Page 1

Data sheet

Thermostatic actuator QT

- return temperature control with AB-QM valves

Description

Benefits

QT is a self-acting thermostatic actuator

designed to be used as return temperature

control thermostat in one-pipe heating systems.

QT is dedicated to be used with AB-QM

automatic balancing & control valve.

AB-QM together with QT is a complete

one-pipe solution: AB-QT.

Main data:

• Setting range: 35-50 °C, 45-60 °C, 65-85 °C

• Designed for AB-QM DN 10-32

• Easy-to-install external surface sensor

• Reduces actual riser flow to match heat

demand

• Improved room temperature control

• Reduced overheating of the building

• Reduced heating cost

Ordering

QT thermostatic actuator

Setting range

(°C)

45 … 60

35 … 50

65 … 85

fit to

AB-QM

DN 10 -20 003Z0382

DN 25-32 003Z0383

DN 10 -20 003Z0384

DN 25-32 003Z0385

DN 10 -20 003Z0386

DN 25-32 003Z0387

Code No.

Accessories

Typ e

Pocket for submersible sensor

Adapter kit QT (DN 10-20)

Adapter kit QT (DN 25-32)

Sensor pocket kit

QT flow set ting tag

Code No.

003Z0391

003Z0392

003Z0393

003Z0394

003Z0395

AB-QM valves

DN

10 LF 150

10 275 00 3Z1211 00 3Z1201

15 LF 275

15 450 003 Z1212 00 3Z1202

20 900 G 1 A 003Z 1213 G 1 A 003Z1203

25 1.700 G 1¼ A 0 03Z1214 G 1¼ A 00 3Z1204

32 3.200 G 1½ A 0 03Z1215 G 1½ A 003Z1205

Q

(l/h)

max.

Ext. thread

(ISO 228/1)

G ½ A

G ¾ A

Code No. AB-QM

00 3Z1261

003Z1262

Ext. thread

(ISO 228/1)

G ½ A

G ¾ A

Code No.

00 3Z1251

00 3Z1252

© Danfoss | 2018.07 VD.C6.U4.02 | 1

Page 2

Data sheet Thermostatic actuator QT

Applications

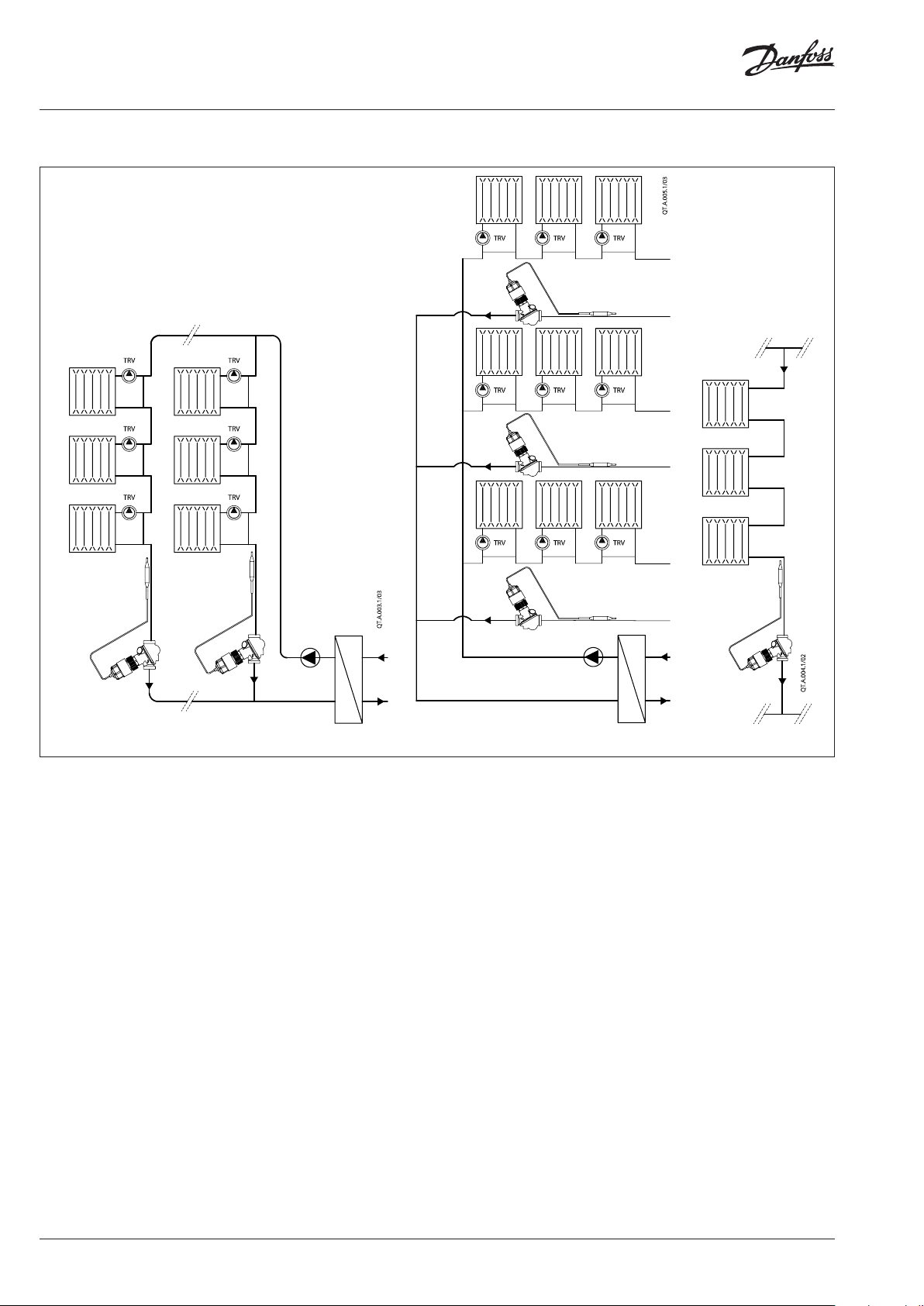

Fig. 1 Fig. 2 Fig. 3

QT is designed to be used in combination with

AB-QM in one-pipe heating systems. AB-QM

together with QT converts one-pipe heating

system into energy efficient variable flow

system, where flow in the risers is dynamically

adjusted to match the load in the riser by control

of return water temperature.

In one-pipe systems flow in the riser is always

present. TRV on the radiator controls room

temperature by controlling flow through

radiator. However, by reducing flow through the

radiator, water flow is not reduced but diverted

to a by-pass and thus total water flow in the riser

remains permanent. Therefore at partial loads

water temperature in the pipe is increasing.

As a result the riser itself with the by-pass pipe

continues to heat the room. This can cause

overheating of the room.

After the building is renovated the heating

system becomes oversized since the heat losses

of the building decrease. As a result overheating

issue increases even more.

AB-QM mounted in the riser provides a robust

solution that offers reliable balance of one-pipe

heating system at all system conditions. As a

result, every riser gets design flow – and never

more than that. Each riser becomes independent

part of installation.

In addition, QT as a self-acting return

temperature thermostat installed on AB-QM

provides flow control through the temperature

of return water in the riser. By this water flow in

the riser is dynamically controlled to match the

actual load in the riser. This results in improved

room temperature control and greatly reduced

overheating of the building. Thus one-pipe

systems become energy efficient variable flow

systems, similar as Two-pipe systems are.

Typical applications are:

- one-pipe vertical riser based heating system

(Fig. 1)

- one-pipe horizontal loop based heating

system (Fig. 2)

- two-pipe vertical riser based heating system

without TRV’s, such as staircase or bathroom

risers (Fig. 3)

2 | VD.C6.U4.02 © Danfoss | 2018.07

Page 3

Data sheet Thermostatic actuator QT

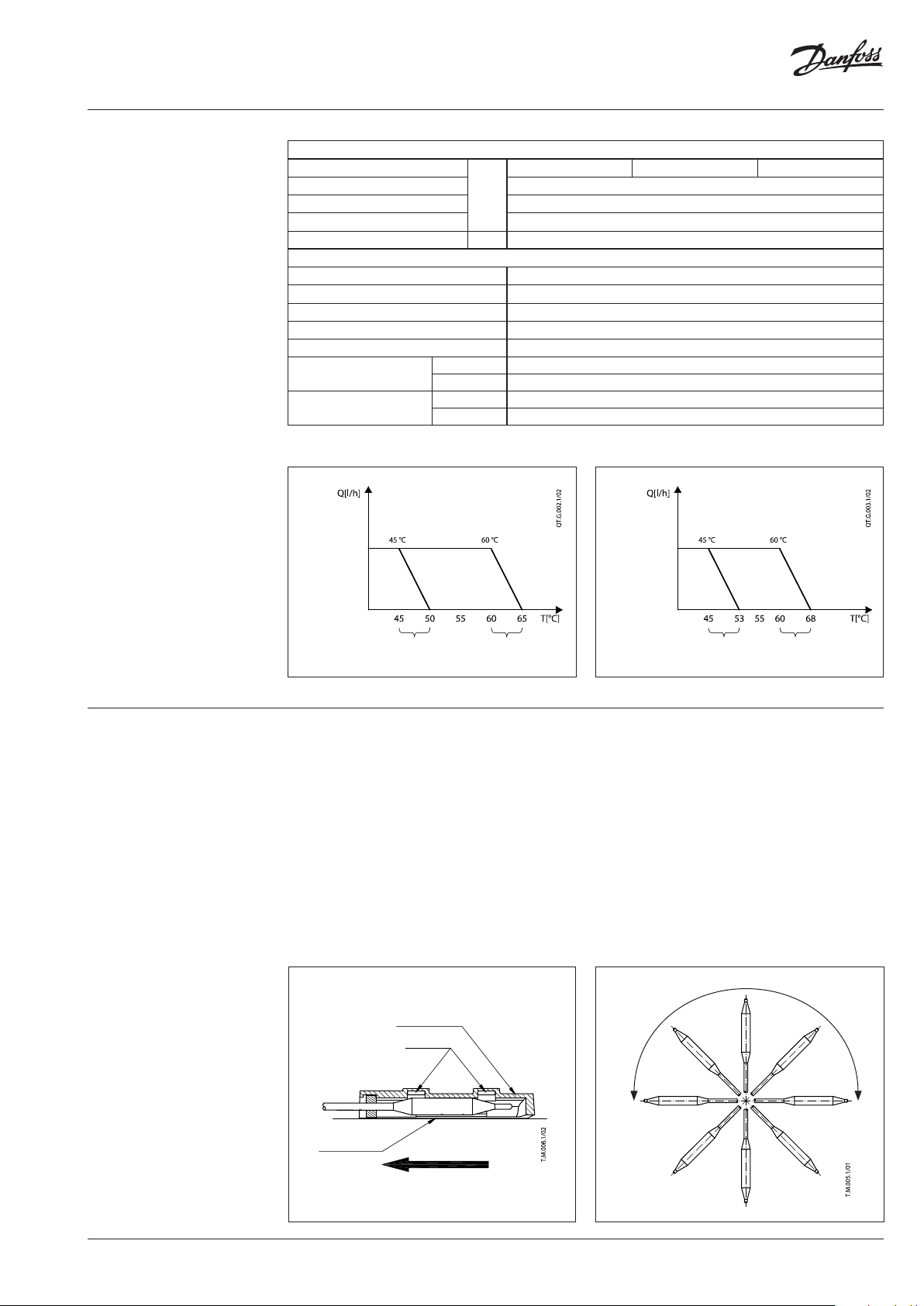

Technical data

General data

Setting range

Temperature tolerance ±3

1)

P-band

Max adm temperature at sensor 90

Capillary tube length m 0.6

Materials

Housing CuZn36Pb2As (CW 602N)

Cone and diaphragm support MPPE (Noryl)

Main spindle (CW 614N) Zn39Pb3

Sensor cap Polypropylene (Borealis HF 700-SA)

Temperature sensor Copper, mat. No. 2.0090

Adapter

Nut

1)

with AB- QM DN 10-20, at 50 % flow setting

2)

with AB-Q M DN 25-32, at 50 % flow setting

QT setti ng 0 (min) QT setti ng 6 (max)

AB-QM

50% setting

°C

DN 10 -20 CuZn39Pb3 (CW 614N), coated with Cu Zn8B

DN 25-32 CuZn39Pb3 (CW 614N)

DN 10 -20 CuZn39Pb3 (CW 614N), coated with Cu Zn8B

DN 25-32 CuZn39Pb3 (CW 614N)

35 … 50 45 … 60 65 … 85

2)

5 1)/8

QT setti ng 0 (min) QT setti ng 6 (max)

AB-QM

50% setting

Mounting

P band P band

P band P ba nd

Fig. 4 Functional graph for QT on AB-QM DN 10-20 Fig. 5 Functional graph for QT on AB- QM DN 25-32

When used in vertical based one-pipe heating

system (Fig.1) AB-QM is to be installed after the

last radiator in the riser.

In horizontal based heating system (Fig.2) AB-QM

can be mounted also elsewhere in the loop, as

long as the temperature sensor can be mounted

after the last radiator in that loop.

QT should be mounted on the AB-QM by hand.

Installation of the sensor

For proper heat transfer between a heating

water pipe and the thermostat sensor, it is very

important to apply thermo paste (included in the

box) on the surfaces in contact.

Sensor itself can be mounted in any direction.

For best performance of QT it is recommended

to install sensor facing up (Fig. 7). It can be

mounted either above or below sensor head.

Maximum allowed torque is 5 Nm.

It is recommended to insulate the sensor if the

thermostat is installed in a very cold place (< 5 °C).

o

r

f

m

r

e

a

n

c

e

Sensor holder

Fastener

p

t

s

e

B

Thermo paste

Fig. 6

Hot water su pply

Fig. 7

VD.C6.U4.02 | 3© Danfoss | 2018.07

Page 4

Data sheet Thermostatic actuator QT

Settings

QT temperature setting depends on AB-QM flow

setting.

It is necessary to set the AB-QM according

to required setting before the thermostat is

mounted. It is recommended to set AB-QM

between 30 and 70 % flow setting.

AB-QM DN 10-20 (45-60 °C)

Temperature

setting

20 % 48.0 50.5 53. 0 55.5 58.0 60.5 63.0

30 % 4 7.0 49.5 52.0 54.5 5 7.0 59.5 62.0

40 % 46.0 48.5 51.0 53.5 56.0 58.5 61.0

50 % 45.0 47. 5 50.0 52.5 55.0 57. 5 60.0

60 % 44.0 46.5 49.0 51.5 54.0 56.5 59.0

70 % 43.0 45.5 48.0 50.5 53.0 55.5 58.0

80 % 42.0 44.5 47.0 49. 5 52.0 54.5 5 7.0

AB-QM (flow set ting)

90 % 41. 0 43.5 46.0 48.5 51. 0 53.5 56.0

100 % 40.0 42.5 45.0 47. 5 50.0 52.5 55.0

QT Sensor setting (turns)

0 1 2 3 4 5 6

AB-QM DN 10-20 (35-50 °C)

Temperature

setting

20 % 38.0 40.5 43.0 45.5 48.0 50.5 53.0

30 % 3 7.0 39.5 42.0 44.5 47.0 49. 5 52.0

40 % 36.0 38.5 41.0 43.5 46.0 48.5 51.0

50 % 35.0 37. 5 40.0 42. 5 45.0 47. 5 50.0

60 % 34.0 36.5 39.0 41.5 44.0 46.5 49.0

70 % 33.0 35.5 38.0 40. 5 43.0 45.5 48.0

80 % 32.0 34.5 37. 0 39.5 42.0 44.5 4 7.0

AB-QM (flow set ting)

90 % 31. 0 33.5 36.0 38.5 41. 0 43.5 46.0

100 % 30.0 32.5 35.0 37. 5 40.0 42. 5 45.0

QT Sensor setting (turns)

0 1 2 3 4 5 6

QT thermostat is set to the desired setting by

hand. When minimum or maximum setting

is required, QT setting knob is to be moved

slightly in opposite direction to ensure optimal

performance of the thermostat.

AB-QM DN 25-32 (45-60 °C)

Temperature

setting

20 % 49.5 52.0 54.5 57.0 59. 5 62.0 64.5

30 % 48.0 50.5 53.0 55.5 58.0 60.5 63.0

40 % 46.5 49.0 51.5 54.0 56.5 59.0 61.5

50 % 45.0 47. 5 50.0 52.5 55.0 57. 5 60.0

60 % 43.5 46.0 48.5 51.0 53.5 56.0 58.5

70 % 42. 0 44.5 47.0 49.5 52.0 54.5 5 7.0

80 % 40.5 43.0 45.5 48.0 50.5 53.0 55.5

AB-QM (flow set ting)

90 % 39.0 41.5 44.0 46.5 49.0 51.5 54.0

100 % 37. 5 40.0 42 .5 45.0 47. 5 50.0 52.5

QT Sensor setting (turns)

0 1 2 3 4 5 6

AB-QM DN 25-32 (35-50 °C)

Temperature

setting

20 % 39.5 42.0 44.5 47.0 49.5 52.0 54.5

30 % 38.0 40.5 43.0 45. 5 48.0 50.5 53.0

40 % 36.5 39. 0 41.5 44.0 46.5 49.0 51.5

50 % 35.0 37. 5 40.0 42. 5 45.0 47. 5 50.0

60 % 33.5 36.0 38.5 41. 0 43.5 46.0 48.5

70 % 32.0 34.5 37.0 39. 5 42 .0 44.5 4 7.0

80 % 30.5 33.0 35. 5 38.0 40. 5 43.0 45.5

AB-QM (flow set ting)

90 % 29.0 31.5 34.0 36.5 39.0 41.5 44.0

100 % 27. 5 30.0 32 .5 35.0 37. 5 40.0 42.5

QT Sensor setting (turns)

0 1 2 3 4 5 6

Factory setting is 4.

AB-QM DN 10-20 (65-85 °C)

Temperature

setting

20 % 68.5 71.0 73.5 76. 5 80.0 83.5 87.5

30 % 6 7.0 70.0 72.5 76.0 79.0 82.5 86.5

40 % 66.0 69.0 71.5 75.0 78.5 81.5 85.5

50 % 65.0 68.0 71.0 74.5 77. 5 81.0 85.0

60 % 63.5 67.0 70.5 74.0 76.5 80.0 84.0

70 % 62.0 65.5 69.0 72.5 75. 5 79.0 83.5

80 % 60.5 64.0 67.5 71.0 74.5 78.0 83.0

AB-QM (flow set ting)

90 % 58.5 62. 5 66.0 69.5 73.5 77. 5 82.0

100 % 57.0 61.0 64.5 68.0 72. 5 7 7.0 81.5

QT Sensor setting (turns)

0 1 2 3 4 5 6

AB-QM DN 25-32 (65-85 °C)

Temperature

setting

20 % 72.5 75.0 77. 5 80.0 84.0 88.0 92.5

30 % 70.0 73.0 75.5 78.0 82.0 86.0 90.5

40 % 6 7.5 70.5 73.3 76 .0 80.0 83.5 87. 0

50 % 65.0 68.0 72.0 74.0 77. 5 80.5 85.0

60 % 62.5 65.8 69.2 72.5 76. 5 79.0 84.0

70 % 60.0 64.5 68.5 71. 5 75.5 78.0 83.0

80 % 58.0 63.0 67. 0 70.0 74.0 77.0 81.5

AB-QM (flow set ting)

90 % 56.5 61.0 65.0 69.0 72. 5 76. 5 80.5

100 % 55.0 59.0 63.0 67. 5 71.5 75.5 79.5

QT Sensor setting (turns)

0 1 2 3 4 5 6

4 | VD.C6.U4.02 © Danfoss | 2018.07

Page 5

Data sheet Thermostatic actuator QT

Commissioning

Flow on AB-QM and temperature setting on QT

need to be set to achieve best performance and

efficiency of one-pipe heating system.

Recommended is a following 3 steps setting

procedure:

1. AB-QM setting

2. QT setting

3. follow up

There are 2 main reasons that influence one-pipe

system efficiency and therefore AB-QM and QT

setting:

1. renovation status of the building since

renovation is a major reason for a heating

system to become oversized; generally, after

building is renovated (wall & roof insulation,

new windows) existing heating system

becomes significantly oversized

2. a dynamic nature of the heating load that is

changing unpredictably in the building due

to partial loads, internal gains and weather

conditions.

Note:

After renovation, one of possible steps to improve

efficiency of the one-pipe heating system is

also optimization (reduction) of supply water

temperature. Together with AB-QT if offers

additional efficiency improvements where

influences mostly upper radiators in the riser/loop.

In such case QT setting would practically not need

to change.

1. AB-QM setting

Required flow after building renovation is

generally much lower than design flow that was

calculated at the time building was designed.

Flow is to be calculated based on actual heat

losses–after renovation. Needed flow calculation

is recommended to be based on original Δt. For

best performance, recommended flow setting

on AB-QM is between 30 and 70 % flow setting.

2. QT setting – Df Dynamic factor method

Temperature setting of the QT is influenced

by dynamic factor Df. Last radiator in the riser

is normally the one which influences dynamic

factor Df at most. Df is to be selected from the

table A. Having dynamic factor selected, the

correction value of return temperature can be

chosen from Fig. B.

There are 2 factor that influence dynamic

factor Df:

1. фr, Renovation effectiveness [%]

2. Room type [A or B]

Df can be selected for a building as a whole.

However, various risers in the same building

can have different characteristics (for example:

kitchen compared to sleeping room, riser in the

middle of the building compared to the one in

the corner, etc). Therefore, for best efficiency

also dynamic factor Df on various riser within the

same building can be different.

VD.C6.U4.02 | 5© Danfoss | 2018.07

Page 6

Data sheet Thermostatic actuator QT

Commissioning (continuous)

1st factor, Renovation effectiveness фr describes

how much actual heat losses have been reduced

after building renovation compared to original,

design value. фr can be derived by:

Q

r

r

1100

%

Q

n

[Qn] - design heat losses (nominal)

[Qr] - actual heat losses (after renovation)

2nd factor depends on the what kind of room is

heated by a particular riser. It is based on ISO

13790:

• Room typa A: bedroom room, utility, other

rooms with low average internal gains of cca

2

3 W/m

• Room type B: kitchen or living room, with

high average internal gains of cca 9 W/m

Table A gives an overview of Df values, based on

value of both factors respectively.

Tab le A

Df - Dyna mic factor

Room type A (3 W/m2) 8 19 31 43 54 66 78

Room type B (9 W/m2) 17 29 41 52 64 76 88

0 10 20 30 40 50 60

Having dynamic factor selected for a particular

building/riser, the correction value of return

temperature can be chosen from Fig. B.

фr =renovation effectiveness [%]

QT setting is calculated so that “return temperature

correction” value is combined (summed up) with design

return temperature (see examples).

Exampl e 1

2

3. Follow up

Achieved energy efficiency of AB-QT solution

depends on QT setting. For maximum results it is

strongly recommended to perform follow up on

the installation during first year of operation.

A- potent ial

energy savings

area

Water T

QT setting

More savings

Exampl e 2

Return temperature correction [°C]

More conservative

Dynami c factor [%]

Fig. B - Return temperature correction

For further details please contact Danfoss

representative or visit

http://www.danfoss.com/onepipesolutions

A- potent ial

energy savings

area

Water T

QT setting

Outside T

supply temperature

design return temperature

actual return temperature without QT

actual return temperature with QT

Fig. 8a: QT Energy saving potential- higher QT setting

supply temperature

design return temperature

actual return temperature without QT

actual return temperature with QT

Fig. 8b: QT Energy saving potential- lower QT setting

Outside T

6 | VD.C6.U4.02 © Danfoss | 2018.07

Page 7

Data sheet Thermostatic actuator QT

Sizing – QT setting design

examples

1. Example

Fig. 9 “Typical one-pipe riser with AB-QM & QT

installed”

A well renovated building.

Given:

Design temperature system 90/70 °C

Room type living room

Design specific heat losses

(before renovation) qn 33 W/m

Specific heat losses

(after renovation) qr 17 W/m

2

2

Required

Temperature setting for QT

Solution:

Based on:

• Room type B (for living room)

• And фr = 50 %, where renovation

effectiveness фr can be calculated as

q

r

r

1100

q

n

17

1100

33

%5 0

dynamic factor Df 76 % can be identified from

table A.

Fig. 9

Based on Df = 76 %, Fig. B gives return

temperature correction of –23 °C.

Required QT setting is:

47 °C (70 °C + (–23 °C) = 47 °C)

2. Example

A partly renovated building (for example

windows renovated only)

Given:

Design temperature system 90/70 °C

Room type bedroom

Design specific heat losses qn

(before renovation) 49 W/m

Actual specific heat losses qr

(after renovation) 37 W/m

2

2

Actual riser heat losses Qr 10.950 W

Required:

1. AB-QM size & setting

2. QT temperature setting

3. QT sensor setting (turns)

Solution

1. AB-QM setting is calculated based on actual

heat losses after renovation and design ΔT.

Qr

q

p

10950

tC

35

3

sm

204190975

hl482sm1034,1q

AB-QM DN 20 is selected, where needed flow

setting is 53 % for required 482 l/h.

2. QT temperature setting

Riser type 2 in table A is a proper match:

• Room type A (bedroom)

• And фr = 25 %, where renovation

effectiveness фr can be calculated as

r

Q

n

1100

Q

r

37

1100

49

%2 5

Dynamic factor Df 37% can be indentified

from table, based on фr value of 25%

(between 20 and 30%)

Based on Df = 37%, Fig B gives return

temperature correction of –13°C.

Required QT setting is:

57 °C (70 °C + (–13 °C) = 57 °C)

3. QT sensor setting

Required

QT temperature setting

AB-QM size DN 20

AB-QM setting 53 %

Solution

On page 3, left setting table is selected

that is valid for AB-QM DN10 –20 sizes. In a

50% AB-QM setting row, required 57 °C QT

temperature setting corresponds to 5 turns.

5 turns for QT sensor setting is selected.

AB-QM DN 10-20 (45-60 °C)

Temperature

setting

20 % 48.0 50.5 53.0 55.5 58.0 60.5 63.0

30 % 4 7.0 49.5 52.0 54.5 57. 0 59.5 62.0

40 % 46.0 48.5 51.0 53.5 56.0 58.5 61.0

50 % 45.0 4 7.5 50.0 52.5 55.0 57. 5 60.0

60 % 44.0 46.5 49.0 51. 5 54.0 56.5 59. 0

70 % 43.0 45.5 48.0 50.5 53. 0 55.5 58.0

80 % 42.0 44.5 47. 0 49.5 52.0 54.5 57.0

AB-QM (flow set ting)

90 % 41. 0 43.5 46.0 48.5 51.0 53.5 56.0

100 % 40.0 42.5 45.0 4 7.5 50.0 52.5 55. 0

QT Sensor setting (turns)

0 1 2 3 4 5 6

VD.C6.U4.02 | 7© Danfoss | 2018.07

Page 8

Danfos

produc

Al

Danfoss A/S

Heating Segment

Data sheet Thermostatic actuator QT

Design

1. Setting knob

2. Adapter

3. AB-QM valve

4. Hot-water pipe

5. Temperature sensor

6. Rubber selling for sensor

7. Sensor holder

Dimensions

DN

H

L

L

1min

10 53 37 105

15 65 31 113

20 82 22 110

25 10 4 19 125

32 130 12 137

L L

mm

1min

H

s can accept no responsibility for possible errors in catalogues, brochures and o ther printed material. Danfoss reserves the right to alter its pro ducts without notice. This also applies to

ts already on order provided that such alterations can be m ade without subsequential changes being necessary in specications already agreed.

l trademarks in this material are property of the r espective companies. Danfoss and all Danfoss logotypes are t rademarks of Danfoss A/S. All rights reserved.

• heating.danfoss.com • +45 7488 2222 • E-Mail: heating@danfoss.com

© Danfoss | DHS-SRMT/SI | 2018.078 | VD.C6.U4.02

Loading...

Loading...