Page 1

User Manual

Electrohydraulic Actuator

PVED-CC4, Series 7

www.danfoss.com

Page 2

User Manual

PVED-CC4, Series 7

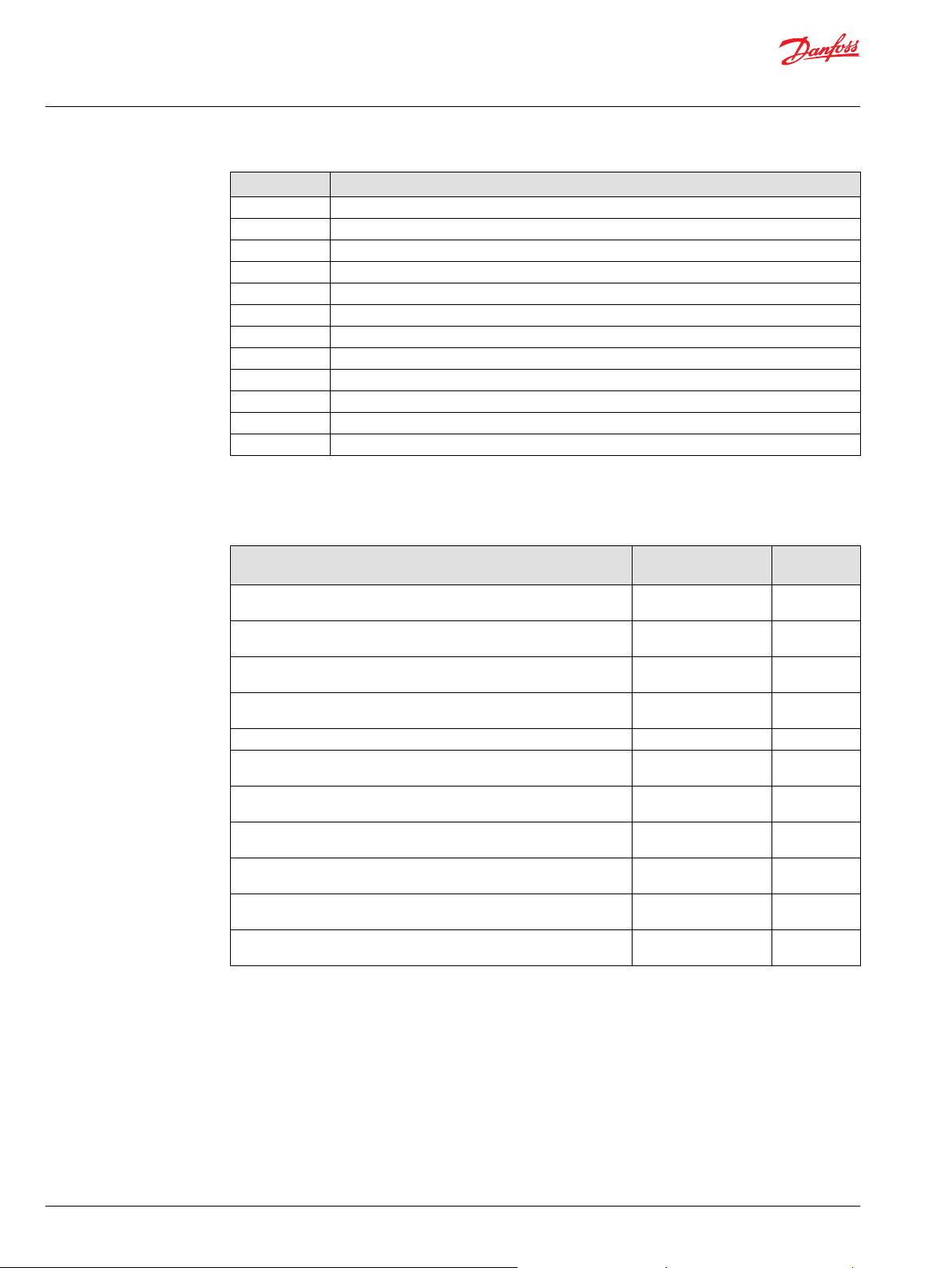

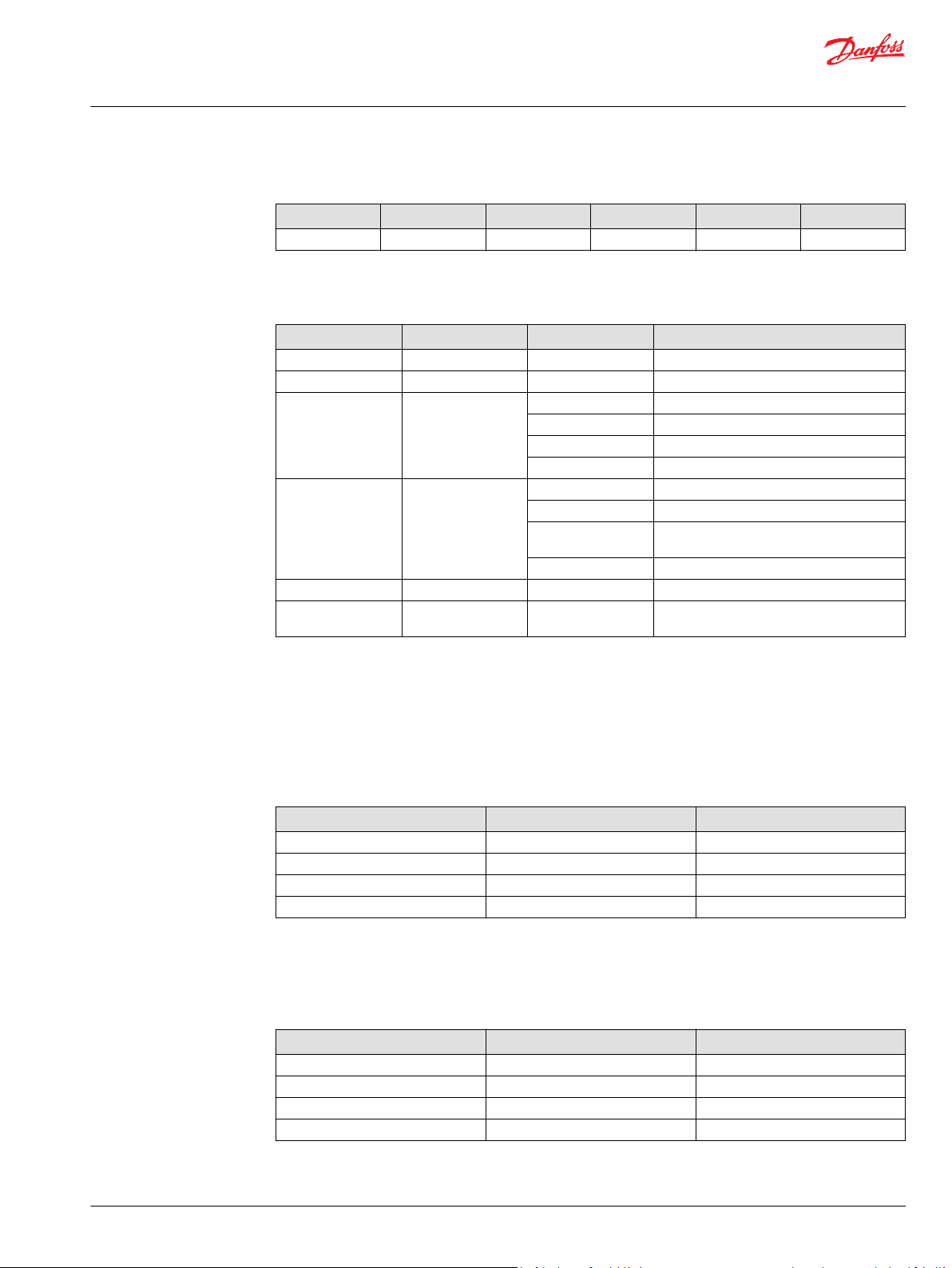

Revision history Table of revisions

Date Changed Rev

February 2021 First edition 0101

2 | © Danfoss | February 2021 BC368572537192en-000101

Page 3

User Manual

PVED-CC4, Series 7

Contents

Reference

General Information

PVED-CC4 functionality

PVED-CC4 safety description

Technical data

Acronyms used for PVG and PVE................................................................................................................................................ 7

Literature reference for PVG/PVE products.............................................................................................................................8

Standards used for PVED-CC4......................................................................................................................................................9

PVED-CC4 introduction................................................................................................................................................................10

PVE stands for PVE actuator ...................................................................................................................................................... 11

Overview for PVED-CC4............................................................................................................................................................... 12

PVG functionality............................................................................................................................................................................14

Mechanical sub-system............................................................................................................................................................... 16

Housing........................................................................................................................................................................................16

PVED-CC4 Cable kit..................................................................................................................................................................16

PVED-CC4 mounting............................................................................................................................................................... 17

Linear Variable Differential Transducer (LVDT)..............................................................................................................18

Spool neutral spring................................................................................................................................................................ 18

Hydraulic subsystem.....................................................................................................................................................................18

Computerized sub-system..........................................................................................................................................................19

Power On Self Test (POST).....................................................................................................................................................19

PVED-CC4 full operational mode overview.....................................................................................................................19

PVED-CC4 hand operational mode overview.................................................................................................................19

Emergency mode......................................................................................................................................................................20

Fault mode overview...............................................................................................................................................................20

Settings and system data............................................................................................................................................................20

PVED-CC4 Process data.......................................................................................................................................................... 20

OEM data..................................................................................................................................................................................... 20

Spool data................................................................................................................................................................................... 20

General part details..................................................................................................................................................................20

PVED-CC4 Logging........................................................................................................................................................................21

Definition.......................................................................................................................................................................................... 22

Concept............................................................................................................................................................................................. 22

POST–Power On Self Test............................................................................................................................................................22

PVED-CC4 runtime fault monitoring.......................................................................................................................................22

Fault origin category............................................................................................................................................................... 22

Fault severity level....................................................................................................................................................................23

PVED-CC4 fault Reaction............................................................................................................................................................. 23

Recorded and reported solenoid disabling ................................................................................................................... 23

Recorded and reported ignorance ....................................................................................................................................23

Unrecorded reaction .............................................................................................................................................................. 23

PVED-CC4 fault recovery............................................................................................................................................................. 23

Reboot ......................................................................................................................................................................................... 23

Resume ........................................................................................................................................................................................23

Declaration of Conformity.......................................................................................................................................................... 24

PVED-CC4 operational conditions........................................................................................................................................... 24

Reaction times.................................................................................................................................................................................24

PVED-CC4 Dimensions and layout...........................................................................................................................................25

Hydraulic data................................................................................................................................................................................. 27

Pilot oil system...........................................................................................................................................................................27

Communication........................................................................................................................................................................ 28

PVED-CC4 LED ..................................................................................................................................................................... 28

CAN...........................................................................................................................................................................................29

Parameter description............................................................................................................................................................ 29

Commercial identifiers ..................................................................................................................................................... 30

Communication identifiers .............................................................................................................................................30

Firmware identifiers........................................................................................................................................................... 30

©

Danfoss | February 2021 BC368572537192en-000101 | 3

Page 4

User Manual

PVED-CC4, Series 7

Contents

Service parameters............................................................................................................................................................. 30

Valve interface settings ....................................................................................................................................................30

Communication parameters...........................................................................................................................................30

Safety parameters............................................................................................................................................................... 31

Behavior parameters..........................................................................................................................................................31

Name field J1939 ................................................................................................................................................................31

Function instance................................................................................................................................................................31

Component ID additional information........................................................................................................................32

Part number.......................................................................................................................................................................... 32

Serial number........................................................................................................................................................................32

Software naming.................................................................................................................................................................32

Scaling.....................................................................................................................................................................................32

Slope curve............................................................................................................................................................................33

Ramp........................................................................................................................................................................................33

Invert ports............................................................................................................................................................................ 34

Float threshold.....................................................................................................................................................................34

AVEF send out time............................................................................................................................................................ 34

AVC time out (AVCTO).......................................................................................................................................................34

Power save enable..............................................................................................................................................................34

Fault recovery – Fault monitoring mode....................................................................................................................35

Fault monitoring General Time Out (GTO).................................................................................................................35

Fault monitoring Float Time Out (FTO).......................................................................................................................35

KWP2000 Enable..................................................................................................................................................................35

KWP2000 Id............................................................................................................................................................................35

KWP2000 max time.............................................................................................................................................................35

Spool curve overview........................................................................................................................................................ 36

Float spools............................................................................................................................................................................36

Warnings

PVED-CC4 warnings...................................................................................................................................................................... 37

ISO 11783 CAN interface

Parameter setting.......................................................................................................................................................................... 38

Software ID.......................................................................................................................................................................................39

Component identification message........................................................................................................................................39

Requesting PGN’ s..........................................................................................................................................................................40

Fault mode error messages........................................................................................................................................................41

State machine and operational modes

Power On Self Test.........................................................................................................................................................................43

uCSM...................................................................................................................................................................................................43

AVEF....................................................................................................................................................................................................44

AVEF interpretation................................................................................................................................................................. 44

AVEF data.....................................................................................................................................................................................46

PVED-CC full operational mode................................................................................................................................................47

Closed loop.......................................................................................................................................................................................47

PVED-CC spool positioning ....................................................................................................................................................... 47

Flow control..................................................................................................................................................................................... 47

PVED-CC entering hand operational mode..........................................................................................................................48

PVED-CC4 emergency stop........................................................................................................................................................ 49

Error description

Error code walk through..............................................................................................................................................................50

Non-expected event................................................................................................................................................................50

Recovery.......................................................................................................................................................................................50

PVED-CC settings......................................................................................................................................................................50

General timeout (GTO)............................................................................................................................................................50

Float timeout (FTO)..................................................................................................................................................................50

Auxiliary valve timeout (AVCTO).........................................................................................................................................50

Power save (OEM).....................................................................................................................................................................50

Spool curve................................................................................................................................................................................. 50

4 | © Danfoss | February 2021 BC368572537192en-000101

Page 5

User Manual

PVED-CC4, Series 7

Contents

Ordering

Code numbers

Service Tool

Float available (spool).............................................................................................................................................................51

PVED-CC4 error messages.......................................................................................................................................................... 51

1’s complement redundancy test.......................................................................................................................................51

1st boot ....................................................................................................................................................................................... 51

Reserved.......................................................................................................................................................................................51

Division by zero.........................................................................................................................................................................51

CapCom values .........................................................................................................................................................................51

Variable truncation...................................................................................................................................................................52

Verified write to cell error .....................................................................................................................................................52

Reserved.......................................................................................................................................................................................52

Interpolation check..................................................................................................................................................................52

Estimate calibration values error........................................................................................................................................ 52

PWM calibration values error .............................................................................................................................................. 52

Mechanical Spool Compensation values.........................................................................................................................53

Reserved.......................................................................................................................................................................................53

Spool data and Float available.............................................................................................................................................53

Reserved.......................................................................................................................................................................................53

Reserved.......................................................................................................................................................................................53

CRC16 check / Parameter memory.....................................................................................................................................53

Fall back to old values.............................................................................................................................................................54

CRC16 check / Program memory........................................................................................................................................54

Main spool cannot reach neutral from retract...............................................................................................................54

LVDT wiring error .....................................................................................................................................................................54

Power supply above specified range................................................................................................................................ 54

Power supply below specified range................................................................................................................................ 54

No answer on handshakes ................................................................................................................................................... 55

Power-on self test failed ........................................................................................................................................................55

Time value for CL control out of range.............................................................................................................................55

Main spool cannot reach neutral........................................................................................................................................55

Main spool cannot reach float position............................................................................................................................55

Main spool not in neutral at boot up.................................................................................................................................56

Main spool position is greater than the reference....................................................................................................... 56

Main spool position and reference are in opposite directions................................................................................ 56

Float threshold has not been passed................................................................................................................................ 56

Time guarding on Auxiliary Valve Command................................................................................................................ 56

Illegal CAN address ................................................................................................................................................................. 57

Command out of range .........................................................................................................................................................57

Scaling error ...............................................................................................................................................................................57

Ramps error ................................................................................................................................................................................57

Float threshold error ...............................................................................................................................................................57

Dead band compensation error .........................................................................................................................................57

Slope error ..................................................................................................................................................................................58

Shape error..................................................................................................................................................................................58

Invert port error ........................................................................................................................................................................58

Illegal combination of Port Flow Command and Blocked state..............................................................................58

Illegal combination of Port Flow Command and Float state....................................................................................58

Port flow command above 100%....................................................................................................................................... 58

Illegal valve state ......................................................................................................................................................................59

Illegal valve state and illegal port flow command........................................................................................................59

Illegal combination of inverted ports and float properties.......................................................................................59

Errors overview table...............................................................................................................................................................59

Parameter Agreement Template..............................................................................................................................................61

Factory settings for spare part PVED-CC4.............................................................................................................................61

PVED-CC4 code numbers............................................................................................................................................................62

Service Tool Overview..................................................................................................................................................................64

©

Danfoss | February 2021 BC368572537192en-000101 | 5

Page 6

User Manual

PVED-CC4, Series 7

Contents

Requirements.................................................................................................................................................................................. 64

PLUS+1® PVE Service Tool...........................................................................................................................................................65

Service pages...................................................................................................................................................................................65

Use of the service tool..................................................................................................................................................................66

Examination of a PVED-CC (ECU)..............................................................................................................................................67

Notes on examination process............................................................................................................................................ 68

Process data screen.......................................................................................................................................................................69

Live view screen..............................................................................................................................................................................70

Spool data screen...........................................................................................................................................................................71

OEM data screen.............................................................................................................................................................................72

Diagnostic screen...........................................................................................................................................................................73

6 | © Danfoss | February 2021 BC368572537192en-000101

Page 7

User Manual

PVED-CC4, Series 7

Reference

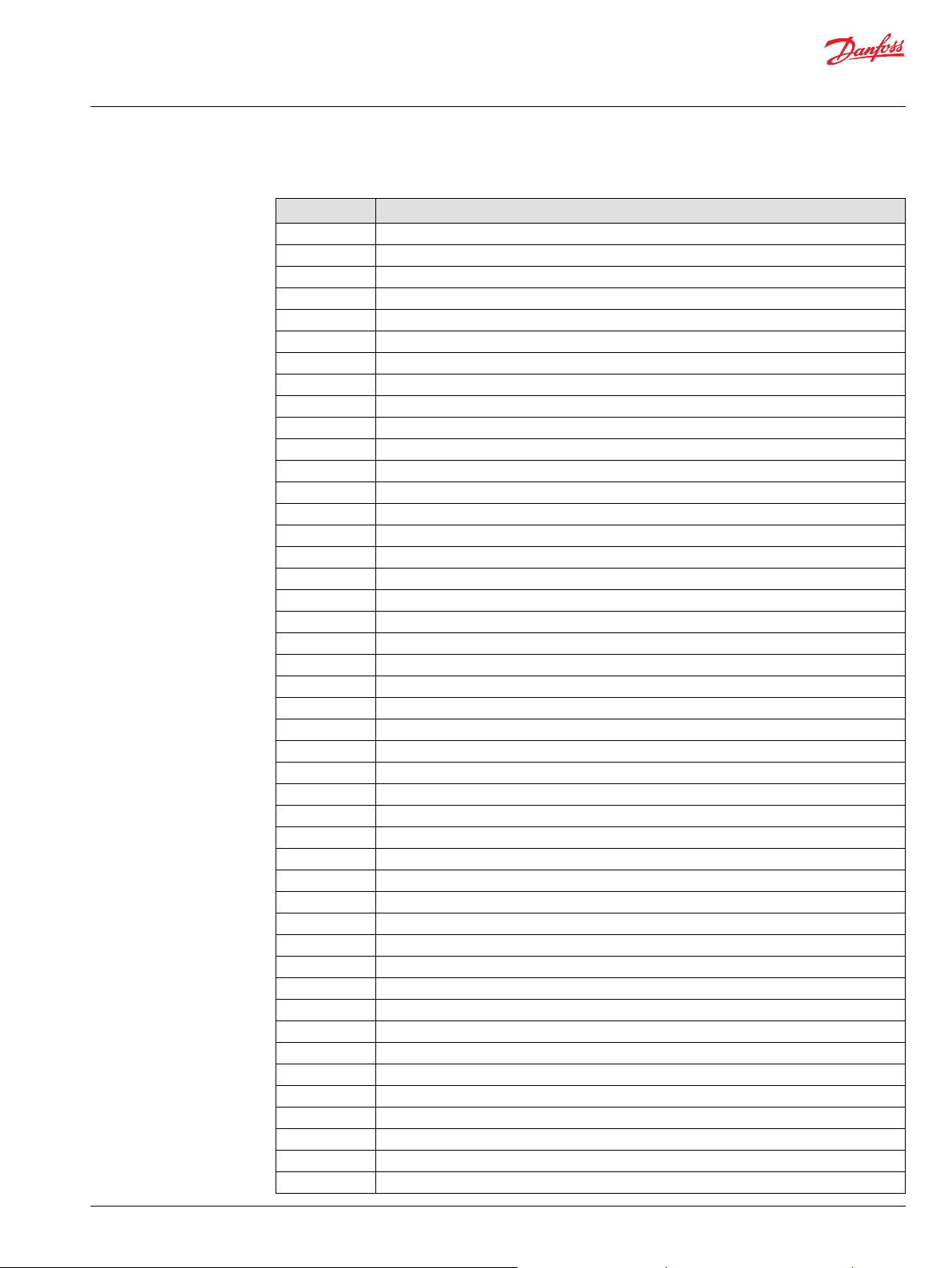

Acronyms used for PVG and PVE

Acronyms Description

ATEX Certificated for use in explosive environment

AVC Auxiliary Valve Command - ISOBUS/J1939 standard signal for valve control

AVCTO Auxiliary Valve Command Time Out - Fault monitoring setting

AVEF Auxiliary Valve Estimated Flow - ISOBUS/J1939 standard signal for valve feedback

CAN Controller Area Network - Communication method used by PVED

CLC Closed Loop Circuit

CRC Cyclic Redundancy Check - Method for ensuring validity of data.

-DI PVE with Direction Indication

DM1 Diagnostic Message 1 - J1939 message informing about present fault

DM2 Diagnostic Message 2 - J1939 message informing about fault history

DM3 Diagnostic Message 3 - J1939 message clearing fault history

DSM Device State Machine. Deterministic description of system process

ECU Electronic Control Unit

EH Electro Hydraulic

-F PVE for Float spool. Two variants: 4 pin with float at 75%. 6 pin with separate float.

FMEA Failure Mode Effect Analysis

ISOBUS Communication standard for CAN

J1939 Communication standard for CAN

LED Light Emitting Diode

LS Load Sensing

LVDT Linear Variable Differential Transducer - Position sensor

NC Normally Closed solenoid valve in PVE

NC-H Normally Closed standard solenoid valve in PVEH

NC-S Normally Closed solenoid valve Super in PVES

NO Normally Open solenoid valve in PVE

PLC Programmable Logical Circuit

PLUS+1

POST Power On Self Test. Boot up evaluation for PVED

Pp Pilot Pressure. The oil gallery for PVE actuation

PVB Proportional Valve Basic module - valve slice

PVBS Proportional Valve Basic module Spool

PVBZ Proportional Valve Basic module Zero leakage

PVE Proportional Valve Electric actuator

PVEA PVE variant with 2-6 % hysteresis

PVED PVE variant Digital controlled via CAN communication

PVEH PVE variant with 4-9% Hysteresis

PVEM PVE variant with 25-35% hysteresis

PVEO PVE variant with ON/OFF actuation

PVEP PVE variant PWM controled

PVES PVE variant with 0-2% hysteresis

PVEU PVE variant with US 0-10V

PVG Proportional multi-section Valve Group

PVHC PV variant with High Current controlled valve actuator

PVM Proportional Valve Manual control with handle

PVP Proportional Valve Pump side module.Inlet

®

Trademark for Danfoss controllers and programming tool

©

Danfoss | February 2021 BC368572537192en-000101 | 7

Page 8

User Manual

PVED-CC4, Series 7

Reference

Acronyms Description

PVS Proportional Valve end plate

PVSK Proportional Valve end plate crane. Inlet module with Spool Control

PWM Pulse Width Modulation

S4 DJ Series 4 Digital J1939 service tool software for PVED-CC

SAE Society Automotive Engineering

-R PVE with Ramp function

-NP PVE with solenoid disable in Neutral Position

-SP PVE with Spool Position feedback

uC Microcontroller

uCSM Microcontroller State Machine

U

DC

U

S

Literature reference for PVG/PVE products

Literature reference

Literature title Type Order

PVG 32 Proportional valve group Technical Information BC152886483

PVG 100 Proportional valve group Technical Information BC152886483

PVG 120 Proportional valve group Technical Information BC152886483

PVG 32 Metric ports Technical Information BC152886484

PVED-CC Electro-hydraulic actuator Technical Information 520L0665

PVED-CX Electro-hydraulic actuator Technical Information BC152886483

Basic module for PVBZ Technical Information BC152886484

PVSK module with integrated diverter valve and P-disconnect function Technical Information BC152886484

PVPV / PVPM pump side module Technical Information BC152886484

Combination module PVGI Technical Information BC152886483

PVSP/M Priority module Technical Information BC152886484

Power supply Direct Current; also called V

Steering voltage for the PVE control; also called V

for battery voltage

bat

S

number

664

475

344

163

682

167

133

316

392

066

8 | © Danfoss | February 2021 BC368572537192en-000101

Page 9

User Manual

PVED-CC4, Series 7

Reference

Standards used for PVED-CC4

International Organization for Standardization:

•

ISO 11898-2 Road vehicles, CAN, Part 2, High-speed medium access unit (physical layer)

‒

ISO 13766:2006(E) Earth moving machinery, Electromagnetic compatibility

‒

ISO 13849 Safety of Machinery

‒

EN 982: 1996 + A1:2008, Safety of machinery – Safety requirements for fluid power systems and their

•

components, Hydraulics

SAE J 1939

•

ISOBUS: ISO 11783 CAN Interface

•

EU Directive: EMC directive 2004/108/EC

•

©

Danfoss | February 2021 BC368572537192en-000101 | 9

Page 10

User Manual

PVED-CC4, Series 7

General Information

PVED-CC4 introduction

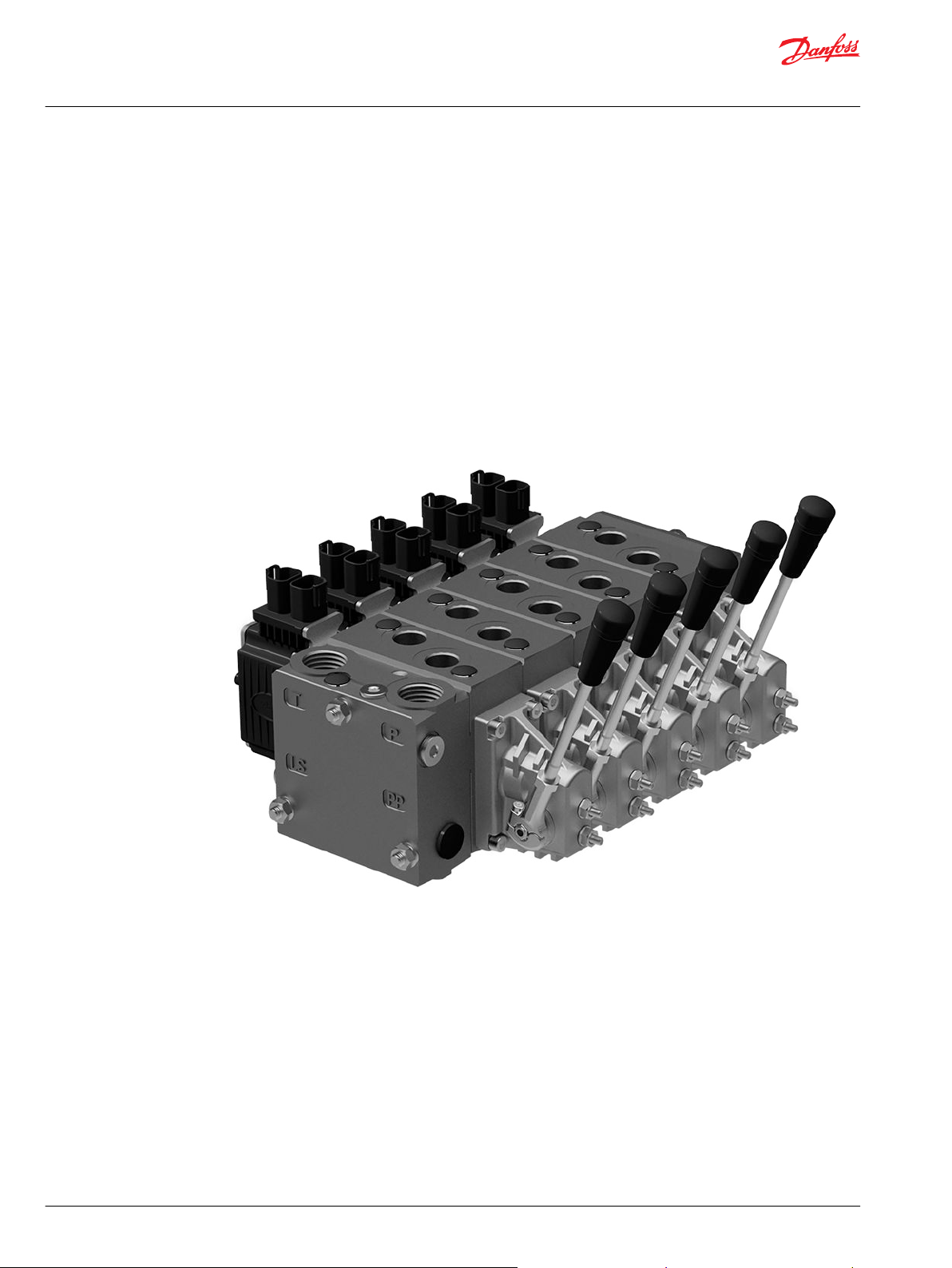

The Danfoss PVED-CC4 is a digital (D) controlled PVE-Series 7 actuator for PVG 32 and PVG 100. The PVEDCC4 follows the modular Danfoss concept.

CC is an abbreviation for CAN bus Communication. The communication is compliant to the SAE J1939

protocol and the ISOBUS standard for flow control.

The PVED-CC4 has proven its worth and is used in various types of mobile hydraulic applications with

high demands to precision and controllability.

The PVED-CC4 can be controlled by a Danfoss PLUS+1® GUIDE application or other devices capable of

using communication as defined in this Technical Information.

Customizing of the PVED-CC4 is done by parameter setting. Settings can be made by the PLUS+1® Service

Tool, the WebGPI service tool or by a CAN gateway that have the same abilities.

PVG with PVED-CC4 can be delivered with customer defined settings out of factory.

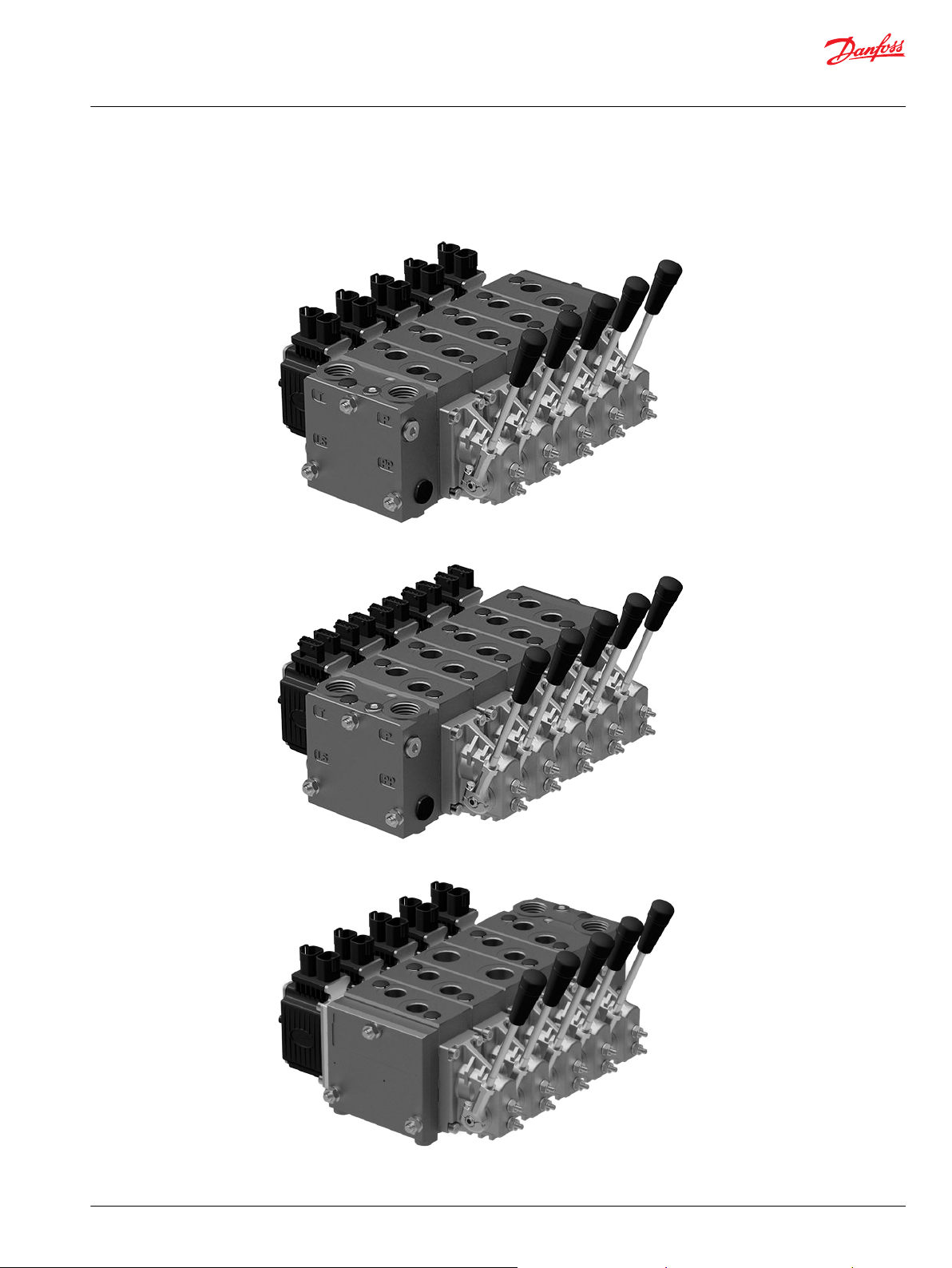

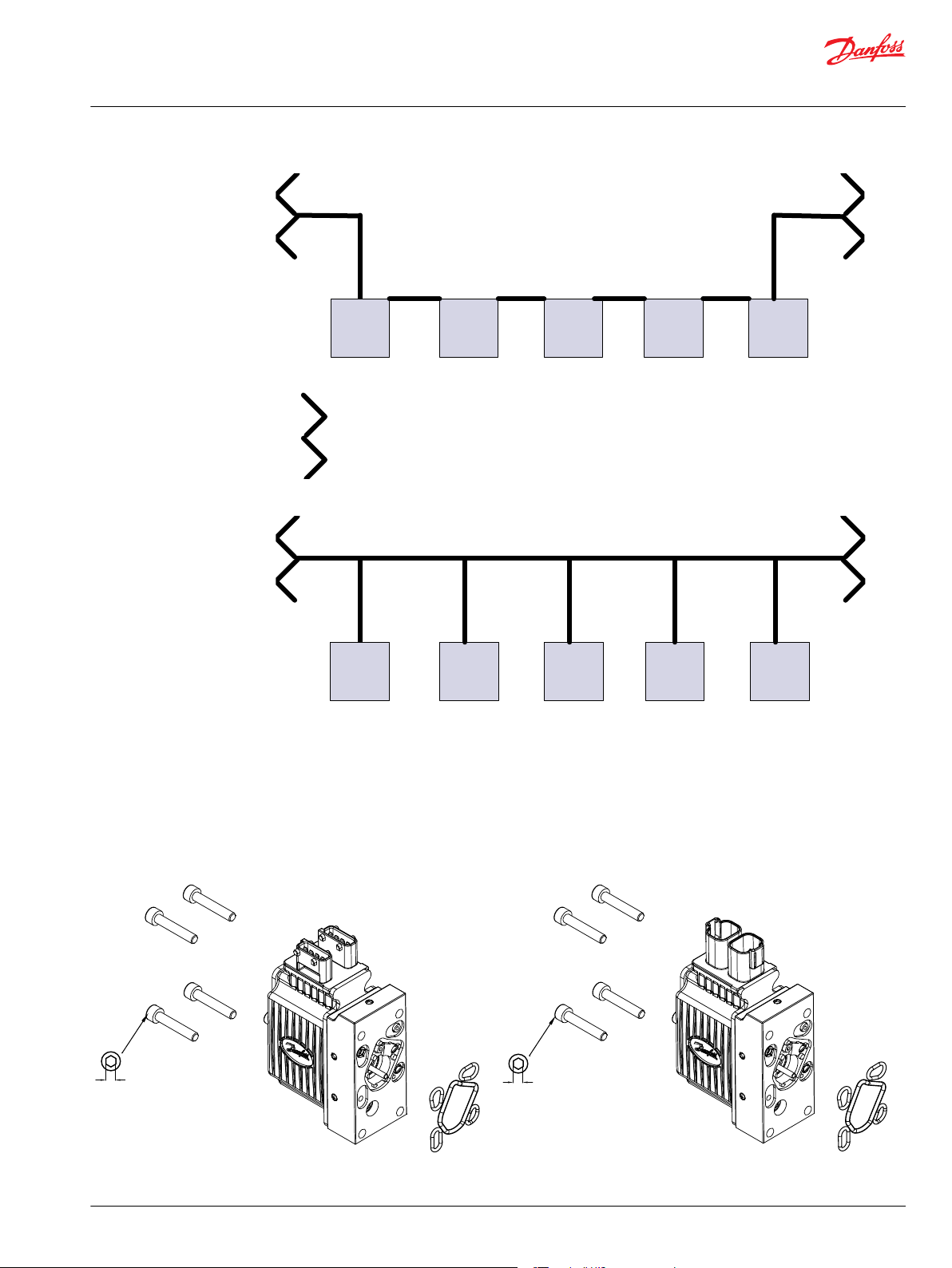

PVG with PVED-CC4

10 | © Danfoss | February 2021 BC368572537192en-000101

Page 11

User Manual

PVED-CC4, Series 7

General Information

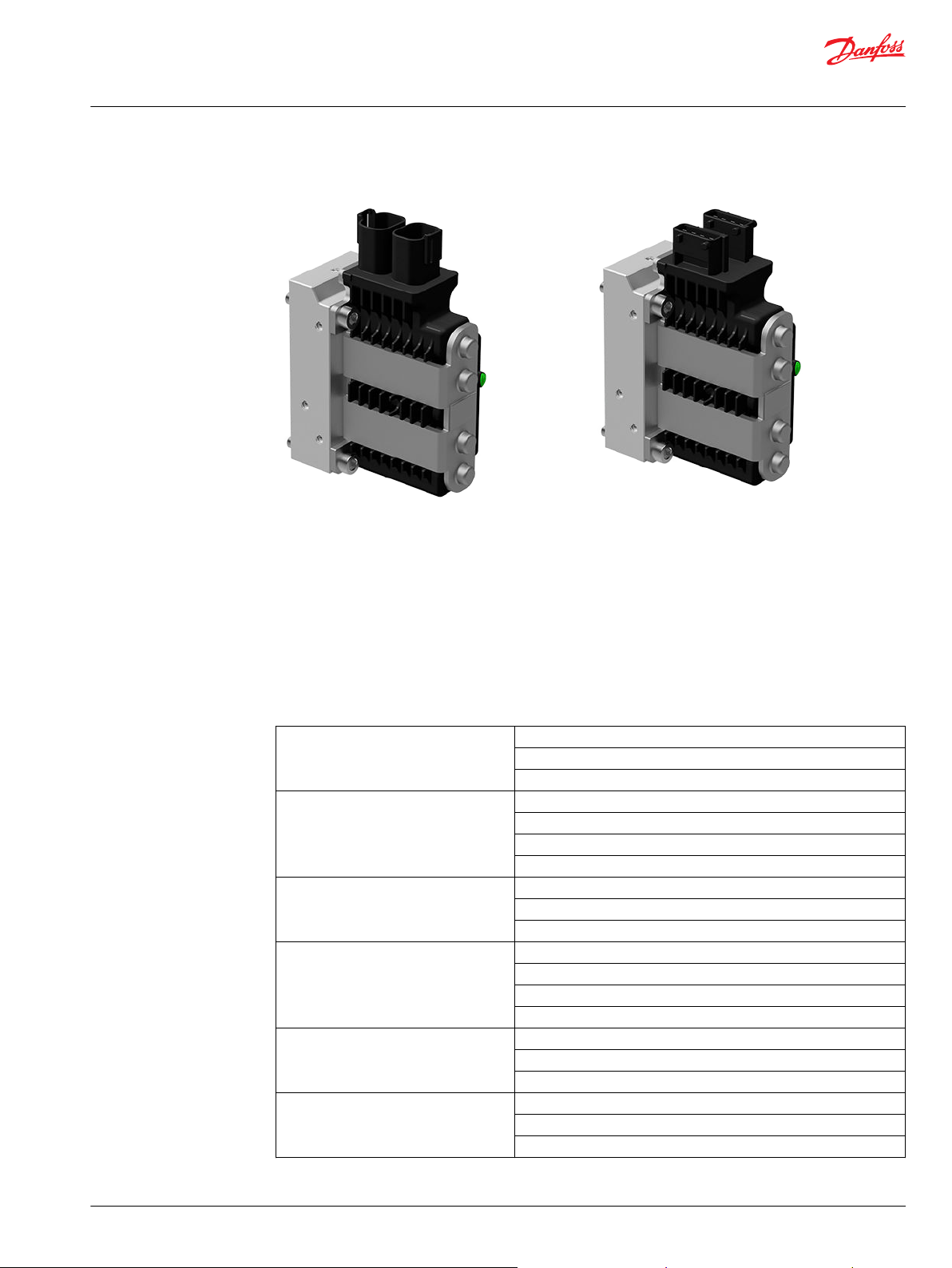

PVED-CC4 with DEUTSCH connector PVED-CC4 with AMP connector

PVE stands for PVE actuator

The Danfoss PVE is built on more than thirty years experience of electrical valve control and is the perfect

fit for our high performance proportional valves PVG 32, PVG 100 and PVG 120, as it is for our EH steering.

All our products are developed in close cooperation with system manufacturers from the mobile

hydraulic market. That is the reason for our high performance in all market segments

The PVE can be controlled from a switch, a joystick, a PLC, a computer or a Danfoss PLUS+1® microcontroller. The PVE is available in multiple variants. A short list here just gives the main variations.

Available PVE variants

Actuation On/Off

Proportional - Closed loop controlled

Proportional - Direct control

Control signal Voltage

PWM

Current (PVHC)

CAN bus

Precision Standard precision

High precision

Super high precision

Feedback Spool position

Direction indicator

Error

None

Connectors DEUTSCH

AMP

DIN/Hirschmann

Fault detection and reaction Active

Passive

None

©

Danfoss | February 2021 BC368572537192en-000101 | 11

Page 12

User Manual

PVED-CC4, Series 7

General Information

Overview for PVED-CC4

Available PVE variants (continued)

Power supply 11 V – 32 V multi-voltage

12 V

24 V

With the PVED-CC4 a hydraulic application with PVG can have up to sixteen individually controlled valves

on one CAN bus. Giving full control and feedback for every work function.

The oil flow out of the work function (A- or B-port) can be controlled by a combination of the following:

PVED-CC4 controlling the spool position using pilot oil pressure.

•

A handle (PVM) in mechanical interface with the spool.

•

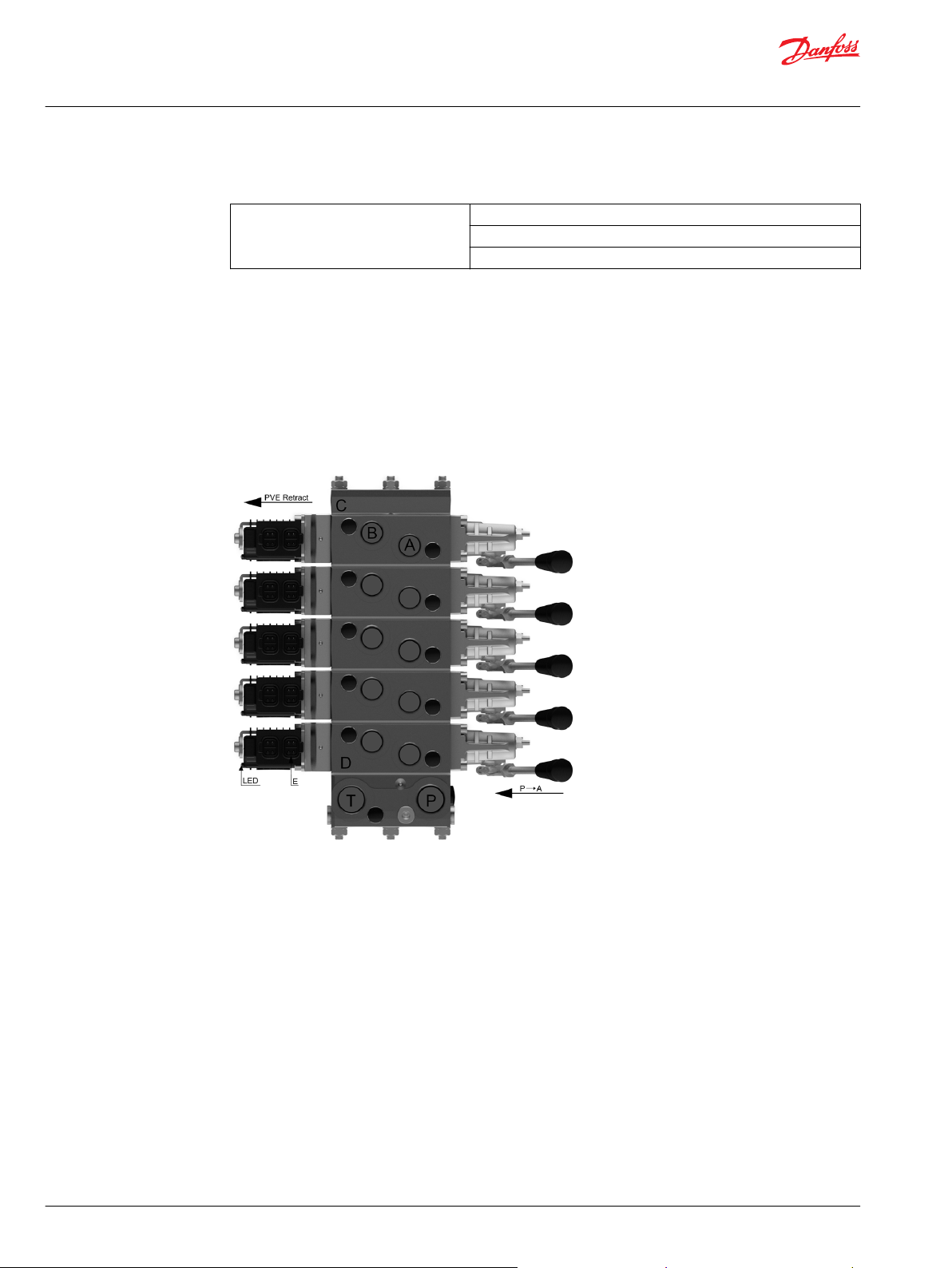

PVG 32 structural lay-out with naming

A A-port

B B-port

C PVS end plate

D PVB basic module

E Connector pin

T Tank port

P Pump supply port

The PVED-CC4 uses the ISOBUS and J1939 protocol, thus following the standard protocols. The physical

layer for CAN communication applies to ISO 11898-2 high speed CAN.

The spool is controlled by flow commands in steps of 0.4% or by spool position with 250 positions in each

direction and dead band compensation. Monitored manual operation is possible.

The embedded system also monitors safety. Spool position, communication, electronics, memory,

calculations and temperature are continuously evaluated and all violations are broadcasted and logged.

12 | © Danfoss | February 2021 BC368572537192en-000101

Page 13

User Manual

PVED-CC4, Series 7

General Information

To avoid unnecessary power consumption, the PVED-CC4 has the Power Save feature, where power

consumption is reduced by almost 90% when the spool is in neutral.

Standard mounted PVG, PVED-CC4 with DEUTSCH connector

Standard mounted PVG, PVED-CC4 with AMP connector

Option mounted PVG with PVSK, PVED-CC4 with DEUTSCH connector

©

Danfoss | February 2021 BC368572537192en-000101 | 13

Page 14

User Manual

PVED-CC4, Series 7

General Information

PVG functionality

Option mounted PVG with PVSK, PVED-CC4 with AMP connector

This chapter will give an overview of the PVG and its functionality.

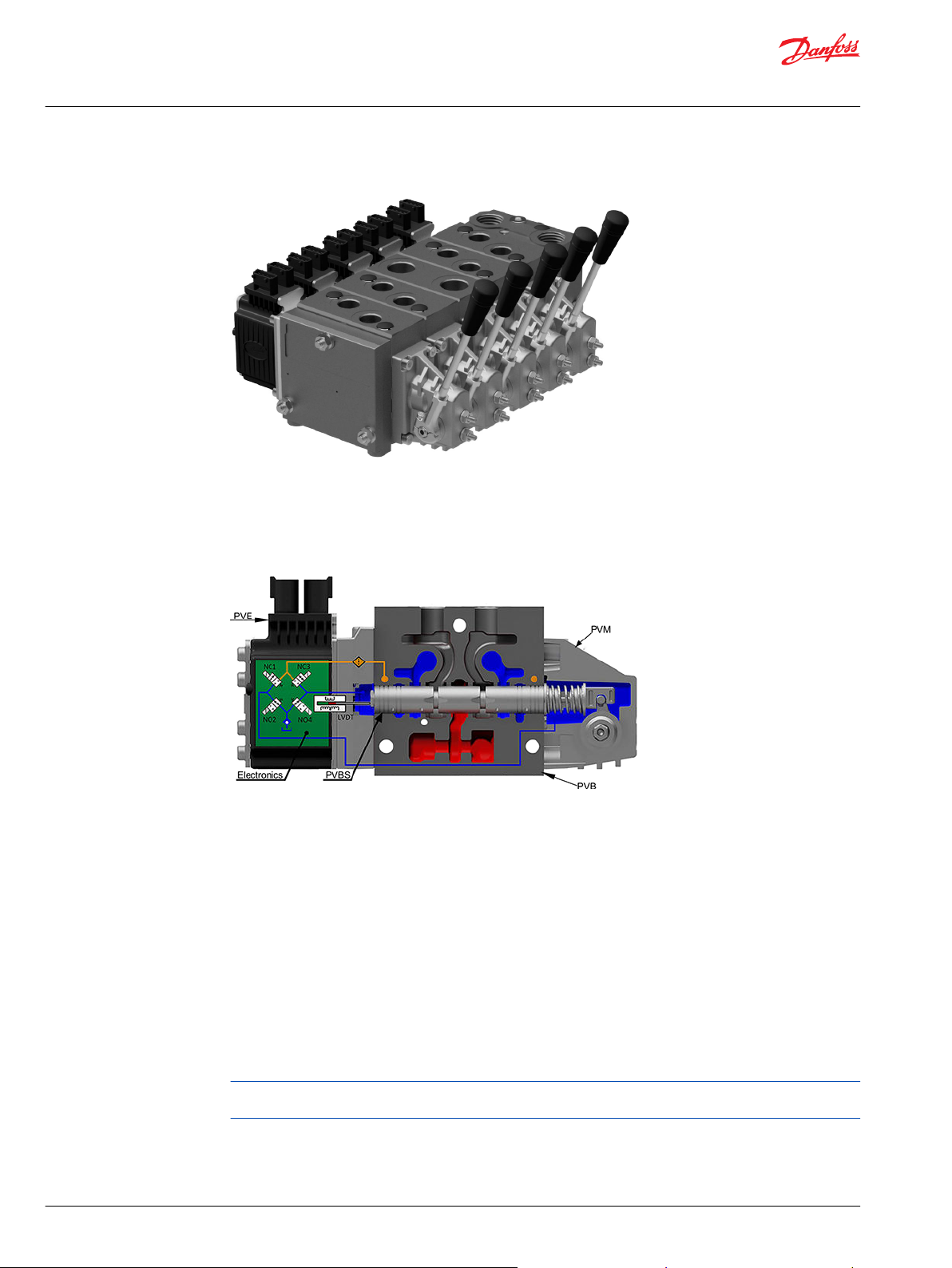

Valve section with naming - standard mounted - seen from PVP

The PVG valve distributes oil from pump flow to a particular work function in the application via a specific

valve section. This is done by moving the spool (PVBS).

Depending on the choice of components the oil work flow enters the PVG through the PVP (proportional

valve pump side module) or the PVSK (proportional valve end plate for crane) and enters the PVB

(proportional valve basic module) via the P gallery and leaves through the T gallery.

In the figure above you see a valve section seen from PVP towards PVSK with the PVM and PVE standard

mounted. PVM and PVE can in general be interchanged, that is called option mounted.

With the spool in neutral, where it is kept by the neutral spring, the connection to the application via

ports is blocked.

Moving the spool towards the PVE, as in figure 4, opens a connection between P and A and also between

B and T. This is done by either pushing the PVM or sending a retract command to PVED. The PVED move

the spool by letting Pilot Oil Pressure (Pp) push on the right end of the PVBS and releasing pressure from

the left end. For details on PVG please see relevant technical information.

Any PVG with PVM can be operated by PVM alone, independent of a power supply. Any PVG with PVEDCC4 can monitor PVBS if power and communication conditions are present.

14 | © Danfoss | February 2021 BC368572537192en-000101

Page 15

POST

Device state

machine

DSM

Full

Operational

mode

Emergency

mode

Fault

mode

Hand

Operational

mode

P301 359

User Manual

PVED-CC4, Series 7

PVED-CC4 functionality

This section main focus is to provide a brief overview before heading into the following technical

chapters. Understanding this section is regarded as a minimum in order to understand the use of the

actuator.

Before any installation and use of the PVED-CC4 it is highly recommended that the user understands the

technical chapters as well.

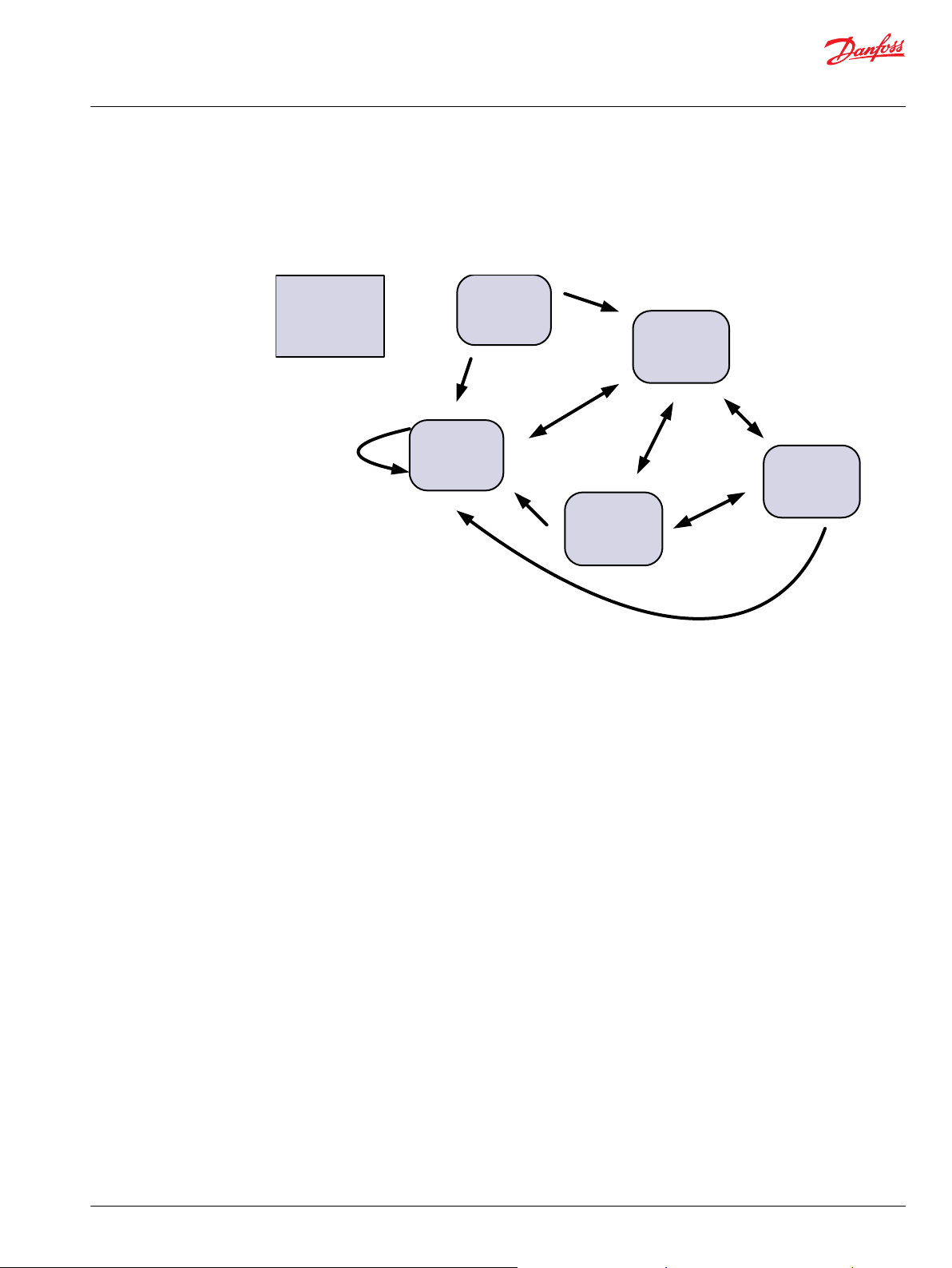

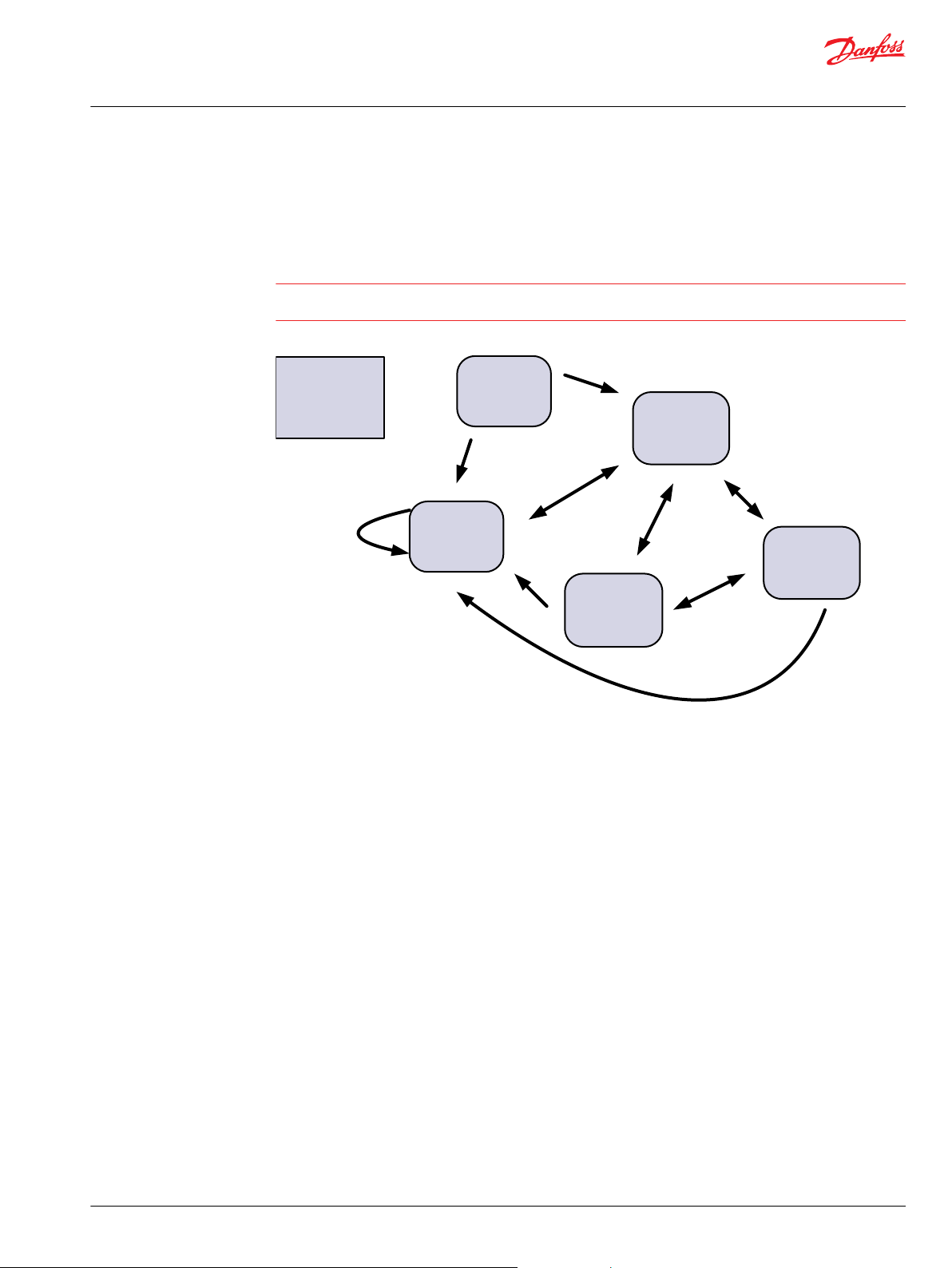

The PVED-CC4 features four different modes of operation: Full Operational mode, Hand Operational

mode, Emergency mode and Fault mode.

Prior to operation the PVED-CC4 performs a Power On Self Test (POST) in order to validate the state of

electronics, settings and software.

If the PVED-CC4 recognizes violations of standard operation it will immediately give a detailed feedback

on this event. If the violation is regarded as possibly dangerous the PVED-CC4 will enter fault mode.

The PVED-CC4 is a mechatronic device, meaning mechanics, hydraulics, electronics and micro-controller

interacting with external systems.

The illustration below gives an overview of the actuator tasks. On the left side is external system

interaction on the right side internal tasks.

©

Danfoss | February 2021 BC368572537192en-000101 | 15

Page 16

User Manual

PVED-CC4, Series 7

PVED-CC4 functionality

PVED-CC4 mechatronical interaction

Mechanical sub-system

Housing

The housing of this product protects the internal parts from the environment and gives by design the

optimal interface to cabling, Pilot pressure and spool.

PVED-CC4 Cable kit

The cabling is one of the great advantages for CAN systems. It reduces the number of cables and gives a

simpler system overview.

All units (ECU e.g. PVED) are connected by the CAN bus, a CAN high and a CAN low wire which are

terminated at the ends. Power and ground wires can with respect to maximum current consumption

follow the bus wires.

The bus can either be made as a daisy chain, where the stub from bus to ECU is inside the PVED

16 | © Danfoss | February 2021 BC368572537192en-000101

Page 17

ECU

1

ECU

n

ECU

4

ECU

3

ECU

2

120 Ω termination

P301 361

ECU

1

ECU

n

ECU

4

ECU

3

ECU

2

P301 362

8±0.5Nm

[70±4.5lbf-in]

5[0.20]

8±0.5Nm

[70±4.5lbf-in]

5[0.20]

User Manual

PVED-CC4, Series 7

PVED-CC4 functionality

or with stubs going from the back bone to the ECU.

PVED-CC4 with AMP connector exploded view

©

Danfoss | February 2021 BC368572537192en-000101 | 17

Both solutions have advantages and disadvantages. Danfoss supports the daisy chain solution with

cables but the PVED-CC4 could easily be used with the back bone solution.

PVED-CC4 mounting

The Danfoss PVG concept is based on parts interchangeability. This is also valid for the PVED-CC4 and

makes field retrofitting possible. PVED can be mounted on both ends of PVB.

PVED-CC4 with DEUTSCH connector exploded view

Page 18

W

W

W

User Manual

PVED-CC4, Series 7

PVED-CC4 functionality

Hydraulic subsystem

Warning

Deviation from recommended torque can harm performance and module.

Linear Variable Differential Transducer (LVDT)

The Linear Variable Differential Transducer (LVDT) or position sensor is the interface between the

mechanical system (spool) and the electronic system.

Warning

The LVDT must never be mechanically adjusted, bent, damaged or partially blocked as this will lead to

incorrect information on spool position.

Spool neutral spring

The PVBS neutral spring is an important safety component as it keeps or moves the PVBS in blocked

position when solenoid valves are disabled. The spring will keep the A and B port.

The hydraulic subsystem is used for moving the spool and thereby opening the valve for work flow.

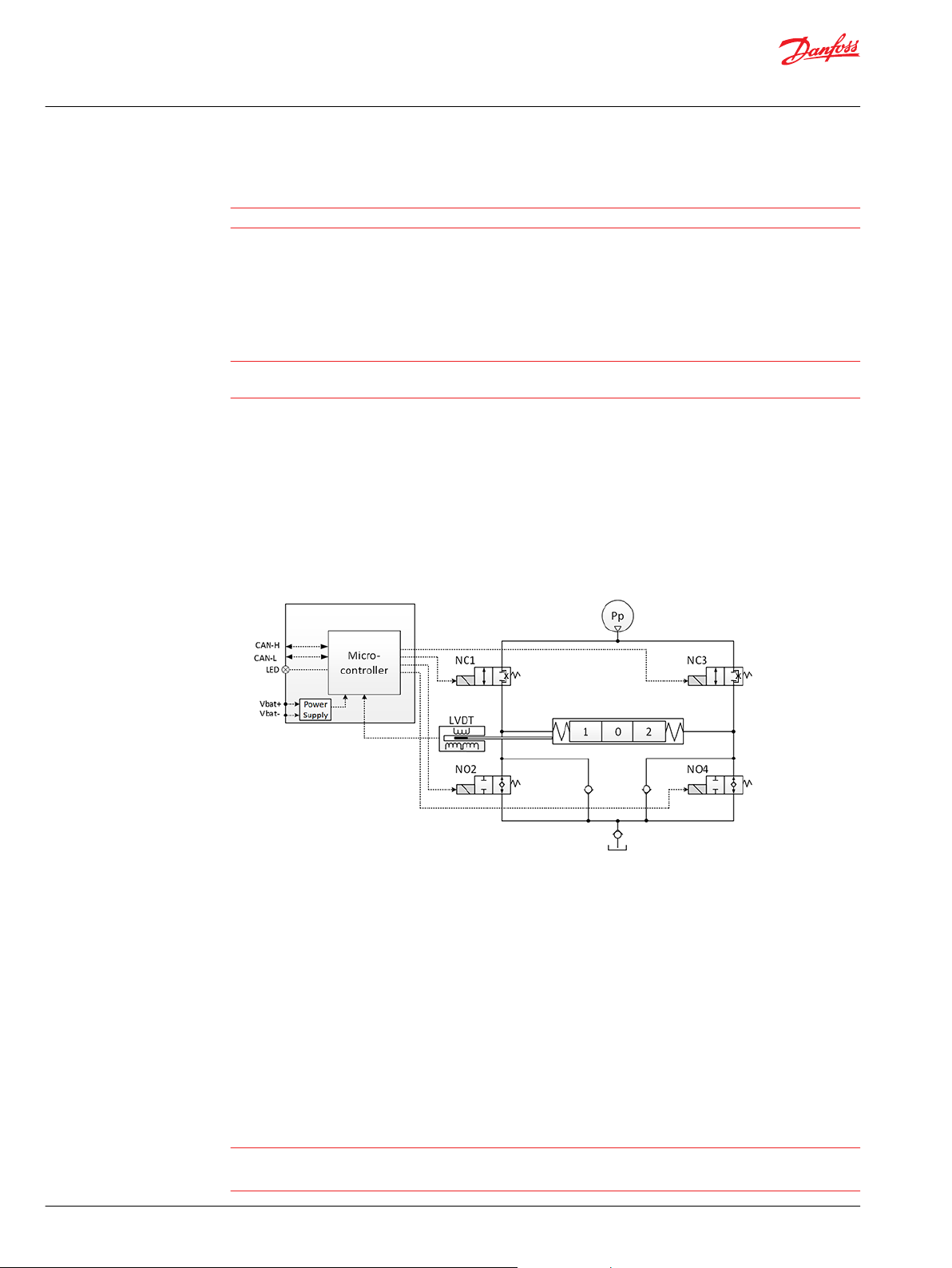

Pilot oil diagram

The heart of the hydraulic subsystem is the solenoid valve bridge. It consist of four poppet valves, the two

upper ones are normally closed (NC-S) with a small bleed, the two lower ones are normally open (NO).

A continuous modulation of solenoid valves NC1 and NO4 together with a simultaneous energization of

NO2 and de-energization of NC3 causes the main spool to move to the right direction and vice versa.

When the main spool is stroked to the far right, a simultaneous energization of both NO2 and NO4 and

de-energization of both NC1 and NC3 balances the main spool in its stroked position. An emergency stop

activated when the spool is stroked will cause all solenoid valves to de-energize causing the main spool

to move back to its neutral position by means of the main spool neutral spring and the hydraulic

principle.

The Pp will work against the PVBS neutral spring when the spool is moved out of blocked (neutral) and

together with the spring when going in blocked. This combined with a larger opening in the NO than in

the NC-S will give a faster movement towards blocked than out of blocked.

Warning

Obstacles for the Pp can have direct influence on spool control. Reduced pilot pressure will limit spool

control. Too high Pp can harm the system.

18 | © Danfoss | February 2021 BC368572537192en-000101

Page 19

W

POST

Device state

machine

DSM

Full

Operational

mode

Emergency

mode

Fault

mode

Hand

Operational

mode

P301 359

User Manual

PVED-CC4, Series 7

PVED-CC4 functionality

Computerized sub-system

The PVED-CC4 operation is based on state machines. The top level is according to this figure. Details are

available in the data section of this Technical Information.

Warning

Depending on PVED-CC4 variant, age and software there are variations in communication and control.

Read this technical information before implementing new PVED-CC4 in applications.

DSM for PVED-CC4

Transition out of POST (Power On Self Test) is controlled by PVED-CC4

•

Transition in and out of fault mode is controlled by PVED-CC4

•

Transition between Full Operational Mode, Hand Operational Mode and Emergency Mode is

•

controlled by operator.

Power On Self Test (POST)

When power is applied to the PVED-CC4 it will initialize components and validate component states and

parameter settings. If test is passed the PVED will enter Full Operational mode otherwise it will enter Fault

mode. In both cases it will, if possible, make itself known to the network by an address claim followed by

if needed a fault message (DM1) and then Auxiliary Valve Estimated Flow message (AVEF).

PVED-CC4 full operational mode overview

In full operational mode the PVED-CC4 controls the spool based on Auxiliary Valves Commands (AVC)

from system master. This mode is characterized by:

No fault is present

•

Full control by CAN bus of PVED

•

Fault monitoring is active

•

Auxiliary Valve Estimated Flow message (AVEF) is transmitted

•

PVED-CC4 hand operational mode overview

Hand operational mode is used when the PVG module should be operated manually without the PVED

going into failure mode.

In hand operational mode the PVED-CC4 cannot control the spool. This mode is characterized by:

©

Danfoss | February 2021 BC368572537192en-000101 | 19

Page 20

User Manual

PVED-CC4, Series 7

PVED-CC4 functionality

No fault is present.

•

Spool control by PVED is disabled.

•

Fault monitoring on spool behavior is disabled. Is maintained on other parameters.

•

Auxiliary Valve Estimated Flow message (AVEF) is transmitted

•

Emergency mode

Emergency mode is similar to Hand operational mode but is entered without any ramping. This mode is

characterized by:

Entered without any delay

•

Similar to hand operational mode

•

Fault mode overview

In fault mode the PVED-CC4 monitors and reports if possible.

This mode is characterized by:

One or more faults are present

•

LED is yellow or red

•

PVED tries to force PVBS to blocked position

•

AVC from Master is not followed by the module

•

Fault monitoring is active and every second present faults are reported

•

Auxiliary Valve Estimated Flow message (AVEF) is transmitted.

•

Settings and system data

The PVED-CC4 offers a number of settings for both spool control, fault monitoring and general system

settings. A number of system information parameters are available via the service tool. Details are

available in the data section of this Technical Information.

PVED-CC4 Process data

Process data can be considered as user or situation specific values. They are the runtime settings Ramp

timing, scaling of set point, variation of progressivity and port inversion and can be changed during

operation by an ISOBUS message.

OEM data

OEM data can be considered as application or system specific values. They are a number of safety

settings, performance settings and the module communication identifier. Also a set of fall back values for

the process data are stored as OEM data.

Spool data

Spool data are parameters used for linearization of the spool. These parameters gives relation between

spool position and flow command in order to comply with the ISOBUS standard of 0.4% flow change for

each step of the Auxiliary Valve Command (AVC).

General part details

Information like part number, production date, software identification and Name field are also available.

20 | © Danfoss | February 2021 BC368572537192en-000101

Page 21

Memory organization

Locked

Process

Data

Active

Parameters

AVC

Process

Data

Spool Data

Basic

Parameters

Fault

Monitoring

General

Settings

(excl node)

Error Log

basic

Temperature

Log

Process

Data in OEM

Calibration

data

Backup

Parameters

Node Id

General

Settings

Error Log

general

Naming

Node ID

Spool / Flow

table

Fault

Monitoring

General

Settings

(excl node)

P301 364

User Manual

PVED-CC4, Series 7

PVED-CC4 functionality

PVED-CC4 Logging

An error log with event counter is stored in the EEPROM.

During runtime a temperature histogram for the electronics are stored in the EEPROM.

©

Danfoss | February 2021 BC368572537192en-000101 | 21

Page 22

User Manual

PVED-CC4, Series 7

PVED-CC4 safety description

Definition

Concept

For a general description on Safety in Application please see PVG 32 Technical Information

BC152886483664.

The Danfoss definition of safe state transition by fault: Depower solenoids and release spool to neutral

spring. PVBS to be forced to blocked position (neutral) by neutral spring.

The PVED-CC4 has Active Fault Reaction, meaning the solenoids are disabled on fault. Less flow than

commanded is not regarded as dangerous by the PVED.

The PVED-CC4 safety concept is based on two elements:

POST – Power On Self Test

•

Runtime fault monitoring and reaction

•

The basic elements for product safety are:

Continuous module self monitoring

•

Fault recognition and reaction

•

Fault reporting and recording

•

Fault recovery

•

POST–Power On Self Test

When powered the PVED evaluates settings, circuit, sensors and spool interface .

Passing of the POST is a precondition for entering Full Operational Mode.

PVED-CC4 runtime fault monitoring

After power on set up and POST the runtime fault monitoring takes over. Every time the uCSM enters the

safety task a number of feedbacks are evaluated. In parallel the internal handshake between

microcontroller and watch dog is running. The faults are categorized by origin and severity level

Fault origin category

Internal PVED

•

‒

‒

‒

‒

‒

PVED PVG interaction

•

‒

System interaction /communication fault

•

‒

‒

‒

‒

Handshake fault

Calculation faults

Memory faults

Components faults

Temperature fault

Spool position faults

Power supply

Invalid commands

Missing commands

CAN bus faults

22 | © Danfoss | February 2021 BC368572537192en-000101

Page 23

User Manual

PVED-CC4, Series 7

PVED-CC4 safety description

PVED-CC4 fault Reaction

Fault severity level

Warning. A changes of settings was attempted but could not be followed

•

Severe. Based on the present state actuation cannot be continued. This is for fault types permanent

•

and temporary.

In case of recognized unintended behavior the PVED-CC4 can react in three ways.

For some events the reaction is at first occurrence for others after a threshold is passed.

By multiple faults the most severe has priority and the PVED-CC4 will stay in fault mode until recovered

from all faults.

Recorded and reported solenoid disabling

Used by severity level Severe and solenoids are disabled.

If the event is regarded safety or performance threatening the solenoids are disabled (spool forced back

to blocked), a distress messages is broadcasted on the CAN bus at occurrence and for as long as present

and a record is made in the error log.

PVED-CC4 fault recovery

Recorded and reported ignorance

Used by severity level Warning and solenoids are not disabled.

A distress messages is broadcasted on the CAN bus at occurrence and as long as present and a record is

made in the error log.

Unrecorded reaction

By missing handshake from microcontroller the Watch dog disables the solenoids and the CAN bus

interface.

For events of severity level Severe there are one of two ways of recovery.

Reboot

The event is regarded as system threatening and a system reconfiguration and reevaluation is required.

Resume

The event is regarded as performance/safety threatening but not system threatening. When the fault

trigger disappears transmission of two AVC Blocked reactivates the PVED.

For events with severity level Warning no recovery needed. The operator might though need to send a

valid setting changes to get a desired performance.

©

Danfoss | February 2021 BC368572537192en-000101 | 23

Page 24

100

0

Spool Position [%]

Time

T0 T1

T2

Spool Position

PFC (%)

Supply Voltage (UDC)

Max. spool pos. to neutral

T2

Neutral to max. spool pos.

T1

Boot-up

T0

P301823

User Manual

PVED-CC4, Series 7

Technical data

Declaration of Conformity

The PVED-CC4 has CE marking according to the EU directive EMC Directive 2004/108/EC. The declarations

are available at Danfoss.

PVED-CC4 operational conditions

The PVED-CC4 will only operate according to the table below:

Operational conditions

Mode Supply

Electronic test POST Mandatory Optional Optional Optional

Manual operation Optional

Full operation Mandatory Mandatory Mandatory Mandatory

*

Mandatory if spool position information is requested.

**

If hydraulic performance is expected.

The PVE is designed for use with pilot oil supply. Use without oil supply except intermittent use can harm

the system.

The PVE is designed for use with pilot pressure range 10 -> 15 bar [145 -> 220 psi]. Intermittent pressure

peaks up to 50 bar [725 psi] can be accepted.

Definition: Extend. Spool is further away from PVED than blocked position. Equals to oil out of B-port by

standard mounted PVED.

Definition: Retract. Spool is closer to PVED than blocked position. Equals to oil out of A-port by standard

mounted PVED.

Definition: Intermittent is no longer than 5 seconds and not more than once per minute.

Power CAN control Pilot oil pressure Oil main pressure

*

Optional

*

Optional Mandatory

**

**

Reaction times

PVED-CC4 S7 reaction time

24 | © Danfoss | February 2021 BC368572537192en-000101

Page 25

118,2[4.65]

92[3.62]

45[1.77]

89,1]3.5]

26,2[1.03]

92[3.62]

30,9[1.22]

45[1.77]

89,1[3.5]

124,8[4.9]

User Manual

PVED-CC4, Series 7

Technical data

Reaction time for actuation (@ Oil viscosity: 21 ± 0.5 cSt; Pilot pressure (P-T): 13.3 ± 0.5 bar)

Reaction time - function Solenoids Minimum Maximum

From neutral to maximum spool travel Powered 50 ms 200 ms

From maximum spool travel to neutral Powered - 150 ms

From power on to maximum spool travel Powered 2050 ms 4000 ms

From maximum spool travel to neutral Disabled - 175 ms

Power up; from power on to CAN active - - 2200 ms

Hysteresis @0.02Hz - 0 % 1 %

PVED-CC4 Dimensions and layout

PVED-CC4 with AMP connector

PVED-CC4 with DEUTSCH connector

©

Danfoss | February 2021 BC368572537192en-000101 | 25

Page 26

1

2

3

4

2 3

41

23

4 1

User Manual

PVED-CC4, Series 7

Technical data

Connectors overview

2 x 4 AMP

2 x 4 pin DEUTSCH

Legend:

1. CAN Low

2. U

DC

3. Ground

4. CAN High

Legend:

1. CAN High

2. CAN Low

3. U

DC

4. Ground

Connection PVED-CC4

Connector CAN low U

AMP pin 1 pin 2 pin 3 pin 4

DEUTSCH pin 2 pin 3 pin 4 pin 1

DC

Ground CAN high

Enclosure and connector

Connector AMP JPT connector DEUTSCH connector

Grade of enclosure

*

According to the international standard IEC 529

*

IP 66 IP 67

In particulary exposed applications, protection in the form of screening is recommended.

Voltage and current

Supply Voltage (DC)

Nominal 11 - 32 V

Minimum 9 V

Maximum 36 V

Max ripple 5 %

Current consumption

12V 24V

Power Save 70 mA 40 mA

Operating 580 mA 300 mA

Power consumption is independent on voltage. Activation of solenoid valves by low voltage outside

nominal is for short term excep-tions, meaning maximum 10 % of operating time and for max 5 minutes

within an hour. Activation of solenoid valves by 9-10 V will give reduced valve performance. Voltage

above 36 V and below 8 V will shut down electronics.

26 | © Danfoss | February 2021 BC368572537192en-000101

Page 27

User Manual

PVED-CC4, Series 7

Technical data

Hydraulic data

The PVED-CC4 is in conformity with the EU EMC directive 2004/108/EC and complies to the standard ISO

13766:2006 (E) Earth moving machinery – Electromagnetic compatibility.

16 PVED-CC4 can be on the same CAN bus simultaneously.

According to J1939, the maximum length for a CAN bus is 50 meter [1970 inch]

Pilot oil system

Oil viscosity

Oil viscosity Recommended range 12 → 75 mm2/s [65 ÷ 347 SUS]

Min. 4 mm2/s [39 SUS]

Max. 460 mm2/s [2128 SUS]

Pilot pressure

Pilot pressure

(relative to T pressure)

Nom. 13.5 bar [196 psi]

Min. 10.0 bar [145 psi]

Max. 15.0 bar [217 psi]

Oil temperature

Oil temperature Recommended range 30 → 60˚C [86 ÷ 140˚F]

Min. -30˚C [-22˚F]

Max. 90˚C [194 ˚F]

Operating temperature

Min. Max.

Ambient -30˚C [-22˚F] 60˚C [140˚F]

Stock -40˚C [-40˚F] 90˚C [194˚F]

Recommended long time storage in packaging 10˚C [50˚F] 30˚C [86˚F]

Filtering in the hydraulic system

Required operating cleanliness level 18/16/13 (ISO 4406, 1999 version)

For further information see Danfoss documentation Hydraulic Fluids and Lubricants, Technical Information

BC152886484524.

©

Danfoss | February 2021 BC368572537192en-000101 | 27

Page 28

157-520.11

0

0 1 2 l/min

bar

20

10

15

5

3 4 5

psi

50

100

150

200

250

300

0

0 0.25 0.5 0.75 1.0 1.25 US gal/min

Max.

Min.

User Manual

PVED-CC4, Series 7

Technical data

PVP modules, pilot pressure curves

Pilot oil consumption for one PVED-CC4

Solenoids depowered 0.2 ÷ 0.4 l/min [0.05 ÷ 0.10 US gal/min]

Spool locked by pilot oil 0.1 ÷ 2 l/min [0.03 ÷ 0.05 US gal/min]

Continuous actuation 0.9 ÷ 1.1 l/min [0.24 ÷ 0.29 US gal/min]

One actuation (neutral to max.) 0.002 l/min [0.0005 US gal/min]

Oil viscosity: 21.0 ± 0.5 cSt, Pilot.

Pilot pressure (P-T): 13.3 ±0.5 bar

Hysteresis overview

NC-S

Maximum 2.0%

Typical <0.5%

Communication

PVED-CC4 LED

The PVED-CC4 has four modes, see the table below:

LED color interpretation

LED color PVED-CC4 mode

Green Full Operation

Yellow Power save (if the spool is in blocked position for more than 1 s)

Manual (error)

Red Fail-silent (ASIC and CAN Transceiver disabled)

28 | © Danfoss | February 2021 BC368572537192en-000101

Page 29

User Manual

PVED-CC4, Series 7

Technical data

CAN

CAN data

Physical layer ISO11898-2 high speed CAN

Protocol ISO11783-7 / SAE J1939 (29 bit identifiers)

Baud rate 250 Kbps

Bit timing TSEG1 = 13

According to this time quanta calculated as per data sheet is tq = 200 n.s. (considering fcpu = 20 MHz).

Therefore:

Before sample point [t(TSEG1)] = (TSEG1 + 1) x tq = 14 x 200 = 2800 n.s.

•

After sample point [t(TSEG2)] = (TSEG2 + 1) x tq = 5 x 200 = 1000 n.s.

•

t(sync-seg) = 1 x tq = 200 n.s.

•

1 Bit time = t(sync-seg) + t(TSEG1) + t(TSEG2) = 200 + 2800 + 1000 = 4000 n.s.

•

One sample point at 75%.

•

According to 250 kbps, 1 Bit time = 4000 n.s.

•

TSEG2 = 4

SJW = 0

BRP = 1

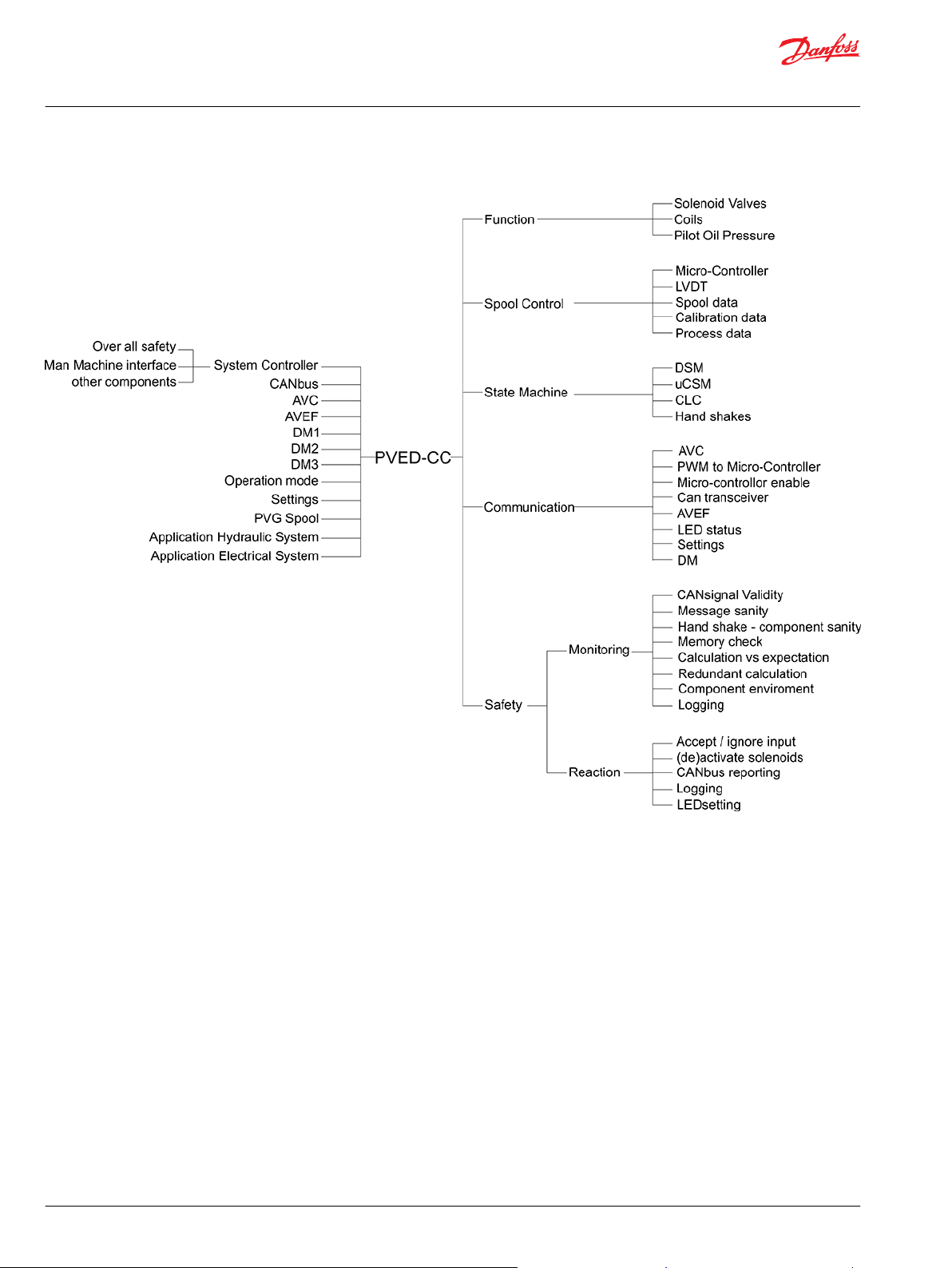

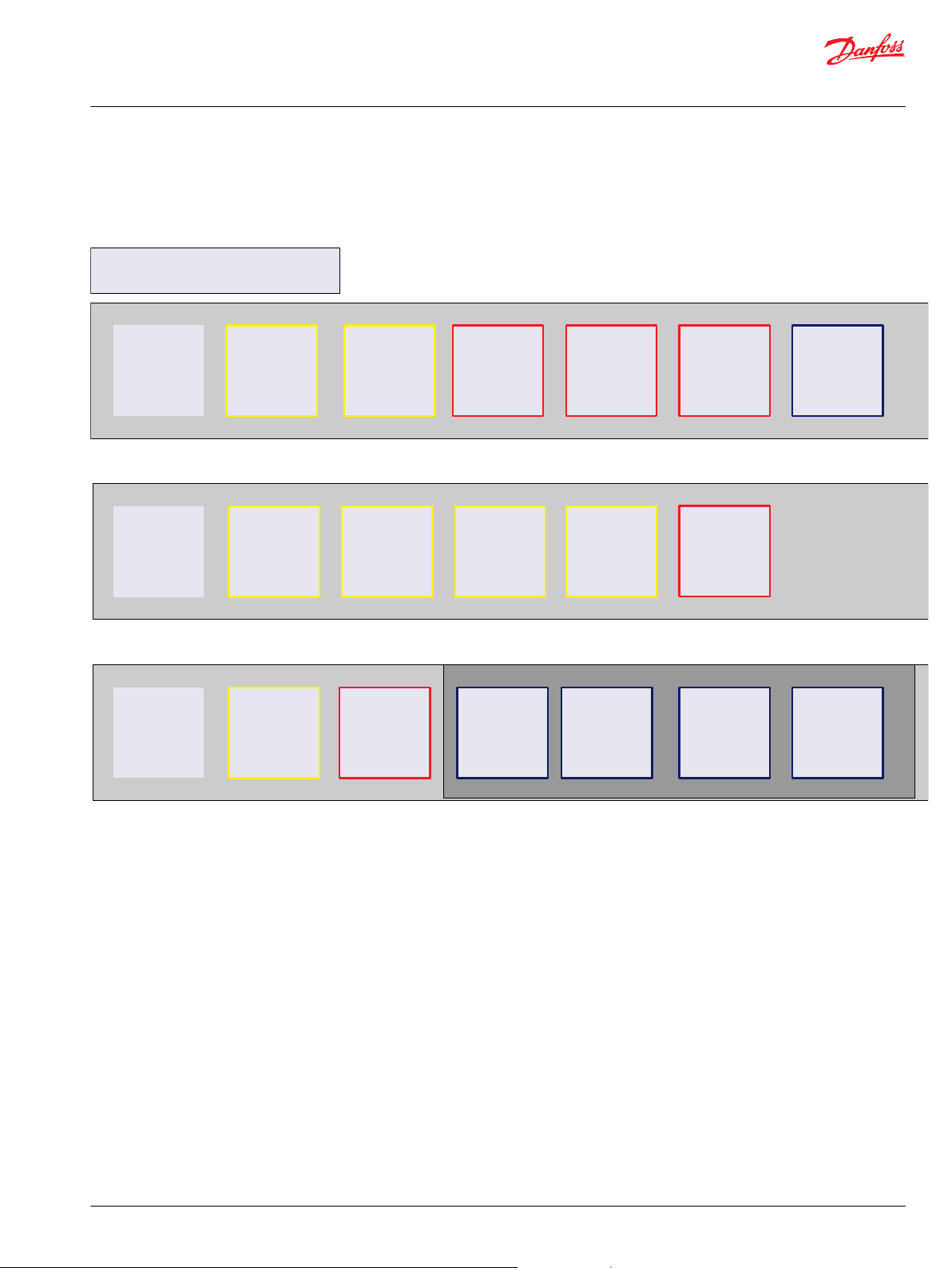

Parameter description

Parameters in the PVED-CC4 are organized in a hierarchy with active parameters as most important and

back up parameters as less important. Yellow framing indicates high accessibility, red low and purple

read only. Changing parameters in one position will not necessarily change parameters at other

positions. For example ramp changed as process data will change performance until next reboot, ramp

value changed and stored as process data will have effect until next restore OEM defaults. Changing

ramp in OEM data will only have effect for performance if restore OEM data is performed in Process Data

screen

©

Danfoss | February 2021 BC368572537192en-000101 | 29

Page 30

Memory organization

Locked

Process

Data

Active

Parameters

AVC

Process

Data

Spool Data

Basic

Parameters

Fault

Monitoring

General

Settings

(excl node)

Error Log

basic

Temperature

Log

Process

Data in OEM

Calibration

data

Backup

Parameters

Node Id

General

Settings

Error Log

general

Naming

Node ID

Spool / Flow

table

Fault

Monitoring

General

Settings

(excl node)

P301 364

User Manual

PVED-CC4, Series 7

Technical data

Memory organization

Commercial identifiers

The part number or sales number gives together with the production day the serial number for the PVEDCC4. This is a unique identification of every PVE which is also engraved on the cover.

Communication identifiers

The CAN bus identification of the PVED-CC4 is defined by the name field. The function instance, in this

document also called node id or source address, is the only accessible parameter in current versions.

Firmware identifiers

Information about firmware and thus on implemented features is present in the PVED-CC4.

Service parameters

Error log and temperature histogram can be read out.

Valve interface settings

Calibration data and spool curve defines software interface to the electrical and mechanical environment.

Communication parameters

Node Id, Estimated Flow Delay, and KWP 2000 parameters defines communication

30 | © Danfoss | February 2021 BC368572537192en-000101

Page 31

Bit

1 2

3 4 5 6 7

8

1

2

3

4

5

6

7

8

Byte

ECU

Instance

Function Instance

Function

Vehicle

System

Vehicle

System

Instance

Industry

Group

reserved

Identity Number

Manufacturer

Code

Arbitrary

Address

Capable

P301 365

User Manual

PVED-CC4, Series 7

Technical data

Safety parameters

For some faults a threshold for recognition can be set. That is done by the General Timeout (GTO), the

Float Time Out (FTO) and the auxiliary valve Command Time Out (CTO). The fault recovery conditions can

be altered for a number of faults, named monitoring. Also the Power Save setting has influence on

system safety and not only power consumption.

Behavior parameters

A number of parameters have a direct influence on how the PVED perform on a flow command. These

parameters are referred to as process data. These are ramping, scaling, progressivity and port inverting.

Also a minimum flow before entering float can be defined. All these parameters can be changed by a

single CAN message.

Name field J1939

Dynamic address claiming is not implemented. Parameters are read only. Function instance can only be

accessed by service tool protocol.

Back up parameters – Node Id General settings – J1939

Identity Number 201001 (0b 00011000 10001001 01001) Read Only

Manufacture code 57 (0b 000 00111001) Danfoss Read Only

ECU instance 0 (0b 000)

Function instance 0 (0b00000) node id 128 (0x80)

Function 129 (0b 10000001) auxiliary valve on a tractor

Reserved 0

Vehicle system 1 (0b 0000001) tractor for industry group 2

Vehicle system instance 0 (0b 0000) front vehicle

Industry group 2 (0b 010)

msb: byte 8 bit 8 lsb: byte 1 bit 1

Function instance

Function instance shows the PVED node id.

©

Danfoss | February 2021 BC368572537192en-000101 | 31

Page 32

User Manual

PVED-CC4, Series 7

Technical data

0 (0b00000) node id 128 (0x80)

•

1 (0b00001) node id 129 (0x81)

•

2 (0b00010) node id 130 (0x82)

•

…

•

15 (0b01111) node id 143 (0x8F)

•

Function instance identifies the PVED-CC4 on the bus as source or target for communication.

In the service tool function instance is shown with decimal number (node Id). Hexa deximal (0x) values

are used in communication description. numbers.

Function instance (node Id) 128 (0x80) is default for none configured PVED-CC4 (spare part).

Back up parameters – Node Id General settings

OEM data. Changes are implemented by boot up

Range: 128 – 143 (0x80 – 0x8F) Default value 128

Example

PGN Signal target Signal source

18EA8006 EA00 80 (PVED 128) 06 (system CTRL)

1CECFF80 EC00 FF (Broadcast) 80 (PVED 128)

Component ID additional information

By use of the service tool part number, serial number, software version and software details are available.

Back up parameters – Node ID General settings- read only – J1939.

Part number

Same as sales number. Also engraved on the PVED-CC4 housing.

Serial number

Example of serial number: 3520B060289

Factory Week Year Day

Engraved --- 35 20 B 05 0289

Soft N 35 20 B --- 0289

*

Day: A-Monday, B-Tuesday, C-Wednesday, D-Thursday, E-Friday, F-Saturday, G-Sunday

Also engraved on the PVED-CC4 housing.

*

Machine Id

Software naming

Three digits giving a revision number. E.g. 1.71

Scaling

Scaling reduces the set point automatically for the PVED. Scaling is relevant if the control speed must be

lowered. The value defines how large a part of the set point is valid. Scaling can be defined

independently for both extend and retract.

32 | © Danfoss | February 2021 BC368572537192en-000101

Page 33

40

60

80

100

1

2

3

4

5

6

7

8

9

10

11

12

13

0

20

PFC

14

15

16

% of max flow

P301 366

User Manual

PVED-CC4, Series 7

Technical data

Active parameters –Process Data – ISOBUS, is not stored for next session.

•

Basic parameters – Process Data – WebGPI, is activated and stored for next session.

•

Back up parameters – Process Data – OEM Data – WebGPI is not activated but stored. Can be moved

•

to Basic Parameters.

Configurable: Range: 0 % –100 % in steps of 0.4 % (0-250); Default value 100 % (250)

•

Slope curve

Slope curve is a progressivity scaling of the set point. Slope curve can be used to get finer solution on set

point with low flow. Slope curve can be defined independently for both extend and retract.

with PFC 125 and slope 0 (linear); the flow will be 50% of max flow.

•

with PFC 125 and slope 15 (maximum progressivity); the flow will be close to 15 % of max flow.

•

Spool characteristic curves

Active parameters – Process Data – ISOBUS, is not stored for next session.

•

Basic parameters – Process Data – WebGPI, is activated and stored for next session.

•

Back up parameters – Process Data – OEM Data – WebGPI is not activated but stored. Can be moved

•

to Basic Parameters

Configurable:

•

Range 1 (linear) to 16

‒

Default value 1 (linear)

‒

Ramp

Ramp builds in a delay in the flow change. Ramp is relevant if fast change in flow can harm the system.

The value defines delay time for transition between 0 % and 100 % of maximum flow. Ramp can be

defined independently for both flow growth and lowering in both extend and retract direction.

Active parameters –Process Data –ISOBUS, is not stored for next session

•

Basic parameters – Process Data –WebGPI, is activated and stored for next session

•

Back up parameters – Process Data- OEM Data –WebGPI is not activated but stored.

•

Can be moved to Basic Parameters

Configurable: Range: 0s to 4s insteps of16ms(0-250); Default value 0s (0)

•

©

Danfoss | February 2021 BC368572537192en-000101 | 33

Page 34

User Manual

PVED-CC4, Series 7

Technical data

Invert ports

Invert port mirrors the flow command in the opposite direction. Invert port can be relevant if joystick is

operated from opposite side than standard.

Cannot be used with float spools

Active parameters – Process Data – ISOBUS, is not stored for next session

•

Basic parameters – Process Data – WebGPI, is activated and stored for next session

•

Back up parameters – Process Data- OEM Data – WebGPI is not activated but stored.

•

Can be moved to Basic Parameters

Configurable: Range: none inverted and inverted (0-1); Default value none inverted (0)

•

Float threshold

Float threshold defines minimum flow before entering float. Float threshold can be used to avoid float

state for lifted load. Float threshold cannot support float entering from opposite flow than float side of

spool. Ramp builds in a delay in the flow change. Ramp is relevant if fast change in flow can harm the

system. The value defines delay time for transition between 0% and 100% of maximum flow. Ramp can

be defined independently for both flow growth and lowering in both extend and retract direction..

Active parameters –Process Data –ISOBUS, is not stored for next session

•

Basic parameters – Process Data –WebGPI, is activated and stored for next session

•

Back up parameters – Process Data- OEM Data –WebGPI is not activated but stored.

•

Can be moved to Basic Parameters

Configurable: Range: 0% –100% in steps of 0.4% (0-250); Default value 0.4% (1)

•

Not applying to float threshold will cause a warning.

AVEF send out time

The Auxiliary Valve Estimated Flow (AVEF) is an average in full percentage of the flow over the last 80ms

(8 samples). The AVEF can be used for flow sharing, monitoring of unintended movement or reduced

flow, handshake from PVED etc.

Basic parameters – OEM data – WebGPI, is activated by send

•

Back up parameters – OEM Data – WebGPI activated and stored for next session

•

Configurable: Range: 0 - 64255 ms in steps of 10ms. 65535 (0 x FFFF) is disable; Default value 100 ms.

•

AVC time out (AVCTO)

The Auxiliary Valve Command (AVC) time out is the maximum time span between two set point

commands from the system controller. See also error code description for Time guarding on Auxiliary

Valve Command. The AVC Time Out is a handshake monitoring of controller.

Basic parameters – OEM data – WebGPI, is activated by send

•

Back up parameters – OEM Data – WebGPI activated and stored for next session

•

Configurable: Range: 0 - 65535 ms in steps of 10 ms. 0 is disable; Default value 5000 ms.

•