Page 1

Technical Information

Electrohydraulic Actuators

PVED-CX Series 4

powersolutions.danfoss.com

Page 2

Technical Information

PVED-CX, Series 4 Electrohydraulic Actuator

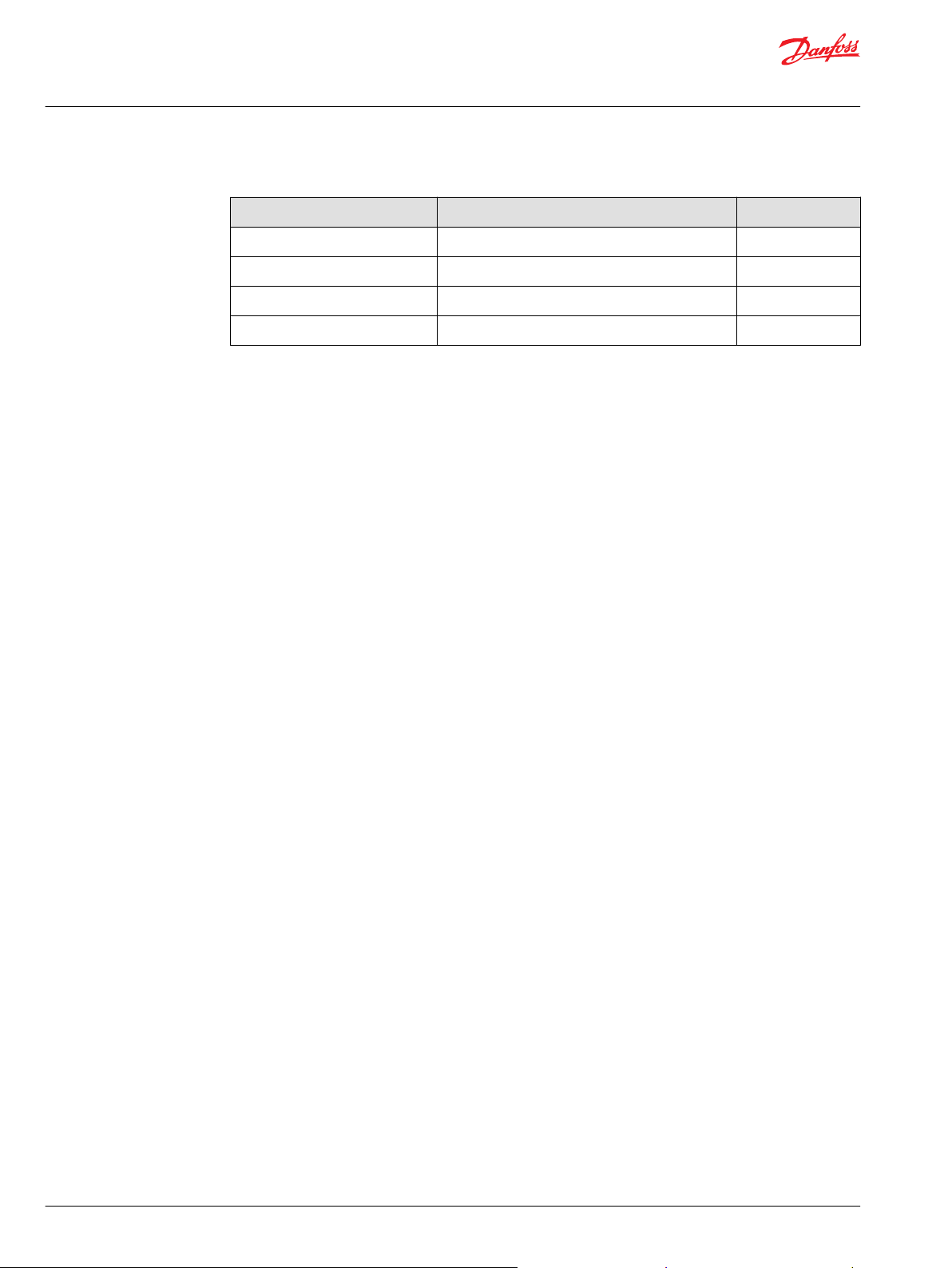

Revision history Table of revisions

Date Changed Rev

Jun 2017 Spool positioning data corrected 0503

September 2014 Index corrected EB

February 2014 Converted to Danfoss layout-DITA CMS EA

October 2009 to May 2011 Various updates AA through DC

2 | © Danfoss | Jun 2017 11070179 | BC00000068en-US0503

Page 3

Technical Information

PVED-CX, Series 4 Electrohydraulic Actuator

Contents

Reference

Acronyms used for PVG and PVE................................................................................................................................................ 7

Literature reference for PVG/PVE products.............................................................................................................................8

Standards used for PVED-CX........................................................................................................................................................ 8

Reading guide....................................................................................................................................................................................9

General Information

PVED-CX introduction.................................................................................................................................................................. 10

Overview........................................................................................................................................................................................... 11

PVG functionality

PVG functionality............................................................................................................................................................................13

PVED-CX functionality

PVED-CX functionality..................................................................................................................................................................14

Mechanical subsystem.................................................................................................................................................................14

Housing........................................................................................................................................................................................14

Cable kit........................................................................................................................................................................................14

Mounting.....................................................................................................................................................................................15

Linear Variable Differential Transducer (LVDT)..............................................................................................................15

Spool neutral spring................................................................................................................................................................ 15

Hydraulic subsystem.....................................................................................................................................................................16

Electrical and electronic subsystem........................................................................................................................................16

Communication..............................................................................................................................................................................17

Computerized subsystem...........................................................................................................................................................18

Operational modes........................................................................................................................................................................19

Full operational......................................................................................................................................................................... 19

Hand operational......................................................................................................................................................................19

Automatic system safety integrity self test – ASSIST ..................................................................................................19

Settings..............................................................................................................................................................................................20

Logging..............................................................................................................................................................................................20

Normal operation – self and neighbor supervision concept

Set point command.......................................................................................................................................................................21

Spool supervision...........................................................................................................................................................................21

Solenoid control.............................................................................................................................................................................22

Position reporting..........................................................................................................................................................................22

Neighbor supervision...................................................................................................................................................................22

Microcontroller supervision....................................................................................................................................................... 22

ASIC supervision.............................................................................................................................................................................22

Temperature supervision............................................................................................................................................................22

Power save........................................................................................................................................................................................22

Safety description

POST – Power On Self Test..........................................................................................................................................................23

ASSIST – Automatic System Safety Integrity Test...............................................................................................................23

Runtime fault monitoring........................................................................................................................................................... 23

Communication fault.............................................................................................................................................................. 23

Spool position fault..................................................................................................................................................................23

System data fault...................................................................................................................................................................... 24

Electrical fault.............................................................................................................................................................................24

Temperature fault and correction...................................................................................................................................... 24

Test fault.......................................................................................................................................................................................24

Fault level..........................................................................................................................................................................................24

Fault reaction...................................................................................................................................................................................25

Fault reporting................................................................................................................................................................................ 25

Fault recovery..................................................................................................................................................................................25

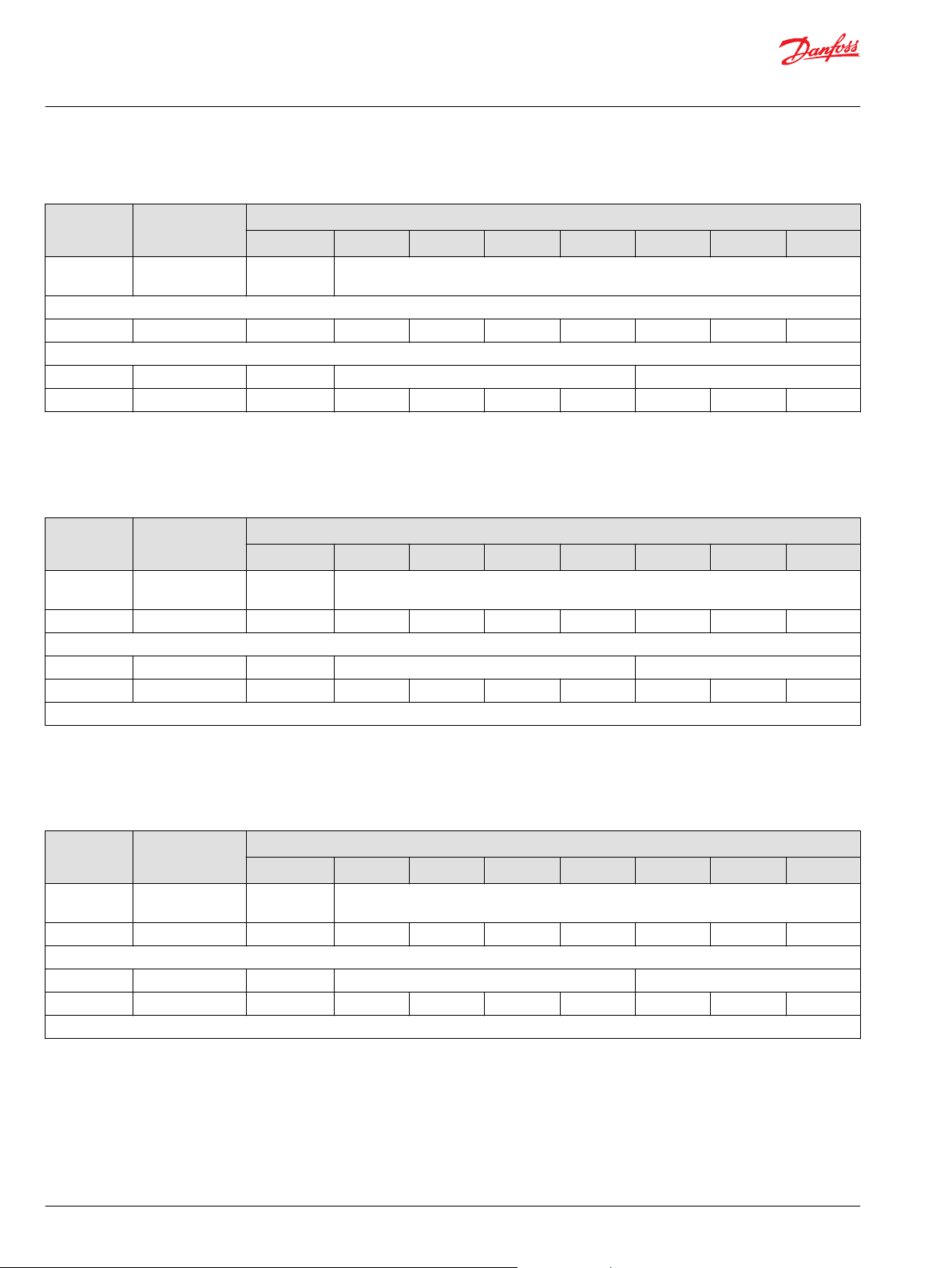

Data section

Operational conditions................................................................................................................................................................26

Performance.....................................................................................................................................................................................26

Dimensions and layout................................................................................................................................................................ 26

©

Danfoss | Jun 2017 11070179 | BC00000068en-US0503 | 3

Page 4

Technical Information

PVED-CX, Series 4 Electrohydraulic Actuator

Contents

Hydraulic data................................................................................................................................................................................. 29

Electrical data.................................................................................................................................................................................. 30

Communication..............................................................................................................................................................................31

LED ................................................................................................................................................................................................31

CAN................................................................................................................................................................................................31

Spool control................................................................................................................................................................................... 32

Spool positioning..................................................................................................................................................................... 32

Closed loop.................................................................................................................................................................................32

Spool monitoring, control and fault reaction.................................................................................................................32

Parameter settings.........................................................................................................................................................................33

Node Id.........................................................................................................................................................................................33

EDS parameters – constants read only............................................................................................................................. 34

EDS parameters – variables read write............................................................................................................................. 34

Error register. Variable read only.........................................................................................................................................35

Conversion of identity parameters to comparable values........................................................................................ 35

Reading guide for product code and serial number....................................................................................................35

Reading guide............................................................................................................................................................................36

Reading guide for numbers .................................................................................................................................................36

Error log. Variables, read only, voilatile.............................................................................................................................36

Error list. Variable read only.................................................................................................................................................. 36

Instantaneous temperature. Variable read only............................................................................................................37

Temperature log....................................................................................................................................................................... 37

Safety Switch status.................................................................................................................................................................37

Safety Relevant Features.............................................................................................................................................................38

Emergency msg. (EMCY)........................................................................................................................................................ 38

EMCY publishing order on CAN bus..................................................................................................................................38

Reset Emergency Message....................................................................................................................................................38

EMCY consumer behavior..................................................................................................................................................... 39

NMT reset application.............................................................................................................................................................39

NMT reset communication....................................................................................................................................................39

Reload Command.....................................................................................................................................................................40

Important Points for PVED-CX Valve Configuration..........................................................................................................40

Changing Node ID using Layer Setting Service.................................................................................................................. 41

Step-1: Switch To Configuration Mode..................................................................................................................................41

Switch To Configuration Mode Global Way....................................................................................................................41

Switch to Configuration Mode Selective Way................................................................................................................41

Step-2: Configure Node ID..........................................................................................................................................................42

Step-3: Store New Assigned Node-ID.....................................................................................................................................42

Step-4: Switch to Normal Mode................................................................................................................................................43

LSS Enquiry Services......................................................................................................................................................................43

Enquire Vendor-ID Command..............................................................................................................................................43

Enquire Product Code Command.......................................................................................................................................43

Enquire Revision Number Command................................................................................................................................44

Enquire Serial Number Command......................................................................................................................................44

Enquire Device Node-ID Command...................................................................................................................................45

EDS access by SDO........................................................................................................................................................................ 45

Set EDS parameter....................................................................................................................................................................45

Set NNI example........................................................................................................................................................................45

Enquire EDS parameter.......................................................................................................................................................... 46

Enquire NNI example...............................................................................................................................................................46

Enquire error log example.....................................................................................................................................................46

Valve Operation..............................................................................................................................................................................47

Normal Operation.....................................................................................................................................................................47

NMT boot up object.................................................................................................................................................................47

Heartbeat Message.................................................................................................................................................................. 47

Getting to Device Mode Active........................................................................................................................................... 48

PVED-CX node 0x21.................................................................................................................................................................48

PVED-CX node NID...................................................................................................................................................................49

Set point.......................................................................................................................................................................................50

4 | © Danfoss | Jun 2017 11070179 | BC00000068en-US0503

Page 5

Technical Information

PVED-CX, Series 4 Electrohydraulic Actuator

Contents

The Sync message:................................................................................................................................................................... 50

Transmission of PVED-CX Spool Pos. Messages on Sync Msg..................................................................................51

Hand Operational Mode and Full Operational Mode configuration .................................................................... 51

ASSIST.................................................................................................................................................................................................52

ASSIST Pre-Trigger Command............................................................................................................................................. 52

ASSIST Run Command............................................................................................................................................................53

LED by ASSIST ........................................................................................................................................................................... 54

CANCEL ASSIST Command....................................................................................................................................................55

ASSIST Abort Message............................................................................................................................................................ 56

State Machine

Important points about PVED-CX DSM Implementation................................................................................................ 57

INIT state:...........................................................................................................................................................................................57

DISABLED state:.............................................................................................................................................................................. 57

HOLD state:.......................................................................................................................................................................................58

DEVICE_MODE_ACTIVE state:....................................................................................................................................................58

Hand Operational Mode........................................................................................................................................................ 59

Full Operational Mode ...........................................................................................................................................................59

ASSIST Mode ..............................................................................................................................................................................59

FAULT_REACTION state:..............................................................................................................................................................59

FAULT_HOLD state:.......................................................................................................................................................................60

FAULT state:..................................................................................................................................................................................... 60

State Transition...............................................................................................................................................................................60

Limitations and Known Software Issues

Warnings

PVED-CX warnings.........................................................................................................................................................................63

Error codes

Index 1 • Common Name: Reserved........................................................................................................................................64

Index 2 • Common Name: Supply voltage too high..........................................................................................................64

Index 3 • Supply voltage too low..............................................................................................................................................64

Index 4 • Illegal state command................................................................................................................................................65

Index 5 • Division by zero, illegal SW operation..................................................................................................................65

Index 6 • Internal table value corrupted, illegal SW operation......................................................................................66

Index 7 • Wrong data interpretation, truncation of values............................................................................................. 66

Index 8 • Interpolation fault, illegal SW operation............................................................................................................. 67

Index 9 • No handshake to uC....................................................................................................................................................67

Index 10 • Watchdog not starting............................................................................................................................................ 67

Index 11 • RTOS error.................................................................................................................................................................... 68

Index 12 • LVDT verification fault............................................................................................................................................. 68

Index 13 • Neighbor LVDT fault.................................................................................................................................................69

Index 14 •Temperature sensor fault........................................................................................................................................ 69

Index 15 • Fault In RAM................................................................................................................................................................ 69

Index 16 • Temperature average to high...............................................................................................................................70

Index 17 • Code memory check fault...................................................................................................................................... 70

Index 18 • Reserved....................................................................................................................................................................... 71

Index 19 • EEPROM write fault...................................................................................................................................................71

Index 20 • EEPROM content fault..............................................................................................................................................71

Index 21 • EEPROM mirror fault.................................................................................................................................................72

Index 22 • Dead band parameter out of range....................................................................................................................72

Index 23 • Reserved....................................................................................................................................................................... 72

Index 24 • CAN error frame warning........................................................................................................................................73

Index 25 • Signal from master missing................................................................................................................................... 73

Index 26 • Recovered from Bus off...........................................................................................................................................74

Index 27 • Command signal error.............................................................................................................................................74

Index 28 • Reserved....................................................................................................................................................................... 74

Index 29 • Reserved....................................................................................................................................................................... 75

Index 30 • Spool not at set point.............................................................................................................................................. 75

Index 31 • Spool out of neutral..................................................................................................................................................76

©

Danfoss | Jun 2017 11070179 | BC00000068en-US0503 | 5

Page 6

Technical Information

PVED-CX, Series 4 Electrohydraulic Actuator

Contents

Index 32 • Spool out of neutral at boot up............................................................................................................................76

Index 33 • Electronics to warm..................................................................................................................................................76

Index 34 • CAN spool position from neighbor missing.................................................................................................... 77

Index 35 • Neighbor CAN spool position fault.....................................................................................................................77

Index 36 • No set point.................................................................................................................................................................78

Index 37 • CAN stack error...........................................................................................................................................................78

Index 38 • DSM initialization failed.......................................................................................................................................... 79

Index 39 • A/D converting fault.................................................................................................................................................79

Index 40 • ASSIST. State fault......................................................................................................................................................79

Index 41 • ASSIST. Timing fault..................................................................................................................................................80

Index 42 • Neighbor. Spool out of neutral at boot up.......................................................................................................80

Index 43 • ASSIST. Neighbor reporting fault.........................................................................................................................80

Index 44 • ASSIST. Spool not returned to neutral...............................................................................................................81

Index 45 • ASSIST. Step fault.......................................................................................................................................................81

Index 46 • ASSIST. Neighbor spool does not steer out..................................................................................................... 82

Index 47 • ASSIST. Neighbor spool not returned to neutral............................................................................................82

Index 48 • ASSIST: A port gives to high flow.........................................................................................................................83

Index 49 • ASSIST: B port gives to high flow.........................................................................................................................83

Index 50 • ASSIST: A port gives to low flow...........................................................................................................................83

Index 51 • ASSIST: B port gives to less flow...........................................................................................................................84

Index 52 • Neighbor. Spool out of neutral.............................................................................................................................84

Index 53 • Neighbor. Spool not at set point......................................................................................................................... 85

Index 54 • Neighbor. Spool position reporting fault......................................................................................................... 85

Index 55 • Reference voltage fault........................................................................................................................................... 86

Index 56 • Node ID fault............................................................................................................................................................... 86

Index 57 • EEPROM address fault..............................................................................................................................................86

Index 58 • Error code buffer........................................................................................................................................................87

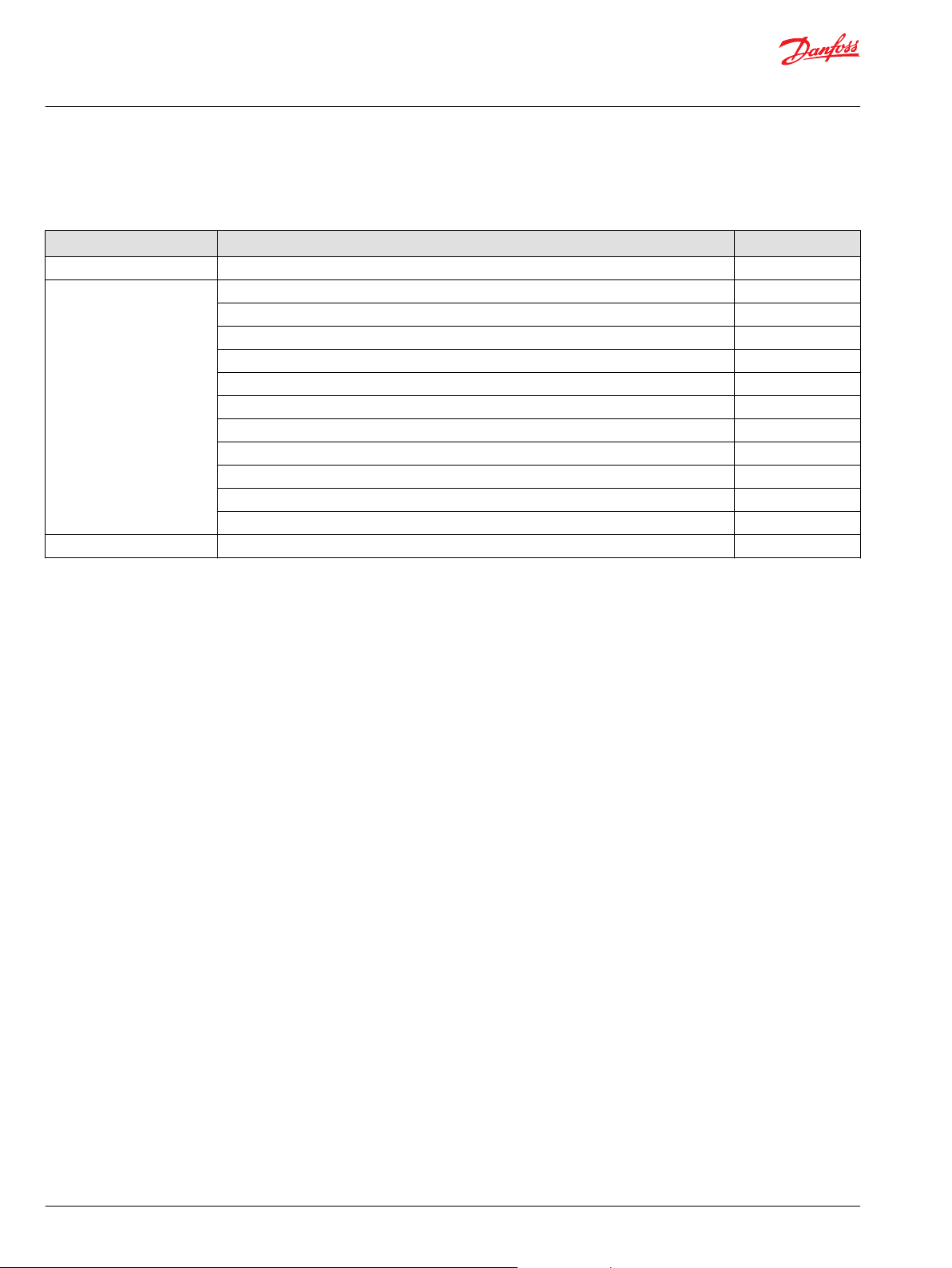

Ordering

Settings Agreement......................................................................................................................................................................88

Parameter Agreement Template..............................................................................................................................................88

Factory settings for spare part PVED-CX.......................................................................................................................... 88

PVED-CX setting agreement for PVG.................................................................................................................................89

PVED-CX code numbers.............................................................................................................................................................. 90

6 | © Danfoss | Jun 2017 11070179 | BC00000068en-US0503

Page 7

Technical Information

PVED-CX, Series 4 Electrohydraulic Actuator

Reference

Acronyms used for PVG and PVE

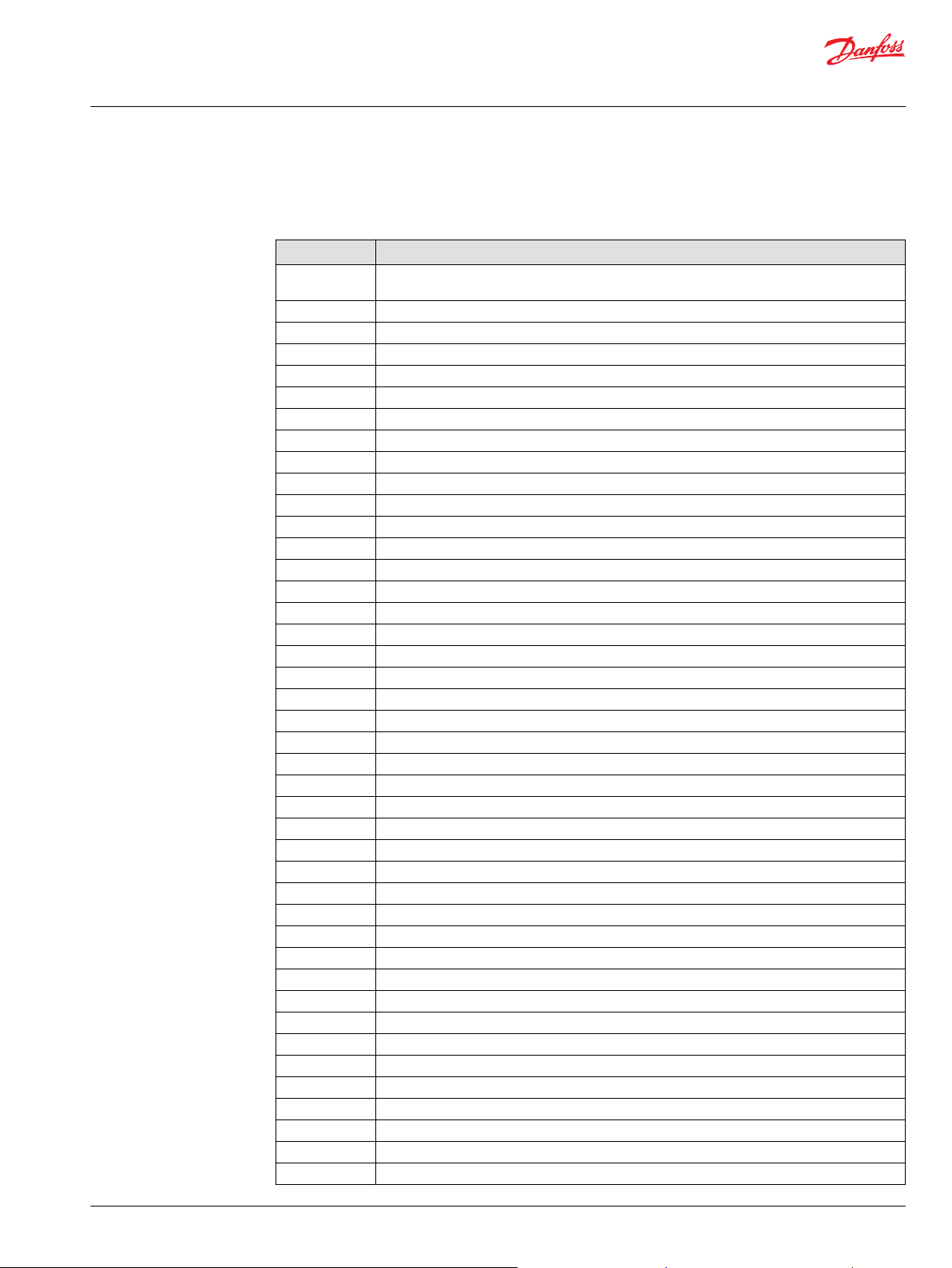

Acronyms Description

ASIC Application Specific Integrated Circuit - the part of the PVE where spool position is controled to

ATEX Certificated for use in explosive environment

AVC Auxillery Valve Comand - ISOBUS/J1939 standard signal for valve control

AVCTO Auxillery Valve Comand Time Out - Fault monitoring setting

AVEF Auxillery Valve Estimated Flow - ISOBUS/J1939 standard signal for valve feedback

CAN Controller Area Network - Communication method used by PVED

CLC Closed Loop Circuit

CRC Cyclic Redundancy Check - Method for ensuring validity of data.

-DI PVE with Direction Indication

DM1 Diagnostic Message 1 - J1939 message informing about present fault

DM2 Diagnostic Message 2 - J1939 message informing about fault history

DM3 Diagnostic Message 3 - J1939 message clearing fault history

DSM Device State Machine. Deterministic description of system process

ECU Electronic Control Unit

EH Electro Hydraulic

-F PVE for Float spool. Two variants: 4 pin with float at 75%. 6 pin with separate float.

FMEA Failure Mode Effect Analysis

ISOBUS Communication standard for CAN

J1939 Communication standard for CAN

LED Light Emitting Diode

LS Load Sensing

LVDT Linear Variable Differential Transducer - Position sensor

NC Normally Closed solenoid valve in PVE

NC-H Normally Closed standard solenoid valve in PVEH

NC-S Normally Closed solenoid valve Super in PVES

NO Normally Open solenoid valve in PVE

PLC Programmable Logical Circuit

®

PLUS+1

POST Power On Self Test. Boot up evaluation for PVED

Pp Pilot Pressure. The oil gallery for PVE actuation

PVB Proportional Valve Basic module - valve slice

PVBS Proportional Valve Basic module Spool

PVBZ Proportional Valve Basic module Zero leakage

PVE Proportional Valve Electric actuator

PVEA PVE variant with 2-6 % hysteresis

PVED PVE variant Digital controlled via CAN communication

PVEH PVE variant with 4-9% Hysteresis

PVEM PVE variant with 25-35% hysteresis

PVEO PVE variant with ON/OFF actuation

PVEP PVE variant PWM controled

PVES PVE variant with 0-2% hysteresis

PVEU PVE variant with US 0-10V

follow setpoint

Trademark for Danfoss controllers and programming tool

©

Danfoss | Jun 2017 11070179 | BC00000068en-US0503 | 7

Page 8

Technical Information

PVED-CX, Series 4 Electrohydraulic Actuator

Reference

Acronyms Description

PVG Proportional multi-section Valve Group

PVHC PV variant with High Current controlled valve actuator

PVM Proportional Valve Manual control with handle

PVP Proportional Valve Pump side module.Inlet

PVS Proportional Valve end plate

PVSK Proportional Valve end plate crane. Inlet module with Spool Control

PWM Pulse Width Modulation

S4 DJ Series 4 Digital J1939 service tool software for PVED-CC

SAE Society Automotive Engineering

-R PVE with Ramp function

-NP PVE with solenoid disable in Neutral Position

-SP PVE with Spool Position feedback

uC Microcontroller

uCSM Microcontroller State Machine

U

DC

U

S

Power supply Direct Current; also called V

Steering voltage for the PVE control; also called V

for battery voltage

bat

S

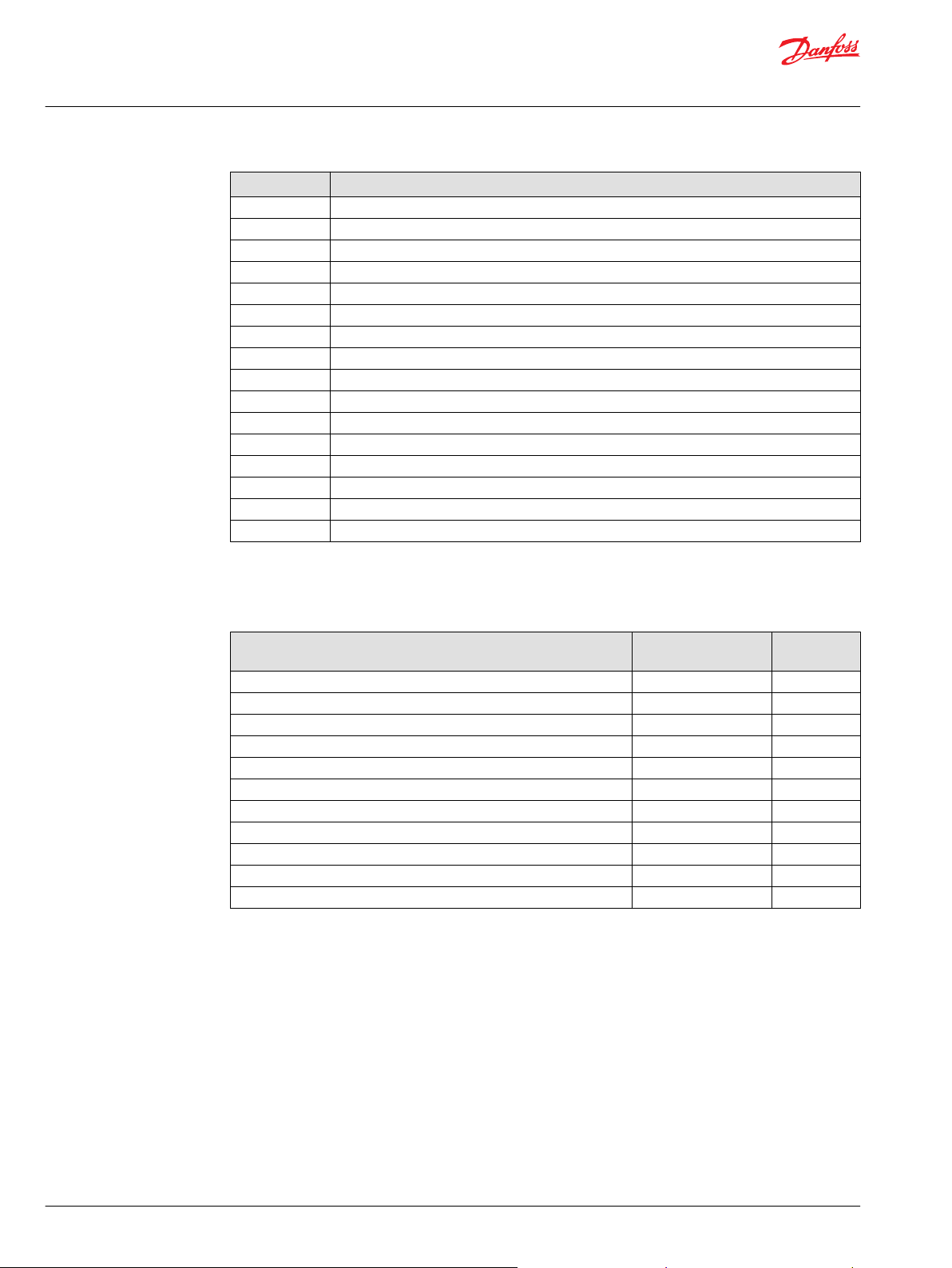

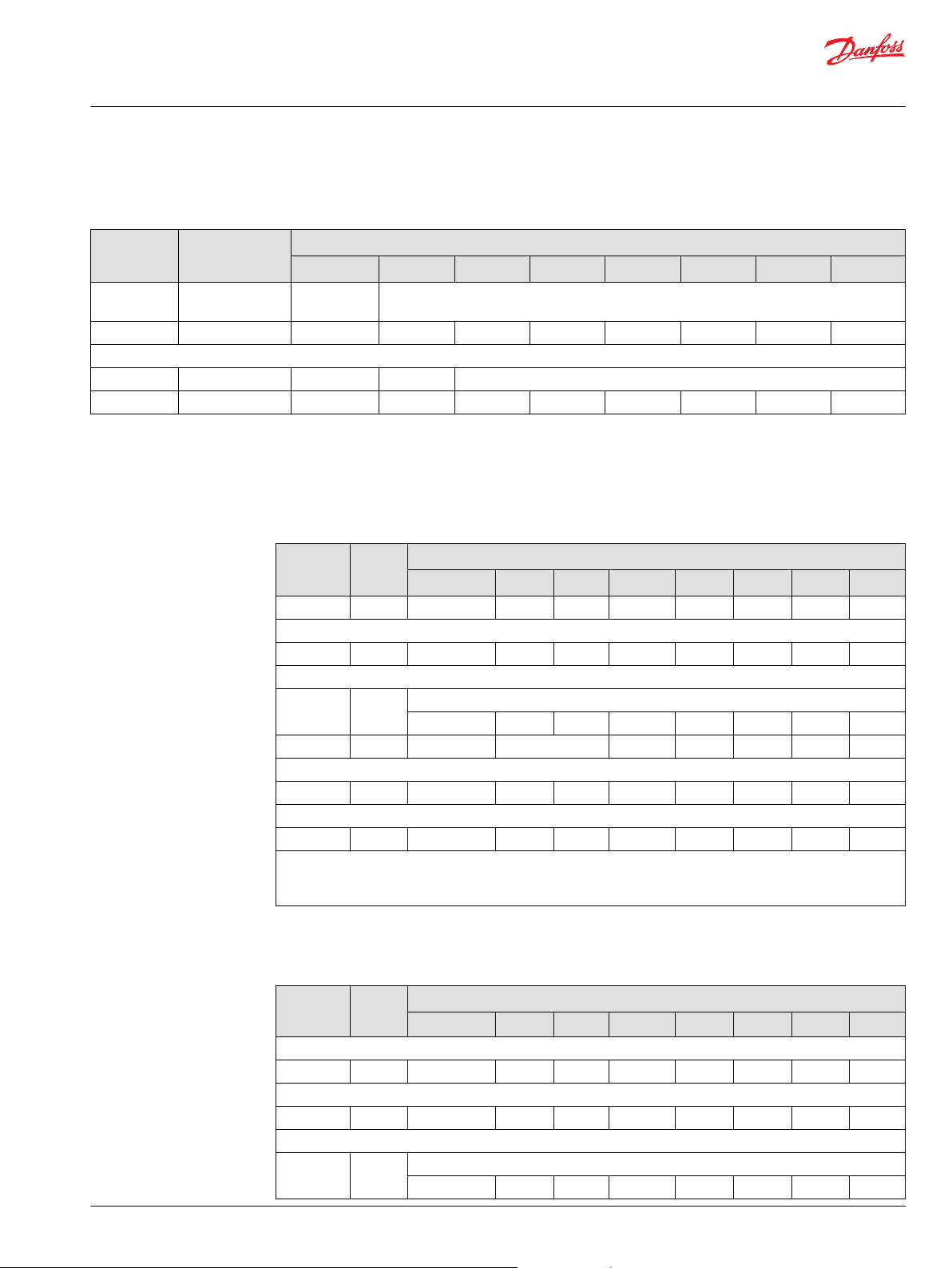

Literature reference for PVG/PVE products

Literature reference

Literature title Type Order

PVG 32 Proportional valve group Technical Information 520L0344

PVG 100 Proportional valve group Technical Information 520L0720

PVG 120 Proportional valve group Technical Information 520L0356

PVG 32 Metric ports Technical Information 11051935

PVED-CC Electro-hydraulic actuator Technical Information 520L0665

PVED-CX Electro-hydraulic actuator Technical Information 11070179

Basic module for PVBZ Technical Information 520L0721

PVSK module with integrated diverter valve and P-disconnect function Technical Information 520L0556

PVPV / PVPM pump side module Technical Information 520L0222

Combination module PVGI Technical Information 520L0405

PVSP/M Priority module Technical Information 520L0291

Standards used for PVED-CX

International Organization for Standardization:

•

ISO 11898-2 Road vehicles, CAN, Part 2, High-speed medium access unit (physical layer)

‒

ISO 13766:2006(E) Earth moving machinery, Electromagnetic compatibility

‒

ISO 13849 Safety of Machinery

‒

CAN in Automation:

•

CiA 3.01 v4.02 CANopen protocol.

‒

CiA 4.08 v1.51 Device specific protocol for proportional valves.

‒

IEC 61508

•

number

8 | © Danfoss | Jun 2017 11070179 | BC00000068en-US0503

Page 9

Technical Information

PVED-CX, Series 4 Electrohydraulic Actuator

Reference

Reading guide

Sections Overview and section PVG functionality give a general description of the PVG to give basic

•

domain knowledge.

Section PVED-CX functionality is a thorough description of PVED-CX subsystems and their interaction.

•

Sections Normal operation – self and neighbor supervision concept on page 21 and section Safety

•

description on page 23 are thorough descriptions of control, monitoring, safety features and

behaviors.

Section Data details for application engineers.

•

Section PVED-CX warnings lists warnings relevant to the PVED-CX.

•

Section Error codes is a walkthrough of module error codes, potential cause and counter action.

•

Section Ordering shows the ordering guidelines.

•

©

Danfoss | Jun 2017 11070179 | BC00000068en-US0503 | 9

Page 10

Technical Information

PVED-CX, Series 4 Electrohydraulic Actuator

General Information

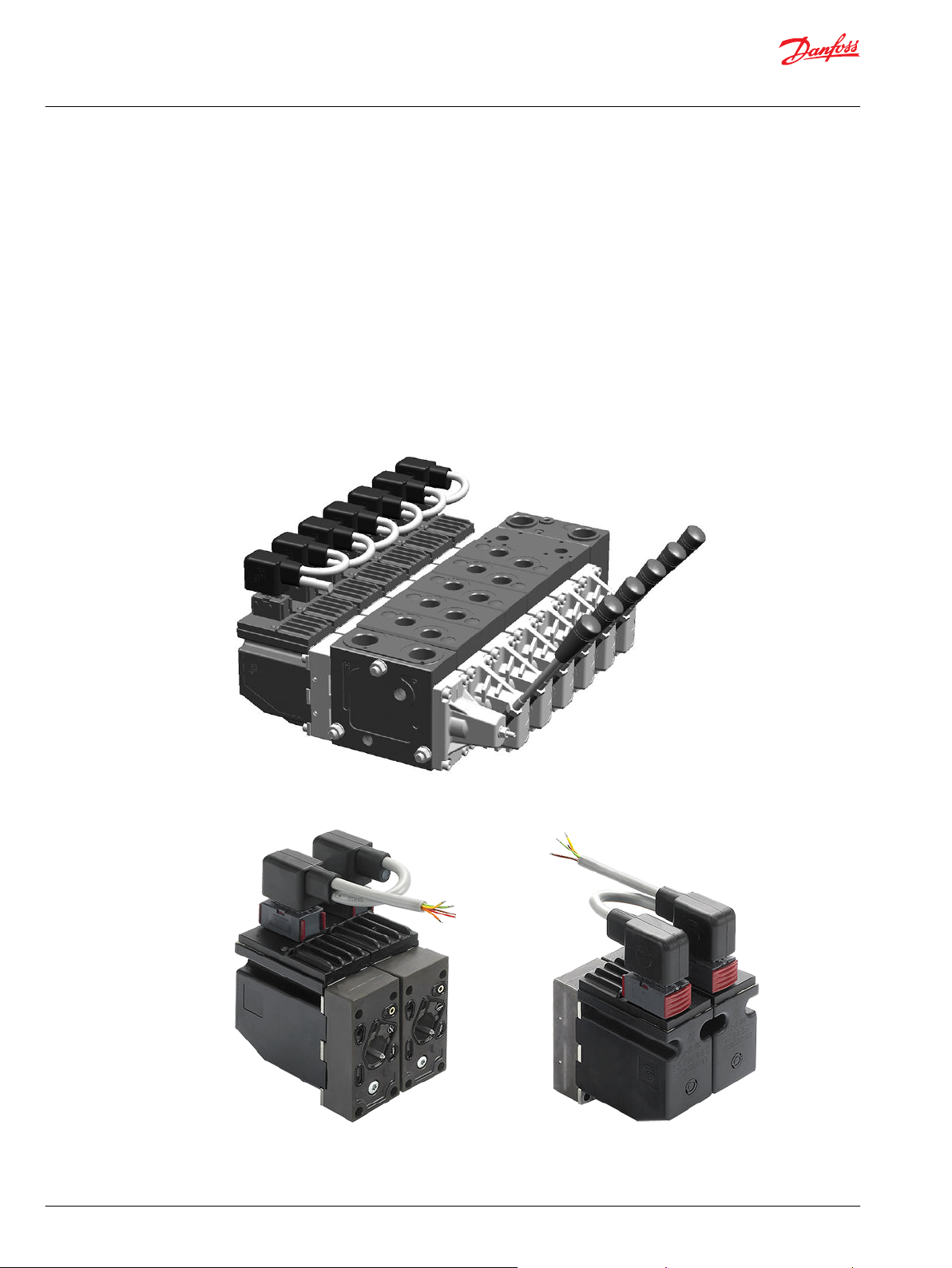

PVED-CX introduction

The Danfoss PVED-CX is a PVE-Series 4 actuator for the PVG 32.

CX is an abbreviation for CAN bus communication and eXtended safety.

The PVED-CX is intended for markets where a documented extended safety is needed. In particular

cranes, man-lifts and telehandlers are in focus.

A PVG with PVED-CX is designed to meet Safety Integrity Level 2 (SIL2). So when performing a Risk and

Hazard Analysis, as mandated by the EU Machinery Directive 2006/42/EC, the Danfoss customer can cut

down on external safety systems and easier get an IEC61508 certified system.

A product specific wiring harness is part of the PVED-CX concept as use of the special Danfoss end plate

for cranes (PVSK) is.

Certification of the PVED-CX system appliance to the IEC61508 is made by TÜV SÜD, Munich, Germany.

PVG with PVED-CX

PVED-CX, front view PVED-CX, back view

10 | © Danfoss | Jun 2017 11070179 | BC00000068en-US0503

Page 11

W

W

Technical Information

PVED-CX, Series 4 Electrohydraulic Actuator

General Information

Warning

Please work through all warnings before implementing actuators in any application. The list of warnings

must not be seen as a full list of potential dangers. Depending on application and use other potential

dangers can occur.

Warning

All brands and all types of directional control valves – including proportional valves – can fail and cause

serious damage. It is therefore important to analyze all aspects of the application. Because the

proportional valves are used in many different operation conditions and applications, the machine

builder/ system integrator alone is responsible for making the final selection of the products – and

assuring that all performance, safety and Warning requirements of the application are met.

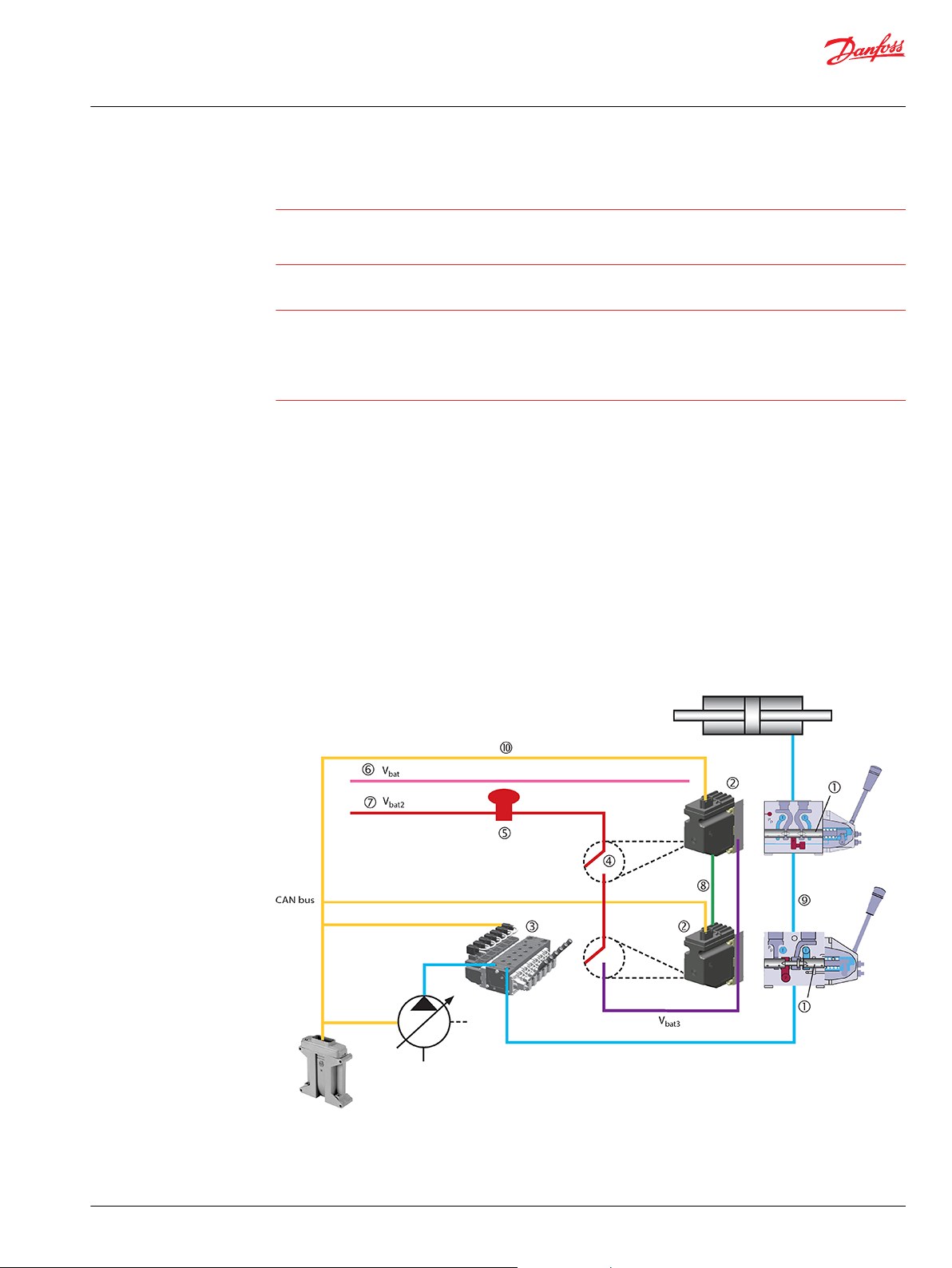

Overview

The PVG is a sectioned spool valve stack with up to 12 individually controlled proportional valves. With

the PVED-CX the PVG can operate as one or more control sections.

A control section is a group of two to eight PVED-CX connected by one cable kit with mutual monitoring

and the feature that any PVED can bring the entire control section to safe state if a fault is found.

The oil flow out of the work section (A- or B-port) can be controlled by a combination of the following:

PVED-CX controlling the spool position using pilot oil pressure.

•

A handle (PVM) in mechanical interface with the spool.

•

The oil flow into the PVG can be controlled using an electrically controlled main oil valve (PVSK) as

•

end cover. The PVED-CX is foreseen as PVSK controller in the Danfoss SIL2 concept. The PVSK can also

supply an additional PVG via the High Pressure Carry Over (HPCO) port.

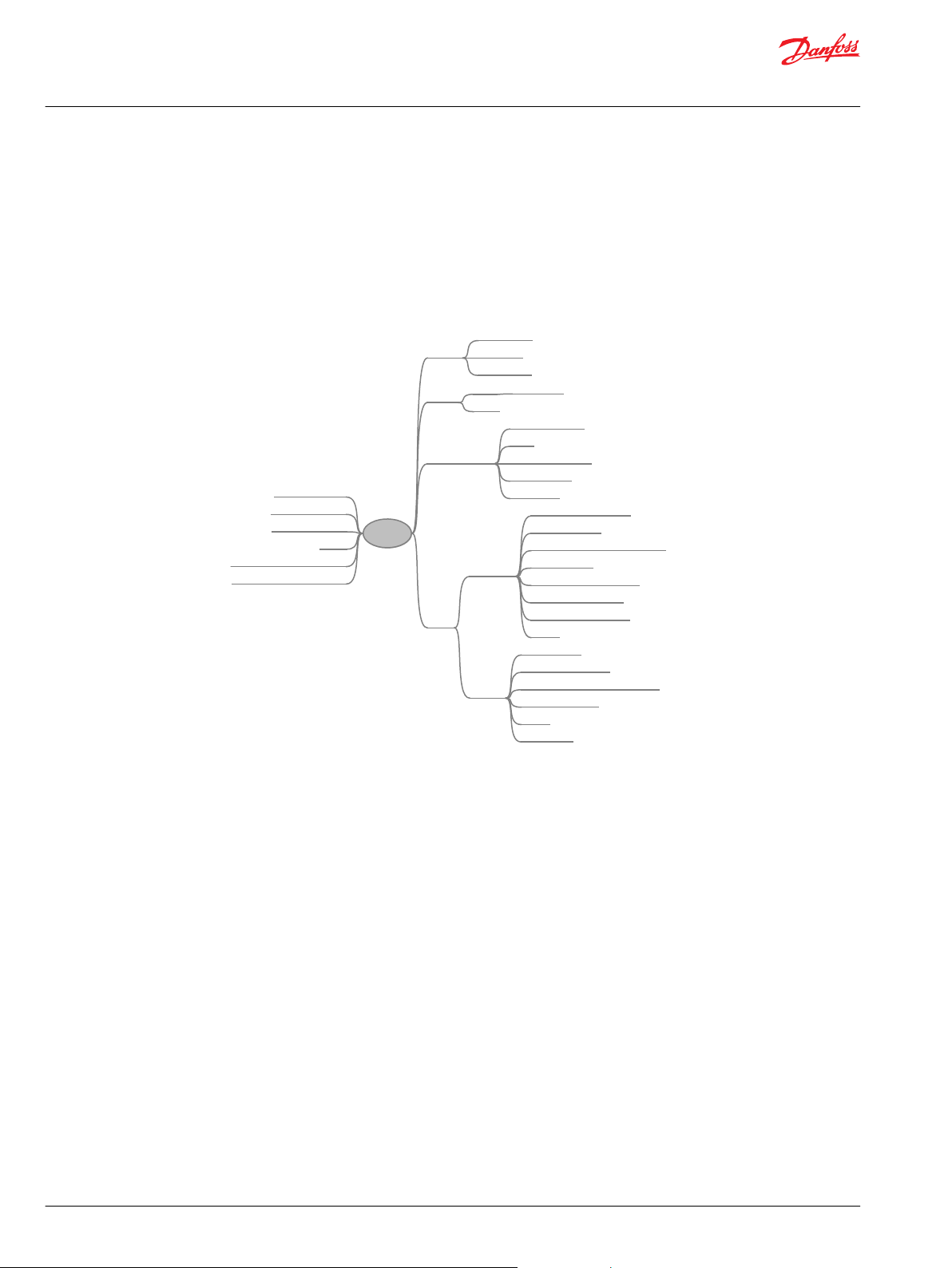

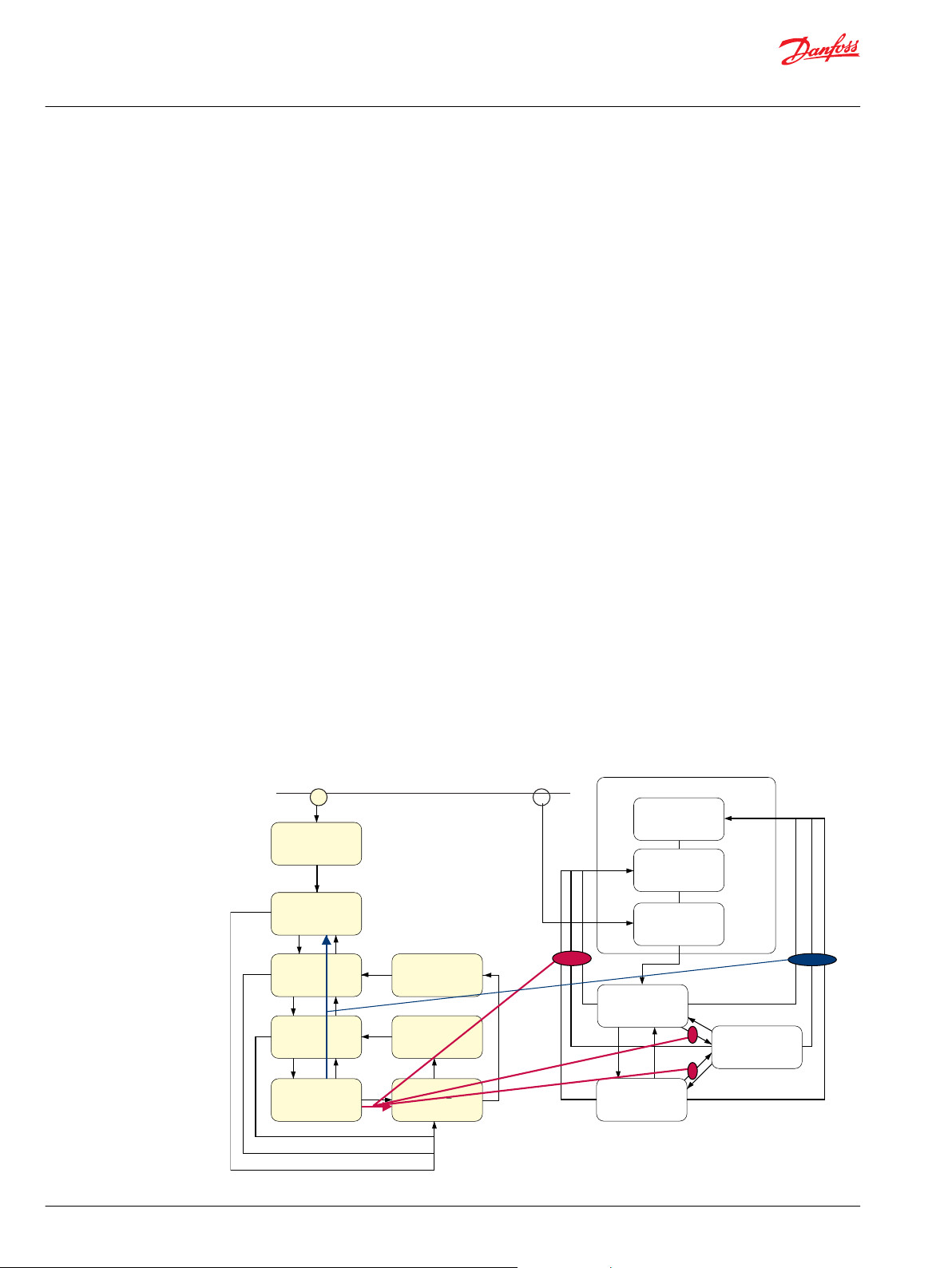

PVED-CX functionalities – block diagram

1 – Neutral springs

2 – Solenoids

3 – PVG with PVED-CX

4 – Safety switch

6 – Electronics

7 – Power for solenoids

8 – Analog neighbor information

9 – Neighbor surveillance can cut the oil flow

©

Danfoss | Jun 2017 11070179 | BC00000068en-US0503 | 11

Page 12

Technical Information

PVED-CX, Series 4 Electrohydraulic Actuator

General Information

5 – Emergency 10 – Set points and feedback

The PVED-CX uses the CANopen protocol, thus following the standard protocol CiA301v402 and the

device specific protocol for proportional valves CiA408v151 with a minimum set of vendor specific

additions.

The physical layer for CAN communication applies to ISO 11898-2 high speed CAN.

The spool is controlled by spool position with 127 positions each direction and dead band compensation.

Monitored manual operation is possible.

Electronics and spool control are independently power supplied and the redundant system monitoring

can shut down the whole control section in case of failures.

The redundant monitoring continuously evaluates spool position, communication, electronics, memory,

calculations and temperature.

To avoid needless power consumption the PVED-CX has the Power Save feature, where power

consumption is reduced by almost 90% when the spool is in neutral.

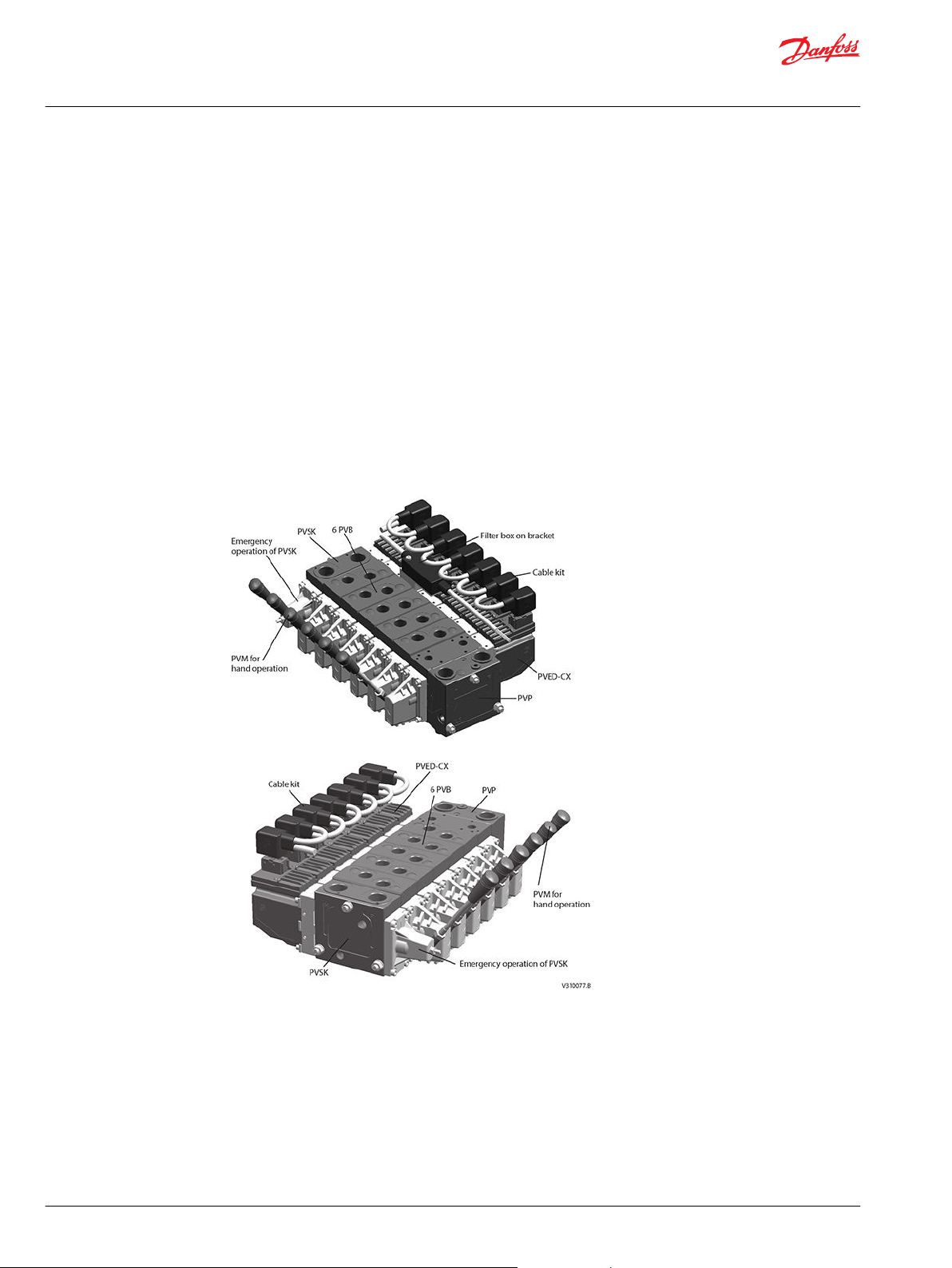

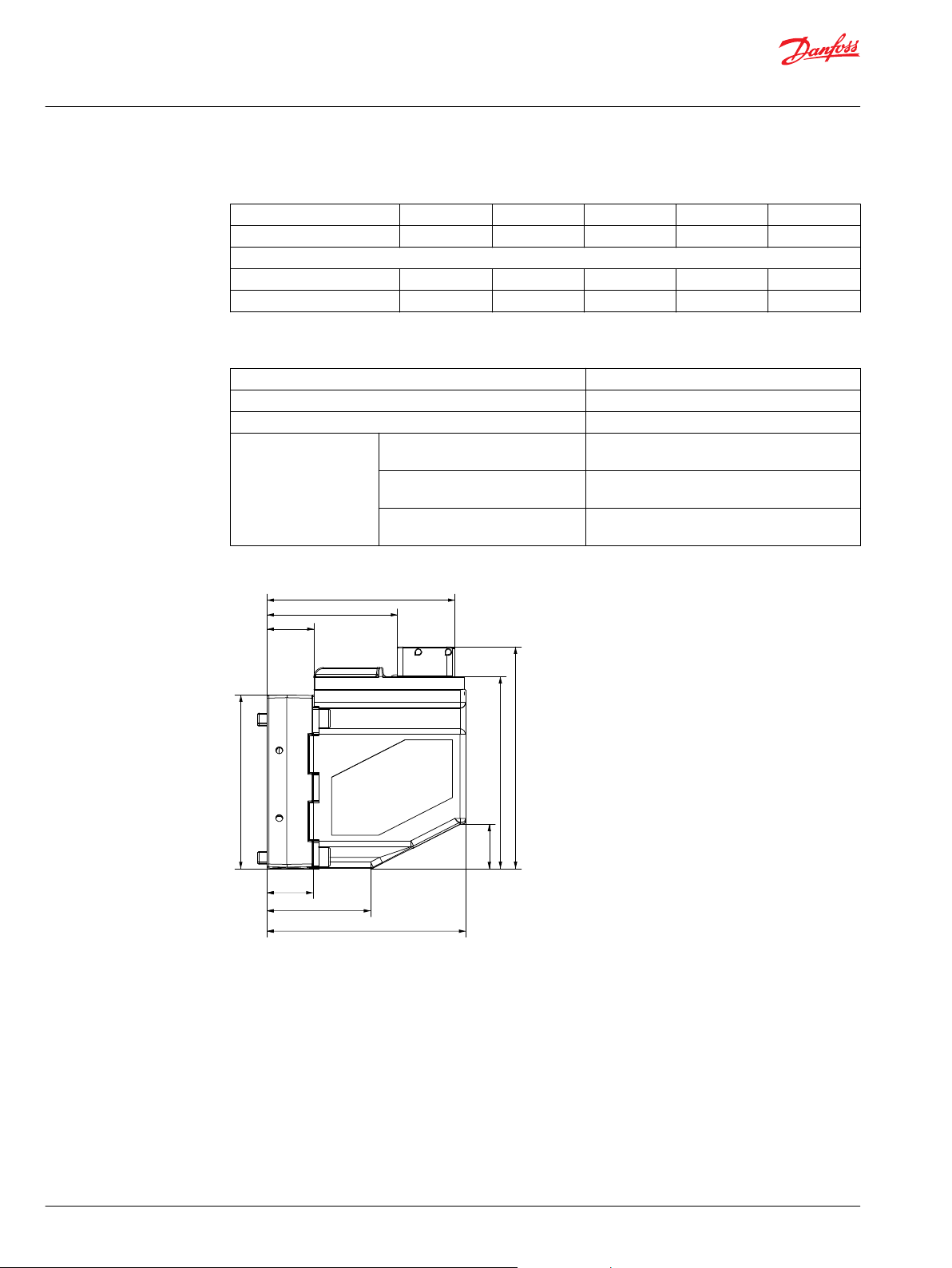

PVG 32 with PVED-CX overview, PVE option mounted

12 | © Danfoss | Jun 2017 11070179 | BC00000068en-US0503

Page 13

V310072.A

PVE

Electronics

NC Solenoid valve

Pilot oil supply

B port

Oil

A port

PVB

PVM

Neutral spring

PVBS

NO solenoid valve

LVDT

<- Retract towards PVE

Extend away from PVE ->

P -> A

Technical Information

PVED-CX, Series 4 Electrohydraulic Actuator

PVG functionality

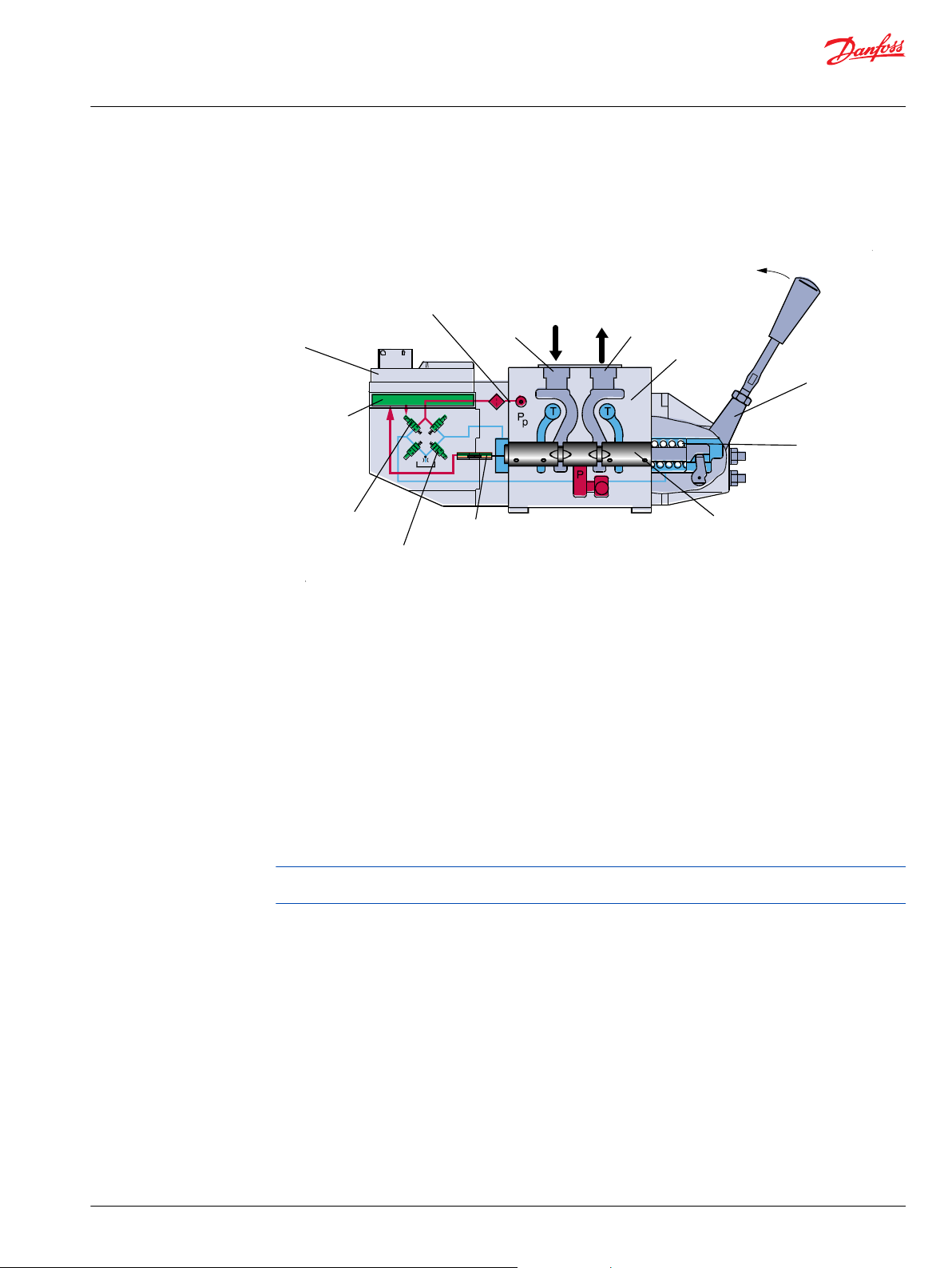

PVG functionality

This chapter will give an overview of the PVG functionality.

Valve section with naming - standard mounted - seen from PVP

The PVG valve distributes oil from pump flow to a particular work function in the application via a specific

valve section. This is done by moving the spool (PVBS).

Depending on the choice of components the oil work flow enters the PVG through the PVP (proportional

valve pump side module) or the PVSK (proportional valve end plate for crane) and enters the PVB

(proportional valve basic module) via the P gallery and leaves through the T gallery.

When looking at figure 4 you see the valve section from PVP towards PVSK with the PVM and PVE

standard mounted. When PVM and PVE are interchanged it’s called option mounted.

With the spool in neutral, where it is kept by the neutral spring, the connection to the application via

ports is blocked.

Moving the spool towards the PVE, as in figure 4, opens a connection between P and A and also between

B and T. This is done by either pushing the PVM or sending a retract command to PVED. The PVED move

the spool by letting Pilot Oil Pressure (Pp) push on the right end of the PVBS and releasing pressure from

the left end. For details on PVG32 please see PVG 32 Proportional valves, Technical information, 520L0334.

Any PVG with PVM can be operated by PVM alone independent of power supply. Any PVG with PVED-CX

can monitor PVBS if power and communication conditions are present.

©

Danfoss | Jun 2017 11070179 | BC00000068en-US0503 | 13

Page 14

V310078.A

Oil pressure

Solenoids

Poppet valve

Function

Control

Communication

ASIC

LVDT

Closed loop

Set point via CAN

PWM

Analogue reporting

CAN reporting

LED status

CAN signal acceptance

Message sanity

Hand shake - component sanity

Memory check

Calculation vs execution

Redundant calculation

Component environment

Logging

Ignore input

Deactivate solenoids

Deactivate all modules in section

CANbus reporting

Logging

LED setting

Reaction

Safety

System controller

Neighbor module

PVED-CX section

Spool

Application hydraulic system

Application electrical system

Monitoring

PVED-CX

Technical Information

PVED-CX, Series 4 Electrohydraulic Actuator

PVED-CX functionality

PVED-CX functionality

This section has focus on how the PVED-CX works and interacts. Understanding of this must be regarded

as a pre-condition for understanding module settings and system operation.

The PVED-CX is a mechatronic device, meaning a mechanical, a hydraulic, an electric, an electronic and a

computer system interacting with external mechanical, hydraulic, electrical, electronic and computerized

systems.

PVED-CX mechatronical interaction

Mechanical subsystem

Housing

The housing of the PVED-CX protects the internal parts from the environment and gives by design the

14 | © Danfoss | Jun 2017 11070179 | BC00000068en-US0503

optimal interface to cabling, Pilot pressure and spool.

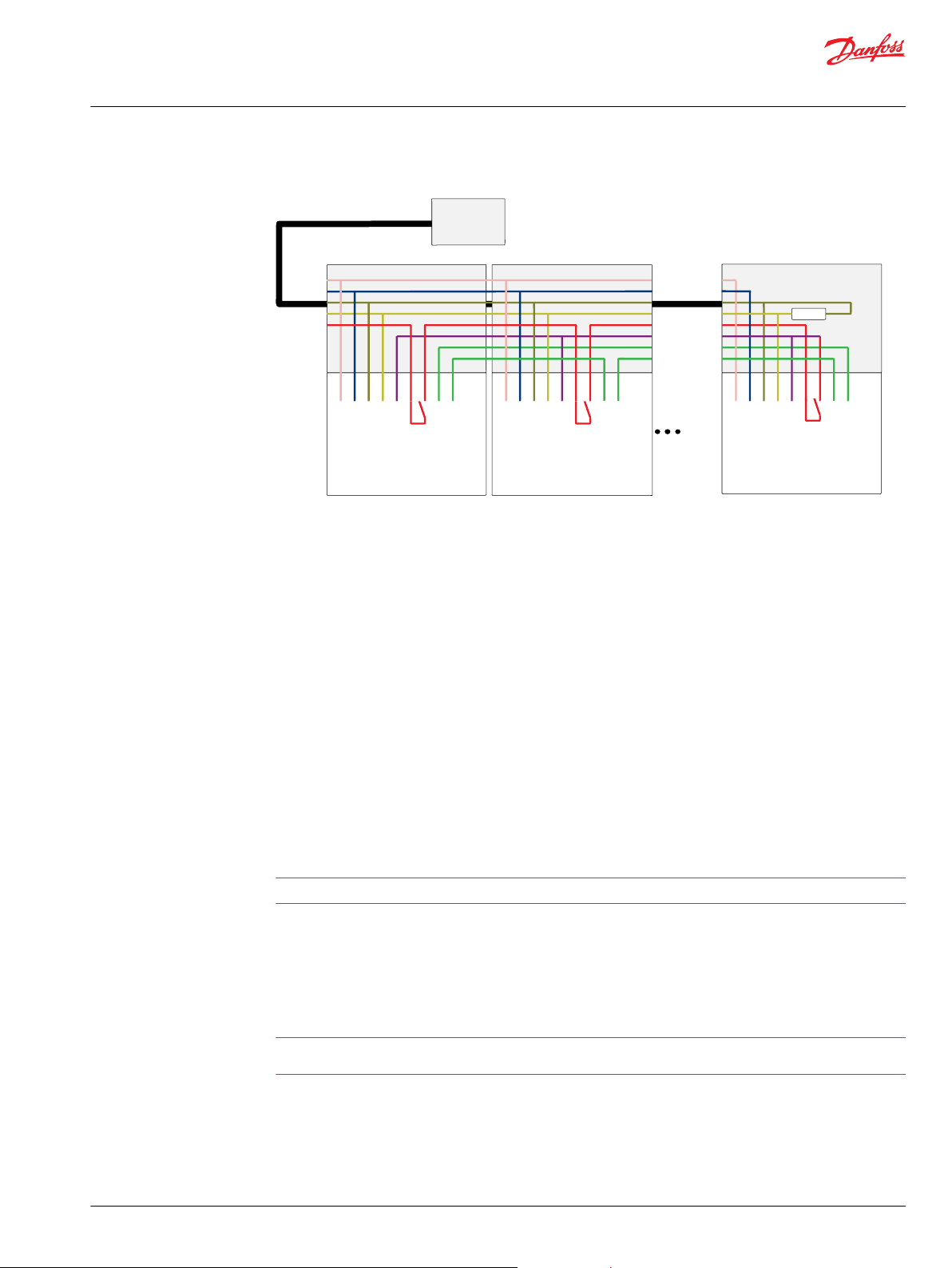

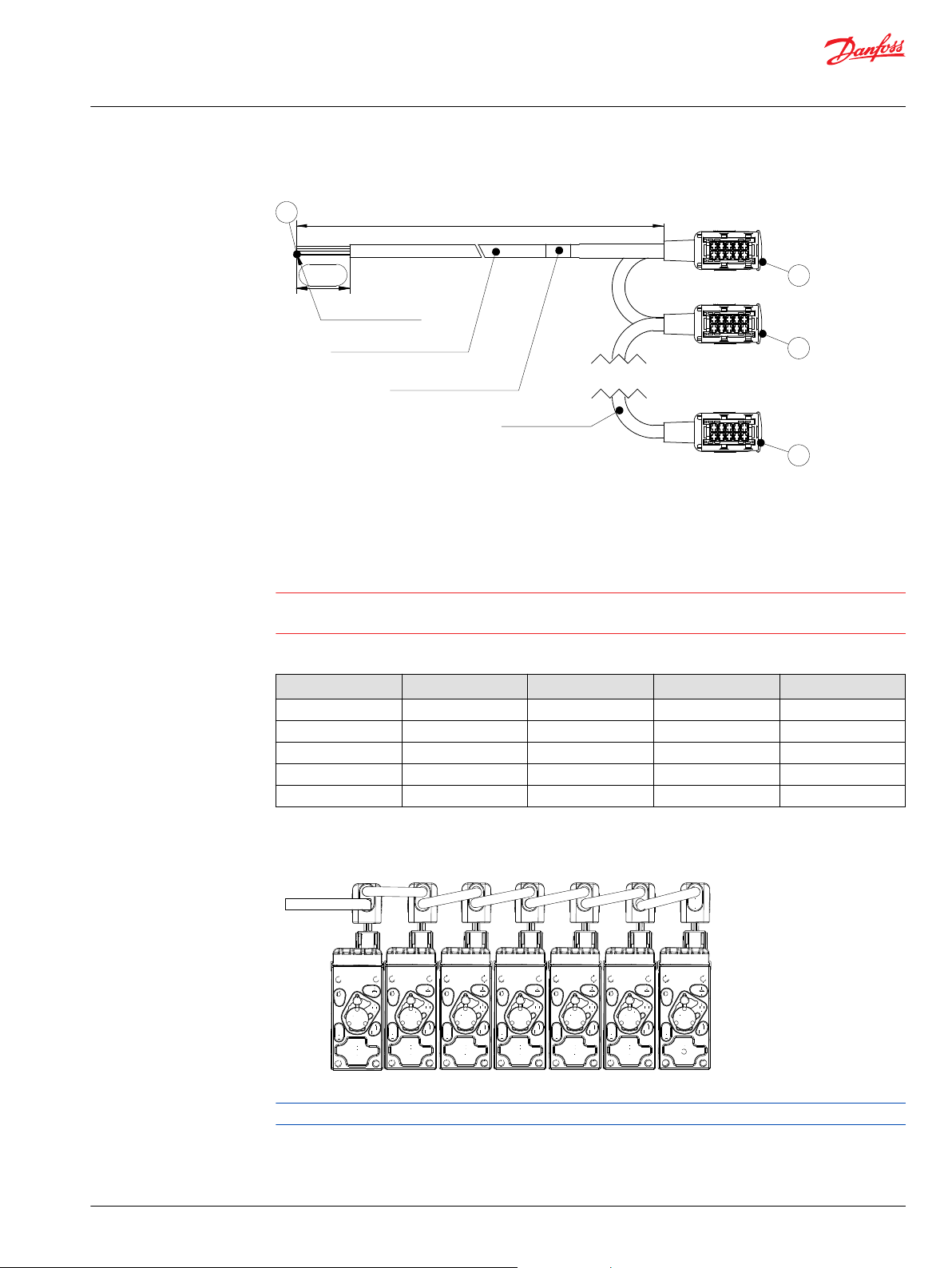

Cable kit

A special cable kit has been designed for the PVED-CX making it possible to operate in control sections of

two to eight modules with neighbor monitoring.

The cable has five incoming wires:

•

•

•

•

•

CAN high signal wire

CAN low signal wire

V

V

Ground

for electronic power supply

bat

for solenoid power supply

bat2

Page 15

System

Controller

Vbat

Vneg

CAN_H

CAN_L

Vbat2

CAN_H

Cable harness

Cable harness

PVED-CX #1 PVED-CX #2 PVED-CX #n

Cable harness

LVDT out

LVDT in

Vbat2 out

Vbat2 in

Vbat3

CAN_L

CAN_H

Vneg

Vbat

LVDT out

LVDT in

Vbat2 out

Vbat2 in

Vbat3

CAN_L

CAN_H

Vneg

Vbat

LVDT out

LVDT in

Vbat2 out

Vbat2 in

Vbat3

CAN_L

CAN_H

Vneg

Vbat

120 ohm

V310008.B

W

W

Technical Information

PVED-CX, Series 4 Electrohydraulic Actuator

PVED-CX functionality

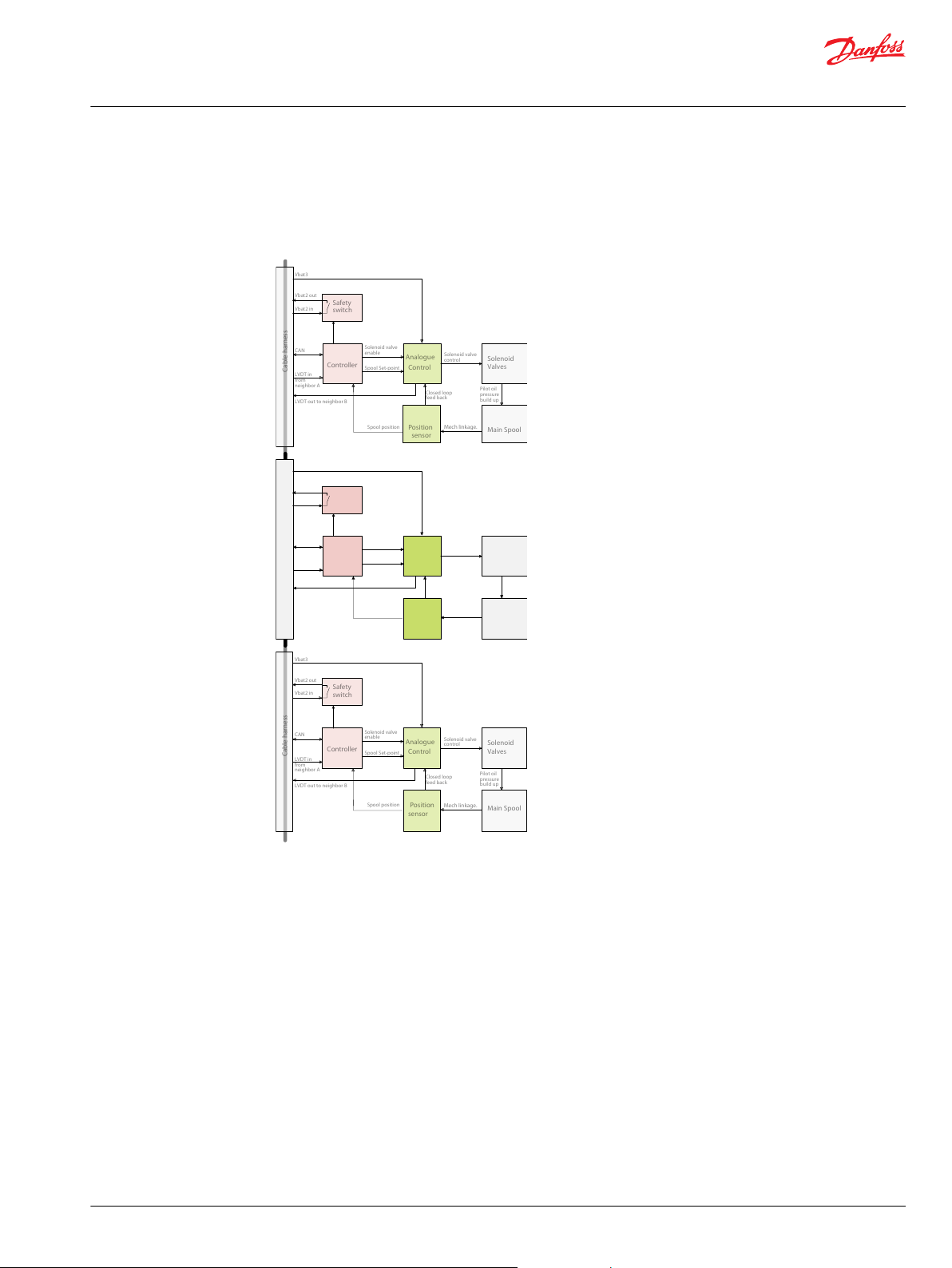

Cable kit principle

Three wires are added between the modules:

1. V

power supply. This wire is looped as a V

bat2

through the safety switches in the modules.

2. V

power supply is a transformation of V

bat3

the solenoid valves.

3. LVDT out – LVDT in signal wire. This connects the analogue spool position signal from one module

to the neighbor microcontroller.

The termination in the last connector is optional.

out – V

bat2

out from the last module and now used for powering

bat2

in between the modules and goes

bat2

Mounting

The Danfoss PVG concept is based on parts interchangeability. This is also valid for the PVED-CX and

makes field retrofitting possible.

PVED can be mounted on both ends of PVB.

•

Cable kit can be mounted with first or last connector next to PVP.

•

Cable kit can be delivered with and without CANbus termination.

•

Warning

Deviation from recommended torque can harm performance and module.

Linear Variable Differential Transducer (LVDT)

The Linear Variable Differential Transducer (LVDT) or position sensor is the interface between the

mechanical system (spool) and the electronic system.

Warning

The LVDT must never be mechanically adjusted, bent, damaged or partially blocked as this will lead to

incorrect information on spool position.

Spool neutral spring

The PVBS neutral spring is an important safety component as it keeps or moves the PVBS in blocked

position when solenoid valves are disabled. The spring will keep the A and B port closed as long as the

differential pressure is below 6 bar.

©

Danfoss | Jun 2017 11070179 | BC00000068en-US0503 | 15

Page 16

Pp

NC3

NC1

Spool

NO4

NO2

Tank

LVDT

Set point

V310073.A

1.0 [0.039]

Electronics

W

Technical Information

PVED-CX, Series 4 Electrohydraulic Actuator

PVED-CX functionality

Hydraulic subsystem

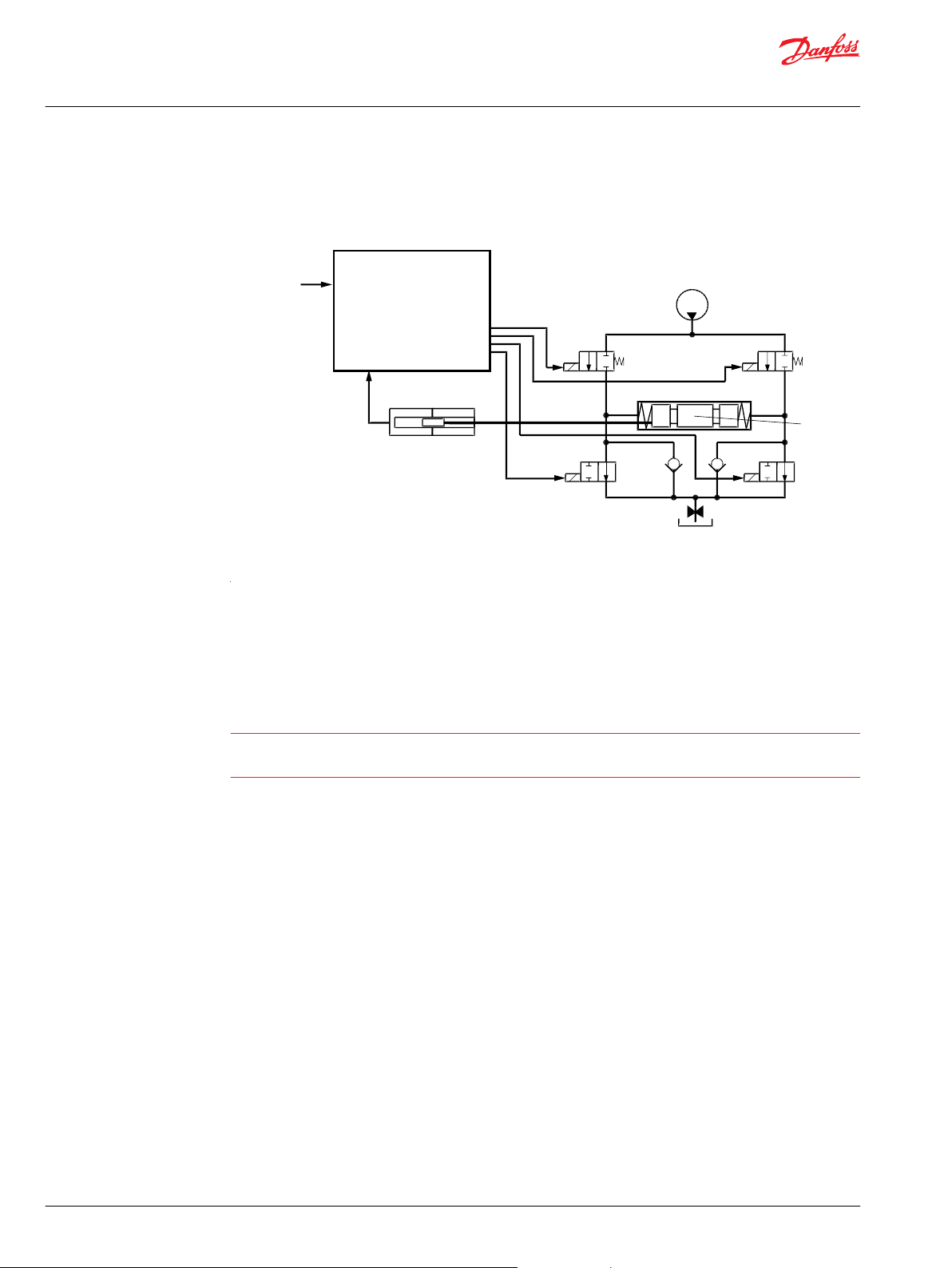

The hydraulic subsystem is used for moving the spool and thereby opening the valve for work flow.

Pilot oil diagram

Electrical and electronic subsystem

The heart of the hydraulic subsystem is the solenoid valve bridge. It consist of four poppet valves, the two

upper ones are normally closed (NC-S) with a small bleed, the two lower ones are normally open (NO).

The Pp will work against the PVBS neutral spring when the spool is moved out of blocked (neutral) and

together with the spring when going in blocked. This combined with a larger opening in the NO than in

the NC-S will give a faster movement towards blocked than out of blocked.

Warning

Obstacles for the Pp can have direct influence on spool control. Reduced pilot pressure will limit spool

control. Too high Pp can harm the system.

The PVED-CX is based on the known PVED-CC series 4 technology with the ASIC core controlling the main

functionality of the solenoid valves, and a micro-controller system as Module Safety Manager and

interface between the analogue ASIC and the CAN bus communication. The micro-controller also

monitors its neighbor PVED-CX and has the ability to disable spool actuation for the whole control

section.

16 | © Danfoss | Jun 2017 11070179 | BC00000068en-US0503

Page 17

Safety

switch

Controller

Analogue

Control

Solenoid

Valves

Main Spool

Position

sensor

Cable harness

CAN

Spool Set-point

Closed loop

feed back

LVDT out to neighbor B

LVDT in

from

neighbor A

Spool position

Solenoid valve

control

Vbat3

Vbat2 in

Vbat2 out

Pilot oil

pressure

build up

Mech linkage.

Solenoid valve

enable

Safety

switch

Controller

Analogue

Control

Solenoid

Valves

Main Spool

Position

sensor

Cable harness

CAN

Spool Set-point

Closed loop

feed back

LVDT out to neighbor B

LVDT in

from

neighbor A

Spool position

Solenoid valve

control

Vbat3

Vbat2 in

Vbat2 out

Pilot oil

pressure

build up

Mech linkage.

Solenoid valve

enable

Neighbor A

Neighbor B

Safety

switch

Controller

Analogue

Control

Solenoid

Valves

Main Spool

Position

sensor

Cable harness

CAN

Spool Set-point

Closed loop

feed back

LVDT out to neighbor B

LVDT in

from

neighbor A

Spool position

Solenoid valve

control

Vbat3

Vbat2 in

Vbat2 out

Pilot oil

pressure

build up

Mech linkage.

Solenoid valve

enable

V310 207.A

Technical Information

PVED-CX, Series 4 Electrohydraulic Actuator

PVED-CX functionality

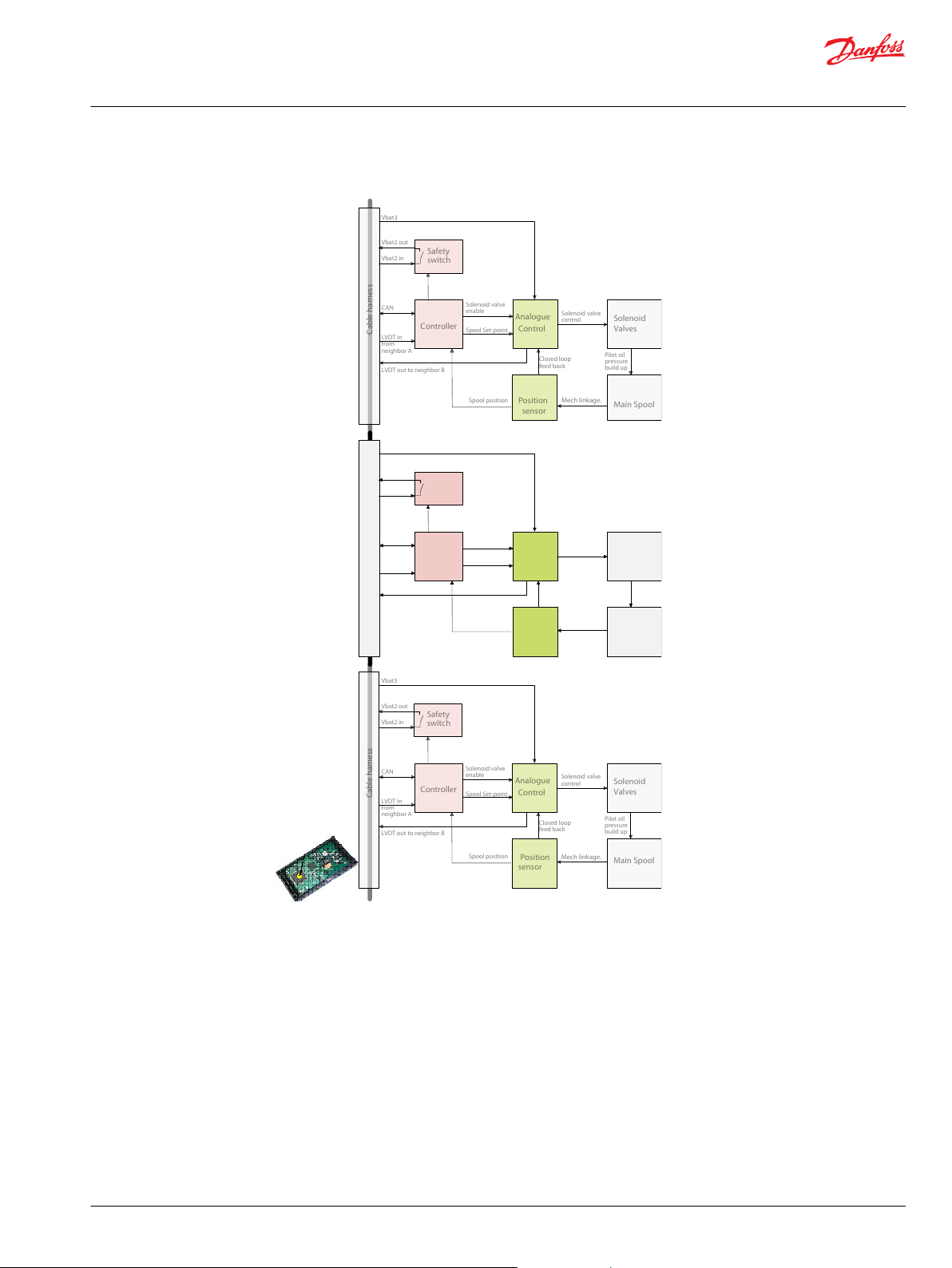

Function blocks for electronics

Controller: The build in micro-controller.

Safety switch: MOSFET for collective solenoid disabling inside the control section.

Position sensor: Mechanical electrical interface.

Analogue control: A closed loop control of spool position based on set point. Feedback to system is actual spool

position and error state.

Communication

©

Danfoss | Jun 2017 11070179 | BC00000068en-US0503 | 17

The PVED-CX has three methods of communication.

Optical from module

•

Analogue one way communication

•

Digital two way communication

•

Page 18

NOT_READY

INIT

FAULTDISABLED

HOLD

FAULT_HOLD

DEVICE_MODE_

ACTIVE

FAULT_

REACTION

Operational

Pre-Operational

Stopped

Communication state machine

Initialisation

Reset

Application

Reset

Communication

Initialising

Device state machine

Power on

V310034.A

Technical Information

PVED-CX, Series 4 Electrohydraulic Actuator

PVED-CX functionality

Optical – LED

Blinking and steady light is implemented to facilitate maintenance and application engineering.

Analogue

Analogue communication is implemented.

An analogue signal is sent from active module to monitoring module to enforce redundancy.

Module under surveillance is referred to as neighbor module in settings.

The operational mode of the module under surveillance (neighbor) decides the behavior of the

monitoring module.

Digital – CANopen

The CANopen communication is the main method. It is used for:

•

Control of module by master. Master defines state transition and set points.

•

Reporting from module to master. Module reports spool position and safety violation

•

Setting in module by master. Some parameters can be changed.

•

Inquiry from master to module.

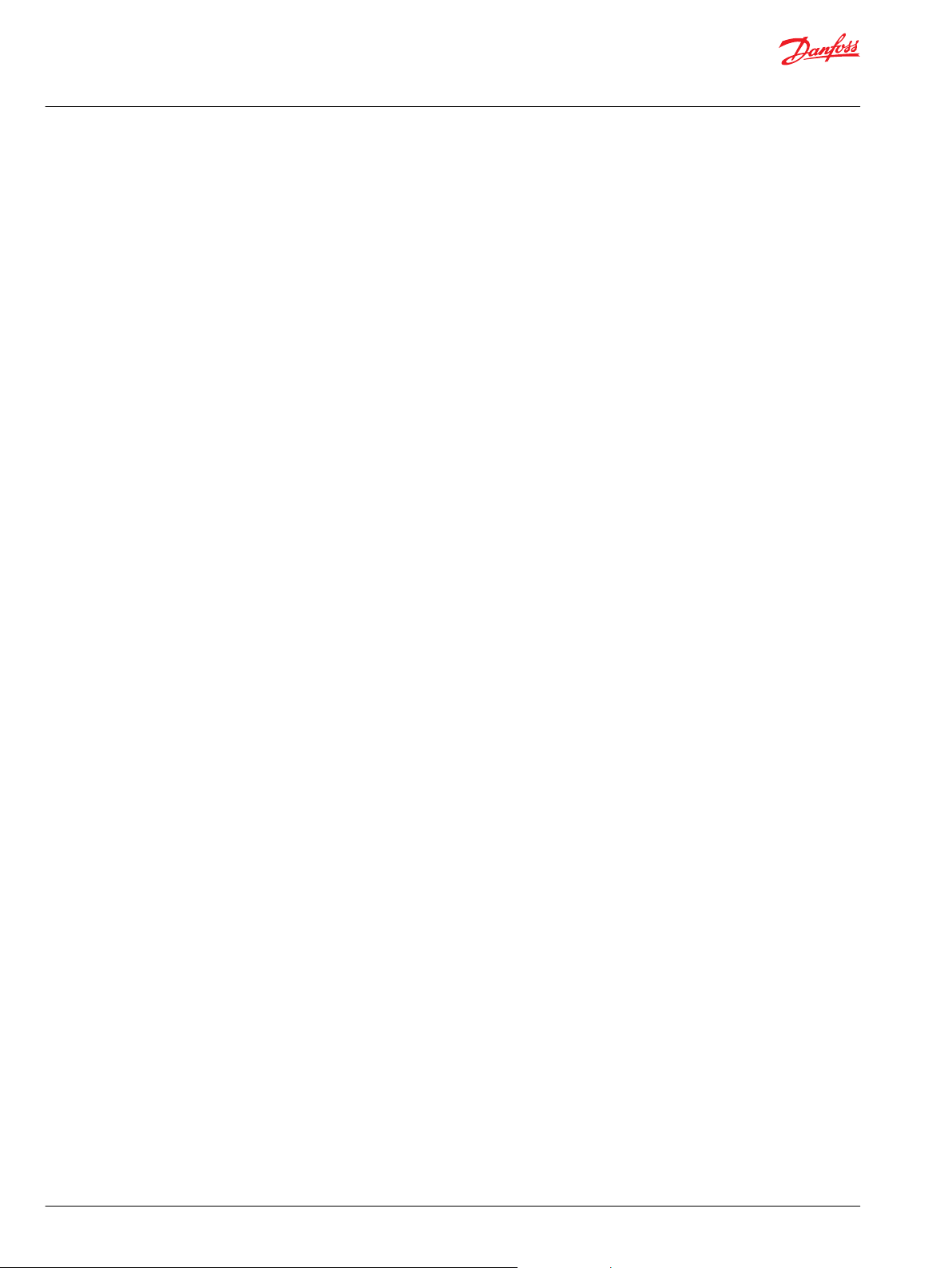

Computerized subsystem

CANopen is a communication protocol defined by the society CAN in Automation (CiA). For details in the

protocol we refer to CiA.

The PVED-CX operates according to defined Device State Machines (DSM) giving conditions for transition

between states. The Communication State Machine (CSM) is pre-condition for the DSM.

State transitions depends on internal conditions e.g. the sanity of the PVED-CX and can also depend on

external conditions e.g. application controller commands and changes in preconditions for normal valve

operation.

DSM and CSM for PVED-CX

18 | © Danfoss | Jun 2017 11070179 | BC00000068en-US0503

Page 19

Technical Information

PVED-CX, Series 4 Electrohydraulic Actuator

PVED-CX functionality

When power is applied to the PVED-CX it will initialize components and validate component states and

parameter settings. This is the power on self test (POST).

If test is passed the PVED will enter Disabled State and make it self known to the controller as active.

Otherwise it will enter Fault mode and if possible also generate a fault message.

When the state is Device Mode Active or Device Mode Disabled module reporting can be trusted when in

fault states report validity is related to the fault type.

Operational modes

The PVED-CX has three accessible operational modes for normal operations.

Full operational. Spool position is controlled and monitored. Device Mode Active.

•

Hand operational. Spool position is monitored. Device Mode Disabled.

•

Automatic system safety integrity self test. Device Mode Active.

•

It is not mandatory for all modules in the same Control Section to be in the same Operational Mode.

Fault monitoring is active independent of operational mode.

See Safety description on page 23 section.

Full operational

In full operational mode the PVED-CX controls the spool and monitors the neighbor spool.

This mode is characterized by:

Set point is received from Master and acted on by the module

•

Solenoid valves are enabled by local switch if not in Power Save

•

Neighbor monitoring of set point and spool position is active

•

Spool position reporting is active

•

No fault is present

•

LED green

•

Hand operational

In hand operational mode the PVED-CX cannot control the spool.

This mode is characterized by:

Spool position is defined by PVM and spool neutral spring

•

Set point is not calculated. Master module does not have to send

•

Solenoid valves are disabled by local switch

•

Neighbor monitoring of spool reporting is active

•

Spool position reporting is active

•

No fault is present

•

LED green.

•

Automatic system safety integrity self test – ASSIST

The ASSIST is as a tool for end-of-line test and maintenance test especially in connection with parts

replacement and system modification.

In the ASSIST the system ability to recognize spool movement as fault and signal incongruence is tested

automatically. This also includes the redundancy created by the cable harness.

The following is tested:

©

Danfoss | Jun 2017 11070179 | BC00000068en-US0503 | 19

Page 20

Technical Information

PVED-CX, Series 4 Electrohydraulic Actuator

PVED-CX functionality

Main spool kept in and brought back to neutral by spring

•

The 4 magnetic solenoids

•

The LVDT sensor

•

The ASIC spool position reporting

•

The ASIC closed loop control of the main spool position

•

Node Id and neighbor node Id validity

•

This mode is characterized by:

Solenoid valves are activated but not controlled by master device

•

Fault monitoring and reporting has a mode specific pattern

•

Settings

The PVED-CX offers a number of settings for both system information and system operation. The

parameters are, as required in CANopen, organized in an Electronic Data Sheet (EDS). The available

parameters are both fixed parameters and variable parameters. For details in the protocol we refer to CiA.

Logging

During operation the PVED-CX logs data, that can be accessed at any time.

Error history. A runtime log, cleared by reset and power off, keeps track of error order in a FIFO buffer

•

Error counts. For each error code an occurrence counter is maintained in the EEPROM

•

Temperature (current)

•

Temperature histogram. For every 6 minutes of run time the current temperature is logged

•

Please find details in the Data section.

20 | © Danfoss | Jun 2017 11070179 | BC00000068en-US0503

Page 21

Safety

switch

Controller

Analogue

Control

Solenoid

Valves

Main Spool

Position

sensor

Cable harness

CAN

Spool Set-point

Closed loop

feed back

LVDT out to neighbor B

LVDT in

from

neighbor A

Spool position

Solenoid valve

control

Vbat3

Vbat2 in

Vbat2 out

Pilot oil

pressure

build up

Mech linkage.

Solenoid valve

enable

Safety

switch

Controller

Analogue

Control

Solenoid

Valves

Main Spool

Position

sensor

Cable harness

CAN

Spool Set-point

Closed loop

feed back

LVDT out to neighbor B

LVDT in

from

neighbor A

Spool position

Solenoid valve

control

Vbat3

Vbat2 in

Vbat2 out

Pilot oil

pressure

build up

Mech linkage.

Solenoid valve

enable

Neighbor A

Neighbor B

Safety

switch

Controller

Analogue

Control

Solenoid

Valves

Main Spool

Position

sensor

Cable harness

CAN

Spool Set-point

Closed loop

feed back

LVDT out to neighbor B

LVDT in

from

neighbor A

Spool position

Solenoid valve

control

Vbat3

Vbat2 in

Vbat2 out

Pilot oil

pressure

build up

Mech linkage.

Solenoid valve

enable

V310 207.A

Technical Information

PVED-CX, Series 4 Electrohydraulic Actuator

Normal operation – self and neighbor supervision concept

The main spool is kept in blocked/neutral position by the neutral spring. By use of the handle (PVM) or

the solenoid valves and the Pp the spool can be moved to any position and so open for system pressure

to the application.

Function cooperation in control section

Set point command

Spool supervision

©

Danfoss | Jun 2017 11070179 | BC00000068en-US0503 | 21

The Set Point for the PVED is broadcasted on CAN bus by the System Main Controller/Master. During

transmission the signal is evaluated for irregularity by all modules on the bus but only modules

programmed for the specific signal will perform further calculations.

Upon reception the micro-controller (relevant module and neighbor) evaluates the validity of the set

point.

If the set point is valid, and not blocked when power save is active, a local switch in the ASIC is conected

by the microcontroller and the solenoid valves are enabled.

The controller transforms the digital message to a PWM signal and sends it to the ASIC.

The ASIC evaluate if the PWM is in the valid range.

At any time the ASIC monitors the spool position via the position sensor (LVDT) feedback. This

determines the spool position for the closed loop control. Additionally the spool position is sent from the

Page 22

Technical Information

PVED-CX, Series 4 Electrohydraulic Actuator

Normal operation – self and neighbor supervision concept

ASIC to the neighbor microcontroller as an analogue signal and the LVDT feedback is also fed to the

microcontroller for generation of the CAN message.

Solenoid control

Based on set point and spool position the ASIC performs a closed loop control at a fixed frequency

controlling the solenoid bridge.

Position reporting

The PVED-CX sends, when operating as a system configured module, continued spool position reports.

This is intended as information for comparison for the application controller and the neighbor module

Neighbor supervision

Microcontroller supervision

ASIC supervision

CAN: Spool position is calculated and broadcasted on the CAN bus with redundant representation of data.

Spool position is reported as blocked when closer to neutral than approx. 0.7 mm.

Spool position is reported as not blocked when further from neutral than approx. 0.7 mm.

When the spool is further from neutral than software dead-band threshold the spool position is

calculated as an averaged value over the last 50 ms.

Analogue: Spool position is sent as an analogue signal to neighbor microcontroller.

The special PVED-CX cable kit ensures that the supervising module has the spool position from the

supervised module as an analogue value and also the reported spool position via CAN bus. If supervised

module is in Full Operational mode the set point from the controller is also known.

The neighbor microcontroller compares the analogue and the CAN spool position values. In Full

Operational Mode the spool position is also compared to the set point. Any deviation will raise an error.

Spool monitoring in PVG, see Cable kit principle.

The microcontroller has mutual watch dog functionality with a PIC giving redundant ability to shut down

the ASIC. The PIC can also shut down CAN communication.

The ASIC feeder signal for the LVDT is monitored by the microcontroller.

Temperature supervision

The temperature of the electronic printed circuit board (PCB) is continuously monitored. This has two

purposes:

Calculated expected system reaction time must reflect temperature changes in oil viscosity.

•

Component temperature conditions are within specified values.

•

Power save

To minimize energy consumption the PVED-CX has a power save functionality. If the set point for the

PVED-CX has been blocked for more than 500ms the solenoids will be deactivated by the local switch.

This reduces power consumption by 90 %.

22 | © Danfoss | Jun 2017 11070179 | BC00000068en-US0503

Page 23

Technical Information

PVED-CX, Series 4 Electrohydraulic Actuator

Safety description

The Danfoss definition of safe state transition by fault is: Spool is placed in blocked position (neutral).

The PVED-CX has Active Fault Reaction, e.g. brings the system into a safe state on fault.

The PVED-CX safety concept is based on three elements:

POST – Power On Self Test

•

ASSIST – Automatic System Safety Integrity Test

•

Runtime fault monitoring and reaction

•

The basic elements for product safety are:

Continuous module monitoring

•

Fault recognition and reaction

•

Fault reporting and recording

•

Fault recovery

•

POST – Power On Self Test

Passing of the Power On Self Test is a pre condition for Full Operational Mode and ASSIST.

The POST evaluates internal signals, memory state, internal settings and neighbor connection.

ASSIST – Automatic System Safety Integrity Test

The Automatic System Safety Integrity Self Test evaluates the electrical wiring connections, module inter

communication, spool monitoring and hydraulic spool control.

The ASSIST is an optional test but must be passed in case of:

First time use of PVG

•

Changes in settings

•

Cable kit replacement and manipulation

•

Module replacement

•

Runtime fault monitoring

The fault monitoring is a part of the continuous self and neighbor monitoring. A number of conditions

will force the Device State Machine transition to fault mode. For details see sections: Data section and

Error codes.

Communication fault

Communication faults interrupts application (system) and module cooperation. These faults are mainly

connected to wiring faults, disabled controllers and illegal commands.

Loss of communication

•

Valid communication with invalid data

•

Communication disturbance

•

The CAN communication is based on a physical layer applying to ISO 11898-2 high speed CAN. Faults

handled by this standard are not considered relevant for this document with recovery from bus off as an

exception.

Spool position fault

Spool position faults are directly related to the hydraulic performance of the application. These faults

indicate difference between demanded and actual spool position.

The following categories of position faults are recognized:

©

Danfoss | Jun 2017 11070179 | BC00000068en-US0503 | 23

Page 24

Technical Information

PVED-CX, Series 4 Electrohydraulic Actuator

Safety description

Spool further out than demanded.

•

Spool in opposite direction to demanded.

•

Spool not in neutral: Target window monitoring

•

The spool position is determined by LVDT contact to spool end. LVDT faults are treated as electrical faults.

Spool position is handled with tolerance as stated in Data section with consideration to mechanical delay

and temperature influence.

System data fault

The data handling is depending on the quality of stored data and the range of input data. To avoid faults

the following is monitored:

Degradation of EEPROM.

•

Degradation of FLASH.

•

Sanity of look up tables

•

Undefined calculations – division by 0

•

Interpolation replaced by extrapolation

•

Unwanted truncation

•

Interrupted write process - Data mirror

•

Inconsistency in spool position calculation

•

Electrical fault

The quality/presence of the following electrical signals is monitored to guarantee behavior within

specification.

Reciprocal watch dog signals between PIC and microprocessor

•

Battery voltage in specified level

•

LVDT feeder signals from ASIC

•

Analogue to digital converter ADC

•

PWM (Pulse width Modulated) signal from micro processor to ASIC

•

Temperature fault and correction

Electronic component reliability and electronic component life time are influenced by temperature as

well as oil viscosity is. Temperature measurements on PCB is used for

Interrupting spool control if PCB temperature is to high

•

Interrupting spool control if PCB average temperature is to high

•

Delay spool monitoring time out if PCB temperature is to low

•

Determine product work hours based on temperature histogram

•

Test fault

The PVED has two tests with special status.

POST. Power On Self Test for module integrity before operation.

•

ASSIST. Automatic System Safety Integrity Self Test for module cooperation in control section.

•

Fault level

The PVED-CX has three fault severity levels.

24 | © Danfoss | Jun 2017 11070179 | BC00000068en-US0503

Page 25

Technical Information

PVED-CX, Series 4 Electrohydraulic Actuator

Safety description

Warning

•

Critical

•

Severe

•

Warning

Warning is entered if the fault is expected to have external origin and the PVED performance is certain

not to suffer once the state is passed. Warning has no influence on neighbor modules activity.

Critical

Critical is entered if reliability of a defined element of the system could be threatened. Critical has

influence on neighbor modules activity.

Severe

Severe is entered if system reliability could be threatened. Severe has influence on neighbor modules

activity.

Threshold not passed

If a fault precondition is present the PVED keeps track but operates as requested until an eventual

threshold is passed e.g. spool not at demanded position but only for a short time.

For every fault related to a time or occurrence threshold a counter is established.

The counter is started and reset according to a fault depending scheme.

Fault reaction

Fault reporting

The fault reaction has highest priority in the PVED-CX. Depending on the fault the PVED immediately

goes into a defined fault state. Any fault of a higher severity will override any present less severe fault.

Warning Local switch is disabled. Solenoid valves disabled.

Critical and

Severe

Spool monitoring and reporting still active. Comparison set point-actual position is disabled

Fault monitoring still active depending on operation mode.

Neighbor monitoring still active

Safety switch is disabled. Solenoid valves disabled in the whole control section.

Spool monitoring and reporting still active. Comparison set point-actual position is disabled

Fault monitoring still active depending on operation mode.

Neighbor monitoring still active

Fault reporting is a part of the communication task and has lower priority than fault reaction.

CAN bus Appropriate emergency messages are sent out according to the CANopen standard.

Error logs Fault is stored in an EDS log in RAM over last 50 errors using a first in first out buffer.

Light emitting diode To ensure easy maintenance the PVED-CX utilizes the LED to indicate state of the

In case of multiple errors Servere has precedence over Critical that has precedence over

Warning. Errors of same severity are broadcast in order of occurrence.

Fault is stored in an EDS log in EEPROM showing occurrence of every fault Id. Max 255.

The Error log in the EEPROM cannot be reset.

module.

Fault recovery

Module and system fault recovery requires that all faults have disappeared.

Warning Recovery is possible with software reset command.

Critical Recovery is possible with software reset command.

Severe Recovery is only possible with power cycle.

©

Danfoss | Jun 2017 11070179 | BC00000068en-US0503 | 25

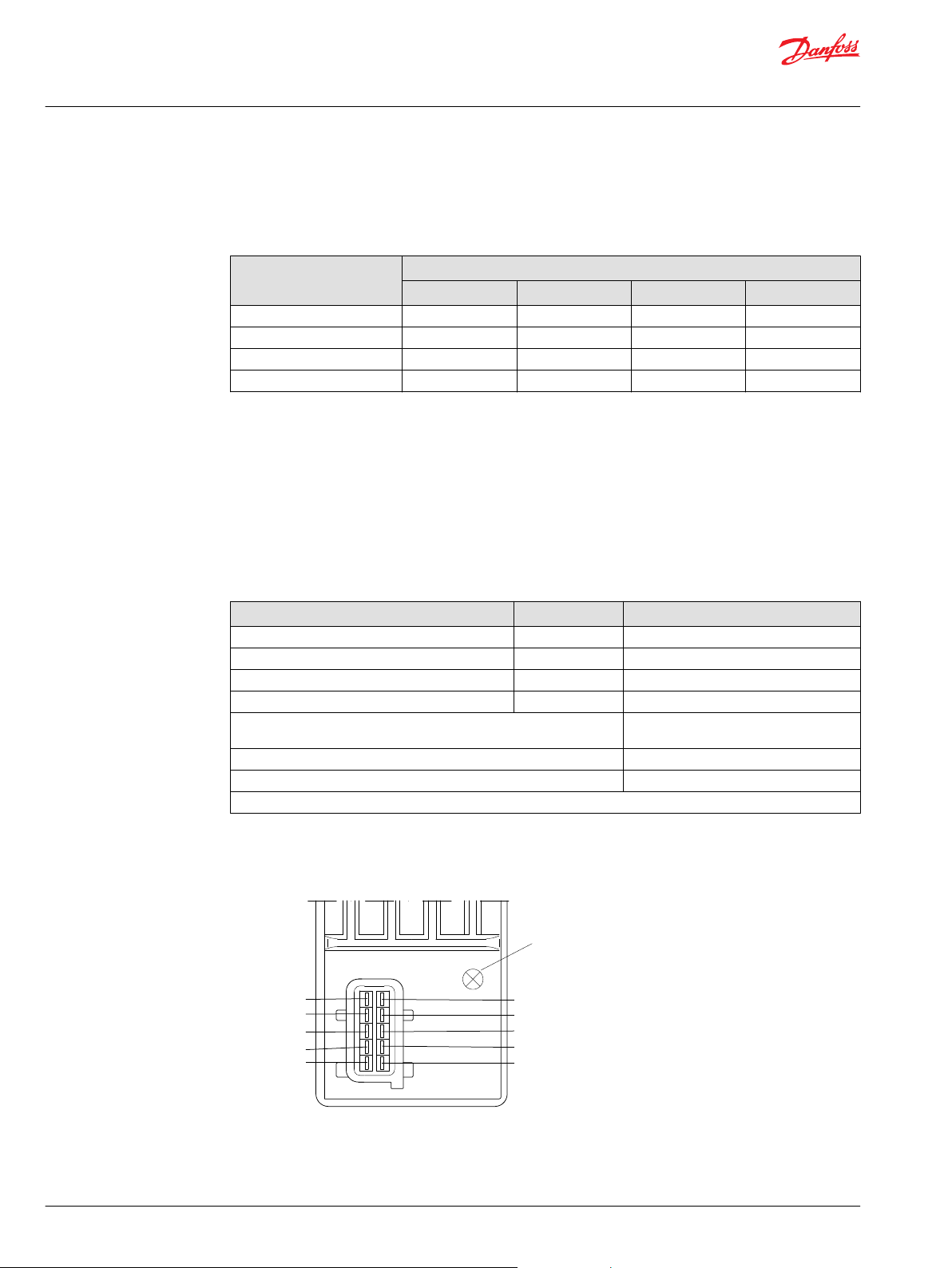

Page 26

5 SP_POS_IN

4 not connected

2 Vbat2 IN

1 Vbat2 OUT

10 SP_POS_OUT

9 CAN_L

8 CAN_H

7 Vneg

6 Vbat

3 Vbat 3

LED

V310 021.A

Technical Information

PVED-CX, Series 4 Electrohydraulic Actuator

Data section

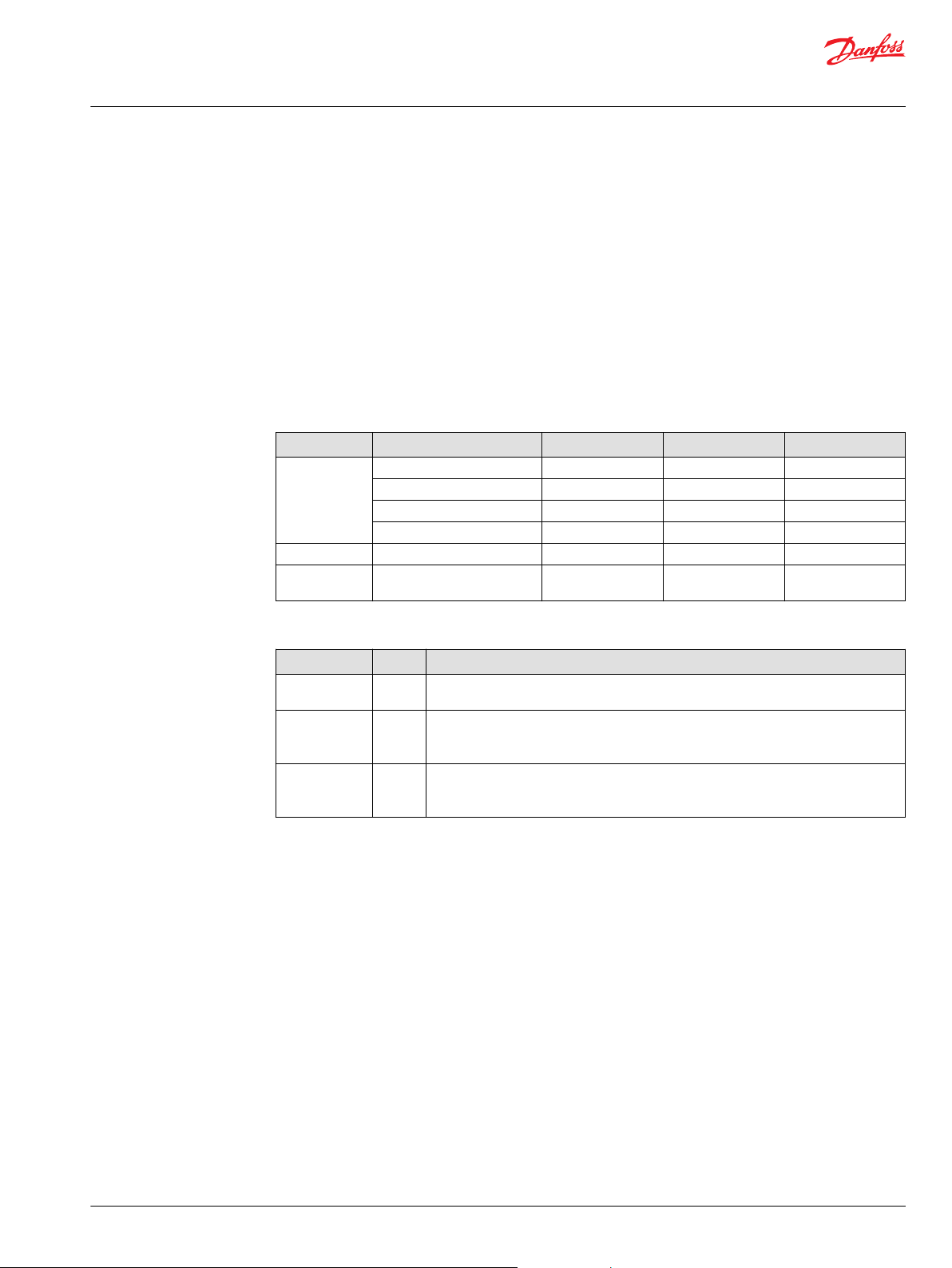

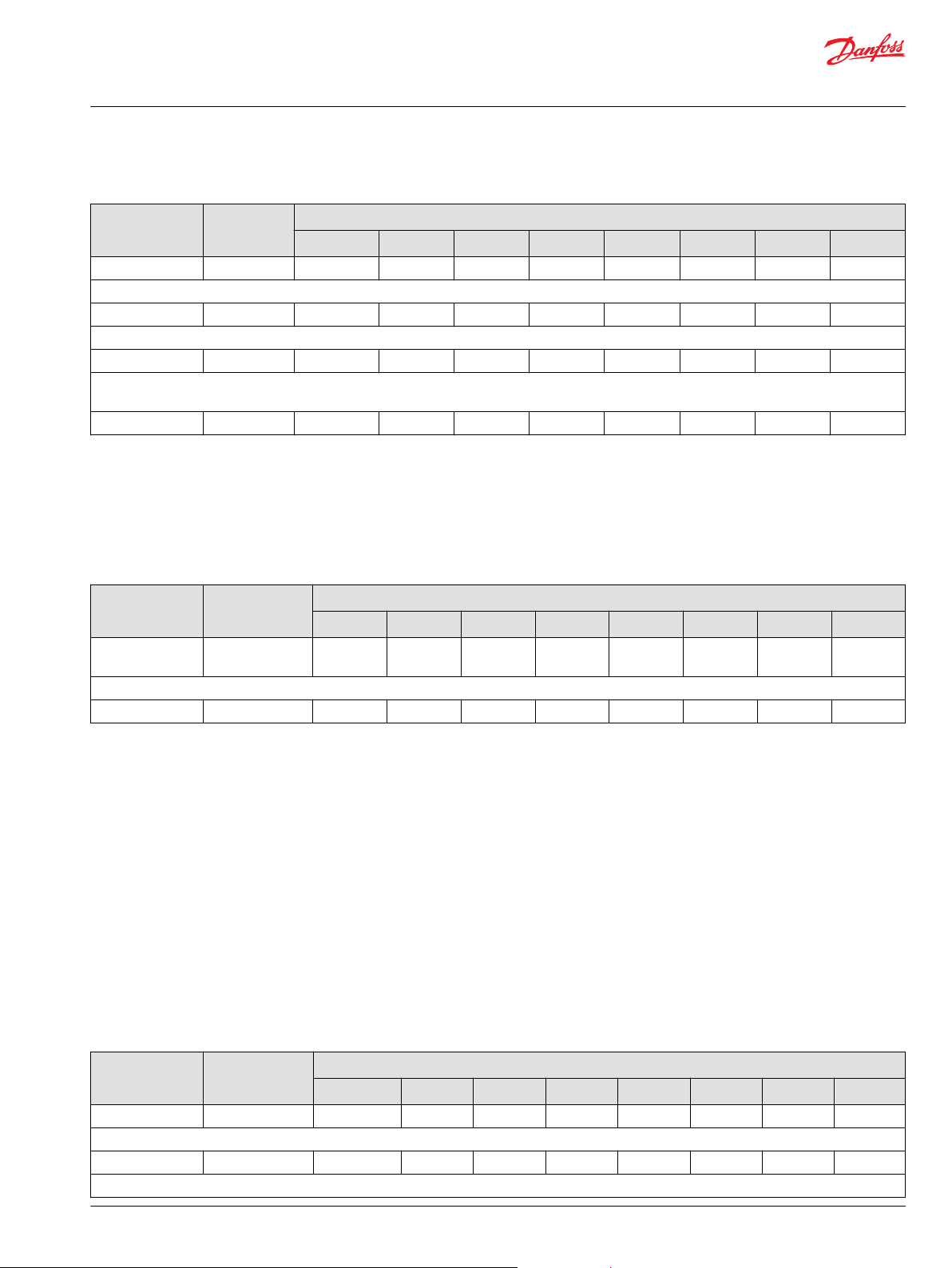

Operational conditions

The PVED-CX will only operate according to this table.

Operational conditions

Mode Supply

Electronic test. POST Mandatory Optional Optional Optional

System test. ASSIST Mandatory Mandatory Mandatory Disabled

Manual operation Optional

Full operation Mandatory Mandatory Mandatory Mandatory

*

Mandatory if spool position information is requested.

**

If hydraulic performance is expected.