Page 1

Safety Manual and Programmer Guide

PLUS+1® Compliant

PVED-CLS Hardware Function Blocks

www.danfoss.com

Page 2

Safety Manual and Programmer Guide

PVED-CLS Hardware Function Blocks

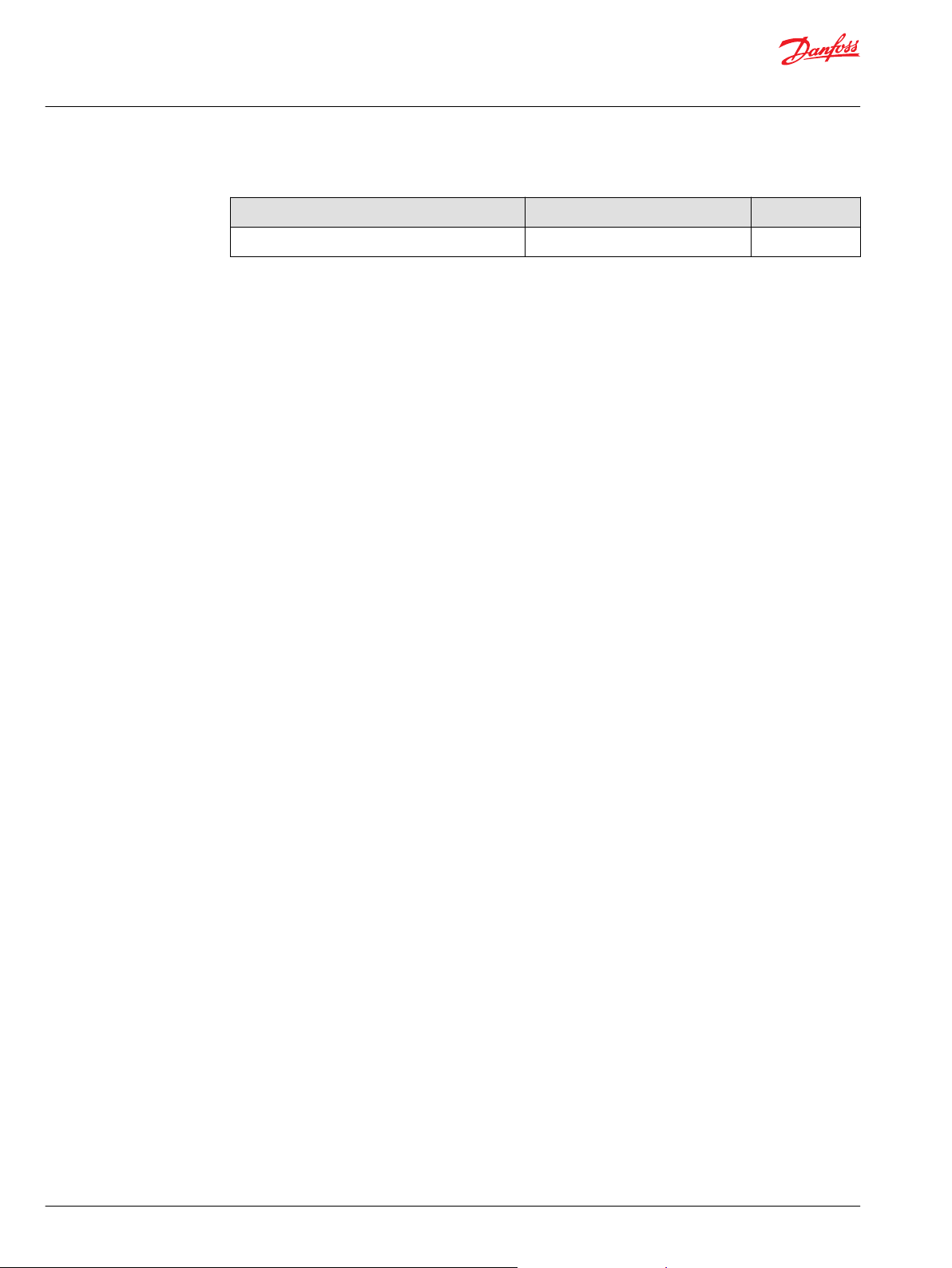

Revision history Table of revisions

Date Changed Rev

November 2018 First edition 0101

2 | © Danfoss | November 2018 AQ00000254en-000101

Page 3

Safety Manual and Programmer Guide

PVED-CLS Hardware Function Blocks

Contents

Document Overview

Quality and Safety Considerations

Applicable Function Blocks for This Safety Manual............................................................................................................. 5

Safety Integrity Level.......................................................................................................................................................................6

Reference Manuals...........................................................................................................................................................................6

Obtaining Technical Literature and Reference Manuals...............................................................................................7

Obtaining Product Support..........................................................................................................................................................7

Common Features of the Function Blocks

All Blocks Have a Common Structure........................................................................................................................................8

All Blocks Have Inputs that Require Defined Data Types...................................................................................................9

All Blocks Have Companion Service Screens..........................................................................................................................9

Import Service Tool Pages from the PLUS+1® GUIDE Library Tab Manager........................................................10

Using Identical Blocks in the Same Application

Identical Function Blocks Need Different Namespace Values to Successfully Compile...................................... 12

Identical Service Tool Screens Need Different Signal Name Prefixes to be Usable............................................... 12

Change Signal Name Prefixes with the Find and Replace Feature..............................................................................13

Switching Between Different Parameter Sets..................................................................................................................... 13

Fault of Input Signals....................................................................................................................................................................14

Status of Parameters.....................................................................................................................................................................14

Best Practices

Using the Same Parameter in Several Function Blocks....................................................................................................15

Controller Memory Consumption............................................................................................................................................15

Glossary

Abbreviations

©

Danfoss | November 2018 AQ00000254en-000101 | 3

Page 4

Safety Manual and Programmer Guide

PVED-CLS Hardware Function Blocks

Document Overview

This manual provides information that is applicable to every function block of the PVED-CLS hardware

function block library.

You must read this Safety Manual and Programmer Guide before you read any user manual for a specific

PVED function block.

4 | © Danfoss | November 2018 AQ00000254en-000101

Page 5

W

Safety Manual and Programmer Guide

PVED-CLS Hardware Function Blocks

Quality and Safety Considerations

You must know and follow appropriate safety standards and specifications when developing a product.

Fulfilling standards and legal requirements results in several development needs — documentation,

development processes, organizational structures, and so on. All these needs have the goal to ensure a

certain product quality and safety. Meeting these requirements also makes your product development

process transparent and traceable for others.

The following are some items to consider when developing your application:

Review your specification of requirements, design, code and tests with peers.

•

Document decisions, actions, specifications, designs and reviews.

•

Assign the different roles to members of your team, such as programmer, tester, review team, and so

•

on.

Ensure the tester is a different person than the programmer.

•

Test all required functions, including functions in machines operating at extremes, on the target

•

platform.

Test all the required functions, including extreme situations and worst case scenarios, on the target

•

platform.

Implement life cycle and change management.

•

Ensure your documentation is complete, comprehensive, and understandable.

•

These considerations are necessary as a minimum. You may have additional considerations for your

application.

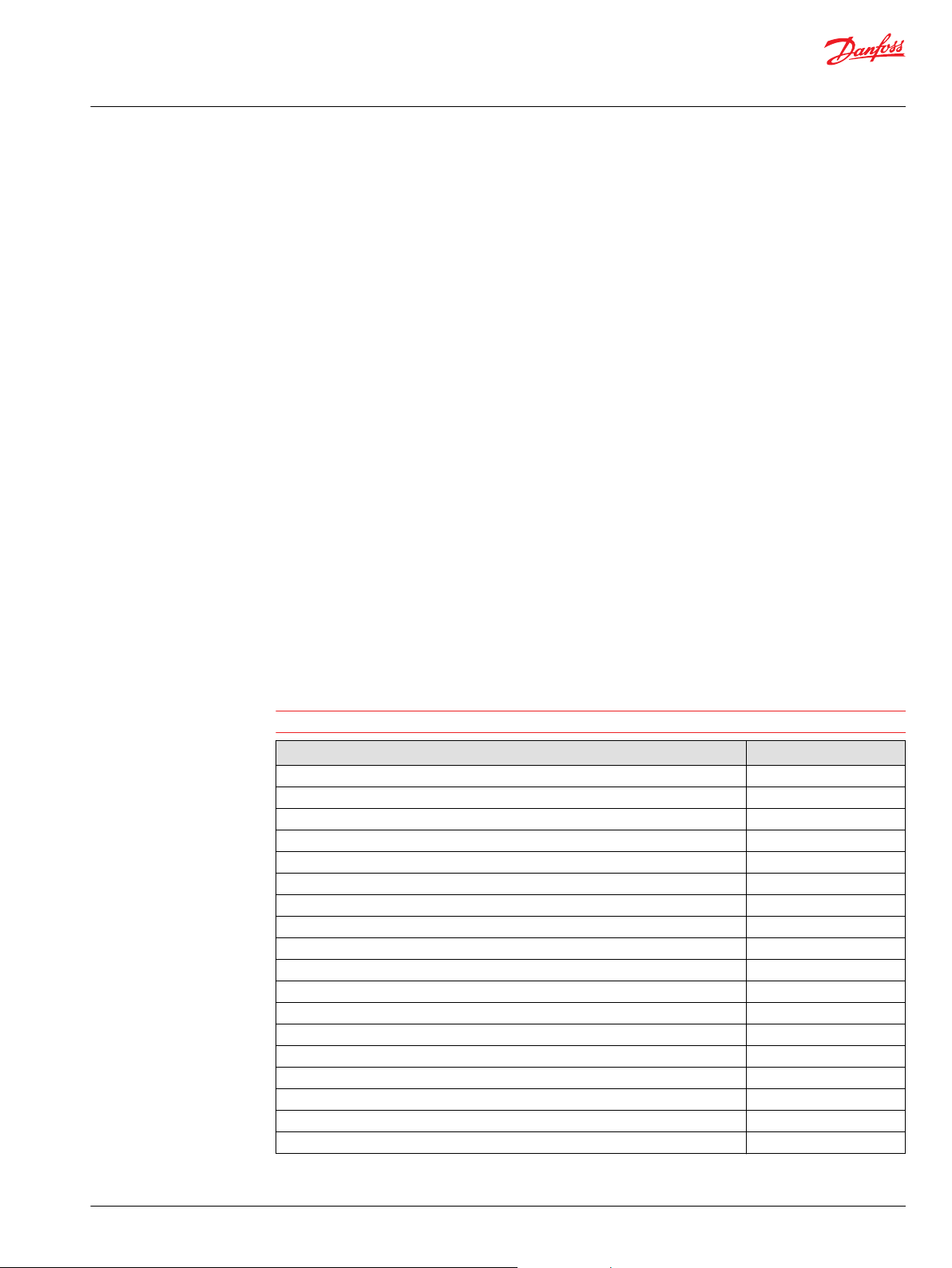

Applicable Function Blocks for This Safety Manual

The content of this safety manual is valid for the following PVED-CLS Hardware Function Blocks

contained in the PVED_CLS_70316311v100.HWD.

Warning

Read this manual completely before programming your application.

Name Version

PVED_CLS_AUX_JOY 1.00

PVED_CLS_AUX_STW 1.00

PVED_CLS_GMC 1.00

PVED_CLS_GMS 1.00

PVED_CLS_MMI 1.00

PVED_CLS_STAT_Msg_0_OP 1.00

PVED_CLS_STAT_Msg_1 1.00

PVED_CLS_STAT_Msg_2 1.00

PVED_CLS_STAT_Msg_3 1.00

PVED_CLS_STAT_Msg_4 1.00

PVED_CLS_STAT_Msg_5 1.00

PVED_CLS_STAT_Msg_6 1.00

PVED_CLS_STAT_Msg_7 1.00

PVED_CLS_STAT_Msg_8 1.00

PVED_CLS_Str_Fdbk 1.00

PVED_CLS_STW 1.00

PVED_CLS_VSP 1.00

PVED_CLS_WAS 1.00

©

Danfoss | November 2018 AQ00000254en-000101 | 5

Page 6

Safety Manual and Programmer Guide

PVED-CLS Hardware Function Blocks

Quality and Safety Considerations

Safety Integrity Level

The PVED-CLS Hardware Function Block Library is designed to meet SIL 2 in accordance with IEC 61508

Ed. 3.

The OEM/customer is responsible for the overall functional safety specification, safety integrity level

requirement, implementation and validation of their application. Detailed analysis, review and

documentation for compliance to ISO 13849 or ISO 25119 must be done by the designer or integrator of

the safety related system.

The OEM/customer must select an appropriate PLUS+1® controller for the application. This selection

depends on the identified target risk reduction required for the application.

The function blocks in the library are unit tested and suitable for direct integration into the OEM/

customer target PLUS+1® GUIDE application software. Each function block is designed for signal

conversion and not for performing any safety functions.

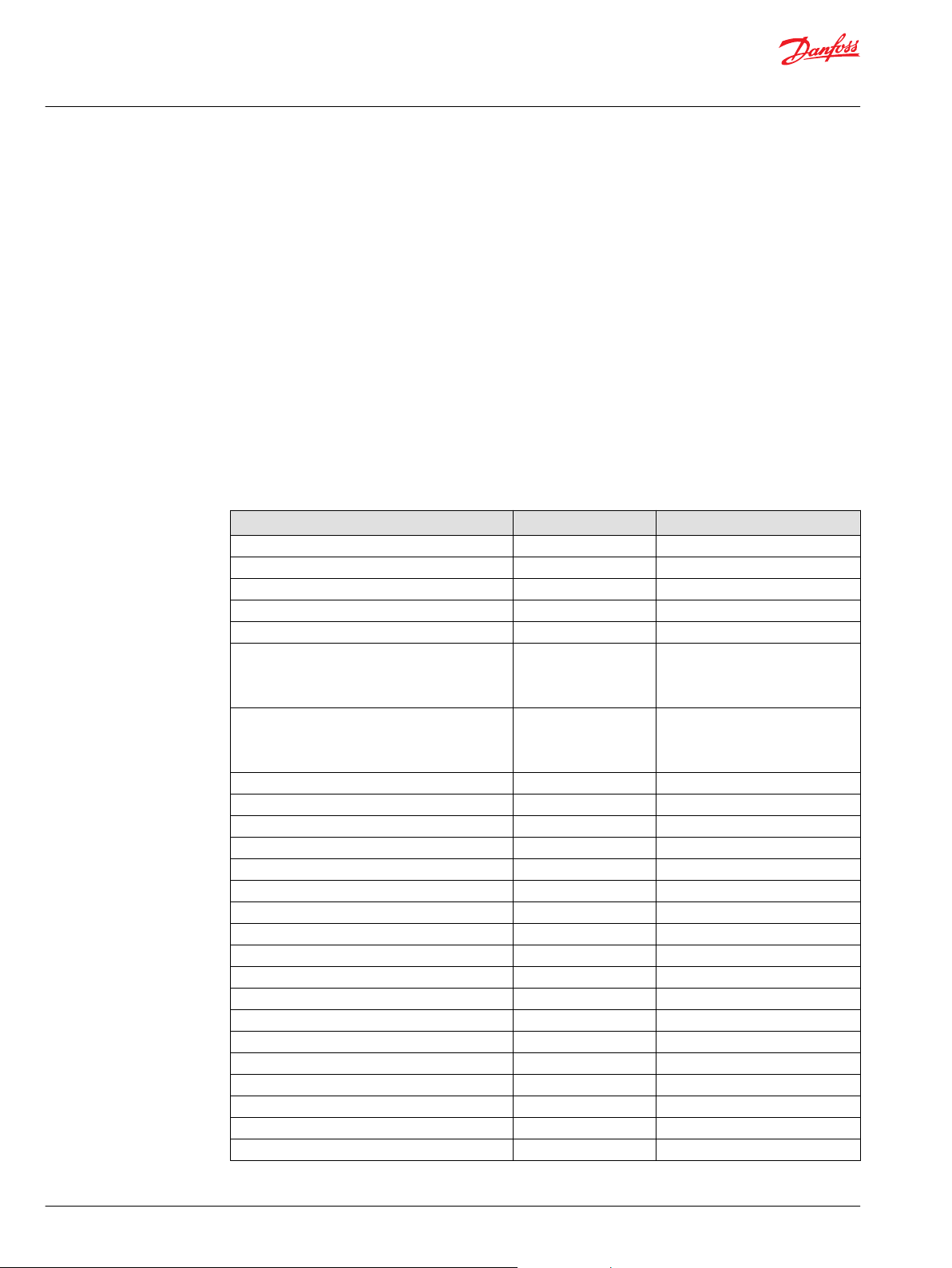

Reference Manuals

The documents described here can help you understand how to use PVED-CLS function blocks.

Title Type Identification number

PLUS+1®SC0XX-1XX Controller Family Technical Information L1415500, L1206334

PLUS+1®SC0XX-1XX Controller Family Safety Manual L1420375, L1228981

PLUS+1®Controller Family Technical Information 520L0719

PLUS+1®GUIDE Software User Manual Operation Manual 10100824

How to Install PLUS +1®GUIDE Upgrades Operation Manual 11078040

PVED-CLS Controller For Electrohydraulic Steering User Manual See Obtaining Technical Literature

PVED-CLS Controller For Electrohydraulic Steering Communication Protocol See Obtaining Technical Literature

PVED_CLS_Safety_ Manual_and_Programmer_Guide User Manual AQ00000254

PVED_CLS_AUX_JOY User Manual User Manual AQ00000255

PVED_CLS_AUX_STW User Manual User Manual AQ00000256

PVED_CLS_GMC User Manual User Manual AQ00000257

PVED_CLS_GMS User Manual User Manual AQ00000258

PVED_CLS_MMI User Manual User Manual AQ00000259

PVED_CLS_STAT_0_OP User Manual User Manual AQ00000260

PVED_CLS_STAT_1 User Manual User Manual AQ00000261

PVED_CLS_STAT_2 User Manual User Manual AQ00000262

PVED_CLS_STAT_3 User Manual User Manual AQ00000263

PVED_CLS_STAT_4 User Manual User Manual AQ00000264

PVED_CLS_STAT_5 User Manual User Manual AQ00000265

PVED_CLS_STAT_6 User Manual User Manual AQ00000266

PVED_CLS_STAT_7_User_Manual User Manual AQ00000267

PVED_CLS_STAT_8 User Manual User Manual AQ00000268

PVED_CLS_Str_Fdbk User Manual User Manual AQ00000269

PVED_CLS_STW User Manual User Manual AQ00000270

PVED_CLS_WAS User Manual User Manual AQ00000271

and Reference Manuals for more

information about obtaining this

document.

and Reference Manuals for more

information about obtaining this

document.

6 | © Danfoss | November 2018 AQ00000254en-000101

Page 7

Safety Manual and Programmer Guide

PVED-CLS Hardware Function Blocks

Quality and Safety Considerations

Obtaining Technical Literature and Reference Manuals

You can find literature about Danfoss products online and in the PLUS+1® GUIDE tool.

Obtain online help for the PLUS+1® GUIDE tool by using the application's Help menu.

PVED-CLS documents are part of the PVED-CLS firmware release packages. You can download the

packages at: https://www.danfoss.com/en/products/steering/dps/steering-components-and-systems/

electrohydraulic-steering/pved-cls/#overview

Obtaining Product Support

You can find information about product support, product news, parts, and more at the link that follows.

https://www.danfoss.com/en/products/software/dps/plus1-software-services-support-and-training/plus1support-and-services

©

Danfoss | November 2018 AQ00000254en-000101 | 7

Page 8

Safety Manual and Programmer Guide

PVED-CLS Hardware Function Blocks

Common Features of the Function Blocks

Function blocks share some common features.

All function blocks have:

A common structure.

•

Inputs that require defined data types.

•

Companion PLUS+1® Service Tool screens

•

All Blocks Have a Common Structure

Function blocks share common features that provide the machine with feedback for its operation.

Item Description

1 Function block description. Describes the general purpose of the function block.

2 Note. General information about data types and the available checkpoints.

3 Parameter page. Contains default parameter values. Values can be changed or replaced with signals from the application via the Para Bus.

4 Logic page. Contains a function block’s operating logic. This is a locked page that you cannot enter.

5 Checkpoints page. Contains Advanced Checkpoints with Namespace components that can make all of a block’s input, output and internal

6

7

8 | © Danfoss | November 2018 AQ00000254en-000101

signals available to the PLUS+1® Service Tool. To disable these signals set a block’s Chkpt input to False before you compile your application.

Input signal description. Explanatory text that describes the input’s:

Purpose

•

Data type

•

Expected range

•

Unit

•

Output signal description. Explanatory text that describes the output’s:

Purpose

•

Data type

•

Expected range

•

Unit

•

Page 9

Safety Manual and Programmer Guide

PVED-CLS Hardware Function Blocks

Common Features of the Function Blocks

All Blocks Have Inputs that Require Defined Data Types

To avoid compiler errors, use only the data type specified for an input.

These blocks do not allow autotyped inputs.

Item Description

1

2 If an incorrect data type is routed to the ErrCode input, then the compiler Error Message tab (with the error message generated by the

3 Compiler Error Message tab. The compilation does not finish.

The ErrCode input requires an input with a U8 data type.

incorrect U32 data type) shows that a wrong type was chosen.

All Blocks Have Companion Service Screens

All function blocks have P1D (PLUS+1 Diagnostic) files with companion Service Tool screens.

You can use these screens to simplify the task of creating PLUS+1® Service Tool screens for applications

that use PVED-CLS hardware function blocks. Refer to the PLUS+1 GUIDE Service Tool Design Manual

(Danfoss document number AQ00000160 for more information on how to create PLUS+1® Service Tool

screens.

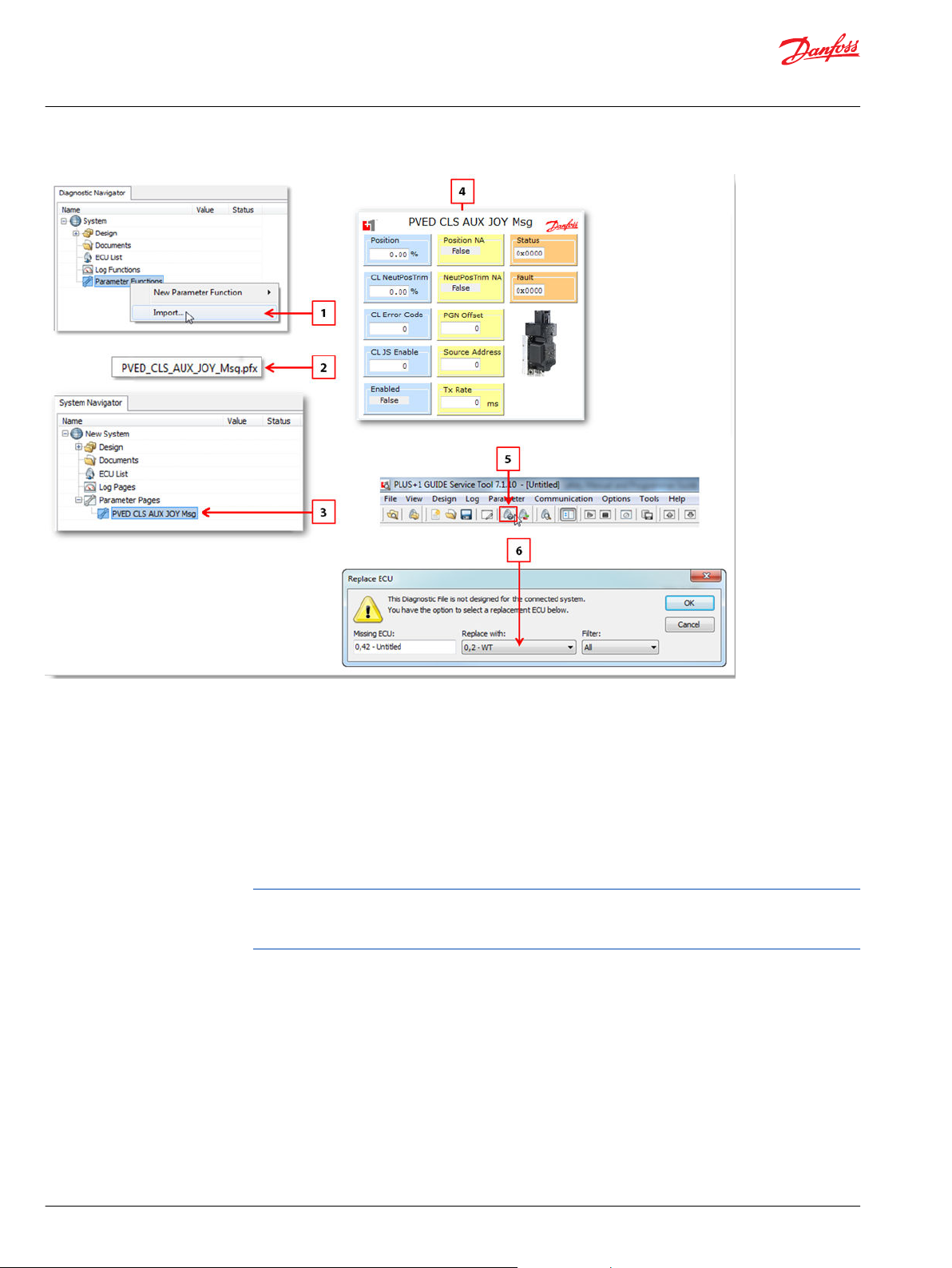

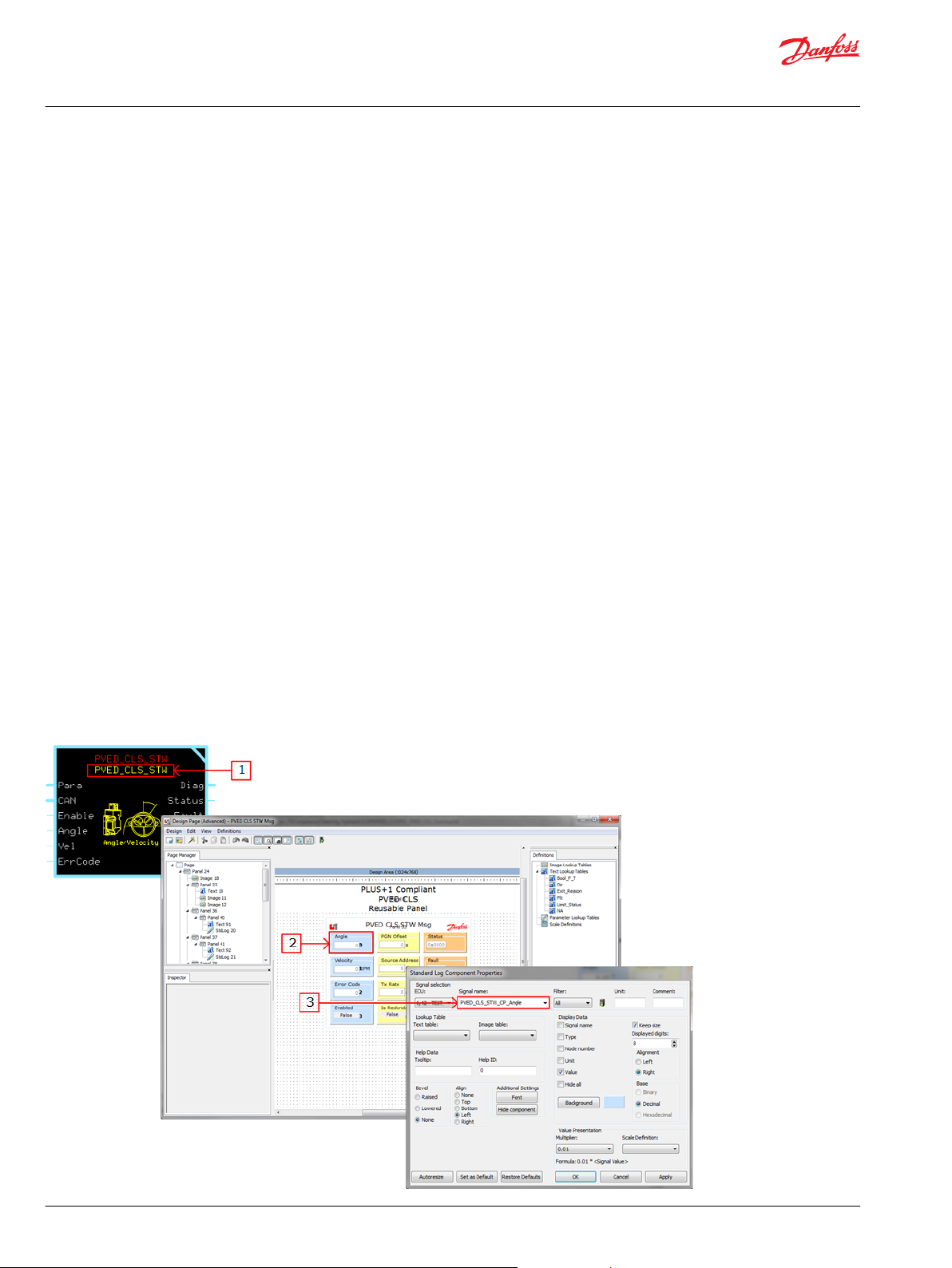

The following figure shows the PLUS+1® Service Tool screen for a PVED-CLS function block. These screens

are typical of the PLUS+1® Service Tool screens supplied with function blocks.

You must set a function block’s Chkpt input to true to make a function block’s input and output signals

available to the PLUS+1® Service Tool program.

©

Danfoss | November 2018 AQ00000254en-000101 | 9

Page 10

Safety Manual and Programmer Guide

PVED-CLS Hardware Function Blocks

Common Features of the Function Blocks

1. Right-click on Parameter Functions to open the dialog for importing service screens.

2. Select the service screen PFX file you want to import. In this figure, PVED_CLS_AUX_JOY_Msg.pfx is

selected.

3. The service screen is imported to the PLUS+1® Service Tool.

4. The service screen shows input, output and internal values to visualize the function block’s signal

flow. Input signals are located on the left side, output signals on the right side. In addition, the service

screen provides access to user-configurable operating parameters. They are always located in a

yellow panel.

5. Click Replace missing ECU in all log and parameter functions to replace the preset ECU “0,42 -

(Missing ECU)”.

Using the Replace missing ECU in all log and parameter functions feature is highly recommended

if service screens have been imported. Otherwise parameter pre-settings are lost. To use this feature,

make sure your ECU is connected to the Service Tool.

6. Select your ECU (here: 0,2 - WT) which replaces the missing ECU.

Import Service Tool Pages from the PLUS+1® GUIDE Library Tab Manager

In PLUS+1® GUIDE versions 8.1 and later, service screens (PFX files) and other documents can be stored in

libraries.

In the PVED-CLS Hardware Function Block Library for each module, the module itself (SCS file), the User

Manual, the Safety Manual and Programmer Guide and the service screen are stored under the

corresponding module – all in one place. Because of this change, use the following steps to import PLUS

+1® Service Tool pages to the PLUS+1® Service Tool.

10 | © Danfoss | November 2018 AQ00000254en-000101

Page 11

Safety Manual and Programmer Guide

PVED-CLS Hardware Function Blocks

Common Features of the Function Blocks

1. Browse to the module of interest.

2. Right-click the service screen of the module.

3. Select Save to, then select the location and save the file.

4. Open the PLUS+1® Service Tool.

5. Continue as described in the topic All Blocks Have Companion Service Screens.

©

Danfoss | November 2018 AQ00000254en-000101 | 11

Page 12

Safety Manual and Programmer Guide

PVED-CLS Hardware Function Blocks

Using Identical Blocks in the Same Application

To use identical function blocks in the same application, perform the following steps.

1. Change the function block’s namespace values.

2. Change the prefixes of the names of the signals displayed in the function block’s companion PLUS+1

Service Tool screens if you want to use these screens.

Identical Function Blocks Need Different Namespace Values to Successfully Compile

If you use the same function block more than once in an application, you must change each function

block’s namespace value to avoid compiler errors.

All function blocks contain Advanced Checkpoint with Namespace components that enable the PLUS+1

Service Tool to read block input and output values.

Some function blocks contain non-volatile memory components that store function block operating

parameters.

Both these components use memory names (“aliases”) to allocate memory. Identical memory names

cause compiler errors.

The namespace value adds a unique prefix to each component name to avoid errors. Keep each

namespace value short to save controller memory.

®

®

Identical Service Tool Screens Need Different Signal Name Prefixes to be Usable

If you use the same work function block more than once in an application, you must change the signal

name prefixes used in the companion PLUS+1® Service Tool screens to make the screens usable.

The input and output signals for blocks all have namespace prefixes. Danfoss configured the companion

PLUS+1® Service Tool screens to read signal names with these prefixes.

You must set a function block’s Chkpt input to true (which is the default value) to make the function

block’s input and output signals available to the PLUS+1® Service Tool program’s companion screens.

The following figure shows how a function block’s namespace value prefixes a signal name from the

function block.

12 | © Danfoss | November 2018 AQ00000254en-000101

Page 13

W

Safety Manual and Programmer Guide

PVED-CLS Hardware Function Blocks

Using Identical Blocks in the Same Application

Item Description

1 The namespace value for this block is now PVED_CLS_STW. All input and output signals from this function block now have a

PVED_CLS_STW_ prefix.

2 The PVED_CLS_STW_CP_Angle signal as it appears in the Design Screen (Advanced) window of the PLUS+1® Service Tool.

3 The Properties window that selects the PVED_CLS_STW_CP_Angle signal for display on the Engine Control Basic service screen.

Change Signal Name Prefixes with the Find and Replace Feature

You can simplify how you change name prefixes by using the Find and Replace feature.

Use the Find and Replace feature of the PLUS+1® Service Tool to change the namespace prefixes in PLUS

+1® Service Tool signal names.

Refer to the PLUS+1 GUIDE Service Tool Design Manual (Danfoss part L1320837) for more information

about the Find and Replace feature.

Switching Between Different Parameter Sets

Schedule changes to parameter sets while the machine is in a safe state.

Warning

Do not change parameters while the machine is driving. Changing parameters while the machine is

driving could result in a dangerous situation. Before changing parameters, ensure that the machine is in a

safe state (for example, with standstill and neutral conditions) to prevent any harm to operators and

bystanders.

©

Danfoss | November 2018 AQ00000254en-000101 | 13

Page 14

Safety Manual and Programmer Guide

PVED-CLS Hardware Function Blocks

Using Identical Blocks in the Same Application

Fault of Input Signals

Input signals that do not use the full range of their data type are checked to determine if they are in the

allowed range.

If they are outside their range they are clamped to fit into their range. The Fault output displays a fault

code.

Value Fault

0x0000 OK, no fault.

0x8001 Input value too low.

0x8002 Input value too high.

Status of Parameters

A status output, rather than a fault output, is given for parameter faults where parameters are out of

range or where parameters are lacking order (for example, Src_Addr > 253).

If a parameter is outside an allowed range, the parameter is clamped to fit into the allowed range. The

allowed range is listed for every parameter in the individual function block’s user manual. The upper and

lower limit are always included as valid values.

Value Fault

0x0000 OK

0x8008 At least one parameter is out of its defined range or in the wrong order.

14 | © Danfoss | November 2018 AQ00000254en-000101

Page 15

Safety Manual and Programmer Guide

PVED-CLS Hardware Function Blocks

Best Practices

The following guidelines can help achieve good outcomes when using the same parameter in several

function blocks and when managing controller memory consumption.

Using the Same Parameter in Several Function Blocks

Sometimes the same parameter is needed in several function blocks.

Because such a parameter is placed independently in each function block where it is used, it has multiple

definitions without any automated alignment.

Recommendations for handling this are:

•

Remove the duplicated parameters and connect them to one common parameter block, so that the

value of the parameter is controlled from one central point.

•

Update the service screens.

Controller Memory Consumption

Every function block included in your application uses a certain amount of the controller’s memory.

Also, every checkpoint consumes a bit of memory. Depending on the amount of the controller’s memory

and the complexity of your application you might run out of memory.

If the controller runs out of memory, you can first remove unnecessary checkpoints to regain memory.

There are two ways to remove the function block’s checkpoints.

Delete single checkpoints inside the Checkpoints page on the second level.

•

Remove all function block’s checkpoints from the compiled code. This can be achieved easily by

•

changing the Chkpt input of the Checkpoints page from True (T) to False (F). After you recompile the

code, none of the function block’s checkpoints are included.

To integrate the checkpoints again, set the Chkpt input back to True (T) and recompile the code.

Be aware that some checkpoints include Status and Fault information. If you deactivate or delete them

you no longer see them on the service screen.

©

Danfoss | November 2018 AQ00000254en-000101 | 15

Page 16

Safety Manual and Programmer Guide

PVED-CLS Hardware Function Blocks

Glossary

Terms and acronyms about safety are defined.

ECU Electronic Control Unit

Fail-Safe State Functional safety term. State where the safety output is de-energized.

HWD The file that defines how the GUIDE application is connected to the controller hardware. The

abbreviation stands for Hardware Description.

IEC International Electrotechnical Commission

OEM Original Equipment Manufacturer

P1D The file format extension used by the PLUS+1 Service Tool. The abbreviation stands for PLUS+1

Diagnostic.

PVED-CLS Valve controller and actuator. The abbreviation stands for Proportional Valve Electronic Digital

– Closed Loop Safety.

SCS A file that contains graphical code used with the PLUS+1® GUIDE application.

SIL Functional Safety Term. Safety Integrity Level.

®

16 | © Danfoss | November 2018 AQ00000254en-000101

Page 17

Safety Manual and Programmer Guide

PVED-CLS Hardware Function Blocks

Abbreviations

Abbreviations used in the PVED-CLS function block user manuals are described.

Abbreviation Meaning

AUX JOY Auxiliary Joystick

AUX STW Auxiliary Steering Wheel

CLS Closed Loop Safety

GMC Guidance System Command

GMS Guidance Machine Status

MMI Man Machine Interface

PVED CLS Proportional Valve Electronic Digital Closed Loop Safety

STAT MSG OP Status Message Operation

STAT MSG Status Message

Str Fdbk Steering Feedback

STW Steering Wheel

VSP Vehicle Speed

WAS Wheel Angle Sensor

©

Danfoss | November 2018 AQ00000254en-000101 | 17

Page 18

Safety Manual and Programmer Guide

PVED-CLS Hardware Function Blocks

18 | © Danfoss | November 2018 AQ00000254en-000101

Page 19

Safety Manual and Programmer Guide

PVED-CLS Hardware Function Blocks

©

Danfoss | November 2018 AQ00000254en-000101 | 19

Page 20

Danfoss

Power Solutions GmbH & Co. OHG

Krokamp 35

D-24539 Neumünster, Germany

Phone: +49 4321 871 0

Danfoss

Power Solutions ApS

Nordborgvej 81

DK-6430 Nordborg, Denmark

Phone: +45 7488 2222

Danfoss

Power Solutions (US) Company

2800 East 13th Street

Ames, IA 50010, USA

Phone: +1 515 239 6000

Danfoss

Power Solutions Trading

(Shanghai) Co., Ltd.

Building #22, No. 1000 Jin Hai Rd

Jin Qiao, Pudong New District

Shanghai, China 201206

Phone: +86 21 3418 5200

Products we offer:

Comatrol

www.comatrol.com

Turolla

www.turollaocg.com

Hydro-Gear

www.hydro-gear.com

Daikin-Sauer-Danfoss

www.daikin-sauer-danfoss.com

DCV directional control

•

valves

Electric converters

•

Electric machines

•

Electric motors

•

Hydrostatic motors

•

Hydrostatic pumps

•

Orbital motors

•

PLUS+1® controllers

•

PLUS+1® displays

•

PLUS+1® joysticks and

•

pedals

PLUS+1® operator

•

interfaces

PLUS+1® sensors

•

PLUS+1® software

•

PLUS+1® software services,

•

support and training

Position controls and

•

sensors

PVG proportional valves

•

Steering components and

•

systems

Telematics

•

Danfoss Power Solutions is a global manufacturer and supplier of high-quality hydraulic and

electric components. We specialize in providing state-of-the-art technology and solutions

that excel in the harsh operating conditions of the mobile off-highway market as well as the

marine sector. Building on our extensive applications expertise, we work closely with you to

ensure exceptional performance for a broad range of applications. We help you and other

customers around the world speed up system development, reduce costs and bring vehicles

and vessels to market faster.

Danfoss Power Solutions – your strongest partner in mobile hydraulics and mobile

electrification.

Go to www.danfoss.com for further product information.

We offer you expert worldwide support for ensuring the best possible solutions for

outstanding performance. And with an extensive network of Global Service Partners, we also

provide you with comprehensive global service for all of our components.

Local address:

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

already on order provided that such alterations can be made without subsequent changes being necessary in specifications already agreed.

All trademarks in this material are property of the respective companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

©

Danfoss | November 2018 AQ00000254en-000101

Loading...

Loading...