Page 1

Installation Guide

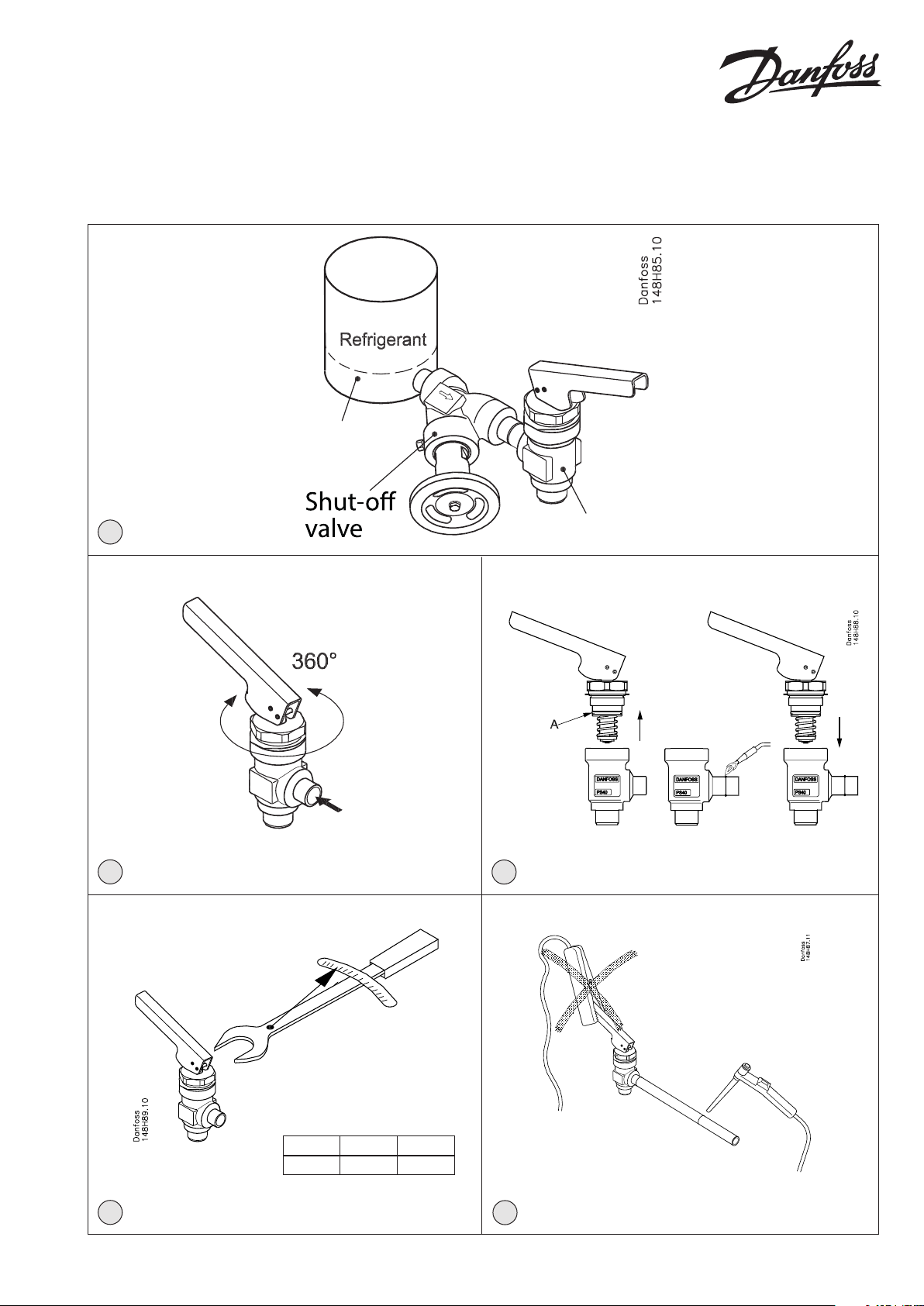

QDV

148H86.1

Shut-o valve

Type QDV 15

148R9540

148R9540

Oil

1

0

Danfoss

2

Nm lb-feet

QDV 15 50 37

4

3

5

© Danfoss A/S (MWA), 2014-12 DKRCI.PI.KL0.A8.ML / 520H0752 1

Page 2

ENGLISH

Refrigerants:

Applicable to R717 (Ammonia).

Flammable hydrocarbons are not

recommended. QDV is a backpressure

dependent valve. The valve is only

recommended for use in open circuits. For

further information please contact Danfoss.

Temperature range:

QDV 15: –50/+150°C (–58/+302°F)

Pressure range:

The valves are designed for a max.

working pressure of 40 bar g (580 psi g).

In order to prevent hydraulic pressure

building up between the stop valve

and the QDV an integral relief device is

included opening the valve slowly if the

pressure exceeds 16 bar (232 psig).

Installation:

The valve must be installed after a stop

valve with the spindle vertically upwards

and with ow direction from the side

branch (g. 1).

If any tube or hose is mounted

on the outlet of the QDV it has to

be calculated to prevent

backpressure building up when

relieving. Blocking the outlet of the QDV

will cause danger (hydraulic pressure

building up).

An outlet hose of the same size as the

outlet connection of the QDV valve must

be used.

The handle can be turned 360° for

optimizing operation position (g. 2).

Valves should only be operated by hand

without the use of tools or other devices.

The valve is designed to withstand a high

internal pressure. However, the piping

system should be designed to avoid liquid

traps and reduce the risk of hydraulic

pressure caused by thermal expansion. It

must be ensured that the valve is protected

from pressure transients like “liquid

hammer” in the system.

Recommended ow direction:

The valve must be installed with ow

direction from the side branch (g. 2).

Welding:

The bonnet should be removed before

welding (g. 4) to prevent damage to

the O-ring between the valve body and

bonnet, as well as the Teon cone ring in

the valve seat.

Only materials and welding methods,

compatible with the valve housing

material, must be welded to the valve

housing.

The valve should be cleaned internally

to remove welding debris on completion

of welding and before the valve is

reassembled.

Avoid welding debris and dirt in the

threads of the housing and the bonnet.

Removing the bonnet can be omitted

provided that:

The temperature in the area between the

valve body and bonnet during welding

does not exceed +150°C/+302°F.

This temperature depends on the welding

method as well as on any cooling of the

valve body during the welding itself.

(Cooling can be ensured by, for example,

wrapping a wet cloth around the valve

body.) Make sure that no dirt, welding

debris etc. get into the valve during the

welding procedure.

Be careful not to damage the Teon cone

ring. The valve housing must be free from

stresses (external loads) after installation.

Fig. 5

Never use QDV or any other Danfoss

product to get an earth connection for

welding as it might cause damage to the

product.

Assembly:

Remove welding debris and any dirt from

pipes and valve body before assembly.

Check that the O-ring between the valve

body and bonnet, as well as the Teon

cone ring in the valve seat is without marks

or scratches.

Tightening:

Tighten the bonnet with a torque wrench,

to the values indicated in the table (g. 4).

Colors and identication:

The QDV 15 valves are painted with a red

oxide primer in the factory.

Precise identication of the valve is made

via the ID ring at the top of the bonnet, as

well as by the stamping on the valve body.

The external surface of the valve housing

must be prevented against corrosion

with a suitable protective coating after

installation and assembly.

Protection of the ID ring when repainting

the valve is recommended.

Maintenance

Dismantling the valve (g. 3):

Do not remove the bonnet while the

valve is still under pressure. Always close

the stop valve before the QDV. Then

proceed with activation of the QDV valve

to make sure that it is not under pressure.

- Check that the O-ring (pos. A) has not

been damaged.

- Check that the spindle is free of

scratches and impact marks.

- Check that the Teon cone ring is

without marks or scratches.

Replacement of the O-ring between the

bonnet and the valve body (g. 4):

The QDV 15 is delivered with an extra

O-ring. Remove the damaged O-ring (pos.

A) from the bonnet and carefully install the

new O-ring.

Assembly:

Remove any dirt from the body before the

valve is assembled.

Check that the O-ring between the valve

body and bonnet, as well as the Teon

gasket in the valve seat is without marks or

scratches.

Tightening:

Tighten the bonnet with a torque wrench,

to the values indicated in the table (g. 4).

Use only original Danfoss parts for

replacement.

New parts must be made of certied

materials applicable for the refrigerant

used.

In cases of doubt, please contact

Danfoss.

Danfoss accepts no responsibility for errors

and omissions.

Danfoss Industrial Refrigeration reserves

the right to make changes to products and

specications without prior notice.

A possible issue with our quick oil drain

valves type QDV which may not fully close

o during an oil draining process.

This may present itself when a drainage

pipe is installed on the outlet of the valve

which generates a back pressure to the

valve such that the valve is unable to fully

close. This will not present itself if there

is no drainage pipe installed on the valve

outlet. Max. back pressure 10 bar.

In applications where a QDV valve is

installed in a system and is normally

operating with an outlet pipe, please

ensure that full safety precautions are

taken when draining oil and make sure the

inlet to the vessel is isolated during the oil

draining process.

2 DKRCI.PI.KL0.A8.ML / 520H0752 © Danfoss A/S (MWA), 2014-12

Page 3

PORTUGUÊS

Refrigerantes:

Aplicável a todos os refrigerantes comuns

não inamáveis, incluindo R717 e gases/

líquidos não corrosivos dependendo da

compatibilidade com o material de vedação.

Não são recomendados hidrocarbonetos

inamáveis. A QDV é uma válvula

dependente de contrapressão. A válvula é

recomendada apenas para utilização em

circuitos abertos. Para obter mais informações,

entre em contato com a Danfoss.

Faixa de temperatura:

QDV 15: –50/+150 °C (–58/+302 °F)

Faixa de pressão:

As válvulas são projetadas para uma

pressão máx. de funcionamento de 40 bar g

(580 psi g).

Para prevenir a geração de pressão hidráulic

entre a válvula de bloqueio e a QDV, um

dispositivo integral de alívio é incluído,

abrindo a válvula lentamente se a pressão

exceder 16 bar (232 psig).

Instalação:

A válvula tem que ser instalada depois de

uma válvula de bloqueio com o eixo em

posição vertical para cima e com direção

de uxo a partir do braço lateral (g. 1).

Caso seja montado um tubo ou

uma mangueira na saída da QDV

é necessário efetuar cálculos para

evitar a acumulação de contrapressão

ao aliviar. Bloquear a saída da QDV causará

perigo (geração de pressão hidráulica).

Deverá ser usada uma mangueira de saída

do mesmo tamanho da conexão de saída

da válvula QDV.

A manivela pode ser girada 360° para

otimização da posição de funcionamento

(g. 2). A válvula deve ser operada

apenas manualmente sem a utilização de

ferramentas ou outros dispositivos. A válvula

foi projetada

pressão interna. No entanto, o sistema da

tubulação deve ser projetado para evitar

retenções de líquido e reduzir o risco de

pressão hidráulica

térmica. Certique-se

protegida de transientes de pressão como

“golpe de líquido” no sistema.

Direção de uxo recomendada:

A válvula tem que ser instalada com direção

de uxo a partir do braço lateral (g. 2).

Soldagem:

A tampa deve ser retirada antes da soldagem

(g. 4) para evitar danos no O-ring entre o

corpo da válvula e a tampa, bem como o

para suportar uma elevada

provocada pela expansão

de que a válvula está

anel de teon do cone no assento da válvula.

Apenas materiais e métodos de soldagem,

compatíveis com o material do corpo da

válvula, devem ser soldados no corpo.

A válvula deve ser limpa internamente para

remover resíduos no nal da soldagem e

antes de ser montada novamente.

Evite a acumulação de resíduos e sujeira

nas roscas do corpo e na tampa. Pode ser

excluído o processo de remoção da tampa,

desde que:

A temperatura na área entre o corpo da

válvula e a tampa durante a soldagem não

exceda os +150 °C/+302 °F.

Essa temperatura depende do método de

soldagem, bem como de um resfriamento do

corpo da válvula durante a própria soldagem.

(O resfriamento pode ser garantido, por

exemplo, colocando-se um

em volta do corpo da válvula.) Certique-se de

que não entra sujeira, resíduos da soldagem,

etc. na válvula durante o procedimento de

soldagem.

Tenha cuidado para não danicar o anel de

teon do cone. O corpo da válvula deve

a

estar livre de tensão (cargas externas) após

a instalação.

Fig. 5

Nunca use a QDV ou qualquer outro

produto Danfoss como aterramento

para soldagem, dado que isso pode

danicar o produto.

Montagem:

Retire os resíduos da soldagem e quaisquer

sujeiras dos tubos e do corpo da válvula

antes da montagem. Verique se o O-ring

entre o corpo da válvula e a tampa, bem

como o anel de teon do cone no assento

da válvula não apresentam marcas ou riscos.

Aperto:

Aperte a tampa com um torquímetro para

os valores indicados na tabela (g. 4).

Cores e identicação:

As válvulas QDV 15 são pintadas na fábrica

com um primer de óxido vermelho.

A identicação precisa da válvula é feita

através do anel de ID na parte superior da

tampa, assim como através da estampagem

no corpo da válvula. A superfície externa

do corpo da válvula deve ser protegida

contra corrosão com um revestimento

protetor adequado após a instalação e

montagem.

É recomendável a proteção do anel de ID

ao pintar a válvula novamente.

pano molhado

Maintenance

Dismantling the valve (g. 3):

Do not remove the bonnet while the

valve is still under pressure. Always close

the stop valve before the QDV. Then

proceed with activation of the QDV valve

to make sure that it is not under pressure.

- Check that the O-ring (pos. A) has not

been damaged.

- Check that the spindle is free of

scratches and impact marks.

- Check that the Teon cone ring is

without marks or scratches.

Replacement of the O-ring between the

bonnet and the valve body (g. 4):

The QDV 15 is delivered with an extra

O-ring. Remove the damaged O-ring (pos.

A) from the bonnet and carefully install the

new O-ring.

Assembly:

Remove any dirt from the body before the

valve is assembled.

Check that the O-ring between the valve

body and bonnet, as well as the Teon

gasket in the valve seat is without marks or

scratches.

Tightening:

Tighten the bonnet with a torque wrench,

to the values indicated in the table (g. 4).

Use only original Danfoss parts for

replacement.

New parts must be made of certied

materials applicable for the refrigerant

used.

In cases of doubt, please contact

Danfoss.

Danfoss accepts no responsibility for errors

and omissions.

Danfoss Industrial Refrigeration reserves

the right to make changes to products and

specications without prior notice.

A possible issue with our quick oil drain

valves type QDV which may not fully close

o during an oil draining process.

This may present itself when a drainage

pipe is installed on the outlet of the valve

which generates a back pressure to the

valve such that the valve is unable to fully

close. This will not present itself if there

is no drainage pipe installed on the valve

outlet. Max. back pressure 10 bar.

In applications where a QDV valve is

installed in a system and is normally

operating with an outlet pipe, please

ensure that full safety precautions are

taken when draining oil and make sure the

inlet to the vessel is isolated during the oil

draining process.

3 DKRCI.PI.KL0.A8.ML / 520H0752 © Danfoss A/S (MWA), 2014-12

Page 4

4 DKRCI.PI.KL0.A8.ML / 520H0752 © Danfoss A/S (MWA), 2014-12

Loading...

Loading...