Danfoss

Danf

17-914.10

Danf

17-915.10

3

Installation guide

min. 20mm

Danfoss

17-917.10

Pressure switch

Types RT 5, RT 110, RT 116, RT 200

1

017R9314

017A1831-01

0.05

5

3

0.5

10

2

1.0

bar

2

psig kp/cm

kPa

Pe

PRESSURE

TYPE RT110

2

1

DC 13

AC

1 10A

421

AC

3 4A

12W

AC15 3A

4030

220 V

400 V

1.1 3.5 psi

0.08 0.25 bar

8 25 kPa

DIFFERENTIAL

Contact load:

AC-1: 10A, 400V

AC-3: 4A, 400V

AC-15: 3A, 400V

DC-13: 12W, 220V

93Z265.10

017R9314

oss

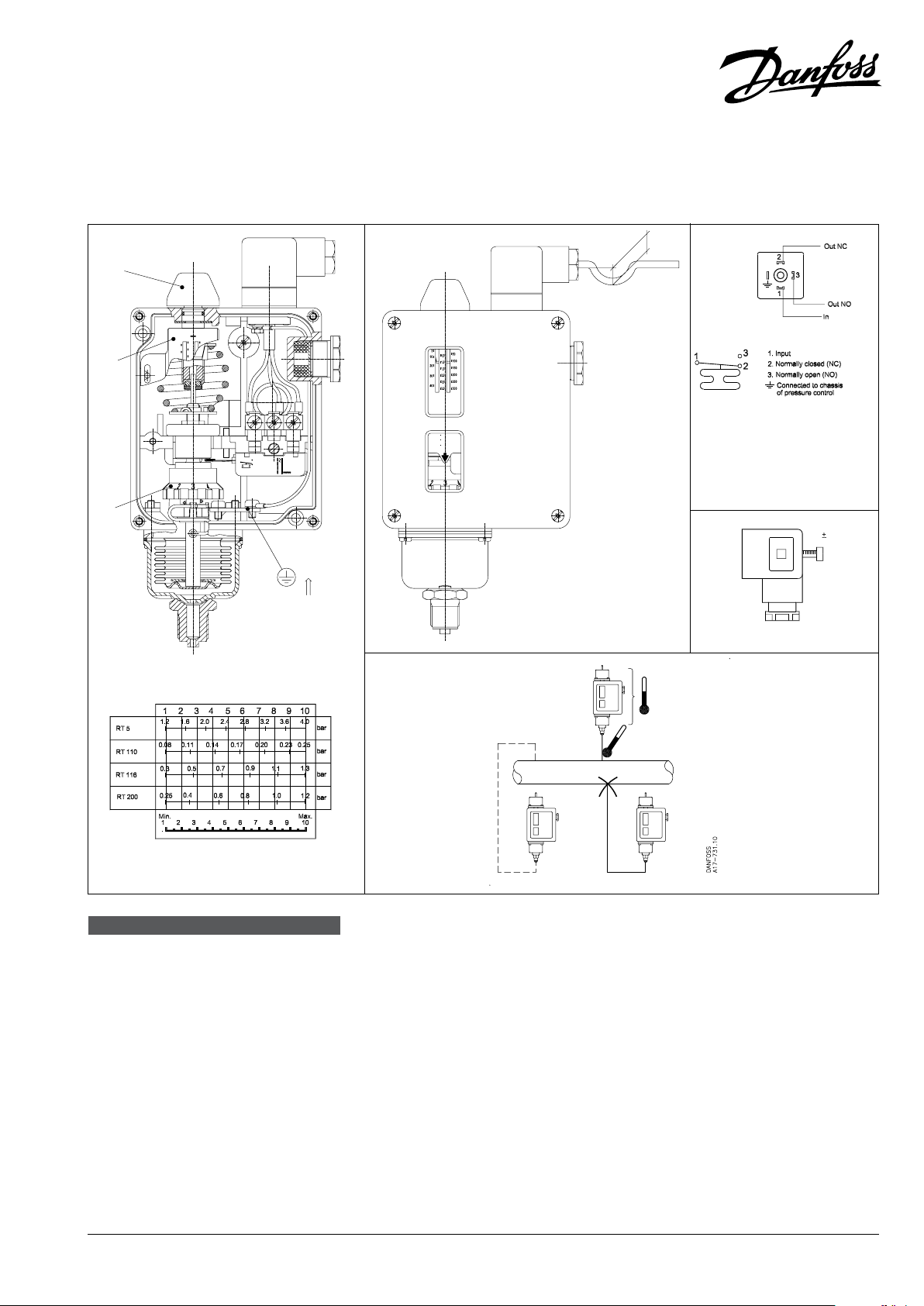

Fig. 4

0.4 0.1 Nm

Code no.

017xxxx

Fig. 3 Fig. 5

Danfoss

17-916.10

Fig. 1

max. 70 °C

min. -40 °C

max. 100 °C

oss

Fig. 2 Fig. 6

ENGLISH

Data

Pressure switches types RT 5, RT 110, RT

116, RT 200

Max. test pressure

RT 110: 8 bar

RT 5, RT 116, RT 200: 25 bar

Fitting

Damp out strong pressure pulsations.

A damping coil will often be sucient.

Insert a water-lled tube loop as a

temperature lock (e.g. a 10 mm Cu tube) if

at high plant temperatures there is a risk

that the pressure connection of the switch

will become heated to more than 150 °C.

Position the pressure control so that on

water plant it cannot be exposed to frost.

© Danfoss | DCS (jmn) | 2015.08 IC.PI.P10.F1.02 / 520B6303 1

It can operate on an air cushion, for

example. To assure IP65 grade of RT

enclosure, it is necessary to assemble the

plug shown in the g. 5.

Setting

To set a pressure switch, the seal cap (1)

must be removed and the range setting

screw must be rotated, at the same time

reading the main scale (2), see g. 1.

The dierential is set by rotating the

dierential adjusting nut (3) to the value

indicated by the use of the nomogram in

g. 2. The maximum operating pressure is

thus the sum of the setting pressure and

the dierential.

Example

It is desired to control the pressure in an

oilred steam boiler by the use of an

RT 116.

Maximum pressure 9 bar.

Minimum pressure 8.2 bar.

Dierential 9 - 8.2 = 0.8 bar.

1. Connect the oil burner to terminals 1-2

of the pressure switch.

2. Set the pressure switch for 8.2 bar by

rotating the range setting screw.

3. Set the dierential adjusting nut (3) at

the digit 6 which is found by reading

the nomogram in g. 2.

Loading...

Loading...