Page 1

MAKING MODERN LIVING POSSIBLE

Electrical Installation

Electrohydraulic Actuator

PVEP

powersolutions.danfoss.com

Page 2

Electrical Installation PVEP Electrohydraulic Actuator

Revision history Table of revisions

Date Changed Rev

September 2015 Minor layout revision DB

August 2015 Converted to Danfoss layout DA

May 2013 Code/part number CA

February 2010 Proportional valve body drawing updated; Basic concept/controller and PVEP drawing

updated

April 2007 First edition AA

BA

2 11022662 • Rev DB • September 2015

Page 3

Electrical Installation PVEP Electrohydraulic Actuator

Contents

Literature references

PVEP electrohydraulic actuator literature references......................................................................................................... 4

Latest version of technical literature.........................................................................................................................................4

Product overview

Product image................................................................................................................................................................................... 5

Part number........................................................................................................................................................................................5

Theory of operation.........................................................................................................................................................................6

Closed loop control....................................................................................................................................................................6

Concept.......................................................................................................................................................................................... 7

Hydraulic schematics...................................................................................................................................................................... 8

Electrical specifications.................................................................................................................................................................. 8

Electrical installation

Pinout....................................................................................................................................................................................................9

Pin compatibility...............................................................................................................................................................................9

Input/output matrix........................................................................................................................................................................ 9

Mating connector.......................................................................................................................................................................... 10

11022662 • Rev DB • September 2015 3

Page 4

Electrical Installation PVEP Electrohydraulic Actuator

Literature references

PVEP electrohydraulic actuator literature references

Literature title Description Literature number

PVG 32 Proportional Valves Technical Information Complete product electrical

PVG 100 Proportional Valves Technical Information 520L0720

PVE Series 4 for PVG 32, PVG 100 and PVG 120 Technical

Information

Instructions for PVG Series 4 for PVEP 520L0921

PVEP Compliant Function Block User Manual Compliant function block

Latest version of technical literature

Danfoss product literature is online at: http://powersolutions.danfoss.com/literature/

and mechanical

520L0344

specifications

520L0553

11020634

set-up information

4 11022662 • Rev DB • September 2015

Page 5

Electrical Installation PVEP Electrohydraulic Actuator

Product overview

Product image

PVEP electrohydraulic actuator

Part number

PVEP

PVEP proportional actuation DEUTSCH DT connector

Standard PVEP Danfoss 11034832

11022662 • Rev DB • September 2015 5

Page 6

p

P

T

P

T

Set Point

Solenoid

Valve Bridge

Spool or

Piston

Spool Position

Feed Back Signal

Transducer

Electrical Installation

Product overview

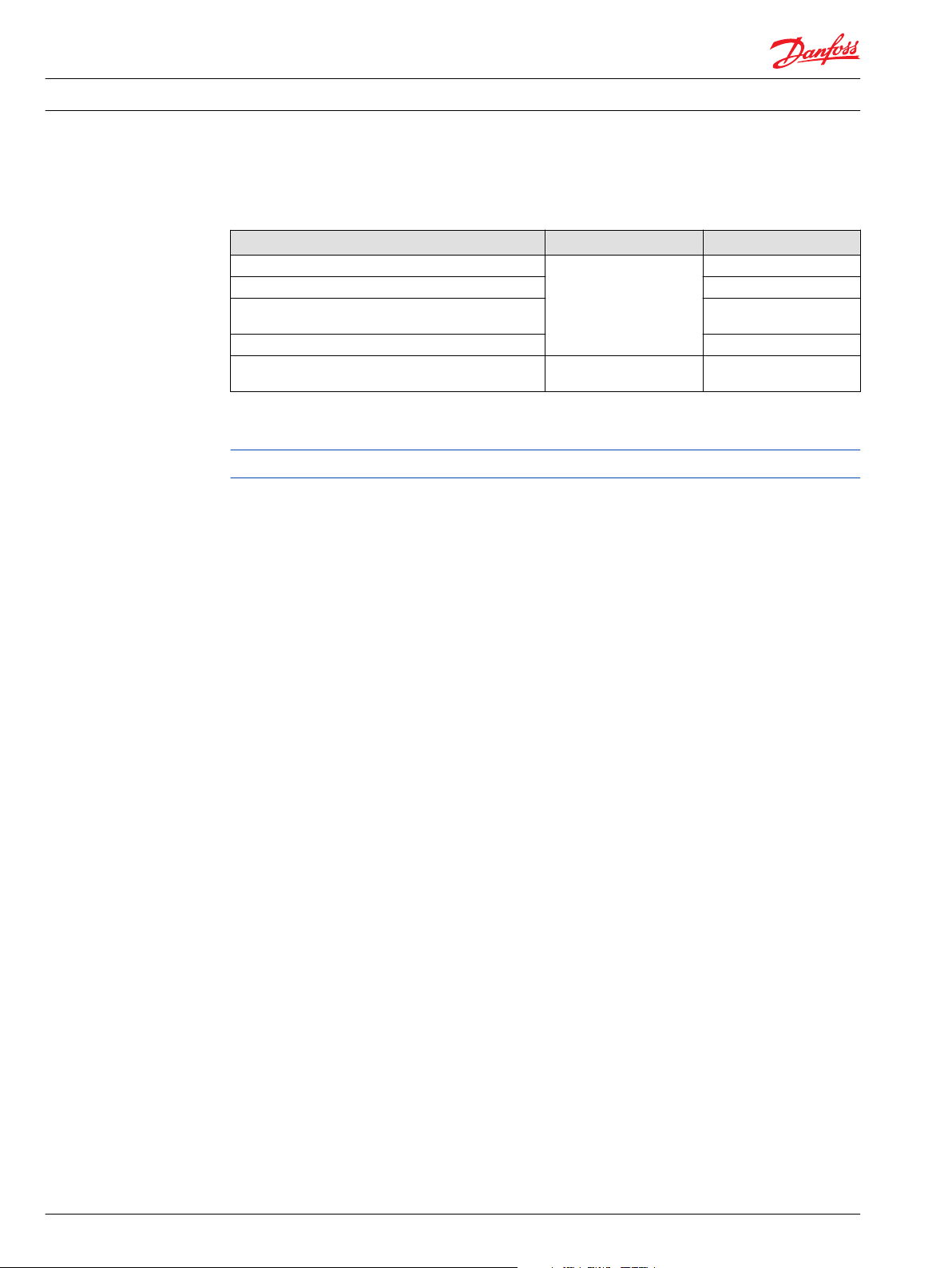

Theory of operation

PVEP Electrohydraulic Actuator

The PVEP has two low frequency PWM inputs that determine the set point for main spool control in the

valve. This differs from the standard PVE programme where an analogue ratio metric signal forms the

input set point to the valve.

The PVEP will be available in two versions, a standard PVEP and a PVEP-F for valves with float position

option.

The philosophy of Danfoss electrohydraulic actuation, type PVE, is integration of electronics, sensors and

actuators into a single unit that interfaces directly to the proportional valve body.

Proportional valve body

Closed loop control

The PVEP and the PVEP-F feature an integrated feedback transducer that measures spool movement in

relation to the input signal from the main micro controller, and by means of a solenoid valve bridge,

controls the direction, velocity, and position of the main spool of the valve.

The integrated electronics compensate for flow forces on the spool, internal leakage, changes in oil

viscosity, pilot pressure, etc. with very low hysteresis and high resolution.

6 11022662 • Rev DB • September 2015

Page 7

11 - 32 V

-

+

PVE

Valve

PositionSet point

PWM

to

-

B

Driver

Sense

Driver

A

PWM B ratio

-7.5

80%

90%

[%]

7.5

-

5.5

-5.5

PWM A ratio

V310137.A

Spool travel

Float posistion

Sense

Control range

Proportional

mminch

0.2

0.3

-0.3

-0.2

ti = Time impulse (< V bat)

T = Period [s]

Duty cycle [%] = (ti/T) * 100%

ti tp

tp = Time pause ( 0 voltage)

Electrical Installation

Product overview

PVEP Electrohydraulic Actuator

Concept

Basic concept/ Controller and PVEP

The PVEP is driven by two low current PWM inputs, called PWM_A and PWM_B. The duty cycle of the

PWM signal determine the spool position.

Duty cycle definition

In the PVEP the duty cycle of the pulse is measured as a true time difference measurement. The PVEP

interprets the duty cycle and positions the spool accordingly.

11022662 • Rev DB • September 2015 7

Page 8

U

s

Input

Signal

LVDT

Signal

PWM

W

Electrical Installation

Product overview

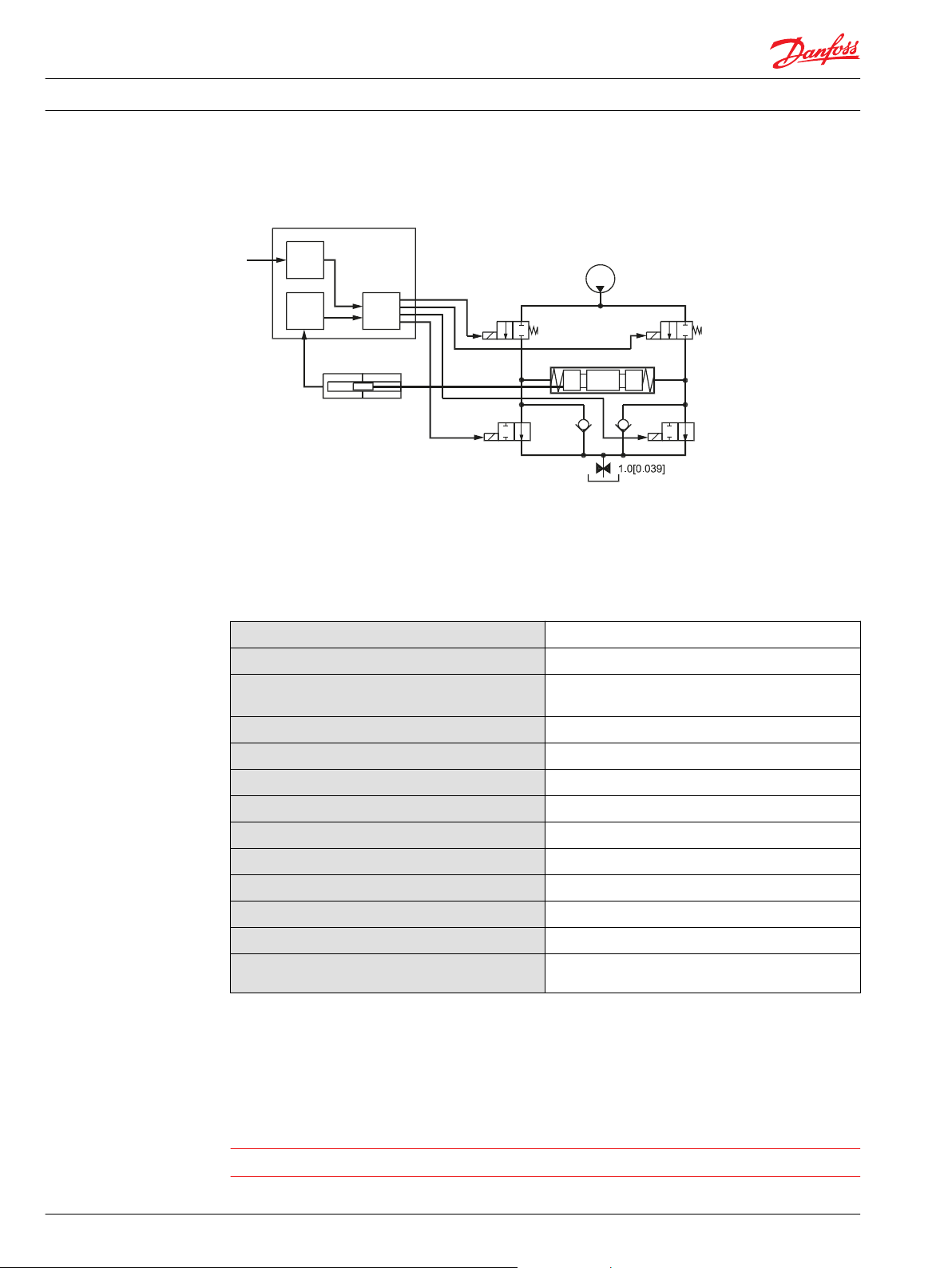

Hydraulic schematics

Electrical specifications

PVEP Electrohydraulic Actuator

PVEP

The following technical data is from typical test results. For the hydraulic system a mineral based

hydraulic oil with a viscosity of 21 mm2/second [102 SUS] and a temperature of 50° C [122° F] were used.

Specifications

Supply voltage Vbat range

Supply voltage Vbat maximum ripple

Supply voltage Vbat over voltage (maximum 5

minutes)

PWM control range (duty cycle)

PWM float position control

PWM frequency

PWM input voltage swing

PWM input low voltage

PWM input high voltage

Input impedance (standard pull down)

Input capacitor

Power consumption

Error voltage (fault monitoring)

10 to 32 Vdc

5%

36 Vdc

10 to 80 %

PWM_A = PWM_B = 90%

100 to 1000 Hz

0 to > Vbat

0 to 0.6 Vdc

5 to 32 Vdc

5 kΩ

— —

7 W

No fault = 0 Voltage

Fault = Vbat

All connector terminals are short circuit protected and protected against reverse connection (and their

combinations).

The main spool position feedback via the LVDT enables PVEP to control the proportional valve main

spool very smoothly and accurately with a hysteresis of typical 3 to 4%. PWM frequency can be chosen

between 100 to 1000 Hz for A or B channel.

Warning

It’s up to the customer to decide on the required degree of safety for the system.

8 11022662 • Rev DB • September 2015

Page 9

3

2

1

4

5

6

Electrical Installation

Electrical installation

Pinout

PVEP Electrohydraulic Actuator

Pin location

Pinout

Pin Function

1 PWM_A

2 Error

3 PWM_B

4 No connection

5 Ground

6 U DC

Pin compatibility

Input/output matrix

PLUS+1® module pin type/ PVEP pin compatibility

Pin Function

6 DOUT/PVG Pwr 1-3

1, 3 PWMOUT/DOUT/PVGOUT 1-3

5 Power ground 2 Dig in

PVEP Input/output matrix

Duty cycle A-signal

(pin 1)

0% 0% Neutral Low

<10% 0%

0% <10%

≥10% ≥10% Fault (error) High

0% 10 to 80% B-port flow Low

10 to 80% 0% A-port flow Low

*

If no internal faults are detected in the PVEP.

Duty cycle B-signal (pin 2) Function Error pin output

(pin 3)

*

For the standard PVEP version full stroke is ±7.0 mm. An area between 86% and 100% DC is used for

failure detection, duty cycle in this area is defined as a fault and the failure detection circuit will be

activated.

11022662 • Rev DB • September 2015 9

Page 10

Electrical Installation PVEP Electrohydraulic Actuator

Electrical installation

Mating connector

PVEP mating connector parts list

Description Quantity Ordering number

Connector 1 DEUTSCH DTO6-6S

Wedge lock 1 DEUTSCH W6S

Socket contact (14 and 16 AWG) 4 DEUTSCH 0462-201-16141

10 11022662 • Rev DB • September 2015

Page 11

Electrical Installation PVEP Electrohydraulic Actuator

11022662 • Rev DB • September 2015 11

Page 12

Danfoss

Power Solutions GmbH & Co. OHG

Krokamp 35

D-24539 Neumünster, Germany

Phone: +49 4321 871 0

Danfoss

Power Solutions ApS

Nordborgvej 81

DK-6430 Nordborg, Denmark

Phone: +45 7488 2222

Danfoss

Power Solutions (US) Company

2800 East 13th Street

Ames, IA 50010, USA

Phone: +1 515 239 6000

Danfoss

Power Solutions Trading

(Shanghai) Co., Ltd.

Building #22, No. 1000 Jin Hai Rd

Jin Qiao, Pudong New District

Shanghai, China 201206

Phone: +86 21 3418 5200

Products we offer:

Comatrol

www.comatrol.com

Schwarzmüller-Inverter

www.schwarzmuellerinverter.com

Turolla

www.turollaocg.com

Hydro-Gear

www.hydro-gear.com

Daikin-Sauer-Danfoss

www.daikin-sauer-danfoss.com

Bent Axis Motors

•

Closed Circuit Axial Piston

•

Pumps and Motors

Displays

•

Electrohydraulic Power

•

Steering

Electrohydraulics

•

Hydraulic Power Steering

•

Integrated Systems

•

Joysticks and Control

•

Handles

Microcontrollers and

•

Software

Open Circuit Axial Piston

•

Pumps

Orbital Motors

•

PLUS+1® GUIDE

•

Proportional Valves

•

Sensors

•

Steering

•

Transit Mixer Drives

•

Danfoss Power Solutions is a global manufacturer and supplier of high-quality hydraulic and

electronic components. We specialize in providing state-of-the-art technology and solutions

that excel in the harsh operating conditions of the mobile off-highway market. Building on

our extensive applications expertise, we work closely with our customers to ensure

exceptional performance for a broad range of off-highway vehicles.

We help OEMs around the world speed up system development, reduce costs and bring

vehicles to market faster.

Danfoss – Your Strongest Partner in Mobile Hydraulics.

Go to www.powersolutions.danfoss.com for further product information.

Wherever off-highway vehicles are at work, so is Danfoss. We offer expert worldwide support

for our customers, ensuring the best possible solutions for outstanding performance. And

with an extensive network of Global Service Partners, we also provide comprehensive global

service for all of our components.

Please contact the Danfoss Power Solution representative nearest you.

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to

products already on order provided that such alterations can be made without changes being necessary in specifications already agreed.

All trademarks in this material are property of the respective companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

11022662 • Rev DB • September 2015 www.danfoss.com

Local address:

©

Danfoss A/S, 2015

Loading...

Loading...