Page 1

Technical Information

Steering

SASA Sensor

powersolutions.danfoss.com

Page 2

Technical Information

SASA Sensor

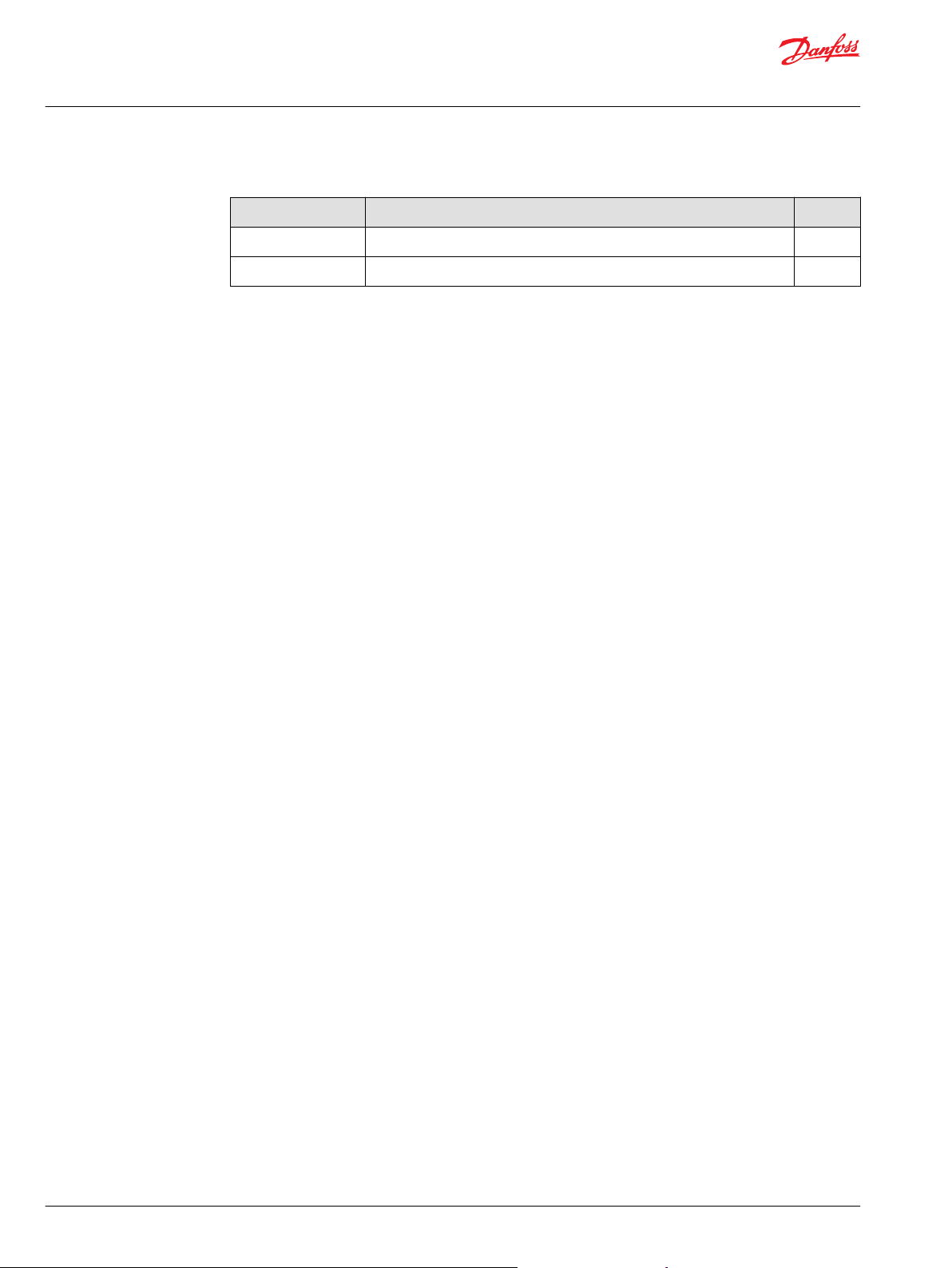

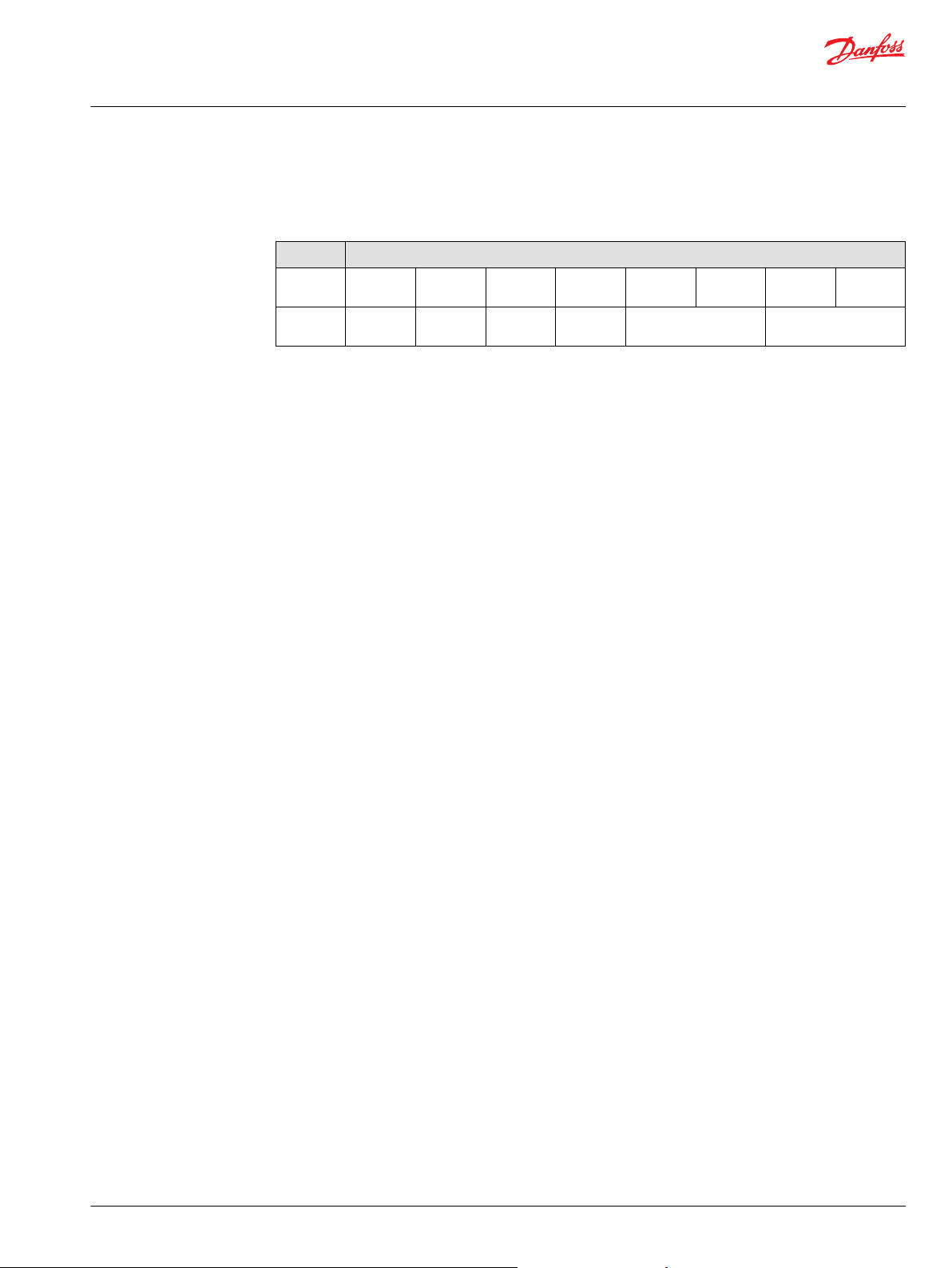

Revision history Table of revisions

Date Changed Rev

Nov 2017 Replaced SAK Adapter image on page 20 0102

March 2016 First edition 0101

2 | © Danfoss | Nov 2017 BC00000356en-US0102

Page 3

Technical Information

SASA Sensor

Contents

Sensor type SASA general

Versions, code numbers and weights for SASA sensor

SASAIIC

SASAIIC CAN message protocol..................................................................................................................................................6

SASAIIC parameter setup...............................................................................................................................................................7

SASAIIC technical data....................................................................................................................................................................8

SASAIID

SASAIID CAN message protocol..................................................................................................................................................9

SASAIID configuration protocol................................................................................................................................................12

Read data by identifier............................................................................................................................................................12

Write data by identifier...........................................................................................................................................................14

SASAIID configuration data list.................................................................................................................................................17

SASAIID technical data.................................................................................................................................................................18

Dimensions SASA sensor

SAK

Code number and weight, SAK adapter kit..........................................................................................................................20

SAK adapter kit................................................................................................................................................................................20

Installation

Wiring guidelines...........................................................................................................................................................................22

©

Danfoss | Nov 2017 BC00000356en-US0102 | 3

Page 4

Technical Information

SASA Sensor

Sensor type SASA general

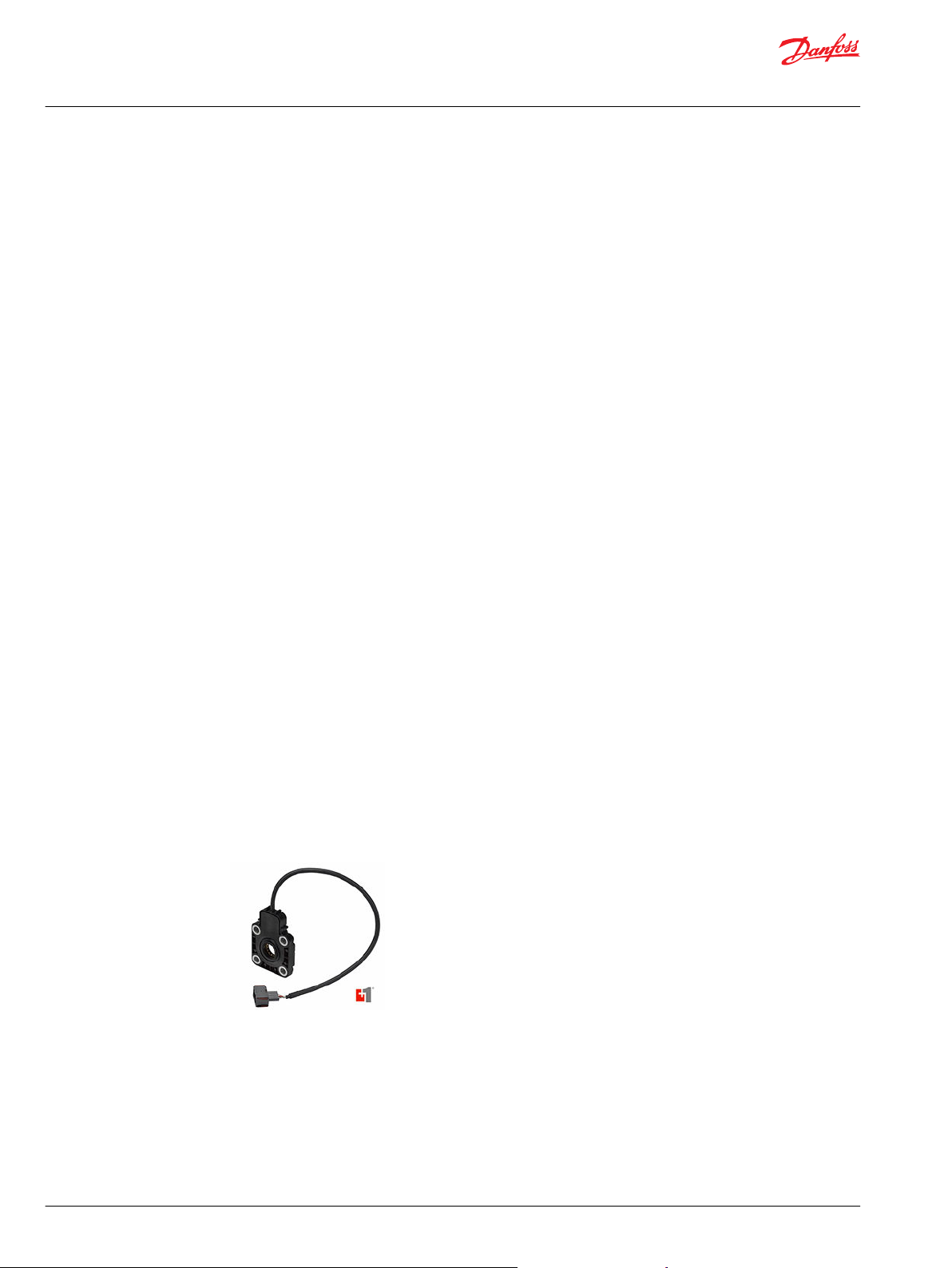

The SASA sensor detects the absolute position and speed of the steering wheel. The sensor can be used

in electro-hydraulic steering systems using Danfoss OSPE, EHI, or EHPS steering valves with

programmable controller or in any other steering system where the rotation of the steering wheel must

be detected as an electronic signal.

There are two versions available of SASA sensors:

SASAIIC used for PVED-CL actuator. SASAIIC has single CAN output signal and “fail silent” concept

SASAIID used for PVED-CLS actuator and general usage. SASAIID has dual CAN output signal.

The use of SASA sensor is relevant e.g. for variable steering ratio and closed loop set-ups where steering

wheel position and steering angle have to match.

The SASA sensor also can be used for “kick out” of Auto-steering. When the steering valve is in autoguidance mode, and the driver wants to swap to manual steering, a signal from the SASA sensor will

deactivate the Auto-steering and the steering wheel movement has priority.

SASA is based on a non-contact inductive principle giving a very high resolution.

The sensor features a robust design and resists e.g. electro-magnetic radiation.

The output is a CAN signal, which makes it easy to interface to advanced vehicle controllers and to

Danfoss PVED-CLS actuators for steering valves.

The steering wheel shaft turns the rotor of the SASA sensor, and the sensor is simply mounted between

steering unit and steering column. The shaft of the steering column must be 15 mm longer when using

SASA sensor.

In cases where customers want to use the same steering column in applications with and without SASA

sensors, Danfoss offers an adapter kit type SAK to built in between column and sensor.

The SASA sensor offers the following features:

High resolution < 0.1°

•

Output CAN signal

•

High safety

•

SASAIIC: “fail silent” concept

‒

SASAIID: two output messages concept

‒

SASAIID is PLUS+1® Compliant

•

Flanged in between steering unit and column

•

Compact design

•

4 | © Danfoss | Nov 2017 BC00000356en-US0102

Page 5

Technical Information

SASA Sensor

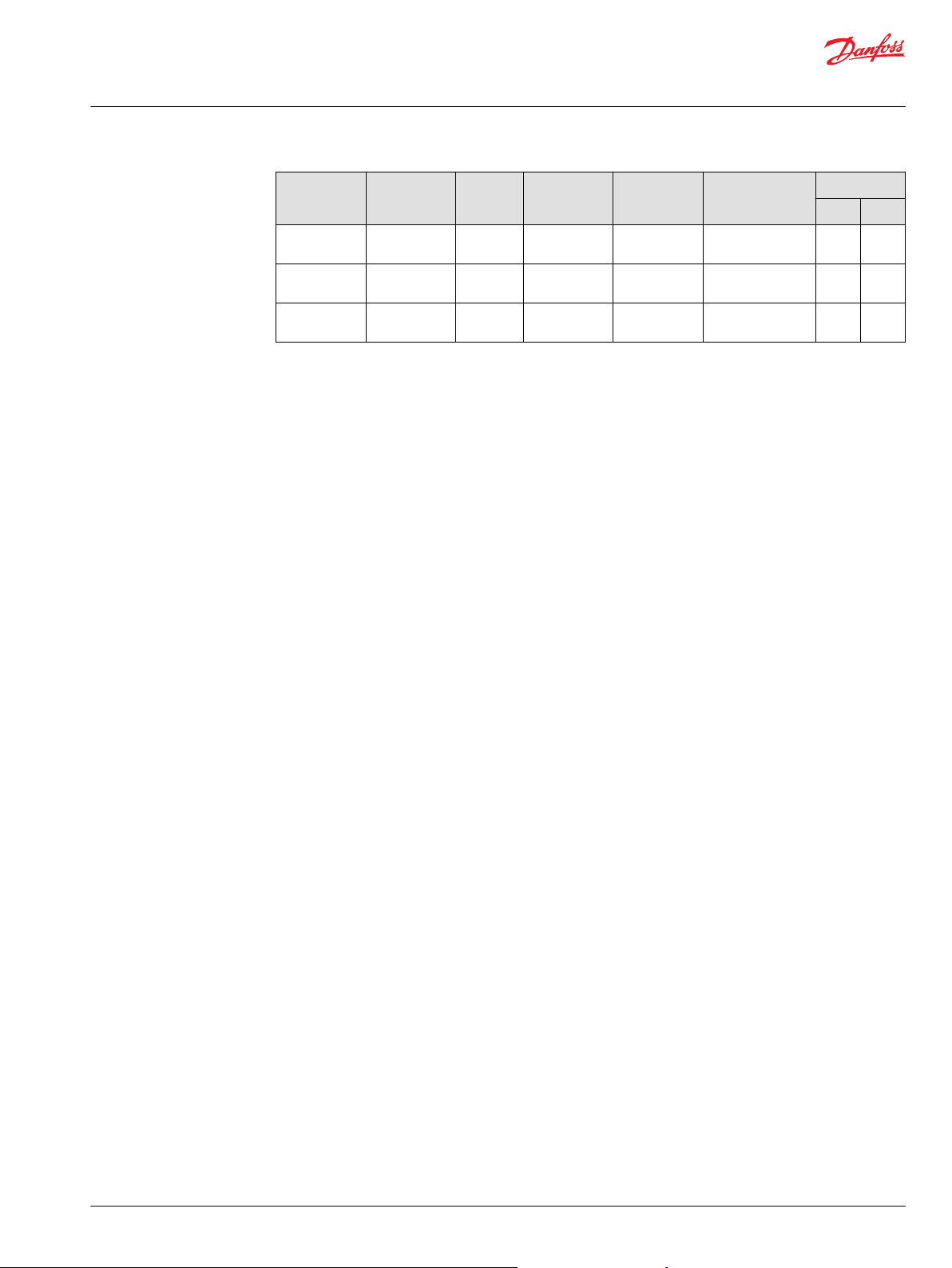

Versions, code numbers and weights for SASA sensor

Code number Type Supply

voltage

11088656 SASAIIC, CAN 9 - 32 VDCNo 500 mm AMP code no.

11099289 SASAIIC, CAN 9 - 32 VDCNo 500 mm DEUTSCH DT04-4P-

11116505 SASAIID, CAN 6 - 36 VDCNo 500 mm DEUTSCH DT04-4P-

Termination

resistor

Cable length Connector Weight

2-967059-1

CE02

CE02

kg [lb]

0.25 [0.55]

0.25 [0.55]

0.25 [0.55]

©

Danfoss | Nov 2017 BC00000356en-US0102 | 5

Page 6

Technical Information

SASA Sensor

SASAIIC

SASAIIC CAN message protocol

Interface: CAN 2.0 B

Baud rate: 125 kBaud, 250 kBaud (default), 500 kBaud

SASA returns cyclic the following CAN message every 5, 10 (default) or 20 ms.

301 h Data

0

Low byte1High byte

ID Steering angle Count Steering angle change Status CRC-16

2 3

5 6

Low byte4High byte

Low byte

Identifier 301h (11 bit)

7

High byte

Steering

angle

12 bit word (0 – 4095) relative to a 0-index point.

0 = 0 degrees

4095 = 359,912 degrees

Overflow at 4095 for CW activation shall increment 0

Underflow at 0 for CCW activation shall decrement 4095

Count Byte (0-255)

Increments 1 for each message

Steering

angle change

Difference between 2 transmitted position values in succession.

16 bit integer with 2’s complementary encoding for negative values (-32768 to 32767).

-4095 = -359,912 degrees

0 = 0 degrees

4095 = 359,912 degrees

Status

7 6 5 4 3 2 1 0

- - - - - - - Progamming mode

Programming

mode

Normal state is 1

Response with a 0 when starting the programming sequence

(See the programming sequence described below under setup

message)

CRC-16 The standard CRC16 polynomial is used (x^16+x^15+x^2+1)

6 | © Danfoss | Nov 2017 BC00000356en-US0102

Page 7

Technical Information

SASA Sensor

SASAIIC

SASAIIC parameter setup

Setup message: sensor can be programmed as shown in the CAN setup message

below.

0C0h Data

0 1 2 3 4 5 6

ID Baud rate Data rate Set 0-

index

Identifier 0C0h (11 bit)

Baud rate During the programming sequence, byte 0 is set to:

02h for 125 kBaud

•

03h for 250 kBaud (default)

•

04h for 500 kBaud

•

Data rate During the programming sequence, byte 1 is set to:

02h for 5 ms

•

03h for 10 ms (default)

•

04h for 20 ms

•

Programming

sequence

Low byte7High byte

CRC-16

Set 0-index If byte 2 is set to AAh during the programming sequence, the actual angle will be

stored as a reference value (0 degree) in persistent memory.

Programming

sequence

CRC-16 The standard CRC16 polynomial is used (x^16+x^15+x^2+1)

The following sequence is used when programming the sensor.

1. The controller unit sends a setup message where byte 4 is set to AAh and byte 5

is set to 55h.

2. The sensor answers with a 0 on the status byte (bit 0).

The control unit then sends a setup message where byte 4 is set to 0Fh and

3.

byte 5 is set to F0h.

The first and second message shall match.

4. After receiving the last message the programming takes place in the sensor if

the parameters are in the defined range, the timeout period has not been

exceeded and the CRC-16 check is correct in both messages.

5. After programming the status bit in the output message changes back from 0

to 1.

6. If the controller's second message does not come within 1 second after the

controller's first message, the programming sequence will be aborted.

©

Danfoss | Nov 2017 BC00000356en-US0102 | 7

Page 8

Technical Information

SASA Sensor

SASAIIC

SASAIIC technical data

Mechanical

Input range: Continuous 360° rotation

Rotor torque: ≤ 0.2 N•m

Expected life: > 10 million cycles

Electrical

Supply voltage: 9 - 32 V

Power consumption: <1 W

DC

Output

CAN V2.0B, (compatible to J1939)

Termination resistor: 120 ohm (optional)

Baud rate: 125, 250 or 500 kb/s

Angle: 12-bit word (0 - 4095) relative to a programmable 0-index point.

Resolution: < 0.1°

Linearity: 1% of full scale

Angle change: 16 bit integer with 2’s complementary encoding for negative values (-32768 to 32767).

Safety function

If a failure occurs, the SASA CAN transceiver will be disabled.

Environmental

Operating temperature: -30° to 85°C [-22 to 185°F]

Storage temperature: -40° to 105°C

Sealing: IP65

EMI/RFI Rating: 100 V/m

Vibration: Meets IEC 60068-2-64

Shock: Meets IEC 60068-2-27 test Ea

8 | © Danfoss | Nov 2017 BC00000356en-US0102

Page 9

Technical Information

SASA Sensor

SASAIID

SASAIID CAN message protocol

Dual CAN output

The PVED-CLS (valve controller) can interface to a SASA with redundant output. A safety function that

compares the two output messages from SASA is implemented in the PVED-CLS. There is a 180-degree

phase shift between the two angles transmitted in the messages. Steering angle 1 and steering angle 2

are sampled with a delay < 2ms. The ID1 and ID2 messages are transmitted with a delay < 5ms. It is

possible to configure the sensor to transmit cyclic 1 or 2 messages.

Interface: CAN 2.0 B

Baud rate: 250 kBaud

Transmit rate: 10, 20, 50 (default), 100, 200 ms (cyclic message transmission, 1 or 2 messages, tolerance: ±

10%)

Proprietary

B

29-bit

ID1 Steering angle 1 Steering angle velocity 1 Reserved Status CRC-16

Data

0 1 2 3 4 5 6 7

Identifier J1939 proprietary B. Programmable 29 bit message id.

ID1 = $0CFFYYXX

PGN-offset1 YY is programmable, default value is $10

Source Address XX is programmable, default value is $4D

Steering

angle 1

Data byte 0-1: Value measured by angle sensor 1 relative to the 0-index point.

16-bit integer

0 corresponds to 0 degrees

4095 corresponds to 359.912 degrees

Overflow at 4095 for CW activation shall increment 0

Underflow at 0 for CCW activation shall decrement 4095

4096 – 65534: Not available

65535:Sensor failure

Steering

angle

velocity 1

Data byte 2-3: Velocity of the rotor measured by sensor 1.

16-bit integer

0 corresponds to -300 RPM (CCW)

20480 corresponds to 0 RPM

40960 corresponds to 300 RPM (CW)

40961 – 65534: Not available

65535: Sensor failure

Reserved Data byte 4: $FF

Status Data byte 5

©

Danfoss | Nov 2017 BC00000356en-US0102 | 9

Page 10

Technical Information

SASA Sensor

SASAIID

7 6 5 4 3 2 1 0

Error Code Sequence number

Error Code Bit 4-7

$0 - Reserved

$1 - Sensor Chip Error

$2 - Steering angle failure

$3 - CAN input message failure

$4 - Power failure

$5 - CPU failure

$6 - Memory failure

$7-$D - Reserved

$E - Temperature warning

$F - No error

Sequence number Bit 0-3

Increments 1 for each message.

Valid range is $0 - $F

CRC-16 Data byte 6-7: The CRC16 polynomial 0xC86C is used to calculate a checksum for byte

0-5.

Width - 16

Init - 0x0000

Ref-In - False

Ref-Out - False

Xor-Out - 0x000

Check - 0x6774

'Check' is the CRC result for UTF-8 string “123456789”.

The above parameters conform to the Rocksoft™ Model CRC Algorithm.

Proprietary

B

29-bit

ID2 Steering angle 2 Steering angle velocity 2 Reserved Status CRC-16

Data

0 1 2 3 4 5 6 7

Identifier 2

(Optional)

J1939 proprietary B. Programmable 29 bit message id.

ID2 = $0CFFZZXX

PGN-offset2 ZZ is programmable, default value is $11

Source Address XX is programmable, default value is $4D

10 | © Danfoss | Nov 2017 BC00000356en-US0102

Page 11

Technical Information

SASA Sensor

SASAIID

Steering

angle 2

Data byte 0-1: Value measured by angle sensor 2 (with a 180 degree offset to Steering

angle 1).

16-bit integer

0 corresponds to 180 degrees

4095 corresponds to 179.912 degrees

Overflow at 4095 for CW activation shall increment 0

Underflow at 0 for CCW activation shall decrement 4095

4096 – 65534: Not available

65535:Sensor failure

Steering

angle

velocity 2

Data byte 2-3: Velocity of the rotor measured by sensor 2.

16-bit integer

0 corresponds to -300 RPM (CCW)

20480 corresponds to 0 RPM

40960 corresponds to 300 RPM (CW)

40961 – 65534: Not available

65535: Sensor failure

Reserved Data byte 4: $FF

Status Data byte 5

7 6 5 4 3 2 1 0

Error Code Sequence number

Error Code Bit 4-7

$0 - Reserved

$1 - Sensor Chip Error

$2 - Steering angle failure

$3 - CAN input message failure

$4 - Power failure

$5 - CPU failure

$6 - Memory failure

$7-$D - Reserved

$E - Temperature warning

$F - No error

Sequence number Bit 0-3

Increments 1 for each message.

Valid range is $0 - $F

CRC-16 Data byte 6-7: The CRC16 polynomial 0xC86C is used to calculate a checksum for byte

0-5.

©

Danfoss | Nov 2017 BC00000356en-US0102 | 11

Page 12

Technical Information

SASA Sensor

SASAIID

SASAIID configuration protocol

The sensor complies with the PLUS+1® Lite Diagnostic Communication Protocol – UDS.

The services to configure the sensor are:

•

•

Width - 16

Init - 0x0000

Ref-In - False

Ref-Out - False

Xor-Out - 0x000

Check - 0x6774

'Check' is the CRC result for UTF-8 string “123456789”.

The above parameters conform to the Rocksoft™ Model CRC Algorithm.

Read data by identifier on page 12

Write data by identifier on page 14

Read data by identifier

This service is used for retrieving the value of a given parameter.

29 bit CAN identifier PCI and Frame data bytes

Byte #0 Byte #1 Byte #2 Byte #3

CAN ID PCI Service ID

ID – Sub function

(MSB first)

CAN ID ID = $1BC788XX (The sensor node address XX is configurable, default value is $4D, and the

Danfoss diagnostic tester node address is $F1)

ID = $1BC78FFF (Used for broadcast requests, i.e. when the Danfoss diagnostic tester is

requesting the configuration address format)

29 bit CAN identifier

Priority Extended

data page

28 27 26 25 24 23 22

1 1 0 1 1 1 1 000 11110001 000 01001101

29 bit CAN identifier

Priority Extended

data page

28 27 26 25 24 23 22

1 1 0 1 1 1 1 000 11110001 111 11111111

Data

page

Data

page

Type of

service (TOS)

$1BC7884D

Type of

service (TOS)

$1BC78FFF

Source address Destination address

net node net node

211918

11

Source address Destination address

net node net node

211918

11

10

8

10

8

7

0

7

0

12 | © Danfoss | Nov 2017 BC00000356en-US0102

Page 13

Technical Information

SASA Sensor

SASAIID

PCI PCI = $03 (PCI type = 0, SF Data Length = 3)

Service ID SID = $22 –Read Data by Identifier

ID - Sub

See SASAIID configuration data list on page 17

function

Positive response

This message is used as positive response to a Read Data by Identifier request.

29 bit CAN identifier PCI and Frame data bytes

Byte #0 Byte #1 Byte #2 Byte #3 Byte #4 Byte #5 Byte #6 Byte #7

CAN ID PCI Service ID

ID – Sub function

(MSB first)

Value

CAN ID ID = $1BC268F1 (Here shown with the default sensor node address $4D, and the Danfoss

diagnostic tester node address $F1)

29 bit CAN identifier

Priority Extended

data page

28 27 26 25 24 23 22

1 1 0 1 1 1 1 000 01001101 000 11110001

Data

page

Type of

service (TOS)

$1BC268F1

Source address Destination address

net node net node

211918

11

10

8

7

0

PCI PCI = $0X (PCI type = 0, SF Data Length = X)

Service ID SID = $62 –Positive response ID to a Read Data by Identifier request.

ID - Sub

See SASAIID configuration data list on page 17

function

Value See SASAIID configuration data list on page 17

Negative response

This message is used as negative response to a Read Data by Identifier request.

29 bit CAN identifier PCI and Frame data bytes

Byte #0 Byte #1 Byte #2 Byte #3

CAN ID PCI Service ID

ID – Sub function

(MSB first)

CAN ID ID = $1BC268F1 (Here shown with the default sensor node address $4D, and the Danfoss

diagnostic tester node address $F1)

©

Danfoss | Nov 2017 BC00000356en-US0102 | 13

Page 14

Technical Information

SASA Sensor

SASAIID

29 bit CAN identifier

Priority Extended

data page

28 27 26 25 24 23 22

1 1 0 1 1 1 1 000 01001101 000 11110001

Data

page

Type of service

(TOS)

$1BC268F1

PCI PCI = $03 (PCI type = 0, SF Data Length = 3)

Service ID SID = $7F –Negative response ID

Source address Destination address

net node net node

211918

11

10

8

7

0

ID - Sub

$22XX (For XX, see the following table)

function

Byte 2 Error message Error cause Service Tool response

$13 Incorrect

Message Length

Or Invalid

Format

$22 Conditions Not

Correct

$31 Request Out Of

Range

$33 Security Access

Denied

$78 Response

pending

The length of the message is wrong Resend correct command

This code shall be returned if operating

conditions of the server for performing

the required action are not met.

This code shall be sent if:

1. none of the requested data

identifier values are supported by

the device

2. the client exceeded the maximum

number of data identifiers allowed

to be requested at a time

This code shall be sent if at least one of

the data identifiers is secured and the

server is not in an unlocked state

Routine needs more time Extend P2_CAN_Server_max

Write data by identifier

This service is used for writing configuration data.

Resend command later

Resend with correct/fewer

IDs

Perform security access

routine

to P2*_CAN_Server_max

29 bit CAN identifier PCI and Frame data bytes

Byte #0 Byte #1 Byte #2 Byte #3 Byte #4 Byte #5 Byte #6 Byte #7

CAN ID PCI Service ID

ID – Sub function

(MSB first)

Value

CAN ID ID = $1BC788XX (The sensor node address XX is configurable, default value is $4D, and the

Danfoss diagnostic tester node address is $F1)

14 | © Danfoss | Nov 2017 BC00000356en-US0102

Page 15

Technical Information

SASA Sensor

SASAIID

29 bit CAN identifier

Priority Extended

data page

28 27 26 25 24 23 22

1 1 0 1 1 1 1 000 11110001 000 01001101

Data

page

Type of

service (TOS)

$1BC7884D

PCI PCI = $0X (PCI type = 0, SF Data Length = X)

Service ID SID = $2E –Write Data by Identifier

Source address Destination address

net node net node

211918

11

10

8

7

0

ID - Sub

See SASAIID configuration data list on page 17

function

Value See SASAIID configuration data list on page 17

Positive response

This message is used as positive response to a Write Data by Identifier request.

29 bit CAN identifier PCI and Frame data bytes

Byte #0 Byte #1 Byte #2 Byte #3

CAN ID PCI Service ID

ID – Sub function

(MSB first)

CAN ID ID = $1BC268F1 (Here shown with the default sensor node address $4D, and the Danfoss

diagnostic tester node address $F1)

29 bit CAN identifier

Priority Extended

data page

28 27 26 25 24 23 22

1 1 0 1 1 1 1 000 01001101 000 11110001

Data

page

Type of

service (TOS)

$1BC268F1

Source address Destination address

net node net node

211918

11

10

8

7

0

PCI PCI = $03 (PCI type = 0, SF Data Length = 3)

Service ID SID = $6E –Positive response ID to a Write Data by Identifier request.

ID - Sub

See SASAIID configuration data list on page 17

function

Negative response

This message is used as negative response to a Write Data by Identifier request.

29 bit CAN identifier PCI and Frame data bytes

Byte #0 Byte #1 Byte #2 Byte #3

CAN ID PCI Service ID

©

Danfoss | Nov 2017 BC00000356en-US0102 | 15

ID – Sub function

(MSB first)

Page 16

Technical Information

SASA Sensor

SASAIID

CAN ID ID = $1BC268F1 (Here shown with the default sensor node address $4D, and the Danfoss

diagnostic tester node address $F1)

29 bit CAN identifier

Priority Extended

data page

28 27 26 25 24 23 22

1 1 0 1 1 1 1 000 01001101 000 11110001

Data

page

Type of service

(TOS)

$1BC268F1

Source address Destination address

net node net node

211918

11

10

8

7

0

PCI PCI = $03 (PCI type = 0, SF Data Length = 3)

Service ID SID = $7F –Negative response ID

ID - Sub

function

$2EXX (For XX, see the following table)

Byte 2 Error message Error cause Service Tool response

$13 Incorrect Message

Length Or Invalid

Format

$22 Conditions Not

Correct

$31 Request Out Of

Range

$33 Security Access

Denied

$72 General

Programming

Failure

$78 Response pending Routine needs more time Extend

The length of the message is wrong Resend correct command

This code shall be returned if

operating conditions of the server for

performing the required action are

not met.

This code shall be sent if:

1. none of the requested data

identifier values are supported by

the device

2. the client exceeded the maximum

number of data identifiers allowed

to be requested at a time

This code shall be sent if at least one

of the data identifiers is secured and

the server is not in an unlocked state

This return code shall be sent if the

server detects an error when writing

to a memory location

Resend command later

Resend with correct ID /

data

Perform security access

routine

Resend command

P2_CAN_Server_max to

P2*_CAN_Server_max

16 | © Danfoss | Nov 2017 BC00000356en-US0102

Page 17

Technical Information

SASA Sensor

SASAIID

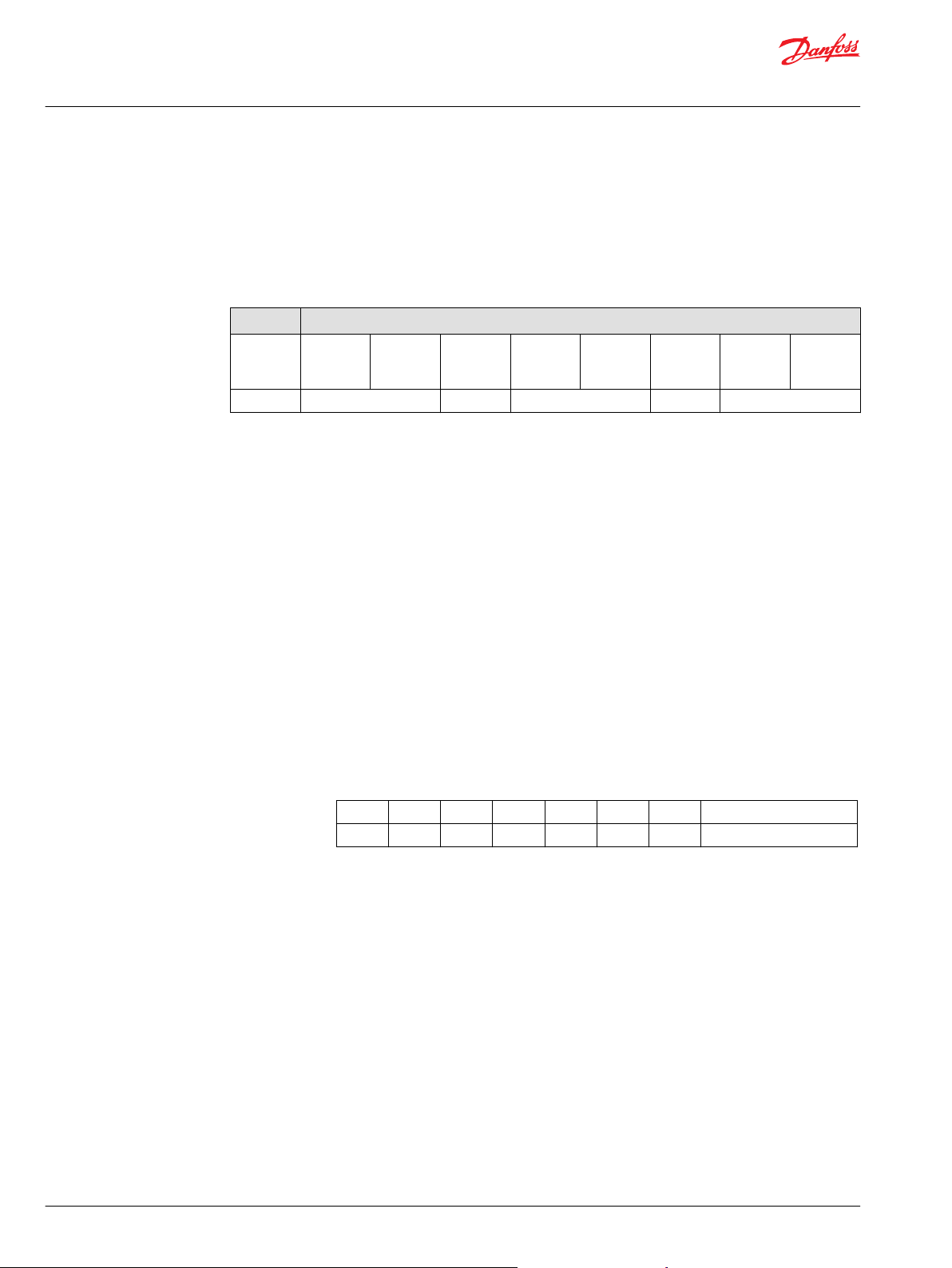

SASAIID configuration data list

This is a list of all configurable parameters.

Identifier Name Access Value/Range Default

$0101 Node Address R/W $01 – $FD $4D

$0102 Output mode R/W

$0103 Message transmission rate (CAN mode) R/W

$0104 Zero-index W $AA – just a trigger value $00

$0109 Temperature R $XX (8 bit integer),[°C]

$010A PGN-offset1 R/W $01 – $FF $10

$010B PGN-offset2 R/W $01 – $FF $11

$0201 - $021F Reserved for supplier

$F010 Address Format R $A5

$F1FA Diagnostic File ID Part A R $350A706F (MSB first)

$F1FB Diagnostic File ID Part B R $0D164B57 (MSB first)

$F1FC Diagnostic File ID Part C R $BC59E069 (MSB first)

$F1FD Diagnostic File ID Part D R $4ACFFEE7 (MSB first)

$F193 Hardware version R XXXXXXXX (4 characters)

$F195 Software version R XXXXXXXX (4 characters)

$F18C Serial Number R $XXXXXXXX (32 bit integer, MSB first)

$F18B Manufacturing date R YY,MM,DD in BCD

$01 (Single message)

$02 (Dual message)

$03 (10 ms)

$04 (20 ms)

$05 (50 ms)

$06 (100 ms)

$07 (200 ms)

$02

$05

©

Danfoss | Nov 2017 BC00000356en-US0102 | 17

Page 18

Technical Information

SASA Sensor

SASAIID

SASAIID technical data

Mechanical

Input range: Continuous 360° rotation

Rotor torque: ≤ 0.2 N•m

Expected life: > 10 million cycles

Electrical

Supply voltage: 6 - 36 V

Power consumption: <2 W

DC

Output

CAN V2.0B, (compatible to J1939)

Termination resistor: 120 ohm (optional)

Baud rate: 250 kb/s

Angle: 12-bit word (0 - 4095) relative to a programmable 0-index point.

Resolution: < 0.1°

Linearity: <1% of full scale

Angle change: 16 bit integer. Values: primary message from 0–40960. Redundant message: the same

but with 20480 offset.

Safety function

Dual CAN output signal (the CAN signals are supervised by the PVED-CLS actuator or alternative external

safety controller).

However, the SASAIID has built in these safety and monitoring functions:

•

Sensor chip diagnostics

•

Steering angle cross-check

•

MCU heartbeat check: the two microcontrollers check each other's aliveness

•

Power-on memory check

Environmental

Operating temperature: -40° to 105°C [-40° to 221°F]

Storage temperature: -55° to 105°C [-67° to 221°F]

Sealing: IP65

EMI/RFI Rating: 150 V/m

Vibration: Meets IEC 60068-2-64

Shock: Meets IEC 60068-2-27 test Ea

18 | © Danfoss | Nov 2017 BC00000356en-US0102

Page 19

∅44.5 [∅1.75]

4x ∅10.8 [4x ∅0.43]

∅

82 ±0.3

[

∅

3.23 ±0.01]

∅44.4 [∅1.75]

83 [3.27]

41.5 [1.63]

118 [4.65]

76.5 [3.01]

Label

(Code No.)

3 [0.12]

15.6

[0.61]

8.6 [0.34]

2.8 [0.11]

P301 221

Technical Information

SASA Sensor

Dimensions SASA sensor

©

Danfoss | Nov 2017 BC00000356en-US0102 | 19

Page 20

1

2

2.8

12

41.5

14 min.

45°

4

.

4

4

-0.1

4

2

5

.

4

2

3

4x ø11

83

R15

ø82±0.3

Technical Information

SASA Sensor

SAK

Code number and weight, SAK adapter kit

Code number Weight

150Z6000 0.8

SAK adapter kit

1. Flexible teeth, 12 pieces to interact with splines on steering column

2. Cable, 500 mm with connector. See “Code numbers” for type of connector

kg

[lb]

[1.76]

1. Distance plate

2. Shaft

20 | © Danfoss | Nov 2017 BC00000356en-US0102

Page 21

min. 22.4 [0.88]

17 [0.67]

15.3

[0.60]

1 2

4 [0.16]

P301 223

C

27.5

[1.08]

4321

4 [0.16]

min. 7.1 [0.28]

P301 222

Technical Information

SASA Sensor

Installation

SASA has to be mounted between steering column and steering unit (OSP) with 4 bolts max 30 N•m

[265.5 lbf•in]. Shaft in column must be 15 mm [0.59 in] longer when using SASA.

Assembly: SASA sensor and OSP steering unit

1. SASA sensor

2. OSP steering unit

Caution

Make sure that the spline profile of the SASA sensor is aligned to the spline profile of the steering column

shaft. A safe method of assembly is to place SASA sensor on the steering column spline shaft first – and

not opposite! In case of using force, there is a risk of bending the spline profile of SASA sensor.

For use of original steering column, use adapter kit type SAK, see sketch below.

Assembly: SAK adapter kit, SASA sensor and OSP steering unit

1. Shaft of SAK adapter kit

2. Distance plate of SAK adapter kit

3. SASA sensor

4. OSP steering unit

©

Danfoss | Nov 2017 BC00000356en-US0102 | 21

Page 22

Technical Information

SASA Sensor

Installation

Wiring guidelines

•

Protect wires from mechanical abuse, run wires in flexible metal or plastic conduits.

•

Use 85˚ C (185˚ F) wire with abrasion resistant insulation and 105˚ C (221˚ F) wire should be

considered near hot surfaces.

•

Use a wire size that is appropriate for the module connector.

•

Separate high current wires such as solenoids, lights, alternators or fuel pumps from sensor and other

noise-sensitive input wires.

•

Run wires along the inside of, or close to, metal machine surfaces where possible, this simulates a

shield which will minimize the effects of EMI/RFI radiation.

•

Do not run wires near sharp metal corners, consider running wires through a grommet when

rounding a corner.

•

Do not run wires near hot machine members.

•

Provide strain relief for all wires.

•

Avoid running wires near moving or vibrating components.

•

Avoid long, unsupported wire spans.

•

Ground electronic modules to a dedicated conductor of sufficient size that is connected to the

battery (-).

•

Power the sensors and valve drive circuits by their dedicated wired power sources and ground

returns.

•

Twist sensor lines about one turn every 10 cm (4 in).

•

Use wire harness anchors that will allow wires to float with respect to the machine rather than rigid

anchors.

22 | © Danfoss | Nov 2017 BC00000356en-US0102

Page 23

Technical Information

SASA Sensor

©

Danfoss | Nov 2017 BC00000356en-US0102 | 23

Page 24

Danfoss

Power Solutions GmbH & Co. OHG

Krokamp 35

D-24539 Neumünster, Germany

Phone: +49 4321 871 0

Danfoss

Power Solutions ApS

Nordborgvej 81

DK-6430 Nordborg, Denmark

Phone: +45 7488 2222

Danfoss

Power Solutions (US) Company

2800 East 13th Street

Ames, IA 50010, USA

Phone: +1 515 239 6000

Danfoss

Power Solutions Trading

(Shanghai) Co., Ltd.

Building #22, No. 1000 Jin Hai Rd

Jin Qiao, Pudong New District

Shanghai, China 201206

Phone: +86 21 3418 5200

Products we offer:

Comatrol

www.comatrol.com

Turolla

www.turollaocg.com

Hydro-Gear

www.hydro-gear.com

Daikin-Sauer-Danfoss

www.daikin-sauer-danfoss.com

Bent Axis Motors

•

Closed Circuit Axial Piston

•

Pumps and Motors

Displays

•

Electrohydraulic Power

•

Steering

Electrohydraulics

•

Hydraulic Power Steering

•

Integrated Systems

•

Joysticks and Control

•

Handles

Microcontrollers and

•

Software

Open Circuit Axial Piston

•

Pumps

Orbital Motors

•

PLUS+1® GUIDE

•

Proportional Valves

•

Sensors

•

Steering

•

Transit Mixer Drives

•

Danfoss Power Solutions is a global manufacturer and supplier of high-quality hydraulic and

electronic components. We specialize in providing state-of-the-art technology and solutions

that excel in the harsh operating conditions of the mobile off-highway market. Building on

our extensive applications expertise, we work closely with our customers to ensure

exceptional performance for a broad range of off-highway vehicles.

We help OEMs around the world speed up system development, reduce costs and bring

vehicles to market faster.

Danfoss – Your Strongest Partner in Mobile Hydraulics.

Go to www.powersolutions.danfoss.com for further product information.

Wherever off-highway vehicles are at work, so is Danfoss. We offer expert worldwide support

for our customers, ensuring the best possible solutions for outstanding performance. And

with an extensive network of Global Service Partners, we also provide comprehensive global

service for all of our components.

Please contact the Danfoss Power Solution representative nearest you.

Local address:

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

already on order provided that such alterations can be made without changes being necessary in specifications already agreed.

All trademarks in this material are property of the respective companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

©

Danfoss | Nov 2017 BC00000356en-US0102

Loading...

Loading...