Installation guide

Industrial Refrigeration Evaporator Control Panels

PXE 02 & PXE 04

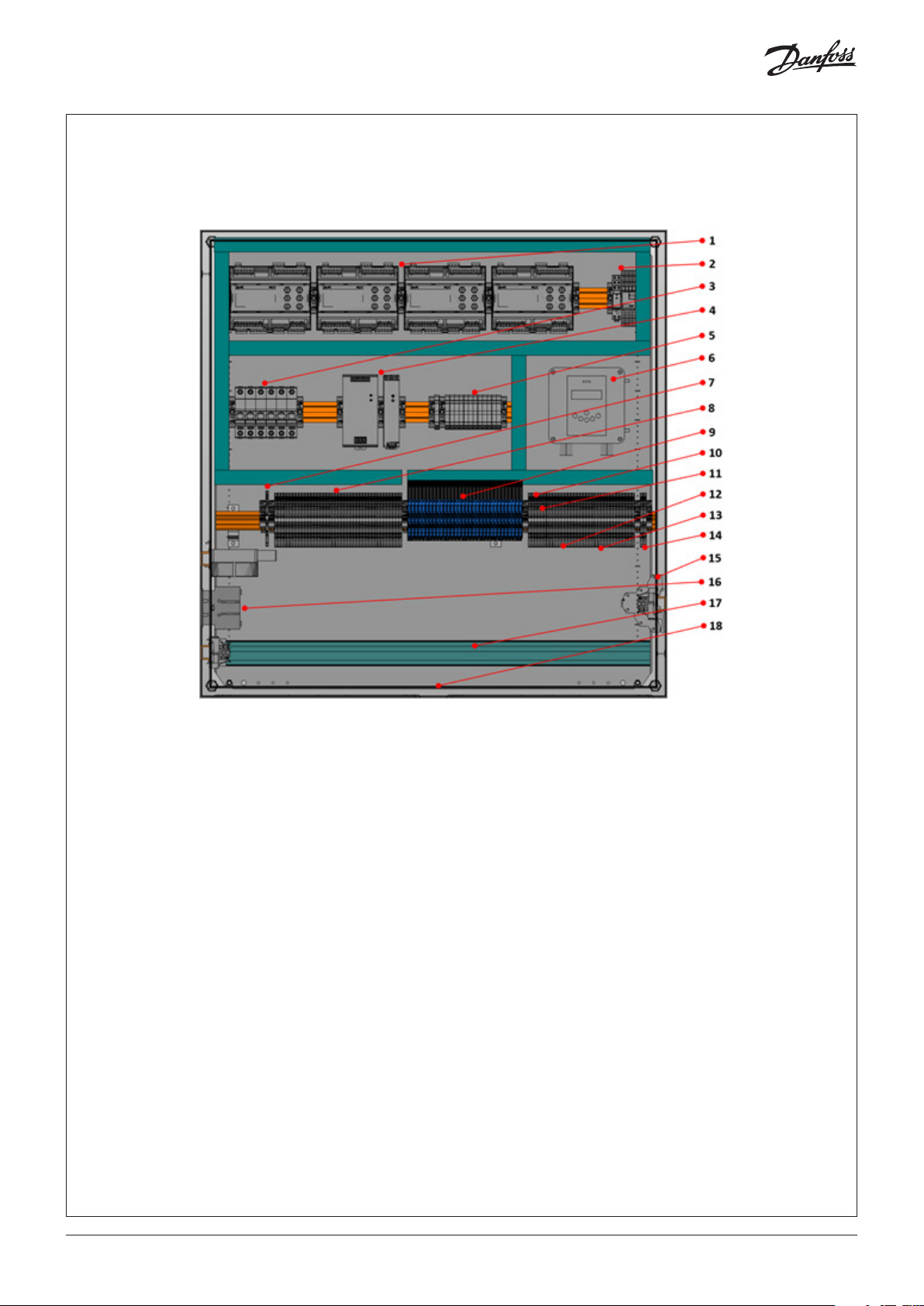

PXE 02: Component layout

For comprehensive wiring details please refer to the detailed wiring diagram that is delivered complete with the PXE 02 panels.

Fig. 01

1. EKE 400 Controllers

2. Gas detector relays

3. MCBs

4. Power supplies

5. Fuses

6. Gas detector

7. Internal PE

8. Gas detector terminals

9. Digital input relay terminals

10. A) Gas detection RS485 terminal

B) EKE 400 controller’s RS485 terminals

11. Gas detection analog outputs

12. Analog inputs

13. Analog outputs

14. Optional motorized valve power

15. DIN rail for accessories (side of panel)

16. Fan and heater (side of panel)

17. Rail for wire organization

18. Baseplate (see baseplate layout diagram below)

© Danfoss | Climate solutions | 2021.07

AN383426363919en-000101 | 1

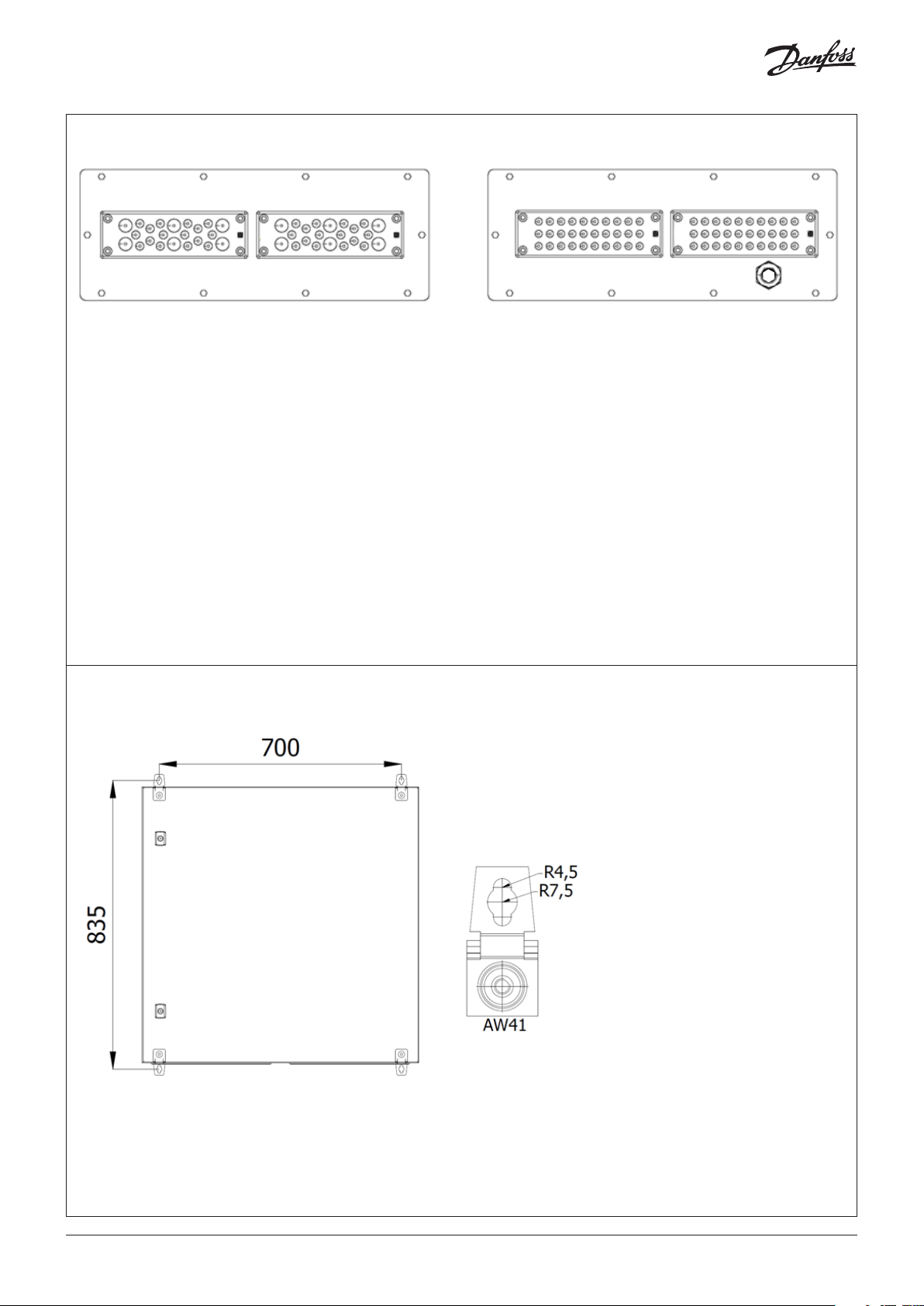

PXE 02: Baseplate layout

Fig. 02

BBA

A - Type SKINTOP MULTI Version 1 – Maximum number of cables – 22 including 6x8-12 mm; 16x3-7 mm

B - Type SKINTOP MULTI Version 5 with SKINTOP BRUSH ADD-ON 24 for EMC screen contact -

Maximum number of cables – 27 including 27x4-8 mm

C - Type SKINTOP ST-M M20 – Gas detector sensor cable.

Note:

1. To ensure an optimum strain relief, the cable bundle can be fixed with help of a cable tie

2. After removing unused cable from SKINTOP MULTI - elastic gel will NOT SEAL, please use silicone to ensure proper

IP (Ingress Protection)

3. Use plug for M20 gas detector gland if gas detector is not present.

C

NB:

DIFFERENT POTENTIALS 24 V AND 230 V SHOULD BE PLACED IN SEPARATE CABLE ENTRY

PXE 02: Mounting instructions

Fig. 03

© Danfoss | Climate solutions | 2021.07

AN383426363919en-000101 | 2

PXE 04: Component layout

For comprehensive wiring details please refer to the detailed wiring diagram that is delivered complete with the PXE 04 panels.

Fig. 04

1. EKE 400 Controllers

2. Gas detector relays

3. MCBs

4. Power supplies

5. Fuses

6. Gas detector

7. Internal PE

8. Gas detector terminals

9. Digital input relay terminals

10. A) Gas detection RS485 terminal

B) EKE 400 controllers RS485 terminal

11. Gas detection analog outputs

12. Analog inputs

13. Analog outputs

14. Optional motorized valve power

15. DIN rail for accessories (side of panel)

16. Fan, heater & thermostat (side of panel)

17. Rail for wire organization

18. Baseplate (see baseplate layout diagram below)

© Danfoss | Climate solutions | 2021.07

AN383426363919en-000101 | 3

PXE 04: Baseplate layout

Fig. 05

BBA A

A – Type SKINTOP MULTI Version 1 – Maximum number of cables – 22 including 6x8-12 mm; 16x3-7 mm

B – Type SKINTOP MULTI Version 5 with SKINTOP BRUSH ADD-ON 24 for EMC screen contact -

Maximum number of cables – 27 including 27x4-8 mm

C - Type SKINTOP ST-M M20 - GDA Sensor Cable

Note:

1. To ensure an optimum strain relief, the cable bundle can be fixed with help of a cable tie

2. After removing unused cable from SKINTOP MULTI - elastic gel will NOT SEAL, please use silicone to ensure proper

IP (Ingress Protection)

3. Use plug for M20 gas detector gland if gas detector is not present.

NB:

DIFFERENT POTENTIALS 24 V AND 230 V SHOULD BE PLACED IN SEPARATE CABLE ENTRY

C

PXE 04: Mounting instructions

Fig. 06

© Danfoss | Climate solutions | 2021.07

AN383426363919en-000101 | 4

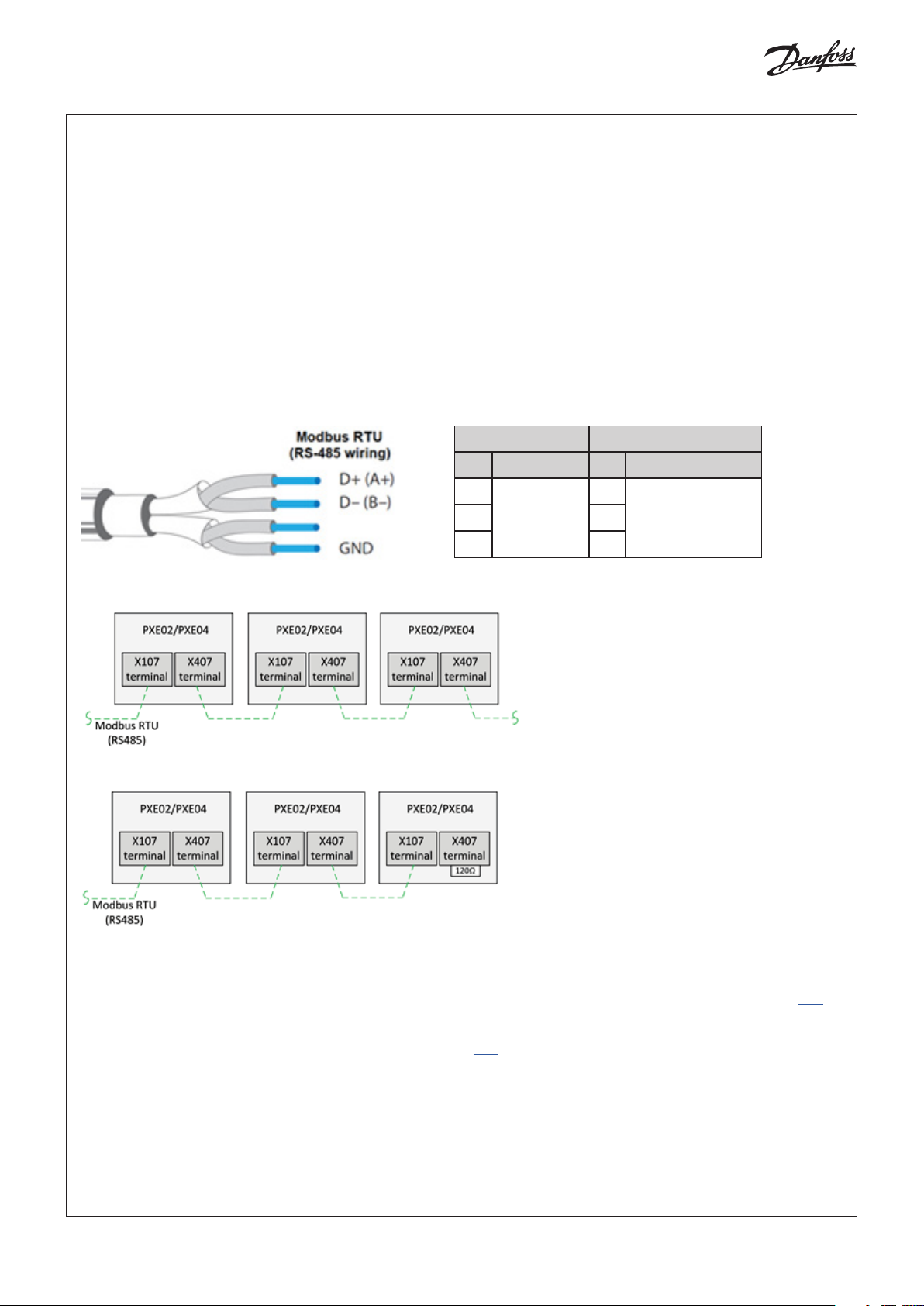

External wiring considerations: Power supply, Signal wiring and Fieldbus

• 230 V cabling to and from the panel, the cable glands should be fed with Ø6-11 mm overall nominal diameter cable with

conductor areas 0.75-1.5 mm. For low voltage signal to and from the panel should be made with Ø6 mm overall nominal

diameter cables with conductor areas 0.75 mm. This is necessary in achieving the panel’s rated IP

• Unused cable gland openings must be closed, and all gland insert bores must be occupied to achieve the panel’s rated IP.

Gland insert bores may be plugged using the supplied sealing plugs. After removing unused cable from SKINTOP MULTI elastic gel will NOT SEAL, please use silicone to ensure proper IP. Note: non-punctured insert bores retain IP level 65/66

(depending on panel variant)

• The wiring of Modbus RTU (RS485) must be carried out in accordance with the standard ANSI/TIA/EIA-485-A-1998.

Galvanic separation shall be provided for segments crossing buildings. Common ground shall be used for all devices on

the same network inclusive router, gateways etc. All bus connections in the cables are made with twisted pair wires.

The recommended cable type for this is AWG 22/0.32 mm

•

The evaporator controllers and Gas Detector are on separate Modbus RTU networks and therefore have 2 separate panel terminals

• Connecting panels (evaporator controllers) in series via the correct terminals is shown in fig. 08

• Remember to terminate the RS485 network following the last physical device with a 120 ohm resistor, as shown in fig. 09

Fig. 07

EKE 400 Controllers GDA Gas detection unit

Panel terminal Panel terminal

Fig. 08

Fig. 09

D+

X107

GND GND

D+

X54D- D-

Available Modbus RTU parameters in each controller and gas detector

For a complete overview of all the available Modbus parameters for each evaporator controller device (there are 500+ Modbus

values available per controller) please refer to the EKE 400 controller datasheet for comprehensive descriptions and details: Link

For a complete overview of all the available Gas Detector Modbus parameters please refer to the Gas Detector Modbus

Communication Guide for comprehensive descriptions and details: Link

© Danfoss | Climate solutions | 2021.07

AN383426363919en-000101 | 5

Quick startup – With CoolConfig software tool

What you will need: CoolConfig software. USB to RS-485 cable. Power to your control panel.

Step 01: Ensure the latest version of CoolConfig is installed on your PC. Link to CoolConfig download: Link

Step 02: Each controller is to be configured individually. After power up, connect your RS485-USB cable from your PC

to the terminal labelled X107 on the PXE 02 or X107 on the PXE 04. The controllers are RS-485 pre-wired in series.

Fig. 10

Step 03: Startup the CoolConfig software. In the CONNECTION tab, choose the correct COM port your PC and cable are using.

Step 04: Choose the Modbus Slave ID (called ‘Modbus address’ in CoolConfig), also in the same CONNECTION tab, of the controller

you wish to configure.

For the PXE 02 variants, the Modbus Slave ID are pre-set from the factory as:

Tab le. 01

Controller Modbus Slave ID

01 1

02 2

For the PXE 04 variants the Modbus Slave ID are pre-set from the factory as:

Tab le. 02

Controller Modbus Slave ID

01 1

02 2

03 3

04 4

Note:

It is a good idea to ensure the CoolConfig settings are aligned with the controller settings before moving onto the next step. This is

done by choosing the CONNECTION DETAILS button in the CONNECTION tab. The default Modbus serial communication settings on

all the controllers from the factory are as follows:

© Danfoss | Climate solutions | 2021.07

AN383426363919en-000101 | 6

Tab le. 03

EKE 400 controller’s default comm settings

Baud rate 38.400 bps

Parity even

Data bits 8

Stop bit 1

Start bit 1

Step 05: Commence controller configuration. Start with either opening a previously configured file from the dropdown menu

FILE and choosing OPEN or start with configuring a new application by choosing the VALVE CONFIGURATION tab.

Other tabs and applications drawings will appear after making a choice in the VALVE CONFIGURATION tab.

Step 06: Once satisfied with your controller configuration, you may write the configuration to the controller by choosing the

WRITE PARAMETERS TO EKE400 button at the top of the software window. Remember to save the different configurations

if required or export to Excel using the FILE dropdown menu in the top left corner of the software window.

Step 07: Repeat Step 04 to Step 06 until all controllers are configured.

Note:

The CoolConfig software allows you to activate the IO for commissioning purposes which you may find useful.

See the I/O CONFIGURATION and ACTION tabs of CoolConfig.

Quick startup – front door display

After powering up the panel navigating to the different controllers can be done via the front door display called the MMI. The MMI

display is an access point via CANbus (separate from and not affecting the Modbus RTU network) to the main status values of each

evaporator controller. Follow these steps to access information in the desired controllers:

Fig. 11 MAIN screen

Step 01: From the “MAIN” screen the “BIOS” screen must be accessed. This is done by holding both the X and return ↵ buttons

simultaneously for 4–5 seconds

Fig. 12 BIOS screen

Step 02: Wait until the BIOS menu (see below) is shown on the screen and release the buttons. The current MCX selection will be

displayed in the upper right

Fig. 13 MCX SELECTION

Step 03: Highlight and select (return ↵ button) “MCX SELECTION”

© Danfoss | Climate solutions | 2021.07

AN383426363919en-000101 | 7

Fig. 14 MAN SELECTION

Step 04: Next, highlight and select (return ↵ button) “MAN SELECTION”

Fig. 15 CAN ID

Step 05: Highlight and select, then scroll up and down to select CAN ID address number and press return

Further information about using the MMI can be found in the MMI instruction guide: Link

Further information about functionality and using the menus can be found in the EKE 400 datasheet: Link

Navigating the front door display

The front door HMI gives an overview of the system status and can easily be navigated via the arrow buttons. The displays give us

easy to understand information about the:

• Active alarms

• The status of each evaporator

Fig. 16

Navigating from controller to controller is explained in the previous section. Other instructions regarding controller/evaporator

information that may be viewed can be found on the EKE 400 datasheet: Link

© Danfoss | Climate solutions | 2021.07

AN383426363919en-000101 | 8

Panels with Gas Detection

Gas Detector cable and sensor

The gas detector remote sensor is supplied detached from the gas detection unit and must be connected after mounting. An M25

gland in the right side of the enclosure bottom plate is reserved for the remote sensor unit cable. Mount the remote sensor unit and

connect the cable as outlined in the final pages of the panel schematics.

Fig. 17

Gas Detector factory default settings – Modbus RTU

The PXE 02 and PXE 04 have variants that are equipped with Danfoss GDA gas detectors, cable and sensors. The gas detector unit

runs on a parallel Modbus RTU fieldbus system to the Evaporator Controllers and may be connected to the customers gas detector

Modbus RTU system via terminal X54 on the PXE 02 panels terminal X54 on the PXE 04 panels equipped with gas detection. The Gas

Detection Modbus RTU fieldbus network settings have the following default settings from the factory:

Tab le. 04

EKE 400 controller’s default comm settings

Slave ID 1

Baud rate 19.200 b ps

Parity even

Data bits 8

Stop bit 1

Start bit 1

NOTE: The Slave ID can be changed but all other serial communication settings

cannot be changed.

© Danfoss | Climate solutions | 2021.07

AN383426363919en-000101 | 9

Gas Detector factory default settings – NH₃ PPM alarm settings

The gas detector will activate an alarm if there is an error detected or if there is a power failure to the unit. The gas detection units

also come with factory default 2-step alarm set-up ready for use. PPM alarm factory settings are as follows:

Tab le. 05

Gas Detector Factory Default Values

Description Default value

NH₃ PPM high level ALARM 1 25 PPM

NH₃ PPM high level ALARM 2 SHUTDOWN 35 PPM

NH₃ PPM range 0–100 PPM

Gas Detector factory default settings - Terminals

The user interface enables the user to configure two individual alarm settings. ALARM 1 is a pre-alarm that, when activated, indicates the gas level has passed a user-defined first threshold. If the gas level then passes a user-defined second threshold, the final

ALARM 2 (shutdown) is activated. For further information on setup of the gas detection unit via the display and information on

alarm schemes, please refer to the links to relevant documentation below. Factory default outputs from the panel gas detection unit

are, as factory default as follows:

Tab le. 06

PXE 02 and PXE 04 panels with gas detection

Description Default value

PPM High Level ALARM 1 (DO) X61

PPM High Level SHUTDOWN ALARM 2 (DO) X63

PPM level (4–20 mA AO) X5 4.1

Connecting the Gas Detection safety circuit to the evaporator controllers

The default factory configurations of the PXE 02 and PXE 04 are not setup to output signals from the gas detector directly to the

inputs of the controllers in the panel. If required, the DO of a selected controller can be setup to de-energize following a High NH₃

PPM SHUTDOWN ALARM 2 output from the gas detection unit. This is done by following these steps:

Step 01: Locate the controller input terminal required to de-energize ALL its DO on a High NH₃ PPM SHUTDOWN ALARM 2 signal

from the gas detection unit.

Tab le. 07

PXE 02 panels

Description Gas Safety Circuit DI Terminal

EKE 400 Controller 1 X10 0

EKE 400 Controller 2 X400

Table. 08

PXE 04 panels

Description Gas Safety Circuit DI Terminal

EKE 400 Controller 1 X100

EKE 400 Controller 2 X200

EKE 400 Controller 3 X300

EKE 400 Controller 4 X400

© Danfoss | Climate solutions | 2021.07

NOTE: In the following example, the Gas Detector in PXE 04 will

be wired to de-energize the DO from Controller 1 on a

High NH₃ PPM ALARM 2 output from the gas detection unit

AN383426363919en-000101 | 10

Step 02: Remove jumper from selected terminal. In this example, remove jumper from Controller 1 at X100.

Fig. 18

Step 03: Wire terminal X63 to terminal X100

NOTE: The control sequence the EKE 400 controller will apply on receipt of this signal may be easily set up by using the CoolConfig

software interface.

IMPORTANT: Only the DO in the controlled evaporator circuit will be de-energized by this function. AO will not be affected and will

continue to operate according to the output signal of the controller.

© Danfoss | Climate solutions | 2021.07

AN383426363919en-000101 | 11

Connecting the Gas Detector PPM reading to the Controller

The Gas Detection PPM analog output signal (mA factory default) may be connected to a controller AI terminal and read on the

Modbus RTU controller network. The actual AI controller terminal the AO terminal from the gas detection unit will depend on the

configuration of the EKE 400 controller. The control AI can be viewed on the software CoolConfig during controller configuration

and the correct terminal can then be located and wired to from the gas detection AO terminal X54.1. See example below where AI2

is to be used.

Fig. 19

The gas detection terminal and Modbus registers to be noted for these purposes are as follows:

Tab le. 09

Gas detector AO terminals for PPM level

4 EKE 400 Panel 2 EKE 400 Panel

PPM AO terminal X5 4.1 X 54.1

Controller Modbus registers for PPM level

The PPM level may be read of the EKE 400 controller Modbus network (if not using the gas detection units Modbus network) and

will of course depend on the EKE 400 controller and terminal used. The following Modbus registers are where the PPM values can be

read (depending on the wiring & controller configuration).

Tab le. 10

2 EKE 400 Controller Panel 4 EKE 400 Controller Panel

Modbus

AI

1 1005 X150 .1 X450: 1 X150.1 X250.1 X35 0.1 X450: 1

2 1006 X150.2 X450: 2 X150.2 X250.2 X350.2 X450: 2

3 1007 X150.3 X450: 3 X150.3 X250.3 X350.3 X450: 3

4 1008 X150.4 X450: 4 X150.4 X250.4 X350.4 X450: 4

Register

EKE 400

Controller 1

Terminal

EKE 400

Controller 2

Terminal

EKE 400

Controller 1

Terminal

EKE 400

Controller 2

Terminal

EKE 400

Controller 3

Terminal

EKE 400

Controller 4

Terminal

Gas Detector Documentation

Further information about using the menus can be found in the GDA Application Guide: Link

Further installation information about installing the GDA can be found in the GDA Installation Guide: Link

Further installation information about the Modbus functionality can be found in the GDA Modbus Communication Guide: Link

© Danfoss | Climate solutions | 2021.07

AN383426363919en-000101 | 12

Accessory: Signal conditioners

The PXE 02 and PXE 04 analog output signals from its controllers to evaporator controlling actuators are 0–10 V type from the

factory. It is possible purchase signal conditioners as accessories from Danfoss that can be installed and wired by the customer

(please contact a Danfoss sales representative). Signal conditioners change the analog output signal at the panel terminal from

0–10 V to 4–20 mA. The following is a quick overview as to how this may be done.

Step 01: Mount the signal conditioner on the DIN rail provided on the right side of the panel.

Fig. 20

Step 02: Wire the power terminal available in the panel (X77) to the signal conditioner power terminals and wire the correct AO

terminals (X160-X460) to the input side of the signal conditioner. Please read the signal conditioner instructions beforehand.

The 4–20mA device may now be wired to the output side of the signal conditioner.

Fig. 21

© Danfoss | Climate solutions | 2021.07

AN383426363919en-000101 | 13

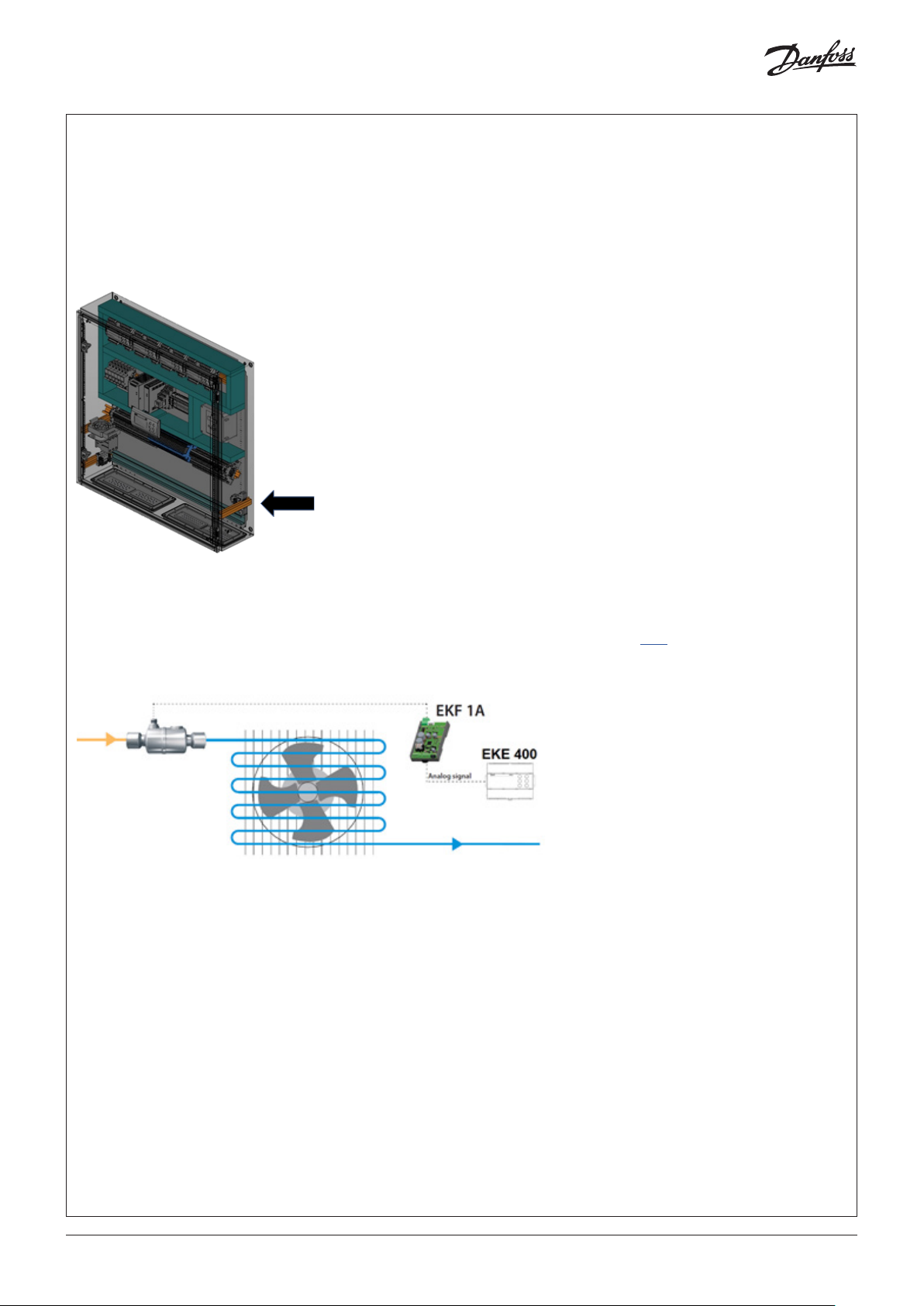

Accessory: Stepper motor drivers

The PXE 02 and PXE 04 analog output signals from its controllers to evaporator controlling actuators are 0-10 V type from the factory. It is possible purchase Danfoss stepper motor drivers EKF 1A to drive 1 stepper motor valve and EKF 2A to drive 2 stepper motor valves as accessories that can be installed and wired by the customer. Stepper motor drivers change the analog output signal at

the panel terminal from 0-10 V to a stepper motor signal that may be configured according to the stepper motor valve’s

specification. The following is a quick overview as to how a stepper motor driver may be installed in the panel.

Step 01: Mount the stepper motor driver on the DIN rail provided on the right side of the panel.

Fig. 22

Step 02: Wire the power terminal available in the panel (X77) to the stepper motor power terminals and wire the correct AO

terminals (X160-X460) to the input side of the stepper motor driver. Please read the stepper motor driver instructions beforehand

and configure the driver according to the required application. The stepper motor valve may now be wired to the stepper motor

driver. See the installation instructions for the Danfoss EKF 1A and EKF 2A stepper motor drivers for stepper motor driver connection

details and observe the wiring recommendations regarding distance to the stepper motor valve: Link

Fig. 23

© Danfoss | Climate solutions | 2021.07

AN383426363919en-000101 | 14

© Danfoss | Climate solutions | 2021.07

AN383426363919en-000101 | 15

Danf

oss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

already on order pro

All trademarks in this material are property of the respec

vided that such alterations can be made without subsequential changes being necessary eady agreed.

tive companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

© Danfoss | Climate solutions | 2021.07

AN383426363919en-000101 | 16

Loading...

Loading...