Page 1

Data Sheet

Industrial Refrigeration Evaporator Control Panels

Type PXE 02 and PXE 04

Distributed control logic panels designed specically for

industrial refrigeration evaporator control applications

The Danfoss evaporator control panel PXE 02

and PXE 04 are distributed control logic panels

designed specically for industrial refrigeration

evaporator control applications. The PXE 02 can

control up to 2 separate evaporators and their

corresponding valve stations while the PXE 04

can control up to 4 evaporators and their

corresponding valve stations. There is 200+

control application options for each evaporator

that cover most industrial refrigeration

evaporator control requirements. Each

evaporator application is congured separately

and may be either duplicated or take

completely dierent congurations to the

other connected evaporators.

Application-specic, energy-ecient control

algorithms in each panel, achieve optimal

space-cooling and defrost sequences for safe,

ecient, trouble-free evaporator operation.

Furthermore, all IIAR1 safety recommendations

for hot gas defrost are complied with. Please

note that evaporator power components such

as motor starter protection, drives and

contactors are not components contained

within the PXE 02 or PXE 04.

Each evaporator application is setup and

congured on your laptop via a free

downloadable user-friendly graphical interface

or via the panel’s display navigation hardware.

AI384930480499en-000101

Page 2

Industrial Refrigeration Evaporator Control Panels, type PXE 02 & PXE 04

Features

• Designed ready-to-mount-and-connect supply power, sensors, solenoid, and actuator wiring needed for all

standard industrial refrigeration evaporator control applications

• High quality standardized panel electrical components

• Rigorously tested control sequences and algorithms

• Well laid-out IP64/65 panels with condensation protection, 360° EMC screen contact glands

• Easy cable penetration with cable tie rail

• Standardized documentation

© Danfoss | Climate Solutions | 2021.08 AI384930480499en-000101 | 2

Page 3

Industrial Refrigeration Evaporator Control Panels, type PXE 02 & PXE 04

Applications

Application principles: General

The Danfoss evaporator control panels have many dierent application choices available that are designed for

Industrial Refrigeration applications. It is possible to assign dierent control applications to each of the evaporators,

if required. Some of the control possibilities oered are as follows:

• Flooded ammonia/CO2 /HCFC/HFC.

• Direct expansion (DX) ammonia/CO2/HCFC/HFC.

• Superheat Control by:

◦ Fixed Superheat reference

◦ Load dened reference

◦ Minimum Stable Superheat

• Modulating or simple ON/OFF room temperature control

• Media temperature control of suction line valve with motorized valve

• Media temperature control of suction line valve with servo valve

• Pressure control of suction line valve with motorized valve

• Pressure control of suction line valve with servo valve

• Modulating room temperature control by modulating the valve in the liquid line of ooded systems

• Supports Multiple Defrost methods:

◦ by pressure

◦ by liquid drain

◦ by water or brine

◦ individual defrost schedules by single weekdays, Saturdays and Sundays

• Defrost starts:

◦ via Modbus or DI start by time interval (time since last defrost start)

◦ according to accumulated cooling time

◦ via defrost schedules and Real Time Clock

◦ forced manual defrost via the HMI or Modbus

• Defrost stops:

◦ on time duration

◦ on temperature

• Separate Drip tray Hot Gas control separate from main Hot Gas valve

• Emergency cooling - failsafe operation

• Safe startup procedure after power failure

• Additional product temperature alarm option

© Danfoss | Climate Solutions | 2021.08 AI384930480499en-000101 | 3

Page 4

PCPCPC

1DO

NC NO

2DO

NC NC

1DO

1DO

Wet return line

Defrost drain line

Liquid feed line

Hot gas defrost line

1AI

1DO

NC

NO

1DO

Suction line

Liquid line

1AI

PCPCPC

1AI

1AI

1DO

NCNO

2DO

NCNC

1DO

1DO

Wet return line

Defrost drain line

Liquid feed line

Hot gas defrost line

1AI

1AO

2DO

NCNC

1DO

1DO

Wet return line

Defrost drain line

Liquid feed line

Hot gas defrost line

1AI

MM

1

3

2

4

Industrial Refrigeration Evaporator Control Panels, type PXE 02 & PXE 04

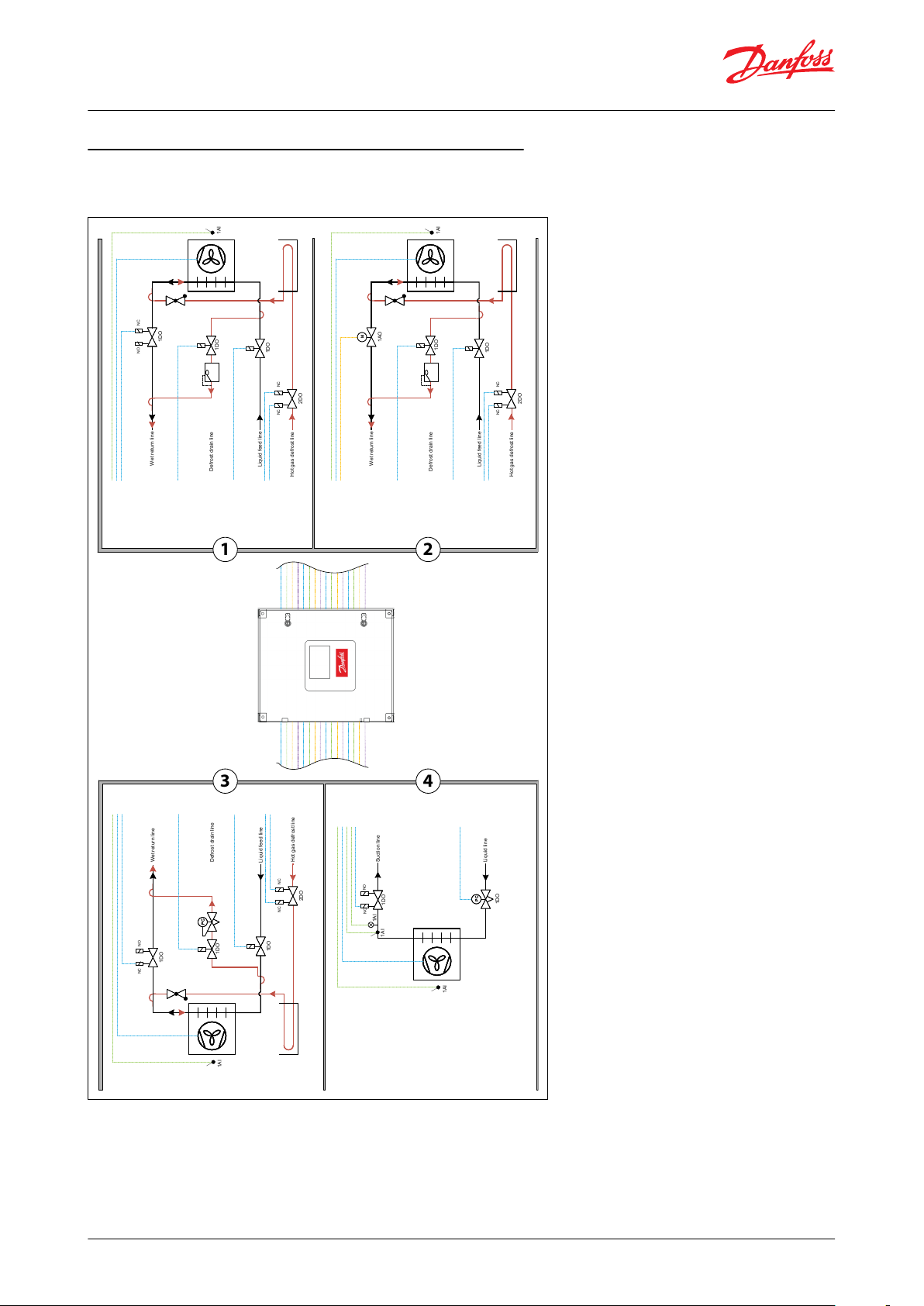

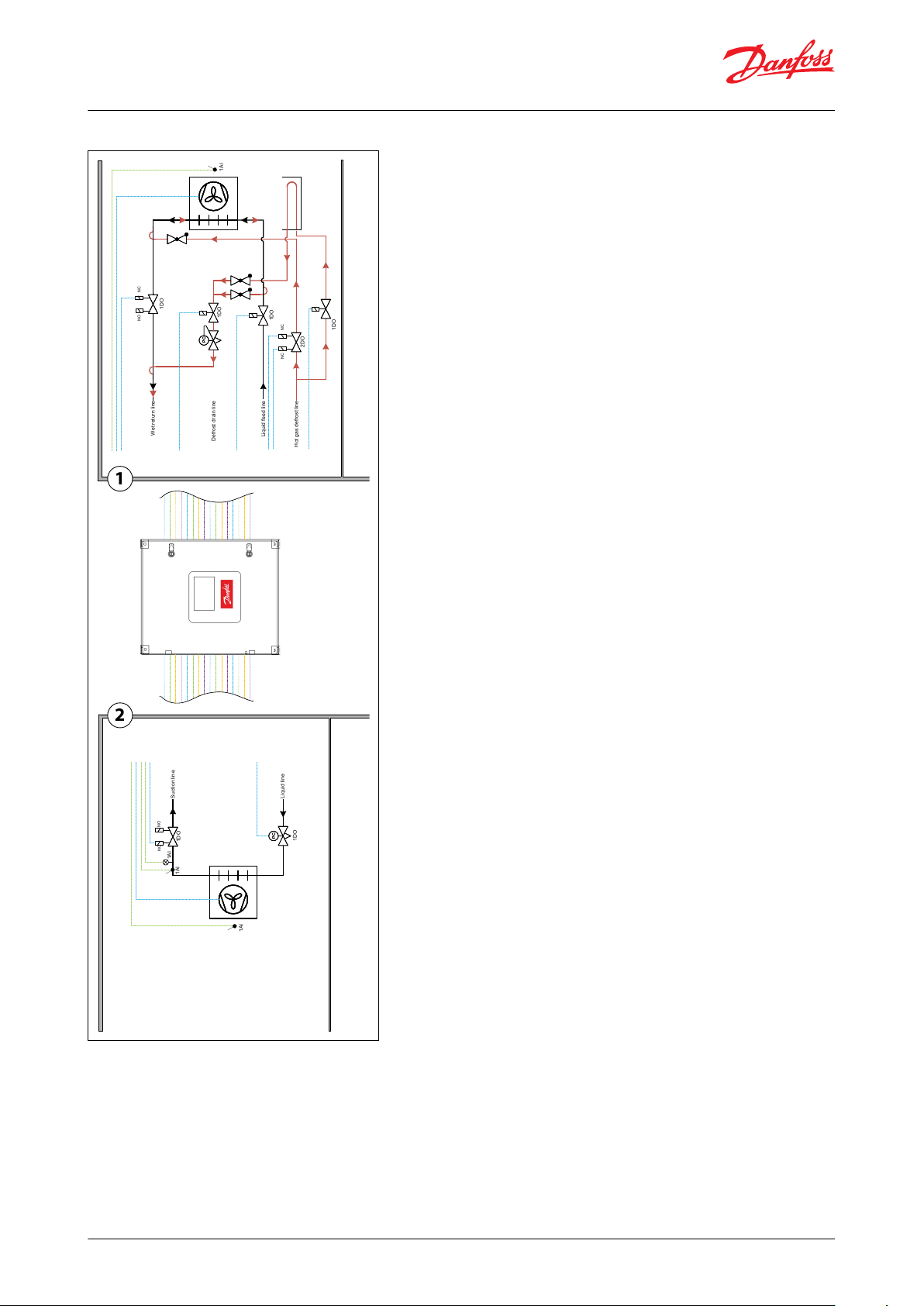

Application principles PXE 04: 4 x Evaporator Control

Examples of quick panel setup for evaporator control applications:

Application example 1:

Evaporator 1: Flooded evaporator with hot gas defrost by liquid drain.

Evaporator 2: Flooded evaporator with hot gas defrost by liquid drain and with wet suction modulating control.

Evaporator 3: Flooded evaporator with hot gas defrost by pressure.

Evaporator 4: DX with PWM liquid line control

© Danfoss | Climate Solutions | 2021.08 AI384930480499en-000101 | 4

Page 5

PCPCPC

1DO

NC NO

2DO

NC NC

1DO

1DO

Wet return line

Defrost drain line

Liquid feed line

Hot gas defrost line

1AI

1DO

NCNO

2DO

NCNC

1DO

1DO

Wet return line

Defrost drain line

Liquid feed line

Hot gas defrost line

1AI

1DO

NC

NO

1DO

Wet return line

Liquid feed line

1AI

Electric or water d efrost

1DO

PCPCPC

1DO

NC NO

2DO

NC NC

1DO

1DO

Wet return line

Defrost drain line

Liquid feed line

Hot gas defrost line

1AI

R

1AI

1AI

1

3

2

4

Industrial Refrigeration Evaporator Control Panels, type PXE 02 & PXE 04

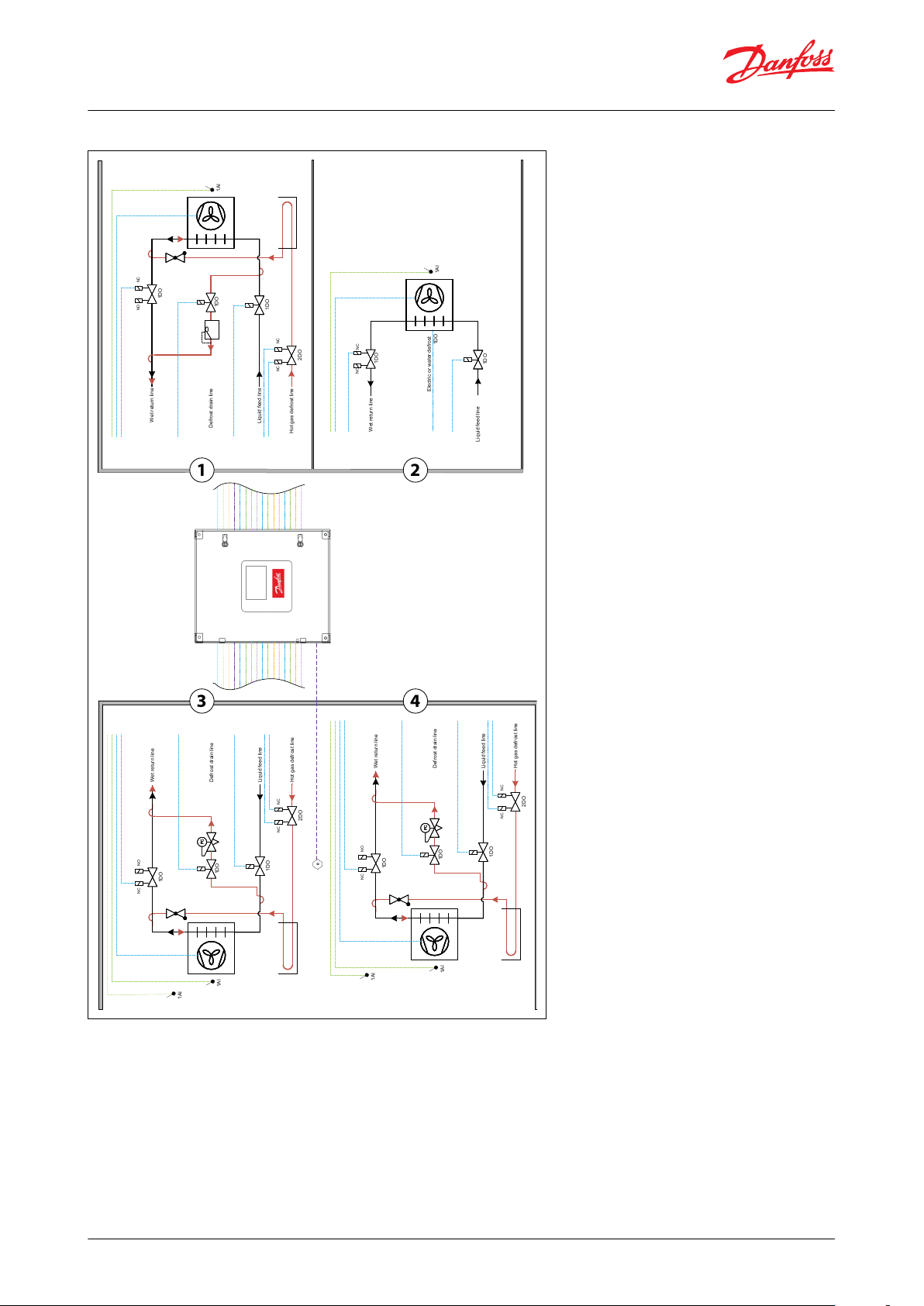

Application example 2:

Evaporator 1: Flooded evaporator with hot gas defrost by liquid drain.

Evaporator 2: Flooded evaporator with PWM liquid line control and electrical or water defrost.

Evaporator 3 & 4: Flooded evaporator with hot gas defrost by pressure. Extra product temperature sensors. Gas

detection.

© Danfoss | Climate Solutions | 2021.08 AI384930480499en-000101 | 5

Page 6

R

PCPCPC

1DO

NC NO

2DO

NC NC

1DO

1DO

Wet return line

Defrost drain line

Liquid feed line

Hot gas defrost line

1AI

1AO

2DO

NCNC

1DO

1DO

Wet return line

Defrost drain line

Liquid feed line

Hot gas defrost line

1AI

MM

1

2

Industrial Refrigeration Evaporator Control Panels, type PXE 02 & PXE 04

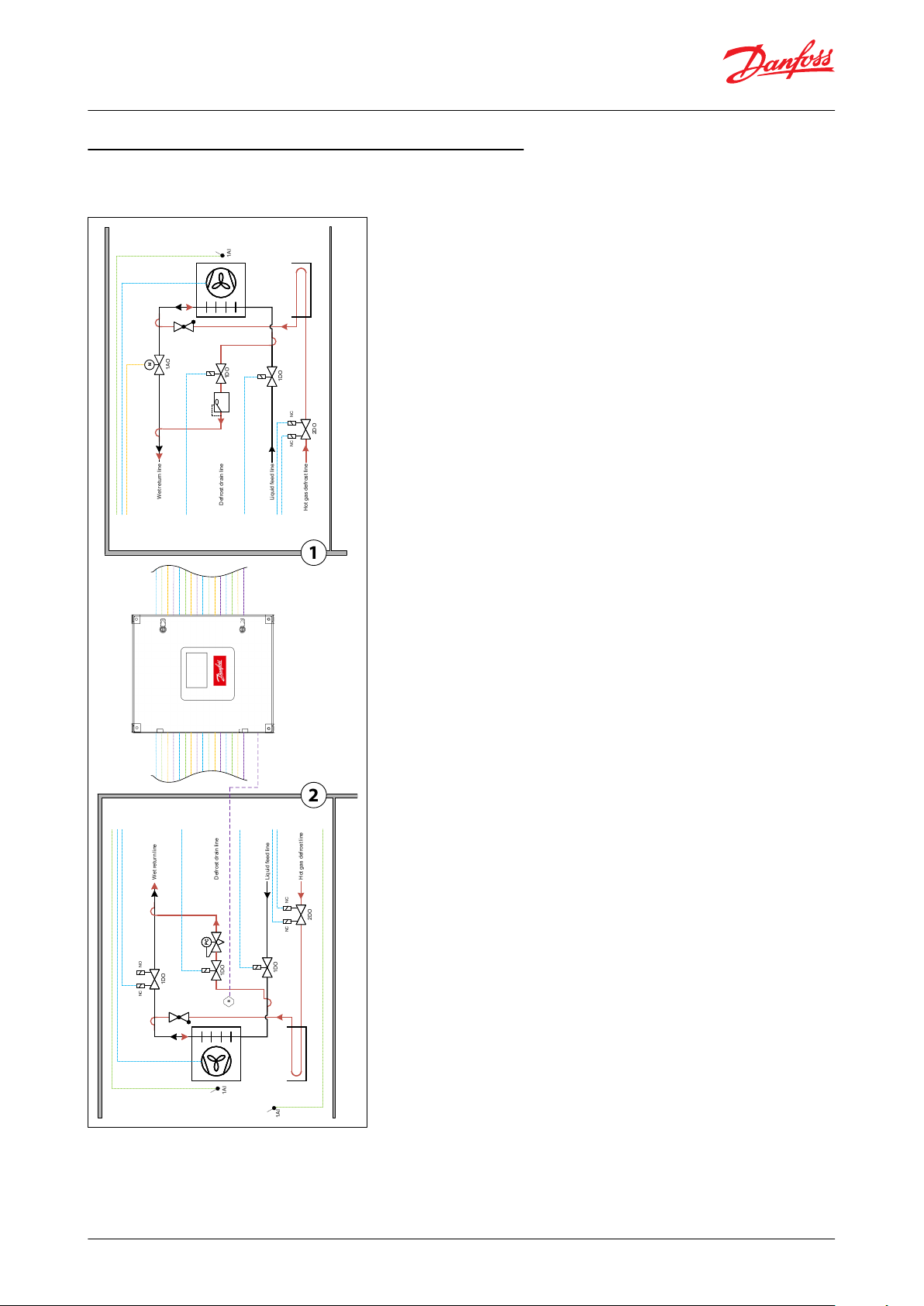

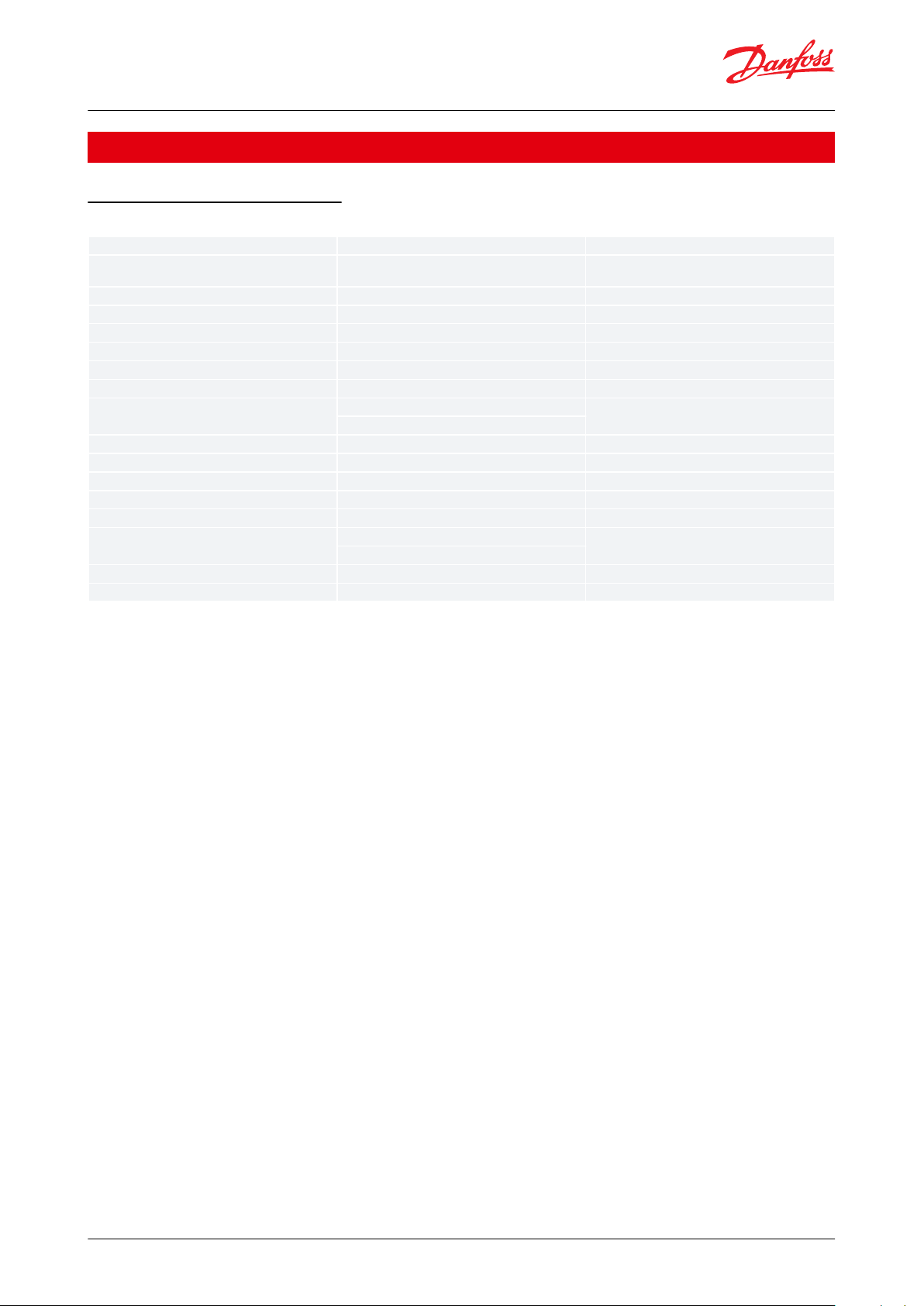

Application principles PXE 02: 2 x Evaporator Control

Examples of quick panel setup for evaporator control applications:

Application example 1:

Evaporator 1: Flooded evaporator with hot gas defrost by liquid drain. Motorized valve control on the wet return

line.

Evaporator 2: Flooded evaporator with hot gas defrost by pressure. Extra product temperature

© Danfoss | Climate Solutions | 2021.08 AI384930480499en-000101 | 6

Page 7

1DO

NC

NO

1DO

Suction line

Liquid line

1AI

PCPCPC

1AI

1AI

PCPCPC

1DO

NCNO

2DO

NCNC

1DO

1DO

Wet return line

Defrost drain line

Liquid feed line

Hot gas defrost line

1AI

1DO

1

2

Industrial Refrigeration Evaporator Control Panels, type PXE 02 & PXE 04

Application example 2:

Evaporator 1: Flooded evaporator with PWM liquid line control and hot gas defrost with pressure. Separate drip

tray line control.

Evaporator 2: DX with PWM liquid line control.

© Danfoss | Climate Solutions | 2021.08 AI384930480499en-000101 | 7

Page 8

Standards:

IEC61439 -2

-

Class of protection:

IP65/66 (depending on variant is with display) Indoor

usage only

Short circuit current rating:

15kAUe Supply voltage:

1x230+N+PE

VAC

Ue Control voltage:

230/24DC

V

Frequency:

50HzSystem earth:

TN-S-Internal separation:

Form 1

-

Dimensions (Height x Width x Depth):

PXE 02: 800x600x210

mm

PXE 04: 800x800x210

Panel color:

RAL 7035

-

EMC Environment:

B-Pollution degree

3-Temperature range ambient

-20 °C to +40 °C

Temperature range transport/storage

Weight range (depending on variant)

PXE 02: 30-35

kg

PXE 04: 35-40

Wire identication by color codes

IEC 61439

Wire numbering

DS/EN 60204 according to connected terminal

Industrial Refrigeration Evaporator Control Panels, type PXE 02 & PXE 04

Product specication

Technical data and dimensions

Table 1: Technical data and dimensions

© Danfoss | Climate Solutions | 2021.08 AI384930480499en-000101 | 8

Page 9

Industrial Refrigeration Evaporator Control Panels, type PXE 02 & PXE 04

General internal components & wiring

The 4 variants of PXE 02 and 4 variants of PXE 04 have generally the same component and panel principals. The

panels have been designed so that 24V and 230V have been separated as much as possible which is generally

indicated in the following pages. All panel variants use the following quality components as standard:

The Danfoss EKE 400 controller is used in PXE 02 and PXE 04 variants. Other panel variants will also include:

• the Danfoss NH3 Premium Flex electrochemical gas detector type GDA with a display and keyboard, PPM rage of

1-100, alarm PPM of 25/35 and Modbus RTU connectivity.

• the Danfoss NH3 remote sensor enabling installation of a sensor head in plastic housing 5m from the unit. This

means that the gas detection unit can be placed outside the room where the sensor is placed to detect hazardous

gases, allowing reading of and interfacing with the unit without entering the dedicated space.

• The Danfoss MMIGRS2 remote interface mounted on the front door of certain panel variants allowing remote

access to the EKE 400 controllers via a CANbus network between all the mounted controllers. No programming is

needed. IP64 protection rating.

• Please note that evaporator power components such as motor starter protection, drives and contactors are not

components contained within the PXE 02 or PXE 04.

© Danfoss | Climate Solutions | 2021.08 AI384930480499en-000101 | 9

Page 10

123456789101112131415161718EKE 400 Controllers

Gas detector relays

MCBs

Power supplies

Fuses

Gas detector

Internal PE

Gas detector terminals

Digital input relay terminals

A) Gas detection RS485 terminal

B) EKE 400 controller’s RS485 terminals

Gas detection analog outputs

Analog inputs

Analog outputs

Optional motorized valve power

DIN rail for accessories (side of panel)

Fan and heater (side of panel)

Rail for wire organization

Baseplate (see baseplate layout diagram

below)

ABC

B B

C

A

Type SKINTOP MULTI Version 1 – Maximum number of cables – 22 including 6x 8-12mm; 16x 3-7mm

Type SKINTOP MULTI Version 5 with SKINTOP BRUSH ADD-ON 24 for EMC screen contact - Maximum

number of cables – 27 including 27x 4-8mm

Type SKINTOP ST-M M20 – Gas detector sensor cable.

Industrial Refrigeration Evaporator Control Panels, type PXE 02 & PXE 04

PXE 02: Component layout

For comprehensive wiring details please refer to the detailed wiring diagram that is delivered complete with the PXE

02 panels.

PXE 02: Baseplate layout

© Danfoss | Climate Solutions | 2021.08 AI384930480499en-000101 | 10

Page 11

R4,5

R7,5

AW41

500mm

835mm

Industrial Refrigeration Evaporator Control Panels, type PXE 02 & PXE 04

NOTE:

1.

To ensure an optimum strain relief, the cable bundle can be xed with help of a cable tie

2.

After removing unused cable from SKINTOP MULTI - elastic gel will NOT SEAL, please use silicone to ensure

proper IP (Ingress Protection)

3.

Use plug for M20 gas detector gland if gas detector is not present.

NB:

DIFFERENT POTENTIALS 24V AND 230V SHOULD BE PLACED IN SEPARATE CABLE ENTRY

PXE 02: Mounting instructions

Figure 1: PXE 02: Mounting instructions

© Danfoss | Climate Solutions | 2021.08 AI384930480499en-000101 | 11

Page 12

123456789101112131415161718EKE 400 Controllers

Gas detector relays

MCBs

Power supplies

Fuses

Gas detector

Internal PE

Gas detector terminals

Digital input relay terminals

A) Gas detection RS485 terminal

B) EKE 400 controller’s RS485 terminals

Gas detection analog outputs

Analog inputs

Analog outputs

Optional motorized valve power

DIN rail for accessories (side of panel)

Fan and heater (side of panel)

Rail for wire organization

Baseplate (see baseplate layout diagram

below)

ABC

A A

B B

C

Type SKINTOP MULTI Version 1 – Maximum number of cables – 22 including 6x 8-12mm; 16x 3-7mm

Type SKINTOP MULTI Version 5 with SKINTOP BRUSH ADD-ON 24 for EMC screen contact - Maximum

number of cables – 27 including 27x 4-8mm

Type SKINTOP ST-M M20 - GDA Sensor Cable

Industrial Refrigeration Evaporator Control Panels, type PXE 02 & PXE 04

PXE 04: Component layout

For comprehensive wiring details please refer to the detailed wiring diagram that is delivered complete with the PXE

04 panels.

PXE 04: Baseplate layout

© Danfoss | Climate Solutions | 2021.08 AI384930480499en-000101 | 12

Page 13

R4,5

R7,5

AW41

700mm

835mm

EKE 400 Controllers

GDA Gas detection unit

Panel terminal

Panel terminal

D+

X107D+X54

D-D-GND

GND

Industrial Refrigeration Evaporator Control Panels, type PXE 02 & PXE 04

NOTE:

1.

To ensure an optimum strain relief, the cable bundle can be xed with help of a cable tie

2.

After removing unused cable from SKINTOP MULTI - elastic gel will NOT SEAL, please use silicone to ensure

proper IP (Ingress Protection)

3.

Use plug for M20 gas detector gland if gas detector is not present

NB:

DIFFERENT POTENTIALS 24V AND 230V SHOULD BE PLACED IN SEPARATE CABLE ENTRY

PXE 04: Mounting instructions

Figure 2: PXE 04: Mounting instructions

External wiring considerations: Power supply, Signal wiring and Fieldbus

• 230V cabling to and from the panel, the cable glands should be fed with Ø6-11 mm overall nominal diameter

cable with conductor areas 0.75-1.5 mm. For low voltage signal to and from the panel should be made with Ø6mm

overall nominal diameter cables with conductor areas 0.75mm. This is necessary in achieving the panel’s rated IP

• Unused cable gland openings must be closed, and all gland insert bores must be occupied to achieve the panel’s

rated IP. Gland insert bores may be plugged using the supplied sealing plugs. After removing unused cable from

SKINTOP MULTI - elastic gel will NOT SEAL, please use silicone to ensure proper IP. Note: non-punctured insert

bores retain IP level 65/66 (depending on panel variant)

• The wiring of Modbus RTU (RS485) must be carried out in accordance with the standard ANSI/TIA/EIA-485-A-1998.

Galvanic separation shall be provided for segments crossing buildings. Common ground shall be used for all

devices on the same network inclusive router, gateways etc. All bus connections in the cables are made with

twisted pair wires. The recommended cable type for this is AWG 22/0.32 mm

2

• The evaporator controllers and Gas Detector are on separate Modbus RTU networks and therefore have 2 separate

panel terminals as shown in Fig.3

• Connecting panels (evaporator controllers) in series via the correct terminals is shown in Fig. 4

• Remember to terminate the RS485 network following the last physical device, as shown in Fig.5

Table 2: Power supply, Signal wiring and Fieldbus

© Danfoss | Climate Solutions | 2021.08 AI384930480499en-000101 | 13

Page 14

Industrial Refrigeration Evaporator Control Panels, type PXE 02 & PXE 04

Figure 3:

Figure 4:

Figure 5:

Available Modbus RTU parameters in each controller and gas detector

For a complete overview of all the available Modbus parameters for each evaporator controller device (there are

500+ Modbus values available per controller) please refer to the EKE 400 controller datasheet for comprehensive

descriptions and details: EKE 400 - Data sheet

For a complete overview of all the available Gas Detector Modbus parameters please refer to the Gas Detector

Modbus Communication Guide for comprehensive descriptions and details: Danfoss Gas Detection - User Guide

Quick startup – With CoolCong software tool

What you will need

CoolCong software. USB to RS-485 cable. Power to your control panel.

Step 01

Ensure the latest version ofCoolCong is installed on your PC. Link to CoolCong download: CoolCong

Step 02

Each controller is to be congured individually. After power up, connect your RS485-USB cable from your PC to the

terminal labelled X107 on the PXE 02 or X107 on the PXE 04. The controllers are RS-485 pre-wired in series.

© Danfoss | Climate Solutions | 2021.08 AI384930480499en-000101 | 14

Page 15

Controller

Modbus Slave ID

112

2

Controller

Modbus Slave ID

1122334

4

EKE 400 controller’s default comm settings

Baud rate

38.400 bps

Parity

even

Data bits

8

Stop bit

1

Start bit

1

Industrial Refrigeration Evaporator Control Panels, type PXE 02 & PXE 04

Step 03

Startup the CoolCong software. In the CONNECTION tab, choose the correct COM port your PC and cable are

using.

Step 04

Choose the Modbus Slave ID (called ‘Modbus address’ in CoolCong), also in the same CONNECTION tab, of the

controller you wish to congure.

For the PXE 02 variants, the Modbus Slave ID are pre-set from the factory as:

Table 3: PXE 02 - Modbus Slave ID

For the PXE 04 variants the Modbus Slave ID are pre-set from the factory as:

Table 4: PXE 04 - Modbus Slave ID

NOTE:

It is a good idea to ensure the CoolCong settings are aligned with the controller settings before moving onto the

next step. This is done by choosing the CONNECTION DETAILS button in the CONNECTION tab. The default

Modbus serial communication settings on all the controllers from the factory are as follows:

Table 5:

Step 05

Commence controller conguration. Start with either opening a previously congured le from the dropdown

menu FILE and choosing OPEN or start with conguring a new application by choosing the VALVE

CONFIGURATION tab. Other tabs and applications drawings will appear after making a choice in the VALVE

CONFIGURATION tab.

© Danfoss | Climate Solutions | 2021.08 AI384930480499en-000101 | 15

Page 16

Industrial Refrigeration Evaporator Control Panels, type PXE 02 & PXE 04

Step 06

Once satised with your controller conguration, you may write the conguration to the controller by choosing the

WRITE PARAMETERS TO EKE400 button at the top of the software window. Remember to save the dierent

congurations if required or export to Excel using the FILE dropdown menu in the top left corner of the software

window.

Step 07

Repeat Step 04 to Step 06 until all controllers are congured.

NOTE:

The CoolCong software allows you to activate the IO for commissioning purposes which you may nd useful. See

the I/O CONFIGURATION and ACTION tabs of CoolCong.

Quick startup – front door display

After powering up the panel navigating to the dierent controllers can be done via the front door display called the

MMI. The MMI display is an access point via CANbus (separate from and not aecting the Modbus RTU network) to

the main status values of each evaporator controller. Follow these steps to access information in the desired

controllers:

Step 01:

From the “MAIN” screen the “BIOS” screen must be accessed. This is done by holding both the X and return ↵

buttons simultaneously for 4-5 seconds.

Figure 6: MAIN screen

Step 02

Wait until the BIOS menu (see below) is shown on the screen and release the buttons. The current MCX selection will

be displayed in the upper right.

Figure 7: BIOS screen

Step 03

Highlight and select (return ↵ button) “MCX SELECTION”

Figure 8: MCX SELECTION

Step 04

Next, highlight and select (return ↵ button) “MAN SELECTION”

© Danfoss | Climate Solutions | 2021.08 AI384930480499en-000101 | 16

Page 17

Industrial Refrigeration Evaporator Control Panels, type PXE 02 & PXE 04

Figure 9: MAN SELECTION

Step 05:

Highlight and select, then scroll up and down to select CAN ID address number and press return.

Figure 10: CAN ID

Further information about using the MMI can be found in the MMI instruction guide: AK-MMI Instruction guide

Further information about functionality and using the menus can be found in the EKE 400 datasheet: EKE 400 Data

sheet

General: Navigating the front door display

The front door HMI gives an overview of the system status and can easily be navigated via the arrow buttons. The

displays give us easy to understand information about the:

• Active alarms

• The status of each evaporator

Figure 11: Front door display

Navigating from controller to controller is explained in the previous section. Other instructions regarding controller/

evaporator information that may be viewed can be found on the EKE 400 datasheet: Electronic valve control, EKE

400 - 080G5004

Panels with Gas Detection

Gas Detector cable and sensor

The gas detector remote sensor is supplied detached from the gas detection unit and must be connected after

mounting. An M25 gland in the right side of the enclosure bottom plate is reserved for the remote sensor unit cable.

Mount the remote sensor unit and connect the cable as outlined in the nal pages of the panel schematics.

© Danfoss | Climate Solutions | 2021.08 AI384930480499en-000101 | 17

Page 18

EKE 400 controller’s default comm settings

Slave ID

1

Baud rate

19.200 bps

Parity

even

Data bits

8

Stop bit

1

Start bit

1

Gas Detector Factory Default Values

Description

Default value

NH

3

PPM high level ALARM 1

25 PPM

NH

3

PPM high level ALARM 2 SHUTDOWN

35 PPM

NH

3

PPM range

0-100 PPM

Industrial Refrigeration Evaporator Control Panels, type PXE 02 & PXE 04

Figure 12: Gas Detector cable and sensor

Gas Detector factory default settings – Modbus RTU

The PXE 02 and PXE04 have variants that are equipped with Danfoss GDA gas detectors, cable and sensors. The gas

detector unit runs on a parallel Modbus RTU eldbus system to the Evaporator Controllers and may be connected to

the customers gas detector Modbus RTU system via terminal X54 on the PXE 02 panels terminal X54 on the PXE 04

panels equipped with gas detection. The Gas Detection Modbus RTU eldbus network settings have the following

default settings from the factory:

Table 6: EKE 400 controller’s default comm settings

NOTE:

The Slave ID can be changed but all other serial communication settings cannot be changed.

Gas Detector factory default settings – NH3 PPM alarm settings

The gas detector will activate an alarm if there is an error detected or if there is a power failure to the unit. The gas

detection units also come with factory default 2-step alarm set-up ready for use. PPM alarm factory settings are as

follows:

Table 7: NH3 PPM alarm settings

Gas Detector factory default settings - Terminals

The user interface enables the user to congure two individual alarm settings. ALARM 1 is a pre-alarm that, when

activated, indicates the gas level has passed a user-dened rst threshold. If the gas level then passes a user-dened

second threshold, the nal ALARM 2 (shutdown) is activated. For further information on setup of the gas detection

unit via the display and information on alarm schemes, please refer to the links to relevant documentation below.

Factory default outputs from the panel gas detection unit are, as factory default as follows:

© Danfoss | Climate Solutions | 2021.08 AI384930480499en-000101 | 18

Page 19

PXE 02 and PXE 04 panels with gas detection

Description

Terminal

PPM High Level ALARM 1 (DO)

X61

PPM High Level SHUTDOWN ALARM 2 (DO)

X63

PPM level (4-20 mA AO)

X54.1

PXE 02 panels

Description

Gas Safety Circuit DI Terminal

EKE 400 Controller 1

X100

EKE 400 Controller 2

X400

PXE 04 panels

Description

Gas Safety Circuit Terminal

EKE 400 Controller 1

X100

EKE 400 Controller 2

X200

EKE 400 Controller 3

X300

EKE 400 Controller 4

X400

Industrial Refrigeration Evaporator Control Panels, type PXE 02 & PXE 04

Table 8: Gas Detector factory default settings - Terminals

Connecting the Gas Detection safety circuit to the evaporator controllers

The default factory congurations of the PXE 02 and PXE 04are not setup to output signals from the gas detector

directly to the inputs of the controllers in the panel. If required, the DO of a selected controller can be setup to deenergize following a High NH3 PPM SHUTDOWN ALARM 2 output from the gas detection unit. This is done by

following these steps:

Step 01

Locate the controller input terminal required to de-energize ALL its DO on a High NH3 PPM SHUTDOWN ALARM 2

signal from the gas detection unit.

Table 9: Gas Detection safety circuit - PXE 02 panels

Table 10: Gas Detection safety circuit - PXE 04 panels

NOTE:

In the following example, the Gas Detector in PXE 04 will be wired to de-energize the DO from Controller 1 on a

High NH3 PPM ALARM 2 output from the gas detection unit.

Step 02

Remove jumper from selected terminal. In this example, remove jumper from Controller 1 at X100.

Figure 13:

Step 03: Wire terminal X63 to terminal X100

NOTE:

The control sequence the EKE 400 controller will apply on receipt of this signal may be easily set up by using the

CoolCong software interface.

© Danfoss | Climate Solutions | 2021.08 AI384930480499en-000101 | 19

Page 20

Gas detector AO terminals for PPM level

4 EKE 400 Panel

2 EKE 400 Panel

PPM AO terminal

X54.1

X54.1

2 EKE 400 Controller Panel

4 EKE 400 Controller Panel

AI

Modbus Register

EKE 400 Control‐

ler 1 Terminal

EKE 400 Control‐

ler 2 Terminal

EKE 400 Control‐

ler 1 Terminal

EKE 400 Control‐

ler 2 Terminal

EKE 400 Control‐

ler 3 Terminal

EKE 400 Control‐

ler 4 Terminal

1

1005

X150.1

X450: 1

X150.1

X250.1

X350.1

X450: 121006

X150.2

X450: 2

X150.2

X250.2

X350.2

X450: 231007

X150.3

X450: 3

X150.3

X250.3

X350.3

X450: 341008

X150.4

X450: 4

X150.4

X250.4

X350.4

X450: 4

Industrial Refrigeration Evaporator Control Panels, type PXE 02 & PXE 04

IMPORTANT:

Only the DO in the controlled evaporator circuit will be de-energized by this function. AO will not be aected and

will continue to operate according to the output signal of the controller.

Connecting the Gas Detector PPM reading to the Controller

The Gas Detection PPM analog output signal (mA factory default) may be connected to a controller AI terminal and

read on the Modbus RTU controller network. The actual AI controller terminal the AO terminal from the gas

detection unit will depend on the conguration of the EKE 400 controller. The control AI can be viewed on the

software CoolCong during controller conguration and the correct terminal can then be located and wired to from

the gas detection AO terminal X54.1. See example below where AI2 is to be used.

Figure 14: Gas Detector PPM reading to the Controller

The gas detection terminal and Modbus registers to be noted for these purposes are as follows:

Table 11: AO terminals for PPM level

Controller Modbus registers for PPM level

The PPM level may be read of the EKE 400 controller Modbus network (if not using the gas detection units Modbus

network) and will of course depend on the EKE 400 controller and terminal used. The following Modbus registers are

where the PPM values can be read (depending on the wiring & controller conguration).

Table 12:

Gas Detector Documentation

Further information about using the menus can be found in the: GDA Application Guide

Further installation information about installing the GDA can be found in the: GDA Installation Guide

© Danfoss | Climate Solutions | 2021.08 AI384930480499en-000101 | 20

Page 21

Industrial Refrigeration Evaporator Control Panels, type PXE 02 & PXE 04

Further installation information about the Modbus functionality can be found in the: GDA Modbus Communication

Guide

© Danfoss | Climate Solutions | 2021.08 AI384930480499en-000101 | 21

Page 22

Industrial Refrigeration Evaporator Control Panels, type PXE 02 & PXE 04

Accessory: Signal conditioners

The PXE 02 and PXE 04 analog output signals from its controllers to evaporator controlling actuators are 0-10V type

from the factory. It is possible purchase signal conditioners as accessories from Danfoss that can be installed and

wired by the customer (please contact a Danfoss sales representative). Signal conditioners change the analog

output signal at the panel terminal from 0-10V to 4-20mA. The following is a quick overview as to how this may be

done.

Step 01

Mount the signal conditioner on the DIN rail provided on the right side of the panel.

Figure 15: Mounting the signal conditioner

Step 02

Wire the power terminal available in the panel (X77) to the signal conditioner power terminals and wire the correct

AO terminals (X160-X460) to the input side of the signal conditioner. Please read the signal conditioner instructions

beforehand. The 4-20mA device may now be wired to the output side of the signal conditioner.

Figure 16: Wiring the power terminal

© Danfoss | Climate Solutions | 2021.08 AI384930480499en-000101 | 22

Page 23

Industrial Refrigeration Evaporator Control Panels, type PXE 02 & PXE 04

Accessory: Stepper motor drivers

The PXE 02 and PXE 04 analog output signals from its controllers to evaporator controlling actuators are 0-10V type

from the factory. It is possible purchase Danfoss stepper motor drivers EKF 1A to drive 1 stepper motor valve and

EKF 2A to drive 2 stepper motor valves as accessories that can be installed and wired by the customer. Stepper

motor drivers change the analog output signal at the panel terminal from 0-10V to a stepper motor signal that may

be congured according to the stepper motor valve’s specication. The following is a quick overview as to how a

stepper motor driver may be installed in the panel.

Step 01

Mount the stepper motor driver on the DIN rail provided on the right side of the panel.

Figure 17: Mounting the signal conditioner

Step 02

Wire the power terminal available in the panel (X77) to the stepper motor power terminals and wire the correct AO

terminals (X160-X460) to the input side of the stepper motor driver. Please read the stepper motor driver

instructions beforehand and congure the driver according to the required application. The stepper motor valve

may now be wired to the stepper motor driver. See the installation instructions for the Danfoss EKF 1A and EKF 2A

stepper motor drivers for stepper motor driver connection details and observe the wiring recommendations

regarding distance to the stepper motor valve: Stepper Valve Driver Installation guide

Figure 18:

© Danfoss | Climate Solutions | 2021.08 AI384930480499en-000101 | 23

Page 24

Description

Evaporator amount

Front-door display

Gas Detection

Code No.

Danfoss evaporator control

panel – PXE 02 P

1-2

128S0033

Danfoss evaporator control

panel – PXE 02 PG

1-2■128S0034

Danfoss evaporator control

panel – PXE 02 PD

1-2■128S0035

Danfoss evaporator control

panel – PXE 02 PDG

1-2■■

128S0036

Danfoss evaporator control

panel – PXE 04 P

1-4

128S0037

Danfoss evaporator control

panel – PXE 04 PG

1-4■128S0038

Danfoss evaporator control

panel – PXE 04 PD

1-4■128S0039

Danfoss evaporator control

panel – PXE 04 PDG

1-4■■

128S0040

Accessory/Spare parts

Accessory

Spare part

Code No.

0–10V to 4-20 mA signal conditioner

■

Ask Danfoss sales

Stepper motor driver, EKF 1A (for 1

valve)

■

080G5030

Stepper motor driver, EKF 2A (for 2

valves)

■

080G5035

Industrial Refrigeration Evaporator Control Panels, type PXE 02 & PXE 04

Ordering

Table 13: Ordering

Accessory/Spare parts

Table 14: Accessory/Spare parts

© Danfoss | Climate Solutions | 2021.08 AI384930480499en-000101 | 24

Page 25

Certicates, declarations and approvals

This product information is a part of the documentation for the Danfoss scope of delivery and serves as product

presentation and customer advisory service. It contains important information and technical data regarding the

product.

This product information should be supplemented with the information about the industrial safety and health

related regulations at the site of installation of the product. The regulations vary from place to place as a result of

the statutory regulations applicable at the site of installation and are therefore not considered in this product

information.

In addition to this product information and the accident prevention regulations applicable for the respective

country and area where the product is used, the technical regulations for safe and professional work must also be

observed.

This product information has been written in good faith. However, Danfoss cannot be held responsible for any errors

that this document may contain or for their consequences.

Danfoss reserves the right to make technical changes during the course of further development of the equipment

covered by this product information.

Illustrations and drawings in this product information are simplied representations. As a result of the

improvements and changes, it is possible that the illustrations do not exactly match the current development

status. The technical data and dimensions are subject to change. No claims will be accepted on the basis of them.

Any information, including, but not limited to information on selection of product, its application or use, product design, weight, dimensions, capacity or any other

technical data in product manuals, catalogues descriptions, advertisements, etc. and whether made available in writing, orally, electronically, online or via download,

shall be considered informative, and is only binding if and to the extent, explicit reference is made in a quotation or order conrmation. Danfoss cannot accept any

responsibility for possible errors in catalogues, brochures, videos and other material. Danfoss reserves the right to alter its products without notice. This also applies to

products ordered but not delivered provided that such alterations can be made without changes to form, t or function of the product. All trademarks in this material

are property of Danfoss A/S or Danfoss group companies. Danfoss and the Danfoss logo are trademarks of Danfoss A/S. All rights reserved.

© Danfoss | Climate Solutions | 2021.08 AI384930480499en-000101 | 25

Loading...

Loading...