Page 1

Data sheet

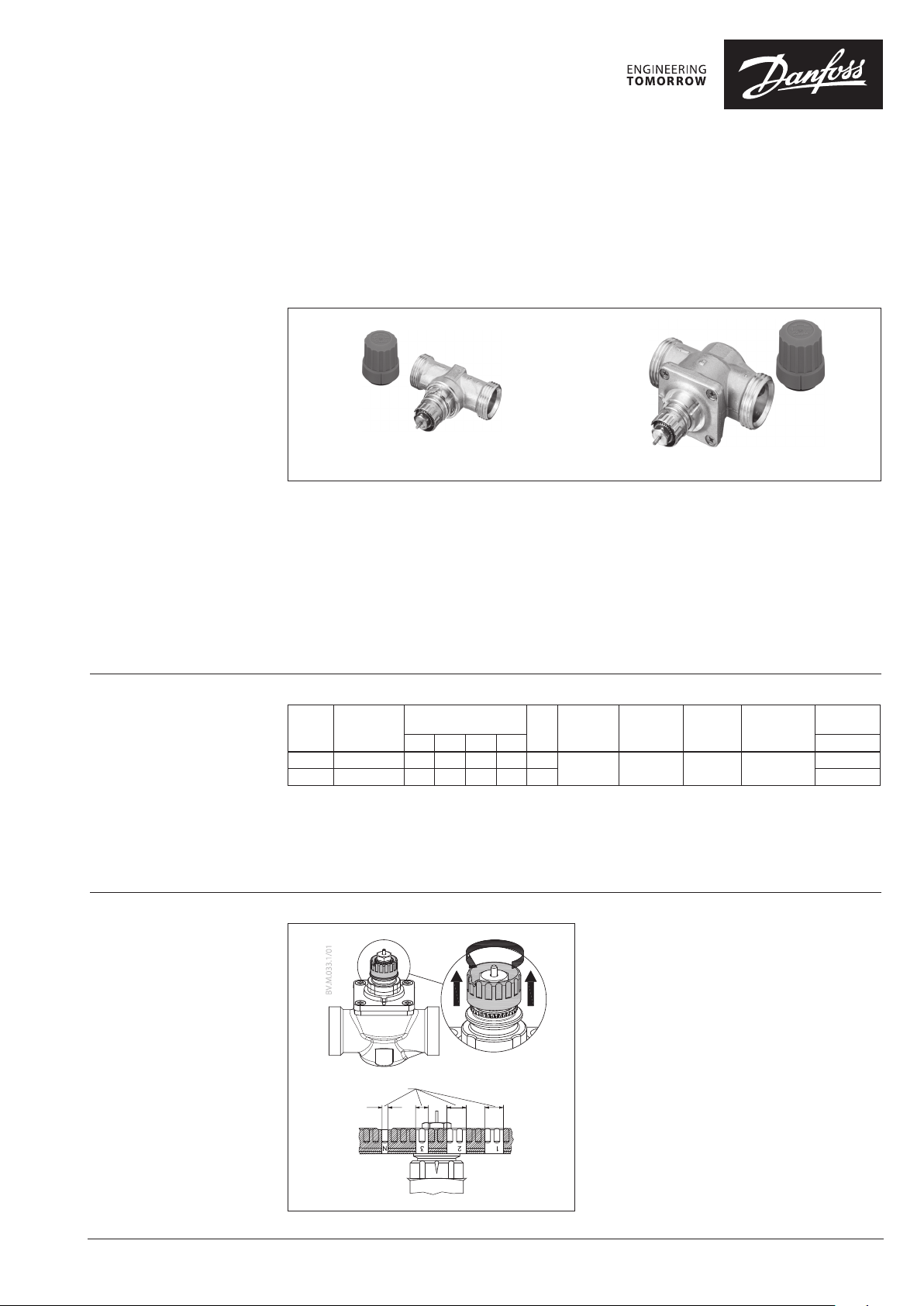

RA-C valves for cooling and heating circuits

Description

Ordering and Specification

RA-C 15 cooling valve

Together with Danfoss selfacting and electronic

controls, RA-C valves make up a perfect

combina-tion for control of cooling and heating

circuits.

The RA-C valve is a normally open valve. In an

application with self-acting sensors type FEK or FED

it is ensured that the cooling valve opens when the

room temperature is rising above the set temperature.

The RA-C valve has 4 presettings, thus the correct

quantity of water is ensured for each cooling circuit

and it is PN16 approved.

The valve has two external threads thus fittings for

various pipe types may be mounted.

Moreover, Danfoss can also offer a comprehensive

range of fittings (see back page).

RA-C 20 cooling valve

Shut-off (for isolation during system maintenance)

using manual shut off knob

Presettings:

Valve

Connections

RA -C 15 2 × G ⁄ A 0.30 0.55 0.75 0.90 1.20

RA-C 20 2 × G 1 A 0.80 1.10 1.70 2.60 3.30 013G3096

1)

The kv-val ues show the flow (Q) in m3/h at a dif ferential pressure (∆p) of 1 bar thr ough the valve. At presettin g N the kv-value is shown

at Xp = 3 K. The X p-value decreases at lowe r presettings thus the kv -value at presetting 1 is show n at Xp = 1 K.

2)

The max. di fferential pressure spe cified is the maximum pre ssure at which the valves give satisfac tory regulation. As wi th any device

which imposes a p ressure drop on the system, no ise may occur under certain f low/pressure conditions. A dif ferential pressure bet ween 0.1

and 0.3 bar ac ross the valves is recommended. T he differential pressur e can be reduced using Danfoss dif ferential pressure regul ators. 2)

3)

Shut-off PN10 approved.

kv-value1), m3/h

1 2 3 N

Max.

k

working

vs

pressure

10 ba r 0.6 bar 16 ba r 10 - 120°C

differential

3)

pressure

Max.

2)

Tes t

pressure

Water

temperature

Code No.

013G3094

Presetting With the valve body type RA-C the calculated setting

can be set easily and exactly without using special

tools:

• remove the protective cap or sensor element,

• raise the setting ring,

• turn the scale on the setting ring until the required

scale value faces the reference mark,

• release the setting ring.

The presetting can be set at the values: 1- 2 - 3 and N.

At setting N, the valve is completely open.

A setting in the shaded areas should be avoided.

When the sensor element is mounted, the pre-setting

is hidden, and is thus protected against alteration.

VD.33.U5.02 | 1

© Danfoss | 2018.12

Presetting range

①

②

Page 2

Data sheet RA-C valves for cooling and heating circuits

Pressure and noise

conditions

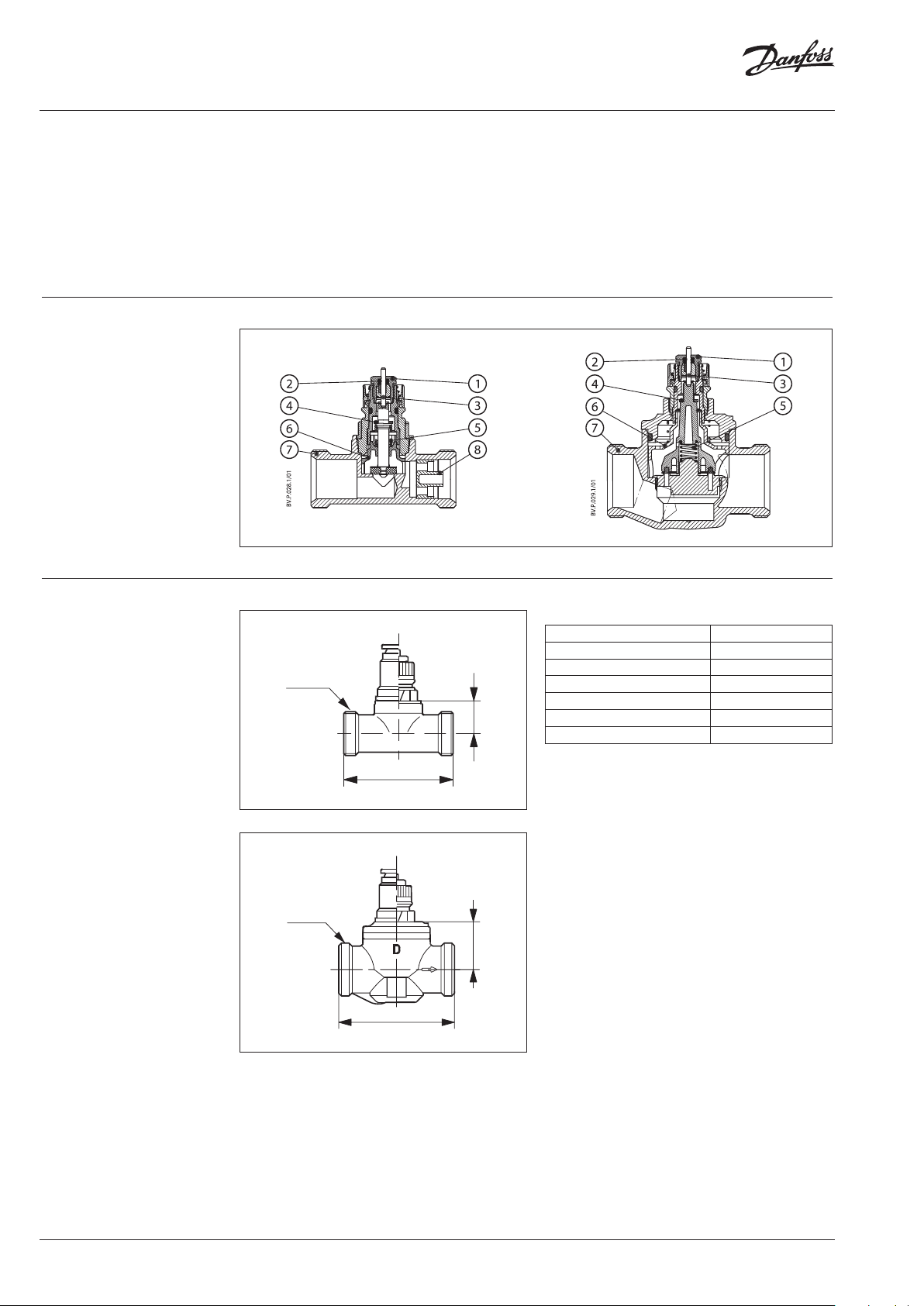

Design

1. Gland seal

2. O-ring

3. Pressure pin

4. Seal

5. Regulation spring

6. Presetting bush

7. Valve body

8. KV-nozzle

Special demands are made on the various

components of the system. This is due to water

temperature conditions, the chosen pipe types and

pipe dimensions of both chilled ceilings and fancoils/

induction units and the structure of the cooling

circuits.

In chilled ceilings and fancoils/induction-units

relatively large differential pressure and water flow are

RA- C 15

often used compared to normal heating systems. This

may lead to noise nuisance.

The RA-C valve has especially been designed to

correspond to these demands, no matter whether

selfacting or electronic controls are used.

RA-C 20

Dimensions Materials in contact with flow medium

RA- C 15

G ⁄ A

20

66

Valve body and other metal parts Corrosion resistant brass

Spindle Corrosion resistant brass

Throttle nozzle PPS

O-rings EPDM

Valve cone NBR

Gland seal pressure pin Chrome steel

kv-nozzle PP

1)

Flow medium: water and water mixture s with secondary

coolants like gl ycols (regarding suitability an d usage especially

in not oxyge n tight systems please see the ins tructions given by

the coolant pro ducer) .

RA-C 20

G 1 A

30.5

74

1)

2 | VD.33.U5.02

© Danfoss | 2018.12

Page 3

Data sheet RA-C valves for cooling and heating circuits

[m

[m

Capacities

RA- C 15

wg]

RA-C 20

wg]

Sizing example, chilled ceiling:

Cooling demand: Φ = 0.55 kW

System temperature rise: ∆t = 2 °C

Differential pressure: ∆p = 0.1 bar

Calculated water quantity: Q =

The setting is found in the capacity diagramme: RA- C 15: Presetting value 3

RA-C 20: Presetting value 1

Capacities with P-band between 1 and 3 K

550

2 × 1.16

= 237 l/h

© Danfoss | 2018.12

VD.33.U5.02 | 3

Page 4

Danf

already on order pro

All trademarks in this material are property of the respec

Data sheet RA-C valves for cooling and heating circuits

Accessories:

Compression fittings for PEX

plastic tubing

Compression f ittings are for connecting

Danfoss valves to circu its in heating

systems only. Compre ssion fittings are

used for connec ting PEX plastic tubings

in accordance with DIN

1689 2/168 93.

Maximum op erating pressure and

temperature are g iven by the tubing

manufacture r. However, 10 bar and 95°

C must not be excee ded.

One set consists of o ne olive, one

supporti ng bush and one union nut.

Einbau im Vor- oder Rück lauf

Compression fittings for Alupex

tubing

Compression f ittings are for connecting

Danfoss valves to circu its in heating

systems only. When con necting circuits

with compression f ittings for Alupex

tubing, alway s observe the maximum

operating pressu re and temperature

which are given by the t ubing

manufacture r. However, 10 bar and 95°

C must not be excee ded.

One set consists of o ne olive, one

supporti ng bush, one insulation washer

and one union nut.

Picture

External thread

Internal thread

Picture

External thread

Internal thread

For PEX pla stic tubing

Connection

G ¾”, internal thread

For PEX pla stic tubing

Connection

G ¾”, internal thread

Tube

dimension

12 × 2 mm 6 bar 10 bar 95 °C 013G 4152

13 × 2 mm 6 bar 10 bar 95 °C 013G 4153

14 × 2 mm 6 bar 10 bar 95 °C 013G 4154

15 × 2.5 mm 6 bar 10 bar 95 °C 013G 415

16 × 1.5 mm 6 bar 10 bar 95 °C 013G4157

16 × 2 mm 6 bar 10 bar 95 °C 013G 4156

16 × 2.2 mm 6 bar 10 bar 95 °C 013G 4163

17 × 2 mm 6 bar 10 bar 95 °C 013G4162

18 × 2 mm 6 bar 10 bar 95 °C 013G 4158

18 × 2.5 mm 6 bar 10 bar 95 °C 013G 4159

20 × 2 mm 6 bar 10 bar 95 °C 013G 4160

20 × 2.5 mm 6 bar 10 bar 95 °C 013 G4161

Tube

dimension

12 × 2 mm 6 bar 10 bar 95 °C 013G4182

14 × 2 mm 6 bar 10 bar 95 °C 013G4184

15 × 2.5 mm 6 bar 10 bar 95 °C 013G4185

16 × 2 mm 6 bar 10 bar 95 °C 013G 4186

16 × 2.25 mm 6 bar 10 bar 95 °C 013G 4187

18 × 2 mm 6 bar

20 × 2 mm

20 × 2.5 mm 6 bar 10 bar 95 °C 013 G4191

Max. working

pressure

Max. working

pressure

6 bar 10 bar 95 °C 013G4190

Tes t

pressure

Tes t

pressure

10 ba r

Max. flow Code No.

Max. flow Code No.

95 °C 013G4188

Compression fittings for steel and

copper tubing

Compression f ittings are for connecting

Danfoss valves to circu its in heating

systems only. Compre ssion fittings

are used for connec ting steel and

copper pip es in accordance with DIN

178 6/ 2391.

One set consists of o ne olive and one

union nut. It is recom mended to use

supporti ng bushes with soft pipes.

Picture

External thread

Internal thread

For PEX pla stic tubing

Connection

G ¾”, internal thread

G 1”

Manual shut off knob, high pressure 013G 3300

Manual shut off knob 013G 5002

Raccords pour joints plats Pour RAC 15 003L0294

Raccords pour joints plats Pour RAC 20 003Z4072

Tube

dimension

10 mm 10 bar 16 ba r 12 0 °C 013G412 0

12 m m 10 ba r 16 bar 120 °C 013G 4122

14 mm 10 b ar 16 bar 12 0 °C 013G4124

15 mm 10 bar 16 b ar 120 °C 013G 4125

16 mm 10 bar 16 bar 12 0 °C 013G4126

18 mm 10 bar 16 bar 12 0 °C 013G4128

18 mm 10 bar 16 bar 12 0 °C 013U0134

22 mm 10 bar 16 bar 120 ° C 013U 0135

Max. working

pressure

Tes t

pressure

Max. flow Code No.

oss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

vided that such alterations can be made without subsequential changes being necessary eady agreed.

4 | VD.33.U5.02

tive companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

© Danfoss | DHS-SRMT/SI | 2018.12

Loading...

Loading...