Page 1

Data sheet

QTL & AB-QM set - QTL 45-60 2m capillary tube with

AB-QM DN 15

Description

Disposal

Ordering

• Small compact thermostat

•

Fast and reliable thermostat / valve connection

• Automatic flow limitation to match energy

demand

• Easy valve selection and commissioning

• Easy to adjust the required max flow

AB-QM QTL set DN 15 45-60/2m

Picture Typ e Code No.

QTL Thermostat 45- 60 2m capillary tube

QTL is self-acting thermostatic actuator primarily

for use for temperature control of small hot water

cylinders.

Main features:

• Thermostat

• Setting range: 45-60 °C

• 2 meter capillary tube length

• Valve AB-QM, DN 15

• PN 16

• Max media temp: 120 °C

• Max differential pressure: 6 bar (600 kPa)

• Housing material: DZR brass

• Connection: External thread ISO228/1

AB- QM 15 G ⁄4 A, 0.09-0.45 m3/h

AB- QM, union connection, DN 15

Service part

Picture Setting range Valve AB-Q M Code No.

QTL thermostatic actuator 45-60°C * 003L3534

* compatible on ly with old range of AB-Q M codes 003Z1261, 003Z1211, 003Z1262, 003Z1212, 003Z1213

Accessories

Picture Typ e Connection Code No.

Immersion pocket Cu Rp ½ x M14 - ø12 x 100 mm 003Z0391

Housing for sensor stuffing box G ½” 013U 8102

Sensor stuffing box / pocket kit M14x1 013U0292

Union connection (1 pcs) DN 15 Rp ½ 003Z0232

Tailpiece connec tion – welding (1 pcs) DN 15 003Z0226

003L3535

© Danfoss | 2021.05

AI228186477433en-010301 | 1

Page 2

Data sheet QTL 45-60 2m capillary tube with AB-QM DN 15

Application

Sizing example

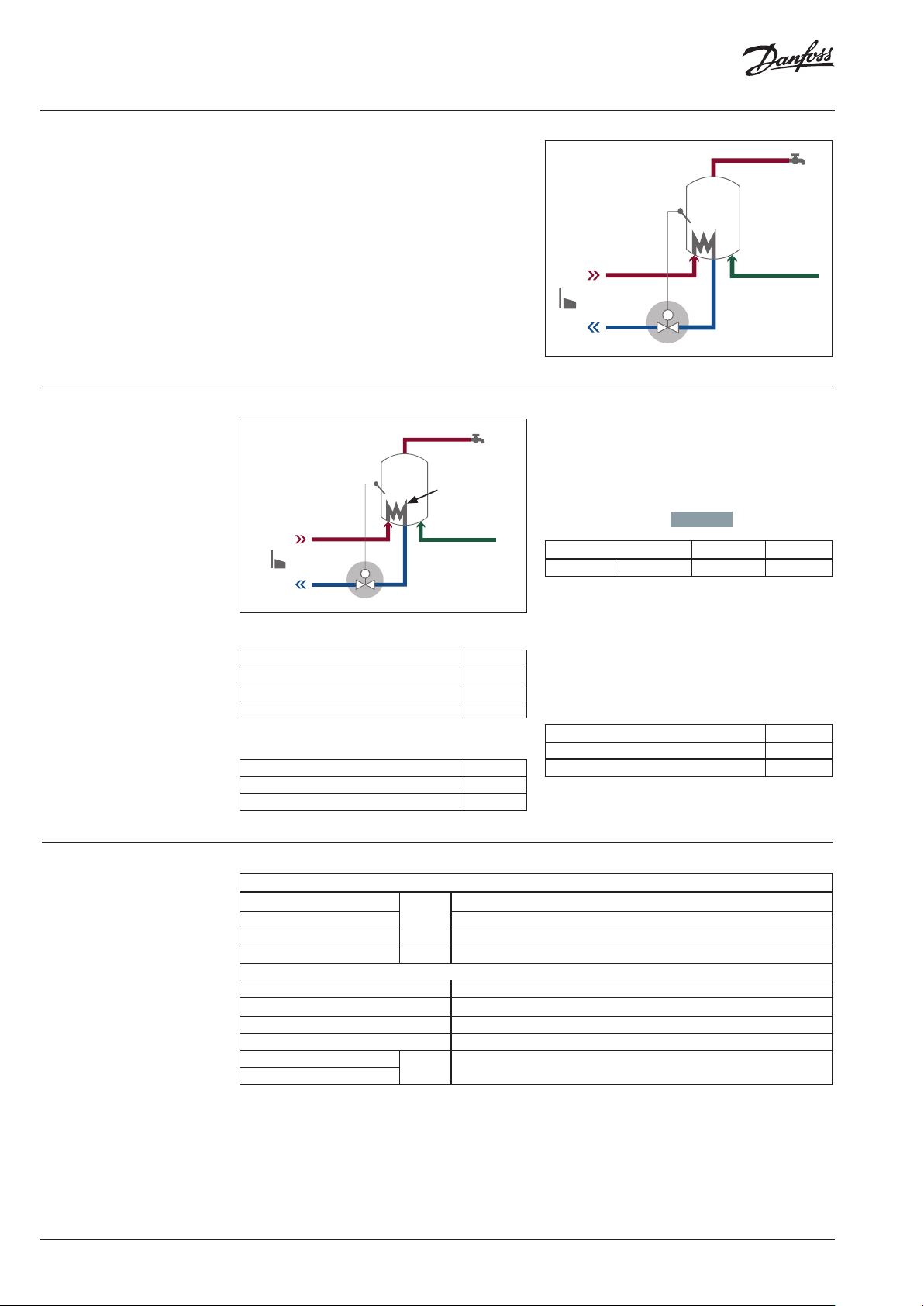

Thermostatic temperature controllers for singlefamily houses and flats are used to control the

flow temperature in storage domestic hot water

and heating systems. With their fast opening

and closing, they protect the heating coil

from scaling and ensure a long lifetime for the

equipment installed in the system.

55°C

15 kW

T

T

Required flow Q m3/h

Q = 0.86 x P / T

= 0.86 x 15 / 40

= 0.3 m3/h

Selected valve:

AB-QM, DN 15, Q

Nominal diameter DN 15

Flow range

Q

nom

= 0.45 m0.45 m33/h/h

nom

(100 %)

l/h 450

Technical Data

Thermostat setting

Valve presetting = 72%

Given data

DHW temp 55°C

Heating coil capacity 15 k W

Temp diff flow - return 40°K

Available ∆p valve 2 bar

Required data

Valve DN ??

Valve presetting setting ??

Thermostat setting ??

General data

Setting range

1)

P-band

Max adm temperature at sensor 90

Capillary tube langth m 2.2

Material

Housing DZR Brass (CuZn36Pb2As - CW 602N)

Cone and diaphragm support MPPE (Noryl)

Main spindle (CW 614N) Zn39Pb3

Temperature sensor Copper, mat. No. 2.0090

Adapter

Nut

1)

with relevant AB- QM, at 50 % flow setti ng

°C

DN 10 -20 CuZn39Pb3 (CW 614N), coated with Cu Zn8B

P-band ≈ 7 °C

DHW temp = 55 °C - 7 °C = 48 °C

Thermostat setting: 2

Thermostat setting

DHW temp 55°C

Valve presetting 72%

Thermostat setting 2

1)

The settin g temperature according to table on p age 3 is indicative.

45 … 60

5

1)

2 | AI228186477433en-010301

© Danfoss | 2021.05

Page 3

Data sheet QTL 45-60 2m capillary tube with AB-QM DN 15

Technical Data (continuous)

1)

Factory se tting of the valve is done at

nominal setting range.

2)

Regardless of t he setting, the valve can

modulate bel ow 1 % of set flow.

3)

∆p = (P1-P3) min~max

4)

When set above 100 %, m inimum

starting pres sure needed is higher.

5)

When set above 100 %, i t can be used

as a flow limite r only.

6)

In case AB-Q M is used above 400 kPa

differe ntial pressure contact Danfoss

design center to assure p roper

design.

Pc - pressure controll er part

Cv - Control valve part

AB-QM (thread version)

Nominal diameter DN

Flow range

Setting range

Diff. pressure

Q

nom

2)

p

3), 4)

p

(100 %)

6)

min

6)

max

1)

l/h 450

% 20-120

kPa 16-400/600

Pressure stage PN 16

Control range 1:1000

Control valve’s characteristic Linear

Leakage rate with recommended actuators No visible leakage

For shut off function Acc. to ISO 5208 class A - no visible leakage

Water and water mixture for closed heating and cooling systems according to

Flow medium

When used in plant Type II for DIN EN 14868 appropriate protective measures are

taken.

Medium temperature

Storage and transport temp. –40 … 70

°C

plant type I for DIN EN 14868.

The requirements of VDI 2035, part 1 + 2 are observed.

Stroke mm 2.25

Connection

ext. thread (ISO 228/1) G ¾ A

actuator M30 × 1.5

Materials in the water

Valve bodies DZR Brass (CuZn36Pb2As - CW 602N)

Membranes and O-rings EPDM

Springs W.Nr. 1.4568, W.Nr. 1.4310

Cone (Pc) W.Nr. 1.43 05

Seat (Pc) EPDM

Cone (Cv) CuZn40Pb3 - CW 614N

Seat (Cv) DZR Brass (CuZn36Pb2As - CW 602N)

Screw Stainless Steel (A2)

Flat gasket NBR

Sealing agent

(only for valves with test plugs)

Materials out of the water

Plastic parts PA

Insert parts and outer screws CuZn39Pb3 - CW 614N; W.Nr. 1.4310; W.Nr. 1.4401

Note: According suitabil ity and usage especiall y in not oxygen tight syste ms please mind the instructi ons given by the coolant produce r.

15

6)

−10 ... +120

Dimethacrylate Ester

Settings AB-QM DN 10-20 (45-60 °C)

Temperature

setting

20% ≈ 2 °C 48.0 50.5 53.0 55.5 58.0 60.5 63.0

30% ≈ 3 °C 4 7.0 49.5 52.0 54.5 57.0 59.5 62.0

40% ≈ 4 °C 46.0 48.5 51.0 53.5 56.0 58.5 61.0

50% ≈ 5 °C 45.0 47. 5 50.0 52.5 55.0 57. 5 60.0

60% ≈ 6 °C 44.0 46.5 49.0 51. 5 54.0 56.5 59.0

70%

80% ≈ 8 °C 42 .0 44.5 47.0 49.5 52.0 54.5 5 7.0

AB-QM (flow setting)

90% ≈ 9 °C 41.0 43. 5 46.0 48.5 51.0 53.5 56.0

100% ≈ 10 °C 40.0 42.5 45.0 47.5 50.0 52.5 55.0

P-band

≈ 7 °C 43.0 45.5 48.0 50.5 53. 0

QTL temperature setting depends on AB-QM

flow setting. The values in the table indicate

the open position of the thermostat. Please

note that the attached table is indicative

and will vary depending on the application.

It is to be used as a guidance only. For exact

temperature verification temperature needs

to be measured at reference point and the

sensor setting adjusted accordingly.

QT Sensor setting (turns)

0 1 2 3 4

It is necessary to set the AB-QM according

to required setting before the thermostat is

mounted. It is recommended to set AB-QM

between 30 and 70 % flow setting.

QTL thermostat is set to the desired setting by

hand. When minimum or maximum setting

is required, QTL setting knob is to be moved

slightly in opposite direction to ensure optimal

performance of the thermostat.

55.5

5

6

58.0

© Danfoss | 2021.05

AI228186477433en-010301 | 3

Page 4

Data sheet QTL 45-60 2m capillary tube with AB-QM DN 15

Design

1. Setting knob

2. Adapter

3. AB-QM valve

4. Hot-water pipe

5. Temperature sensor

①

②

③

④

⑤

Dimensions

H

DN

15 65 31 113

L

L

1min

L L

mm

1min

H

4 | AI228186477433en-010301

© Danfoss | DCS-S/SI | 2021.05

Loading...

Loading...