Data Sheet

RA 2000 Series

RA 15/6T & TB

Conversion Valve

Applications:

The RA 15/6T and TB is a special

conversion valve that allows a single

connection point-at the side of the

radiator- to serve as both the supply &

return for a hot water based system. An

example of its application is the

transformation of a 1-pipe steam system

into a hot water based system.

There are two versions to this valve:

RA15/ 6T

Internal bypass allowing for series piping

to the radiators/baseboards. This series

piping provides continuous ow but the

supply water temperature will decrease.

RA15/ 6TB

A conventional two-pipe system where

each radiator/baseboard is supplied. A

traditional supply and return manifold

can be utilized.

With the installation of the RA 15/6T and

TB valves any RA2000 thermostatic

operator or TWA electronic actuator can

be mounted, providing individual

temperature regulation and controlled

comfort for the room.

Features:

• Compact design

• Minimized installation area

• Thermostatic operator or electric

actuator control of valve

• Single entry valve connection to

radiator

• Valve assembly for 1-pipe steam

conversion to hot water

• Alternative method of piping for n

tube or baseboard addition

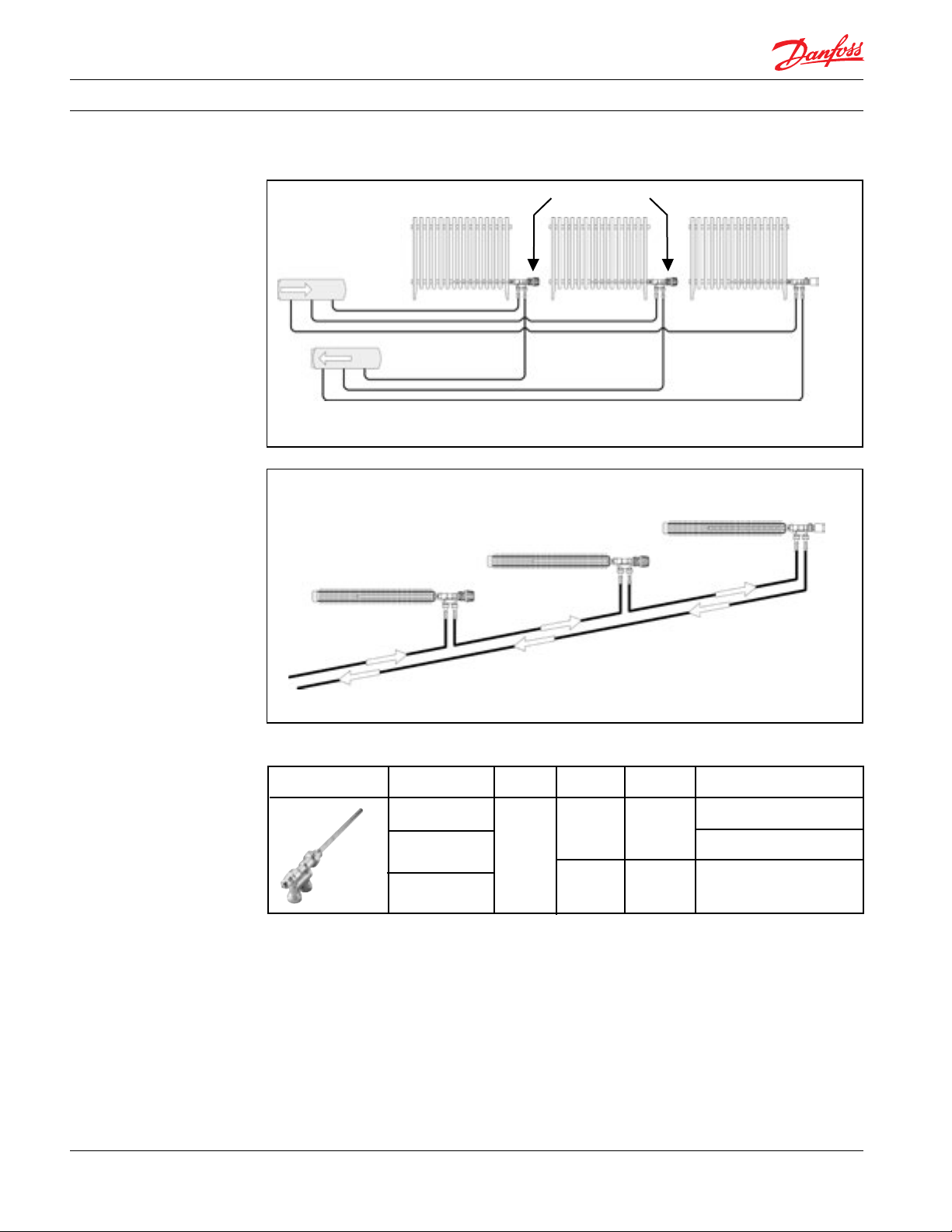

Converted 1-pipe

steam radiator

VDTQZ222 © Danfoss 03/14

Fin tube baseboard,

system extension

Alternative piping for baseboard application, piped

as a conventional 2-pipe system

1

Data Sheet RA 2000 Series RA 15/6T & TB Conversion Valve

Applications (Cont.):

Manifold

Fin tube baseboard

Radiator

Thermostatic

RA 15/6T piped to a manifold for

individual distribution

Operators

24Vac,

Electric

Actuator

24Vac, Electric

Actuator

Thermostatic

Operator

Ordering Information:

Alternative piping for baseboard

application piped as a diverter system

Valve

Code No.

Size

Model

013G3270

RA15/6T

013G326 8

013G3215

1

Cv = Cv bypass + Cv radiator. Max ow through radiator, approx. 35%.

2

1/2

Rp

int. thread are straight thread, non-NPT thread.

3

3/4

G

ext. threading require ttings.

1/2”

RA15/6TB

Cv

2.34

1.17

Connection

1/2

Rp

3/4

G

ext. thread

1/2

Rp

int. thread

int. thread

1

2

3

2

2

VDTQZ222 © Danfoss 03/14

Data Sheet RA 2000 SERIES RA 15/6T & TB Conversion Valve

Fittings & Spare Parts:

Fittings

Spare Parts

Code No.

013 G4116

013U0476

013U8608

013U 0496

Code No.

013G 0290

013G1350

Description

1/2” Copper compression tting for RA 15/6T & TB, 2 pcs

required, use with 013G3215 & 013G3270 only

1/2” M. NPT tailpiece for RA 15/6T, 2 pcs required, use with

013G3268 only

1/2” F. solder tailpiece for RA 15/6T, 2 pcs required,

use with 013G3268 only

1/2” Union nut for RA 15/6T, 2 pcs required, use with

013G3268 only

Description

Packing gland

Angle Adaptor

RA2000 Thermostatic

Operator:

Operator

Code No.

013G 8250

013G 8252

013G 8240

013G2922

013G 8562

013G 8562

013G 8562

013G 8564

Description

Standard valve mounted

dial and sensor

Standard valve mounted

dial with remote sensor

Tamper resistance valve

mounted dial and sensor

Tamper resistant valve

mounted dial with remote

sensor

Combined remote

mounted dial and sensor

Seperate remote mounted

dial and sensor

Sensor Capillary

Built-in

Remote

Built-in

Remote

Built-in

Remote

-

6’

-

6’

6’

16’

26’

6’ + 6’

VDTQZ222 © Danfoss 03/14

3

Data Sheet RA 2000 Series RA 15/6T & TB Conversion Valve

Electronic Thermowax Actuators:

Specications:

Design and Function:

Actuator

Suitable applications

Max. working pressure

Max. dierential pressure

Max. test pressure

Max. ow temperature

Connection

Code No.

088H3110

088 H3111

088H3114

082 F1091

TWA-A actuator 24VAC, 2VA

c/w valve position indicator

ABNM actuator 24VAC,

1.5VA requires control signal

The RA 15/6T and TB valves are a unique

design assembly that oer control of

radiators or n tube baseboard through

a thermostatic operator or electronic

1/2

actuator control. The

” connection to

the radiator allows supply hot water to

enter and through the same connection

allows return water to leave. This

circulation through the radiator is

achieved through the 8” straight ow

tube which is inserted into the radiator.

The ow tube receives the return water,

while hot water is delivered through the

radiator connection. If the length of the

radiator is long, the ow tube can be

1/4

extended by soldering on a

” copper

tube to the end of the ow tube. The

extension to the ow tube results in a

pressure drop of 0.02 FOH/in. The

extension will allow cooler water furthest

from the connection to leave the

radiator and be replaced by hot water.

Typ e

1) 1-pipe steam conversion to hot water systems

2) Hot water n tube or baseboard applications

RA 15/6T

1/2

int. thread

Rp

3/4

G

ext. thread

Operation Actuator Position

NC

ON/OFF

Proportional

(0 -10VDC)

145 psi (10 bar)

8.7 psi (0.6 bar)

232 psi (16 bar)

248 º F (120 º C)

1

2

Rp

NO

NC, w/ end switch

NC

RA 15/6T B

1/2

int. thread

1

The valve body is also an ideal alternative

in the conversion of a one pipe steam

system into a hot water system. In

considering the conversion valve for a

1-pipe steam system, verify that across

the top of the radiator are push nipples.

The push nipples located at the top of

the radiator provides circulation for hot

water within the radiator. Unfortunately,

if the radiator lacks push nipples at the

top, the eectiveness of the conversion

valve is greatly reduced.

Prior to installation of the conversion

valve, the potential 1-pipe steam radiator

should be pressure tested to ensure it

will be capable of handling the increased

pressure from a hot water system. In

addition the radiator should also be

ushed to remove any debris from within

that could potentially clog the valve or

other components within the system.

4

VDTQZ222 © Danfoss 03/14

Data Sheet RA 2000 SERIES RA 15/6T & TB Conversion Valve

Design and Function

(Cont.):

Construction:

RA 15/6T B

1- Pressure pin

2- O-ring gland seal

3- Valve cone

4- Valve body

5- Flow tube

RA 15/6T

Materials in contact with water

Pipe supporting bushing

O-ring

Valve cone

Pressure pin

Lock washer

Valve body and other

metal parts

PP

EPDM

NBR rubber

Chrome steel

Tin alloy

Ms 58 brass

Dimensions inches

(mm):

VDTQZ222 © Danfoss 03/14

5

Data Sheet RA 2000 Series RA 15/6T & TB Conversion Valve

Typical Specication:

The valve shall be nickel plated and

capable of delivering supply hot water

and receiving return water through a

single connection to the radiator. An

incorporated ow tube shall receive the

return from the radiator and be capable

of extending its length. The valve shall

be used on a closed loop water based

system and have the option of a bypass

function. The mountable control for the

valve shall have the option of either a

non-electric thermostatic operator or a

24V electric actuator. The thermostatic

operator shall be available in either a

valve or wall mounted dial operator. The

valve mounted dial shall be a vapor

charged operator and installed via

snap-action mechanism or Allen key.

The brass valve body shall have a

packing gland assembly capable of

replacement while the system is in

operation.

Danfoss can accept no responsibility for possible errors in printed materials and reserves the right to alter its products without notice. All trademarks

in this material are property of the respective companies. Danfoss and Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

Danfoss Inc.

Toronto, ON

Toll Free: 866-375-HVAC (4822)

Tel.: 905-285-2050, Fax: 905-285-2055

www.na.heating.danfoss.com

6

VDTQZ222 © Danfoss 03/14

Danfoss Inc.

Baltimore, MD

Toll Free: 866-375-HVAC (4822)

Tel.: 443-512-0266, Fax: 443-512-0270

www.na.heating.danfoss.com

Loading...

Loading...