Page 1

Data sheet

Liquid Level Alarms, Safety Control, Liquid Level Regulator

RT 280A, RT 281A

RT 280A and RT 281A are primarily used as liquid

level alarms and safety switches to prevent too

high a liquid level in liquid separators.

Secondarily, RT 280A and RT 281A can be used

as liquid level regulators where a liquid level

dierential of up to ±40 mm can be permitted.

When used as safety switches, RT 280A and RT

281A ensure that the max. permissible refrigerant

level in ooded evaporators, pump tanks or

liquid separators is not exceeded.

As liquid level regulators, RT 280A and RT 281A

maintain a constant average refrigerant level

in ooded evaporators, pump tanks or liquid

separators.

Features

Approvals

• Waterproof versions, enclosure IP66

• Single pole changeover switch (SPDT) suitable

for AC / DC loads

CE-approved according to

EN 60947-4, -1 EN 60947-5, -1

• Interchangeable contact system

Meets the requirements of VDE 0660 (VDE:

Verband Deutscher Elektrotechniker)

© Danfoss | DCS (jmn) |2016.07

DKRCC.PD.GF0.A4.02 | 520H11306 | 1

Page 2

Data sheet | Liquid Level Alarms, Safety Control, Liquid Level Regulator, types RT280A, RT281A

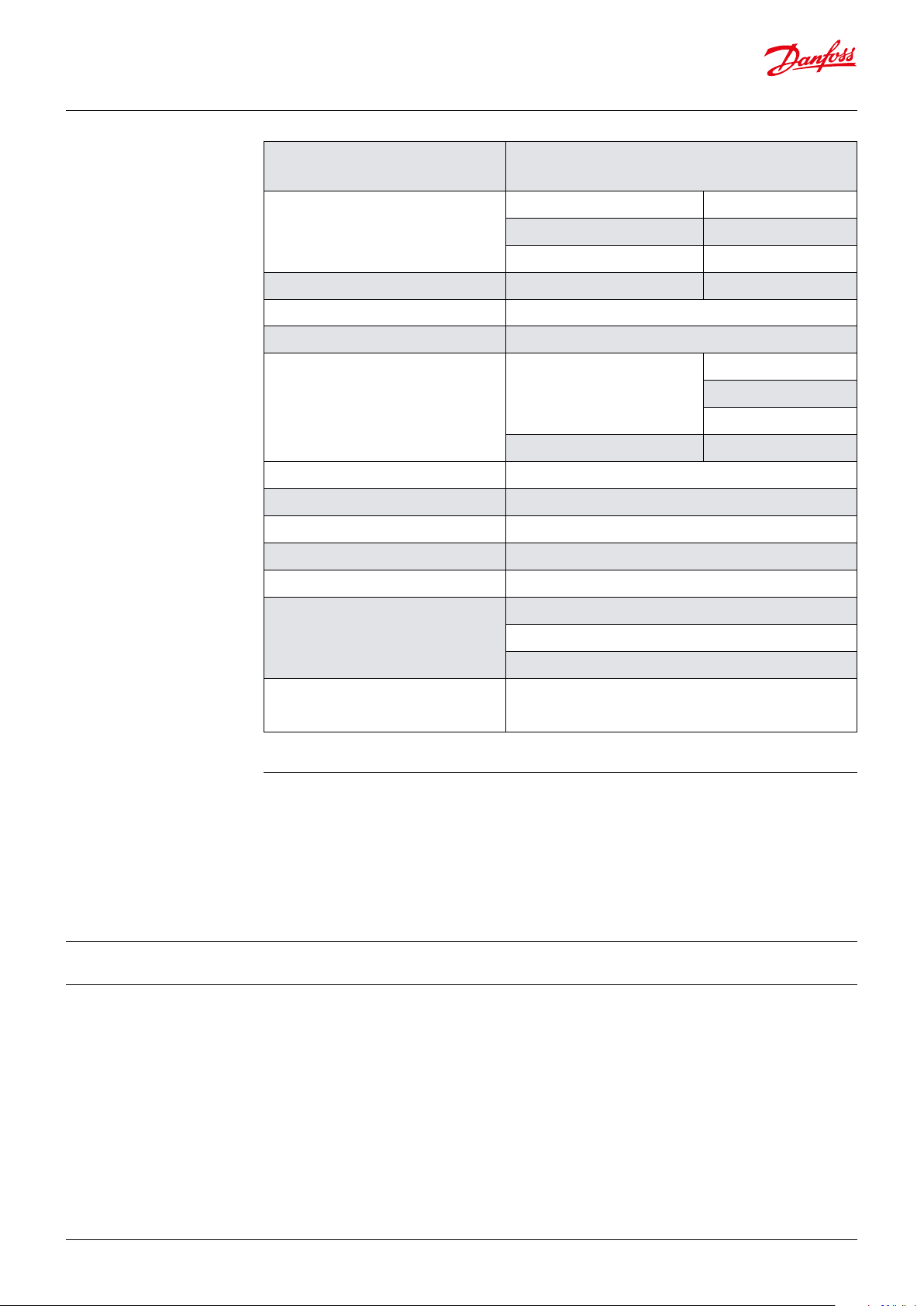

Technical data

Refrigerants

R717 (NH3), R22 and R502

"For other refrigerants, please contact Danfoss."

R12 -50 – 10 °C

Operating ranges for RT 280A

R22 and R717 (NH

) -50 – 0 °C

3

R502 -65 – -5 °C

Operating ranges for RT 281A R22 and R717 (NH

) -30 – 20 °C

3

Ambient temperature -50 – 70 °C

Switch Single pole changeover switch (SPDT), code no. 017- 4030 66

AC1: 10 A, 400 V

Alternating current

AC3: 4 A, 400 V

1

)

Contact load

AC15: 3 A, 400 V

Direct current DC13: 12 W, 220 V

Weight 2.0 kg

Enclosure IP66 to IEC 529.

Pressure connection G

3

⁄8 A with ø 6.5 / ø 10 mm weld nipple

Max. working pressure PB = 22 bar

Max. test pressure Pe = 25 bar

Materials

Ordering

Adsorption charge

Thermostatic element

3 m capillary tube

Max. permissible bulb temperature: 80 °C

Bulb with electric heater

1)

Max. short-time AC3 current: 28 A

10 W heater for 24 V DC or AC The heater must be constantly

energised whilst the system is in operation. 1.5 m connection cable.

Liquid level dierential

With a steady liquid level and a liquid level

variation rate of max. 15 mm/min, the dierential

will be approx. 10 mm on a rise in level and

approx. 20 mm on a fall in level. In unfavourable

operating conditions, dierentials of approx.

20 mm on a rise in level and approx. 60 mm on a

fall in level must be expected.

Gaskets are non-asbestos.

RT 280A code no. 017D004066

RT 281A code no. 017D004666

© Danfoss | DCS (jmn) |2016.07

DKRCC.PD.GF0.A4.02 | 520H11306 | 2

Page 3

Data sheet | Liquid Level Alarms, Safety Control, Liquid Level Regulator, types RT280A, RT281A

Design / Function

3. Pressure connection

4. Bellows element

5. Setting disc

9. Scale

10. Loop terminal

11. Pg 13.5 screwed cable

entry

12. Spring

14. Terminals

15. Spindle

16. Switch (17-4030)

17. Upper guide bush

18. Contact arm

20. Lower guide bush

38. Earth terminal

RT 280A and RT 281A units are based on RT 260A.

The lower element is thermal and has an

electrically heated bulb.

As stated, the units are primarily for use as liquid

level alarms and safety switches. In designing the

units, emphasis was placed on the failsafe function

In the event of a defect in the thermal element,

the compressor is stopped and liquid injection

cut o. Restart is only possible after the defect

has been rectied.

Note:

If the evaporating temperature, and with it the

reference pressure, is higher than the max.

regulation range temperature, the unit will react

as though the liquid level in the liquid container

was too high.

This also applies in the case of loss of charge, for

example if the capillary tube or heating element

in the bulb is damaged, or if current to the

heating element falls.

The element heating or cooling signal is

compared to the reference pressure and then

.

converted to an electric on / o impulse.

The regulating principle is based on the heat

conduction dierence between the liquid and

vapour phases of the refrigerant.

© Danfoss | DCS (jmn) |2016.07

DKRCC.PD.GF0.A4.02 | 520H11306 | 3

Page 4

Dimensions [mm] and

weights [kg]

Net weight 2.0 kg

© Danfoss | DCS (jmn) | 2016.07

DKRCC.PD.GF0.A4.02 | 520H11306 | 4

Loading...

Loading...