Page 1

Data sheet RA 2000 1PS

Thermostatic Radiator Valve

For Use on One-Pipe Low-Pressure

Steam Systems

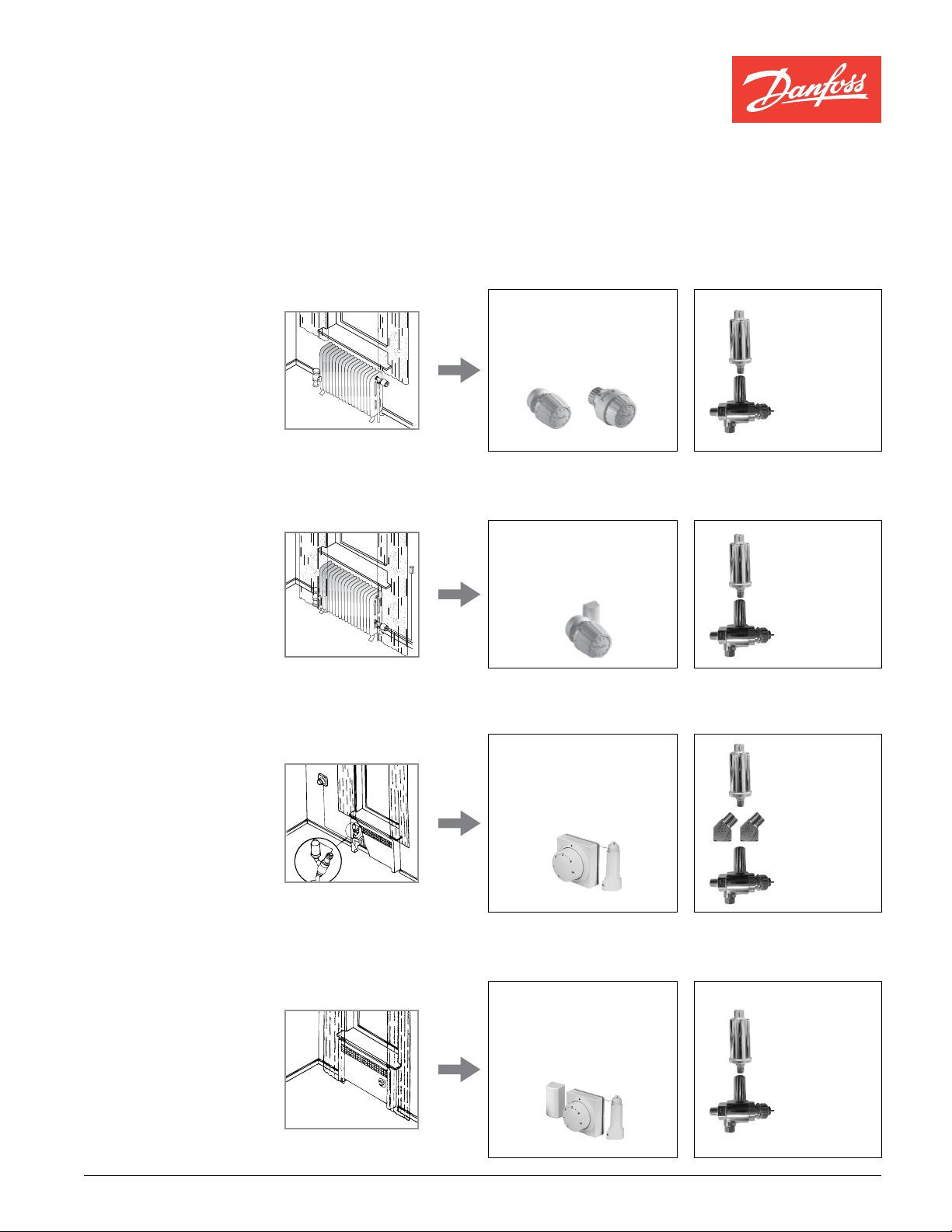

Typical

Installation:

Dial / Operator / Sensor + Valve

FREE STANDING RADIATORS

The free-standing one-pipe low-pressure steam radiator is positioned where air continually passes

freely over the operator

Use standard or tamper resistant

model with combined dial/

operator/sensor. Always install

the operator horizontally

FREE STANDING RADIATORS

The free-standing one-pipe low-pressure steam radiator is accessible, but due to obstruction air

cannot continually pass freely over the operator

Use dial / operator with remote

sensor. The sensor and capillary

tube may be extended up to 6’

and can be easily wall mounted.

Use air vent

PLUS

1/8” one-pipe

steam valve

Use air vent

PLUS

1/8” one-pipe

steam valve

CONVECTORS

The one-pipe low-pressure steam convector is inaccessible; room air cannot continually pass freely

over the sensing element

Use operator with combined

remote dial / sensor. The dial/

sensor and capillary tube may be

extended up to 6’ and are wall

mounted.

Use air vent

PLUS

Two 45° elbows

PLUS

1/8” one-pipe

steam valve

ENCLOSED RADIATORS

The cabinet enclosed radiator conguration requires that the dial and sensor be mounted separately,

away from the valve

Use operator with separate

remote dial and remote sensor.

Place the remote sensor on a

draft-free wall. The remote dial

mounts on the enclosure or wall.

Use air vent

PLUS

1/8” one-pipe

steam valve

VDSXA222 © Danfoss 06/16

1

Page 2

Data sheet

3-5/32”

31-32”

RA 2000 1PS

Thermostatic Radiator Valve

For Use on One-Pipe Low-Pressure

Steam Systems

Design & Function:

• Danfoss’ RA 2000 1PS one-pipe steam

thermostatic radiator valve provides

accurate temperature control and quite

operation.

• The movement of air across the

thermostatic operator eects the

modulation control in regulating the

venting of air from the radiator or

convector.

• Based on the set temperature on the

operator, the 1PS regulates the amount

of steam allowed into the emitter by

controlling the amount of air allowed to

vent out.

• The venting action occurs during each

system (boiler) on-cycle only when heat

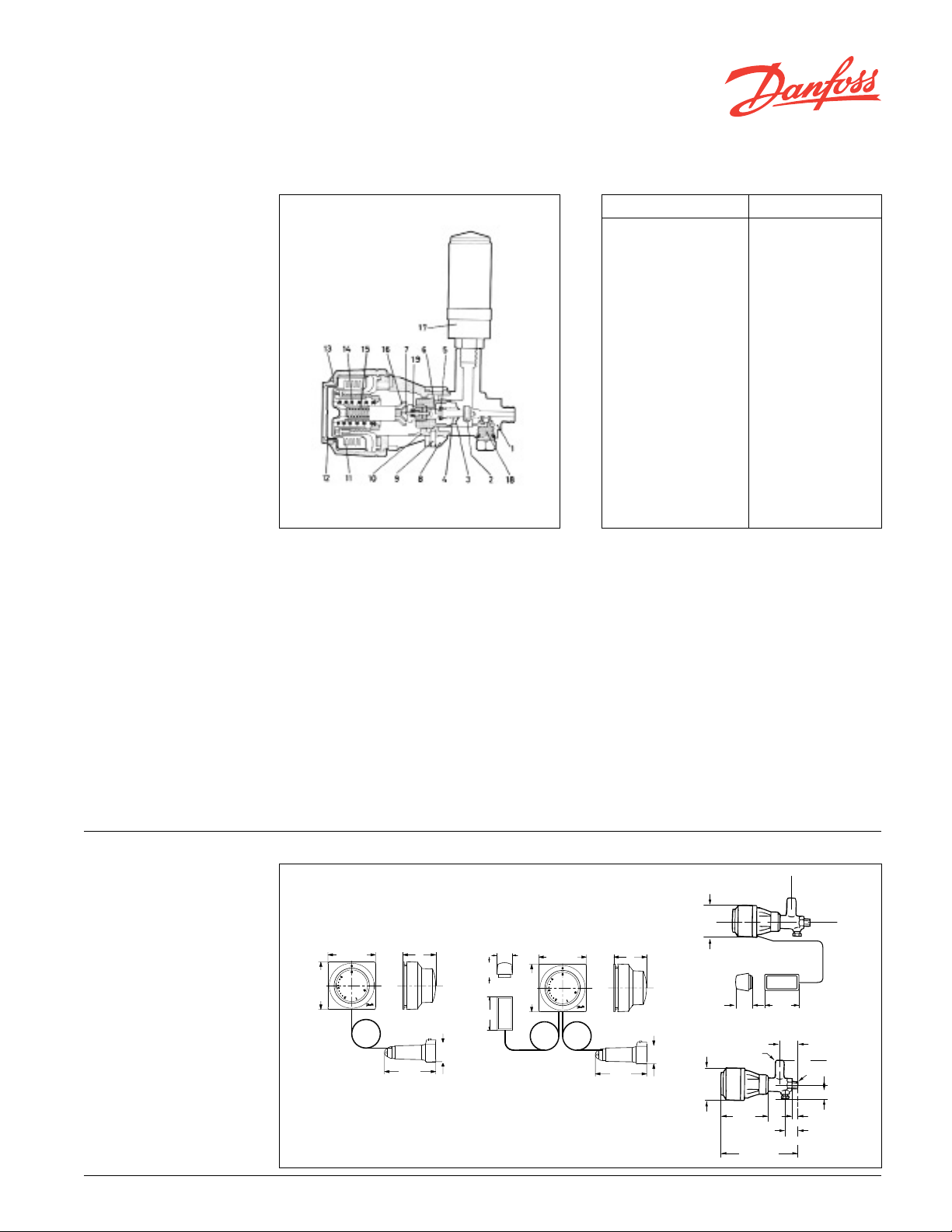

Part Material

1. Valve

2. Valve disc

3. Spindle guide

4. Spring

5. Back seat washer

6. Valve Spindle

7. Pressure pin

8. Clamping band

9. Allenscrew

10. Socket

11. Bellows

12. Handle

13. Adjustment spring

14. Safety spring

15. Pressure spindle

16. Air vent

17. Retainer

18. Packing gland

19. Capillary Tube

Nicel plated brass

EPDM

Phosphor bronze

Stainless Steel

EPDM

Brass

Stainless steel

Al. alloy

Steel

Zytel Nylon

Phosphor bronze

ABS

Steel

Steel

Polymide No. 6

Brass

Steel

is required. Air will re-enter the system

during the boiler o-cycle via a patened

“across the seat” vacuum breaker. This

eliminates condensate buildup and allows

natural system aspiration to take place.

• The RA 2000 1PS assembly is specically

designed for low pressure steam systems.

The system pressure should not be

constant preventing air to get back into

the system.

• Thermostatic radiator valve assembly-

valve, thermostatic operator and air ventcan be used for free standing radiators,

convectors, and enclosed radiators. 1PS

is not recommended for copper n tube

radiators.

Dimensions:

1-1/32

”

2-7/3 2”

3-1/8 ”

3-5/32”

3-1/8 ”

2

2-11/64”

2-1/4”

3-7/16”

VDSXA222 © Danfoss 06/16

1-3/8”

1-27/64”

2-13/16”

3-1/8 ”

3-5/32”

3-5/32”

3-1/8 ”

3-7/16”

2-11/64”

2-7/32”

1-1/16”

2-1/4”

2-7/32”

3-3/16”

1/8” NPT

5-3/16”

1-1/4”

27/32 ”

1-1/4”

11/3 2”

13/32”

1/8” NPT

1-21/32”

29/32”

Page 3

Data sheet RA 2000 1PS

Thermostatic Radiator Valve

For Use on One-Pipe Low-Pressure

Steam Systems

Technical Data:

RA 2000 Operators:

Typ e Maximum Temperature Maximum Pressure

RA 2000 1PS 250°F (121°C) 15psig

Operator Code No. Description Sensor Capillary

013G 825 0 Valve mounted dial & sensor Built-in -

013G 8252 Valve mounted dial with remote sensor Remote 6’

013G 824 0

013G2922

013G 8562 Combined remote mounted dial & sensor - 6’

013G 8565 Combined remote mounted dial & sensor - 16’

013G 8568 Combined remote mounted dial & sensor - 26’

013G 8564

Valve mounted dial and sensor, tamper

resistant

Valve mounted dial with remote sensor

tamper resistant

Separate remote mounted dial and

sensor

Built-in -

Remote 6’

Remote 6’ + 6’

Parts and Accessories

For RA 2000 Operators:

013G 825 0

013G 8252

013G 824 0

013G2922

013G 8562

013G 8565

013G 8568

013G2564

RA 2000 1PS Valve :

Code No. Description

013G12 36 Screwdriver tool set for RA 8240 / 2922

013G1215 Limitation pins for RA 8250/52 (30 pcs)

013G12 37 Limitation pins for tamper resistant operators RA 8240 / 2922 (30 pcs)

013G52 45 Anti-theft protection clips for RA 8250/52 (20 pcs)

013G12 32 Locking screw plugs for tamper resistant operators RA 8240 / 2922 (50 pcs).

013G1672 Cover plate for setting Window of tamper resistant operators (20 pcs)

1

2

Design Code No. Valve size Pattern

Code No. Description Position No.

013G5191 Socket Body for RA 2000 1

013G5503 Bellows Holder (set of 2 pcs) 2

Connection

Inlet x Outlet

013G 0140 1/8” 1PS MPT x FTP

VDSXA222 © Danfoss 06/16

3

Page 4

Data sheet

RA 2000 1PS

Thermostatic Radiator Valve

For Use on One-Pipe Low-Pressure

Steam Systems

Parts and Accessories

For RA 2000 1PS Valve :

How to avoid problems:

Code No. Description

013L8011 1-Pipe steam air vent

013L 8300 Brass 45° street elbow for convector, for space consideration

013G 0290 Packing gland for valves

The operator with valve-mounted dial and sensor must be

mounted horizontally.

IMPORTANT

In one-pipe steam systems sucient pitch is required to

permit condensate return. Condensate should not be

trapped in the valve or vent. The vent (when not supplied)

should be checked to assure it is properly working.

Boiler/steam supply must not run at constant pressure. This

prevents the ability for air to enter back into the system.

Make sure that free-standing radiators or cast iron convectors

are properly pitched and that hand valves are FULLY open.

To aid in preventing overheating of rooms that are

temperature satised, boiler steam pressure must be kept

low, recommended normally at or below 2psig. Otherwise

air will be compressed in the radiator, allowing steam to

enter when not required.

Setting:

Danfoss can accept no responsibility for possible errors in printed materials and reserves the right to alter its products without notice.

All trademarks in this material are property of the respective companies. Danfoss and Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

4

The user can easily set room temperature by

turning the dial clockwise or counterclockwise.

The diagram to the right shows the appropriate

relationship between dial scale numbers and

room temperature.

At its lowest setting, the RA 2000 1PS

provides frost protection and maintains room

Danfoss

Toronto, ON

Tel.: 866-372-4822, Fax: 416-352-5981

www.heating.danfoss.us

VDSXA222 © Danfoss 06/16

temperature at approximately 45°F (7°C).

At its highest setting, the RA 2000 1PS

maintains room temperature at approximately

85°F (30°C).

The temperature on all RA 2000 1PS models

may be limited or locked.

Danfoss

Baltimore, MD

Tel.: 866-372-4822, Fax: 416-352-5981

www.heating.danfoss.us

Loading...

Loading...