Page 1

MAKING MODERN LIVING POSSIBLE

Data sheet

Liquid Distributor

Type RD

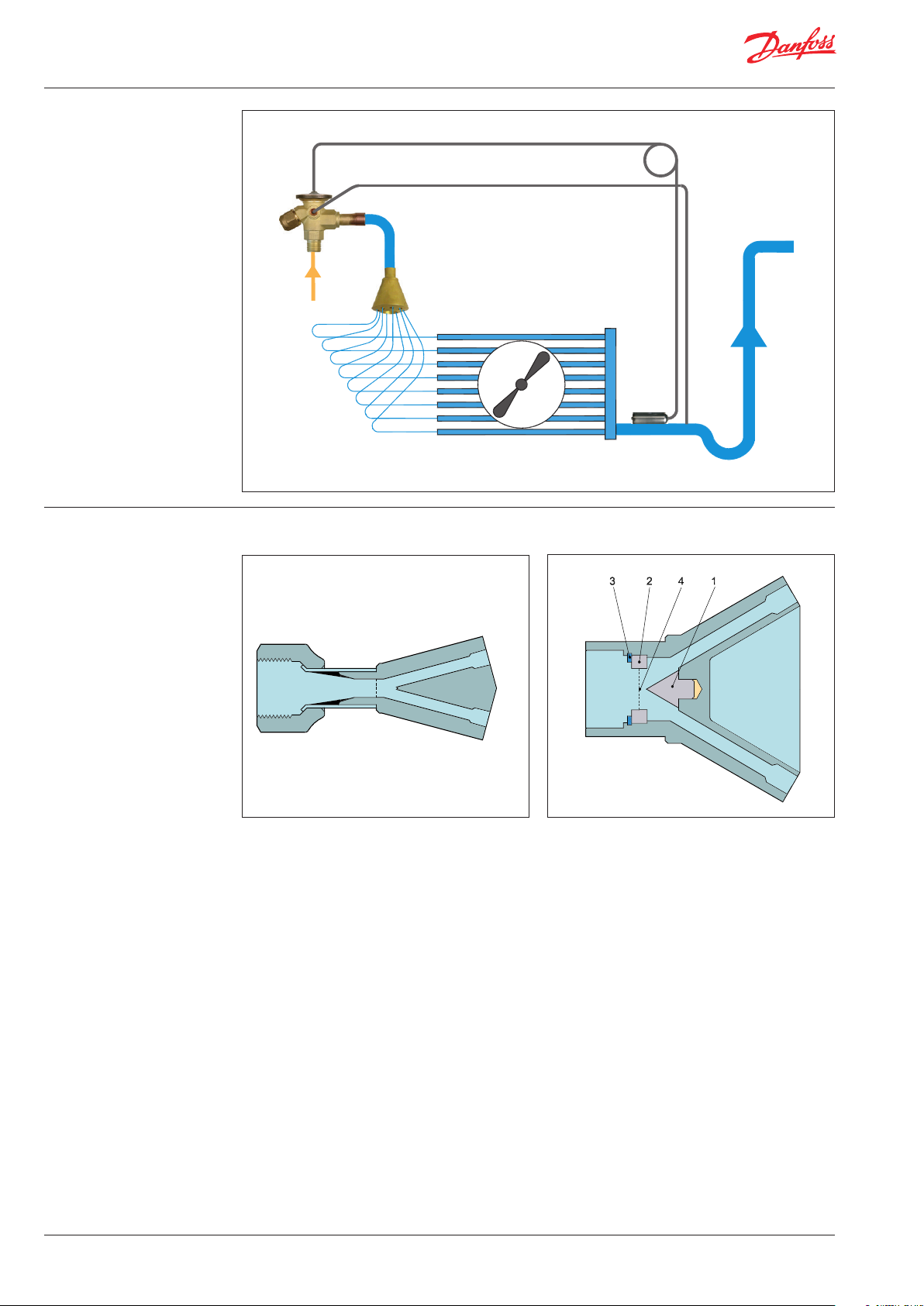

The RD refrigerant distributors distribute

liquid refrigerants from the thermostatic

expansion valve to individual sections of the

evaporator.

Note!

The thermostatic expansion valve must have

external pressure equalization.

Features y A wide range of RD refrigerant distributors is

available, covering the majority of customer

demands.

y RD design ensures a uniform distribution of

refrigerant to each evaporator section.

y Suitable for refrigerants R22, R134a,

R404A, R407C, R507, R410A.

Concerning other refrigerants

please contact Danfoss.

y Maximum working pressure:

MWP/PS 48 bar/700 psig.

DKRCC.PD.FF0.A2.02 / 520H7413

Page 2

Data sheet Liquid Distributor, type RD

R64-2102.10

Application example

Danfoss

Design RD, are RD, solder ODM

Danfoss

69G184.12.12

Danfoss

69G183.12

1. Cone

2. Nozzle

3. Locking ring

4. Nozzle diameter

2 DKRCC.PD.FF0.A2.02 / 520H7413

Page 3

Data sheet Liquid Distributor, type RD

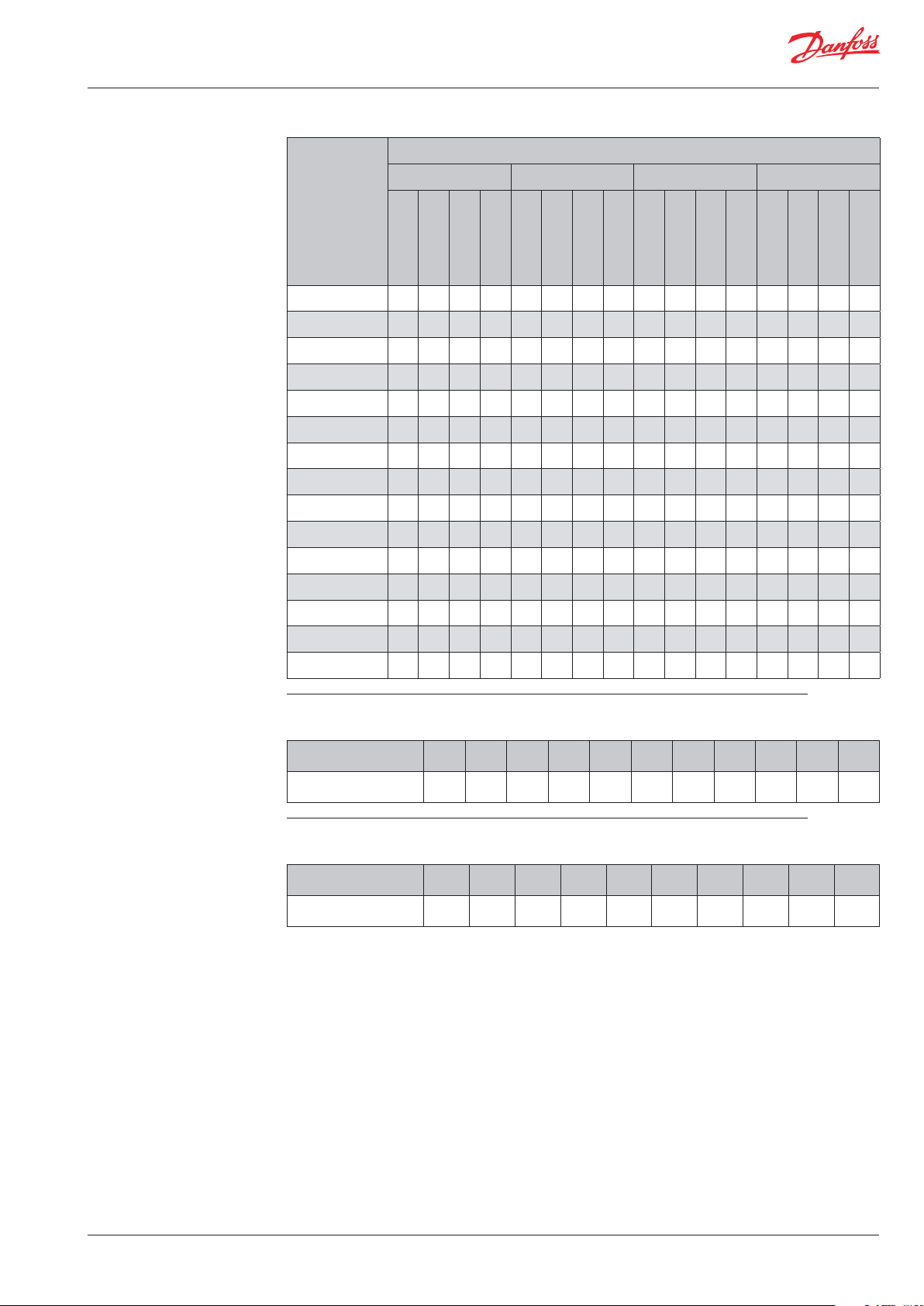

Capacity Table 1. Capacity in kW for 1 m distributor tube with ∆p = 0.5 bar

Outer diameter of distributor tubes

3

Evaporating

/16 in. / 5 mm

temperature

t

e

[°C]

R22 / R407C

R134a

R404A / R507

10 2.4 2.1 1.9 2.6 5.1 4.2 3.8 5.6 9.7 8 7.2 10.7 15.8 13.1 12 17.4

5 2.2 1.8 1.6 2.4 4.5 3.7 3.4 5.0 8.5 7 6.4 9.4 14 11.6 10.6 15.4

0 1.9 1.6 1.5 2.1 4 3.3 3 4.4 7.4 6.1 5.6 8.1 12.3 10.1 9.3 13.5

-5 1.6 1.3 1.3 1.8 3.4 2.8 2.6 3.7 6.4 5.3 4.6 7.0 10.6 8.7 8 11.7

-10 1.4 1.2 1.1 1.5 2.9 2.4 2.2 3.2 5.5 4.5 4.2 6.1 9.1 7.4 6.9 10

-15 1.2 0.99 0.93 1.3 2.4 2 1.9 2.6 4.7 3.8 3.5 5.2 7.7 6.3 5.8 8.5

-20 0.99 0.87 0.76 1.1 2.1 1.7 1.6 2.3 4 3.3 3 4.4 6.5 5.4 5 7.2

-25 0.87 0.7 0.64 0.96 1.7 1.5 1.3 1.9 3.3 2.7 2.5 3.6 5.6 4.5 4.2 6.2

-30 0.7 0.58 0.52 0.77 1.5 1.2 1.1 1.7 2.8 2.3 2.1 3.1 4.7 3.8 3.5 5.2

-35 0.58 0.47 0.47 0.64 1.2 0.99 0.93 1.3 2.3 1.9 1.7 2.5 3.9 3.1 2.9 4.3

-40 0.52 0.41 0.41 0.57 1.1 0.87 0.81 1.2 2 1.7 1.5 2.2 3.3 2.7 2.5 3.6

-45 0.47 0.35 0.35 0.52 0.87 0.76 0.7 0.96 1.7 1.4 1.3 1.9 2.8 2.3 2.2 3.1

-50 0.41 0.29 0.29 0.45 0.76 0.64 0.6 0.84 1.5 1.2 1.1 1.7 2.4 2 1.9 2.6

-55 0.35 0.23 0.23 0.39 0.64 0.52 0.52 0.70 1.3 1 0.93 1.4 2.2 1.7 1.6 2.4

-60 0.29 0.2 0.18 0.32 0.52 0.47 0.47 0.57 1.2 0.81 0.76 1.3 1.9 1.4 1.5 2.1

R410A

1

/4 in. / 6 mm

R22 / R407C

R134a

R404A / R507

R410A

5

/16 in. / 8 mm

R22 / R407C

R134a

R404A / R507

R410A

3

/8 in. / 10 mm

R22 / R407C

R134a

R404A / R507

R410A

Table 2. Correction factor for tube length

Tube length [mm] 250 400 550 700 850 1000 1150 1300 1450 1600 1750

Correction Factor 1.55 1.29 1.19 1.11 1.05 1.00 0.95 0.90 0.87 0.84 0.78

Table 3. Correction factor for liquid temperature

Liquid temperature [°C] 10 15 20 25 28 30 35 40 45 50

Correction factor 1.59 1.40 1.24 1.09 1.00 0.95 0.82 0.71 0.61 0.52

DKRCC.PD.FF0.A2.02 / 520H7413 3

Page 4

Data sheet Liquid Distributor, type RD

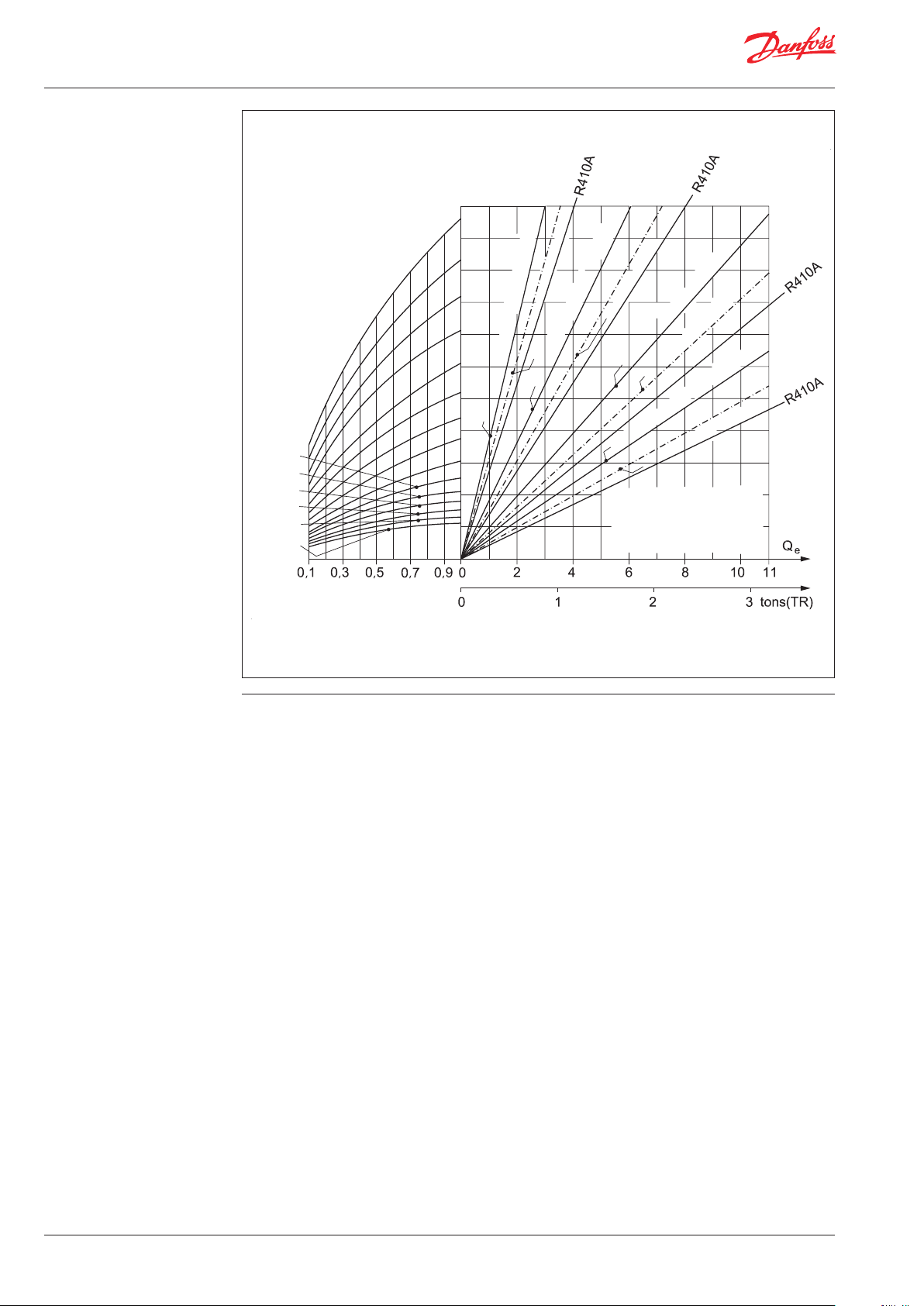

Capacity

(continued)

Danfoss

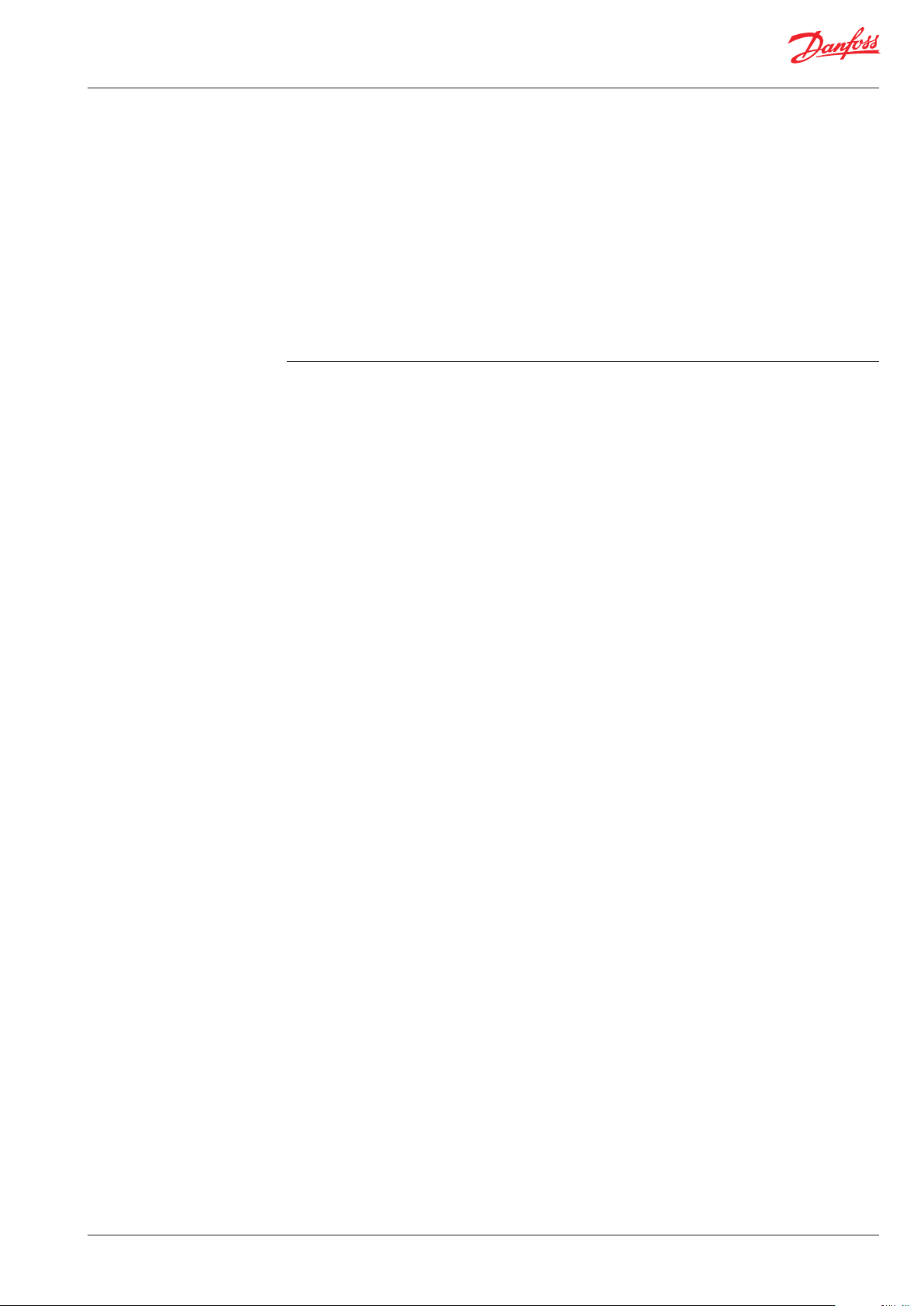

A69-141.11_FW

= 10 °C

e

t

5 °C

0 °C

1/4 in. / 6 mm

R22

-5 °C

-10 °C

-35 °C

-40 °C

-15 °C

-20 °C

-25 °C

-30 °C

R134a, R404A 3/16 in. / 5 mm

-45 °C

-50 °C

-55 °C

-60 °C

Δp [bar]

Figure 1

It is recommended that distributor tubes are

sized for a pressure drop of approx. 0.5 bar.

Table 1, which gives the capacities for dierent

tube sizes, is based on this pressure drop.

R22 3/16 in. / 5 mm

R134a, R404A 5/16 in. / 8 mm

R22 5/16 in. / 8 mm

R134a, R404A 1/4 in. / 6 mm

R134a, R404A 3/8 in. / 10 mm

R22 3/8 in. / 10 mm

3

/

in.: ø4.80 × 3.00 mm

16

1

/

in.: ø6.35 × 4.80 mm

4

5

/

in.: ø7.94 × 6.16 mm

16

3

/

in.: ø9.53 × 7.75 mm

8

[kW]

Figure 1 shows the relation between evaporator

capacity Qe, refrigerant, tube diameter, evaporating

temperature t

and pressure drop Δp for 1 m

e

distributor tube.

For tube lengths exceeding 1 m, tubes should be

selected with larger diameters than indicated in

table 1.

4 DKRCC.PD.FF0.A2.02 / 520H7413

Page 5

Data sheet Liquid Distributor, type RD

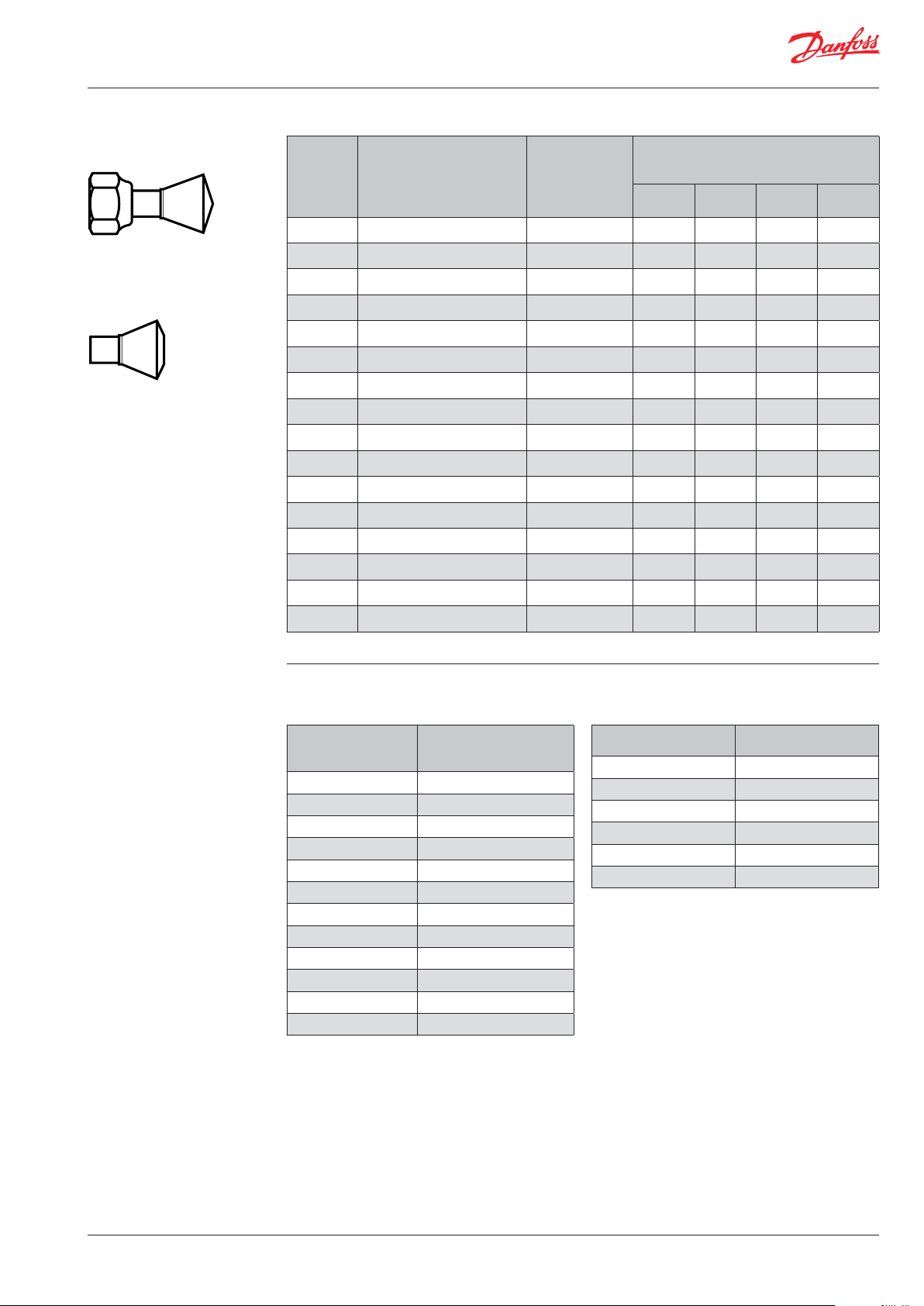

Ordering

RD, are

RD, solder

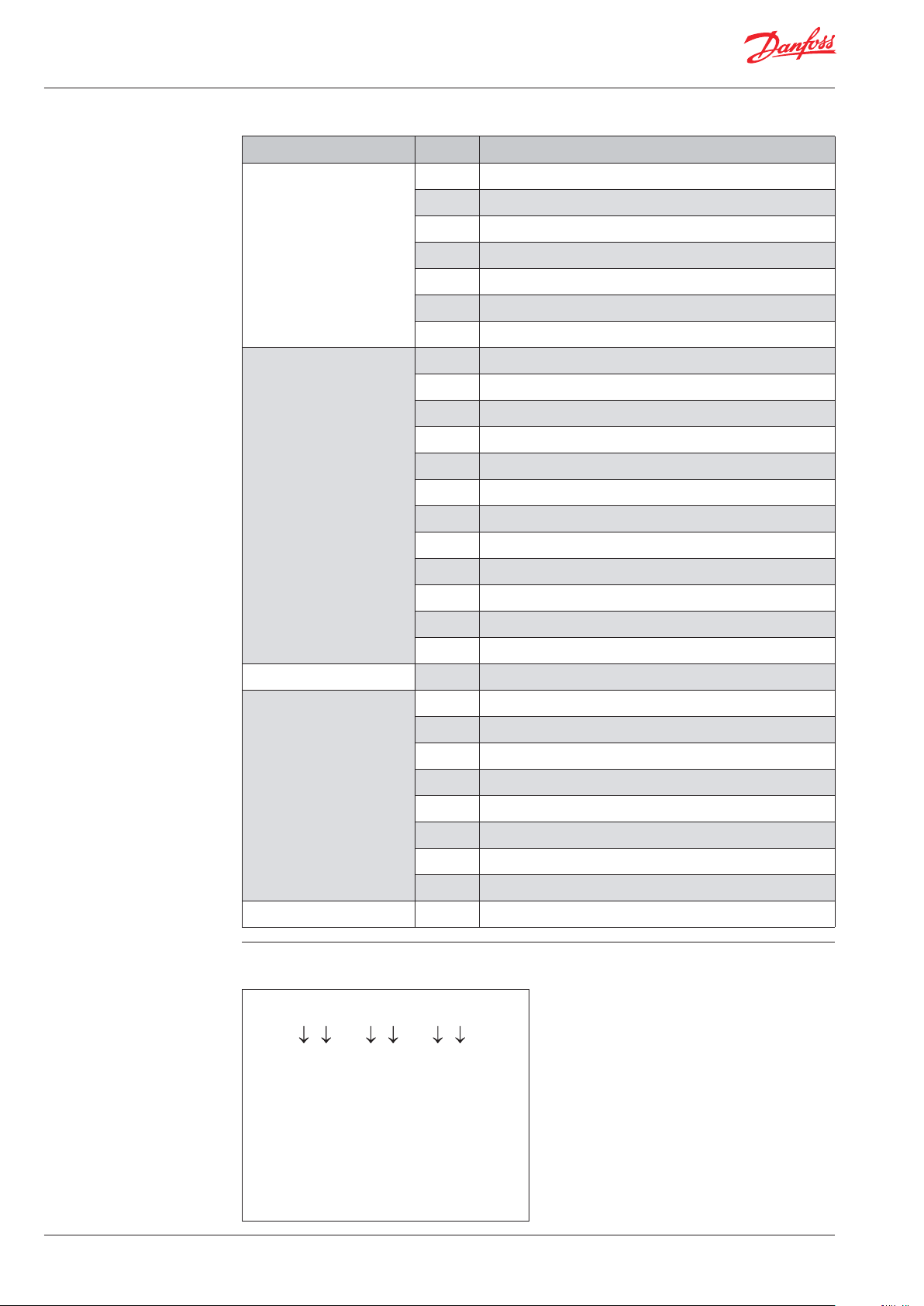

Table 4

Distributor

type

RD 21

RD 27

RD 21

RD 27

RD 33

RD 33

RD 42

RD 33

RD 33

RD 42

RD 49

RD 49

RD 62

1)

RD 79

1)

RD 85

1)

RD 85

1)

Replaceable nozzle, for nozzles with other diameters, see table 5

Distributor inlet

1

/2 in. are ≤ 25 kW (7 TR) 4 3 — —

1

/2 in. are ≤ 25 kW (7 TR) 6 5 — —

1

/2 in. / 12 mm solder ODM ≤ 25 kW (7 TR) 4 3 — —

1

/2 in. / 12 mm solder ODM ≤ 25 kW (7 TR) 6 5 — —

1

/2 in. are ≤ 35 kW (10 TR) 9 6 — —

1

/2 in. / 12 mm solder ODM ≤ 35 kW (10 TR) 9 6 — —

1

/2 in. / 12 mm solder ODM ≤ 35 kW (10 TR) 13 9 — —

5

/8 in. are ≤ 35 kW (10 TR) 8 6 4 —

5

/8 in. / 16 mm solder ODM ≤ 35 kW (10 TR) 8 6 4 —

5

/8 in. / 16 mm solder ODM ≤ 35 kW (10 TR) 13 9 7 —

5

/8 in. / 16 mm solder ODM ≤ 85 kW (25 TR) 17 14 10 —

7

/8 in. / 22 mm solder ODM ≤ 85 kW (25 TR) 17 14 10 —

7

/8 in. / 22 mm solder ODM ≤ 120 kW (35 TR) — 18 14 —

11/8 in. / 28 mm solder ODM ≤ 250 kW (70 TR) — 24 19 15

11/8 in. / 28 mm solder ODM ≤ 300 kW (85 TR) — 27 22 18

13/8 in. / 35 mm solder ODM ≤ 300 kW (85 TR) — 27 22 18

Rated capacity of

expansion valves

(R407C)

Max. number of holes and size of distributor

outlet (ODF)

3

/16 in. /

5 mm

1

/4 in. /

6 mm

5

/16 in. /

8 mm

3

/8 in. /

10 mm

Table 5. Standard nozzle size Table 6. Rated capacity correction factor depending

on refrigerant (for use in conjunction with table 4)

Distributor type Nozzle diameter 1) [mm]

RD 21 5.0

RD 27 5.0

RD 33 6.0

RD 42 6.0

RD 49 8.0

RD 62 9.0

RD 79 8.0

RD 79 10.1

RD 79 12.4

RD 79 14.3

RD 85 17.5

RD 85 18.5

1)

The optimum nozzle diameter depends on the plant conditions.

Refrigerant Correction factor

R407C 1.00

R22 0.92

R134a 0.72

R507 0.68

R404A 0.68

R410A 1.14

DKRCC.PD.FF0.A2.02 / 520H7413 5

Page 6

Data sheet Liquid Distributor, type RD

Type nomenclature

Table 7

Type RD Refrigerant Distributor

21 ø21 mm

27 ø27 mm

33 ø33 mm

Body

Inlet connector

42 ø42 mm

49 ø49 mm

79 ø79 mm

85 ø85 mm

A 12 mm solder ODM

B 16 mm solder ODM

C 22 mm solder ODM

D 28 mm solder ODM

E 35 mm solder ODM

1

J

L 1

/2 in. solder ODM

5

/8 in. solder ODM

7

/8 in. solder ODM

1

/8 in. solder ODM

3

/8 in. solder ODM

1

/2 in. are F

5

/8 in. are F

H

K

M 1

P

Q

Nozzle size ## mm

A 5 mm solder ODF

B 6 mm solder ODF

C 8 mm solder ODF

D 10 mm solder ODF

Outlet connector

3

J

L

/16 in. solder ODF

1

/4 in. solder ODF

5

/16 in. solder ODF

3

/8 in. solder ODF

H

K

Number of holes ## 2 – 27

Example of a type code:

RD 21 — H 05 — J 03

Body

Nozzle size

Inlet connector

Refrigerant distributor

Number of holes

Outlet connector

6 DKRCC.PD.FF0.A2.02 / 520H7413

Page 7

Data sheet Liquid Distributor, type RD

Selection of refrigerant

distributor

The following data must be known:

1. Refrigerant

2. Evaporator capacity

3. Evaporating temperature

4. Liquid temperature

5. Number of evaporator sections

6. Evaporator section inlet size

7. Distributor tube length

8. Expansion valve type

It is then possible to determine:

I. Size of distributor tubes

Example

Given data:

1. Refrigerant: R404A

2. Evaporator capacity Q

3. Evaporating temperature t

4. Liquid temperature T

: 20 kW

e

: 20 °C

l

: -15 °C

e

5. Number of evaporator sections: 10

6. Evaporator section inlet size: 6 mm

7. Distributor tube length: 850 mm

8. Expansion valve with 22 mm ODF solder

connection on outlet side

The capacity of the individual distributor tube is

calculated by dividing the total evaporator capacity

by the number of uniform evaporator sections.

The tube diameter can then be determined from

table 1 or gure 1.

Sizing should be based on the average capacity

of the evaporator.

A suciently uniform distribution can be expected

at capacities of between 40% and 125% of the values

given in table 1.

The capacity of each individual distributor tube is

20 / 10=2.0 kW.

Table 1 shows that with an evaporating temperature

of -15 °C and R404A, a ø6 mm tube with a length

of 1 meter will yield 1.9 kW.

Correction factors for tube length and liquid

temperature are found in tables 2 and 3.

For a tube length of 850 mm, the correction

factor is 1.05. For a liquid temperature of 20 °C,

the correction factor is 1.24.

Under the given conditions, the distributor tubes

yield 1.9×1.24×1.05=2.47 kW.

The actual load, as a percentage of the listed rating,

is thus 2.0 / 2.47=0.81 or 81%.

The type of distributor, inlet size and type are

determined from table 4.

There are two options: RD 49 or RD 62.

The rated capacity of the expansion valve can be

found using table 6 together with table 4:

– RD 49: 85×0.68=58 kW

– RD 62: 120×0.68=82 kW

Both distributors can be used, but RD 49 is

selected because the rated capacity is closer to

the evaporator capacity.

The standard nozzle diameter is determined from

table 5: 8 mm.

The required distributor type is determined from

table 7: RD49-C08-B10.

Please contact Danfoss for the code number.

DKRCC.PD.FF0.A2.02 / 520H7413 7

Page 8

Data sheet Liquid Distributor, type RD

Dimensions [mm]

and weights [kg]

RD, are RD, solder ODM

Table 8

Distributor

type

Distributor inlet L L

1

D

RD 21 Flare 55 — 21 0.1 24

RD 21 Solder 31 10 21 0.1 24

Approx. net

weight

Industrial

pack

RD 27 Flare 65 10 27 0.1 24

RD 27 Solder 41 10 27 0.1 24

RD 33 Flare (

RD 33 Solder (

RD 33 Flare (

RD 33 Solder (

1

⁄2 in.) 71 — 33 0.2 24

1

⁄2 in. / 12 mm) 50 12 33 0.2 24

5

⁄8 in.) 76 — 33 0.2 24

5

⁄8 in. / 16 mm) 50 17 33 0.2 24

RD 42 Solder 52 12 42 0.2 15

5

RD 49 Solder (

RD 49 Solder (

⁄8 in. / 16 mm) 62 17 49 0.3 15

7

⁄8 in. / 22 mm) 62 24 49 0.3 15

RD 62 Solder 66 24 62 0.7 9

RD 79 Solder 81 25 79 0.9 6

RD 85 Solder 81 30 85 0.9 6

8 DKRCC.PD.FF0.A2.02 / 520H7413

© Danfoss A/S (AC-MCI / jmn), 2013-03

Loading...

Loading...