Page 1

Technical Information

Electrohydraulic Actuators for PVG32,

PVG100 and PVG120

PVE-EX Ex db version

powersolutions.danfoss.com

Page 2

Technical Information

Electrohydraulic Actuators PVE-EX

Revision history Table of revisions

Date Changed Rev

October 2017 Major revision 0102

January 2017 First edition 0101

2 | © Danfoss | October 2017 BC00000393en-US0102

Page 3

Technical Information

Electrohydraulic Actuators PVE-EX

Contents

General information

PVE-EX Introduction........................................................................................................................................................................ 5

Literature Reference........................................................................................................................................................................5

Product Certification....................................................................................................................................................................... 5

Protection............................................................................................................................................................................................5

Warnings..............................................................................................................................................................................................5

Nameplate Description (PVE-EX db version)..........................................................................................................................7

Description of the EX Code (PVE-EX db).................................................................................................................................. 8

EPL / Equipment Category............................................................................................................................................................ 8

Functionality

PVE-EX functionality........................................................................................................................................................................9

PVE hydraulic subsystems........................................................................................................................................................9

PVE-EX control

PVE-EX: PVE control by voltage.................................................................................................................................................10

PVE-EX ON/OFF activation..........................................................................................................................................................10

PVE-EX: PVE hysteresis..................................................................................................................................................................11

Specifications

7-pin Layout.....................................................................................................................................................................................12

4-Pin layout...................................................................................................................................................................................... 12

Radiometric Control Signal........................................................................................................................................................ 12

Radiometric Fixed Control Signal (0-10 V)............................................................................................................................ 12

Radiometric Control Signal – On/Off Activation.................................................................................................................13

Adjustment/calibration............................................................................................................................................................... 13

Technical data

Fluid specification..........................................................................................................................................................................14

PVE-EX electrical data...................................................................................................................................................................14

Reaction times.................................................................................................................................................................................15

Adjustment/calibration............................................................................................................................................................... 15

Installation

PVE-EX Dimensions ...................................................................................................................................................................... 16

Mounting of PVE-EX......................................................................................................................................................................16

Cable...................................................................................................................................................................................................17

Mounting of Cable................................................................................................................................................................... 17

Cable Gland......................................................................................................................................................................................18

Supplied Built-in Cable Gland..............................................................................................................................................18

PVE-EX Pre-certified Cable Gland........................................................................................................................................18

Mounting of PVG............................................................................................................................................................................19

Mounting options and guidelines......................................................................................................................................19

Direction of cable exit.............................................................................................................................................................20

Safety and monitoring

Safety in application..................................................................................................................................................................... 21

Safety guidelines............................................................................................................................................................................21

PVE-EX fault monitoring and reaction....................................................................................................................................22

Control signal monitoring.....................................................................................................................................................22

Transducer supervision.......................................................................................................................................................... 22

Supervision of spool position...............................................................................................................................................22

PVE-EX fault monitoring.........................................................................................................................................................23

Direction indication feedback (-DI)......................................................................................................................................... 23

Internal and external earth-connection

Earthing terminals......................................................................................................................................................................... 25

Internal earth-connection...........................................................................................................................................................25

External earth-connection..........................................................................................................................................................26

Maintenance, service, troubleshooting

PVE-EX installation, start-up, and operation ....................................................................................................................... 27

©

Danfoss | October 2017 BC00000393en-US0102 | 3

Page 4

Technical Information

Electrohydraulic Actuators PVE-EX

Contents

Warnings

PVE-EX warnings.............................................................................................................................................................................28

Code numbers

PVE-EX Ex part numbers..............................................................................................................................................................29

Declaration of confromity

EC-Declaration of Conformity....................................................................................................................................................30

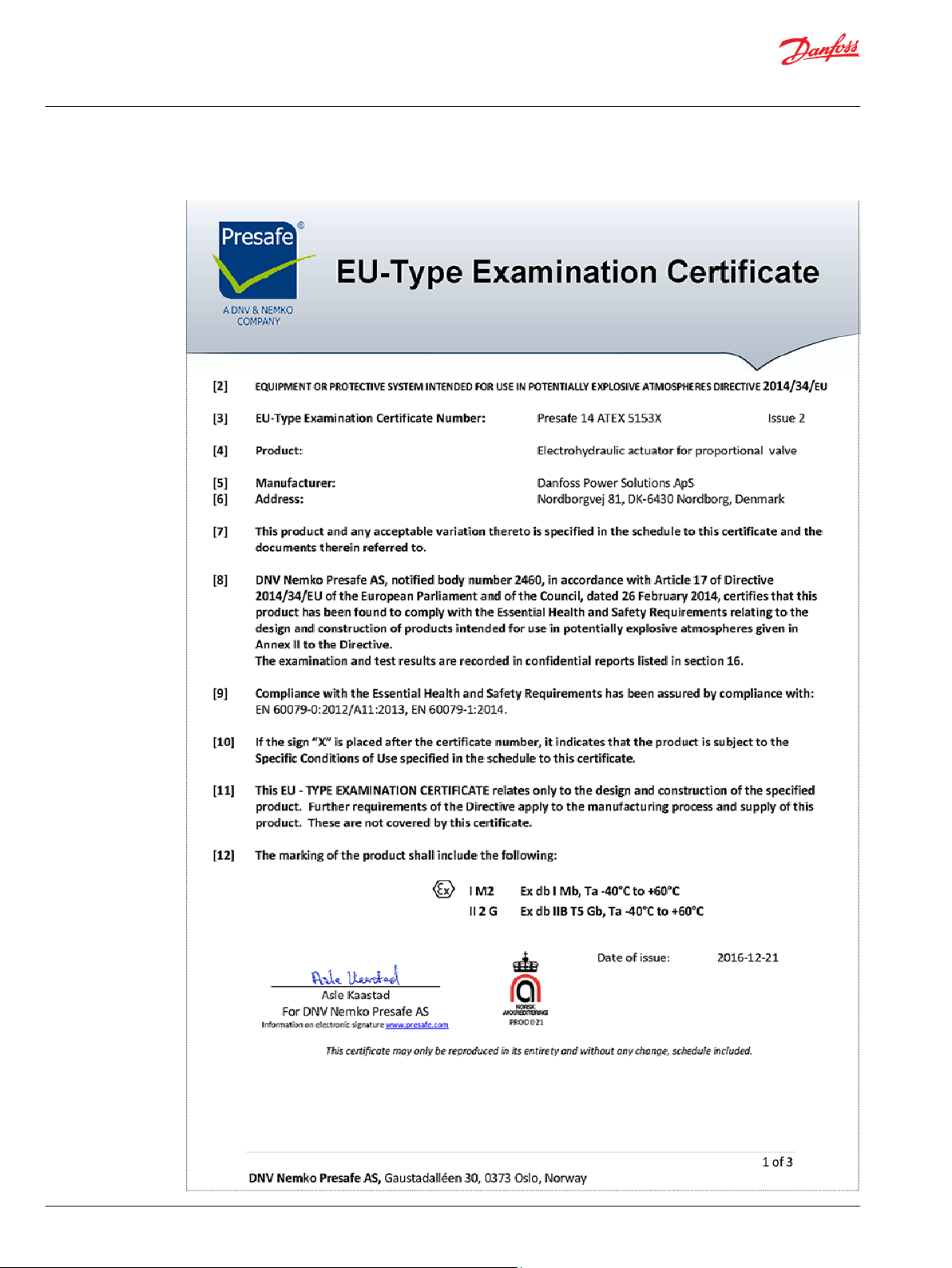

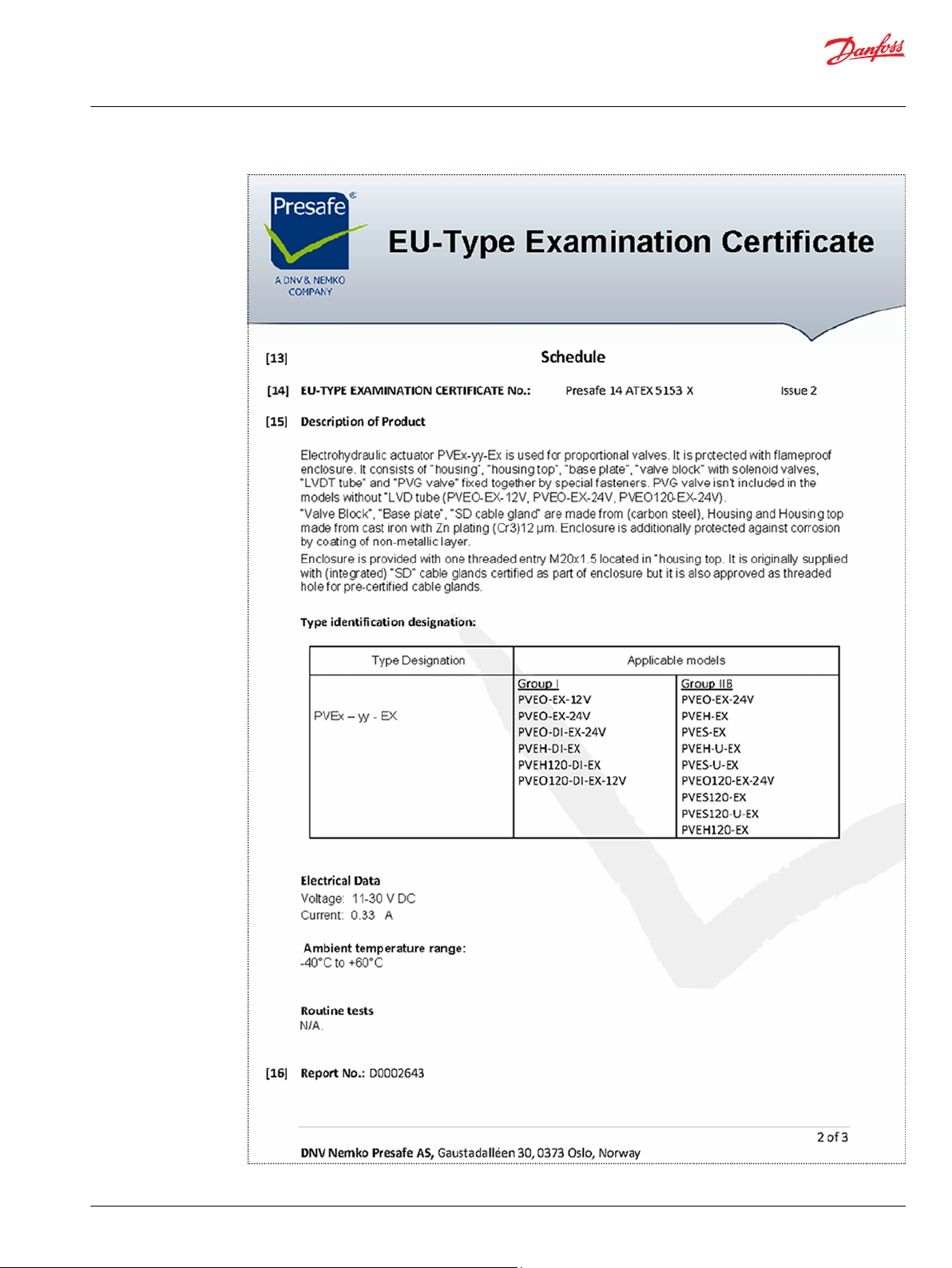

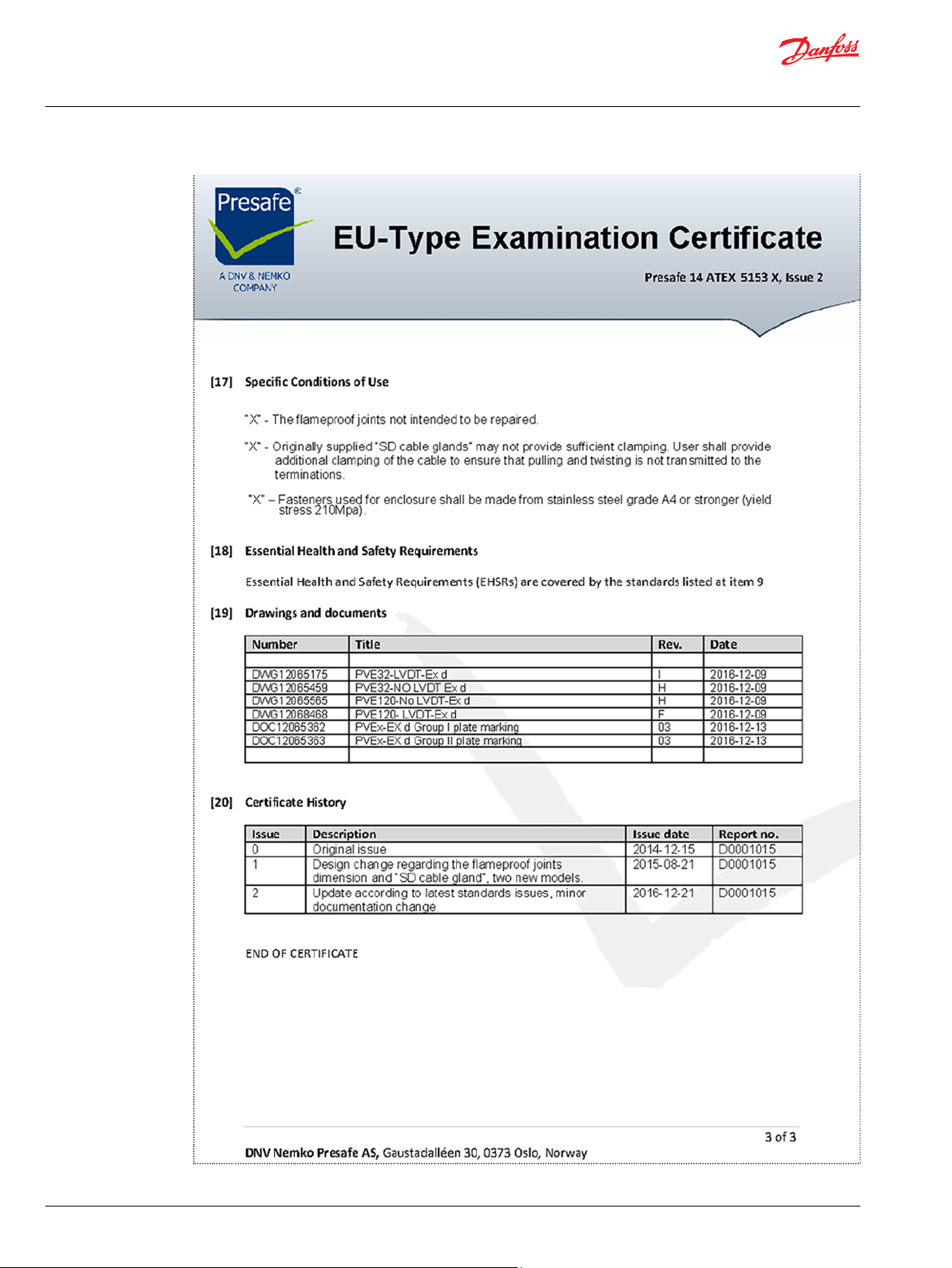

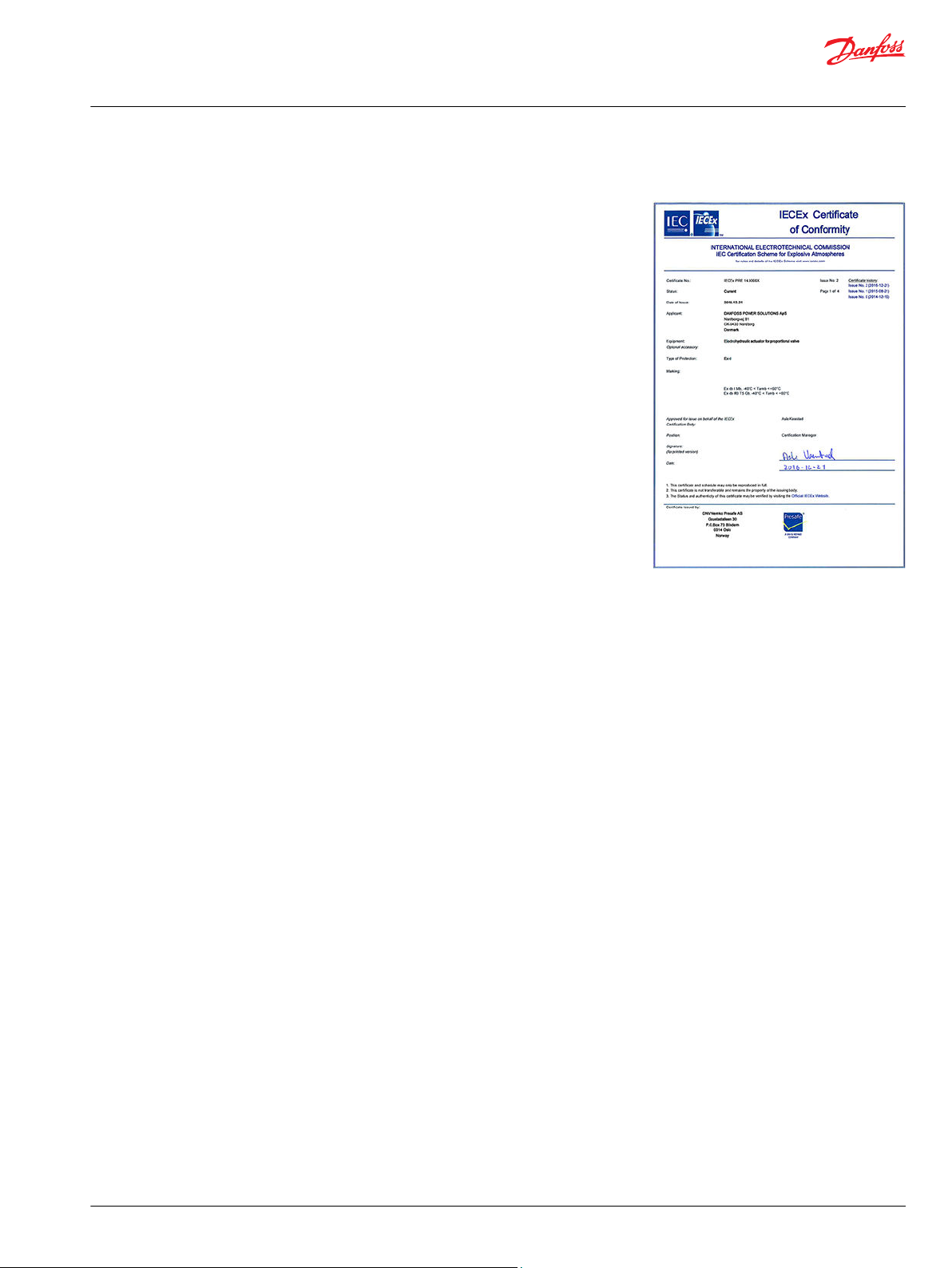

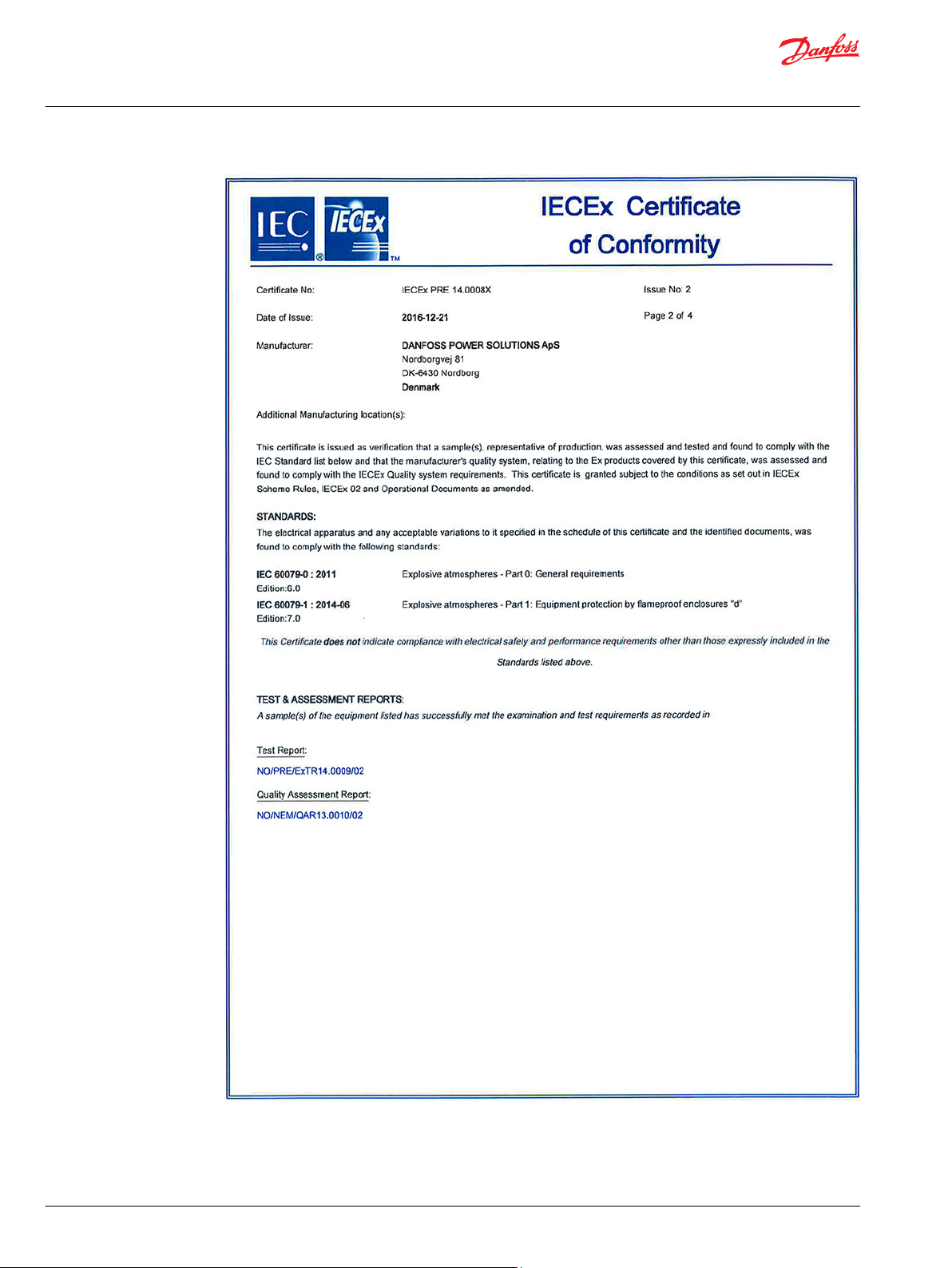

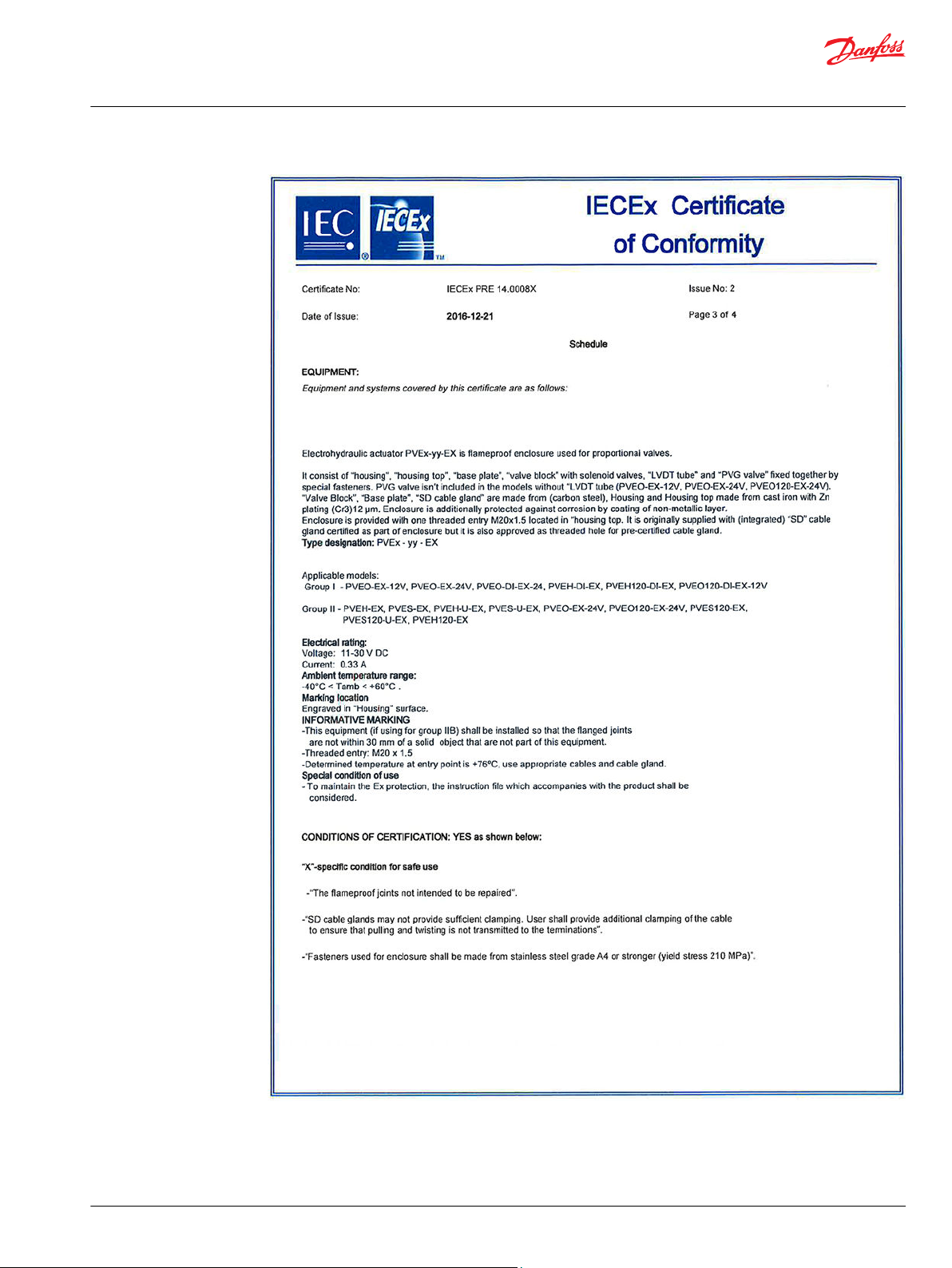

Certificates

EU-Type Examination Certificate..............................................................................................................................................32

IECEx Certificate of Conformity.................................................................................................................................................35

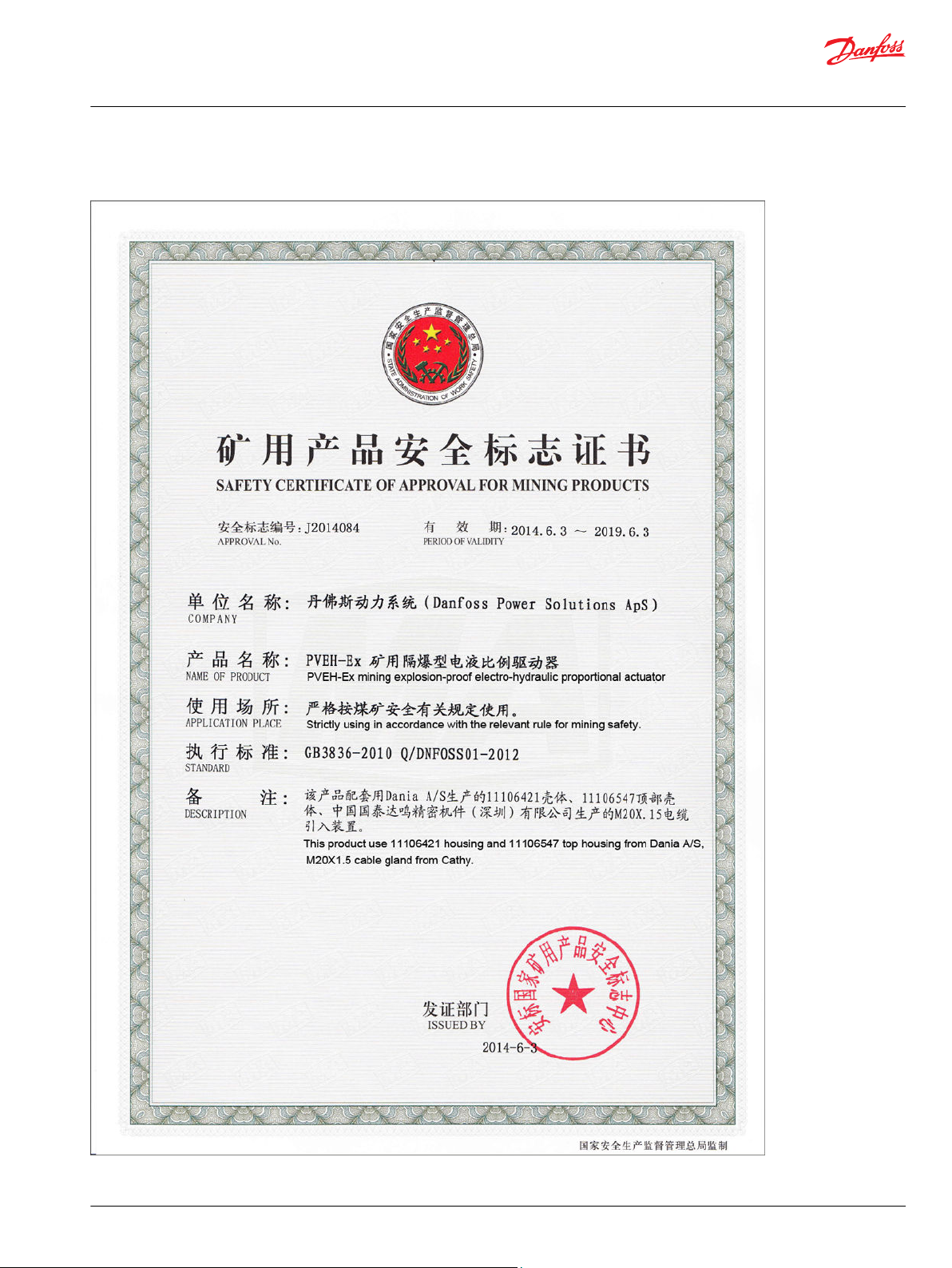

Safety certificate J2014084.........................................................................................................................................................39

Safety certificate J2014085.........................................................................................................................................................40

4 | © Danfoss | October 2017 BC00000393en-US0102

Page 5

Technical Information

Electrohydraulic Actuators PVE-EX

General information

PVE-EX Introduction

The Danfoss PVE-EX is a PVE series 7 actuator for PVG32, PVG100 and PVG120.

The PVE-EX is an explosion proved PVE designed to be used in harsh environments like mining and oil

and gas industries.

The PVE-EX has been certified by NEMKO, IECEx and MA.

Literature Reference

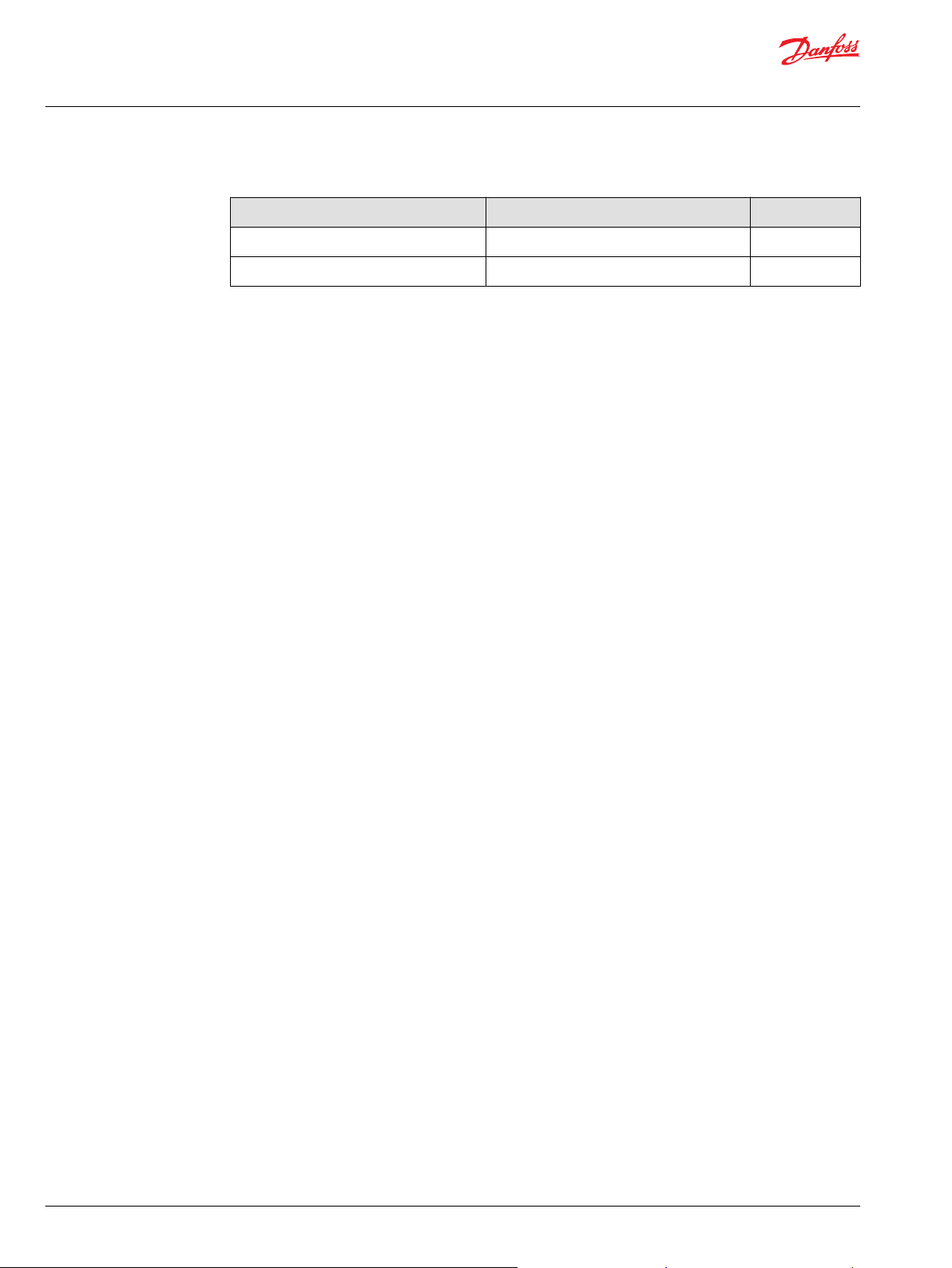

Literature reference for PVG and PVE products

Title Type Order number

PVG 32 Proportional Valve Groups Service Manual 11039167

PVG 100 Proportional Valve Groups Service Manual 11048807

PVG 32 Proportional Valve Groups Technical Information 520L0344

PVG 100 Proportional Valve Groups Technical Information 520L0720

PVG 120 Proportional Valve Groups Technical Information 520L0356

PVG 32 Metric ports Technical Information 11051935

Product Certification

The PVE-EX db version is developed according to and in compliance:

•

EN ISO 4413:2010 Hydraulic fluid power - General rules and safety requirements for systems and their

components

•

EN 60079-0:2012/A11:2013, IEC 60079-0:2011 Explosive atmospheres - Part 0: Equipment - General

requirements

•

EN/IEC 60079-1:2014 Electrical apparatus for explosive gas atmospheres-part 1: Flameproof

enclosures “d”

Installation and Maintenance standards:

•

EN/IEC 60079-14 Explosive atmospheres - Part 14: Electrical installations design, selection and

erection

•

EN/IEC 60079-17 Explosive atmospheres - Part 17: Electrical installations inspection and maintenance

The PVE-EX is in conformity with listed EU Directive(s):

•

EMC Directive 2004/108/EC

•

EN/IEC 61000-6-2:2005 Electromagnetic compatibility (EMC) - Part 6-2: Generic standards - Immunity

for industrial environments

•

EN 61000-6-4:2007/A1:2011, IEC 61000-6-4:2006 Electromagnetic compatibility (EMC) - Part 6-4:

Generic standards - Emission standard for industrial environments

Protection

All PVE-EX modules comply with protection class IP66 and IP69k according to EN60529. However, in

particularly exposed applications, protection in the form of shielding is recommended.

Warnings

Before implementing actuators in any application, read all warnings.

Warnings are listed next to the most relevant section and repeated in Warnings chapter.

©

Danfoss | October 2017 BC00000393en-US0102 | 5

Page 6

W

Technical Information

Electrohydraulic Actuators PVE-EX

General information

Do not regard the warnings as a full list of potential dangers. Depending on the application and use,

other potential dangers can occur.

Warning

All brands and all types of directional control or proportional valves, which are used in many different

operation conditions and applications, can fail and cause serious damage.

Analyze all aspects of the application. The machine builder/system integrator alone is responsible for

making the final selection of the products and assuring that all performance, safety and warning

requirements of the application are met.

The process of choosing the control system and safety levels is governed by the machine directives EN

13849 (Safety related requirements for control systems).

6 | © Danfoss | October 2017 BC00000393en-US0102

Page 7

V310 459

Danfoss

6430 Nordborg, Denmark

Type PVEx-yy-EX

111xxxxx wwyyd47xxxx

Ta -40° to + 60°C xx-yyVDC

Ex db I Mb

0470

Ԑx

I M 2

Presafe 14ATEX5153X Thread:

IECEx PRE14.0008X "M20"

MA: J201408x

10

8

7

4

3

1

9

6

2

5

Danfoss

6430 Nordborg, Denmark

Type PVEx-yy-ZZ

111xxxxx wwyyd47xxxx

Ta -40° to + 60°C xx-yyVDC

Ex db IIB T5 Gb

0470 Ԑx

II 2G

Presafe 14ATEX5153X Thread:

IECEx PRE14.0008X "M20"

MA: J201408x

10

8

7

4

3

1

9

6

2

5

Technical Information

Electrohydraulic Actuators PVE-EX

General information

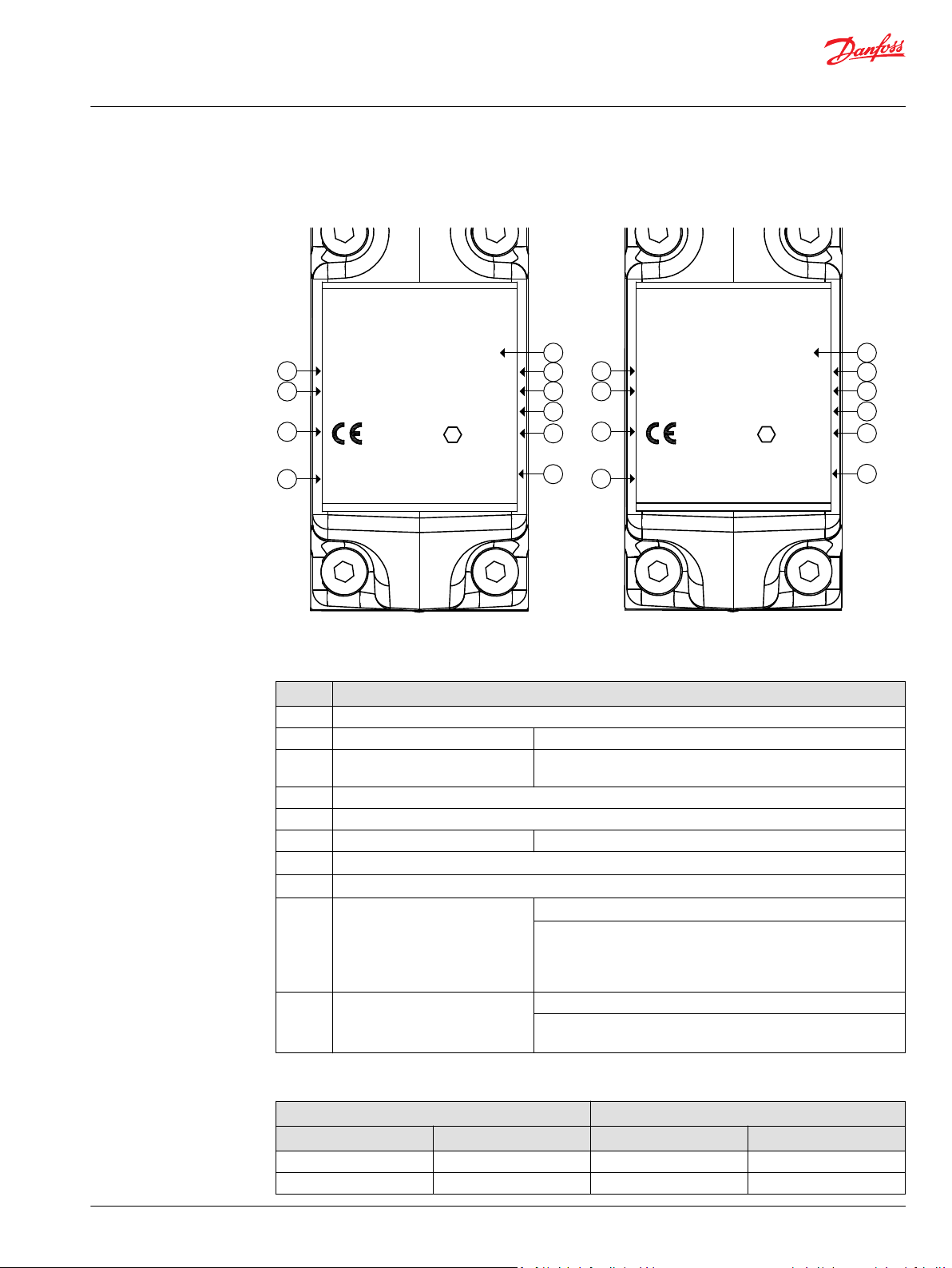

Nameplate Description (PVE-EX db version)

PVE-EX Ex db version, Group I (left) and Group II (right)

Nameplate legend

Number Description

1 PVE-EX type, see the table below.

2 Part Number Example: 111xxxxx

3

4 Supply voltage

5 Ambient temperature range

6 Notified body Example: NEMKO/Presafe

7

8

9 Ex Certificate Number

Production date and serial number

IECEx Equipment Group and protection category X-marking

ATEX Equipment Group and protection category X-marking

10 Thread Threaded entry: M20 x 1.5

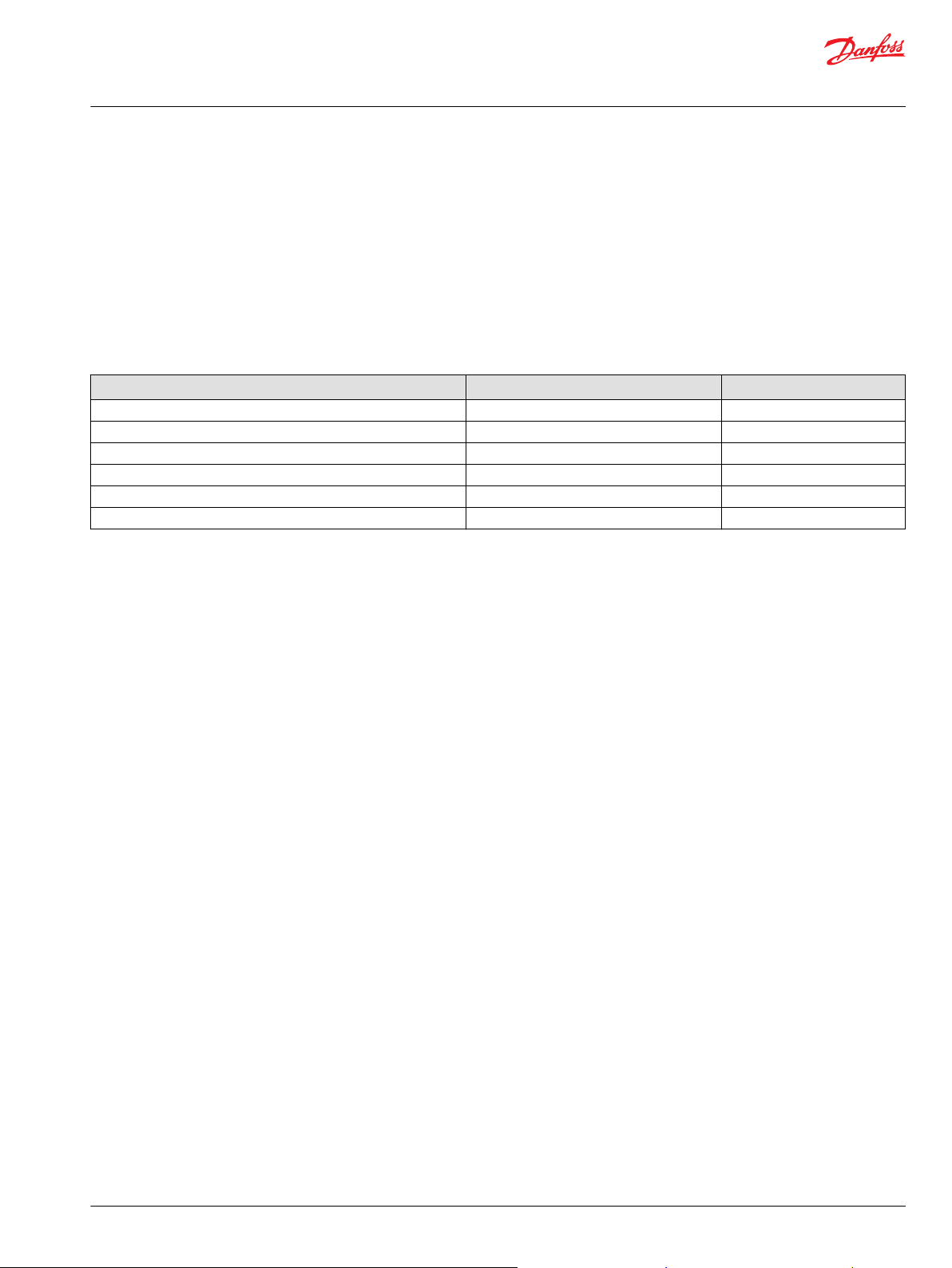

PVE-EX Ex db types with part numbers, Group I and Group II

Type Part No. Type Part No.

PVEO-EX-12V 11156462 PVEO-EX-24V 11156467

PVEO-EX-24V 11123165 PVEH-EX 11156463

Group I Group II

Example: 42 12 C xxxxxx

Week: 42 Year: 2012 Day: C=Wednesday (A=Monday) serial Number

Specific conditions for safe use (“X”-mark)

Originally supplied “SD cable glands” may not provide sufficient

clamping. User shall provide additional clamping of the cable to

ensure that pulling and twisting is not transmitted to the

terminations.

Determined temperature at entry point is +76º C, use appropriate

cables and cable gland

©

Danfoss | October 2017 BC00000393en-US0102 | 7

Page 8

Technical Information

Electrohydraulic Actuators PVE-EX

General information

PVE-EX Ex db types with part numbers, Group I and Group II (continued)

Type Part No. Type Part No.

PVEO-DI-EX-24V 11156461 PVES-EX 11156464

PVEH-DI-EX 11127696 PVEH-U-EX 11156465

PVEH120-DI-EX 11166357 PVES-U-EX 11156466

PVEO120-DI-EX-12V 11170401 PVES120-U-EX 11156568

Description of the EX Code (PVE-EX db)

IEC marking of the EX code db version

Description IEC Marking

Explosion protection marking Ex

Protection type db

Equipment Group I IIB

T-class N/A T5

Equipment Protection Level (EPL) Mb Gb

Group I Group II

PVEO120-EX-24V 11156468

PVES120-EX 11156567

PVEH120-EX 11161000

EPL / Equipment Category

EU marking of the EX code db version

Description EU Marking

CE conformity marking CE

Identification number of notified body involved in production control stage 0470

Explosion protection marking

Equipment Group I II

Equipment Category M2 2G

EPL/Equipment Category

Definition

Mines

Gas atmospheres

Level of

protection

very high N/A Ma

high Mb M2

very high 0 Ga

enhanced 2 Gc 3G

Typical zone of

application

EPL Group Category Group

IEC EU

I

II

M1

1G

I

IIhigh 1 Gb 2G

8 | © Danfoss | October 2017 BC00000393en-US0102

Page 9

Pp

NC3

NC1

Spool

NO4

NO2

Tank

LVDT

Set point

V310073.A

1.0 [0.039]

Electronics

W

Technical Information

Electrohydraulic Actuators PVE-EX

Functionality

PVE-EX functionality

The PVE-EX is an electro mechanical device, meaning that functionality is depending on mechanical,

hydraulic, electrical and control conditions given by PVE, PVG, application and vehicle. The result of this is

that implementing operation and safety conditions also must include vehicle specific considerations.

PVE hydraulic subsystems

The hydraulic subsystem is used for moving the spool and thereby open the valve for work flow.

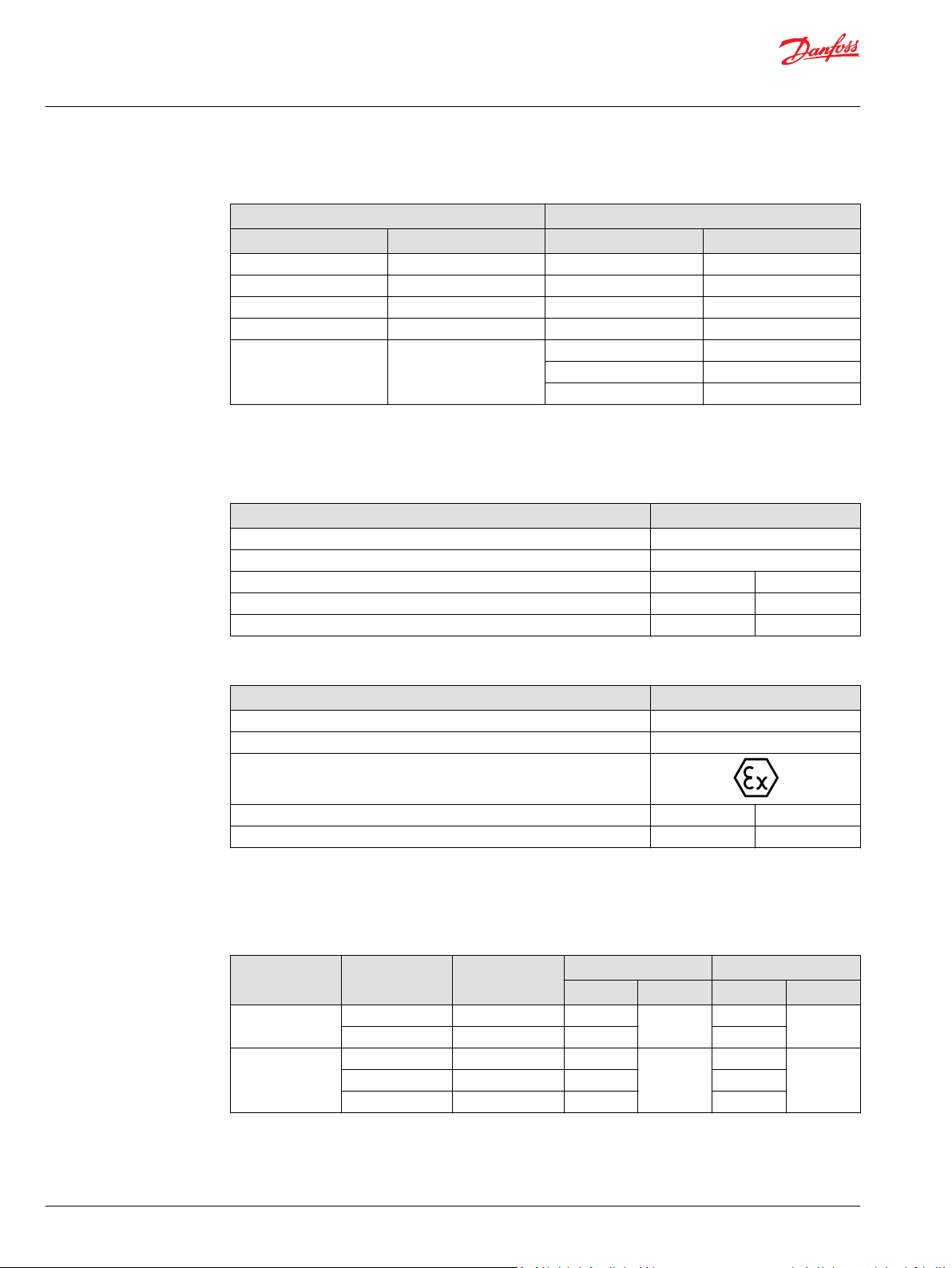

Pilot oil diagram

The hydraulic subsystem moves the spool and thereby opens the valve for work flow. The heart in the

hydraulic subsystem is the solenoid valve bridge which controls the Pilot Pressure (Pp) on spool ends. It

consist of four poppet valves, the two upper are normally closed (NC) and the two lower are normally

open (NO).

The Pp will work against the PVBS neutral spring when the spool is moved out of blocked (neutral) and

together with the spring when going in blocked. This combined with a larger opening in the NO than in

the NC will give a faster movement towards blocked than out of blocked.

When the PVE is powered the solenoids are all put in closed state. To move the PVBS to the right NC1 and

NO4 are opened and NC3 and NO4 are kept closed.

The activation of the solenoid valves represents oil consumption and thereby also a pressure drop in the

pilot oil gallery. By simultaneous use of multiple PVE the Pp can fall and result in performance problems.

The two check valves next to the NO are anti-cavitation valves. The orifice to tank reduces tank pressure

spikes and can also be used for ramp function.

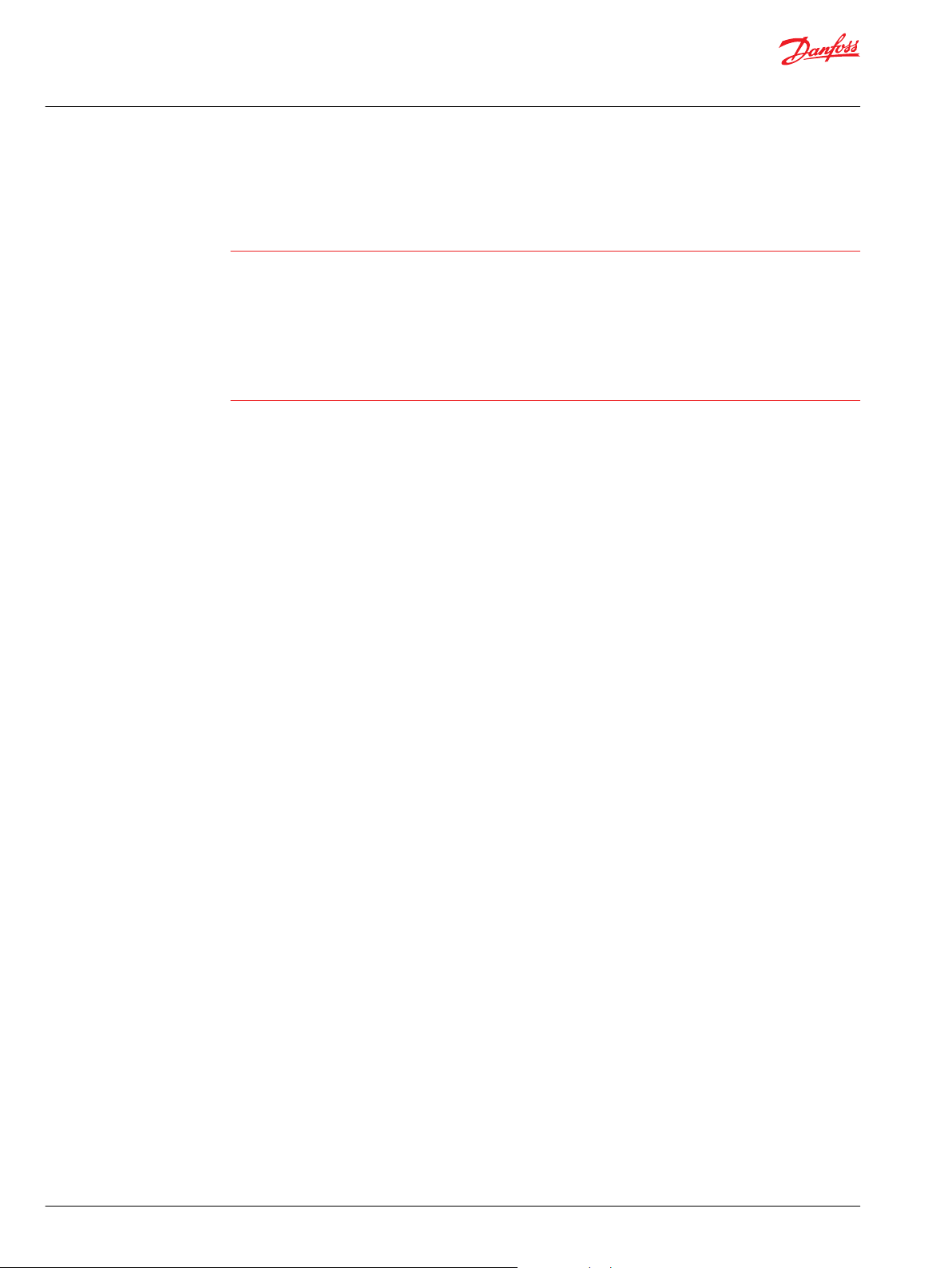

Warning

Obstacles for the Pilot oil pressure (Pp) can have direct influence on spool control. Reduced Pp will limit

spool control. Too high Pp can harm the PVE.

©

Danfoss | October 2017 BC00000393en-US0102 | 9

Page 10

PVEU

fixed

7.5V

5V2.5V

kwa1463778286972

Technical Information

Electrohydraulic Actuators PVE-EX

PVE-EX control

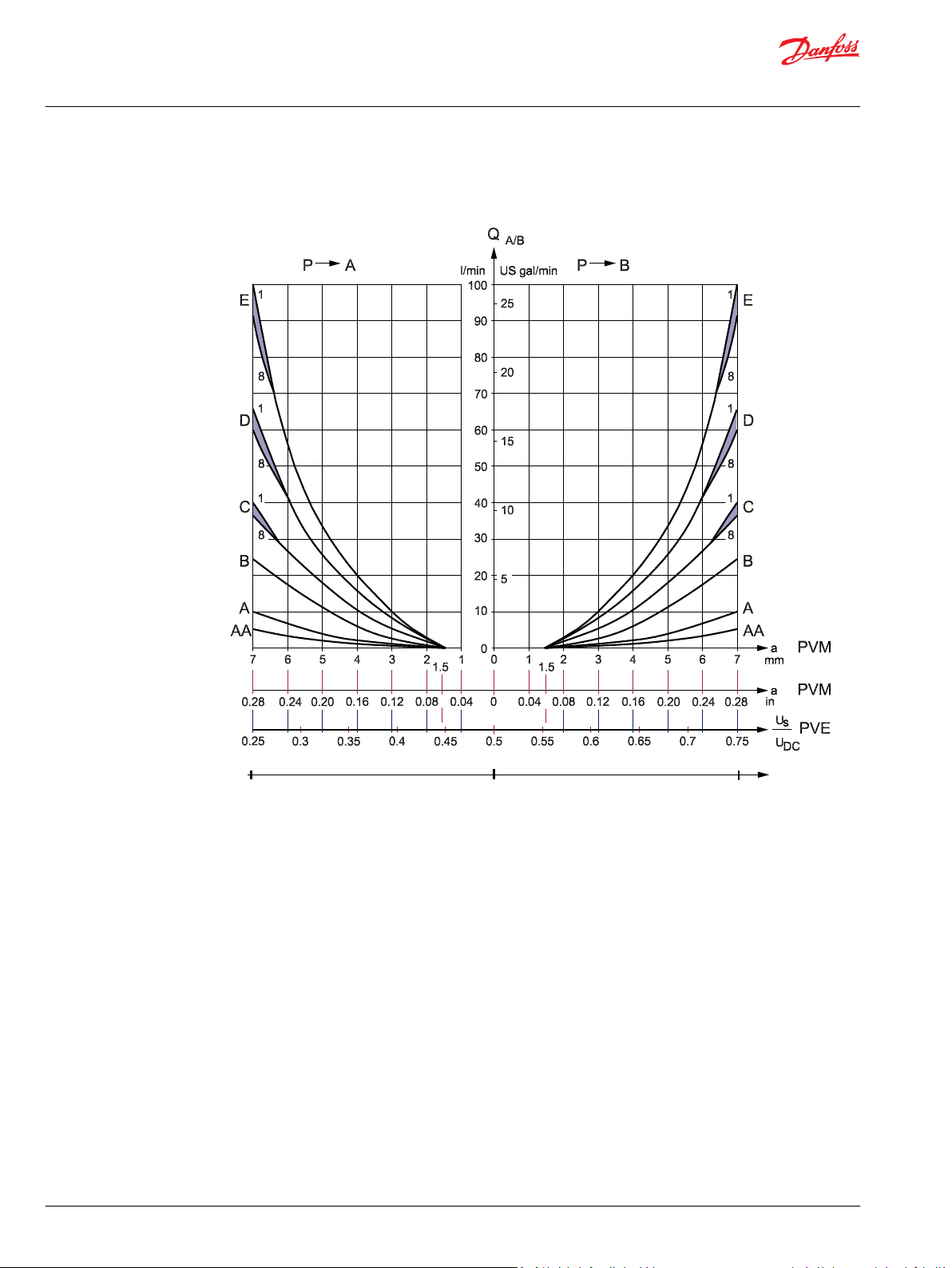

PVE-EX: PVE control by voltage

PVE characteristic – control by voltage

PVE-EX ON/OFF activation

The PVEO has two independent powered sets of solenoids. By powering a set of pins the actuator is

activated. By standard mounted PVE the A set gives full flow on A port and B gives on B port. Both

directions activated at same time will keep the spool in neutral.

10 | © Danfoss | October 2017 BC00000393en-US0102

Page 11

kwa1464035903701

W

kwa1464034339820

Technical Information

Electrohydraulic Actuators PVE-EX

PVE-EX control

PVEO schematic and characteristic

Warning

The PVEO is designed to have UDC=12 V or UDC=24 V.

The solenoids might be activated by voltage down to 6 V.

PVE-EX: PVE hysteresis

The controllability of the PVE depends on the solenoid valve bridge and the electronic capacity of the

module. Hysteresis is a measurement on spool position precision and repeatability. Hysteresis is not a

description of position maintaining.

PVES (left) and PVEH (right) position diagrams

The PVES has an ASIC closed loop circuit and NC-S solenoids.

The PVEH has an ASIC closed loop circuit and NC solenoids.

©

Danfoss | October 2017 BC00000393en-US0102 | 11

Page 12

1 2 3 4 5 6 7

1 2 3 4

Technical Information

Electrohydraulic Actuators PVE-EX

Specifications

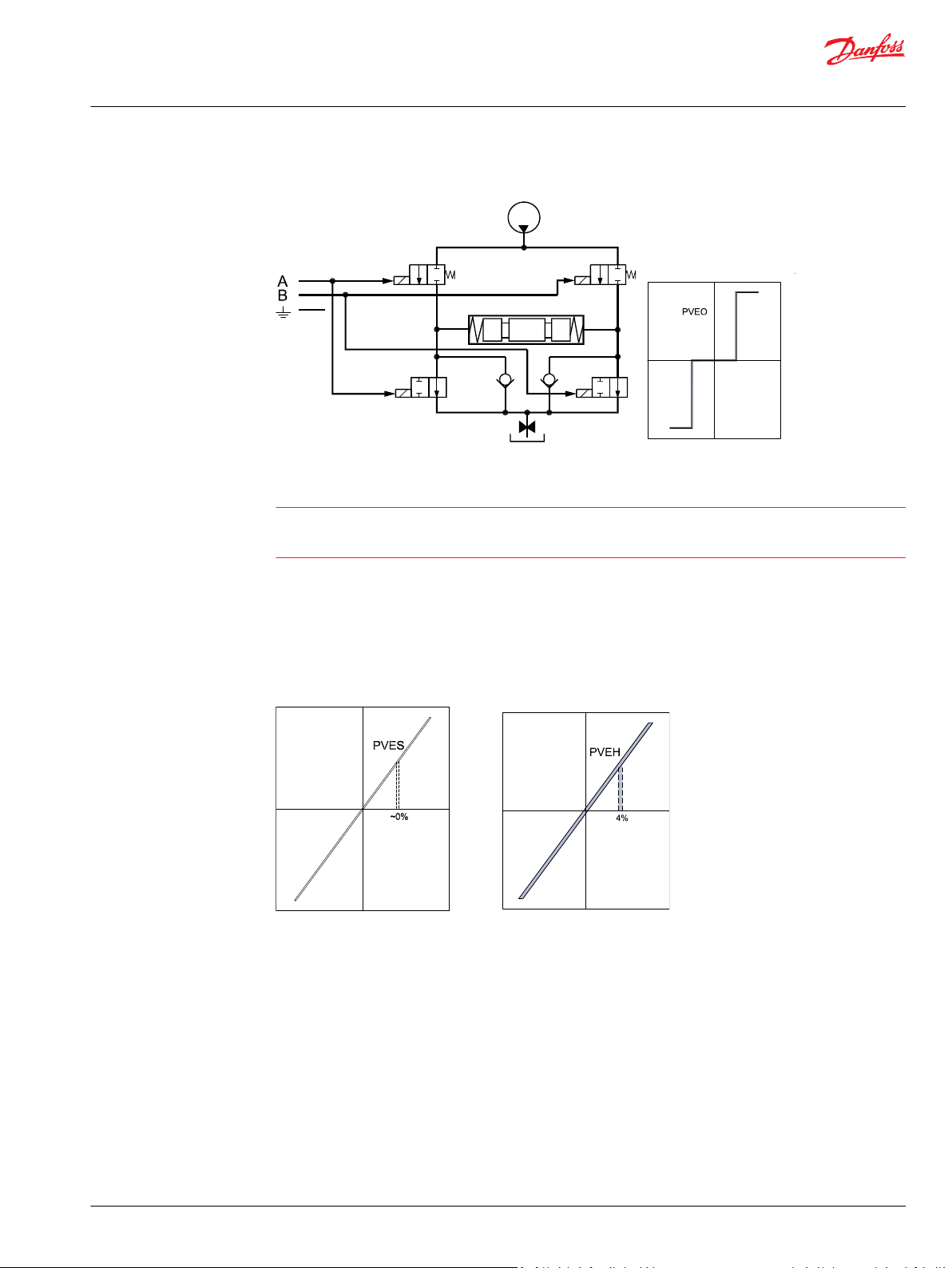

7-pin Layout

7-pin connector

4-Pin layout

4-Pin connector, Group II

Radiometric Control Signal

Versions Pin 1 Pin 2 Pin 3 Pin 4

PVEO-EX-24V, PVEO120-EX-24V UDC-A UDC-B GND —

PVEH/-EX/-U-EX, PVES/-EX/-U-EX, PVES120/-EX/-U-EX, PVEH120-EX U

V

s

bat

GND Error

Radiometric control signal for PVEH/PVES

PIN Function of the pin Versions

1 U

2 V

S

bat2

3 GND Ground

4 Error Error pin (See PVE-EX fault monitoring on page 23)

5 GND DI-A Signal low when spool is stroked to A side (Only for DI versions)

6 GND DI-B Signal low when spool is stroked to B side (Only for DI versions)

7 V

*

Pin 2 and 7 shall be connected together for PVE modules without the DI function.

bat

*

Demand signal

Supply voltage to solenoid valves (can be switched off separately)

Supply voltage to DI versions

PVES-EX

PVEH-EX

PVES120-EX

PVEH120-EX

PVEH-DI-EX

PVEH120-DI-EX

Signal voltage (US) Control

Neutral Q: P → A Q: P → B

US = 0.5 • U

DC

US = (0.5 → 0.25) • U

DC

US = (0.5 → 0.75) • U

DC

Radiometric Fixed Control Signal (0-10 V)

Radiometric control signal for PVEH/PVES

PIN Function of the pin Versions

1 U

2 V

S

bat

3 GND Ground

Demand signal

Supply Voltage

PVEH-U

PVES-U-EX

PVES120-U-EX

4 Error Error pin (See PVE-EX fault monitoring on page 23)

12 | © Danfoss | October 2017 BC00000393en-US0102

Page 13

Technical Information

Electrohydraulic Actuators PVE-EX

Specifications

Signal voltage (US) Control

Neutral Q: P → A Q: P → B

US = 5 V US = 5 V → 2.5 V US = 5 V → 7.5 V

Radiometric Control Signal – On/Off Activation

Radiometric control signal for PVEO versions

PIN Function of the pin Versions

1 UDC(A) Input signal direction A

2 UDC(B) Input signal direction B

3 GND Ground

4 GND Ground

5 DI-A Signal low when spool is stroked to A side (Only for DI

6 DI-B Signal low when spool is stroked to B side (Only for DI

7 V

bat

versions)

versions)

Supply voltage to DI versions

PVEO-EX-12V

PVEO-EX-24V

PVEO-DI-EX-24V

PVEO120-EX-24V

PVEO120-DI-EX-12V

Adjustment/calibration

Signal voltage Control

Signal voltage Neutral Q: P → A Q: P → B

A 0 UDC (A) 0

B 0 0 UDC (B)

The PVE-EX is pre-calibrated from the factory to be inside the dead band of the proportional valve. The

position sensor built into the PVE-EX cannot be adjusted by user. Any biasing of the position has to be

incorporated in the demand signal.

©

Danfoss | October 2017 BC00000393en-US0102 | 13

Page 14

W

Technical Information

Electrohydraulic Actuators PVE-EX

Technical data

Fluid specification

The following data is from typical test results. Mineral based hydraulic oil with a viscosity of 21 mm2/s

[102 SUS] and a temperature of 50 °C [122 °F] was used for the hydraulic system testing.

Warning

The PVE is designed for use with pilot oil supply. Use without oil supply can harm the system.

Intermission is no longer than 5 seconds and not more than once per minute.

Oil consumption

Supply voltage Pilot oil flow per

Without Neutral 0 0 0

With Locked 0.1 0.1 0.1

Oil viscosity, Oil temperature and Pilot pressure

Parameter Minimum Maximum Range

Oil viscosity

Oil temperature

Pilot pressure (relative to T pressure)

Intermittent pressure peaks up to

PVE-EX Function

Actuating 0.7 0.7 0.8

PVEO Versions PVEH Versions PVES Versions

l/min l/min l/min

4 mm2/s

[39 SUS]

-30 ˚C

[-22 ˚F]

10 bar

[145 psi]

– 50 bar [725 psi] –

460 mm2/s

[2128 SUS]

90 ˚C

[194 ˚F]

15 bar

[217 psi]

12 - 75 mm2/s

[65 - 347 SUS]

30 to 60 ˚C

[86 to140 ˚F]

Nominal 13.5 bar

[196 psi]

PVE-EX electrical data

Filtering in the hydraulic system

Required operating cleanliness level (ISO 4406, 1999 version)

Specification PVEO Versions PVEH and PVES Versions

Grade of enclosure EN 60529 IP 66 and IP 69k

Ambient temperature Minimum -40 °C [-40 °F]

Maximum 60 °C [140 °F]

Maximum (submitting) surface temperature, T5 100 °C [212 °F]

Supply voltage Rated 12 / 24 V

Range PVEx-EX-12V 11-16 V

Range PVEx-EX-24V 22-30 V

Maximum ripple 5% 5%

Current consumption at

rated voltage (12/24 VDC)

Power consumption at rated voltage 9 W 7 W

Current via DI 0.1 A 0.1 A

Input impedance in relation 0.5 x U

Fault monitoring Maximum load N/A 60 mA

Typical 0.74 A / 0.37 A 0.57 A / 0.33 A

Minimum 0.55 A / 0.29 A N/A

Maximum 0.82 A / 0.42 A N/A

DC

Reaction time at fault N/A 500 ms

DC

DC

DC

N/A 12 kΩ

18/16/13

11-30 V

N/A

N/A

DC

For more information about PVEO, PVES and PVEH versions please refer to Nameplate description.

14 | © Danfoss | October 2017 BC00000393en-US0102

Page 15

Technical Information

Electrohydraulic Actuators PVE-EX

Technical data

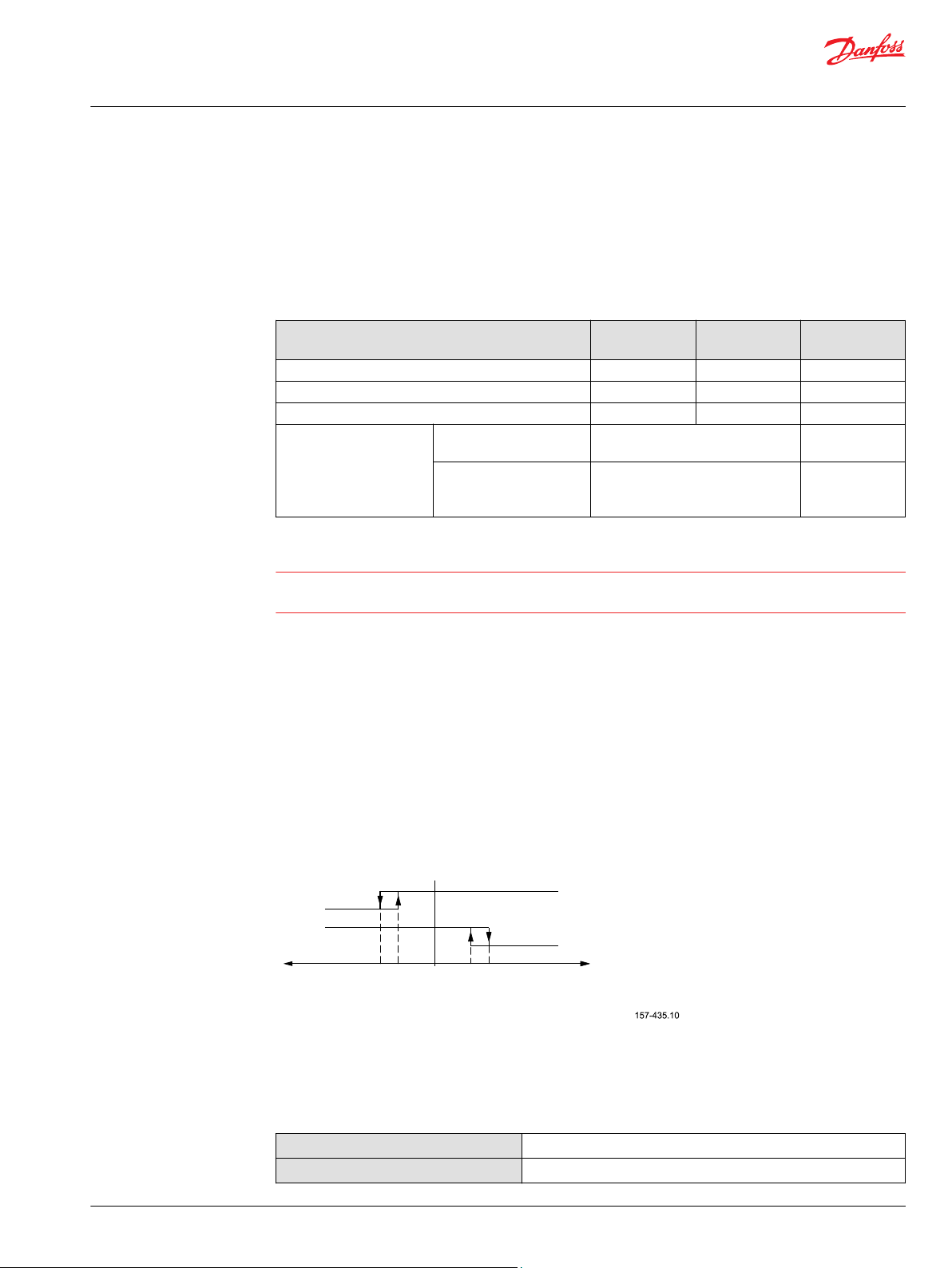

Reaction times

Reaction time for PVES/PVEH versions

Supply voltage Function Minimum Rated Maximum

Disconnected by means of neutral switch From neutral position to max. spool travel 120 ms 150 ms 230 ms

From max. spool travel to neutral position 65 ms 90 ms 175 ms

Constant voltage From neutral position to max. spool travel 50 ms 120 ms 200 ms

From max. spool travel to neutral position 65 ms 90 ms 100 ms

Reaction time for PVEO versions

Supply voltage Function Minimum Rated Maximum

Power on From neutral position to max. spool travel

Power off From max. spool travel to neutral position

Adjustment/calibration

The PVE-EX is pre-calibrated from the factory to be inside the dead band of the proportional valve. The

position sensor built into the PVE-EX cannot be adjusted by user. Any biasing of the position has to be

incorporated in the demand signal.

120 ms 180 ms 235 ms

©

Danfoss | October 2017 BC00000393en-US0102 | 15

Page 16

47.0 [1.85]

106.0 [4.17]

88.0 [3.35]

85.0 [3.35]

P006 084

115.0 [3.35]

158.0 [6.18]

V310 461

9 ±2N•m

4

W

Technical Information

Electrohydraulic Actuators PVE-EX

Installation

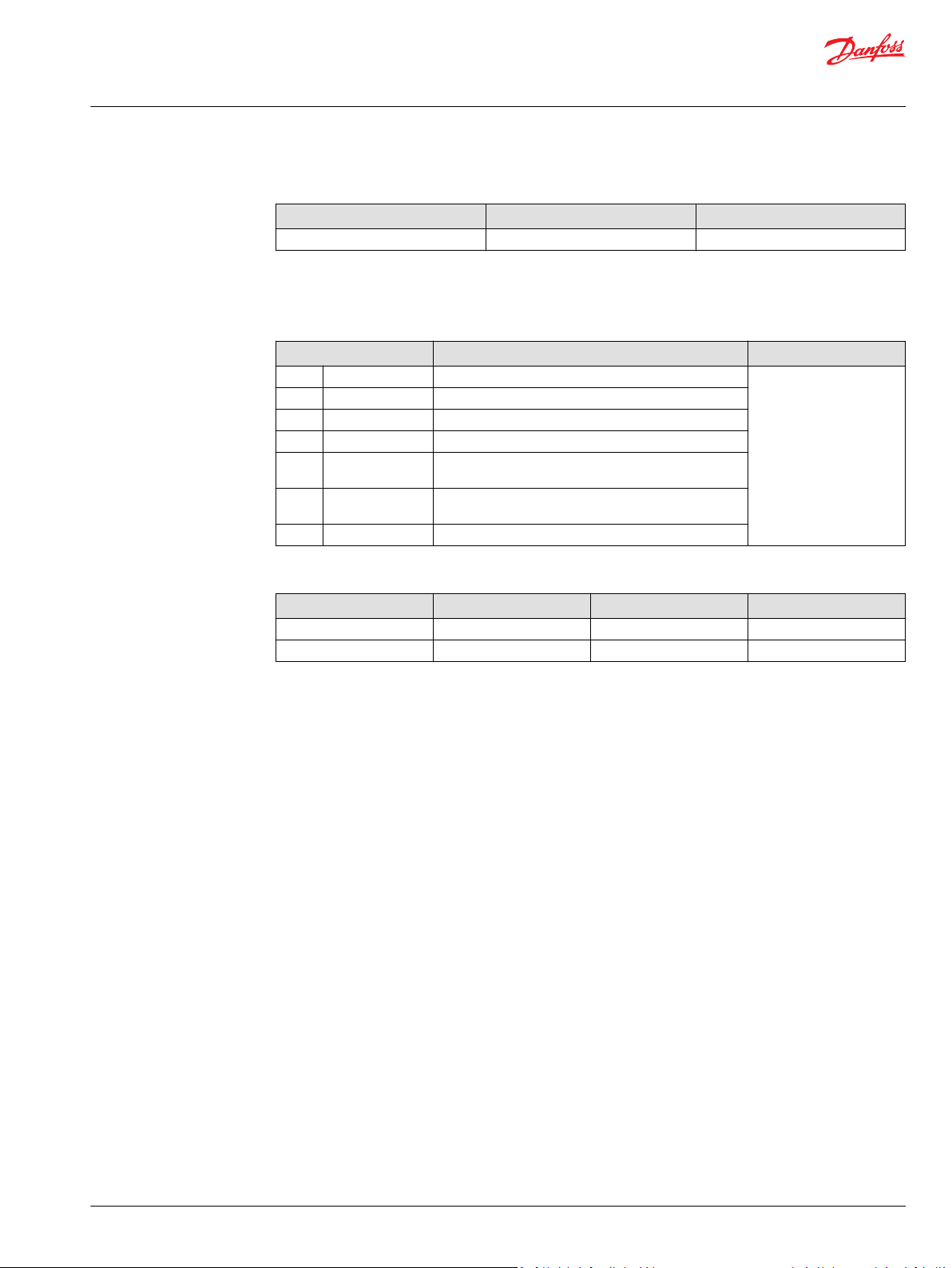

PVE-EX Dimensions

PVE-EX dimensions, mm [in]

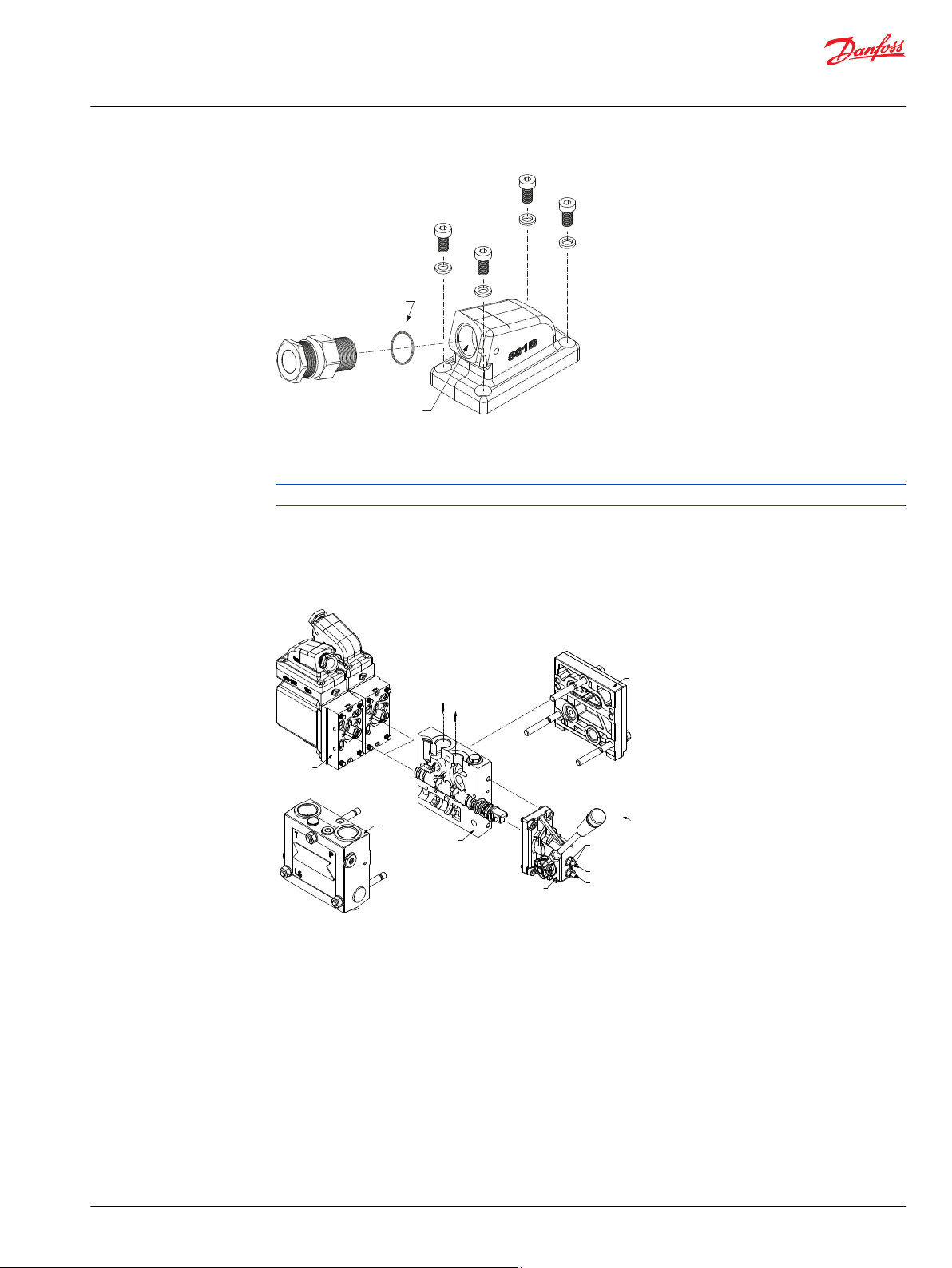

Mounting of PVE-EX

1. Protect the LVDT pin (PVEH-EX and PVES-EX modules)

2. Ensure all O-rings are mounted and properly aligned in the grooves before mounting the PVE-EX to

the PVG valve.

3. The four screws (M6x40 mm) must be tightened to 9 ± 2 N•m [6.63 ± 1.48 lbt•ft]

Warning

The installation must be performed as intended in order to have a safe system and a proper functional

application. In a case of damage to enclosure, plug or cable, the PVE-EX module must be replaced. Please

refer to the information in this manual for an assistance, or consult with a professional.

16 | © Danfoss | October 2017 BC00000393en-US0102

Page 17

kwa1464204172786

Technical Information

Electrohydraulic Actuators PVE-EX

Installation

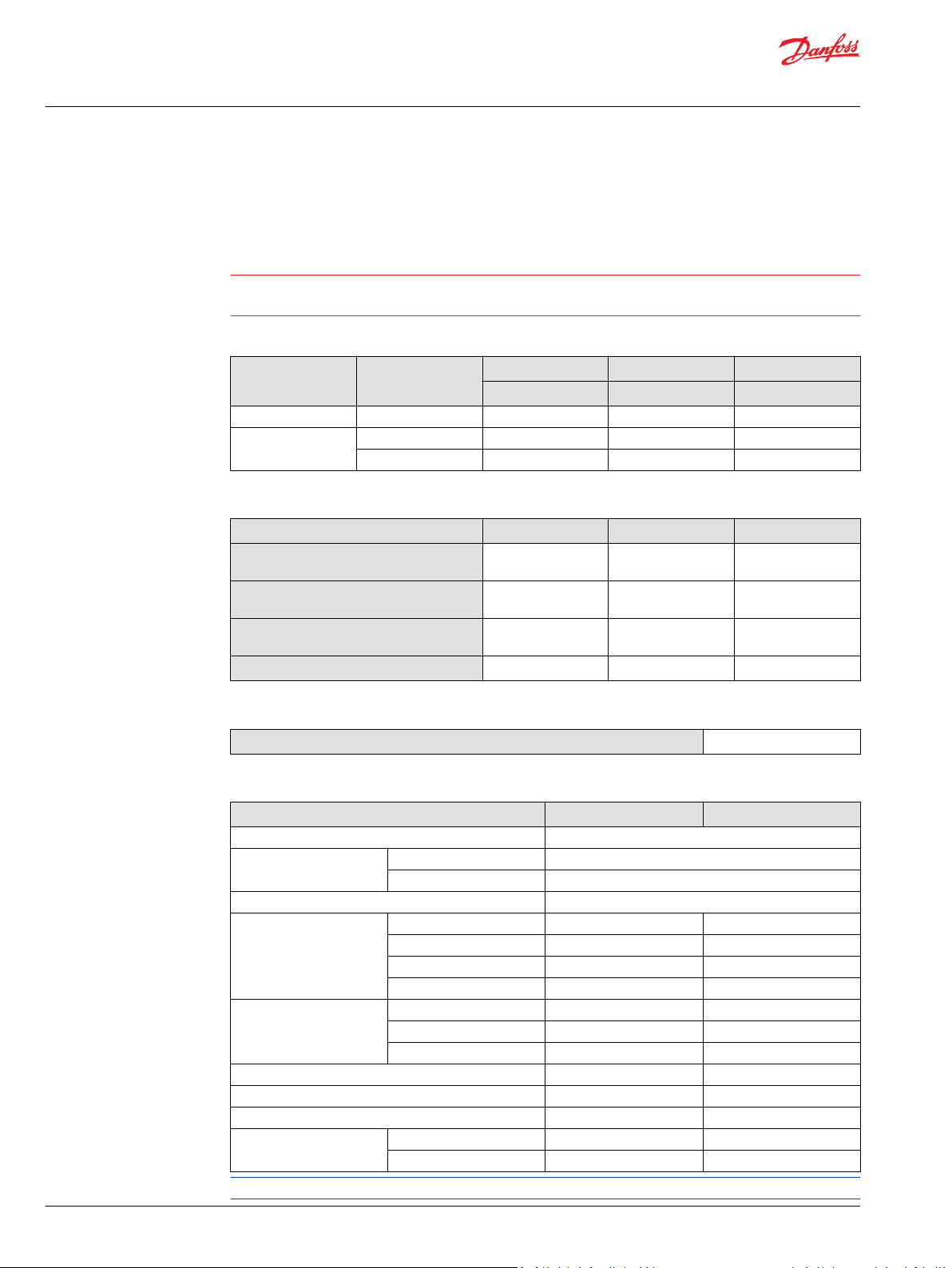

Cable

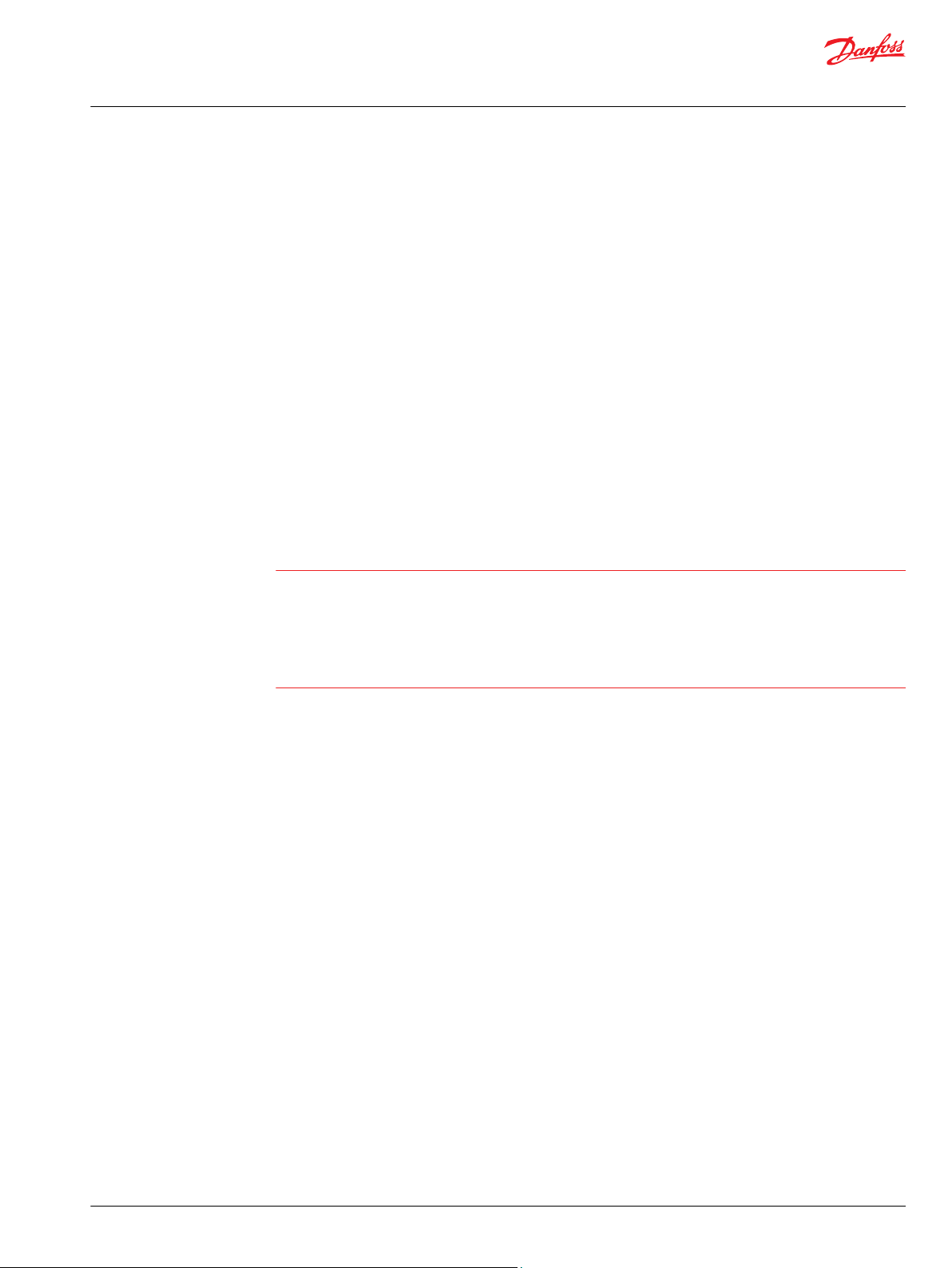

Mounting of cable, Group I (left) and Group II (right)

Use screws made from stainless steel grade A4 or stronger (enclosed).

Mounting of Cable

The PVE-EX is equipped with a top part that holds the cable gland for cable installation.

1. Remove the shield of an appropriate length to expose the wires.

If shield shall be connected to the earthing terminal, make sure to have shield enough to crimp into

the cable shoe and attach properly to the chassis.

Cable material must be according to the specification.

2. Strip the wires such that a suitable length of cooper is exposed.

3. Insert wires and cable through the gland and grommet.

4. Insert wires into screw terminals and tighten the screws.

5. Pull the cable back to the position where the cable jacket is still going through the grommet.

6. Immerse the terminal compartment and mate the male and female connector.

7. Ensure that the O-ring is properly seated in its groove and that excess wires are not trapped between

the two elements.

8. Tighten the screws to the specified torque 6 ± 1 N•m.

9. Tighten the gland to the specified torque in which the cable is locked correctly.

Use screws made from stainless steel grade A4 or stronger (enclosed).

©

Danfoss | October 2017 BC00000393en-US0102 | 17

Page 18

kwa1464202599582

W

Technical Information

Electrohydraulic Actuators PVE-EX

Installation

Cable Gland

The PVE-EX is required to be installed with a cable specified to the surrounding conditions and to the

given diameter of the cable gland. There are two options available for cable glands:

•

Supplied built-in cable gland (certified with the product)

•

Pre-certified standard cable gland (M20 x 1.5 mm threaded entry and 20 x 1.5 mm O-ring).

Supplied Built-in Cable Gland

The PVE-EX has a built in cable gland for cable installation. The cable gland and grommet ensures that

the internal components are not exposed to the outside. Furthermore, the cable gland arrangement has

to retain any flame and pressure that can occur inside the PVE-EX.

1. Choose the grommets delivered with PVE-EX for different cable diameters. (see the table below)

The cable gland needs to meet the diameter of the cable and to the PVE-EX.

Grommet (inner dia)

Cable diameter span

Thread type, size

Temperature span

Tightening torque

2. Screw the cable gland at least 5 full threads.

3. Tighten the cable gland to the specified torque.

4. Install the safety wire (not included) between the cable gland and the top gland.

9.9 to 10.5 mm

[0.4 to 0.42 in]

M20, 1.5 mm [0.06 in]

-40 °C to +76 °C [-40 °F to +168.8 °F]

20 N•m

12.7 to 13.5 mm

[0.51 to 0.54 in]

PVE-EX Pre-certified Cable Gland

For cable diameter specification, refer to the relevant instruction from the supplier of the pre-certified

gland. In order to comply with the product certification the pre-certified cable gland must be marked

with the following markings:

Marking EU IEC

Group I

Group II

I M2 Ex I Mb (-40° C ≤ ta ≤ +80° C) [-40° F to +176° F]

II 2G Ex IIB Gb (-40° C ≤ ta ≤ +80° C) [-40° F to +176° F]

Warning

Pre-certified cable gland must have thread: M20 x 1.5 mm and must be sealed with O-ring 20 x 1.5 mm at

the threaded entry.

18 | © Danfoss | October 2017 BC00000393en-US0102

Page 19

M20 × 1.5 mm

20 × 1.5 mm

kwa1464203083245

Q max: P → B

Q max: P → A

PVS

PVB

PVP

PVE-EX

V310474.A

PVM

7-9 N•m

[61-79 lbf•in]

P → A

B

A

Technical Information

Electrohydraulic Actuators PVE-EX

Installation

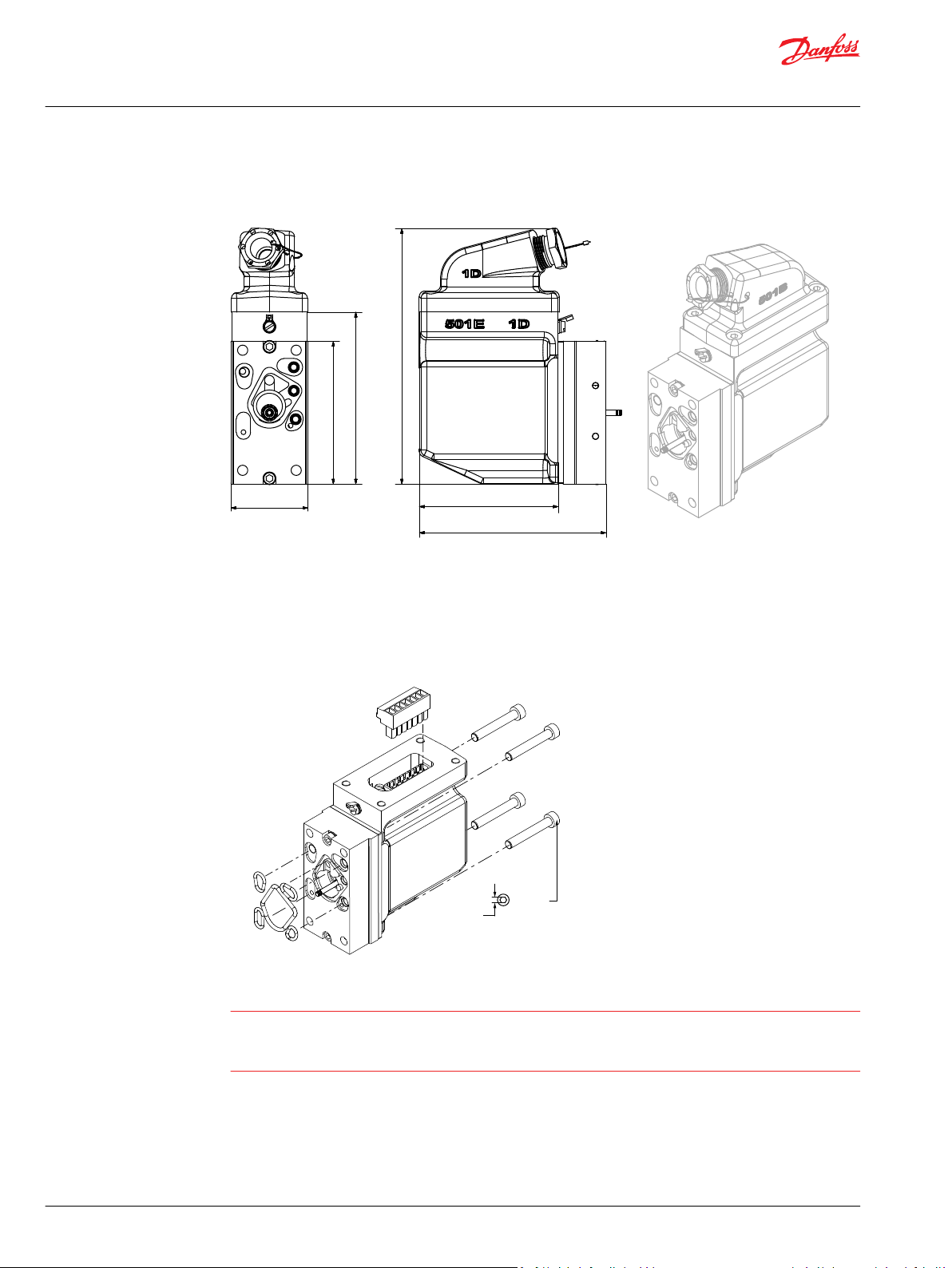

Mounting of PVG

For mounting information regarding PVG products, see Literature reference.

Mounting options and guidelines

The PVE-EX can be installed as either standard mount or optional mount.

Standard assembly

©

Danfoss | October 2017 BC00000393en-US0102 | 19

Page 20

Q max: P → B

Q max: P → A

PVS

PVB

PVP

PVE-EX

V310465.A

PVM

7-9 N•m

[61-79 lbf•in]

P → A

B

A

kwa1464295111132

Technical Information

Electrohydraulic Actuators PVE-EX

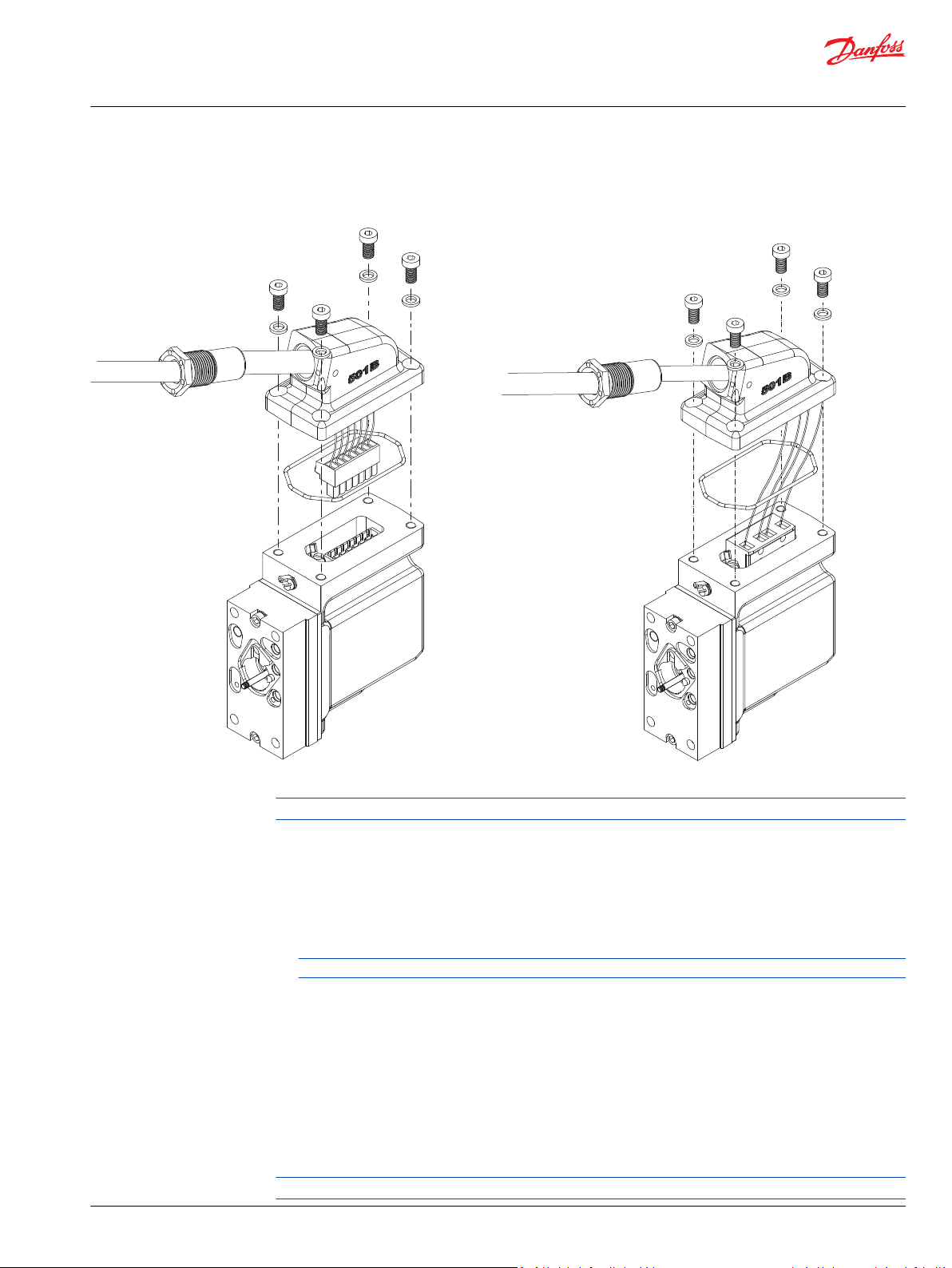

Installation

Optional assembly

Direction of cable exit

The design of the PVE-EX enables the customer to choose if the cable will exit towards or away from the

PVG group.

Cable exits towards PVG (left); Cable exits away from PVG (right)

20 | © Danfoss | October 2017 BC00000393en-US0102

Page 21

W

Technical Information

Electrohydraulic Actuators PVE-EX

Safety and monitoring

Safety in application

All types of control valves (incl. proportional valves) can fail, thus the necessary protection against the

serious consequences of function failure should always be built into the system. For each application an

assessment should be made for the consequences of pressure failure and uncontrolled or blocked

movements. To determine the degree of protection that is required to be built into the application,

system tools such an FMEA (Failure Mode and Effect Analysis) and Hazard and Risk Analysis can be used.

FMEA – IEC EN 61508

FMEA (Failure Mode and Effect Analysis) is a tool used for analyzing potential risks. This analytical

technique is utilized to define, identify, and prioritize the elimination or reduction of known and/or

potential failures from a given system before it is released for production. Please refer to the standard IEC

FMEA 61508.

Hazard and risk analysis ISO 12100-1/14121

This analysis is a tool used in new applications as it will indicate whether there are special safety

considerations to be met according to the machine directives EN 13849. Dependent on the determined

levels conformity this analysis will detirmine if any extra requirements for the product design,

development process, production process or maintenance, example the complete product life cycle.

Safety guidelines

Warning

All brands and all types of directional control or proportional valves, which are used in many different

operation conditions and applications, can fail and cause serious damage.

Analyze all aspects of the application. The machine builder/system integrator alone is responsible for

making the final selection of the products and assuring that all performance, safety and warning

requirements of the application are met. The process of choosing the control system and safety levels is

governed by the machine directives EN 13849 (Safety related requirements for control systems).

•

When failure, damage or defect occurs, the PVE-EX has to be replaced.

•

A failing PVE-EX must under no circumstance be repaired.

•

No modifications, which could damage the explosion-safety and protection, are allowed to the PVEEX, the cable gland, or on the cable.

•

Demounting a PVE-EX should be done in an atmosphere with no potenential for explosions.

•

The machine and system approval has to be issued before using the PVE-EX in explosive-areas.

•

The manufacturer has the application responsibility and is solely responsible for the safety of the

system.

•

Deviations from recommended torque when mounting parts can harm performance and the PVE-EX.

•

Do not adjust, bend or damage the position transducer (LVDT) as this will influence the safety and

performance.

•

When replacing the PVE-EX, the electrical and the hydraulic systems must be turned off and the oil

pressure released.

•

Hydraulic oil can cause both environmental damage and personal injuries.

•

Module replacement can introduce contamination and errors to the system. It is important to keep

the work area clean and components should be handled with care.

©

Danfoss | October 2017 BC00000393en-US0102 | 21

Page 22

W

Technical Information

Electrohydraulic Actuators PVE-EX

Safety and monitoring

PVE-EX fault monitoring and reaction

PVE-EX is available with fault monitoring and spool direction indication.

The fault monitoring system is available in two versions:

Active fault monitoring provides a warning signal and deactivates the solenoid valves. A reboot of the

•

PVE is required to reactivate.

Passive fault monitoring provides a warning signal only. A reboot is not required.

•

Both active and passive fault monitoring systems are triggered by the same three main events:

•

Control signal monitoring

•

Transducer supervision

•

Supervision of spool position

Control signal monitoring

The Control signal voltage (US) is continuously monitored. The permissible range is between 15% and

85% of the supply voltage. Outside this range the PVE-EX will switch into an error state.

Transducer supervision

The internal LVDT wires are monitored. If the signals are interrupted or short-circuited, the PVE-EX will

switch into an error state.

Supervision of spool position

The actual position must always correspond to the demanded position (US).

If the actual spool position is further out from neutral than the demanded spool position >12% or in

opposite direction, the PVE will switch into an error state.

With neutral/blocked setpoint the tolerance is +- 0.5 mm relative the calibrated neutral position. Spool

position closer to neutral and in same direction will not cause an error.

Active fault reaction is activated when the failure has been active for 500 ms

•

The solenoid valve bridge is disabled and the PVBS is released to spring control

‒

The error output pin goes high

‒

The state is memorized and continues until PVE reboot

‒

Passive fault reaction is activated when the failure has been active for 500 ms

•

The solenoid valve bridge is NOT disabled and the PVBS is NOT released

‒

The error output pin goes high (for PVE with direction indication both DI pins goes low by fault)

‒

The state is active for minimum 100 ms and is reset when error disappears

‒

To avoid the electronics in undefined state a general supervision of power supply (UDC) an internal clock

frequency is implemented. This function applies to PVEH and PVES independently of fault monitoring

version and will not activate fault monitoring.

Warning

Error pins from more PVEs may not be interconnected. Not activated error pins are connected to ground

and will disable any active signal. Error pins are signal pins and can only supply very limited power

consumption.

The solenoid valves are disabled when

•

22 | © Danfoss | October 2017 BC00000393en-US0102

Page 23

C

DI-A low

DI-B high

DI-A high

DI-B low

Spool position ‘x’

mm [in]

B-port

PVBS away from PVE

A-port

PVBS towards PVE

0.4 0.8-0.8 -0.4 0

Technical Information

Electrohydraulic Actuators PVE-EX

Safety and monitoring

the supply voltage exceeds 36 V

‒

the supply voltage falls below 8.5 V

‒

the internal clock frequency fails

‒

PVE-EX fault monitoring

Fault monitoring overview

PVE type PVEH/PVES-U

Fault monitoring Active Passive No

Delay before error out 500 ms 250 ms —

Closed loop deactivated memory (reset needed) Yes No —

Error mode

versions

No fault Error output status – Low

Input signal fault

Transducer (LVDT)

Close loop fault

Fault output on PVE: < 2 V

Error output status – High

Fault output on PVE: U

PVES versions PVEO versions

DC

—

—

The installation must be performed as intended in order to have a safe system.

Please refer to the information in this manual for an assistance, or consult with a professional.

Direction indication feedback (-DI)

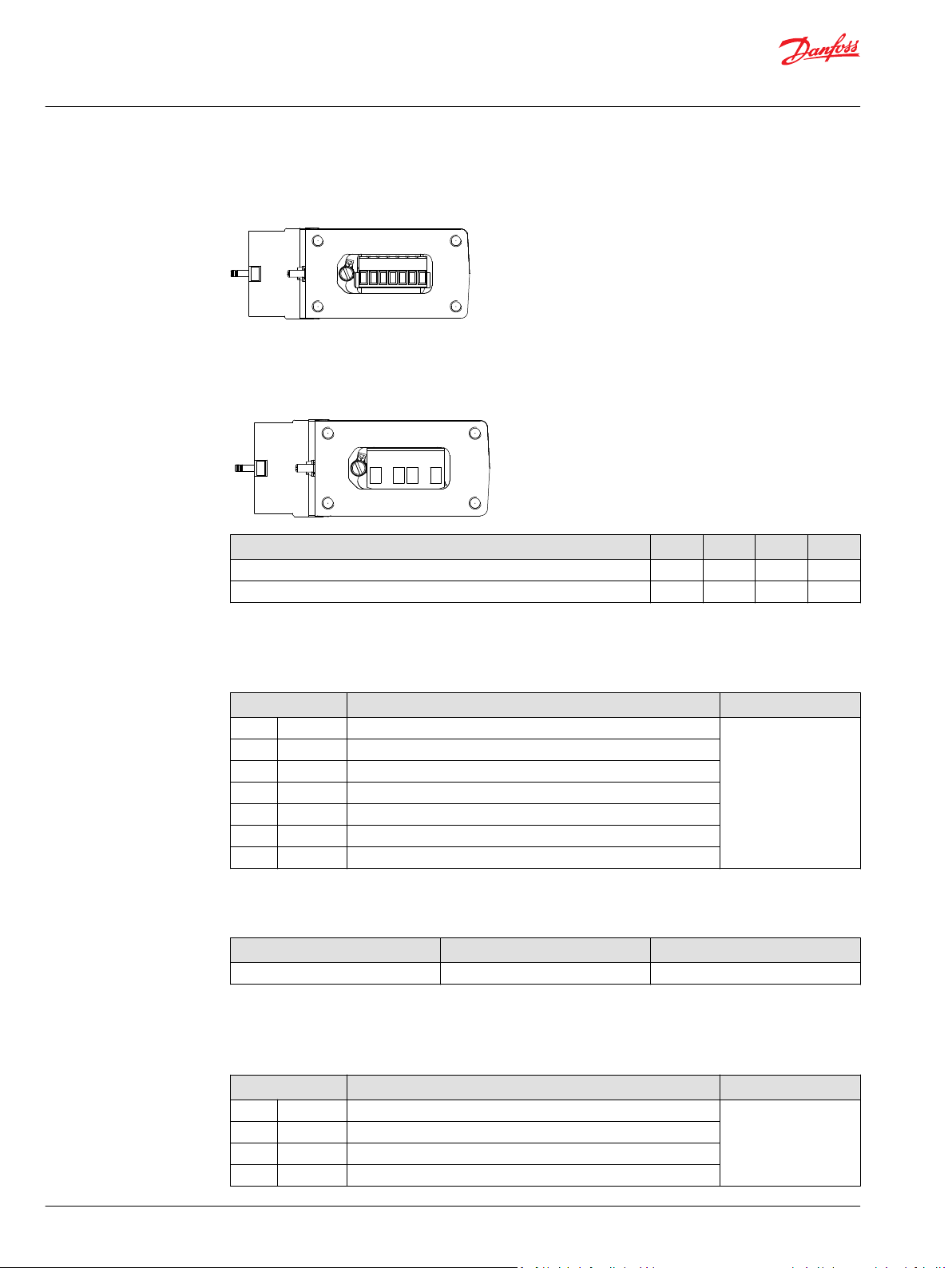

PVE with build in indication for spool movement direction are available.

The PVE–DI has dual power supply. U

back. The PVE does not work without U

signal fault monitoring is disabled if U

The DI has two direction feeedback signals with output high (close to UDC) when the spool is in neutral

position. If the spool moves out of neutral position, the direction signal switches to low (< 0.2 V). One of

the signals goes low by spool ~0.8 mm out of neutral and high by spool within 0,4 mm out of neutral.

Both direction indication signals go low when the error indicator goes high.

Direction indication feedback

Caution

only supplies solenoid valves. U

DC1

. DI-A and DI-B are relative standard mounting. The input

DC2

is disabled. DI-A and DI-B are relative standard mounting.

DC1

supplies electronics and feed

DC2

As shown in the figure, both “DI-A” and “DI-B” signals are “High” when the spool is in neutral position.

When the spool is moving in the A direction, the “DI-A” signal goes “Low” and the “DI-B” signal stays

“High”. The reverse is true when the spool is moved in the B direction.

Values for Direction Indicators (-DI)

Transition from high to low

Transition from low to high

©

Danfoss | October 2017 BC00000393en-US0102 | 23

0.8 ± 1 mm [0.031 in]

0.4 ± 1 mm [0.015 in]

Page 24

Technical Information

Electrohydraulic Actuators PVE-EX

Safety and monitoring

Values for Direction Indicators (-DI) (continued)

Transition to low both pins

Maximum load of DI-A, DI-B

Voltage DI high by load 20 mA

Voltage DI high by load 50 mA

Voltage DI low

error pin goes high

50 mA

> UDC – 1.5 V

> UDC – 2.0 V

< 0.2 V

24 | © Danfoss | October 2017 BC00000393en-US0102

Page 25

1

2

Technical Information

Electrohydraulic Actuators PVE-EX

Internal and external earth-connection

Earthing terminals

4-pin earthing terminal

1. Internal earthing terminals

2. External earthing terminals

Internal earth-connection

Internal earthing terminal enables a shield to be connected to chassis.

1. Remove the jacket from the shield at a length that allows mounting the cable shoe into the threaded

hole next to the connector.

2. Crimp or solder the shield into the cable shoe.

3. Attach the cable shoe to the chassis via the M4 screw and the self-locking ring.

4. Tighten the screws to the specified torque 5 ± 2 N•m.

©

Danfoss | October 2017 BC00000393en-US0102 | 25

Page 26

Technical Information

Electrohydraulic Actuators PVE-EX

Internal and external earth-connection

External earth-connection

External earthing terminal enables a earth wire to be connected to the PVE-EX.

1. Crimp or solder the earth wire into the cable shoe.

2. Attach the cable shoe to the chassis via the M4 screw and the self-locking ring.

3. Tighten the screws to the specified torque 5 ± 2 N•m.

26 | © Danfoss | October 2017 BC00000393en-US0102

Page 27

W

W

W

Technical Information

Electrohydraulic Actuators PVE-EX

Maintenance, service, troubleshooting

PVE-EX installation, start-up, and operation

The PVE-EX is primarily maintenance free, except for the flame paths that need to be inspected regularly

according to the code of protection Ex db.

The inspection intervals and definitions are to be seen in the standard IEC 60079-17 and the

corresponding Inspection schedules-table. Operators must under no circumstance try to repair or open a

PVE-EX. A failing or damaged PVE-EX is to be replaced.

Warning

The installation must be performed as intended in order to have a safe system and a proper functional

application. In a case of damage to enclosure, plug or cable, the PVE-EX module must be replaced. Please

refer to the information in this manual for an assistance, or consult with a professional.

Warning

All national safety regulations must be fulfilled in connection with installation, start-up and operation of

Danfoss PVE-EX electrical actuation's. Furthermore, the requirements of the Declaration of Conformity

and national regulations for installations in potentially explosive atmospheres applies as well.

Disregarding such regulations involves a risk of serious personal injury or extensive material damage.

Warning

Work in connection with the electrical actuations must be performed only by professionals and qualified

persons.

©

Danfoss | October 2017 BC00000393en-US0102 | 27

Page 28

W

W

W

Technical Information

Electrohydraulic Actuators PVE-EX

Warnings

PVE-EX warnings

Warning

All brands and all types of directional control or proportional valves, which are used in many different

operation conditions and applications, can fail and cause serious damage.

Analyze all aspects of the application. The machine builder/system integrator alone is responsible for

making the final selection of the products and assuring that all performance, safety and warning

requirements of the application are met.

The process of choosing the control system and safety levels is governed by the machine directives EN

13849 (Safety related requirements for control systems).

Warning

The installation must be performed as intended in order to have a safe system and a proper functional

application. In a case of damage to enclosure, plug or cable, the PVE-EX module must be replaced. Please

refer to the information in this manual for an assistance, or consult with a professional.

Warning

•

Not applying to the Operational Conditions can compromise safety.

•

A PVG with PVE-EX can only perform according to description if conditions in this Technical

Information are met.

•

In particularly exposed applications, protection in the form of a shield is recommended.

•

When the PVE-EX is in fault mode the quality of performance and validity of feedback is limited

depending on the fault type.

•

Error pins from more PVE-EX’s may not be connected. Inactive error pins are connected to ground

and will disable any active signal. Error pins are signal pins and can only supply very limited power

consumption.

•

After replacement of modules or cables wiring quality must be verified by a performance test.

•

By actuation at voltage below nominal PVG will have reduced performance.

•

The PVE-EX is not designed for use with voltage outside nominal.

•

Obstacles for the Pilot oil can have direct influence on spool control.

•

Reduced pilot oil pressure will limit spool control.

•

Too high pilot oil pressure can harm the PVE-EX.

28 | © Danfoss | October 2017 BC00000393en-US0102

Page 29

Technical Information

Electrohydraulic Actuators PVE-EX

Code numbers

PVE-EX Ex part numbers

PVE-EX Ex db types with part numbers, Group I and Group II

Type Part No. Type Part No.

PVEO-EX-12V 11156462 PVEO-EX-24V 11156467

PVEO-EX-24V 11123165 PVEH-EX 11156463

PVEO-DI-EX-24V 11156461 PVES-EX 11156464

PVEH-DI-EX 11127696 PVEH-U-EX 11156465

PVEH120-DI-EX 11166357 PVES-U-EX 11156466

PVEO120-DI-EX-12V 11170401 PVES120-U-EX 11156568

Group I Group II

PVEO120-EX-24V 11156468

PVES120-EX 11156567

PVEH120-EX 11161000

©

Danfoss | October 2017 BC00000393en-US0102 | 29

Page 30

Technical Information

Electrohydraulic Actuators PVE-EX

Declaration of confromity

EC-Declaration of Conformity

30 | © Danfoss | October 2017 BC00000393en-US0102

Page 31

Technical Information

Electrohydraulic Actuators PVE-EX

Declaration of confromity

©

Danfoss | October 2017 BC00000393en-US0102 | 31

Page 32

Technical Information

Electrohydraulic Actuators PVE-EX

Certificates

EU-Type Examination Certificate

32 | © Danfoss | October 2017 BC00000393en-US0102

Page 33

Technical Information

Electrohydraulic Actuators PVE-EX

Certificates

©

Danfoss | October 2017 BC00000393en-US0102 | 33

Page 34

Technical Information

Electrohydraulic Actuators PVE-EX

Certificates

34 | © Danfoss | October 2017 BC00000393en-US0102

Page 35

Technical Information

Electrohydraulic Actuators PVE-EX

Certificates

IECEx Certificate of Conformity

©

Danfoss | October 2017 BC00000393en-US0102 | 35

Page 36

Technical Information

Electrohydraulic Actuators PVE-EX

Certificates

36 | © Danfoss | October 2017 BC00000393en-US0102

Page 37

Technical Information

Electrohydraulic Actuators PVE-EX

Certificates

©

Danfoss | October 2017 BC00000393en-US0102 | 37

Page 38

Technical Information

Electrohydraulic Actuators PVE-EX

Certificates

38 | © Danfoss | October 2017 BC00000393en-US0102

Page 39

Technical Information

Electrohydraulic Actuators PVE-EX

Certificates

Safety certificate J2014084

©

Danfoss | October 2017 BC00000393en-US0102 | 39

Page 40

Technical Information

Electrohydraulic Actuators PVE-EX

Certificates

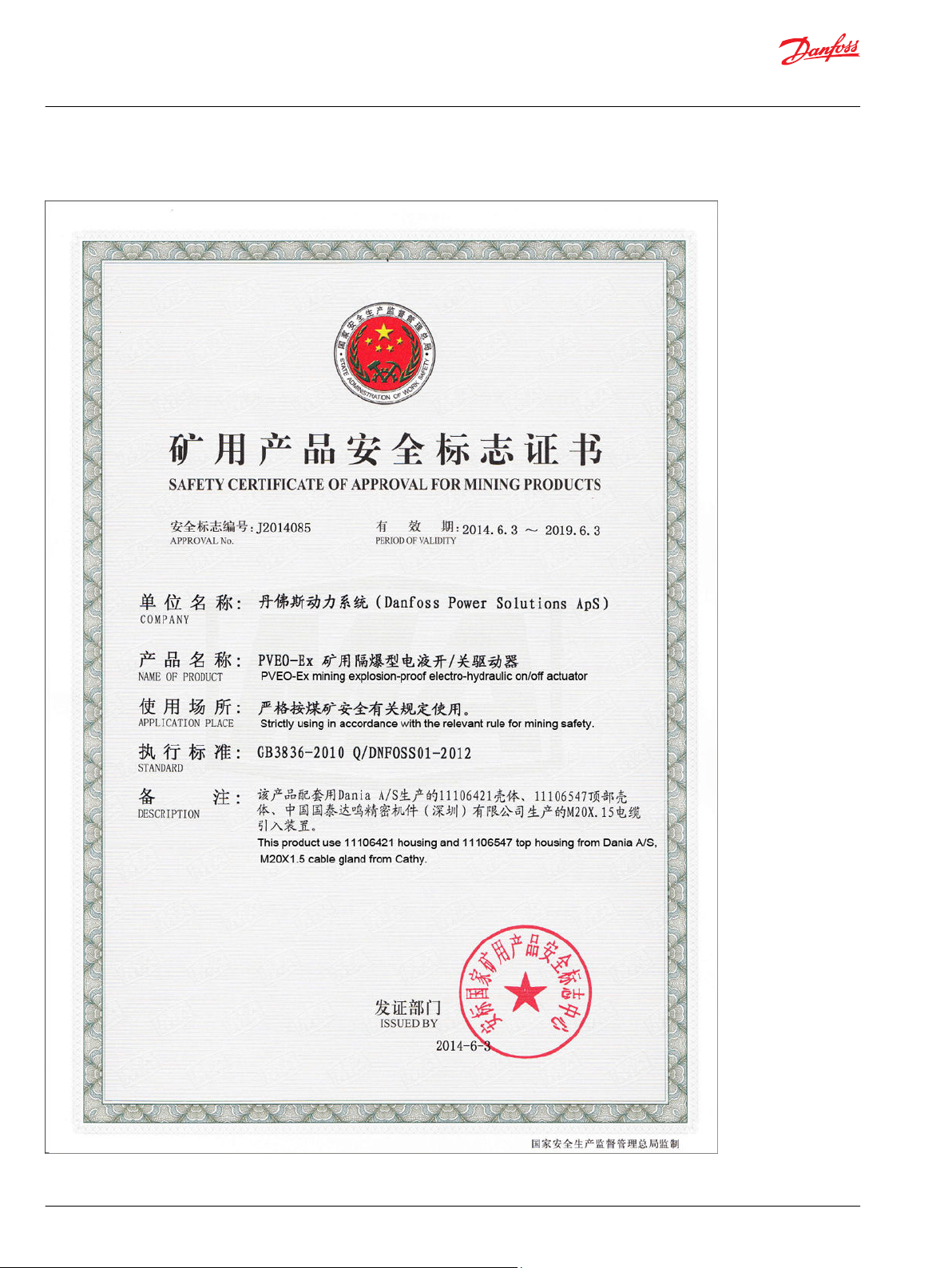

Safety certificate J2014085

40 | © Danfoss | October 2017 BC00000393en-US0102

Page 41

Technical Information

Electrohydraulic Actuators PVE-EX

©

Danfoss | October 2017 BC00000393en-US0102 | 41

Page 42

Technical Information

Electrohydraulic Actuators PVE-EX

42 | © Danfoss | October 2017 BC00000393en-US0102

Page 43

Technical Information

Electrohydraulic Actuators PVE-EX

©

Danfoss | October 2017 BC00000393en-US0102 | 43

Page 44

Danfoss

Power Solutions GmbH & Co. OHG

Krokamp 35

D-24539 Neumünster, Germany

Phone: +49 4321 871 0

Danfoss

Power Solutions ApS

Nordborgvej 81

DK-6430 Nordborg, Denmark

Phone: +45 7488 2222

Danfoss

Power Solutions (US) Company

2800 East 13th Street

Ames, IA 50010, USA

Phone: +1 515 239 6000

Danfoss

Power Solutions Trading

(Shanghai) Co., Ltd.

Building #22, No. 1000 Jin Hai Rd

Jin Qiao, Pudong New District

Shanghai, China 201206

Phone: +86 21 3418 5200

Products we offer:

Comatrol

www.comatrol.com

Turolla

www.turollaocg.com

Hydro-Gear

www.hydro-gear.com

Daikin-Sauer-Danfoss

www.daikin-sauer-danfoss.com

Bent Axis Motors

•

Closed Circuit Axial Piston

•

Pumps and Motors

Displays

•

Electrohydraulic Power

•

Steering

Electrohydraulics

•

Hydraulic Power Steering

•

Integrated Systems

•

Joysticks and Control

•

Handles

Microcontrollers and

•

Software

Open Circuit Axial Piston

•

Pumps

Orbital Motors

•

PLUS+1® GUIDE

•

Proportional Valves

•

Sensors

•

Steering

•

Transit Mixer Drives

•

Danfoss Power Solutions is a global manufacturer and supplier of high-quality hydraulic and

electronic components. We specialize in providing state-of-the-art technology and solutions

that excel in the harsh operating conditions of the mobile off-highway market. Building on

our extensive applications expertise, we work closely with our customers to ensure

exceptional performance for a broad range of off-highway vehicles.

We help OEMs around the world speed up system development, reduce costs and bring

vehicles to market faster.

Danfoss – Your Strongest Partner in Mobile Hydraulics.

Go to www.powersolutions.danfoss.com for further product information.

Wherever off-highway vehicles are at work, so is Danfoss. We offer expert worldwide support

for our customers, ensuring the best possible solutions for outstanding performance. And

with an extensive network of Global Service Partners, we also provide comprehensive global

service for all of our components.

Please contact the Danfoss Power Solution representative nearest you.

Local address:

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

already on order provided that such alterations can be made without changes being necessary in specifications already agreed.

All trademarks in this material are property of the respective companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

©

Danfoss | October 2017 BC00000393en-US0102

Loading...

Loading...