Page 1

Installation Instruction

Danfoss RX-C Roof and

Gutter De-Icing System

Page 2

Installation Instruction

Danfoss RX-C Roof and Gutter De-Icing System

Table of contents

1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

3 Certifications / Approvals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

4 Technical data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

5 Personnel requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

6 System design. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

7 Power connection components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

8 End-termination . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

9 Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

10 Trace heater installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Determination of the trace heater length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Number of heating circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Required tools / equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Unrolling the trace heater . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Trace heater fixation on roofs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Placement of connection / splice kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Application of warning labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

11 Tests and putting into operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

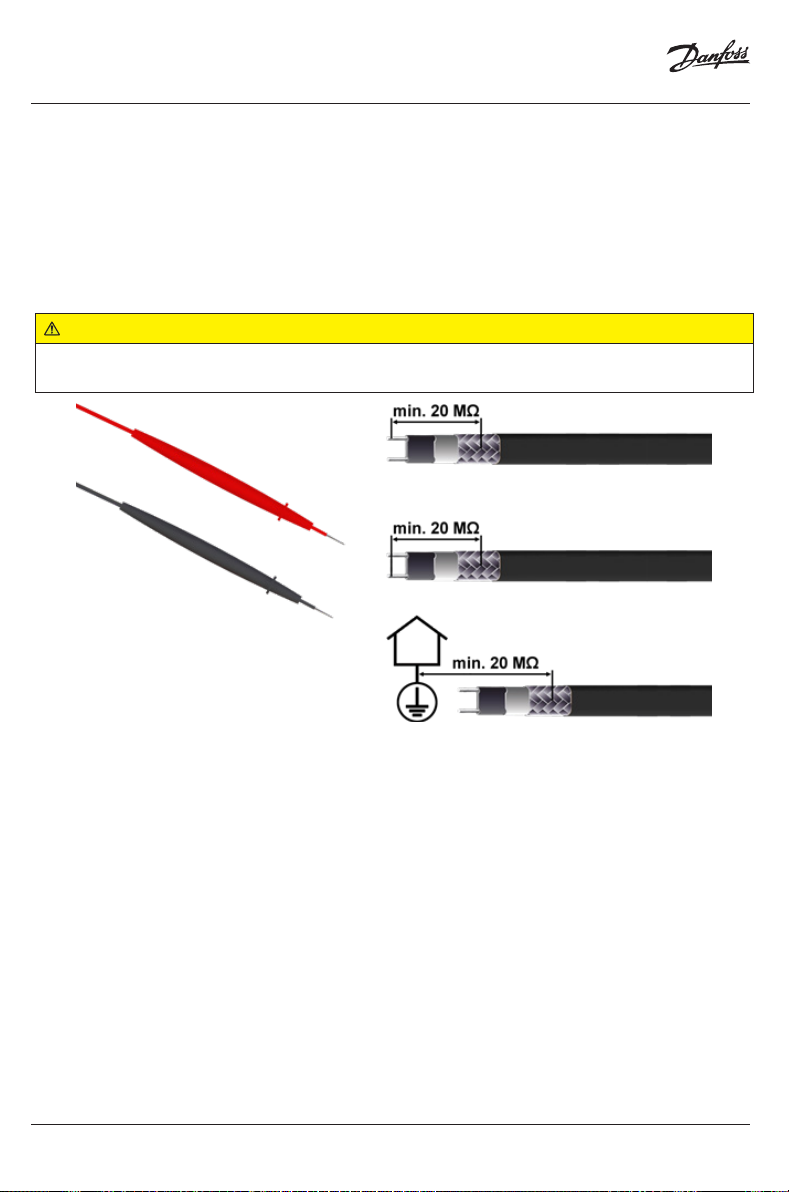

Measurement of the insulation resistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Acceptance test and acceptance test report. . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Putting into operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

12 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

System documentation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

13 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Visual and functional inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Electrical inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Inspection intervals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Personnel training courses. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Repairwork on roofs and gutters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

14 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

15 Acceptance report . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

16 Limited product warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Scope . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

How to claim the warranty. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Applicability of implied warranties, state or provincial laws . . . . . . . . . . . . . . . . . . 20

17 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

18 Sécurité et avertissements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2 | © Danfoss | 2019.11

VIKZE222

Page 3

Installation Instruction

Danfoss RX-C Roof and Gutter De-Icing System

1 Overview

This manual introduces the installation and operation of trace heating circuits using the following

self-regulating trace heaters:

• Danfoss RX-C Roof and Gutter De-Icing System

The self-regulating trace heater features a temperature-dependent resistive element between two

parallel copper conductors, that regulates and limits the heat output of the trace heater according to

the ambient temperature. If the ambient temperature rises, the power output of the trace heater is

reduced. This self-regulating property prevents overheating which would cause damage to the trace

heater. Even crossing or overlapping with other trace heaters (or other portions of the same trace heater) are possible as given from table on page 13.

The heating system is set up as a fixed equipment heating system for roof and gutter de-icing in ordinary locations. Thanks to the parallel design the trace heater can be cut and installed to any required

length.

Multiple options for connection, splicing and end-termination of the heating circuit are available to

meet the individual requirements on site. A large variety of accessories allows for easy customization

and extensibility.

2 Safety

For safe installation and operation of the RX-C trace heater the technical requirements and instructions

given in this manual must be followed.

WARNING:

Risk of fire or electrical shock. Follow these guidelines to avoid personal injury or material damage.

• All electrical systems and installations must comply with Danfoss requirements and be installed in

accordance with the relevant electrical codes and any other applicable national and local codes.

• The US and Canadian electrical codes require ground fault protection to be provided for all trace

heating circuits.

• Install the connection system and trace heaters carefully.

• Use the trace heater and connection system in accordance with the intended purpose and strictly

comply with the operational data specified in section Technical Data.

• The bending radius of the trace heater must be at least 1” (25 mm). Do not bend on the narrow axis.

• Any defective component of the kit must be replaced before installation.

• To avoid short circuits, do not connect the trace heater bus wires together.

• Keep all components and the trace heaters dry before and during installation.

• Beware of hot surfaces when using the heat gun.

• Keep these instructions for future reference. If applicable, leave them with the end user.

• De-energize before installation or servicing.

• Use only original Danfoss accessories.

VIKZE222

© Danfoss | 2019.11 | 3

Page 4

Installation Instruction

Danfoss RX-C Roof and Gutter De-Icing System

3 Certifications / Approvals

Danfoss RX-C self-regulating trace heater for roof and gutter de-icing.

4 Technical data

Ambient temperature range -67 °F to 185 °F / -55 °C to +85 °C

Operation temperatures -40 °F to 149 °F / -40 °C to +65 °C

Voltage 110 to 120 VAC / 208 to 254 VAC

Heat output 5 W/ft @ 50 °F / 15 W/m @ 10 °C

Resistance Grounding braid: < 18.2 Ω/km

Dimensions

polyolefin outer jacket

Minimum bending radius 1” (25 mm)

0.46” x 0.23” (11.6 x 5.8 mm)

Do not bend on the narrow axis.

5 Personnel requirements

The personnel executing installation and maintenance tasks must have acquired the skills and specialized knowledge relating to the types of protection and types of devices concerned. At least, the

personnel must have:

• a general understanding of the relevant electrical engineering (Qualified Electrician)

• a working knowledge and understanding of the relevant standards for electrical installations in

general and trace heating in particular

• a basic knowledge of quality assurance, including the principles of auditing documentation, traceability of measurements and calibration of measurement instruments.

4 | © Danfoss | 2019.11

VIKZE222

Page 5

Installation Instruction

Danfoss RX-C Roof and Gutter De-Icing System

6 System design

A heating circuit with self-regulating trace heaters usually consists of:

• Power supply cable connection;

• End-termination;

• Control and monitoring units (optional).

The following figure shows a sample trace heating system including typical components:

junction box trace heater roof clip

end-termination

The following pages list all compatible components for the RX-C heating system for roof and gutter

applications. The respective installation instructions are included in the scope of delivery.

VIKZE222

© Danfoss | 2019.11 | 5

Page 6

Installation Instruction

Danfoss RX-C Roof and Gutter De-Icing System

7 Power connection components

The following components can be used for power connection with the RX-C trace heater:

Power connection kit

Catalog No.: 088L0023

Cable to Junction Box with

½” NPT cable gland

For connection of selfregulating trace heaters in

a junction box. Electrical

insulation is ensured by heat

shrink tubes.

Junction is not included.

Includes end-temination.

8 End-termination

The following components can be used for trace heater splices / junctions with the RX-C trace heater:

End-termination –

Connecto NA B-E Silicone end

seal for insulation of the end

of the trace heater.

Includes 5 x endcap and 2 x

Silicone adhesive.

End-termination

Catalog No.: 088L0767

Catalog No.: 088L1457

6 | © Danfoss | 2019.11

Heat shrinkable end cap for

insulation of the end of the

trace heater.

Includes 5 kits.

VIKZE222

Page 7

Installation Instruction

Danfoss RX-C Roof and Gutter De-Icing System

9 Accessories

The following original Danfoss accessories are available for the Danfoss RX-C Roof and Gutter De-Icing

System applications:

NOTICE: To ensure compliance with the existing technical regulations, use only original accessories

from Danfoss. The use of original accessories from Danfoss is a precondition for the consideration of

any warranty claims.

Downspout Edge Protection

Plate

Spaceclip for self-limiting

cables. One per kit.

RX-C Roof Clips

The clips are designed to

secure the cables to asphalt

shingles, metal seam roofs,

and gutters. 50 per bag.

Catalog No.: 088L3002

Catalog No.: 088L3001

10 Trace heater installation

Preparation

Before installing any electric trace heating, the person installing must check if the trace heating has

been designed and planned correctly. It is particularly essential to verify the following points:

• complete project planning documentation, operating instructions and installation instructions.

• correct selection of the trace heater and accessories with respect to:

· calculation of heat losses;

· min. permissible start-up temperature;

· max. permissible operating temperature;

· max. permissible ambient temperature.

Before installing, make sure that the roof covering, gutters and downspouts are properly installed.

Determination of the trace heater length

The total required trace heater length is determined by the length of the roof, the number of valleys

and dimensions of gutters and downspouts.

© Danfoss | 2019.11 | 7VIKZE222

Page 8

Installation Instruction

Danfoss RX-C Roof and Gutter De-Icing System

Step 1

Determine the required trace heater length for the roof.

Standard sloped roofs Standing seam roofs

Roof overhang Roof multiplier Roof overhang Loop height

12 in (30 cm) 2 12 in (30 cm) 18 in (45 cm)

24 in (60 cm) 3 24 in (60 cm) 30 in (75 cm)

36 in (90 cm) 4 36 in (90 cm) 42 in (105 cm)

length for roofs = roof edge length * roof

multiplier

length for roofs = roof edge length + loop height

* number of seams

Step 2

Determine the required trace heater length for valleys.

Snow and ice often accumulate in valleys. The trace heater should be routed up and down the valley to

maintain a clear path of melted snow. Add approximately 6 ft. (180 cm) of heating cable for each valley.

length for valleys = number of valleys * 6 ft. (180 cm)

8 | © Danfoss | 2019.11

VIKZE222

Page 9

Installation Instruction

Danfoss RX-C Roof and Gutter De-Icing System

Step 3

Determine the required trace heater length for gutters.

To allow melted snow and ice to be evacuated, the trace heater must be routed through the gutters. In

large gutters, multiple trace heaters are necessary.

Gutter width Number of trace heaters

< 4 ¾” (12 cm) 1

< 9 ½” in (24 cm) 2

> 9 ½” in (24 cm) 3 or more

length for gutters = gutter length

* number of trace heaters

Separate cable in gutter using clips, 3” separation.

Step 4

Determine the required trace heater length for downspouts.

To allow melted snow and ice to be evacuated, the trace heater must be routed

through downspouts (down and up).

NOTICE: Always use a Downspout protector plate when entering and exiting

the downspouts.

length of all downspouts * 2

VIKZE222

length for downspouts =

© Danfoss | 2019.11 | 9

Page 10

Installation Instruction

Danfoss RX-C Roof and Gutter De-Icing System

Step 5

Determine the total required trace heater length.

Add the calculated lengths of all sections together to obtain the total required trace heater length.

Section Calculation method Cable length

standard sloped roofs:

roof edge length * roof multiplier

Roof

Valleys number of valleys * 6 ft. (180 cm)

Gutters gutter length * number of trace heaters

Downspouts length of all downspouts * 2

TOTAL REQUIRED LENGTH _________________

standing seam roofs:

roof edge length + loop height *

number of seams

Number of heating circuits

The following table shows the maximum circuit lengths in ft (m) for the Danfoss RX-C Roof and Gutter

De-Icing System for different installation locations with standard circuit breaker amperages. Breaker

sizing should be based on the National Electrical Code, Canadian Electrical Code or any other local or

applicable code. Use only circuit breakers with type C tripping characteristics.

10 | © Danfoss | 2019.11

VIKZE222

Page 11

Installation Instruction

WARNING:

Danfoss RX-C Roof and Gutter De-Icing System

Risk of fire, electrical shock or dysfunction. Observe the maximum amperage of all components of the

trace heating circuit. If the required trace heater length exceeds the maximum heating circuit length

you must install multiple heating circuits.

Power output

Location

On roofs and valleys

and in gutters and

downspouts

Start-up

temp.

°F (°C)

ice water 131 (40) 131 (40) 131 (40) 230 (70) 230 (70) 230 (70) 262 (80) 262 (80) 262 (80)

Operating Voltage: 120 Vac Operating Voltage: 208 Vac Operating Voltage: 240 Vac

20 A 30 A 40 A 20 A 30 A 40 A 20 A 30 A 40 A

Maximum heating circuit length in ft. (m) based on circuit breaker sizing

NOTICE: Automatic circuit breaker has to be “C” tripping characteristic.

Required tools / equipment

The following tools are required for installation of the Danfoss RX-C Roof and Gutter De-Icing System:

• Hammer

• Cross-head screwdriver

The following protective equipment is required:

• Safety gloves

Recommended adhesive for metal roofs:

• Roof Clip Glue RX-C Roof Clip Adhesive (10.3 fl. oz. tube)

VIKZE222

© Danfoss | 2019.11 | 11

Page 12

Installation Instruction

Danfoss RX-C Roof and Gutter De-Icing System

Unrolling the trace heater

WARNING:

Risk of short cuts and/or material damage. Keep the trace heater ends dry before and during installation. Observe the trace heater’s installation instructions.

Unroll the required trace heater in a straight line and cut to the correct length. Cut off the trace heater

ensuring a straight cut.

Do not bend or pinch the trace heater, or pull it over sharp edges.

12 | © Danfoss | 2019.11

VIKZE222

Page 13

Installation Instruction

Danfoss RX-C Roof and Gutter De-Icing System

Trace heater fixation on roofs

Attach the clip to the roof as follows:

For metal roofs use adhesive

(for adhesive selection refer to page 11):

Attach the trace heater to the clip using UV-resistant cable ties.

Standard sloped roofs Standing seam roofs

On standard sloped roofs, locate the trace heater

in a triangle pattern according to the following

table:

Roof overhang Loop height Loop spacing Roof overhang Loop height Loop spacing

12 in (30 cm) 18 in (45 cm) 24 in (60 cm) 12 in (30 cm) 18 in (45 cm) on every seam

24 in (60 cm) 30 in (75 cm) 24 in (60 cm) 24 in (60 cm) 30 in (75 cm) on every seam

36 in (90 cm) 42 in (105 cm) 24 in (60 cm) 36 in (90 cm) 42 in (105 cm) on every seam

On sloped roofes with standing seams, run the

trace heater along the seams according to the

following table:

NOTICE: The bending radius of the trace heater

must be at least 1” (25 mm); do not bend in an

upright position.

Use as many roof clips as necessary to provide

proper fixation of the trace heater.

VIKZE222

NOTICE: The bending radius of the trace heater

must be at least 1” (25 mm); do not bend in an

upright position.

Use as many roof clips as necessary to provide

proper fixation of the trace heater.

© Danfoss | 2019.11 | 13

Page 14

Installation Instruction

Danfoss RX-C Roof and Gutter De-Icing System

Placement of connection / splice kits

All connection / splice kits must be placed in a dry place, e.g.:

• under roof overhangs

• under gutters

• on the edge of the roof gutter

Application of warning labels

Apply electrical warning labels on a clearly visible place.

11 Tests and putting into operation

Measurement of the insulation resistance

The measurement of the insulation resistance is used to determine damage to the trace heater and

possible installation faults. It must be carried out at the following times:

• Preliminary test (shortly before beginning installation of the trace heater on the construction site;

refer to section Acceptance Report on page 19)

• Acceptance test (after the complete installation of the heating circuit or fitting of the thermal insulation; refer to section Acceptance Report on page 19)

• Final inspection (immediately after completion of work on the thermal insulation)

• Upon commissioning

• Before switching on the installation

14 | © Danfoss | 2019.11

VIKZE222

Page 15

Installation Instruction

Danfoss RX-C Roof and Gutter De-Icing System

To do the measurement, proceed as follows:

• Use an isolation tester with a minimum testing voltage of 500 VDC and a maximum testing voltage

of 2500 VDC. Recommended testing voltage: 1500 VDC. Required insulation resistance: > 20 MΩ.

• Measure the resistance between each bus wire of the trace heater and the grounding braid.

• Measure the resistance between the grounding braid and the earth potential (for this measurement

the heating circuit must not be grounded yet).

WARNING:

Risk of fire or electrical shock. If the insulation resistance is insufficient you must fix the heating circuit

before putting it into operation.

NOTICE: The heating circuit must not be grounded.

Acceptance test and acceptance test report

After completion of the installation work (before fitting the thermal insulation) each heating circuit

must be accepted, if possible in the presence of the client.

All further tests must also be documented in an acceptance test report (refer to section Acceptance

Report on page 19).

NOTICE: Claims under warranty will not be considered if the acceptance report is not filled in

completely.

After completion of work on the thermal insulation final inspection and acceptance of the individual

heating circuits is recommended. Usually, this is the task of the client or the final customer (final inspection).

VIKZE222

© Danfoss | 2019.11 | 15

Page 16

Installation Instruction

Danfoss RX-C Roof and Gutter De-Icing System

Putting into operation

Each heat tracing system can only be put into operation if the following conditions are fulfilled:

• The acceptance test reports for each heating circuit are available and the perfect state of the trace

heating system has been confirmed.

• All components of the heating circuit are completely installed and are in working order.

• It has been ensured that the heating circuit is operated in conformance with the technical data

specified by Danfoss.

12 Operation

During operation of the electric trace heating system you must ensure that all components of the

system are operated within the operating data specified by Danfoss.

This applies particularly to observation of the maximum temperature. Operation within these operating data is a precondition for possible later warranty claims.

System documentation

Complete documentation must be carried out for each system, from the project planning stage,

through installation and putting into operation up to periodic maintenance of the trace heating

system.

This documentation should include the following:

• Project planning documents

• Manuals of all of the components of the heating system

• Heat loss calculation

• Selection of the trace heater

• Layout plans with division of heating circuits

• Circuit diagrams

• Acceptance reports

• Reports on repair work and any operations carried out on the de-icing system

• Inspection reports

16 | © Danfoss | 2019.11

VIKZE222

Page 17

Installation Instruction

Danfoss RX-C Roof and Gutter De-Icing System

13 Maintenance

Visual and functional inspection

Remove any deposit of leaves, mud etc. from gutters and downspouts.

Regulary check the trace heater for possible damage.

Damaged trace heaters must be replaced.

Parts subject to wear must be replaced (e.g. seals, locking plates etc).

Check junction boxes, splices and end-terminations for corrosion and possible mechanical damage.

Make sure that all enclosure covers are properly in place.

If present, check the temperature regulator (Thermostat/automatic sensing system) connecting cables and capillary tube systems for damage and that their installation is protected against mechanical

damage.

Electrical inspection

Measurement of the insulation resistance should be seen as a permanent part of regular maintenance.

For instructions on how to perform the test refer to section Measurement of the insulation resistance

on page 14.

Inspection intervals

Inspections should be carried out annually before the heating period begins.

Personnel training courses

Regular maintenance should be carried out by trained, experienced maintenance personnel.

Repairwork on roofs and gutters

Make sure that all power circuits are de-energized before beginning any repairwork.

Take care that the heat tracing system is not damaged during repairwork on roofs and gutters.

After completion of the repairwork:

• Make sure that the heating circuits are properly installed anew according to the project planning

documentation.

WARNING:

Risk of fire or electrical shock due to damaged components. Remember that self-regulating trace

heaters are designed to be installed only once.

Carry out a visual, functional and electrical test (refer to section Tests and putting into operation on

page 14).

VIKZE222

© Danfoss | 2019.11 | 17

Page 18

Installation Instruction

Danfoss RX-C Roof and Gutter De-Icing System

14 Troubleshooting

Problem Possible cause Remedy

Trace heater remains cold No power supply

Trace heater or cold lead cable not

properly connected

Control unit adjusted incorrectly

Automatic circuit breaker

disengages

Automatic circuit breaker

defective

Automatic circuit breaker has

wrong tripping characteristics, e.

g. “B” instead of “C”

Nominal circuit breaker size is

insufficient

Maximum heating circuit length

has been exceeded

End seal has not been installed

Short circuit

Humidity inside the connection

system or end seal

Ground fault protection

Trace heater damaged

is disengaged

Moisture in the junction box /

connection system

Maximum monitoring length of

the ground fault protection has

been exceeded

Ground fault protection defective

Check the supply line

Connect the trace heater and

cold lead cable according to the

installation instructions

Adjust the control unit according

to the installation instructions

Replace the automatic circuit

breaker

Install an automatic circuit

breaker with Type C tripping

characteristics

Install an automatic circuit breaker

with higher capacity (Refer to

section “Maximum heating circuit

length”)

Split the heating circuit into

separate circuits

Install the end seal according to

the installation instructions

Identify the cause and remedy the

fault (e. g. ensure that tape tails

are not twisted)

Replace the connection system /

end seal

Replace the trace heater at the

point where it is damaged

Dry the junction box / connection

system

Be sure that the conduit drain is

installed and breathing properly.

Install additional ground fault

protection devices

Replace the ground fault

protection device(s)

18 | © Danfoss | 2019.11

VIKZE222

Page 19

Installation Instruction

Danfoss RX-C Roof and Gutter De-Icing System

15 Acceptance report

Protocol type

Acceptance test of the heating system Inspection before commissioning Maintenance and re-commissioning

Project information

Project

Customer

Heating circuit type

Roof and gutter de-icing Pipe trace h eating

Visual inspection

Trace heaters Connection components Control units

Carried out: ____________________________________ ____________________________________

Date Signature, Company

Functional test

Connect the trace heater to the power supply (a temporary connection to the construction site power supply is also

possible). The ground fault protection devices and automatic circuit breakers must not be triggered. Each heating cable end

must be warm after approx. 5 to 10 minutes (test by hand).

Carried out: ____________________________________ ____________________________________

Date Signature, Company

Insulation resistance test

Use an isolation tester with a minimum testing voltage of 500 VDC and a maximum testing voltage of 2500 VDC (recommended testing voltage: 1500 VDC, required insulation resistance: > 20 MΩ). Measure the resistance between each bus wire

of the trace heater and the grounding braid. Measure the resistance between the grounding braid and the earth potential

(for this measurement the heating circuit must not be grounded yet).

Heating Circuit No.

Trace heater length ft. (m) ft. (m) ft. (m) ft. (m)

Insulation resistance at ________ V > MΩ > MΩ > MΩ > MΩ

Carried out: ____________________________________ ____________________________________

Date Signature, Company

Remarks: _________________________________________________________________________________

__________________________________________________________________________________________

____________________________ ____________________________ ____________________________

City/Date Qualified electrician Name / Signature Customer Name / Signature

NOTICE: Claims under warranty will not be considered if the acceptance report is not filled in completely.

VIKZE222

© Danfoss | 2019.11 | 19

Page 20

Installation Instruction

Danfoss RX-C Roof and Gutter De-Icing System

16 Limited product warranty

Scope

This limited product warranty is running for a period of 2 years from the date of purchase. It applies for all

Danfoss products and accessories, that are subject of this manual, against:

• faulty components, and

• faulty manufacturing.

Not covered are any damages caused by:

• accidents,

• improper installation, operation, maintenance or repairs,

• neglect, or

• alteration.

Furthermore Danfoss cannot be hold liable under this warranty for:

• installation or removal costs,

• loss or damage to property,

• loss of revenue or anticipated profits, or

• any other damages or costs directly or indirectly related to the warranty issue.

If all warranty conditions are met, Danfoss will, at its sole discretion:

• repair the concerning product,

• replace the concerning product, or

• refund the purchasing price.

Conditions

The limited product warranty is subject to the following conditions:

• proper installation, operation and maintenance in compliance with the state of the technology and the

product documentation

• presence of completely filled in acceptance reports for all installation, maintenance and repairwork

operations

How to claim the warranty

To claim the limited product warranty, you have to:

• Notify Danfoss or your local Danfoss representative by written correspondence or email within 30 days

after identification of a possible warranty issue.

• If requested, you must provide any warranty related information to Danfoss, such as:

project planning documents

acceptance reports for installation, operation, maintenance or repairwork

etc.

Applicability of implied warranties, state or provincial laws

THE FOREGOING WARRANTY IS IN LIEU OF ALL OTHER REPRESENTATIONS, WARRANTIES, OR CONDITIONS,

EXPRESS OR IMPLIED, INCLUDING WITHOUT LIMITATION ANY IMPLIED WARRANTY OF MERCHANTABILITY,

FITNESS FOR A PARTICULAR PURPOSE OR NONIN-FRINGEMENT, AND OF ANY OTHER OBLIGATION OR LIABILITY ON THE PART OF DANFOSS THERMAL MANAGEMENT, WHETHER BY STATUTE, CONTRACT, STRICT LIABILITY, TORT OR OTHERWISE.

If the goods are a consumer product in Buyer’s jurisdiction, Buyer may have additional legal rights under the applicable national/state/provincial legislation governing the sale of consumer goods. As a result, the above exclusions and/or limitations

on the warranty may or may not apply.

20 | © Danfoss | 2019.11

VIKZE222

Page 21

Installation Instruction

Danfoss RX-C Roof and Gutter De-Icing System

© Danfoss | 2019.11 | 21VIKZE222

Page 22

Installation Instruction

Danfoss RX-C Roof and Gutter De-Icing System

17 Safety

For safe installation and operation of the RX-C trace heater the technical requirements and instructions

given in this manual must be followed.

WARNING:

Risk of fire or electrical shock. Follow these guidelines to avoid personal injury or material damage.

• All electrical systems and installations must comply with Danfoss requirements and be installed in

accordance with the relevant electrical codes and any other applicable national and local codes.

• The US and Canadian electrical codes require ground fault protection to be provided for all trace

heating circuits.

• Install the connection system and trace heaters carefully.

• Use the trace heater and connection system in accordance with the intended purpose and strictly

comply with the operational data specified in section Technical Data.

• The bending radius of the trace heater must be at least 1” (25 mm). Do not bend on the narrow axis.

• Any defective component of the kit must be replaced before installation.

• To avoid short circuits, do not connect the trace heater bus wires together.

• Keep all components and the trace heaters dry before and during installation.

• Beware of hot surfaces when using the heat gun.

• Keep these instructions for future reference. If applicable, leave them with the end user.

• De-energize before installation or servicing.

• Use only original Danfoss accessories.

WARNING:

Risk of fire, electrical shock or dysfunction. Observe the maximum amperage of all components of

the trace heating circuit. If the required trace heater length exceeds the maximum heating circuit

length you must install multiple heating circuits.

WARNING:

Risk of fire or electrical shock. If the insulation resistance is insufficient you must fix the heating

circuit before putting it into operation.

WARNING:

Risk of fire or electrical shock due to damaged components. Remember that self-regulating trace

heaters are designed to be installed only once.

22 | © Danfoss | 2019.11

VIKZE222

Page 23

Installation Instruction

Danfoss RX-C Roof and Gutter De-Icing System

18 Sécurité et avertissements

Afin de garantir la sécurité lors de l’installation et de l’utilisation du câble chauffant RX-C, il est impératif

de respecter les exigences techniques ainsi que les consignes mentionnées dans le présent manuel.

AVERTISSEMENT:

Risque d’incendie ou d’électrocution. Suivez ces consignes pour éviter toute blessure ou dommage

matériel.

• Tous les systèmes et installations électriques doivent satisfaire aux exigences imposées par la société Danfoss et doivent être installés conformément aux normes électriques en vigueur ainsi qu’aux

autres prescriptions nationales et locales applicables.

• Les normes électriques américaines et canadiennes imposent une protection contre les défauts à la

terre pour tous les circuits de traçage électrique.

• La pose du système de connexion et des câbles chauffants doit être réalisée avec le plus grand soin.

• Utilisez le câble chauffant et le système de connexion adaptés à l’usage prévu et répondant aux

caractéristiques de fonctionnement spécifiées à la section Caractéristiques techniques.

• Le rayon de courbure du câble chauffant ne doit pas être inférieur à 1” (25 mm). Ne pas courber le

câble chauffant sur la tranche.

• Tout élément défectueux dans le kit doit être remplacé avant l’installation.

• Pour éviter un court-circuit, ne jamais raccorder ensemble les deux conducteurs du câble chauffant.

• Conservez tous les éléments et les câbles chauffants au sec avant et pendant l’installation.

• Soyez prudent lors de l’utilisation du pistolet à air chaud, certaines surfaces peuvent devenir

brûlantes.

• Conservez ces instructions pour un usage ultérieur. Le cas échéant, remettez-les à l’utilisateur final.

• Mettre hors tension avant toute installation ou opération de maintenance.

• Utilisez exclusivement des pièces et accessoires d’origine Danfoss.

AVERTISSEMENT:

Risque d’incendie, d’électrocution ou de dysfonctionnement. Respectez l’ampérage maximal de

tous les composants du circuit de traçage électrique ! Si la longueur de traçage requise dépasse la

longueur maximale autorisée pour le circuit de traçage, plusieurs circuits de traçage devront être

installés.

AVERTISSEMENT:

Risque d’incendie ou d’électrocution. Si la résistance d’isolement est insuffisante, le circuit de

traçage devra être réparé avant d’être mis en service.

AVERTISSEMENT:

Risque d’incendie ou d’électrocution dû à la présence de composants endommagés. N’oubliez pas

que les câbles chauffants autorégulés sont conçus pour n’être installés qu’une seule fois.

Vous pouvez trouver des instructions en Français ici: lx.danfoss.com

© Danfoss | 2019.11 | 23VIKZE222

Page 24

Danfoss

11655 Crossroads Circle

Baltimore, MD 21220 USA

Phone: 1-888-DANFOSS (326-3677)

Fax: 416-352-5981

lx.danfoss.com

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without

notice. This also applies to products already on order provided that such alterations can be made without subsequential changes being necessary in specifications

already agreed. All trademarks in this material are property of the respective companies. DEVI and the DEVI logo-type are trademarks of Danfoss A/S. All rights reserved.

24 | © Danfoss | 2019.11

VIKZE222

Loading...

Loading...