Page 1

Data sheet

Solenoid valves for R 410A and R744 (CO2)

EVR 2 to EVR 8 and EVRH 10 to EVRH 40

EVR 2 and EVR 3 (direct operated) and EVR 4 to

EVR 8 / EVRH 10 to EVRH 40 (servo-operated) are

high pressure solenoid valves specially designed

to meet the requirements of high pressure

refrigerants such as R410A and R744 (CO2).

The EVRH valve can be used for liquid, suction

and hot gas lines.

Features • Normally Closed and Normally Open

• Coils for AC and DC voltages

• Suitable for R410A and R744 (CO2)

• Media temperatures up to 221°F

• Design pressure 655 psig

© Danfoss | DCS (rja) | 2017.03

• MOPD up to 350 psi

• Solder connections up to 7/8 inch

• Extended soldering ends

• Solders without dismantling the valve

DKRCC.PD.B00.C3.22 | 1

Page 2

Data sheet | Solenoid valves for R410A and R744 (CO2), EVR 2 to EVR 8, EVRH 10 to EVRH 40

Approvals

Technical data

The Low Voltage Directive (LVD) 2014/35/EU with

amendments EN 60730-2-8.

Listed

Temperature of medium

-40 – 105 °C for 10 or 12 W coil

Max. 130 °C during defrost

-40 – 80 °C for 20 W coil

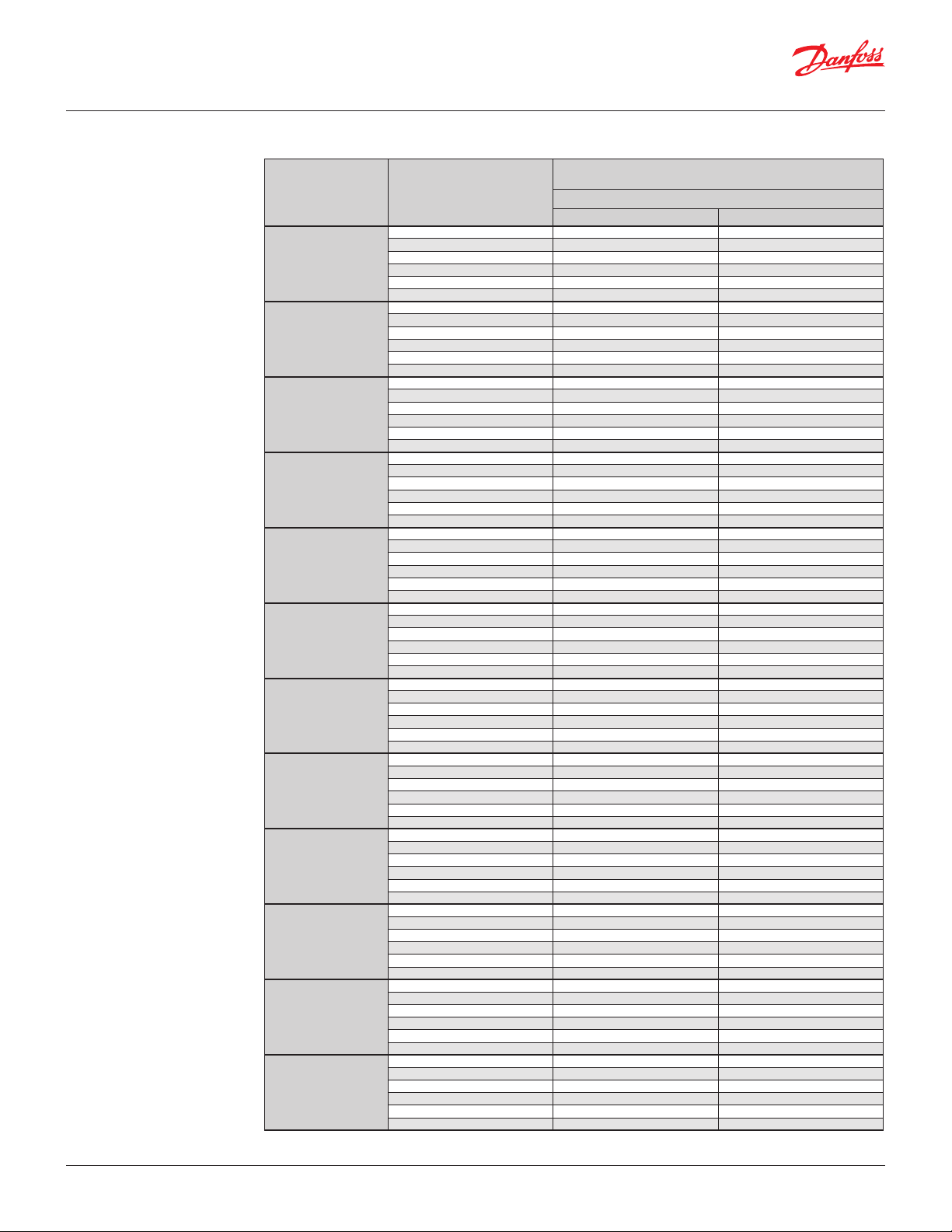

Opening dierential pressure Δp [psig]

Type

Min. ODP

EVR 2 0 350 260 0.19

EVR 3 0 300 260 0.32

EVR 4 0.7 300 260 0.7

EVR 6 0.7 300 260 0.92

EVR 6 NO 0.7 300 300 0.92

EVR 8 0.7 300 260 1.3

EVRH 10 0.7 300 260 2.2

EVRH 15 0.7 300 260 3.0

EVRH 20 0.7 300 190 5.8

EVRH 22 0.7 300 190 6.9

EVRH 25 1.0 300 260 12

EVRH 32 1.0 300 260 18

EVRH 40 1.0 300 260 29

(with standard coil)

14 – 17 W AC 20 W DC

Refrigerants

R744, R22/R407C, R404A/R507, R410A,

R134a, R407A, R23, R744.

For other refrigerants, please contact Danfoss.

Note: EVR 2 – EVR 3 and EVRH 25 – EVRH 40 are not suitable for

R744 (CO2)applications with media temperatures constantly below

0 °C.

For other media temperatures, please contact Danfoss.

MOPD

Cv value

[gal/min]

© Danfoss | DCS (rja) | 2017.03

DKRCC.PD.B00.C3.22 | 2

Page 3

Data sheet | Solenoid valves for R410A and R744 (CO2), EVR 2 to EVR 8, EVRH 10 to EVRH 40

Ordering Solenoid valve – Normally Closed (NC) – Soldering ODF without coil

EVR / EVRH Valves

1)

Type Coil type Connection size [in.] Code no.

EVR 2 AC/DC 1/4

EVR 3

EVR 4

AC/DC 1/4

AC/DC 3/8

AC/DC 3/8

AC/DC 1/2

AC/DC 3/8

EVR 6

AC/DC 1/2

AC/DC 5/8

EVR 8

AC/DC 1/2

AC/DC 5/8

EVRH 10 AC/DC 1/2

EVRH 15 AC/DC 5/8

EVRH 20 AC 7/8

EVRH 25 AC/DC 1 1/8

1)

EVRH 32

AC/DC –

EVRH 40 AC/DC 1 5/8

Only available with mm connections

Solenoid valve – Normally Open (NO)

Type Coil type Connection size [in.] Code no.

EVR 6 AC/DC 3/8

EVRH 10 AC/DC 1/2

032F7100

032F7105

032F1157

032F7110

032F7111

032F7115

032F1162

032F7117

032F7121

032F7122

032G1077

032G1078

032G1079

032G1059

032G1081

032G1062

032F1164

032F1329

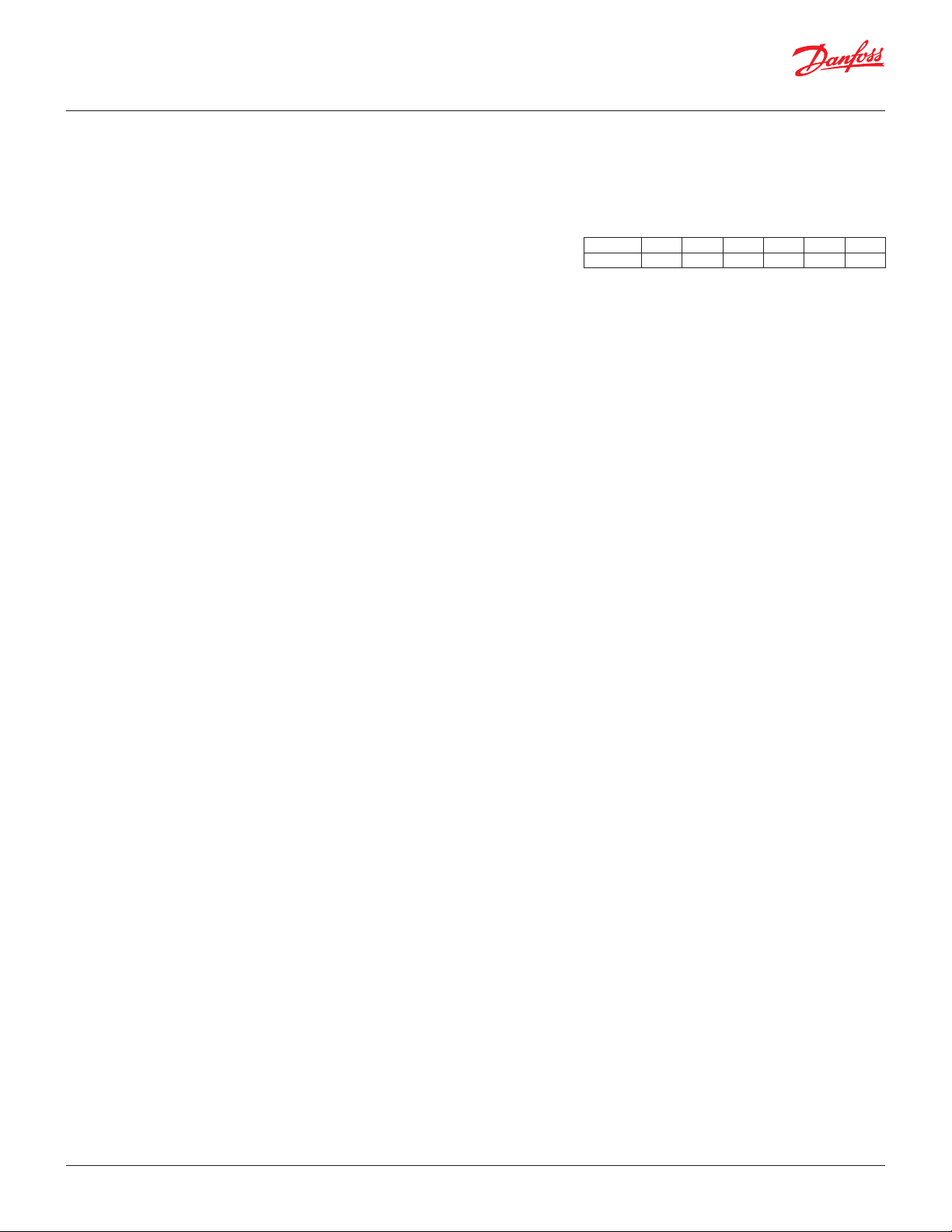

BJ and BX Coils

Wire length

Coil type

Voltage

[V AC]

Frequency

[Hz]

Junction box NEMA 2

BJ024CS 7 18 24 50 / 60 14

BJ120CS 7 18

BJ240CS 7 18

110 – 120

110

208 – 240

230

60

50

60

50

BJ120BS 7 18 120 60 16

BJ208BS 7 18 208 60 16

BJ240BS 7 18 240 60 16

Conduit boss NEMA 4

BX024CS 18 46 24 50 / 60 14

BX024CS 71 180 24 50 / 60 14

BX024CS 98 250 24 50 / 60 14

BX120CS 18 46

BX120CS 36 91

BX120CS 71 180

110 – 120

110

60

50

BX120CS 98 250

BX240CS 18 46

BX240CS 98 250

208 – 240

230

60

50

BX120BS 98 250 120 60 16

BX208BS 98 250 208 60 16

BX240BS 98 250 240 60 16

Power

consumption

[W] Code no.[in] [cm]

15

16

14

17

15

16

14

17

018F4100

018F4110

018F4120

018F4130

018F4132

018F4134

018F4102

018F4103

018F4104

018F4112

018F4113

018F4114

018F4115

018F4122

018F4123

018F4131

018F4133

018F4135

Technical data

© Danfoss | DCS (rja) | 2017.03

Design

In accordance with UL 429

Power supply

Alternating current (AC)

Permissible voltage variation

Alternating current (AC):

50 Hz and 60 Hz: -10% – 15%

50/60 Hz: ± 10%

Power consumption

Alternating current (AC): Inrush: 49 VA;

Holding: 28 VA, 14 – 17 W

Insulation of coil wire

Class H according to IEC 85

Connection

Junction box or Conduit boss

Enclosure, IEC 60529

Junction box NEMA 2 ~ IP 12–32

Conduit boss NEMA 4 ~ IP 54

Ambient temperature

-40 °F – 122 °F (-40 °C – 50 °C)

DKRCC.PD.B00.C3.22 | 3

Page 4

Data sheet | Solenoid valves for R410A and R744 (CO2), EVR 2 to EVR 8, EVRH 10 to EVRH 40

Capacity, R410A

Liquid capacity

Type

EVR 2 0.56 0.78 0.96 1.1 1.23 1.35 1.46

EVR 3 0.98 1.37 1.68 1.93 2.15 2.36 2.55

EVR 4 2.12 2.98 3.65 4.2 4.69 5.14 5.55

EVR 6 2.79 3.92 4.8 5.52 6.16 6.75 7.3

EVR 8 3.94 5.54 6.78 7.8 8.7 9.54 10.3

EVRH 10 6.63 9.31 11.4 13.1 14.6 16 17.3

EVRH 15 9.07 12.7 15.6 17.9 20 21.9 23.7

EVRH 20 17.5 24.5 30 34.5 38.5 42.2 46.6

EVRH 22 20.82 29.4 36 41.4 46.2 50.6 54.8

EVRH 25 33.65 47.59 58.29 67.31 75.25 82.44 89.04

EVRH 32 53.85 76.15 93.27 107.69 120.41 131.90 142.47

EVRH 40 84.14 118.99 145.73 168.27 188.13 206.09 222.60

1 2 3 4 5 6 7

Liquid capacity Q0 tons at pressure drop across valve p psi

Capacities are based on:

liquid temperature tl = 100 °F

Evaporating temperature te = 40 °F

Superheat 10 °F

Capacity, R410A

Suction vapour capacity

Type

EVR 2

EVR 3

EVR 4

EVR 6

EVR 8

EVRH 10

EVRH 15

EVRH 20

EVRH 22

EVRH 25

EVRH 32

EVRH 40

Note: Bold gures refer to rated capacity

Pressure

drop Δp [psi]

1 0.04 0.05 0.07 0.07 0.08 0.09 0.10 0.11

2 0.06 0.07 0.09 0.11 0.12 0.13 0.14 0.16

3 0.07 0.09 0.12 0.13 0.14 0.16 0.18 0.19

1 0.07 0.09 0.12 0.13 0.14 0.16 0.18 0.20

2 0.10 0.13 0.16 0.18 0.21 0.23 0.25 0.28

3 0.12 0.16 0.20 0.23 0.25 0.28 0.31 0.34

1 0.15 0.20 0.25 0.28 0.31 0.35 0.39 0.43

2 0.22 0.28 0.36 0.40 0.45 0.49 0.55 0.60

3 0.27 0.35 0.44 0.49 0.55 0.61 0.67 0.74

1 0.20 0.26 0.33 0.37 0.41 0.46 0.51 0.56

2 0.29 0.37 0.47 0.53 0.59 0.65 0.72 0.79

3 0.35 0.46 0.58 0.65 0.72 0.80 0.88 0.97

1 0.28 0.36 0.46 0.52 0.57 0.64 0.71 0.78

2 0.41 0.52 0.66 0.74 0.82 0.91 1.01 1.10

3 0.49 0.64 0.81 0.91 1.01 1.12 1.23 1.36

1 0.48 0.62 0.79 0.89 0.98 1.09 1.20 1.33

2 0.68 0.88 1.12 1.25 1.39 1.54 1.70 1.87

3 0.84 1.08 1.37 1.54 1.71 1.89 2.09 2.30

1 0.66 0.85 1.09 1.21 1.35 1.50 1.65 1.81

2 0.93 1.21 1.53 1.72 1.91 2.11 2.33 2.56

3 1.14 1.48 1.88 2.10 2.33 2.59 2.85 3.14

1 1.27 1.64 2.09 2.33 2.59 2.88 3.17 3.49

2 1.79 2.32 2.95 3.30 3.67 4.06 4.48 4.93

3 2.20 2.85 3.61 4.04 4.49 4.98 5.49 6.04

1 1.51 1.95 2.49 2.77 3.08 3.43 3.77 4.15

2 2.13 2.76 3.51 3.93 4.37 4.83 5.33 5.87

3 2.62 3.39 4.29 4.81 5.34 5.92 6.53 7.19

1 2.46 3.23 4.13 4.63 5.16 5.72 6.33 6.96

2 3.39 4.50 5.78 6.49 7.25 8.05 8.91 9.82

3 4.04 5.42 7.01 7.89 8.82 9.81 10.87 11.98

1 3.93 5.17 6.61 7.40 8.25 9.16 10.12 11.14

2 5.42 7.20 9.25 10.39 11.60 12.89 14.26 15.70

3 6.46 8.68 11.22 12.62 14.11 15.70 17.38 19.17

1 6.15 8.08 10.32 11.57 12.90 14.31 15.82 17.41

2 8.47 11.25 14.45 16.23 18.12 20.14 22.27 24.54

3 10.09 13.56 17.53 19.72 22.05 24.53 27.16 29.95

Suction vapour capacity Q0 tons at evaporating temperature te °F

-40 -20 0 10 20 30 40 50

© Danfoss | DCS (rja) | 2017.03

The table values refer to evaporator capacity

and are given as a function of evaporating

temperature te and pressure drop ∆p across the

valve. Capacities are based on liquid temperature

tl = 100 °F ahead of the expansion valve and

superheat ts = 7 °F. For each additional 10 °F of

superheat, the table capacities must be reduced

by 2%.

Correction factors for liquid temperature t

l

When liquid temperature tl ahead of the

expansion valve is other than 100°F, adjust

the table capacities by multiplying them by

the appropriate correction factor found in the

following table:

tl˚F 80 90 100 110 120

Factor 1.10 1.05 1.00 0.95 0.90

DKRCC.PD.B00.C3.22 | 4

Page 5

Data sheet | Solenoid valves for R410A and R744 (CO2), EVR 2 to EVR 8, EVRH 10 to EVRH 40

Capacity R410A

Hot gas capacity

Type

EVR 2

EVR 3

EVR 4

EVR 6

EVR 8

EVRH 10

EVRH 15

EVRH 20

EVRH 22

EVRH 25

EVRH 32

EVRH 40

Pressure drop

p [psi]

2 0.19 0.20

5 0.30 0.31

10 0.42 0.44

15 0.52 0.54

20 0.60 0.62

25 0.67 0.69

2 0.33 0.34

5 0.52 0.54

10 0.74 0.76

15 0.90 0.94

20 1.04 1.08

25 1.16 1.21

2 0.72 0.75

5 1.13 1.17

10 1.61 1.65

15 1.97 2.02

20 2.27 2.33

25 2.54 2.60

2 0.94 0.98

5 1.49 1.55

10 2.11 2.19

15 2.59 2.68

20 2.98 3.10

25 3.34 3.46

2 1.31 1.37

5 2.08 2.17

10 2.95 3.06

15 3.62 3.75

20 4.17 4.33

25 4.67 4.84

2 2.24 2.33

5 3.54 3.68

10 5.02 5.20

15 6.14 6.36

20 7.08 7.36

25 7.92 8.22

2 3.07 3.18

5 4.85 5.03

10 6.86 7.11

15 8.40 8.70

20 9.69 10.00

25 10.8 11.2

2 5.90 6.12

5 9.32 9.68

10 13.2 13.7

15 16.1 16.7

20 18.6 19.3

25 20.8 21.6

2 7.02 7.28

5 11.1 11.5

10 15.7 16.3

15 19.2 19.9

20 22.1 23.0

25 24.7 25.7

2 12.95 13.91

5 20.32 21.89

10 28.34 30.70

15 34.22 37.28

20 38.94 42.68

25 42.88 47.30

2 20.73 22.26

5 32.51 35.02

10 45.34 49.12

15 54.75 59.65

20 62.30 68.29

25 68.61 75.68

2 32.39 34.78

5 50.79 54.72

10 70.85 76.75

15 85.54 93.20

20 97.34 106.70

25 107.21 118.25

Hot gas capacity Qh tons at evaporating temp. te=40 °F.

hotgas temp. th=tc+40 °F. subcooling tu=10 °F

Condensing temperature tc °F

70 100

© Danfoss | DCS (rja) | 2017.03

DKRCC.PD.B00.C3.22 | 5

Page 6

Data sheet | Solenoid valves for R410A and R744 (CO2), EVR 2 to EVR 8, EVRH 10 to EVRH 40

Hot gas capacity values in the table are given

as a function of condensing temperature tc and

pressure drop across the valve ∆p.

Capacities are based on gas superheated 40 °F

above condensing temperature,

(th= tc + 40 °F)

For each additional 10 °F of superheat above

40 °F, the table capacities must be reduced by

1%.

In a hot gas defrost circuit, evaporator

temperature aects valve capacity.

When the evaporator temperature diers from

40 °F, adjust the table capacities by multiplying

them by applying a correction factor from the

following table.

Correction factors for th and t

tl˚F -40 -20 0 20 40 50

Factor 1.18 1.14 1.09 1.04 1 0.97

Note: The MOPD is depending on the choise of coil, please refer

to page 4.

c

© Danfoss | DCS (rja) | 2017.03

DKRCC.PD.B00.C3.22 | 6

Page 7

Danfoss

32F9024.10

4

16

18

45

49

83

90

20

40

Data sheet | Solenoid valves for R410A and R744 (CO2), EVR 2 to EVR 8, EVRH 10 to EVRH 40

Capacity R744 (CO2) With CO

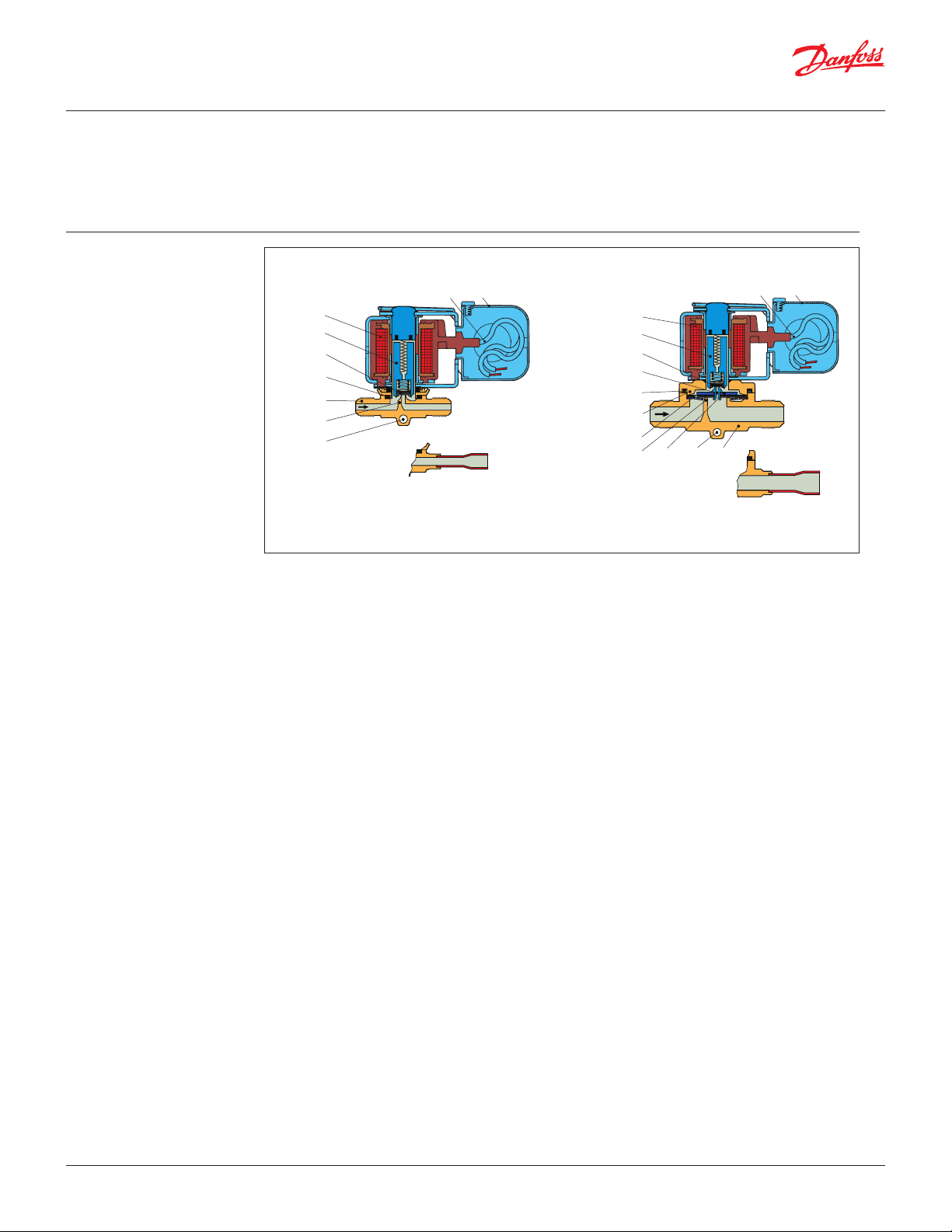

Design and Function

4. Coil

16. Armature

18. Valve plate/ Pilot valve plate

20. Ground terminal

28. Gasket

29. Pilot orice

40. Protective cap, Junction box

43. Valve cover

45. Valve cover gasket

49. Valve body

73. Equalization port

80. Diaphragm and servo piston

83. Valve seat

90. Mounting hole

© Danfoss | DCS (rja) | 2017.03

EVRH valves can only be used in

2

subcritical applications.

For CO

capacity tables, refer to Cool selector® or

2

contact your local Danfoss oce.

Direct operated

EVR 2 and EVR 3

EVRH solenoid valves are designed on two

dierent principles:

1. Direct operation

2. Servo operation

1. Direct operation

EVR 2 and EVR 3 are direct operated. The valves

open directly for full ow when the armature (16)

moves up into the magnetic eld of the coil. This

means that the valves operate with a min.

dierential pressure of 0 bar. The valve plate (18)

is tted directly on the armature (16). Inlet

pressure acts from above on the armature and

the valve plate. Thus, inlet pressure, and spring

force act to close the valve when the coil is

currentless.

2. Servo operation

EVR 4 to EVR 8 and EVRH 10 – EVRH 20 are servo

operated with a “oating” diaphragm (80). The

pilot orice (29) is placed in the centre of the

diaphragm. The pilot valve plate (18) is tted

direct to the armature (16). When the coil is

currentless, the main orice and pilot orice are

closed. The pilot orice and main orice are held

closed by the armature spring force and the

dierential pressure between inlet and outlet

sides. When current is applied to the coil the

armature is drawn up into the magnetic eld and

opens the pilot orice. This relieves the pressure

above the diaphragm, i.e. the space above the

diaphragm becomes connected to the outlet

side of thevalve.

Note: EVR 2-3 and EVRH 25-40 are not suitable for R744 (CO2)

applications with media temperatures constantly below 0 °C.

For other media temperatures, please contact Danfoss.

40

20

4

16

18

29

45

43

73

83

80

90

49

Danfoss

32F9025.10

Servo operated

EVR 4 to EVR 8 and EVRH 10 to EVRH 40

The dierential pressure between inlet and

outlet sides then presses the diaphragm away

from the main orice and opens it for full ow.

Therefore a certain minimum dierential

pressure is necessary to open the valve and

keep it open. For EVR 4 to EVR 8 and EVRH 10

– EVRH 20 valves this dierential pressure is

0.05 bar. When current is switched o, the pilot

orice closes. Via the equalization holes (73) in

the diaphragm, the pressure above the

diaphragm then rises to the same value as the

inlet pressure and the diaphragm closes the

main orice.

EVRH 25 – EVRH 40 are servo operated piston

valves. The valves are closed with currentless

coil. The servo piston (80) with main valve plate

(84) closes against the valve seat (83) by means

of the dierential pressure between inlet and

outlet side of the valve and the force of the

compression spring (76).

When current to the coil is switched on, the

pilot orice (29) opens. This relieves the

pressure on the piston spring side of the valve.

The dierential pressure will then open the

valve. The minimum dierential pressure

needed for full opening of the valves is 0.2 bar.

DKRCC.PD.B00.C3.22 | 7

Page 8

32F665.10.20FW

Data sheet | Solenoid valves for R410A and R744 (CO2), EVR 2 to EVR 8, EVRH 10 to EVRH 40

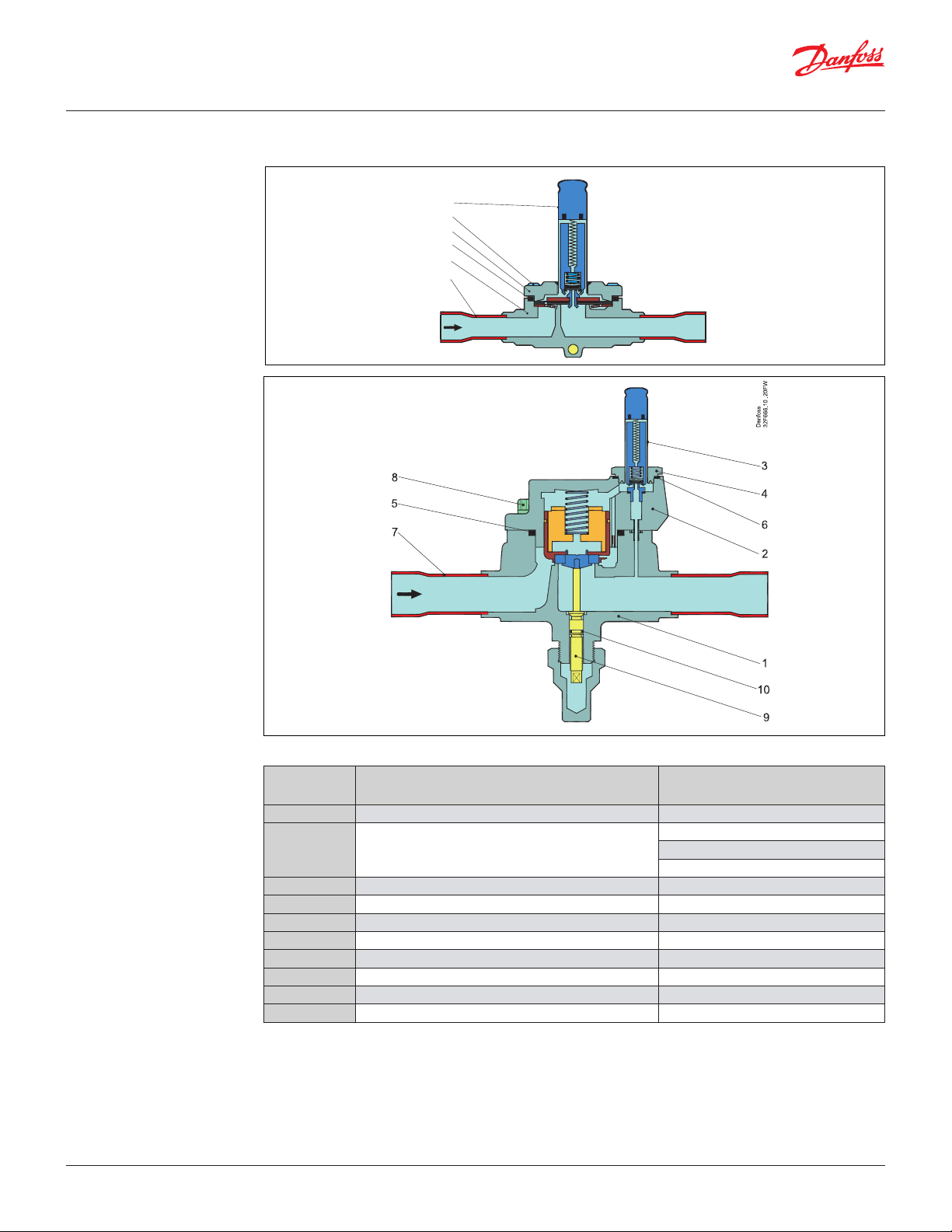

Material specications

EVR 2 – EVR 8 and EVRH 10 – EVRH 25

3

8

2

5

1

7

Danfoss

© Danfoss | DCS (rja) | 2017.03

No. Description Material

1 Valve body Brass

2 Cover

3 Armature tube Stainless steel

4 Armature tube nut Stainless steel

5 Gasket Rubber

6 Gasket Al. gasket

7 Solder tube Copper

8 Screws Stainless steel

9 Spindle for man. operat. Stainless steel

10 Gasket Rubber

Stainless steel

Brass

Cast iron

DKRCC.PD.B00.C3.22 | 8

Page 9

32G1062 FW

Data sheet | Solenoid valves for R410A and R744 (CO2), EVR 2 to EVR 8, EVRH 10 to EVRH 40

Material specications

(continued)

EVRH 32 – EVRH 40

57 4

3

6

2

8

1

No. Description Material

1 Valve body Cast Iron

2 Cover Brass

3 Armature tube Stainless steel

4 Armature tube nut Stainless steel

5 Gasket Rubber

6 Gasket Al. gasket

7 Solder tube Bi-metallic tube

8 Screws Stainless steel

Danfoss

© Danfoss | DCS (rja) | 2017.03

DKRCC.PD.B00.C3.22 | 9

Page 10

Data sheet | Solenoid valves for R410A and R744 (CO2), EVR 2 to EVR 8, EVRH 10 to EVRH 40

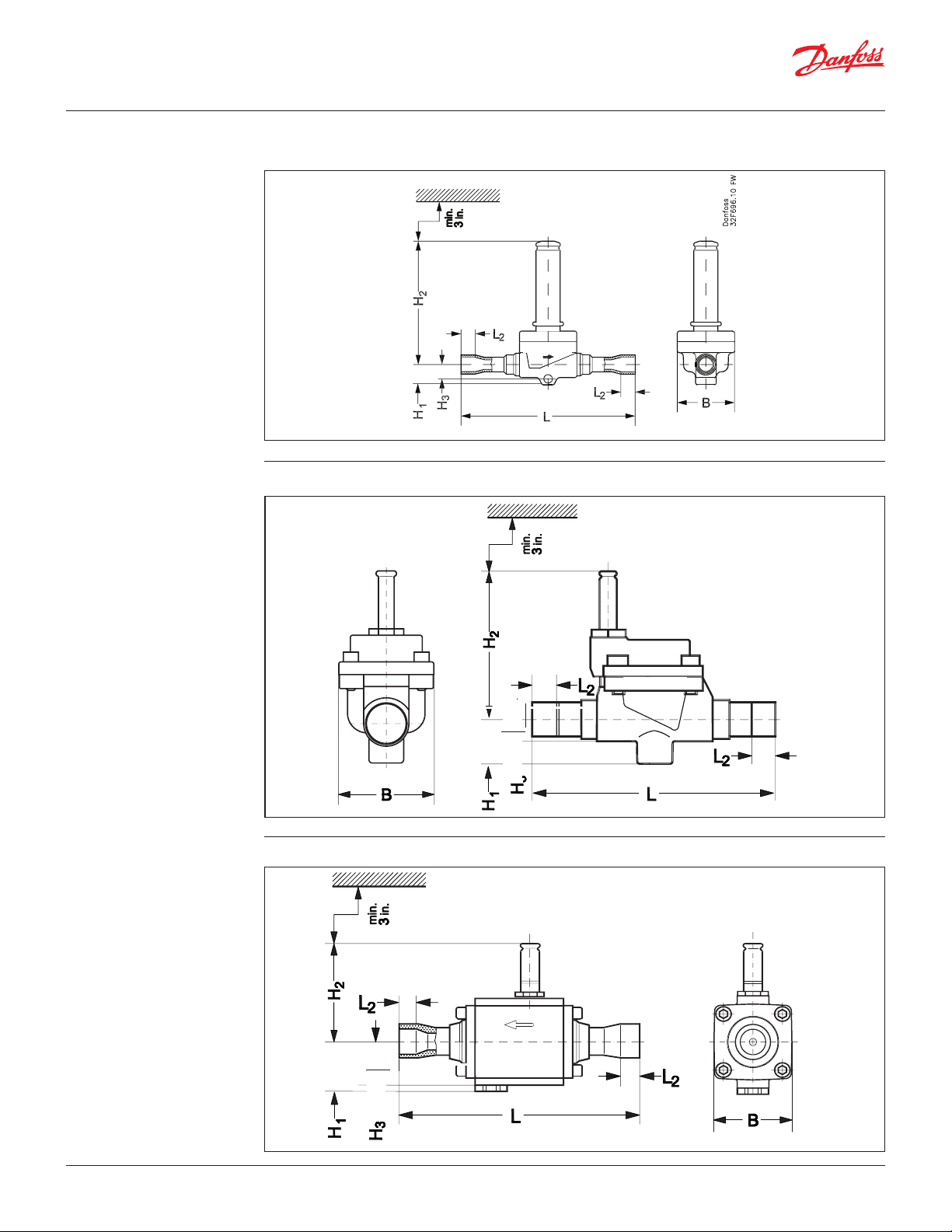

Dimensions and weight

EVR 2 – 6 and EVRH 10 – 20

Danfoss

EVRH 25

EVRH 32

Danfoss

Danfoss

© Danfoss | DCS (rja) | 2017.03

DKRCC.PD.B00.C3.22 | 10

Page 11

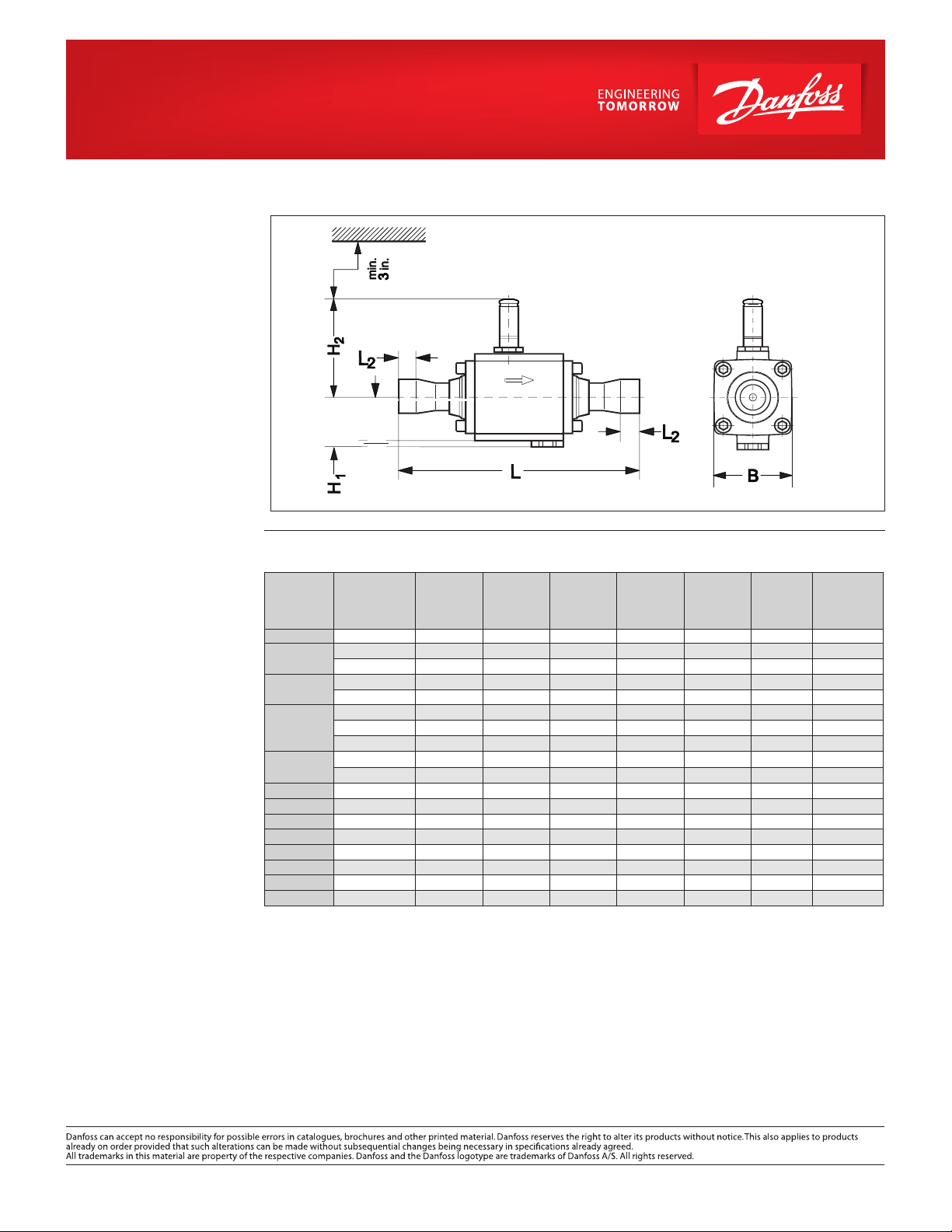

EVRH 40

EVRH 25, EVRH 32 – 40, solder connection

Danfoss

Type

connection

[in]

Solder

EVR 2 1⁄4 lbs

EVR 3

EVR 4

EVR 6

1

3⁄8

3

1⁄2

3⁄8

1

⁄4

⁄8

⁄2

5⁄8

EVR 8

1⁄2

5⁄8

EVRH 10 1⁄2 5⁄8 3

EVRH 15 5⁄8

EVRH 18 –

EVRH 20 7⁄8

EVRH 22

7

⁄8 25⁄32 3 7⁄16 – 7 1⁄2 5⁄8 2 13⁄16 –

EVRH 25 1 1⁄8 – 5 1⁄8 1 1⁄2 8 1⁄8

EVRH 32 – – 1 1⁄16 2 9 1⁄2

H1

[in]

9

⁄16 2 1⁄2 5⁄16 4

9

⁄16 2 1⁄2 5⁄16 4 9⁄32 1 5⁄16 0.44

9

⁄16 2 1⁄2 5⁄16 4 5⁄8

9

⁄16 2 3⁄4

9

⁄16 2 3⁄4

9

⁄16 2 3⁄4

9

⁄16 2 3⁄4

9

⁄16 2 3⁄4

9

⁄16 2 3⁄4

9

⁄16 2 3⁄4 3⁄8 6

3

⁄4 3 1⁄4 – 6 15⁄16 1⁄2 2 3⁄16 1.76

3

⁄4 3 1⁄4 – – – 2 3⁄16 –

25

⁄32 3 7⁄16 – 7 1⁄2 5⁄8 2 13⁄16 2.20

H

[in]

2

H

3

[in]

3

⁄8 4 1⁄4 5⁄16 1 5⁄16 –

3

⁄8 5 3⁄8 1 5⁄16 –

3

⁄8 4 1⁄4 5⁄16 1 5⁄16 0.66

3

⁄8 5

3

⁄8 6

3

⁄8 5

7

⁄16 5

L

[in]

L2

[in]

9

⁄32 1 5⁄16 0.44

5

⁄16 1 5⁄16 0.44

3

⁄8 1 5⁄16 0.66

1

⁄2 1 5⁄16 0.66

3

⁄8 1 5⁄16 –

1

⁄2 1 5⁄16 –

3

⁄8 1 13⁄16 1.10

7

⁄8 3 3⁄4 3.0

11

⁄16 3 1⁄8 4.3

B

[in]

EVRH 40 1 5⁄8 – 1 1⁄16 2 1⁄16 10 1⁄4 1 1⁄8 3 1⁄8 4.3

Net weight of coil: 0.67 lbs

Weight

[lbs]

© Danfoss | DCS (rja) | 2017.03 DKRCC.PD.B00.C3.22 | 11

Loading...

Loading...