Page 1

Instructions

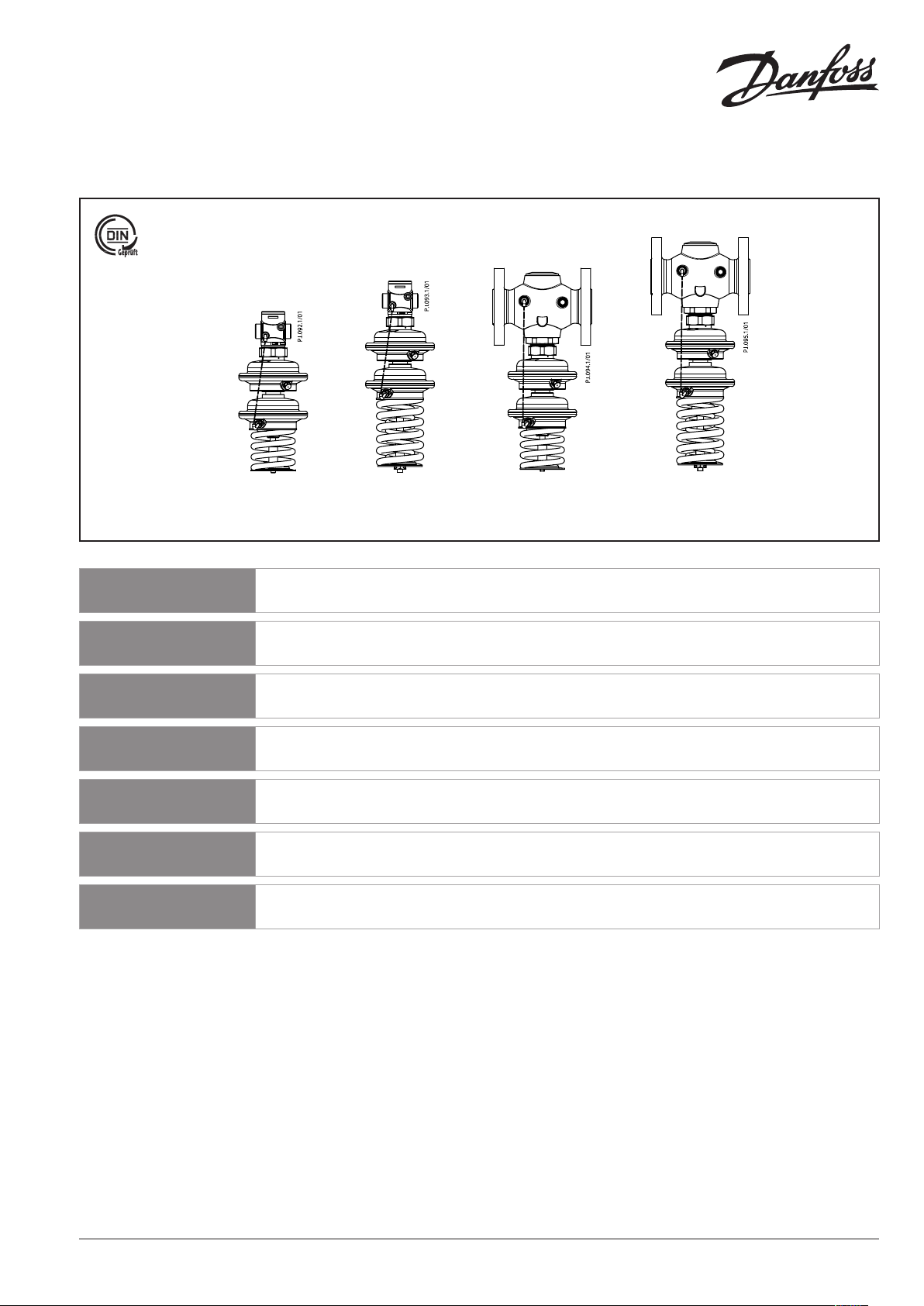

SAVD – PN 25 / DN 15 - 50

DN 15 - 50 DN 15 - 50 DN 32 - 50 DN 32 - 50

p = 1 - 5 p = 2 - 8 p = 1 - 5 p = 2 - 8

p = 3 - 12 p = 3 - 12

ENGLISH

DANSK

DEUTSCH

ESPAÑOL

SLOVENŠČINA

POLSKI

РУССКИЙ

Safety pressure reduction controller

SAVD

Regulator for sikkerhedstrykreduktion

SAVD

Sicherheitsabsperrventil (SAV) mit Druckminderer

SAVD

Reductor de presión con función de seguridad

SAVD

Varnostni reducirni regulator nadtlaka

SAVD

Reduktor ciśnienia z funkcją bezpieczeństwa

SAVD

Регулятор давления «после себя» c функцией

безопасности SAVD

www.danfoss.com Page 5

www.danfoss.dk Side 6

www.danfoss.de Seite 7

www.danfoss.es Page 8

www.danfoss.si Stran 9

www.danfoss.pl Strona 10

www.danfoss.ru Стр. 12

73695090 DH -SMT/SI VI.DC .E2.8M © Danf oss04/2011 1

Page 2

❺

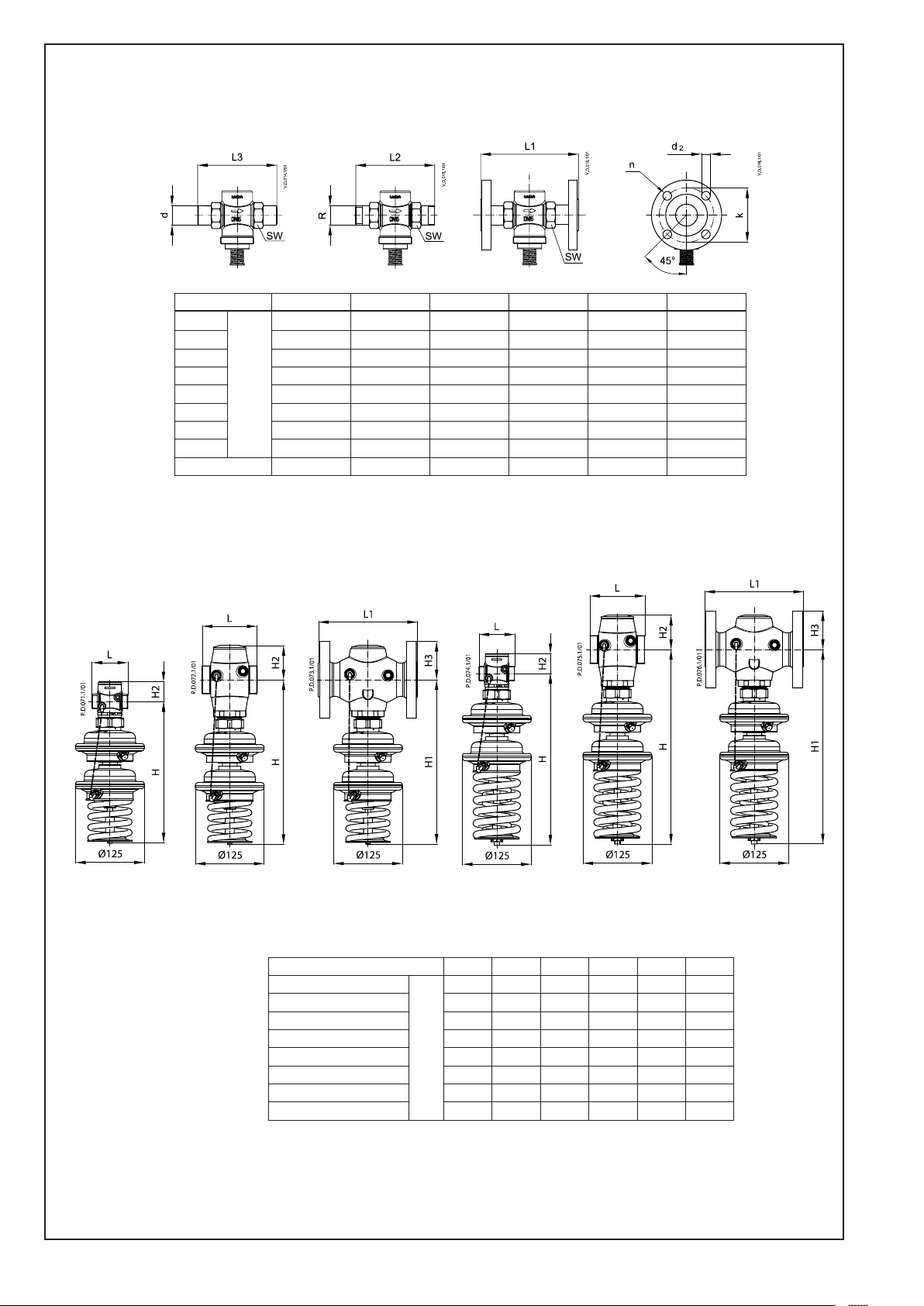

DN 15 20 25 32 40 50

SW

d 21 26 33 42 47 60

R 1) ⁄ ⁄ 1 1⁄ - L1 2) 130 150 160 - - L2 131 144 160 177 - L3 139 154 159 184 204 234

k 65 75 85 100 110 125

d2 14 14 14 18 18 18

n 4 4 4 4 4 4

32 (G ¾A) 41 (G 1A) 50 (G 1¼A) 63 (G 1¾A) 70 (G 2A) 82 (G 2½A)

mm

DN 15 - 25 DN 32 - 50 DN 32 - 50 DN 15 - 25 DN 32 - 50 DN 32 - 50

∆p = 1 - 5 ∆p = 1 - 5 ∆p = 1 - 5 ∆p = 2 - 8 ∆p = 2 - 8 ∆p = 2 - 8

∆p = 3 - 12 ∆p = 3 - 12 ∆p = 3 - 12

DN 15 20 25 32 40 50

L

L1 - - - 180 200 230

H ∆p = 1 - 5 257 257 257 299 299 299

H ∆p = 2 - 8 / 3 - 12 313 313 313 355 355 355

H1 ∆p = 1 - 5 - - - 299 299 299

H1 ∆p = 2 - 8 / 3 - 12 - - - 355 355 355

H2 34 34 37 62 62 62

H3 - - - 70 75 82

73695090 DH -SMT/SI VI.DC .E2.8M © Danf oss04/2011 2

mm

65 70 75 100 110 130

Page 3

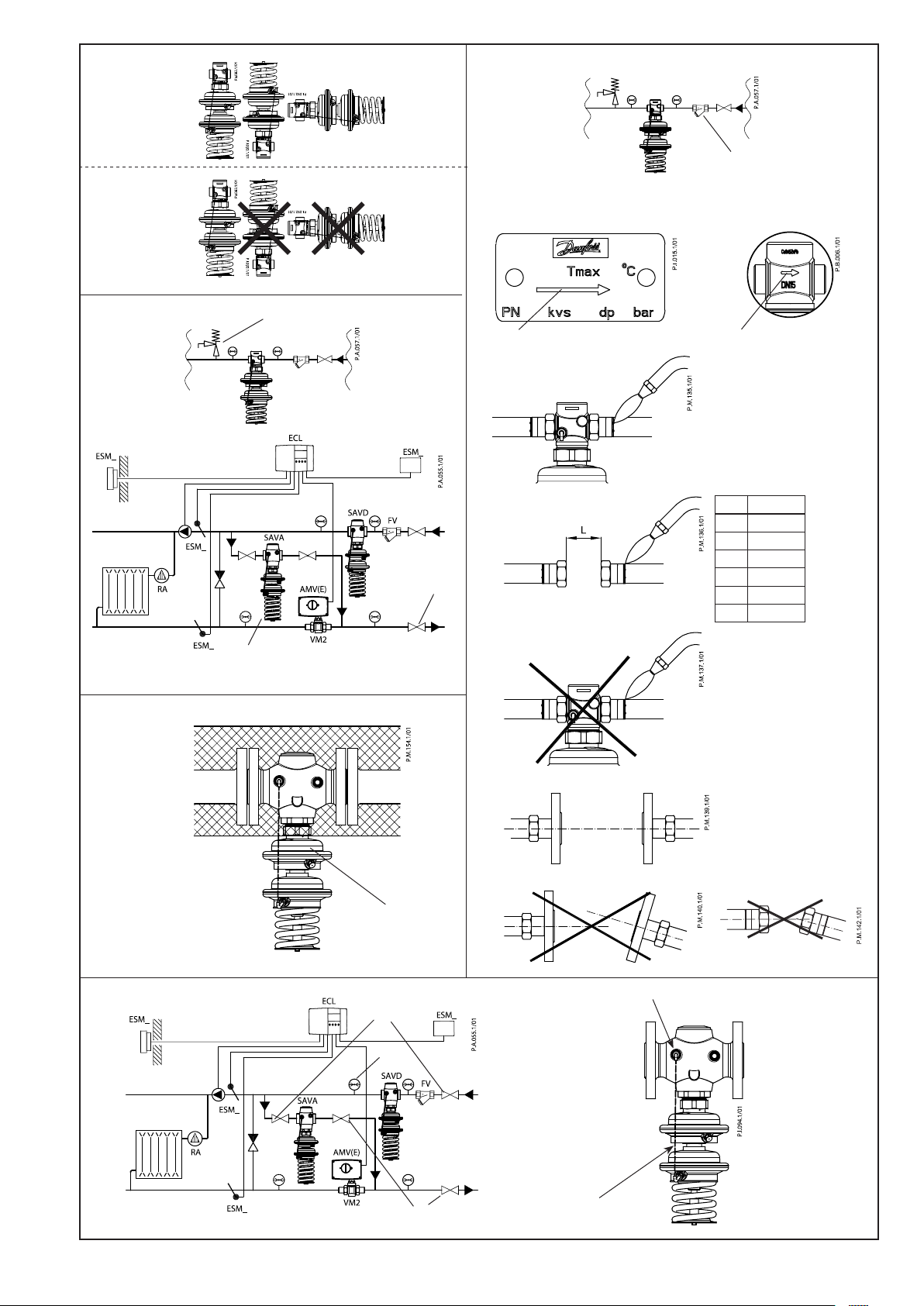

❶

❸

①

①

②

❷

❹

②

①

③

④

②

⑤

⑥

③

DN L (mm)

15 69

20 74

25 79

32 104

40 114

50 134

⑦

⑧

①

❻

⑤

①

③

②

73695090 DH -SMT/SI VI.DC .E2.8M © Danf oss04/2011 3

④

Page 4

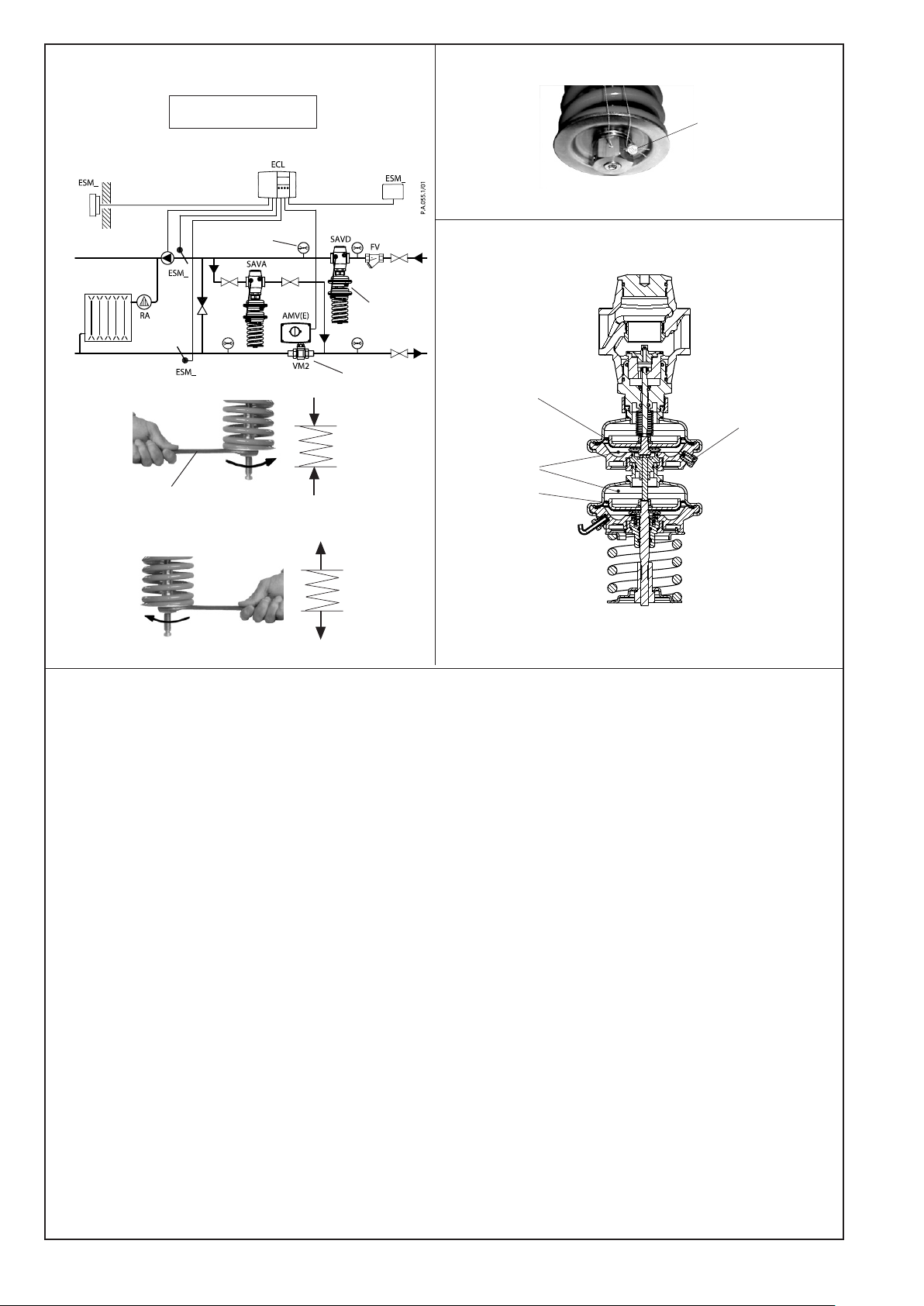

❼ ❽

①

∆p = 1.0 - 5.0 bar

①

⑤

17 mm

⑥

④

❾

③

②

③

④

②

①

73695090 DH -SMT/SI VI.DC .E2.8M © Danf oss04/2011 4

Page 5

ENGLISH

Safety Notes

Prior to assembly and commissioning

to avoid injury of persons and damages

of the devices, it is absolutely necessary

to carefully read and observe these

instructions.

Necessary assembly, start-up, and

maintenance work must be performed

only by qualified, trained and authorized

personnel.

Prior to assembly and maintenance work

on the controller, the system must be:

- depressurized,

- cooled down,

- emptied and

- cleaned.

Please comply with the instructions of the

system manufacturer or system operator.

Definition of Application

The controller is used for pressure

reduction control and as a protection

against excess pressure behind the valve.

The controller is used for water and water

glycol mixtures for heating, district heating

and cooling systems.

Controller is design-tested according to

DIN 4747 (SAV) and the AGFW guidelines.

The technical parameters on the product

labels determine the use.

Disposal instruction

This product should be

dismantled and its

components sorted, if

possible, in various groups

before recycling or disposal.

Always follow the local disposal

regulations.

Assembly

The system must be protected behind

the safety pressure reducer by a safety

monitoring unit SV ① or SÜV ②.

Secure the shut-off unit ③ against

unauthorized opening.

Valve Installation ➌

1. Clean pipeline system prior to assembly.

2. Install a strainer in front of the

controller ①.

Max. mesh width

DN 15 - 25: 0.5 mm

DN 32 - 50: 0.8 mm

3. Install pressure indicators in front of and

behind the system part to be controlled.

4. Install valve

• The flow direction indicated on the

product label ② or on the valve ③

must be observed.

• The valve with mounted weld-on

tailpieces may only be spot welded to

the pipeline ④.

The weld-on tailpieces may be welded

only without the valve and seals! ⑤⑥

If these instructions are not observed,

high welding temperatures may

destroy the seals.

• Flanges ⑦ in the pipeline must be in

parallel position and sealing surfaces

must be clean and without any

damage.

Tighten screws in flanges crosswise

in 3 steps up to the maximum torque

(50 Nm).

5. Caution:

Mechanical loads of the valve body by the

pipelines are not permitted ⑧.

Insulation ➍

Do not insulate the pressure actuator ①.

Dimensions, Weights ❺

(See page 2)

1)

Conical ext. thread acc. to EN 10226-1

2)

Flanges PN 25, acc. to EN 1092-2

Leak and Pressure Tests

To avoid inadmissible pressures on the

actuator (admissible excess pressure during

operation is 14 bar) it is absolutely necessary

to remove the impulse tube ④. Close

connections with plugs G ⁄ ISO 228 ⑤. In

this case valve is always closed.

Pressure must be gradually increased at

the +/- connection.

Non-compliance may cause damages at

the actuator or the valve.

A pressure test of the entire system

must be carried out in accordance with

manufacturer’s instructions.

The maximum test pressure is: 1.5 × PN

PN - see product label!

Putting out of operation

1. Slowly close shut-off devices ① in the

flow pipeline.

2. Slowly close shut-off devices ② in the

return pipeline.

Settings ❼

Pressure Setting

The pressure setting range is indicated on

the product label ①.

Procedure:

1. Set flow rate on a motorized valve ②

after the safety pressure reducer ③ to

about 50 % of the max. flow rate.

2. Adjustment

(of the pressure behind the valve)

Observe pressure indicators ④.

• Turning to the right ⑤ (clockwise)

increases the set-point (stressing the

spring).

• Turning to the left ⑥ (counterclockwise) reduces the set-point

(releasing the spring).

Admissible Installation Positions ❶

Medium temperatures up to 100 °C:

- Can be installed in any position ①.

Medium temperatures > 100 °C:

- Installation permitted only in

horizontal pipelines with the actuator

oriented downwards ②.

Start-up ❻

The valve is opened without pressure. The

valve closes when the pressure behind

the valve ③ rises above the adjusted

set-point.

Installation Location and

Installation Scheme ❷

SAVD mounting

73695090 DH -SMT/SI VI.DC .E2.8M © Danf oss04/2011 5

Filling the system, first start-up

1. Slowly open shut-off devices ① in the

flow pipeline.

2. Slowly open shut-off device ② in the

return pipeline.

Seal ❽

The set-point adjuster can be sealed by a

seal wire ①, if necessary.

Safety function ❾

If the control diaphragm ① beaks, pressure

gets in the two intermediate chambers ②.

This pressure acts upon the safety

diaphragm ③ and causes the following:

- The valve closes

- The control function does not operate

- A slight water leakage at the threaded

joint ④ of the upper casing indicates a

break of the diaphragm.

The controller must be replaced when the

diaphragm is broken.

Page 6

DANSK

Sikkerhedsnoter

Disse instruktioner SKAL læses

omhyggeligt forud for montering og

indkøring samt respekteres for at undgå

skader på personer og udstyr.

Nødvendigt monterings-, opstart- og

vedligeholdelsesarbejde må kun udføres af

faglært og autoriseret personale.

Forud for monterings- og

vedligeholdelsesarbejde på regulatoren

skal systemet være:

- trykløst,

- nedkølet,

- tømt og

- rengjort.

Systemproducentens eller -operatørens

instruktioner skal overholdes.

Anvendelse

Regulatoren anvendes til

trykreduktionsstyring og som

beskyttelse mod overtryk bag ventilen.

Regulatoren anvendes til vand og vandglycolblandinger til varme-, ernvarme- og

kølesystemer.

De tekniske parametre på

produktetiketterne fastlægger

anvendelsen.

Bortskaffelsesinstruktion

Dette produkt skal, om

muligt, adskilles og sorteres i

dets forskellige

materialegrupper, før det

genbruges eller bortskaffes.

Lokal lovgivning for bortskaffelse skal

altid overholdes.

Montering

Ventilinstallation ➌

1. Rengør rørledningssystemet før

montering.

2. Installer et filter før regulatoren ①.

Maks. maskevidde

DN 15 - 25: 0,5 mm

DN 32 - 50: 0,8 mm

3. Installer trykvisere før og efter den

systemdel, der skal reguleres.

4. Installer ventilen

• Den flowretning, der vises på

produktetiketten eller på ventilen, skal

respekteres ② ③.

• Ventilen med monterede

svejsestudser må kun klemmes fast til

rørledningen ④.

Svejsestudserne må kun svejses uden

ventil og pakninger! ⑤⑥

Høje svejsetemperaturer kan

ødelægge pakningerne, hvis disse

instruktioner ikke overholdes.

• Flanger ⑦ i rørledningen skal være

placeret parallelt, og pakfladerne

skal være rene og uden skader.

Krydsspænd skruerne i flangerne i 3

trin til maks. moment (50 Nm).

5. Forsigtig:

Ventilhuset må ikke udsættes for

mekaniske belastninger fra rørsystemet ⑧.

Isolering ➍

Trykaktuatoren ① må ikke isoleres.

Mål, vægt ❺

(See page 2)

1)

Konisk udv. gevind iht. EN 10226-1

2)

Flanger PN 25 iht. EN 1092-2

Opstart ❻

Ventilen åbnes uden tryk. Ventilen lukker,

når trykket bag ventilen ③ overstiger det

indstillede sætpunkt.

Trykket skal øges gradvist ved

+/- tilslutningen

Overholdes dette ikke, kan der opstå

skader på aktuatoren eller ventilen.

Der skal udføres en trykprøvning af

hele systemet i overensstemmelse med

producentens instruktioner.

Det maksimale prøvetryk er: 1,5 × PN

PN fremgår af produktetiketten!

Standsning

1. Luk langsomt for

afspærringsanordningerne ① i

flowledningen.

2. Luk langsomt for

afspærringsanordningerne ② i

returledningen.

Indstilling af sætpunkter ❼

Trykindstilling

Trykindstillingsområdet fremgår af

produktetiketten ①.

Fremgangsmåde:

1. Indstil flowhastigheden ved

en afspærringsventil ② efter

sikkerhedstrykregulatoren ③ ttil ca. 50

% af den maksimale flowhastighed.

2. Justering

(af trykket bag ventilen)

Aflæs trykviserne ④.

• Drejes der til højre ⑤, øges

sætpunktet (ederen spændes).

• Drejes der til venstre ⑥, reduceres

sætpunktet (ederen udløses).

Plombering ❽

Sætpunktsstilleskruen kan om nødvendigt

forsegles med en plombe ①.

Tilladelige installationsstillinger ❶

Medietemperaturer op til 100 °C:

- Kan monteres i alle stillinger ①.

Medietemperaturer > 100 °C:

- Må kun installeres i vandrette

rørledninger og med aktuatoren

hængende nedad ②.

Påfyldning af systemet, første

opstart

1. Åbn langsomt for

afspærringsanordningerne ① i

flowledningen.

2. Åbn langsomt for

afspærringsanordningerne ② i

returledningen.

Installationsplacering og

installationsplan ❷

SAVD-montering

Systemet skal beskyttes af en

sikkerhedsovervågningsenhed SV ① eller

SÜV ②bag sikkerhedstrykregulatoren.

Sørg for, at afspærringsenheden ③ ikke

kan åbnes uautoriseret.

73695090 DH -SMT/SI VI.DC .E2.8M © Danf oss 04/2011 6

Lækage- og trykprøvning

For at undgå utilladeligt høje tryk på

aktuatoren (tilladeligt overtryk under drift

er 14 bar) er det absolut nødvendigt at

erne impulsledningen ④. Luk tilslutninger

med propper G 1⁄8 ISO 228 ⑤.

Sikkerhedsfunktion ❾

Hvis reguleringsmembranen ① brister,

kommer der tryk i de to mellemkamre ②.

Dette tryk påvirker sikkerhedsmembranen

③ og medfører følgende:

- Ventilen åbner

- Styringsfunktionen virker ikke

- En mindre vandlækage ved

gevindsamlingen ④ til den øverste del

af huset indikerer, at membranen er

bristet.

Regulatoren skal udskiftes, hvis

membranen er bristet.

Page 7

DEUTSCH

Sicherheitshinweise

Um Verletzungen an Personen und

Schäden am Gerät zu vermeiden, ist diese

Anleitung vor der Montage unbedingt zu

beachten.

Montage, Inbetriebnahme und

Wartungsarbeiten dürfen nur von

sachkundigen und autorisierten Personen

durchgeführt werden.

Vor Montage und Wartungsarbeiten am

Regler die Anlage:

- drucklos machen,

- abkühlen,

- entleeren und

- reinigen.

Die Vorgaben des Anlagenherstellers und

Anlagenbetreibers sind zu beachten.

Bestimmungsgemäße Verwendung

Der Regler verhindert durch selbsttätiges

Schließen die Überschreitung des

Druckes nach dem Ventil von Wasser und

Wasser-Glykol-Gemischen in Heizungs-,

Fernheizungs- und Kühlungsanlagen.

Bauteilgeprüft nach AGFW Arbeitsblatt

FW 504 (SAV).

Die technischen Daten auf den

Typenschildern sind für den Einsatz

maßgebend.

Anweisung zur Entsorgung

Dieses Produkt sollte

ausgebaut und in dessen

Bestandteile zerlegt werden.

Sortieren Sie die einzelnen

Bestandteile entsprechend

der Entsorgungsgruppen zur

Wiederverwertung oder Entsorgung.

Beachten sie dabei immer die lokalen

Entsorgungsrichtlinien.

Die Anlage muss durch eine

Sicherheitsarmatur (SV ① oder SÜV ②)

hinter dem Druckminderer abgesichert

werden.

Absperrarmatur ③ gegen unbefugtes

Schließen sichern.

Einbau Ventil ➌

1. Rohrleitung vor der Montage reinigen.

2. Schmutzfänger ① vor dem Regler

einbauen.

Max. Maschenweite

DN 15 - 25: 0,5 mm

DN 32 - 50: 0,8 mm

3. Druckanzeiger vor und hinter dem

Ventil bzw. den entsprechenden

Anlageteilen einbauen.

4. Ventil einbauen

• Durchflussrichtung ② auf dem

Typenschild oder Ventil beachten ③.

• Ventil mit angeschraubten

Anschweißenden nur an die

Rohrleitung anheften ④.

Das Einschweißen der

Anschweißenden ist nur ohne Ventil

und Dichtungen zulässig! ⑤⑥

Bei Nichtbeachtung zerstören die

hohen Schweißtemperaturen die

Dichtungen des Ventils.

• Flansche ⑦ in der Rohrleitung müssen

parallel, Dichtflächen sauber und ohne

Beschädigungen sein.

Schrauben über Kreuz in 3 Stufen bis

zum max. Drehmoment anziehen

(50 Nm).

5. Achtung:

Mechanische Belastungen des

Ventilgehäuses durch die Rohrleitungen

sind nicht zulässig ⑧.

Isolierung ➍

Druckantrieb ① nicht isolieren.

Dichtheits- und Druckprüfung

Um unzulässig hohen Druck am

Druckantrieb zu vermeiden (zulässiger

Überdruck während des Betriebs ist 14

bar), ist es erforderlich, die Steuerleitung ④

zu entfernen. Die Anschlüsse mit einer

Plombe G ⁄ ISO 228 ⑤ schließen.

Die Druckerhöhung muss am +/Anschluss gleichmäßig erfolgen.

Nichtbeachtung kann zu Schäden am

Antrieb und/oder Ventil führen.

Die Druckprüfung der Anlage muss nach

den Vorgaben des Anlagenherstellers

durchgeführt werden.

Max. Prüfdruck ist: 1,5 × PN

PN siehe Typenschild!

Außerbetriebnahme

1. Absperrarmaturen ① im Vorlauf

langsam schließen.

2. Absperrarmaturen ② im Rücklauf

langsam schließen.

Einstellung Sollwerte ❼

Druckeinstellung

Sollwertbereich siehe Typenschild ①.

Vorgehensweise:

1. Volumenstrom an einer Armatur ②

hinter dem Druckminderer ③ auf

ca. 50 % des max. Volumenstroms

einstellen.

2. Einstellung

(des Druckes hinter dem Ventil)

Druckanzeigen ④ beachten.

• Rechtsdrehung ⑤ erhöht den Sollwert

(Feder spannen).

• Linksdrehung ⑥ reduziert den

Sollwert (Feder entspannen).

Abmessungen, Gewichte ❺

Montage

Zulässige Einbaulagen ❶

Mediumstemperaturen bis 100 °C:

- Einbaulage beliebig ①.

Mediumstemperaturen 100 °C:

- Einbau nur in waagerechte Rohrleitung

mit nach unten hängendem Antrieb

zulässig ②.

Einbauort, Einbauschema ❷

SAVD Einbau

(See page 2)

1)

Kegeliges Außengewinde nach

EN 10226-1

2)

Flansche PN 25, nach EN 1092-2

Inbetriebnahme ❻

Ohne Druck bleibt das Ventil geöffnet. Das

Ventil schließt, wenn der Druck hinter dem

Ventil ③ über den eingestellten Sollwert

steigt.

Füllung der Anlage, Inbetriebnahme

1. Absperrarmaturen ① im Vorlauf

langsam öffnen.

2. Abperrarmaturen ② im Rücklauf

langsam öffnen.

73695090 DH -SMT/SI VI.DC .E2.8M © Danf oss04/2011 7

Plombierung ❽

Bei Bedarf kann der Sollwertsteller ①

durch Plombierdraht gesichert werden.

Sicherheitsfunktion ❾

Bei einem Membranbruch der

Regelmembrane ① wird in den beiden

Zwischenkammern ② ein Druck

aufgebaut. Der Druck wirkt auf die

Sicherheitsmembrane ③ dadurch:

- wird das Ventil geschlossen

- ist die Regelfunktion außer Betrieb

- Anzeige des Membranbruchs durch

geringen Wasseraustritt an der

Verschraubung ④.

Der Regler muss nach einem

Membranbruch ausgetauscht werden.

Page 8

ESPAÑOL

Notas de seguridad

El sistema debe protegerse detrás del

Antes del montaje y de la puesta en

marcha, para evitar daños personales

y perjuicios en los dispositivos,

es absolutamente necesario leer

cuidadosamente estas instrucciones.

El montaje, la puesta en marcha y el trabajo

de mantenimiento necesario deberán ser

realizados solo por personal cualificado y

autorizado.

Antes del montaje y el trabajo de

mantenimiento del controlador, el sistema

debe ser:

- despresurizado

- enfriado,

- vaciado y

- limpiado.

Por favor, cumpla con las instrucciones del

fabricante del sistema o del operador del

sistema.

Aplicación

El regulador se utiliza para el control de

la reducción de presión y como proteccón

contra el exceso de presión después de

la válvula. El regulador se utiliza para

agua y mezcla agua/glycol en sistemas

de Calefacción, District Heating y

Refrigeración.

Los parámetros técnicos en la etiquetas del

producto determinan su uso.

Instucciones de eliminación

Este producto debe ser

desmontado y si es posible,

sus componentes deben ser

separados en varios grupos

antes de su reciclado o

destrucción.

Siga siempre la regulación local sobre

eliminación.

reductor de presión con función de

seguridad por una unidad de seguridad

(SV, SÜV) ① ②.

Unidad de cierre de seguridad ③ contra la

apertura no autorizada.

Instalación de la válvula ➌

1. Limpie el sistema de tuberías antes del

montaje.

2. Instale un filtro antes del regulador ①.

Anchura máx.:

DN 15 - 25: 0.5 mm

DN 32 - 50: 0.8 mm

3. Instale indicadores de presión delante

y detrás de la parte del sistema a

controlar.

4. Instale la válvula

• Observe la dirección del caudal

indicada en la etiqueta del producto o

en la válvula ② ③.

• La válvula con conectores para soldar

solo pueden ser fijados a la tubería ④.

Los conectores para soldar solo

pueden soldarse sin la válvula y sin

sellos! ⑤⑥

Si estas instrucciones no se tienen en

cuenta, las altas temperaturas al soldar

pueden destruir los sellos.

• Las bridas ⑦ en la tubería deben estar

en posición paralela y las superficies

que sellan deben estar limpias y sin

ningún daño.

Apriete los tornillos en las bridas en

diagonal en 3 pasos hasta el máximo

(50 Nm).

5. Precaución:

No se permiten cargas mecánicas del

cuerpo de la válvula ⑧.

Aislamiento ➍

No aísle el actuador de presión ①.

Dimensiones, Pesos ❺

(See page 2)

Montaje

1)

Rosca externa cónica acc. to EN 10226-1

2)

Bridas PN 25, acc. to EN 1092-2

Posiciones permitidas de

instalación ❶

Temperatura del medio hasta 100 °C:

- Puede ser instalado en cualquier

posición ①.

Temperatura del medio > 100 °C:

- Instalación permitida sólo en

horizontal con el actuador hacia

abajo ②.

Posición de instalación y Esquema

de instalación ❷

SAVD montaje

73695090 DH -SMT/SI VI.DC .E2.8M © Danf oss 04/2011 8

Puesta en marcha ❻

La válvula está abierta si no hay presión.

La válvula cierra cuando la presión

después de la válvula ③ sobrepasa el

valor fijado.

Llenado del sistema, primera puesta

en marcha

1. Abra lentamente todos los dispositivos

de corte ① en la tubería de impulsión.

2. Abra lentamente todos los dispositivos

de corte ② en la tubería de retorno.

Escapes y Pruebas de presión

Para evitar presiones inadmisibles en el

actuador (el exceso de presión admisible

durante el funcionamiento 14 bar) es

absolutamente necesario quitar el tubo

de impulsión ④. Conexiones cerradas G ⁄

ISO 228 ⑤. En este caso la válvula está

siempre cerrada.

La presión debe ir aumentando

gradualmente en la conexión +/- .

El incumplimiento puede causar daños en

el actuador o la válvula.

Una prueba de presión del sistema

completo debe ser realizada de acuerdo

con las instrucciones del fabricante.

La presión máxima de prueba es: 1.5 × PN

PN ver etiqueta del producto!

Fuera de operación

1. Cierre lentamente los dispositivos de

corte ① en la tubería de impulsión.

2. Cierre lentamente los dispositivos de

corte ② en la tubería de retorno.

Ajustes ❼

Ajuste de la presión

El rango de ajuste de la presión se indica en

la etiqueta del producto ①.

Procedimiento:

1. Fije el caudal en la válvula de cierre ②

después del reductor de presión ③ en

aproximadamente el 50 % del caudal

máximo.

2. Ajuste

(de la presión detrás de la válvula)

Observe los indicadores de presión ④.

• Girando a la derecha ⑤ aumenta el

punto de ajuste (comprimiendo el

muelle).

• Girando a la izquierda ⑥ reduces el

punto de ajuste (relajando el muelle).

Sellado ❽

El punto de ajuste fijado puede sellarse con

un alambre sellado ①, i fuera necesario.

Función de seguridad ❾

Si el diafragma de control ① se rompe, la

presión llega en las dos cámaras intermedias ②.

Esta presión actúa sobre el diafragma de

seguridad ③ y ocurre lo siguiente:

- La válvula abre

- La función de control no funciona

- Una pérdida leve de agua a través de la

unión roscada ④ de la cubierta superior

indica la rotura del diafragma.

El regulador debe ser substituido cuando el

diafragma se rompe.

Page 9

SLOVENŠČINA

Varnostna opozorila

Izjemno pomembno je, da pred montažo

in zagonom skrbno preberete navodila in

se jih držite. S tem se izognete poškodbam

ljudi in okvaram na opremi.

Nujna sestavna, zagonska in vzdrževalna

dela lahko izvajajo samo kvalificirani, šolani

in pooblaščeni delavci.

Pred sestavo in vzdrževalnimi deli na

regulatorju mora biti sistem:

- tlačno izravnan,

- ohlajen,

- izpraznjen in

- očiščen.

Prosimo, upoštevajte navodila proizvajalca

sistema ali sistemskega operaterja.

Opis naprave

Regulator se uporablja za reduciranje tlaka

in kot zaščita proti previsokemu tlaku za

ventilom v sistemih ogrevanja, daljinskega

ogrevanja in hlajenja napolnjenih z vodo ali

z mešanico vode in glikola.

Tehnični podatki na etiketi izdelka določajo

uporabo.

Navodila za rokovanje z odsluženim

izdelkom

Pred recikliranjem ali

odlaganjem odsluženega

izdelka na odpad, ga je

potrebno razstaviti in

njegove sestavne dele, če je

le mogoče, sortirati po

skupinah.

Vedno upoštevajte lokalno zakonodajo

glede rokovanja z odpadki.

Montaža

Sistem za varnostnim reducirnim

ventilom mora biti varovan z varnostnim

nadzornikom SV ① or SÜV ②.

Preprečite nepooblaščeno odpiranje

zapornega ventila ③.

Vgradnja ventila ➌

1. Pred montažo očistite cevovod.

2. Pred regulator ① vgradite čistilni kos.

Maksimalna delitev mrežice:

DN 15 - 25: 0,5 mm

DN 32 - 50: 0,8 mm

3. Vgradite manometer pred in za sistem,

ki ga regulirate.

4. Vgradite ventil

• Upoštevajte puščico na etiketi

proizvoda oz. na proizvodu samem, ki

kaže smer pretoka ② ③.

• Ventil z vgrajenimi varilnimi priključki

se lahko samo pritrdi na cevovod ④.

Varilni priključki so nato lahko polno

varjeni samo brez ventila in tesnil! ⑤⑥

Ob neupoštevanju teh navodil lahko

visoke temperature pri varjenju uničijo

tesnila.

• Protiprirobnice ⑦ morajo biti

vzporedne, tesnilne površine morajo

biti čiste.in brez poškodb.

Pritegnite vijake na prirobnicah križem

v treh korakih do maksimalnega

momenta (50 Nm).

5. Opozorilo:

Mehanske obremenitve cevovoda na telo

ventila niso dovoljene ⑧.

Izolacija ➍

Tlačnega pogona ① ne izolirajte.

Dimenzije, masa ❺

(Glej stran 2)

1)

Konični zunanji navoj po EN 10226-1

2)

Prirobnice PN 25, glede na EN 1092-2

Test tesnosti in tlaka

Da bi preprečili nedopustno visoke tlake na

tlačnem pogonu (dopusten nadtlak med

delovanjem je 14 bar) je med preizkusom

absolutno potrebno odstraniti impulzno

cev ④. Priključke zaprite s čepi z navojem

G ⁄ ISO 228 ⑤. V tem primeru je ventil

vseskozi zaprt.

Na priključkih mora tlak naraščati

postopoma +/- .

Neskladnost z navodili lahko povzroči

poškodbe na pogonu ali na ventilu.

Tlačni preizkus celotnega sistema se mora

izvajati po navodilih proizvajalca..

Maksimalni preizkusni tlak je: 1,5 × PN

PN glejte napisno ploščico!

Jemanje iz obratovanja

1. Počasi zaprite zaporne organe ① v

dovodu.

2. Počasi zaprite zaporne organe ② v

povratku.

Nastavitev regulatorja ❼

Nastavitev nadtlaka

Področje nastavitev nadtlaka je prikazano

na etiketi na ohišju ①.

Postopek:

1. Nastavite pretok na zapornem ventilu

② za reducirnim ventilom ③ na okrog

50 % nazivnega pretoka.

2. Nastavitev tlaka za ventilom

Opazujte indikator tlaka ④.

• Z obračanjem v desno ⑤ (povišate

nastavitveno točko tlaka (napenjate

vzmet).

• Vrtenje v levo ⑥ znižuje nastavitveno

točko (sprostite vzmet).

Dopustni položaji vgradnje ❶

Temperatura medija do 100 °C:

- Lahko se vgradi v kateremkoli

položaju ①.

Temperatura medija > 100 °C:

- Vgradnja dovoljena samo v

horizontalni položaj tako, da je pogon

obrnjen navzdol. ②.

Lokacija namestitve in shema

vgradnje ❷

SAVD vgradnja v dovod

73695090 DH -SMT/SI VI.DC .E2.8M © Danf oss04/2011 9

Zagon ❻

TVentil je brez tlaka odprt. Ventil zapira

kadar tlak za ventilom ③ naraste nad

nastavljeno vrednost.

Polnjenje sistema, prvi zagon

1. Počasi odprite zaporne ventile v

povratnem vodu ①.

2. Počasi odprite zaporne ventile v

dovodnem cevovodu ②.

Plombiranje ❽

Element za nastavitev diferenčnega tlaka se

lahko plombira s plombirno žico ①, če je to

zahtevano.

Varnostna funkcija ❾

Če se regulacijska membrana ① poškoduje,

tlak v vmesnem prostoru ② naraste. Ta

tlak deluje na varnostno membrano ③ in

povzroči naslednje:

- Ventil se zapre

- Delovna regulacija tlaka ne deluje

- Majhno puščanje na navojnem stiku ④

zgornjega ohišja nakazuje poškodbo

delovne membrane.

Ob poškodbi membrane je potrebno

regulator zamenjati.

Page 10

POLSKI

Warunki bezpieczeństwa

W celu uniknięcia zranienia osób

i uszkodzenia urządzeń należy

bezwzględnie przed montażem i

uruchomieniem zaworu zapoznać się

dokładnie z niniejszą instrukcją.

Czynności związane z montażem,

uruchomieniem i obsługą mogą

być dokonywane wyłącznie przez

osoby uprawnione i odpowiednio

wykwalifikowane.

Przed montażem i obsługą konserwacyjną

regulatora należy:

- zrzucić ciśnienie,

- ostudzić urządzenia,

- opróżnić układ,

- oczyścić.

Prosimy stosować się do instrukcji

producenta lub operatora układu.

Zastosowanie

Regulator jest stosowany do redukcji

ciśnienia oraz dla ochrony przed

nadmiernym ciśnieniem za zaworem.

Regulator jest stosowany dla wody i

roztworów wody z glikolem w instalacjach

grzewczych, sieciach cieplnych i

instalacjach chłodzenia.

Regulator zaprojektowany i badany zg. z

DIN 4747 (SAV) i wytycznymi AGFW.

Instrukcja usuwania odpadów

Ten produkt powinien być

rozebrany a jego

komponenty

posegregowane, jeśli to

możliwe, na różne grupy

przed poddaniem

recyklingowi lub utylizacji.

Zawsze stosuj się do miejscowych

przepisów w zakresie usuwania

odpadów.

Montaż

Miejsce i schemat montażu ❷

Montaż SAVD

Układ za reduktorem z funkcją

bezpieczeństwa musi być wyposażony w

zawór bezpieczeństwa SV ① albo SÜV ②.

Należy zabezpieczyć armaturę

odcinającą ③ przed otwarciem przez

osoby niepowołane.

Montaż zaworu ➌

1. Przed zamontowaniem zaworu

przepłukać instalację.

2. Przed regulatorem zamontować filtr ①.

Max. rozmiar oczek siatki

DN 15 - 25: 0,5 mm

DN 32 - 50: 0,8 mm

3. Zamontować manometry przed i

za tą częścią układu, która będzie

regulowana.

4. Zamontować zawór.

• Należy zachować kierunek przepływu

zaznaczony na tabliczce znamionowej

lub na korpusie zaworu ② ③.

• Zawór z zamocowanymi końcówkami

do przyspawania może być tylko

punktowo przyspawany do

rurociągu ④.

Końcówki mogą być przyspawane

tylko bez zaworu i uszczelnienia! ⑤⑥

Nie zastosowanie się do tego zalecenia

może spowodować uszkodzenie

uszczelnień wskutek wysokiej

temperatury.

• Kołnierze ⑦ na rurociągu muszą

być równoległe a powierzchnie pod

uszczelki czyste i bez uszkodzeń.

Dokręcać śruby przy kołnierzach po

przekątnej, w trzech krokach, aż do

uzyskania maksymalnego momentu

(50 Nm).

5. Uwaga:

Nie można dopuścić do powstania

mechanicznych obciążeń korpusu zaworu

od rurociągów ⑧.

Izolacja. ➍

Nie izolować siłownika ①.

Uruchomienie ❻

Bez oddziaływania ciśnienia zawór

pozostaje otwarty. Zawór zamyka się,

kiedy ciśnienie ③ za zaworem wzrasta

powyżej nastawionej wartości.

Napełnienie układu, pierwsze

uruchomienie.

1. Powoli otworzyć zawory odcinające ①

na rurociągu zasilającym.

2. Powoli otworzyć zawory odcinające ②

na rurociągu powrotnym.

Próby szczelności i ciśnienia.

Dla uniknięcia nadmiernego ciśnienia

na siłowniku (dopuszczalne cinienie

nadmiarowe w czasie pracy wynosi 14

bar) należy koniecznie odłączyć rurkę

impulsową ④. Podłączenia zamknąć

korkami G ⁄ ISO 228 ⑤.

Ciśnienie na podłączeniach +/- należy

zwiększać stopniowo.

Nie przestrzeganie powyższych zasad

może spowodować uszkodzenie siłownika

lub zaworu.

Próba ciśnienia dla całego układu musi

być przeprowadzona zgodnie z instrukcją

producenta lub projektanta.

Maksymalne ciśnienie próbne wynosi:

1,5 × PN

Ciśnienie nominalne PN podano na

tabliczce znamionowej urządzenia.

Odłączenie zaworu.

1. Powoli zamknąć armaturę odcinającą ①

na rurociągu zasilającym.

2. SPowoli zamknąć armaturę

odcinającą ② na rurociągu powrotnym.

Dopuszczalne pozycje montażu. ❶

Temperatury czynnika do 100 °C:

- montaż w dowolnej pozycji ①.

Temperatury czynnika > 100 °C:

- Montaż dozwolony tylko na rurociągu

poziomym, z siłownikiem skierowanym

w dół ②.

73695090 DH -SMT/SI VI.DC .E2.8M © Danf oss 04/2011 10

Dimensions, Weights ❺

(See page 2)

1)

Stożkowy gwint zewnętrzny wg

EN 10226-1

2)

Kołnierze PN 25 wg EN 1092-2

Page 11

Nastawy. ❼

Nastawa ciśnienia.

Zakres nastawy ciśnienia podano na

tabliczce znamionowej zaworu ①.

Tok postępowania:

1. Ustawić przepływ zaworem

regulacyjnym ② przez zawór

redukcyjny ③, na ok. 50% przepływu

maksymalnego.

2. Dokonać nastawienia

(ciśnienia za zaworem).

Obserwować wskazania manometru ④.

• Obracanie w prawo ⑤ zwiększa

wartość nastawy (ściskanie sprężyny).

• Obracanie w lewo ⑥ zmniejsza

wartość nastawy (luzowanie sprężyny).

Plomba. ❽

Nakrętka nastawcza może zostać w razie

potrzeby zaplombowana ①.

Funkcja bezpieczeństwa. ❾

Jeżeli membrana regulująca ① przecieka,

ciśnienie przedostaje się do dwóch

komór pośrednich ② i oddziaływując na

membranę bezpieczeństwa ③ powoduje:

- zamknięcie zaworu,

- zaprzestanie działania regulacyjnego

zaworu,

- niewielki wypływ czynnika przez

gwintowane złącze ④ w górnej części

obudowy, wskazujący na przerwanie

membrany.

Jeżeli membrana jest przerwana, należy

wymienić regulator.

73695090 DH -SMT/SI VI.DC .E2.8M © Danf oss04/2011 11

Page 12

РУССКИЙ

Правила техники безопасности

Для предупреждения травматизма и

повреждения оборудования перед

началом производства работ по его

монтажу и вводу в эксплуатацию

следует изучить и соблюдать настоящую

инструкцию.

Монтаж, наладку и техническое

обслуживание оборудования может

выполнять только квалифицированный

персонал, имеющий допуск к таким

работам.

В целях соблюдения правил техники

безопасности перед началом работ по

монтажу или обслуживанию регулятора

необходимо произвести следующие

действия с трубопроводной системой:

- сбросить давление;

- охладить;

- опорожнить;

- прочистить.

При этом также должна соблюдаться

инструкция по эксплуатации системы.

Область применения

Регулятор используется для понижения

давления воды или водного раствора

гликоля после клапана и защиты от

превышения давления в системах

централизованного теплоснабжения или

охлаждения.

Условия применения регулятора

определяются техническими

характеристиками, указанными на

этикетке изделия.

Инструкция по утилизации

Данная продукция

подлежит демонтажу на

части, для раздельной

утилизации составных

компонентов.

Монтаж

Монтажные положения

регулятора ❶

Температура регулируемой среды до

100 °C:

- Регулятор может устанавливаться в

любом положении ①.

Температура регулируемой среды выше

100 °C:

- IУстановка регулятора разрешается

только на горизонтальном

трубопроводе регулирующим

элементом вниз ②.

Размещение регулятора и схема

установки ❷

Установка SAVD на подающем

трубопроводе

Система, находящаяся после

регулятора, должна быть защищена

с помощью предохранительных

устройств ① или ②.

Убедитесь что запорная арматура ③

защищена от несанкционированного

доступа.

Монтаж клапана ➌

1. Перед монтажом клапана промойте

трубопроводную систему.

2. До регулятора установите сетчатый

фильтр ① с максимальным размером

ячейки его сетки:

для Ду = 15-25 мм – 0,5 мм;

для Ду = 32-50 мм – 0,8 мм.

3. Для контроля давлений до и

после ррегулятора необходимо

предусмотреть показывающие

манометры.

4. Установите клапан так, чтобы

направление стрелки на этикетке

клапана ② или на его корпусе ③

совпадало с направлением движения

регулируемой среды.

• Резьбовой клапан монтируется с

помощью приварных фитингов,

которые при установленном

между ними клапане должны

предварительно фиксироваться на

трубопроводе прихваткой ④.

Окончательная приварка фитингов к

трубопроводу может производиться

только при отсутствии клапана и

уплотнительных прокладок! ⑤⑥

• При несоблюдении этих инструкций

высокая температура сварки может

повредить уплотнения фитингов и

самого клапана.

• Фланцы ⑦ на трубопроводе должны

быть установлены параллельно и их

уплотняемые поверхности должны

быть чистыми и без повреждений.

Болты на фланцах следует затягивать

крестообразно в три этапа до

достижения максимального

крутящего момента (50 Hм).

5. Внимание!

Механические нагрузки на корпус

клапана от трубопроводов

недопустимы ⑧.

Тепловая изоляция ➍

Не изолируйте регулирующий элемент

регулятора давления ①.

Габаритные и присоединительные

размеры ❺

(See page 2)

1)

Коническая наружная резьба

соответствует EN 10226-1

2)

Фланцы Pу 25 соответствуют

EN 1092-2

Запуск ❻

Клапан открыт при отсутствии

давления. Клапан закрывается при

увеличении давления после него ③

выше установленного значения.

Заполнение системы, первый пуск

1. Медленно откройте запорные

устройства ① на подающем

трубопроводе.

2. Медленно откройте запорные

устройства ② на обратном

трубопроводе.

Испытания на прочность и

герметичность

При гидравлическом испытании

во избежание недопустимого

давления на регулирующем элементе

(максимальное испытательное давление

14 бар) обязательно должна быть снята

импульсная трубка ④. Закройте место

присоединения трубки заглушкой G ⁄

ISO 228 ⑤.

Показания манометров,

установленных в точках +/-, должны

увеличиваться.

Если этого не происходит, то вероятно

поврежден клапан или регулирующий

элемент.

Испытания на герметичность всей

системы должны проводиться

в соответствии с инструкциями

производителей оборудования.

Максимальное испытательное давление

определяется как: 1,5 Pу

Pу (PN) указывается на этикетках

оборудования.

Вывод из эксплуатации

1. Медленно закройте запорные

устройства ① на подающем

трубопроводе.

2. Медленно закройте запорные

устройства ② на обратном

трубопроводе.

73695090 DH -SMT/SI VI.DC .E2.8M © Danf oss 04/2011 12

Page 13

Установка значений

регулируемых величин ❼

Установка давления

Диапазон установки давления указан на

этикетке регулирующего блока ①.

Последовательность:

1. SУстановите с помощью клапана

② после регулятора давления ③

расход на уровне примерно 50 % от

максимального значения.

2. Настройка давления

(после клапана).

Следя за показаниями манометра ④,

поверните настроечную гайку по

часовой стрелке ⑤ для увеличения

устанавливаемого значения (пружина

сжимается).

Вращение против часовой стрелки ⑥

снижает устанавливаемое значение

(ослабляет пружину).

Пломбирование ❽

При необходимости устройство

регулировки давления может быть

опломбировано пломбировочной

проволокой ①.

Функция безопасности ❾

Если прорывается регулирующая

мембрана, давление распределяется

между вспомогательными

камерами ②, которое воздействует

на предохранительную мембрану ③ и

вызывает:

- закрытие клапана;

- отказ регулятора;

- небольшую протечку воды через

резьбовое отверстие ④, что

сигнализирует о разрыве мембраны.

Регулирующий элемент должен быть

заменен, если мембрана повреждена.

73695090 DH -SMT/SI VI.DC .E2.8M © Danf oss04/2011 13

Page 14

73695090 DH -SMT/SI VI.DC .E2.8M © Danf oss 04/2011 14

Page 15

73695090 DH -SMT/SI VI.DC .E2.8M © Danf oss04/2011 15

Page 16

16 VI.DC .E2.8M

Produce d by Danfoss A/S © 04/ 2011

Loading...

Loading...