Page 1

Data sheet RA-C valves

for cooling and heating circuits

Products

RA-C 15

Together with Danfoss selfacting and electronic controls, RA-C valves make up a perfect combination for control of cooling and

heating circuits.

The RA-C valve is a normally open valve. In

The RA-C valve has 4 presettings, thus the

correct quantity of water is ensured for each

cooling circuit.

The valve has two external threads thus fittings for various pipe types may be mounted.

RA-C 20

an application with self-acting sensors type

FEK or FED it is ensured that the cooling

valve opens when the room temperature is

Moreover, Danfoss can also offer a comprehensive range of fittings (see back page).

rising above the set temperature.

Specifications

Presettings: kv-value 1), m3/h Max. Max.

Valve Code no. Connections k

RA-C 15 013G3094 2 x G 3/4 A 0.30 0.55 0.75 0.90 1.20

RA-C 20 013G3096 2 x G 1 A 0.80 1.10 1.70 2.60 3.30

1) The kv-values show the flow (Q) in m3/h at a differential pressure (Dp) of 1 bar through the valve. At presetting N the kv-value is shown at Xp

= 3 K. The Xp-value decreases at lower presettings thus the k

2) The max. differential pressure specified is the maximum pressure at which the valves give satisfactory regulation. As with any device which

imposes a pressure drop on the system, noise may occur under certain flow/pressure conditions. A differential pressure between 0.1 and 0.3

bar across the valves is recommended. The differential pressure can be reduced using Danfoss differential pressure regulators.

1 2 3 N pressure pressure

-value at presetting 1 is shown at Xp = 1 K.

v

working diff.

vs

10 bar 0.6 bar 16 bar 10 - 120 °C

Test- Water

2)

pressure temperature

Presetting With the valve body type RA-C the calculated

setting can be set easily and exactly without

using special tools:

- remove the protective cap or sensor element,

- raise the setting ring,

- turn the scale on the setting ring until the

required scale value faces the reference

mark,

- release the setting ring.

The presetting can be set at the values: 1- 2 3 and N.

At setting N, the valve is completely open. A

Presetting area

setting in the shaded areas should be avoided. When the sensor element is mounted, the

presetting is hidden, and is thus protected

against alteration.

CD-ST VD.33.U1.02 © Danfoss 06/99 1

Page 2

Data sheet Climate controls: RA-C valves

Pressure and noise conditions

Design

Special demands are made on the various

components of the system.

This is due to water temperature conditions,

the chosen pipe types and pipe dimensions of

both chilled ceilings and fancoils/induction

units and the structure of the cooling circuits.

In chilled ceilings and fancoils/induction-units

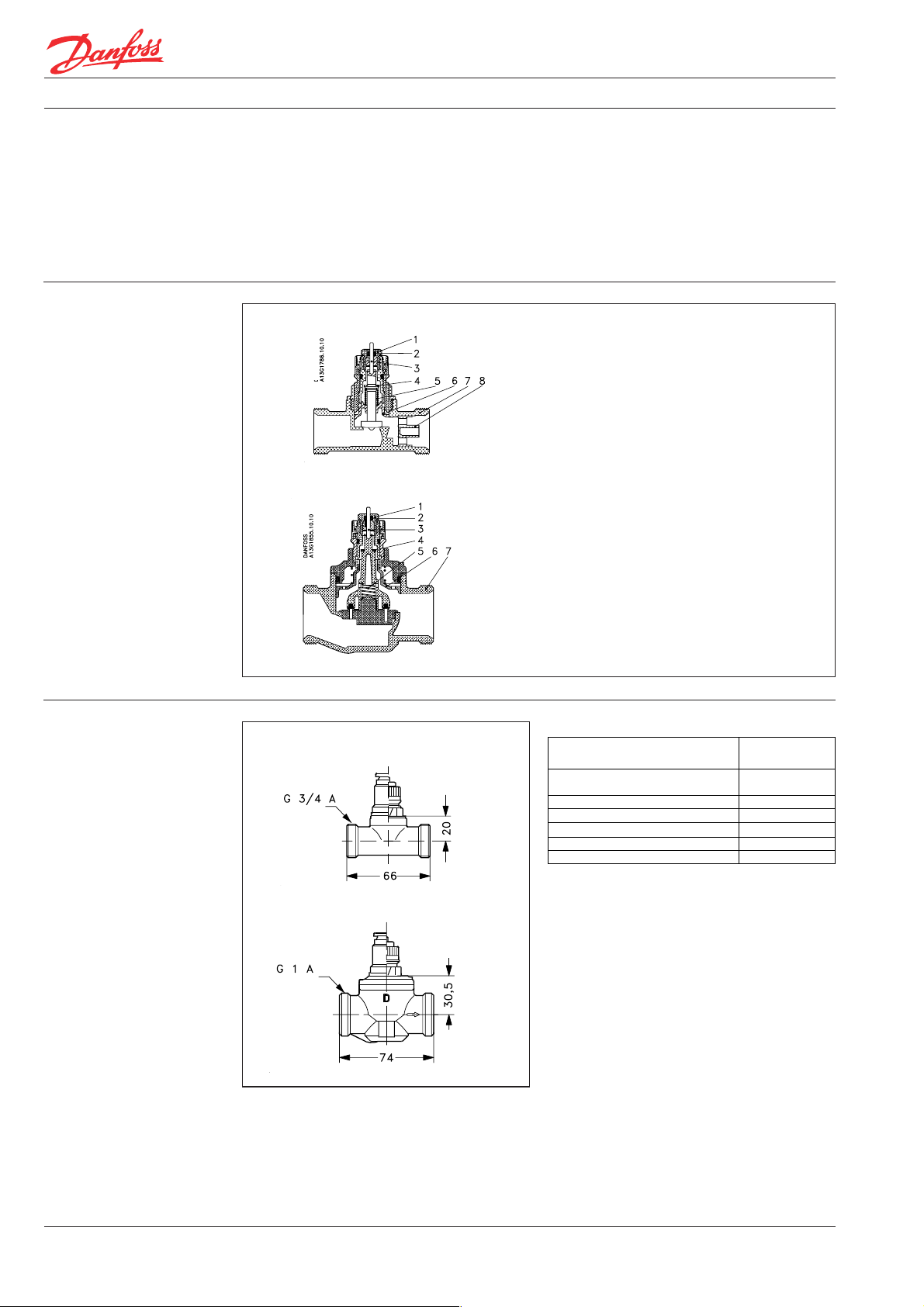

RA-C 15

RA-C 20

relatively large differential pressure and water

flow are often used compared to normal heating systems. This may lead to noise nuisance.

The RA-C valve has especially been designed

to correspond to these demands, no matter

whether selfacting or electronic controls are

used.

1. Gland seal

2. O-ring

3. Pressure pin

4. Seal

5. Regulation spring

6. Presetting bush

7. Valve body

-nozzle

8. k

v

Dimensions

RA-C 15

RA-C 20

Materials in contact with water

Valve body and other metal parts

Spindle

Throttle nozzle PPS

O-ring EPDM

Valve cone NBR

Pressure pin in gland seal Chrome steel

Nozzle PP

Corrosionresistant brass

Corrosionresistant brass

2 VD.33.U1.02 © Danfoss 06/99 CD-ST

Page 3

Data sheet Climate controls: RA-C valves

Capacities

RA-C 15

RA-C 20

Sizing example, chilled ceiling:

Cooling demand: ................................... F = 0.55 kW

System temperature rise: ............................ Dt = 2 °C

Differential pressure: ............................. Dp = 0.1 bar

Calculated water quantity: Q = = 237 l/h

550

2 x 1.16

The setting is found in the capacity diagramme:

RA-C 15: Presetting value 3,

RA-C 20: Presetting value 1.

Capacities with P-band between 1 and 3 K

CD-ST VD.33.U1.02 © Danfoss 06/99 3

Page 4

Data sheet Climate controls: RA-C valves

Accessories:

Fittings

For PEX plastic tubing Tube Code no. Max. working Test Max. flow

Connection dimension pressure pressure temperature

G 3/4, 16x1.5 mm 013G4157 6 bar 10 bar 95° C

internal thread 16x2 mm 013G4156

For Alupex tubing Tube Code no. Max. working Test Max. flow

Connection dimension pressure pressure temperature

G 3/4, 16x2 mm 013G4186 6 bar 10 bar 95° C

internal thread 16x2.25 mm 013G4187

For steel and copper tubing Tube Code no. Max. working Test Max. flow

Connection dimension pressure pressure temperature

G 3/4, 14 mm 013G4124

internal thread 15 mm 013G4125 10 bar 16 bar 120 °C

G 1

12x2 mm 013G4152

13x2 mm 013G4153

14x2 mm 013G4154

15x2.5 mm 013G4155

16x2.2 mm 013G4163

17x2 mm 013G4162

18x2 mm 013G4158

18x2.5 mm 013G4159

20x2 mm 013G4160

20x2.5 mm 013G4161

12x2 mm 013G4182

14x2 mm 013G4184

15x2.5 mm 013G4185

18x2 mm 013G4188

20x2 mm 013G4190

20x2.5 mm 013G4191

10 mm 013G4120

12 mm 013G4122

16 mm 013G4126

18 mm 013G4128

18 mm 013U0134

22 mm 013U0135

VD.33.U1.02 © Danfoss 06/99 CD-ST

Loading...

Loading...