Page 1

T

T

T

Submittal RA2000 for 2-Pipe Valve Assembly

Job Name Job Location

Engineer Approval

Contractor Approval

Representative Contractor P.O. No.

Application

RA 2000 Thermostatic Radiator Valves regulate

the flow of hot water or low pressure steam

through free-standing radiators, baseboards, or

convectors in hot water and two-pipe steam

systems. Operators and valves are packaged

separately to allow an installer an ability to select

a suitable combination for each application.

Features

• Replaceable packing assembly while system is

in operation

• Non-electric thermostatic radiator valve

conforms to ASHREA/ANSI standard 102-1983

• Same valve body can be used for both hot

water or low pressure steam applications

• Patented vapor charged bellows for quick

response from valve mounted operators

• “Snap-action” mechanism for standard valve

mounted operators for ease of installation and

removal without the use of tools

• Available version of tamper resistant operators

Operational Capabilities

Adjustable Temp. Range

Max. Sensor Temperature

45-86°F (7-30°C)

140°F (°60C)

Hot Water Systems

Max. Temperature

250°F (°121C)

Max. Static Pressure 145 psi

Max. Test Pressure 232 psi

Max. Diff. Pressure (water) 15 psi

Two Pipe Low Pressure Steam Systems

Max. Temperature

250°F (°121C)

Max. Test Pressure 232 psig

Max. Steam Pressure 15 psig

RA2000 Valve Bodies

◊

Cv value in GPM at pressure drop of 1 psi

Code No.

013G8015 ½” NPT 1.6

013G8020 ¾” NPT 2.7

013G8025 1” NPT 2.8

013G8032

013G8014 ½” NPT 1.6

013G8019 ¾” NPT 2.7

013G8024 1” NPT 2.8

013G8031

013G8013 ½” NPT 1.6

013G8018 ¾” NPT 2.7

013G8023 1” NPT 2.8

013G8030

013G8042 ½” solder 1.6

013G8044

RA2000 Operators

Code No. Sensor Capillary Qnty

013G8250 Built-in -

013G8252 Remote 6’

013G8240

013G2922

013G8562 6’

013G8565 16’

013G8568

013G8564 Wall mount remote 6’ + 6’

Tamper resistant,

built-in

Tamper resistant,

Remote

Wall mount remote

Valve

Type

Straight

Angle

Side

Mount

Angle

Straight

Connection

1-¼” NP

1-¼” NP

1-¼” NP

¾” solder 2.7

-

6’

26’

Cv

2.8

2.8

2.8

Qnty

◊

013G5002 Manual handle -

Page 2

Specification

The thermostatic radiator valve assembly shall be

selected to maintain room temperature within ±1°F.

The operator shall be of a bellows design with a vapor

or liquid charge and shall be connected to the valve

via a snap-on fast mounting system or secured by an

Allen screw. The thermostatic operator shall be

capable of temperature adjustment between 45° and

86°F (7 and 30°C) and be locked and limited by the

use of limiting pins or internal mechanism.

The valve shall be of nickel plated brass

construction with a fully replaceable packing gland

capable of replacement while the system is in

operation. The valve disc shall be constructed of

EPDM, capable of withstanding 250°F (121°C).

The thermostatic radiator valve shall be Danfoss or

an approved equal.

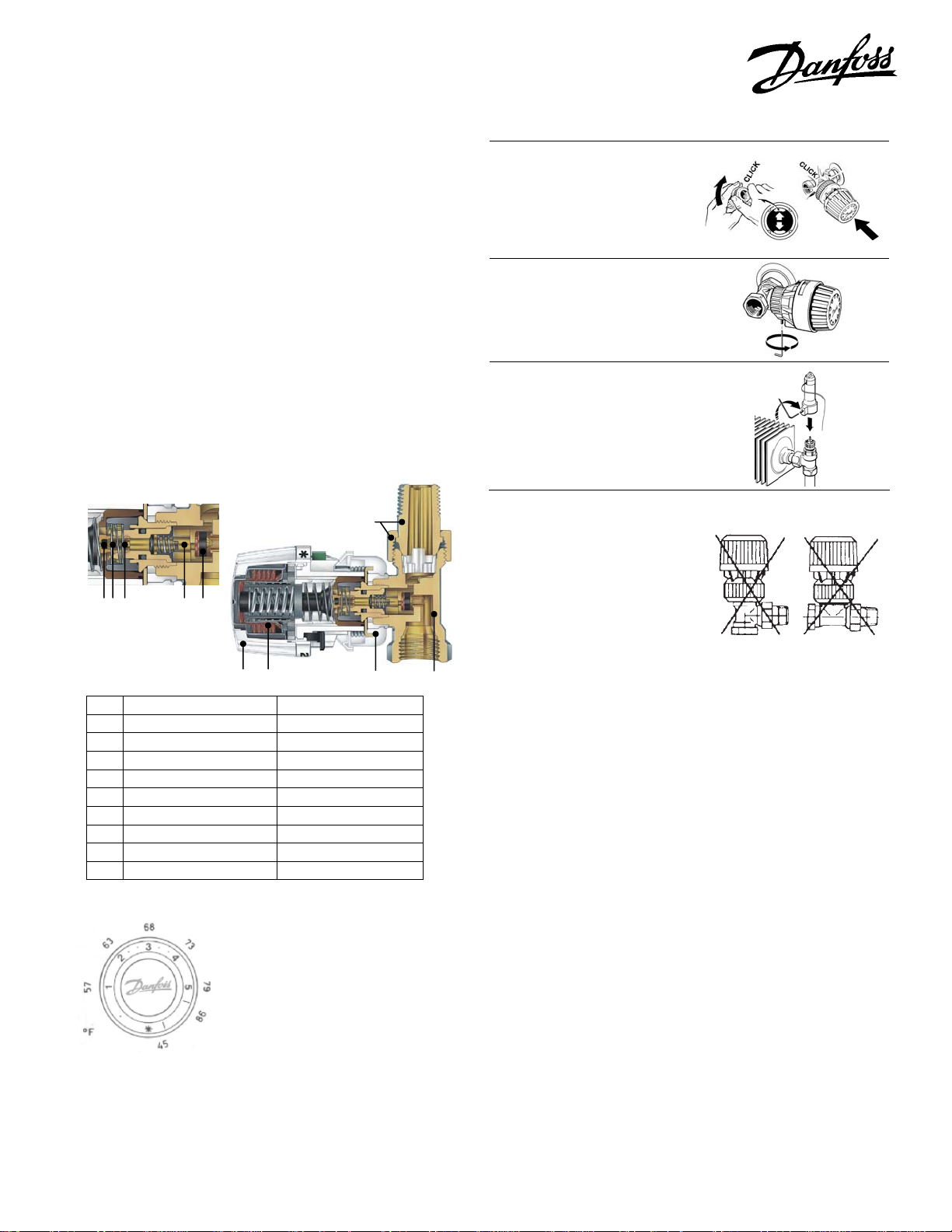

Construction

5

8 9 10

7 6

1. Operator ABS plastic

2. Bellows Vapor charged

3. Mounting base Plastic

4. Valve body Nickel plated brass

5. Union nut/Tail piece Nickel plated brass

6. Valve disc EPDM

7. Valve spindle Brass

8. Pressure pin Stainless Steel

9. Packing O-ring EPDM

10. Packing gland DRZ brass

1 2 3 4

Temperature settings

The numbers reflected on the

dial (1-5) correlate to available

temperature positions. The

lowest setting (*) provides

frost protection and maintains

the room temperature at

approximately 45°F.

Mounting of Operator

013G8250 & 013G8252

Snap on attachment

Rotation of the base

retracts teeth allowing the

operator to be pushed and

mounted onto the valve

013G8240 & 013G2922

Allen key requirement

Firmly seat the operator to

the valve then tighten

operator with an Allen key

Wall mounted versions

Allen key requirement

Firmly seat the remote

operator to the valve then

tighten remote operator

with an Allen key

Operator Orientation

The valve mounted built-in

thermostatic operator

(013G8250) should not be

installed in a vertical

orientation. The result will

cause the operator to close

prematurely. The operator should be installed in a

horizontal position allowing proper air flow across the

sensing element. If the operator is unable to be

reoriented, a different thermostatic operator should

be selected with a remote sensor.

Limiting and Locking Operator Setting

All RA2000 operators have the ability to limit or lock

the temperature range or setting. For built-in style

operators pins are inserted on the back of the

operator, while wall mounted versions require the

face plate to be removed and tabs located on the dial

to be set.

Theft protection

To prevent the removal of standard built-in operators

(013G8250 and 013G8252) from the valve an optional

anti-theft protection clip is inserted at the base of the

operator.

Page 3

Dimensions

Valve Type

Straight

Angle

Side Mount

Angle

Solder Union

Danfoss can accept no responsibility for possible errors in printed materials and reserves the right to alter its products without notice.

All trademarks in this material are property of the respective companies. Danfoss and Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

Connection

Type

½” NPT 25/8” 3¾” 157/64” 3¾”

¾” NPT 229/32” 43/16” 21/16” 315/16”

1” NPT 317/32” 431/32” 21/16” 315/16”

1-¼” NPT 4¼” 529/32” 29/64” 41/64”

½” NPT 13/16” 29/32” 11/64” 157/64” 3¾”

¾” NPT 111/32” 25/8” 19/64” 21/16” 315/16”

1” NPT 19/16” 3” 111/32” 21/16” 315/16”

1-¼” NPT 1¾” 33/8” 19/16” 21/16” 315/16”

½” NPT 11/8” 2¼” 11/64” 23/8” 4¼”

¾” NPT 111/32” 25/8” 19/64” 27/16” 45/16”

1” NPT 19/16” 3” 111/32” 23/8” 4¼”

1-¼” NPT 1¾” 33/8” 19/16” 23/8” 4¼”

½” 25/8” 315/16” 157/64” 3¾” Double

¾” 215/16” 45/8” 21/16” 315/16”

Danfoss Inc.

Mississauga, ON, L5N 2W3

Tel: 866-375-4822 Fax: 905-285-2055

www.danfossheating.com

L1 L2 L3 L4 L5 H1 H2

Danfoss Inc.

Baltimore, MD 21236 USA

Tel: 866-375-4822 Fax: 443-512-0270

www.danfossheating.com

Loading...

Loading...