LEGEND

DRAWING LIST

RX-1

Legend/Drawing List

RX-2

RX Constant Watt Cable Specification

RX-4

RX Self-Regulating Cable Specification

RX-5

RX Typical Roof Install

RX-3

RX Typical Dorm, Valley & Downspout Install

Spacer Clips

088L3004

RX Downspout Edge Protection Plate

088L3002

RX-C Roof Clips Type A

088L3024

RX-C Roof Clips Type B

088L3003

Shingle Clips

088L3005

DS-8C Application

RX-6

RX-7

GX-850M Application

Shingle Clips

088L3012

RX Roof Clips

088L3001

RX-8

RX-1200 Application

Drawing No:

Drawn By: Scale:

Date:

Quote No:

The Contractor shall verify all job site

dimensions all drawing, details &

specifications.

The Contractor shall report any

discrepancies, in writing to Danfoss

prior to commencing with any work.

11655 Crossroads Circle

Baltimore, Maryland 21220

Tel: 1-888-326-3677 Option: 3 Fax : 1 410-931-8256

www.Heating.Danfoss.us

Drawing Title:

Project:

Rep:

No:

Date:

Description:

Date Desc.

1.

March 2018

RX General Submittal

Legend/Drawing List

RX-1

1.3. Automatic Snow Controller shall have an

adjustable timer providing up to ninety minutes of

system operation after snowfall ceases for

complete melting.

1.4. Automatic Snow Controller shall have the following

modes.

a. Automatic

b. Constant OFF

c. Constant ON (manual timer)

1.5. Automatic Snow Controller shall have adjustable

parameters

a.Melting Temperature (32°F to 49°F)

b. Timer (5 to 95 minutes)

1.6. Automatic Snow Controller shall be able to indicate

the actual temperature and moisture levels for

sensors.

1.7. Automatic Snow Controller shall have info-button

for help/information.

1.8. Automatic Snow Controller shall have

self-doagnosis program, which will detect faults and

give them an alarm.

1.9. Automatic Snow Controller shall have individual

LEDs to provide indication of alarm and heater

operation.

1.10. Automatic Snow Controller shall be capable of

accepting four roof sensors.

1.11. Automatic Snow Controller shall have

milti-language capabilities (English, Spanish, and

French)

1.12. Sensors shall include 50' lead.

Option 2: Snow Switch Control

The system shall be controlled by Danfoss DS-8

temperature and moisture sensor either directly or

through an appropriate contactor.

2.1. DS-8 shall be microprocessor-based to provide

effective, economical, automatic control.

2.2. DS-8 shall have an adjustable timer providing

up to ninety minutes of system operation after

snowfall ceases for complete melting.

RX Constant Watt Cable Specification

1. General

Supply and install a complete system comprised of

heating cables, accessories and controls for keeping

roof eaves, gutters and downspouts from being

clogged by ice and snow.

2. Material

2.1. Shall be Danfoss RX kits dual conductor heating

cable.

2.2. Conductor: Copper or copper alloy with nickel

coating.

2.3. Insulation: FEP DuPont with an average thickness

not less than 0.25 mm and than layer of XLPE.

2.4. Shield: Tin coated drain wire combined with 0.050

mm aluminium foil coated with 0.012 mm PBT, 100%

coverage.

2.5. Jacket: PVC with an average thickness not less than

0.75 mm.

2.6. Lead free 1/4" round heating cable that is both

flexible and UV protected.

2.7. Rated temperature: 220 °F (105 °C), maximum

voltage 277 V.

2.8. Shall include 6' cold lead with heavy duty grounded

plug.

2.9. Heating cable circuit shall be protected by a ground

fault device in accordance with section 426 of the

NEC.

2.10. Shall be approved to applicable UL and CSA

standards.

3. System Controls

Option 1: Automatic Snow Controller

The system shall be controlled by Danfoss GX 850

control panel with external digital temperature and

moisture sensors either directly or through an appropriate

contactor.

1.1. Automatic Snow Controller shall be

microprocessor based to provide effective,

economical, automatic control.

1.2. Automatic Snow Controller shall have dual zone

capability.

2.3. DS-8 Snow Controller shall have the following

modes.

a. Manual ON

b. Automatic

c. Stanby/Reset

2.4. DS-8 Snow Controller shall have adjustable

parameters

a.Melting Temperature (34°F to 44°F)

b. Timer (30 to 90 minutes)

2.5. DS-8 Snow Controller shall have two sensors:

Moisture and Temperature.

Option 3: Thermostat

The system shall be controlled by an ambient

sensing thermostat Danfoss 088L3422 either directly

or through an appropriate contactor.

Option 4: Manual Switch

The system shall be controlled by a manual switch

either directly or through an appropriate contactor.

4. Execution

4.1. Installation

a. System must be installed as per manufacturer's

recommendation using method described in

installation guide.

b. Place the heating cables and sensors in the

surface material as per the installation guide.

c. Inspect the cable and controls upon receiving

the shipment. Note any damage and ensure

materials received match the order and shopping

documents.

4.2. Tests

a. Refer the manufacturer's literature for

requirements for testing and documenting cable

resistance and insulation-to-ground readings.

b. Take test as outlined in the Installation manual.

c. If problems are discovered consult the

manufacturer.

d. If unable to correct problems notify the engineer

before proceeding with installation.

e. Keep record of all readings for inspection ny the

engineer or for submittal to the manufacturers to

ensure a valid warranty.

5. Warranty

5.1. Manufacturer shall offer a 2-year, non-prorated

warranty.

Drawing No:

Drawn By: Scale:

Date:

Quote No:

The Contractor shall verify all job site

dimensions all drawing, details &

specifications.

The Contractor shall report any

discrepancies, in writing to Danfoss

prior to commencing with any work.

11655 Crossroads Circle

Baltimore, Maryland 21220

Tel: 1-888-326-3677 Option: 3 Fax : 1 410-931-8256

www.Heating.Danfoss.us

Drawing Title:

Project:

No:

Date:

Description:

RX Constant Watt

Specifications

N.T.S

Date Desc.

1.

Rep:

March 2018

RX General Submittal

RX-2

TPE

Tin Plated

Copper Braid

TPE Insulation

Jacket

Bonded

Jacket

Self-Limiting

Heating Element

Tin Plated

Copper Bus Wires

RX-C Self Regulating Cable

RX-C Self Regulating Cable Specification

1.2. Automatic Snow Controller shall have dual zone

capability.

1.3. Automatic Snow Controller shall have an

adjustable timer providing up to ninety minutes of

system operation after snowfall ceases for

complete melting.

1.4. Automatic Snow Controller shall have the following

modes.

a. Automatic

b. Constant OFF

c. Constant ON (manual timer)

1.5. Automatic Snow Controller shall have adjustable

parameters

a.Melting Temperature (32°F to 49°F)

b. Timer (5 to 95 minutes)

1.6. Automatic Snow Controller shall be able to indicate

the actual temperature and moisture levels for

sensors.

1.7. Automatic Snow Controller shall have info-button

for help/information.

1.8. Automatic Snow Controller shall have

self-doagnosis program, which will detect faults and

give them an alarm.

1.9. Automatic Snow Controller shall have individual

LEDs to provide indication of alarm and heater

operation.

1.10. Automatic Snow Controller shall be capable of

accepting four roof sensors.

1.11. Automatic Snow Controller shall have

multi-language capabilities (English, Spanish, and

French)

1.12. Sensors shall include 50' lead.

Option 2: Snow Switch Control

The system shall be controlled by Danfoss DS-8

temperature and moisture sensor either directly or

through an appropriate contactor.

2.1. DS-8 shall be microprocessor-based to provide

effective, economical, automatic control.

1. General

Supply and install a complete system comprised of

heating cables, accessories, and controls for

keeping roof eaves, gutters and downspouts from

being clogged by ice and snow.

2. Material

2.1. Shall be Danfoss RX-C self-regulating heating

cable.

2.2. The self-regulating heating cables shall consist

of two (2) 16 AWG nickel-plated copper bus

wires embedded in parallel in a radiation-cross

linked polymer core that varies its power output

in response to temperature all along its length,

allows the heating cable to be cut in the field.

2.3. The heating cable shall be covered with a

radiation cross-linked polyolefin dielectric jacket

and protected by a tinned-copper braid and a

polyolefin outer jacket.

2.4. The heating cable shall operate on line voltage

of (select: 120V, 240V, 208V or 277V)

2.5. The heating cable shall have a nominal power

output of 12W per foot in snow and ice and 5W

per foot in air.

2.6. Power connection, end seal, splice, and tee

connection kit, shall be able to be applied on site.

2.7. Heating cable circuit shall be protected by a

ground fault device in accordance with section

426 of the NEC.

2.8. Shall be approved to applicable UL and CSA

standards.

3. System Controls

Option 1: Automatic Snow Controller

The system shall be controlled by Danfoss GX850

control panel with external digital temperature and

moisture sensors either directly or through an

appropriate contractor.

1.1. Automatic Snow Controller shall be

microprocessor based to provide effective,

economical, automatic control.

2.2. DS-8 shall have an adjustable timer providing

up to ninety minutes of system operation after

snowfall ceases for complete melting.

2.3. DS-8 Snow Controller shall have the following

modes.

a. Manual ON

b. Automatic

c. Stanby/Reset

2.4. DS-8 Snow Controller shall have adjustable

parameters

a.Melting Temperature (34°F to 44°F)

b. Timer (30 to 90 minutes)

2.5. DS-8 Snow Controller shall have two sensors:

Moisture and Temperature.

Option 3: Thermostat

The system shall be controlled by an ambient

sensing thermostat Danfoss 088L3422 either directly

or through an appropriate contactor.

Option 4: Manual Switch

The system shall be controlled by a manual switch

either directly or through an appropriate contactor.

4. Execution

4.1. Installation

a. The heating cable should be laid in gutters; shall

be suspended in downspouts either as a loop or

a single length and held in place by a downspout

hanger (edge protection plate); and shall be

attached to the roof using the roof clips.

b. The heating cable shall be protected from

damage and installed according to

manufacturer's instructions.

c. Inspect the cable and controls upon receiving the

shipment. Note any damage and ensure

materials received match the order and shopping

documents.

4.2. Tests

a. After installation, the dielectric jacket's insulation

resistance from the conductors to the shield shall

be greater than 1000 mega-ohms.

5. Warranty

5.1. Manufacturer shall offer a 2-year, non-prorated

warranty.

Drawing No:

Drawn By: Scale:

Date:

Quote No:

The Contractor shall verify all job site

dimensions all drawing, details &

specifications.

The Contractor shall report any

discrepancies, in writing to Danfoss

prior to commencing with any work.

11655 Crossroads Circle

Baltimore, Maryland 21220

Tel: 1-888-326-3677 Option: 3 Fax : 1 410-931-8256

www.Heating.Danfoss.us

Drawing Title:

Project:

No:

Date:

Description:

RX-C Self Regulating

Specifications

N.T.S

Date Desc.

1.

Rep:

March 2018

RX General Submittal

RX-3

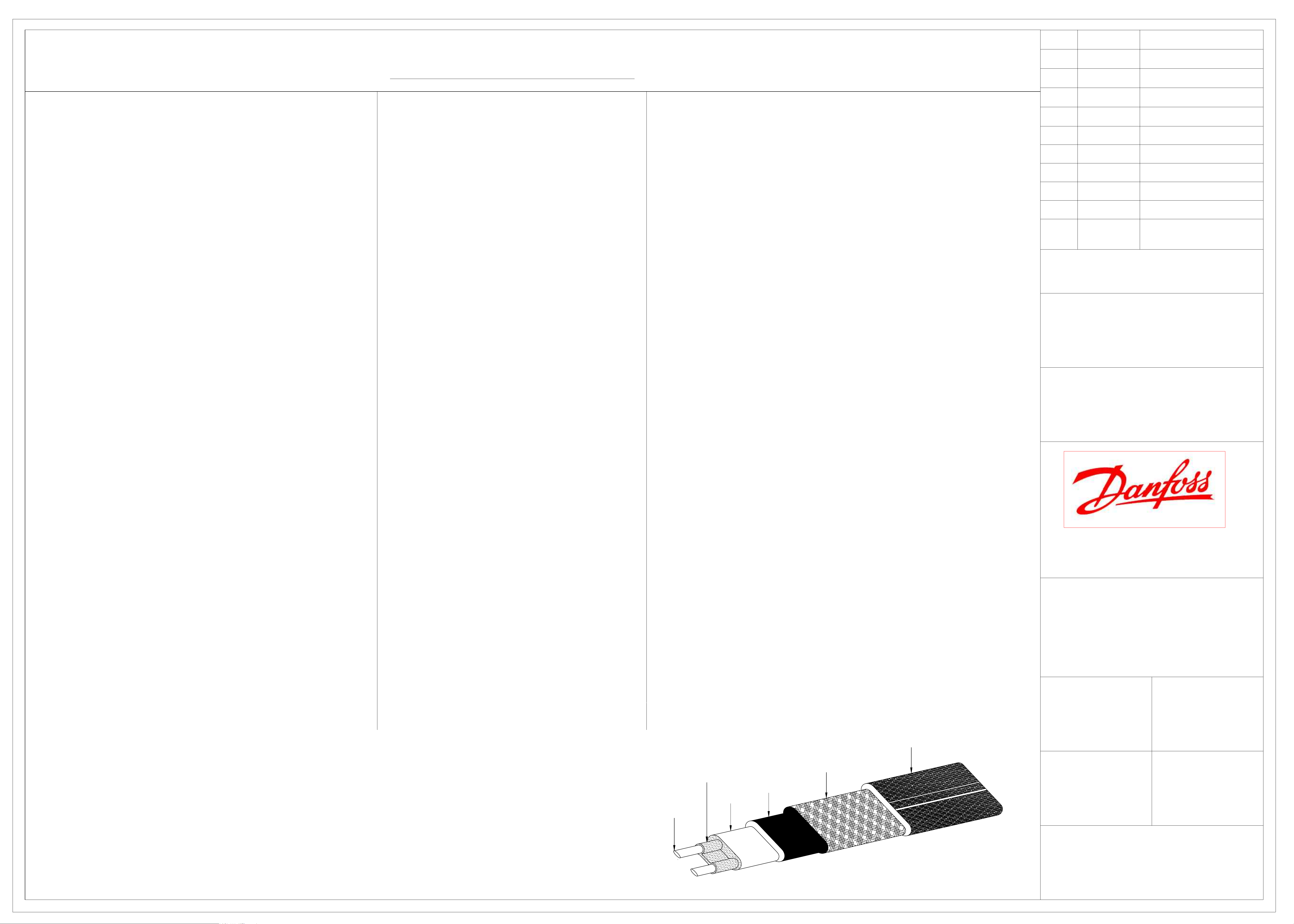

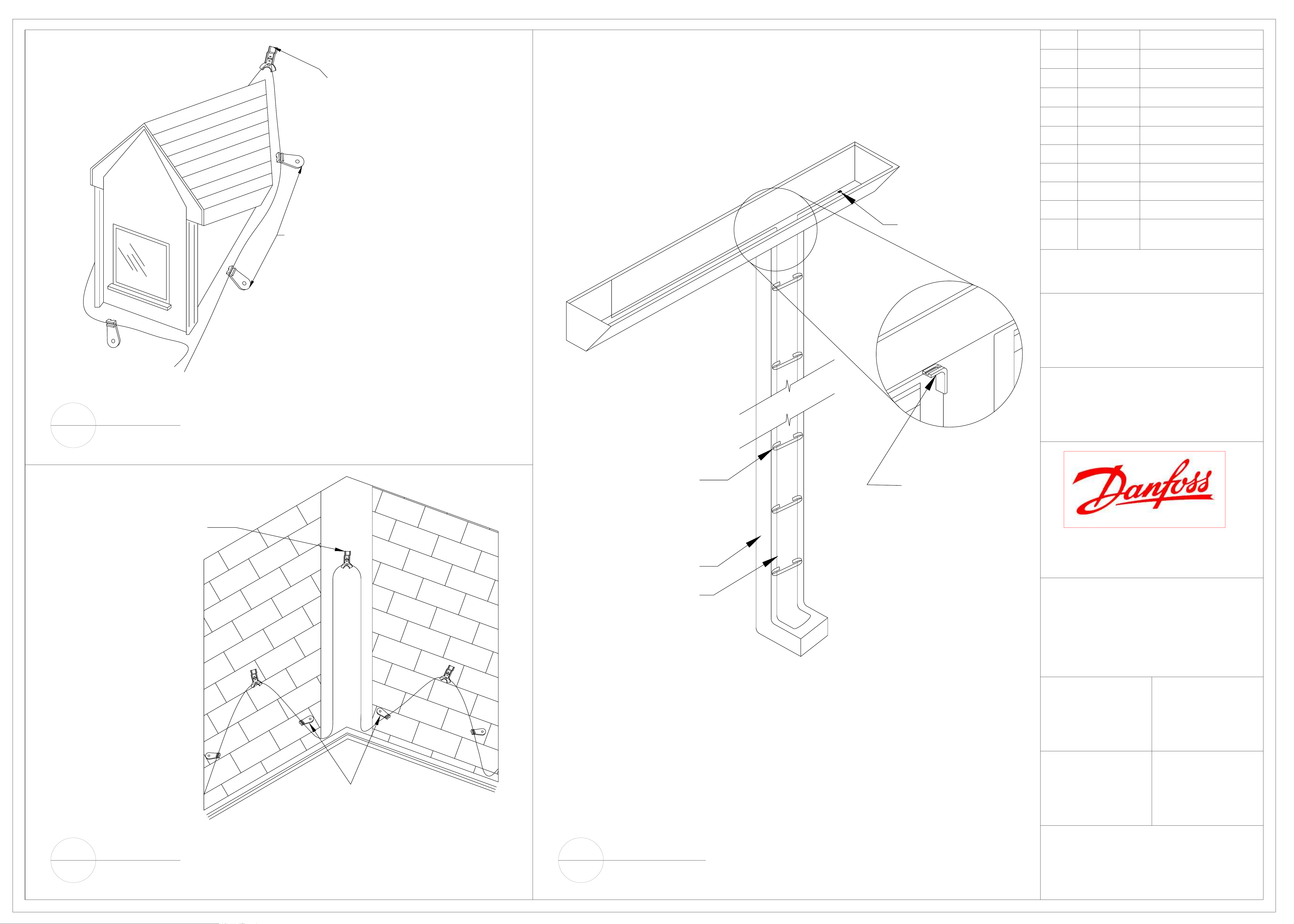

Downspout

Junction Box

RX Type B Roof Clip

088L3003

Shingle Roof

RX Type A Roof Clip

088L3024

RX Type B Roof Clip

088L3003

RX Type A Roof Clip

088L3024

Gutter

15"

Triangle Base

L/3

L=Length of Roof

Triangle Height

Metal Roof

Heating Cable

Junction Box

Type A Roof Clip

088L3024

Downspout

Edge Protection Plate

088L3002

Drawing No:

Drawn By: Scale:

Date:

Quote No:

The Contractor shall verify all job site

dimensions all drawing, details &

specifications.

The Contractor shall report any

discrepancies, in writing to Danfoss

prior to commencing with any work.

11655 Crossroads Circle

Baltimore, Maryland 21220

Tel: 1-888-326-3677 Option: 3 Fax : 1 410-931-8256

www.Heating.Danfoss.us

Drawing Title:

Project:

No:

Date:

Description:

Typical Roof Install

N.T.S

Date Desc.

1.

Rep:

March 2018

RX General Submittal

RX-4

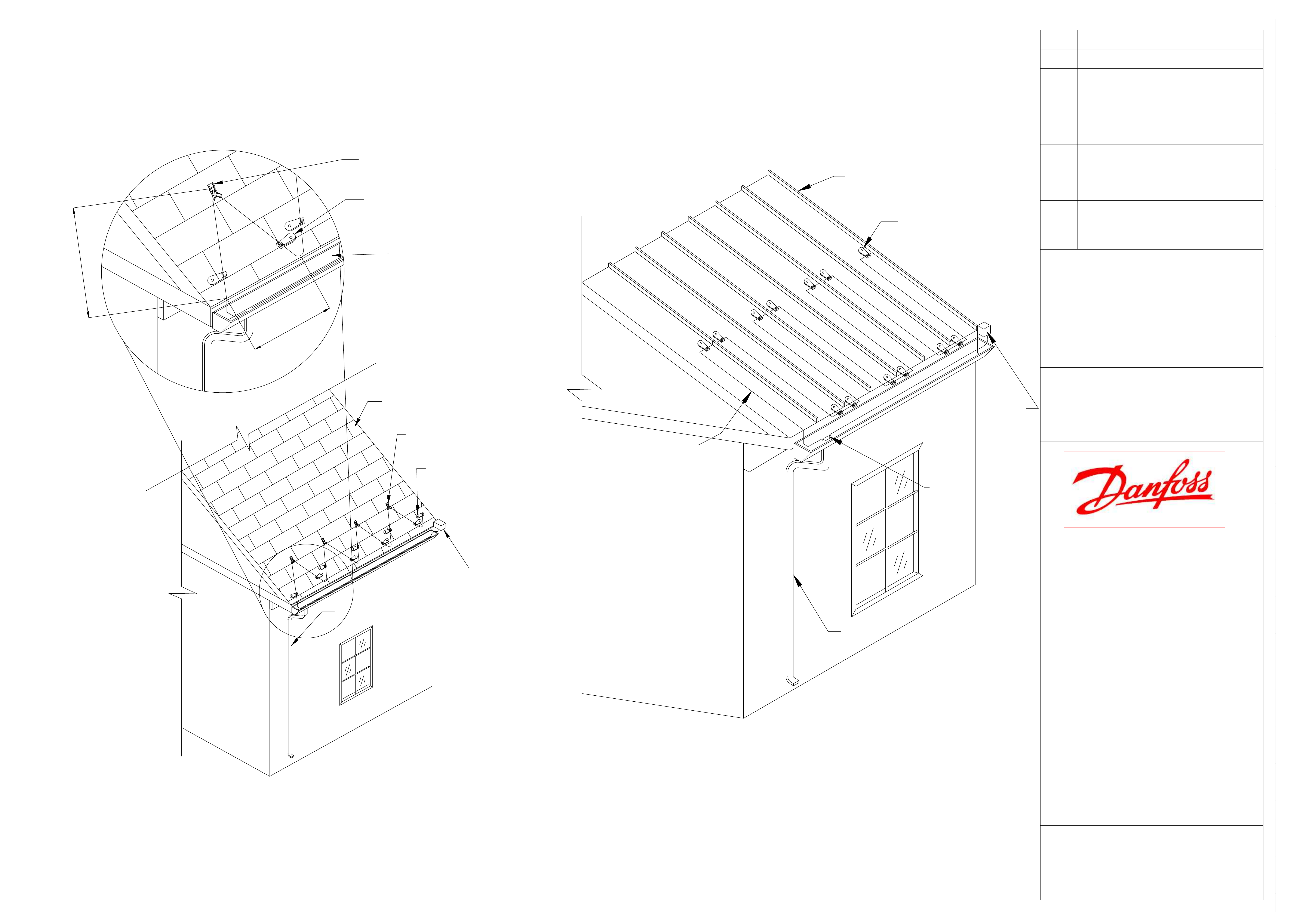

RX-C Roof Clips-Type A

088L3024

RX-C Roof Clips- Type B

088L3003

RX-C Roof Clips- Type B

088L3003

RX-C Roof Clips-Type A

088L3024

Heating Cable

Downspout

Edge Protection

Plate

088L3002

End Cap

Spacer Clips

088L3004

Drawing No:

Drawn By: Scale:

Date:

Quote No:

The Contractor shall verify all job site

dimensions all drawing, details &

specifications.

The Contractor shall report any

discrepancies, in writing to Danfoss

prior to commencing with any work.

11655 Crossroads Circle

Baltimore, Maryland 21220

Tel: 1-888-326-3677 Option: 3 Fax : 1 410-931-8256

www.Heating.Danfoss.us

Drawing Title:

Project:

No:

Date:

Description:

Detail Typical Roof Install

N.T.S

Date Desc.

1.

Rep:

RX-5

Detail:1

Dormer Pattern

RX-5

Detail:2

Valley Pattern

RX-5

Detail:3

Downspout Pattern

March 2018

RX General Submittal

RX-5

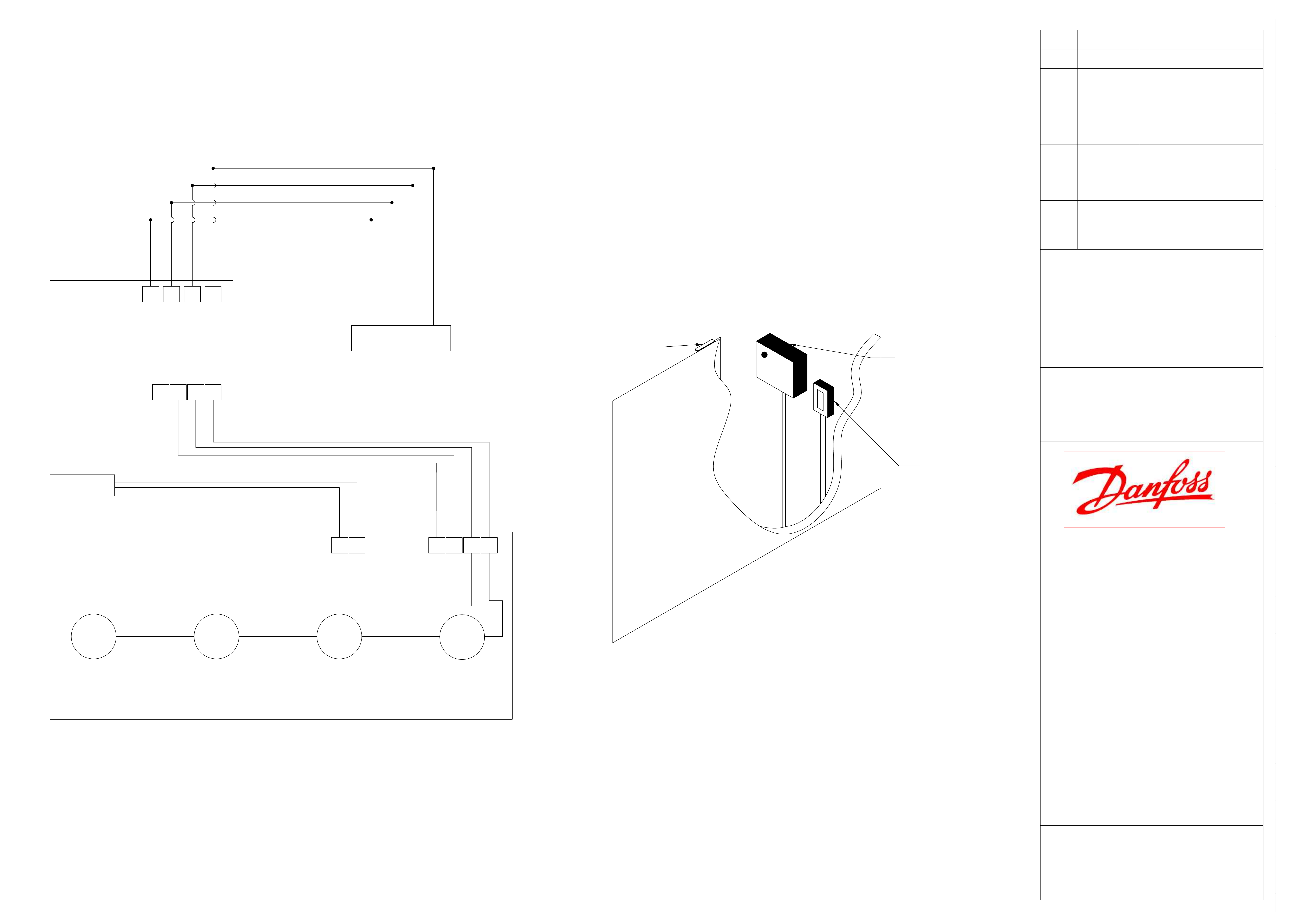

DS-8C

120 (240) VAC

120 (240) VAC

Heating Cables

30A max.

L1

L2 (N)

L1

L2 (N) Yellow Yellow

Brown Blue

Under 30A Configuration

Part # 088L3045

Note:

1.The cable conductors must be tinned, stranded, minimum 22AWG copper. Overall

shielding is required

2. The CDP-2 can be installed as much as 500 feet away from the snow sensor if proper

cable is used.

DS-8C

CDP-2

DS-8C

L N Y Y

Part # 088L3045

BLUE

BROWN

YELLOW

YELLOW

L N

LA

NA

S1 S2

100A GFEP CONTACTOR PANEL

(TWO (2) 50A 3P CONTACTOR INSIDE)

Part # 088L3444

CC

120V SUPPLIED

BY CUSTOMER

Drawing No:

Drawn By: Scale:

Date:

Quote No:

The Contractor shall verify all job site

dimensions all drawing, details &

specifications.

The Contractor shall report any

discrepancies, in writing to Danfoss

prior to commencing with any work.

11655 Crossroads Circle

Baltimore, Maryland 21220

Tel: 1-888-326-3677 Option: 3 Fax : 1 410-931-8256

www.Heating.Danfoss.us

Drawing Title:

Project:

No:

Date:

Description:

DS-8C Typical Application

N.T.S

Date Desc.

1.

March 2018

RX General Submittal

RX-6

GX-850M

L N

LA

NA

S1 S2

200A GFEP CONTACTOR PANEL (FOUR (4) 50A 3P CONTACTOR INSIDE)

L N

3

4

C C C

C

Part # 088L3415

BLACK

RED

WHITE

WHITE

ROOF SENSOR

BLACK

RED

WHITE

WHITE

Part # 088L3052

Part # 088L3446

120V SUPPLIED

BY CUSTOMER

171615 18

(1 to 4 sensors)

Contactor

Panel

GX-850 Automatic

Controller

Roof Sensor

Drawing No:

Drawn By: Scale:

Date:

Quote No:

The Contractor shall verify all job site

dimensions all drawing, details &

specifications.

The Contractor shall report any

discrepancies, in writing to Danfoss

prior to commencing with any work.

11655 Crossroads Circle

Baltimore, Maryland 21220

Tel: 1-888-326-3677 Option: 3 Fax : 1 410-931-8256

www.Heating.Danfoss.us

Drawing Title:

Project:

No:

Date:

Description:

GX-850M Typical

Application

N.T.S

Date Desc.

1.

Rep:

March 2018

RX General Submittal

RX-7

Drawing No:

Drawn By: Scale:

Date:

Quote No:

The Contractor shall verify all job site

dimensions all drawing, details &

specifications.

The Contractor shall report any

discrepancies, in writing to Danfoss

prior to commencing with any work.

11655 Crossroads Circle

Baltimore, Maryland 21220

Tel: 1-888-326-3677 Option: 3 Fax : 1 410-931-8256

www.Heating.Danfoss.us

Drawing Title:

Project:

No:

Date:

Description:

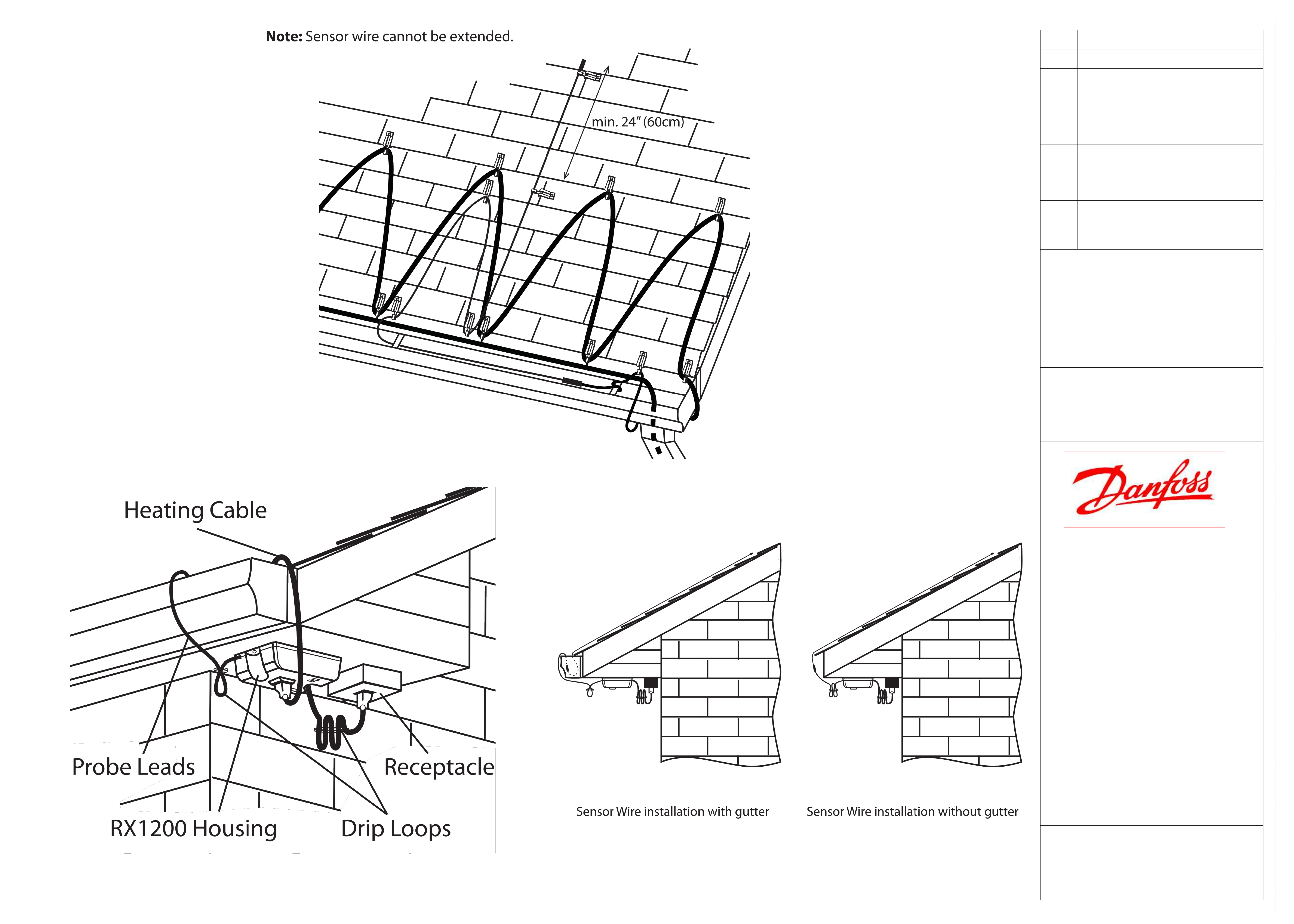

RX-1200 Typical

Application

N.T.S

Date Desc.

1.

Rep:

March 2018

RX General Submittal

RX-8

Loading...

Loading...