquid-holding capacity that can vary with the

where low load conditions may require the

frequent cycling of compressors. This can lead

to liquid refrigerant entering the compressor

if the expansion valve does not provide stable

refrigerant superheat control under varying

loads. The superheat setting of the expansion

device should be sucient to ensure proper

superheat levels during low loading periods.

A minimum of 5K stable superheat is required.

In addition, the refrigerant charge should be

sucient to ensure proper subcooling within the

condenser so as to avoid the risk of ashing in the

liquid line before the expansion device.

system. Normally this should not be less than

50% of the system charge. If possible, this value

should be checked based on actual tests.

2. The accumulator should perform without

adding excessive pressure drop to the system.

3. An accumulator should have the capability of

returning oil at the proper rate and under a range

of load conditions.

Guideline of suction accumulator needs to be

respected in making a selection.

Suction header

For ecient oil management in parallel systems

the oil should return to the compressor at

approximately the same rate as it leaves so

that an appropriate oil level can always be

maintained.

Danfoss recommends an adequately sized

suction header which provides equal distribution

of returning refrigerant and oil to each individual

compressor. The suction lines from the header

towards each individual compressor must be

tted into the suction header. This conguration

will result in a higher gas velocity at the pick-up

tube inlet and proper oil return when the oil

level in the suction header rises. The compressor

suction lines must always enter the suction

header on the topside. A recommended suction

header design is shown below.

Suction gas

Suction gas to

compressor

10 FRCC.PC.032.A4.02

Page 11

Application Guidelines

System design recommendations

Oil level regulator

To ensure ideal pressure equalization, the suction

header must be symmetrical and the lines from

the suction header to each compressor must be

short and identical. These recommendations are

not so critical when using an active system.

Danfoss recommends the following as necessary

for secure a suction header installation:

• The suction header should be adequately sized

Oil level regulator monitors the oil level and

controls oil injection by switching the solenoid

valve on and o to maintain an acceptable oil

level in the compressor the crankcase. When

crankcase oil level cannot be restored within a

period of time (setting value), the alarm contactor

will be activated and stop the compressor to

protect it from damage (some oil level regulator

do not have an alarm function).

According to the function, there are three

types of oil level regulator: electronic,

electromechanical and mechanical. For a

high-pressure oil reservoir system, Danfoss

recommends individual electronic oil control

regulators over the mechanical oat ball oil

regulator system for eective oil regulation. For

the a low-pressure system, all types are allowed.

Danfoss has qualied the below oil level

regulators. Due to various operations in

refrigeration systems, the customer needs to

verify the conguration specied for their own

solutions.

for equal distribution of returning refrigerant gas

and oil to each individual compressor; also the

suction header should be installed horizontally.

• The gas velocity in the suction header must be a

maximum of 4 m/s.

• The suction line and the suction header must be

insulated to limit suction gas superheat.

• TEKLAB:

TK3-DANF-R01: Danfoss recommends this kind

of Oil level regulator for its overall quality. It can

judge the oil level precisely even when there is

some oil foaming. The total time before the alarm

is four minutes with the new control module,

which is suitable for LLZ compressors. The

adaptor of TEKLAB perfectly matches the oil sight

glass tting of LLZ compressor. A lter is needed

before Oil level regulator.

• Henry AC&R:

OP-02: The action and control logic works well

with LLZ compressors, while adaptors can t, but

not very well, with the oil sight glass tting. A

lter is needed before oil level regulator.

Note: Customers must refer to the manufacturer's

guidelines on oil level regulators for proper setup and operation.

11FRCC.PC.032.A4.02

Page 12

Application Guidelines

Oil separator / oil

reservoir

System design recommendations

Oil separator for passive

system

The role of the oil separator is to intercept the

mixed oil from the compressed refrigerant gas

and returns it back to the compressor to assure

ecient lubrication of its moving parts, and

also to improve the system heat exchangers’

eciency. In our manifolding system, the oil

separator is installed in the compressor discharge

line as shown below.

Passive system

Non return valve

Oil equalization

line

Compressor 1 Compressor 2

Suction header

No oil separator category is included in this

guidelines. For more details, please refer to the

manufacture’s guidelines.

Regarding passive solutions, it is recommended

to use an oil separator with a oating-ball

valve. The oating-ball valve can control the

oil ow and act as a capillary in the oil return

line; therefore, there is no need to install an oil

capillary in the system.

To condenser

Non return valve

Oil separator with

oating-ball valve

Oil lter

Oil separator / Oil

reservoir for active

system

From evaporator

When an active system is adopted by the

customer, the oil separator is always considered

together with oil reservoir.

Active system

Suction

header

Non return

valve

Compressor 1

Oil level regulator Oil level regulator Oil level regulator Oil level regulator

Non return

valve

Compressor 2 Compressor 3 Compressor 4

Due to system design, loads and defrost cycles,

etc, there will be varying amounts of oil returning

to the oil separator. Because of this, a safety

reserve of oil is required for successful operation

of the active system.

High pressure

Low pressure

Non return

valve

Non return

valve

Oil lter

Non return

valve

Combined oil

separator/reservoir

12 FRCC.PC.032.A4.02

Page 13

Application Guidelines

System design recommendations

High pressure oil reservoir (combined oil

separator/oil reservoir)

Danfoss recommends that high-pressure systems

are congured in active solutions. These systems

store the oil in a common oil separator / reservoir

at compressor discharge pressure (see the gure

below). The advantage is that these systems

do not need a separated oil reservoir but make

use of a combined oil separator / reservoir

arrangement ,which normally results in a cost

saving over traditional low-pressure systems.

Common suction header

From an application point of view, high-pressure

systems are more critical than traditional low

pressure systems and care must be taken to

make sure that the separator / reservoir installed

is of sucient size and oil content (as per

manufacturer’s recommendation) so that there

is always oil stored. And pay special attention to

avoid discharge gas entering the compressor oil

sump, which could lead to some negative eects

such as higher discharge and oil temperatures,

less lubrication capability and the loss of

eciency due to hot-gas bypass.

To condenser

From evaporator

Oil separator/Oil

reservoir

Active solution with high pressure oil reservoir (combined oil separator/oil reservoir)

Low pressure oil reservoir with separate oil

separator

valve). Therefore, the amount of refrigerant

dissolved in the oil will be limited. The pressure

drop is low when the oil enters the compressor

Usage of an oil reservoir is very common in lowpressure systems to control the variations in oil

quantity during operation (see below). In this

conguration, the oil reservoir is maintained at a

pressure slightly above the compressor suction

and the amount of ash gas formed in the sump

is small. The dierential pressure required for

sucient oil ow from the oil reservoir to the

compressor is system specic, depending upon

the application and components chosen.

pressure using a dierential pressure valve (check

Common suction header

Oil filter

To condenser

From evaporator

Oil separator with

float ball valve

Diffe rential pressu re

Check valve

Oil reservoir

Active solution with low pressure oil reservoir

Oil filter

13FRCC.PC.032.A4.02

Page 14

Compressor 1

Compressor 2

Application Guidelines

System design recommendations

In brief, oil separator and oil reservoir are always

considered together regarding active system.

For active solution with high pressure oil reservoir

system it is recommended to use oil separator(no

oat ball valve) with oil stored function. In

it is recommended to work together with oil

separator which with oat ball valve.

Generally Danfoss recommend to use high

pressure oil reservoir system (one oil seperator

with oil reserve function).

other words, a combined oil separator/oil

reservoir. For low pressure oil reservoir system,

Danfoss has qualied the below oil separator.

Due to various applications in refrigeration

systems, the customer needs to verify the

conguration specied for their own solutions.

Please refer to oil separator's guideline for more

information.

Passive solution

Country* CN NAM/CN NAM/CN EMA EMA EMA

Company Fasike O&F Emerson ALCO Henry AC&R Frigomec Frigomec Carly

Model F-65 A-WE S-CE SO/ERS SO/ER Turboil-F for PVE oil

Typ e Filter Impingement Impingement Filter Filter-demister Centrifugal

Note*: The countries listed here only indicate whether the product is available in local country or not for now. Regardless the

availability, all the OS above has been qualied by Danfoss under certain conguration.

Active solution

Country* CN EMA EMA

Company Fasike O&F Frigomec Carly

Model F-66Q SRO/ERS Turboil-R for PVE oil

Typ e Centrifugal Oil-stored Filter Oil-stored Centrifugal Oil-stored

Note*: The countries listed here only indicate whether the product is available in local country or not for now. Regardless the availability, all the OS above has been qualied by Danfoss under certain conguration.

Economizer for parallel

vapour injection

compressors

Refrigerant charge limits

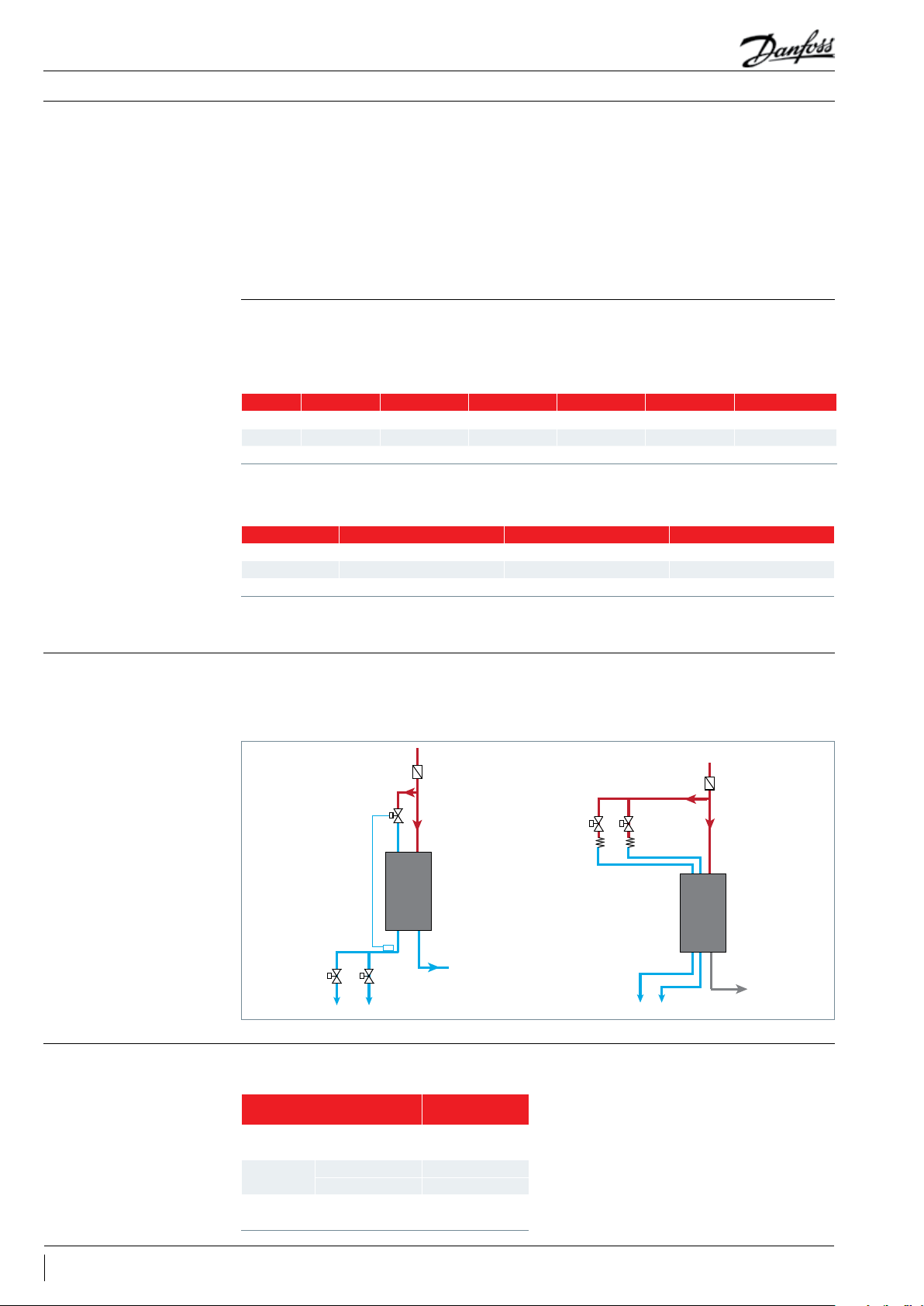

A single economiser (heat exchanger) can be

applied in a parallel economiser conguration.

A system may use one economizer with a single

circuit on the liquid line and multiple circuits

From condenser /

liquid receiver

Drier lter

Expansion valve

Heat exchanger

Solenoid valve

To evaporator

on the vapour side. In the case of refrigerant

being fed into the injection port of a stationary

compressor, a non return valve should always be

tted.

From condenser /

liquid receiver

Filter

Solenoid valve

Cap tube

Heat exchanger

To evaporator

Compressor 1 Compressor 2

If refrigerant charge exceeds the limit, a liquid receiver and suction accumulator will be essential to

ensure that the system runs reliably.

Compressor models

Tandem

Trio

Quadro

LLZ013- 015 -018 5.9

LLZ024 9.4

LLZ013- 015 -018 7.7

LLZ024 12. 3

LLZ013- 015 -018 10.0

LLZ024 16.0

Refrigerant charge

limit(kg)

14 FRCC.PC.032.A4.02

Page 15

Application Guidelines

Installation and service

Piping design

Wiring and rotation

direction

Failure analysis

Due to the various LLZ parallel congurations,

Danfoss only provides an even tandem piping

design. For uneven, trio and quadro active

systems, the customer can make their own

design based on the velocity limits.

For each tandem conguration specic outline

drawings are available as indicated on the

following pages. These drawings must always be

followed.

All compressors in a tandem unit must be

electrically wired individually.

When one compressor in a parallel system fails,

the chance of foreign particles entering other

compressors is greatly increased. Therefore a

No changes shall be made to the indicated

tubing diameter and tting types. As for passive

systems, the oil equalisation line shall be made of

copper tube and assembled in such a way so that

it does not extend above the connection height

and must be horizontal so as not to trap oil.

Please contact Danfoss Sales for specic

drawings.

Compressors should run with the correct rotation

direction. This can be achieved by having the

correct phase sequence on each compressor

motor terminal (L1-T1, L2-T2, L3-T3).

failure analysis must be done quickly to ensure

further proper running conditions for the overall

installation (i.e.: oil analysis).

15FRCC.PC.032.A4.02

Page 16

Application Guidelines

Sound and vibration management

Running sound level

Average sound levels below is at ARI LBP condition

50Hz 60Hz

Model

LLZ013 tandem 80 72 82 74

LLZ015 tandem 82 74 85 77

LLZ018 tandem 85 75 86 76

LLZ024 tandem 87 77 88 78

Sound power(dBA)

Without jacket

Sound power(dBA)

With jacket

Sound power(dBA)

Without jacket

Sound power(dBA)

With jacket

16 FRCC.PC.032.A4.02

Page 17

Application Guidelines

Ordering information

To build a complete tandem, one must order two

compressors and the tandem kit. Danfoss LLZ

compressors can be ordered in either industrial

packs or in single packs. Please refer to the single

Kit code number 120Z5073

Designation Qty

1 Flat washer 8

2 Spacer 8

3 Rotolock sleeve 2

4 Rotolock nut 2

5 Adaptor 2

6 O-ring 2

7 Teon seal 2

compressor application guidelines for ordering.

All LLZ tandem conguration will share the same

tandem kit.

17FRCC.PC.032.A4.02

Page 18

Application Guidelines

Parallel units LLZ013-15-18-24

Composition of LLZ013024 uneven tandem/trio/

quadro

Composition of LLZ013024 even tandem

Active system

These compositions can only work with active

systems.

Danfoss will not provide drawings for these

congurations. Pipe sizes can be calculated based

on the velocity the limits in “Essential piping

design" section. And Customers need to do their

own validation.

A

Active system (50 Hz)

Tandem model A B C

LLZ013- 018 1/2 " 3/4" 1"1/8

LLZ024 3/4" 1"1/8 1"3/8

For more details, please refer to drawing 0ZZ0218B(50Hz).

Note: the dimensions are external diameters

B

C

18 FRCC.PC.032.A4.02

Page 19

Application Guidelines

Passive system

Parallel units LLZ013-15-18-24

E

D

A

C

B

Passive system (50 Hz)

Tandem model A B C D E

LLZ013- 018 1/2" Ø64.00 1"1/8 3/4" 1/2"

LLZ024 1/2" Ø79.38 1"3/8 1"1/8 3/4"

For more details, please refer to drawing 0ZZ0217B(50Hz).

Note: the dimensions are external diameters

Compressor mounting The tandem is xed on the frame using the

exible grommets supplied with the compressor.

The compressors are xed on the rails (not

supplied) using at washers rigid spacer

included in the “tandem kit” reference 120Z5073

(to be ordered with the compressors). An

additional rigid spacer (mounting kit for single

compressors) must be placed under the rail

grommets (see below drawing).

Tightening

torque 15Nm

Tightening

torque 15Nm

19FRCC.PC.032.A4.02

Page 20

Application Guidelines

Parallel units LLZ013-15-18-24

Suction and discharge

connection

Both suction and discharge line go through a

rotolock connection. Pipes are brazed to the

sleeve ‘ and xed to the compressor with nuts

’.

Note: sleeve ‘ and nut ’ are the supplied with

LLZ single service kit (120Z5067-LLZ013/015/018

and 120Z5068-LLZ024).

’

’

Suction line Discharge line

’

’

Oil equalisation

connection

As for passive systems, an oil equalisation line

is brazed to the sleeve .

A rotolock nut xes the sleeve and adaptor

, which is connected with oil sight glass port

. The O-ring and Teon ring guarantee the

seal.

20 FRCC.PC.032.A4.02

Page 21

Page 22

Danfoss Commercial Compressors

Danfoss Inverter Scrolls

is a worldwide manufacturer of compressors and condensing units for refrigeration and HVAC applications. With a wide range

of high quality and innovative products we help your company to find the best possible energy efficient solution that respects

the environment and reduces total life cycle costs.

We have 40 years of experience within the development of hermetic compressors which has brought us amongst the global

leaders in our business, and positioned us as distinct variable speed technology specialists. Today we operate from engineering

and manufacturing facilities spread across three continents.

Danfoss Turbocor Compressors

Danfoss Scrolls

Danfoss Optyma Condensing Units

Danfoss Maneurop Reciprocating Compressors

Secop Compressors for Danfoss

Our products can be found in a variety of applications such as rooftops, chillers, residential air conditioners,

heatpumps, coldrooms, supermarkets, milk tank cooling and industrial cooling processes.

http://cc.danfoss.com

Danfoss Commercial Compressors, BP 331, 01603 Trévoux Cedex, France | +334 74 00 28 29

FRCC.PC.032.A4.02 - January 2015 - Replaces FRCC.PC.032.A3.02 - April 2014 © Copyright Danfoss | Commercial Compressors | 2015.01

Loading...

Loading...