User Manual

PLUS+1® GUIDE

Extended Dynamic RedCAN

www.danfoss.com

User Manual

PLUS+1® GUIDE Extended Dynamic RedCAN User Manual

Revision history Table of revisions

Date Changed Rev

December 2019 Converted to Engineering Tomorrow standards 0201

January 2013 Check Appendix modes added AD

February 2012 Wording, parameter changes AC

March 2010 First revision AB

January 2010 Original revision AA

2 | © Danfoss | December 2019 AQ00000114en-000201

User Manual

PLUS+1® GUIDE Extended Dynamic RedCAN User Manual

Contents

Risk Reduction

Downloading and testing your applications..........................................................................................................................4

Important information to reduce risk....................................................................................................................................... 4

Fault checking and error handling.............................................................................................................................................4

Introduction

Overview..............................................................................................................................................................................................5

Normal CAN structure............................................................................................................................................................... 5

RedCAN structure........................................................................................................................................................................5

Transparent connection mode...............................................................................................................................................6

Normal connection mode........................................................................................................................................................6

Redundant connection mode................................................................................................................................................ 7

RedCAN Overview

Overview..............................................................................................................................................................................................8

Description.................................................................................................................................................................................... 8

RedCAN inputs.............................................................................................................................................................................8

RedCAN Outputs......................................................................................................................................................................... 8

Block Functions

Block types........................................................................................................................................................................................10

Link block..........................................................................................................................................................................................10

Link block inputs............................................................................................................................................................................ 10

Link block outputs.........................................................................................................................................................................11

Beat block......................................................................................................................................................................................... 11

Beat block inputs............................................................................................................................................................................11

Beat block outputs.........................................................................................................................................................................12

Diagnostic block.............................................................................................................................................................................13

Diagnostic block inputs...............................................................................................................................................................13

Diagnistic block outputs..............................................................................................................................................................13

Freeze block.....................................................................................................................................................................................14

Freeze block inputs....................................................................................................................................................................... 14

Freeze block outputs.................................................................................................................................................................... 14

Relays block......................................................................................................................................................................................14

Relays block inputs........................................................................................................................................................................14

Relays block outputs.....................................................................................................................................................................15

Theory of Operations

Theory of operation...................................................................................................................................................................... 16

Troubleshooting

Possible error conditions.............................................................................................................................................................21

Fixing errors..................................................................................................................................................................................... 21

Table of errors and system reactions......................................................................................................................................21

©

Danfoss | December 2019 AQ00000114en-000201 | 3

W

User Manual

PLUS+1® GUIDE Extended Dynamic RedCAN User Manual

Risk Reduction

Downloading and testing your applications

Once you have created an application, you have the responsibility to download and test the application.

You should only download your application to hardware or change software parameters while the

vehicle is not in operation. After downloading, test application operation under normal and abnormal

operating conditions. You should make sure that:

•

Individual inputs produce expected outputs .

•

Combinations of inputs do not produce unexpected or dangerous outputs

•

Fault handling and error checking work as designed

Important information to reduce risk

The applications that you create with the PLUS+1® GUIDE Service Tool program typically control heavy,

powerful, and mobile off-road equipment such as tractors, cranes, and harvesters.

Fault checking and error handling

The PLUS+1® GUIDE Service Tool program has no automatic protections against these risks. The Service

Tool has no protection against the risks that result from bugs in the Service Tool software, errors in the

Service Tool manual, or incompatibilities between software versions of the Service Tool.

You must design and test your application to reduce these risks.

You have the responsibility when designing a Service Tool application to include the checking and the

error handling needed to reduce risks in normal and abnormal operating conditions.

The following are some items to consider when developing fault checking and error handling for your

application:

•

How the machine is normally used.

•

Possible operator errors and their consequences.

•

Industry safety standards and legal requirements.

•

Input and output failures and their consequences. These failures can include:

•

Joystick, sensor, and other inputs suddenly going to 100 % or to O %.

‒

Outputs that control machinery direction, speed, and force suddenly changing direction or going

‒

to 100 % or to O %.

Decide how likely each failure is. The more likely a failure, the more you need protect against the

consequences of the failure .

•

The sequence of events and consequences of a fault or error.

•

The sequence of events and consequences of an emergency stop.

Warning

Under normal operating conditions, using this type of machinery always involves risk of personal injury

and equipment damage. Abnormal operating conditions increase the risk of personal injury and

equipment damage.

4 | © Danfoss | December 2019 AQ00000114en-000201

0

1 2

3

0

1 2

3

Connecting

Circuit

Driver

CAN

Controller

CPU

Software

User Manual

PLUS+1® GUIDE Extended Dynamic RedCAN User Manual

Introduction

Overview

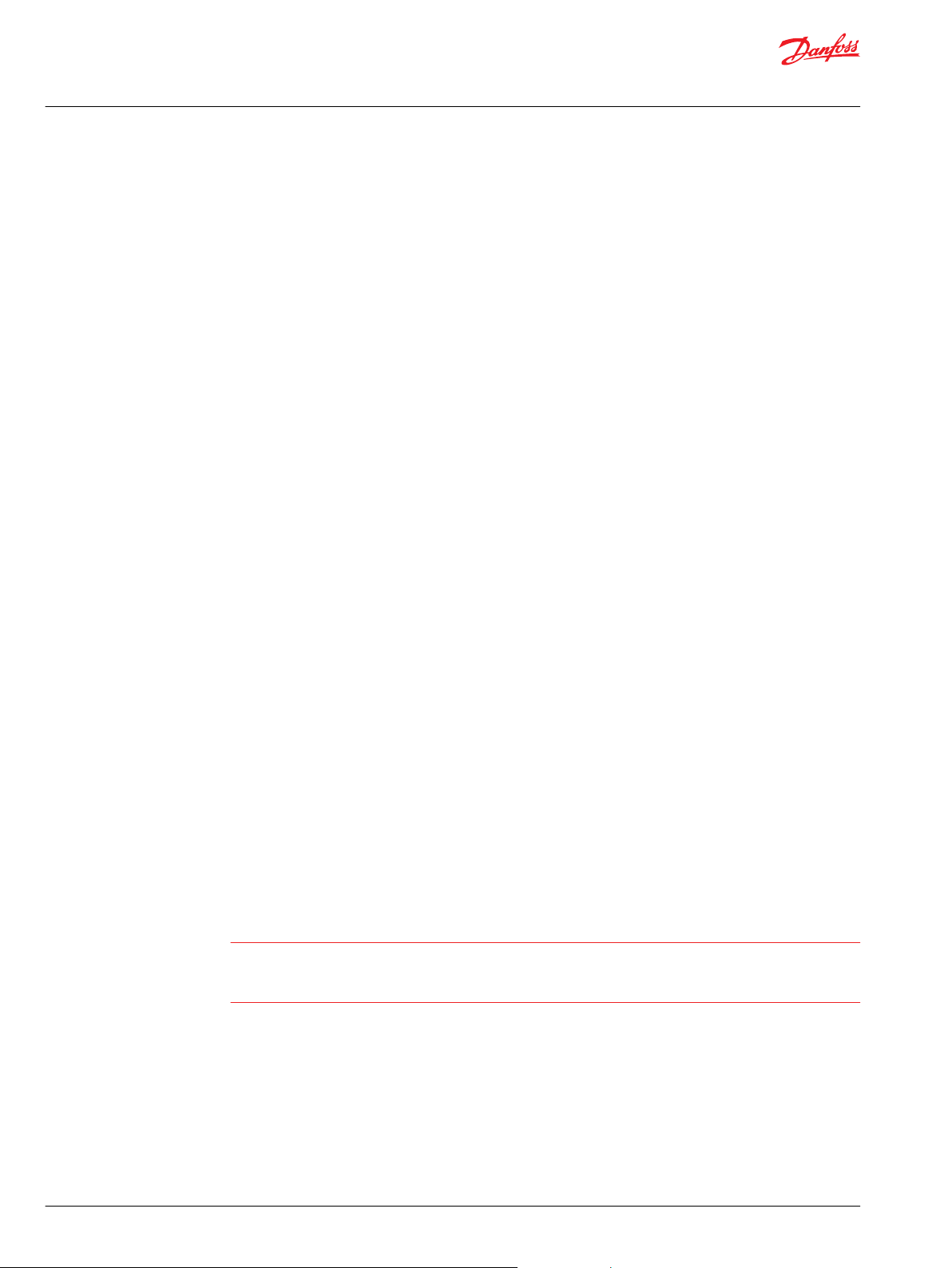

Normal CAN structure

A normal CAN structure is illustrated below. There is one single CAN connection per module. Bus

termination is handled with external resistors.

Normal CAN Structure

Danfoss RedCAN is based on a redundant CAN communication principal. RedCAN uses two CAN

connections per module. The modules are connected in a ring structure to provide a second path for

communication in the event of a segment error.

RedCAN structure

RedCAN Structure

Termination of the bus is handled automatically inside the ECU by the RedCAN connection. No external

resistors are required.

System behavior depends on parameter settings. Incorrect parameters may lead to system malfunction. It

is recommended to disconnect the controller from the system and set parameters before reconnecting it

to the system.

RedCAN uses one standard CAN driver with controller but has the additional connecting circuit logics to

terminate the bus and provide the second communication path in the event of a bus failure.

©

Danfoss | December 2019 AQ00000114en-000201 | 5

CAN Driver

with Controller

R1 R2

RE1

RE2

CAN Driver

with Controller

R1 R2

RE1

RE2

User Manual

PLUS+1® GUIDE Extended Dynamic RedCAN User Manual

Introduction

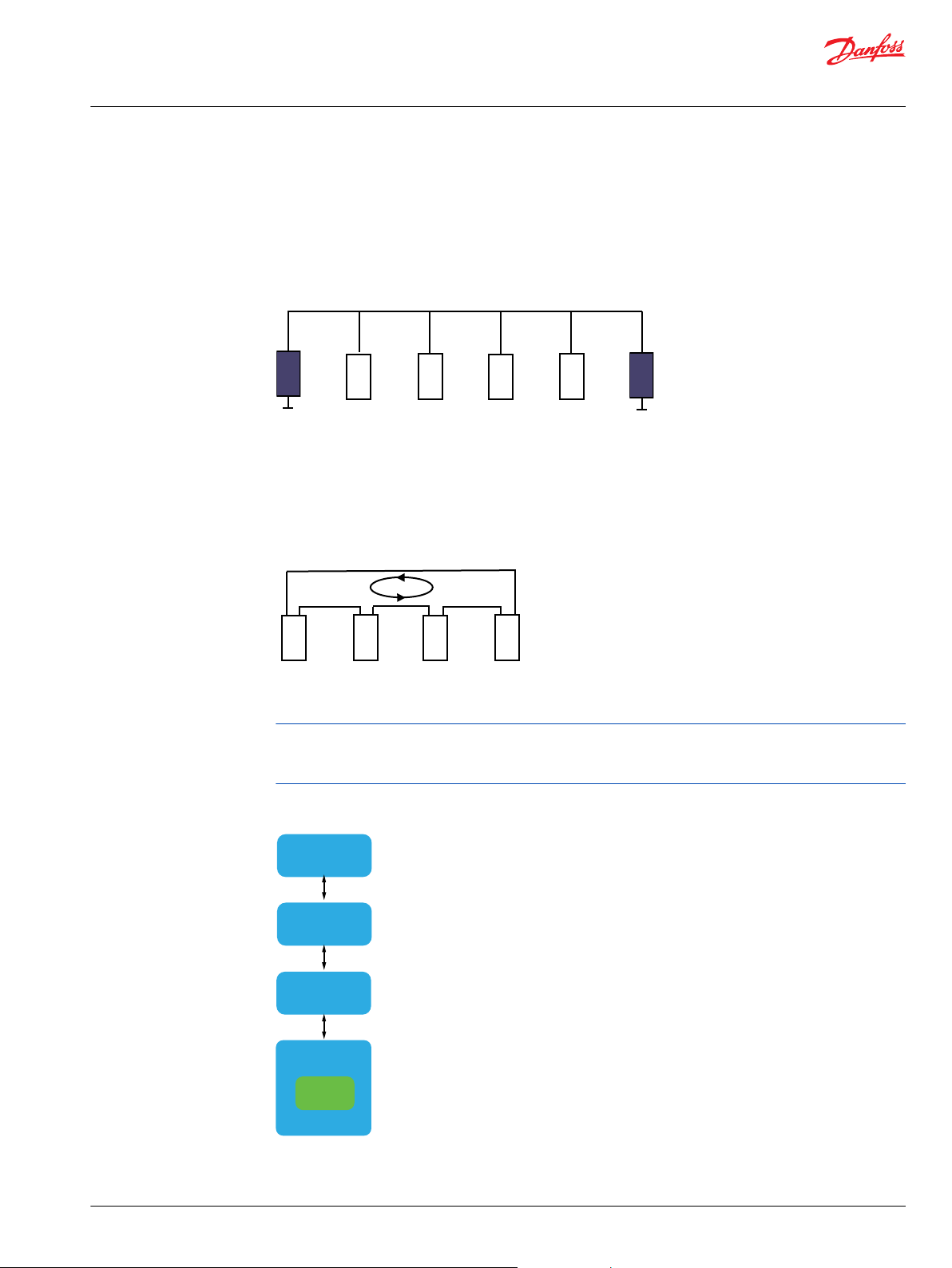

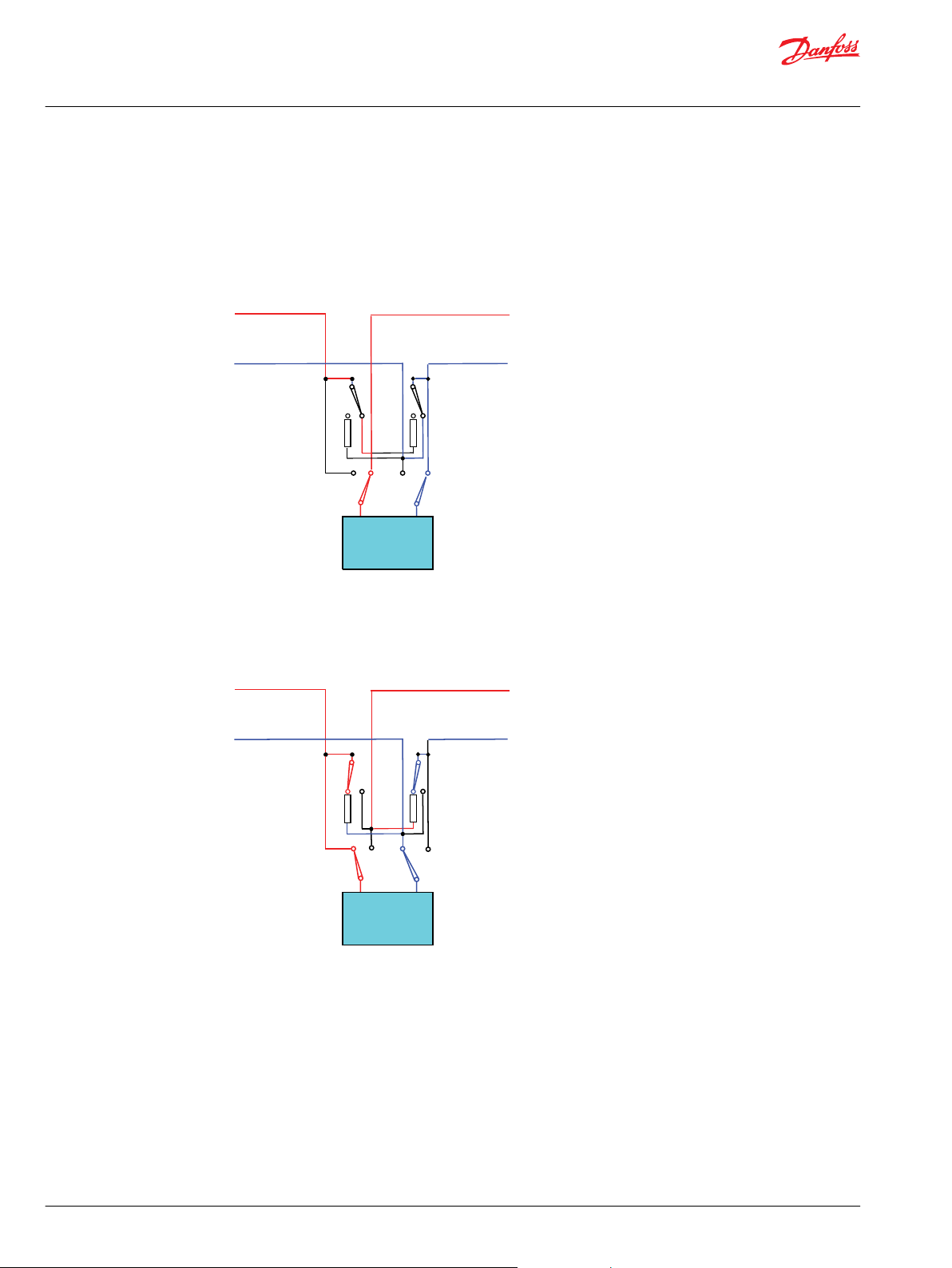

Transparent connection mode

The Connecting Circuit consists of relays that provide three different connection options:

Transparent Mode Normal and Redundant connections are both connected to the CAN controller.

Terminators are not connected.

Transparent connection mode

Normal connection mode

Normal Connection

Mode

Both Normal and Redundant connections are terminated. Only Normal

connection is connected to the CAN controller.

6 | © Danfoss | December 2019 AQ00000114en-000201

CAN Driver

with Controller

R1 R2

RE1

RE2

User Manual

PLUS+1® GUIDE Extended Dynamic RedCAN User Manual

Introduction

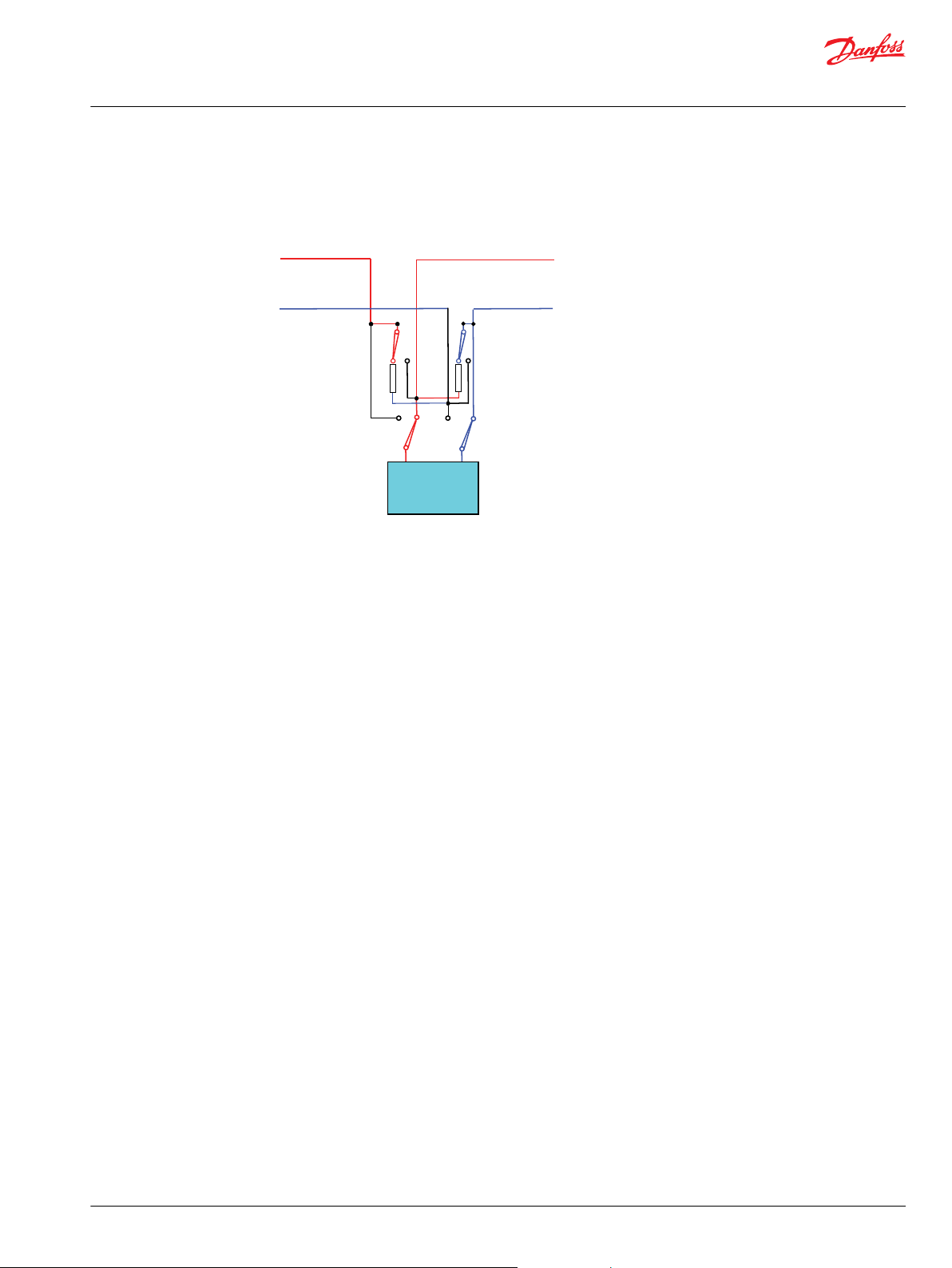

Redundant connection mode

Redundant Connection

Mode

Both Normal and Redundant connections are terminated. Only Redundant

connection is connected to the CAN controller.

©

Danfoss | December 2019 AQ00000114en-000201 | 7

User Manual

PLUS+1® GUIDE Extended Dynamic RedCAN User Manual

RedCAN Overview

Overview

Description

When using Dynamic RedCAN each node has knowledge about its closest neighbors and with that

information determines if it should act as a master holding the termination and initiating the fault

detection heartbeat or go transparent while waiting for the heartbeat to initiate.

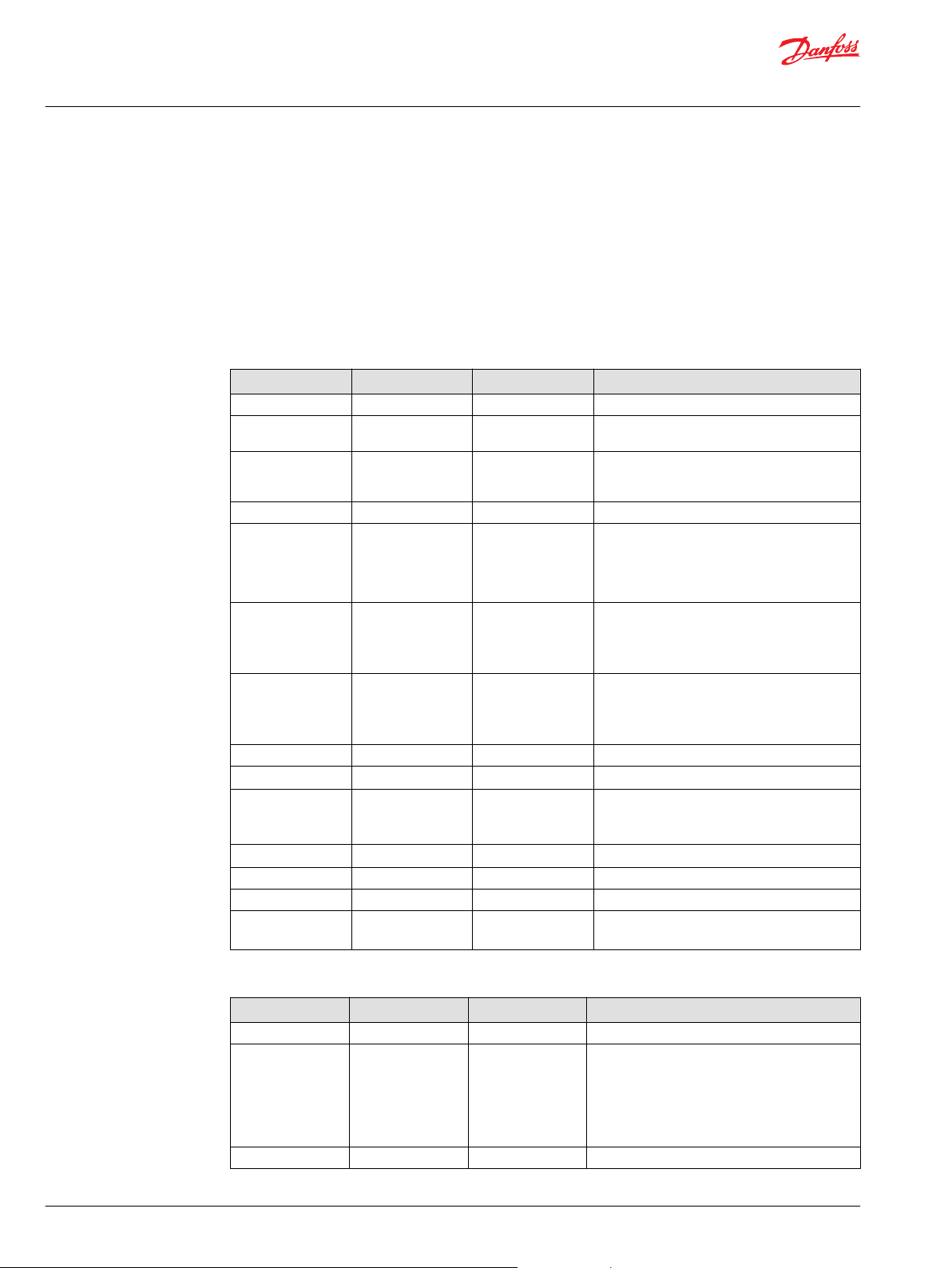

RedCAN inputs

RedCAN function block inuputs

Input Type Range Description

Freeze BOOL — Used to turn off RedCAN

Check Appendix BOOL — Used to turn master relays to look opposite

Def System ARRAY (128) U8 — Array containing predefined system. (Lowest ID

Scan BOOL — Initialize a system scan

Max Exectime U8 5–255 Maximum execution time during system scan.

Max Timeout U16 75–50000

TimeBase U16 15–10000

CAN Bus — —

Extended_ID BOOL —

CAN_ID_Offset U32 0x0-0x1FFFFF00

Node U8 0–127

Port Port — CAN port to use

BusOff BOOL — Error on CAN wire

Reset BOOL —

direction.

in position 0, Normal neighbor in position 1,

etc).

This is the execution time of the slowest unit on

the RedCAN loop and, is used for all units

connected to the RedCAN loop. Constant

recommended (default 30 ms).

Sets how long to wait for heartbeat message

before regarded as error. Minimum default

setting is 5 times greater than Time Base (450

ms).

Sets detection timeout and heartbeat rate. (how

often the heartbeat should be sent). Minimum

default setting is 3 times greater than

Max_ExecTime (90 ms).

Use extended CAN message IDs

Offset for CAN ID to put messages in a desirable

range. Messages used are in this range (0x00–

0xFF) + Offset.

Number to distinguish nodes from each other

Output activated -> Reset BusOff (delete

connection in Unit_Config).

RedCAN Outputs

Ouput Type Range Description

OS_Out

RedCAN_RelayMode U8 0–2

Status Bus

0: Transparent

1: Normal

2: Redundant

This signal is either the signal from the RedCAN_

Link block or the signal decided from the

diagnostic tool.

8 | © Danfoss | December 2019 AQ00000114en-000201

User Manual

PLUS+1® GUIDE Extended Dynamic RedCAN User Manual

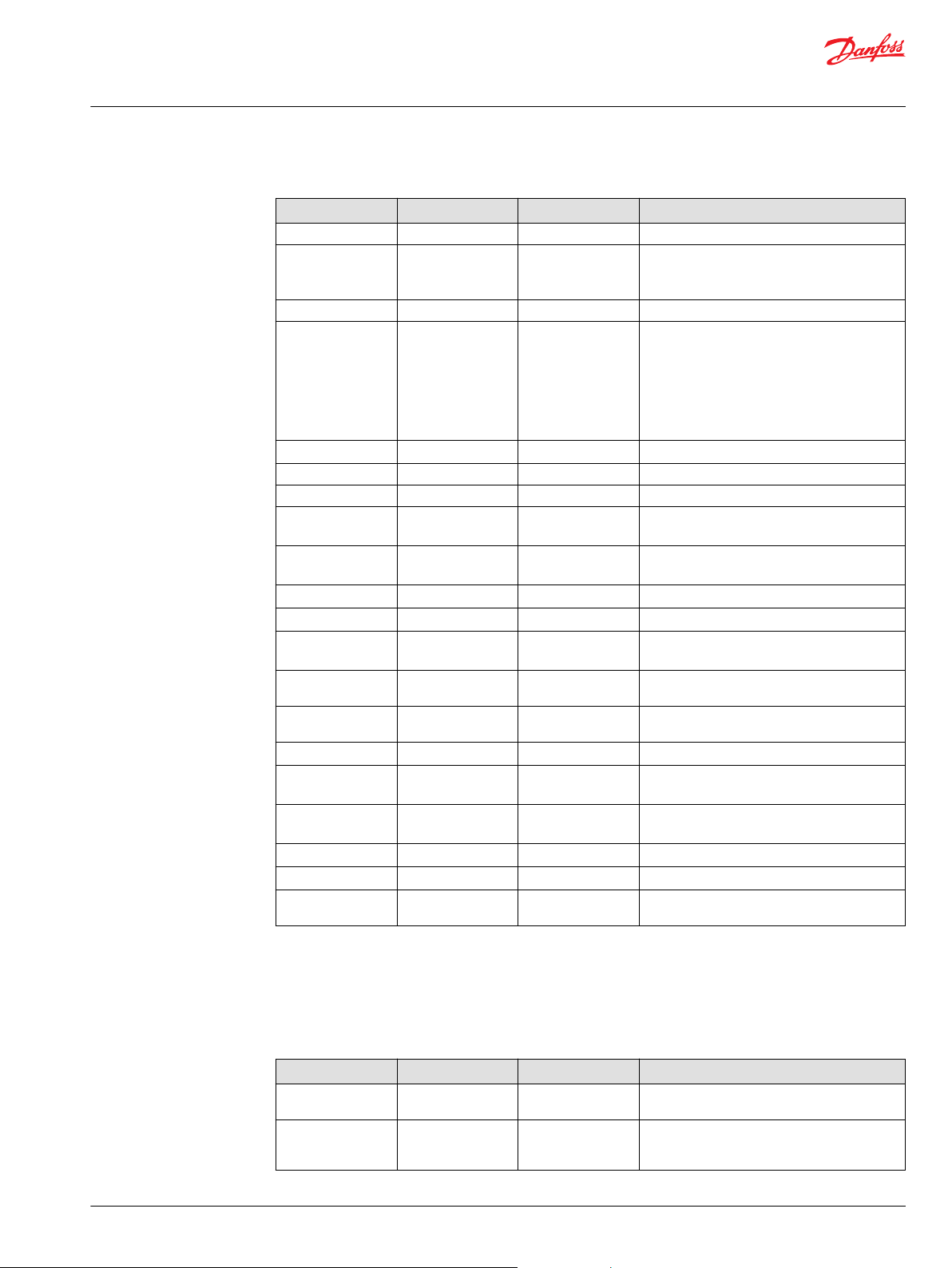

RedCAN Overview

Ouput Type Range Description

Mode S16 -1–4

NbrOfNodes U8 0–128

MisplacedArray ARRAY (128) U8 —

NodeMisplaced BOOL —

NodeNvrFnd BOOL —

NodeNvrFndArray ARRAY (128) U8 —

Fault Bus

BusError BOOL —

Node1 U8 0 – 127

Node2 U8 0 – 127

NodeGone BOOL —

NodeGoneArray ARRAY (128) U8 —

-1: Undefined (no mode has been detected after

Startup or Check Appendix)

0: System Ready

1: System Scan

2: Freeze

3: Download

4: Check Appendix

Total number of connected RedCAN nodes in the

system.

Holds information about nodes that are not

placed as defined system describes.

Flag that informs that there are nodes in the

designed system that are not connected.

Flag that informs that there are nodes in the

designed system that are not connected.

Holds information about nodes that are not

connected.

A wire error has been detected.

The error is on Normal side of this node (only

certain if all N-R connections).

The error is on the Redundant side of this node

(only certain if all N-R connections).

Flag that informs that a node has disappeared

from the system after startup.

Holds information about nodes that have been

lost since startup.

©

Danfoss | December 2019 AQ00000114en-000201 | 9

User Manual

PLUS+1® GUIDE Extended Dynamic RedCAN User Manual

Block Functions

Block types

The Extended implementation consists of five separate block parts:

•

Link Block

•

Beat Block

•

Diagnostic Block

•

Freeze Block

•

Relays Block

The blocks could all be used in every controller but it could also be that one controller acts as the

diagnostic interface and is the only one using the Diagnostic block. Other controllers in the system only

need Link and/or Beat blocks.

Link block

The Link Block detects the nodes in the System and their relative positions. It also takes care of bus

termination and disconnects faulty segments to keep the bus intact.

Link block inputs

Input Type Range Description

Freeze BOOL — Use to turn off RedCAN

Check Appendix BOOL —

System ARRAY (128) U8 —

Scan BOOL — Initialize a system scan

Init BOOL —

Delay U16 0–65535

Max Exectime U8 5–255

CAN Bus — —

Extended_ID BOOL —

CAN_ID_Offset U32

Node U8 0–127

Port — — CAN port to use

BusOff BOOL — Error on CAN wire

Reset BOOL —

0x00x1FFFFF00

Use to turn master relays to look opposite

direction. Enables detection of some faults that

may otherwise be missed.

Array containing actual system (Lowest ID in

position 0, Normal neighbor in Position 1, etc).

Controls whether a scan should be initiated on

power up.

T: Scan is initiated on power up.

F: No scan, system is regarded as correct.

Sets the delay time before heartbeat is enabled.

This is to handle differences in startup time for

the nodes in the system. Only valid when

init=false.

Maximum execution time during system scan.

Constant recommended (default 30 ms).

Use extended CAN message IDs.

Offset for CAN ID to put messages in a desirable

range. Messages used in the range (0x00–0xFF)

+ offset.

Number to distinguish nodes from each other.

Output activated-> Reset BusOff (delete

connection in Unit_Config.

10 | © Danfoss | December 2019 AQ00000114en-000201

User Manual

PLUS+1® GUIDE Extended Dynamic RedCAN User Manual

Block Functions

Link block outputs

Output Type Range Description

OS_out Bus — —

RedCAN_RelayMode U8 0–2

Status Bus — —

Mode S16 -1–4

NodeError BOOL —

Ready BOOL — System scan completed

Neighbors Bus — —

ClosestNeighb U8 0–127

IStartSprint BOOL —

ImMaster BOOL —

ImMstrOpsitNeigh BOOL —

LowestRandID U32 0–4294967295

Max_ExecTime U8 0–255 Maximum Max_ExecTime value in the system.

MyRandomID U32 0–4294967295 Needed to handle multiples with same node

NormNeighbNodeID U8 0–127

NormNeighbRandID U32 0–4294967295

OpRandID U32 0–4294967295

OppstNeighb U8 0–127

RedNeighbNodeID U8 0–127

RedNeighbRandID U32 0–4294967295 Needed to handle multiples with same node

0: Transparent

1: Normal

2:Redundant

-1: Undefined (no mode has been detected after

Startup or Check Appendix)

0: System Ready

1:System Scan

2: Freeze

3: Download

4: Check Appendix

Error found during system scan

Node ID of the neighbor the side that relays are

turned towards.

The lowest node in the system that initiates the

heart beat. First position in system array.

The lowest terminating node. Master.

The node on the opposite side of the master.

Needed to handle multiples with same node

number.

Used to set the limits for beat block timings.

number.

Node ID of the normal side neighbor.

Needed to handle multiples with same node

number.

Needed to handle multiples with same node

number.

Node ID of the opposite side neighbor.

Node ID of the Redundant side neighbor.

number.

Beat block

The Beat Block detects the absolute position of the nodes (actual system) and detects errors in runtime

Beat block inputs

Input Type Range Description

Enable BOOL — Enable heartbeat function. Connected to Link

Neighbors Bus — Information about the system to determine how

©

Danfoss | December 2019 AQ00000114en-000201 | 11

block output ready by default.

the heartbeat should be sent through the

system.

User Manual

PLUS+1® GUIDE Extended Dynamic RedCAN User Manual

Block Functions

Input Type Range Description

IStartSprint BOOL — The lowest node in the system that initiates the

ImMaster BOOL — The lowest terminating node. Master.

ImMstrOpsitNeigh BOOL — The node on the opposite side of the master.

LowestRandID U32 0–4294967295 Needed to handle multiples with the same node

Max_ExecTime U8 0–255 Maximum Max_ExecTime

MyRandomID U32 0–4294967295 Needed to handle multiples with the same node

NormNeighbNodeID U8 0–127 Node ID of the Normal side neighbor.

NormNeighbRandID U32 0–4294967295 Needed to handle multiples with the same node

OpRandID U32 0–4294967295 Needed to handle multiples with the same node

OppstNeighb U8 0–127 Node ID of the opposite side neighbor.

RedNeighbNodeID U8 0–127 Node ID of the redundant side neighbor.

RedNeighbRandID U32 0–4294967295 Needed to handle multiples with same node

Max Timeout U16 75–50000

TimeBase U16 15–10000

CAN Bus — —

Extended_ID BOOL — Use extended CAN message IDs.

CAN_ID_Offset U32

Node U8 0–127 Numbers to distinguish nodes from each other.

Port — — CAN port to use

0x00x1FFFFF00

heartbeat. First position in system array.

number.

number.

number.

number.

number.

Sets how long to wait for heartbeat message

before regarded aserror. Minimum default

setting is 5 times greater than Time Base (450

ms).

Sets detection timeout and heartbeat rate. (how

often the heartbeat should be sent).

Minimum default setting is 3 times greater than

Max_ExecTime (90 ms).

Offset for CAN ID to put messages in a desirable

range (0x00–0xFF) + Offset.

Beat block outputs

Output Type Range Description

Status Bus — —

FirstDone BOOL — First heartbeat loop done.

MasterMsg ARRAY (128) U8 —

NbrOfNodes U8 0–128

System_OK BOOL — No errors detected.

System ARRAY (128) U8 —

Scan BOOL — Initiate a system scan.

Holds information about terminating nodes.

Used to report wire errors.

Total number of connected RedCAN nodes in

system

Array containing actual system (Lowest ID in

position 0, Normal neighbor in Position 1, etc).

12 | © Danfoss | December 2019 AQ00000114en-000201

User Manual

PLUS+1® GUIDE Extended Dynamic RedCAN User Manual

Block Functions

Diagnostic block

The Diagnostic block recieves information from the other two blocks to report different types of error

situations.

Diagnostic block inputs

Input Type Range Description

Link Status Bus —

Mode S16 -1 –4

NodeError BOOL —

BeatStatus Bus — —

FirstDone BOOL — First heartbeat loop done

MasterMsg ARRAY (8) U8 —

NbrOfNodes U8 0–128

NodeFault BOOL —

Def System ARRAY (128) U8 —

Act System ARRAY (128) U8 —

CAN Bus — —

Extended_ID BOOL —

CAN_ID_Offset U32

Port — — CAN port to use

0x00x1FFFFF00

-1: Undefined (no mode has been detected after

Startup or Check Appendix)

0: System Ready

1: System Scan

2: Freeze

3: Download

4: Check Appendix

An error has been detected during system scan.

Holds information about terminating nodes.

Total number of connected RedCAN nodes in

system.

A node has failed to pass on the heart beat.

Predefined system, what the desired system

looks like.

Actual system, how the system looks (Lowest ID

in position 0, Normal neighbor in position 1,

etc).

Use Extended CAN message IDs

Offset for CAN ID to put messages in a desirable

range. (0x00–0xFF) + Offset

Diagnistic block outputs

Output Type Range Description

Status Bus — —

Mode S16 -1–4

NbrOfNodes U8 0–128

MisplacedArray ARRAY (128) U8 —

NodeMissplaced BOOL —

NodeNvrFnd BOOL —

©

Danfoss | December 2019 AQ00000114en-000201 | 13

-1: Undefined (no mode has been detected after

Startup or Check Appendix)

0: System Ready

1: System Scan

2: Freeze

3: Download

4: Check Appendix

Total number of connected RedCAN nodes in

system.

Holds information about nodes that are not

placed as defined system implies.

Flag that informs that there are nodes with

wrong position in system.

Flag that informs that there are nodes in the

designed system that are not connected.

User Manual

PLUS+1® GUIDE Extended Dynamic RedCAN User Manual

Block Functions

Output Type Range Description

NodeNvrFndArray ARRAY (128) U8 —

Fault Bus — —

BusError BOOL —

Node1 U8 0–127

Node2 U8 0–127

NodeGone BOOL —

NodeGoneAway ARRAY (128) U8 —

Freeze block

The Freeze block listens to CAN message KP0 from the Service Tool to set RedCAN to freeze. Therefore it

will keep its current status and will not react to any faults.

Holds information about nodes that are not

connected.

A wire error has been detected.

There is an error between Node 1 and Node 2.

The error is on the Normal side of this node.

(Only certain if all N–R connections).

There is an error between Node 1 and Node 2.

The error is on the Redundant side of this node.

(only certain if all N–R connections)

Flag that informs that a node has disappeared

from the system after startup.

Holds information about nodes that have been

lost since startup.

Freeze block inputs

Freeze block outputs

Relays block

Relays block inputs

Input Type Range Description

CAN Bus — —

Node U8 0–127

Port — — CAN port to use

Output Type Range Description

Freeze BOOL —

Checkpoint — — —

CP_RedCANFreeze

Number to distinguish nodes from each other

Freeze set from diagnostic tool

Shows current freeze status

The Relays block controls the steering of the RedCAN relays. When the RedCAN block is in freeze, it is

possible to set the relays to either Transparent, Normal or Redundant. The Relays block listens to CAN

message KP136.

Input Type Range Description

Freeze BOOL —

CAN Bus — —

Node U8 0–127

Port — — CAN port to use

Freeze set from diagnostic tool

Number to distinguish nodes from one another

14 | © Danfoss | December 2019 AQ00000114en-000201

User Manual

PLUS+1® GUIDE Extended Dynamic RedCAN User Manual

Block Functions

Input Type Range Description

OS_In Bus — —

RedCAN_RelayMode U8 0–2

Relays block outputs

Output Type Range Description

OS_Out — — —

RedCAN_RelayMode U8 0–2

Checkpoint — — —

CP_RedCANRelayMod U8 0–2

0: Transparent

1: Normal

2: Redundant

The signal coming from the RedCAN_Link block.

This is the signal determined from the last

linking of the units.

0: Transparent

1: Normal

2: Redundant

This signal is either the signal from the

RedCANLink block or the signal decided from

the service tool.

Shows the current status of the RedCAN relay

mode.

©

Danfoss | December 2019 AQ00000114en-000201 | 15

2

2

3

2

2

3

2

2

2

1

1

3

User Manual

PLUS+1® GUIDE Extended Dynamic RedCAN User Manual

Theory of Operations

Theory of operation

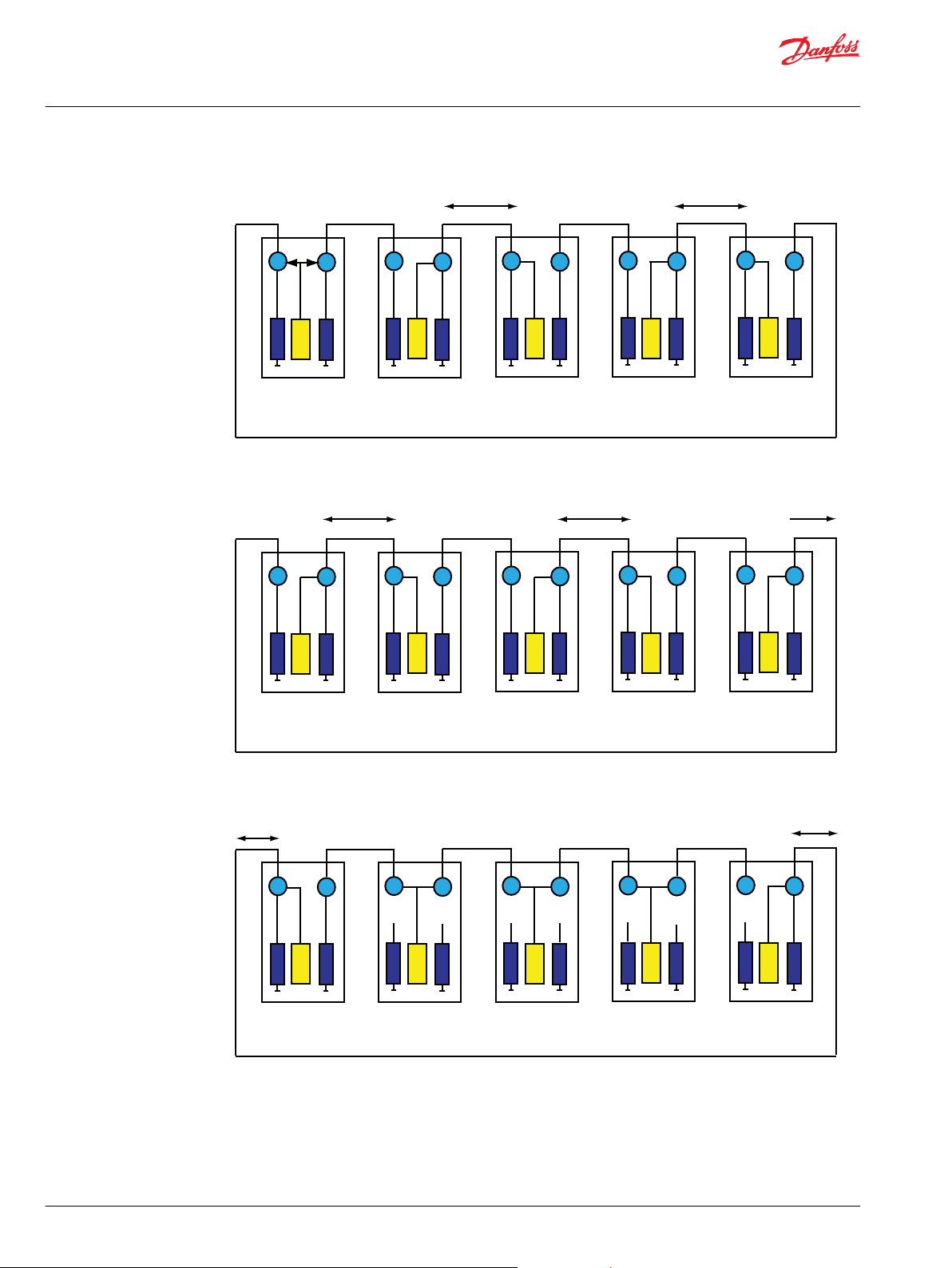

When the system is complete and there are no faults, each node could be in any of the following states:

Scanning. No Neighbor found

Normal neighbor found. Perform

handshake.

Redundant neighbor found. Perform

handshake

Own node ID: 2, Lowest node ID: 2.

None found: Lowest = Own

Own node ID: 2, Lowest node ID: 2,

Normal neighbor: 3

Own node ID: 3, Lowest node ID: 2,

Redundant neighbor: 2

Lower node ID detected. Set

Transparent

16 | © Danfoss | December 2019 AQ00000114en-000201

Own node ID: 2, Lowest node ID: 1,

Own ID (2) >Lowest ID (1), Normal

neighbor : 3, Redundant neighbor : 1

2

1

5

5

1

5

Done

1

4 1

5

Done

1

4 1

5

4

3

2

1

1 2 3 4 5

Lowest Known ID

User Manual

PLUS+1® GUIDE Extended Dynamic RedCAN User Manual

Theory of Operations

Node is detected as lowest Node ID,

terminate and ask for opposite

neighbor

Node is asked for as opposite

neighbor. Reply

Lowest Node ID has recieved reply

from opposite neighbor. Ring is

complete and • heart beat is initiated

Own Node ID : 1, Lowest Node ID : 1,

Own ID (1) = Lowest ID, Normal

neighbor : 2, Redundant neighbor : 5,

Opposite neighbor : 5

Own Node ID :5, Lowest Node ID : 1,

Normal neighbor : 1, Redundant

neighbor : 4, Opposite neighbor : 5,

Own ID (5) : Opposite neighbor

At start up, or if an error is detected, a scan system is initialized:

©

Danfoss | December 2019 AQ00000114en-000201 | 17

5

4

3

2

1

1 2 2 4 4

3

5

Lowest Known ID

2 4

5

4

3

2

1

1 1 2 4

2 1

3

2

4

3

4

5

Lowest Known ID

3

5

4

3

2

1

1 1 2 1

2 1

3

2

4

3

45

2 >1

3 > 2

1

1

Lowest Known ID

4 > 3

3

User Manual

PLUS+1® GUIDE Extended Dynamic RedCAN User Manual

Theory of Operations

The position in the system determines if the node should turn to the normal or the redundant side:

When the neighbor has been detected or if the random time out passes, the node turns toward the opposite

side.

When the Node ID is not the lowest known ID in the system and both neighbors are found, the node turns

transparent.

18 | © Danfoss | December 2019 AQ00000114en-000201

5

4

3

2

1

1 1 2 1

2 1

3

2

4

3

45

5 > 1

1

1=1

5

5

Lowest Known ID

3

5

4

3

2

1

1 1 1 1 1

2 1

3

2

4

3

4

5

5 = 5

1

1=1

5

5

Lowest Known ID

5

4

3

2

1

1 1 1 1 1

2 1

3

2

4

3

45

1

5

2

1=1

2=2

Lowest Known ID

User Manual

PLUS+1® GUIDE Extended Dynamic RedCAN User Manual

Theory of Operations

The lowest known ID in the system takes the role of master and holds termination for the system.

The lowest known ID in the system takes the role of master and holds termination for the system.

Then turns and ask for other opposite neighbor to ensure a complete system and the opposite neighbor

applies.

©

Danfoss | December 2019 AQ00000114en-000201 | 19

5

4

3

2

1

1 1 1

2 1

3

2

4

3

45

1

Done

5

Lowest Known ID

1

1

User Manual

PLUS+1® GUIDE Extended Dynamic RedCAN User Manual

Theory of Operations

The master then sends out a system OK and initiates the heart beat.

Theory of operation: Summary

When the system is connected (Mode = 0), a heartbeat message is transmitted to confirm a healthy

communication path. Each node then listens to the heartbeat messages from its two neighbors and if

one of the messages does not come through an error is declared and a new scan is initiated.

To determine the exact setup of the system, a sequence of messages is sent from the master node to it’s

neighbor in normal direction. The messages are then passed on to the next neighbor until the complete

system is covered. In this way, all nodes will get information about the complete system setup and it can

be compared with the predefined system to detect errors in node order.

It is optional to scan at power up. If init is false, a scan is not triggered and the system input is used as a

predefined system to determine the master node (terminating and starting the heart beat). The entire

ring is always checked at startup by the master asking for opposite neighbors in both directions.

20 | © Danfoss | December 2019 AQ00000114en-000201

User Manual

PLUS+1® GUIDE Extended Dynamic RedCAN User Manual

Troubleshooting

Possible error conditions

This table identifies errors that could possibly occur:

Problem Possible Cause

Bus/segment errors CAN wires shortened, faulty ground connection

Node missing/ not responding or ‘babbling idiot’

behavior

Node misplaced Positions in actual system differ from defined system

Fixing errors

The time to detect an error and fix it depends on the parameter settings. The parameter ‘Time Base’ sets

the timeout for the heartbeat message. This is the error detection time. The parameter ‘Max_ExecTime’ is

used to calculate how long a node will wait for a response before changing direction during a scan. The

theoretical worst case scan time is 112*Max_ExecTime, calculated based on the total timeout. The

theoretical best time is 32*Max_ExecTime, based on the time for communicating only (no waiting time).

The total fix time is the sum of error detection time and scan time:

•

Worst Case fix time: TimeBase + 112*Max_ExecTime

•

Best Case fix time: Time Base + 32*Max_ExecTime

All nodes in defined system are not present in actual

system

Table of errors and system reactions

If several errors appear at once, they are all reported but a functional system cannot be guaranteed if

more than one error occurs at the same time.

RedCAN is able to handle the first error and report where the first error occurs so it can be fixed. But, if

that error is not fixed then there is no guarantee that the system will continue to work if another error is

occurring.

Output Type Range Description

Status Bus — —

Mode S16 -1–4

NbrOfNodes U8 0–128

MisplacedArray ARRAY (128) U8 —

NodeMissplaced BOOL —

NodeNvrFnd BOOL —

NodeNvrFndArray ARRAY (128) U8 —

Fault Bus — —

BusError BOOL —

Node1 U8 0–127

-1: Undefined (no mode has been detected)

0: System Ready

1: System Scan

2: Freeze

3: Download

4: Check Appendix

Total number of connected RedCAN nodes in

system

Holds information about nodes that are not placed

as defined system implies.

Flag that informs that there are nodes with wrong

position in system.

Flag that informs that there are nodes in the

designed system that are not connected.

Holds information about nodes that are not

connected.

A wire error has been detected.

There is an error between Node 1 and Node 2.

The error is on the Normal side of this node. (Only

certain if all N–R connections).

©

Danfoss | December 2019 AQ00000114en-000201 | 21

User Manual

PLUS+1® GUIDE Extended Dynamic RedCAN User Manual

Troubleshooting

Output Type Range Description

Node2 U8 0–127

NodeGone BOOL —

NodeGoneAway ARRAY (128) U8 —

There is an error between Node 1 and Node 2. The

error is on the Redundant side of this node (only

certain if all N–R connections).

Flag that informs that a node has disappeared from

the system after startup.

Holds information about nodes that have been lost

since startup.

22 | © Danfoss | December 2019 AQ00000114en-000201

Danfoss

Power Solutions GmbH & Co. OHG

Krokamp 35

D-24539 Neumünster, Germany

Phone: +49 4321 871 0

Danfoss

Power Solutions ApS

Nordborgvej 81

DK-6430 Nordborg, Denmark

Phone: +45 7488 2222

Danfoss

Power Solutions (US) Company

2800 East 13th Street

Ames, IA 50010, USA

Phone: +1 515 239 6000

Danfoss

Power Solutions Trading

(Shanghai) Co., Ltd.

Building #22, No. 1000 Jin Hai Rd

Jin Qiao, Pudong New District

Shanghai, China 201206

Phone: +86 21 2080 6201

Products we offer:

Hydro-Gear

www.hydro-gear.com

Daikin-Sauer-Danfoss

www.daikin-sauer-danfoss.com

DCV directional control

•

valves

Electric converters

•

Electric machines

•

Electric motors

•

Gear motors

•

Gear pumps

•

Hydrostatic motors

•

Hydrostatic pumps

•

Orbital motors

•

PLUS+1® controllers

•

PLUS+1® displays

•

PLUS+1® joysticks and

•

pedals

PLUS+1® operator

•

interfaces

PLUS+1® sensors

•

PLUS+1® software

•

PLUS+1® software services,

•

support and training

Position controls and

•

sensors

PVG proportional valves

•

Steering components and

•

systems

Telematics

•

Danfoss Power Solutions is a global manufacturer and supplier of high-quality hydraulic and

electric components. We specialize in providing state-of-the-art technology and solutions

that excel in the harsh operating conditions of the mobile off-highway market as well as the

marine sector. Building on our extensive applications expertise, we work closely with you to

ensure exceptional performance for a broad range of applications. We help you and other

customers around the world speed up system development, reduce costs and bring vehicles

and vessels to market faster.

Danfoss Power Solutions – your strongest partner in mobile hydraulics and mobile

electrification.

Go to www.danfoss.com for further product information.

We offer you expert worldwide support for ensuring the best possible solutions for

outstanding performance. And with an extensive network of Global Service Partners, we also

provide you with comprehensive global service for all of our components.

Local address:

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

already on order provided that such alterations can be made without subsequent changes being necessary in specifications already agreed.

All trademarks in this material are property of the respective companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

©

Danfoss | December 2019 AQ00000114en-000201

Loading...

Loading...