Technical Information

Proportional Valves

PVED-CC, Series 5 ISObus

www.danfoss.com

Technical Information

PVED-CC Series 5 ISObus

Revision history Table of revisions

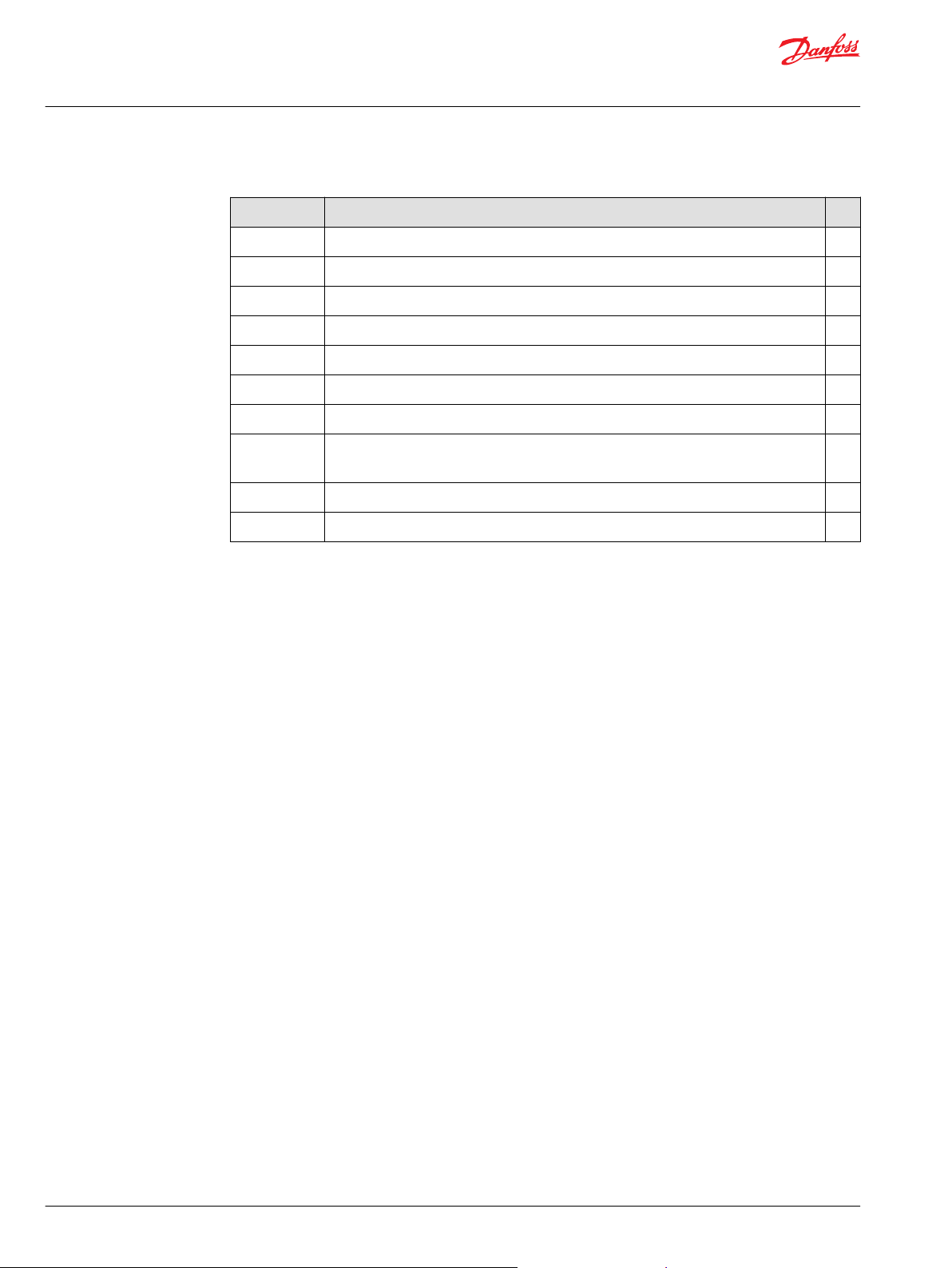

Date Changed Rev

October 2021 Minor data corrections 0107

June 2020 Updated code numbers 0106

November 2019 Added 4m EMC proof cables to ISOBus code numbers 0105

October 2017 Correction - AMP connector 0104

July 2017 Correction to image 'AMP 2x 4pin AMT Junior Power Timer.' 0103

February 2016 Literature order number changed. 0102

Changed document number from 'BC00000361' to 'BC187186484889' XX

February 2016 Parameter overview table, Temperature dependent spool timeout float addon parameter:

Range and default updated

October 2015 ISObus added to the title 0001

June 2015 First version 0000

0101

2 | © Danfoss | October 2021 BC187186484889en-000107

Technical Information

PVED-CC Series 5 ISObus

Contents

Introduction

Technical data

Communication

Parameters

Diagnostics

PVED-CC ISObus code numbers..................................................................................................................................................4

Operating data overview...............................................................................................................................................................5

Connectors..........................................................................................................................................................................................6

LED coloring for PVED-CC Series 5............................................................................................................................................. 7

Physical dimensions........................................................................................................................................................................ 7

PVED-CC Hysteresis and Ripple...................................................................................................................................................8

PVED-CC Reaction Times............................................................................................................................................................... 8

PVED-CC ISObus message overview..........................................................................................................................................9

PVED-CC Address claim..................................................................................................................................................................9

Commanded address................................................................................................................................................................... 10

PGN: Auxiliary Valve Command................................................................................................................................................10

PGN: Auxiliary Valve Estimated Flow...................................................................................................................................... 11

PGN: Vehicle Fluid Temperature...............................................................................................................................................12

PGN: Diagnostic Message 1........................................................................................................................................................13

PGN: Diagnostic Message 2........................................................................................................................................................15

PGN: Diagnostic Message 3........................................................................................................................................................18

PGN: Diagnostic Message 4........................................................................................................................................................18

PGN: Diagnostic Message 11..................................................................................................................................................... 22

PGN: Diagnostic Message 13..................................................................................................................................................... 23

Parameter overview......................................................................................................................................................................24

PVED-CC ISObus Process data...................................................................................................................................................26

Process data messages...........................................................................................................................................................26

Process data overview............................................................................................................................................................ 26

Setpoint transfer feature: Write process data.................................................................................................................27

Frame format..............................................................................................................................................................................27

Write data.................................................................................................................................................................................... 27

Linked fault flags.......................................................................................................................................................................27

Read data.....................................................................................................................................................................................28

PVED-CC (ISObus) Diagnostics log ......................................................................................................................................... 29

Diagnostic history..........................................................................................................................................................................31

Temperature histogram...............................................................................................................................................................31

©

Danfoss | October 2021 BC187186484889en-000107 | 3

Technical Information

PVED-CC Series 5 ISObus

PVED-CC ISObus Introduction

The PVED-CC Series 5 ISOBUS is a high performance digital actuator for the valve families PVG 32 and PVG

100.

The PVED-CC Series 5 ISOBUS offers CAN bus control through loop cables simplifying the wire harness

and build-in intelligence where actuator specific features tailor the actuator behavior to the exact

function need.

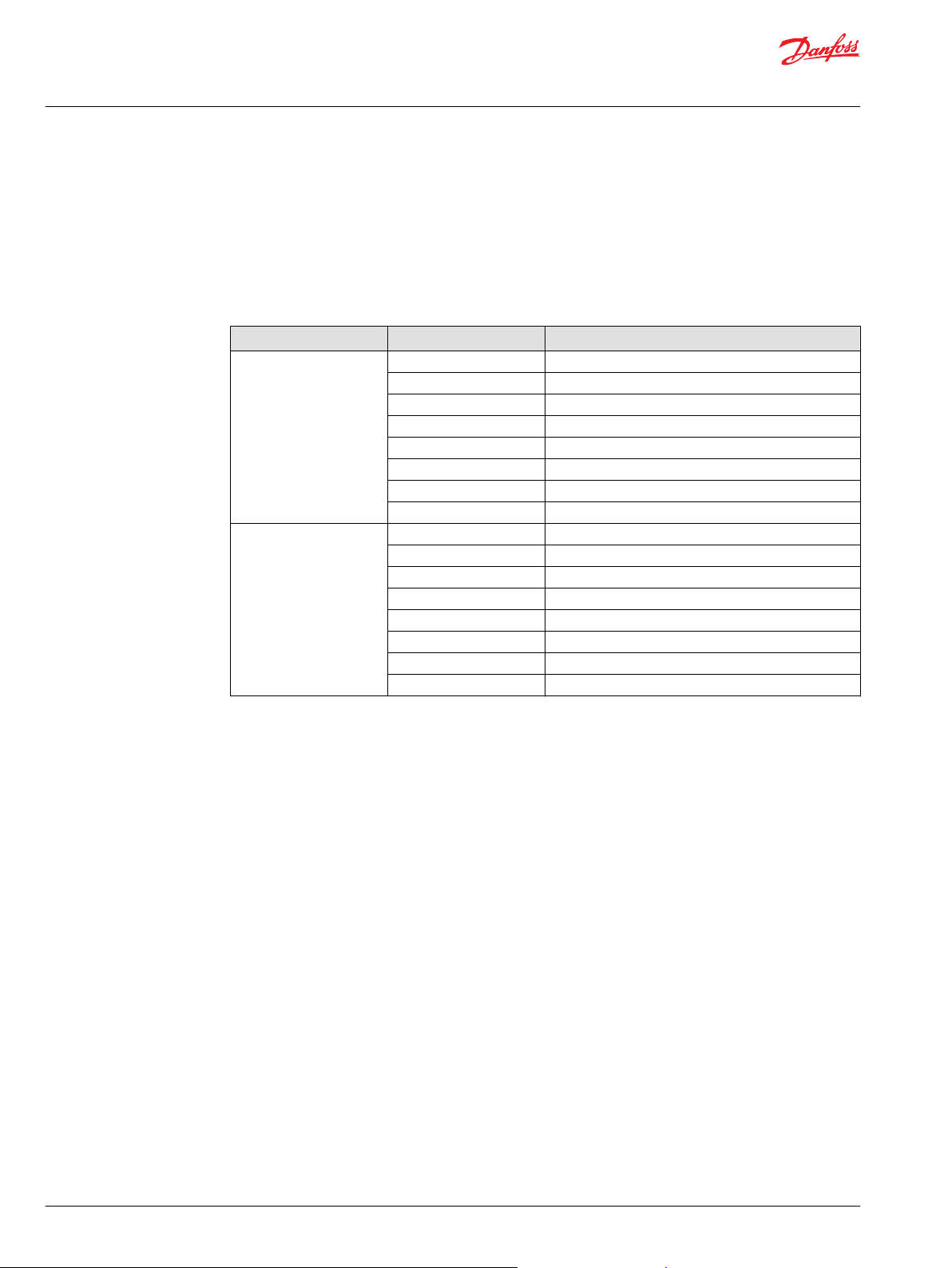

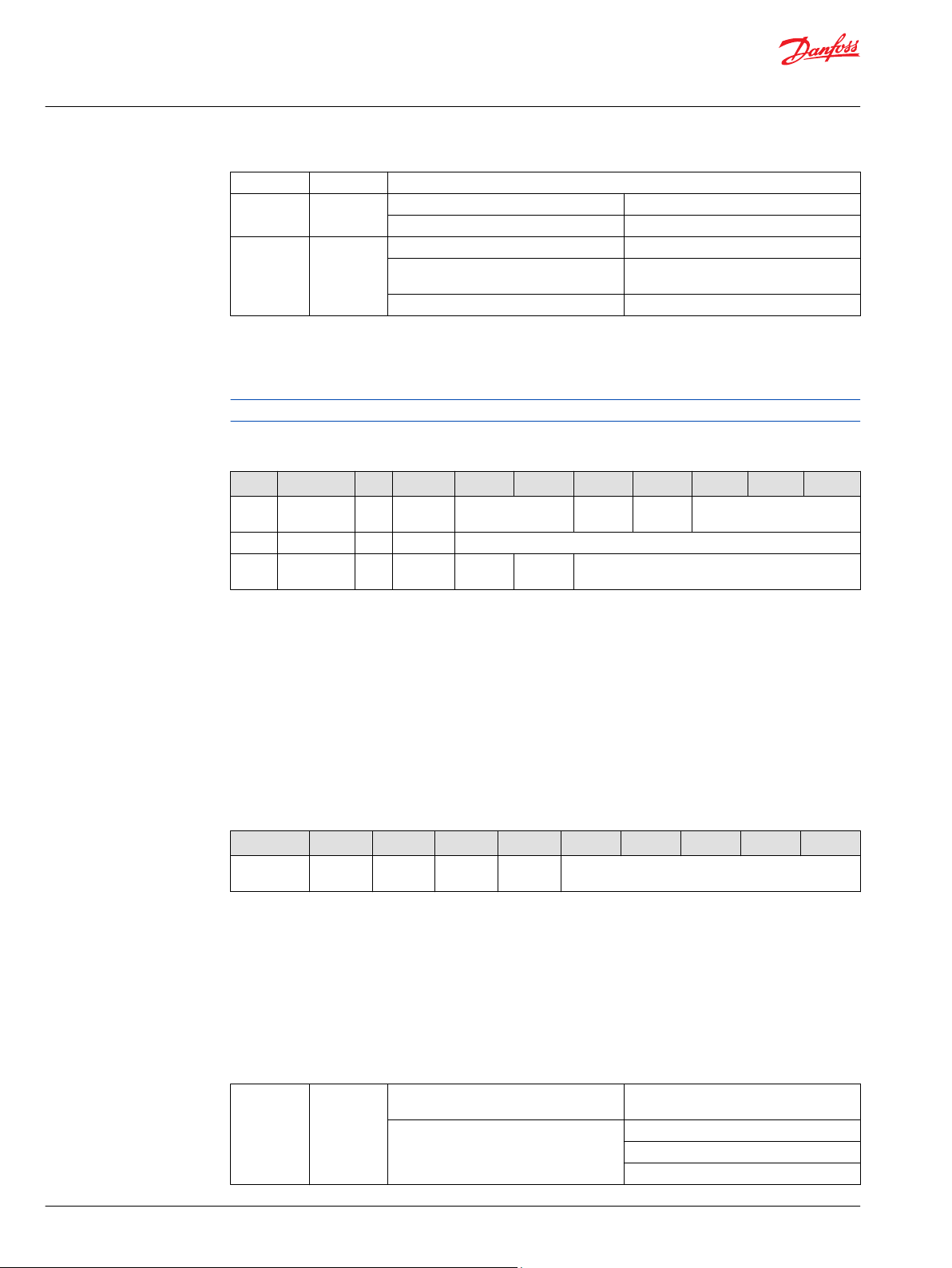

PVED-CC ISObus code numbers

Connector type Code number Description

DEUTSCH 11107869 PVED-CC

AMP 11107870 PVED-CC

11189931 PVED-CC for PVG 128/256

11007498 4 m cable

11095741 4 m EMC proof cable (twisted pair)

11007531 0.1 m loop cable

11111916 0.3 m loop cable

11095622 0.175 loop cable

11007561 CAN bus terminator

157B4994 4 m cable with gray connector

157B4995 4 m cable with black connector

11095740 4 m EMC proof cable (twisted pair)

157B4987 0.1 m loop cable

11095581 0.175 m loop cable

11163647 CAN bus terminator with gray connector

157B4988 CAN bus terminator with black connector

4 | © Danfoss | October 2021 BC187186484889en-000107

Technical Information

PVED-CC Series 5 ISObus

Technical data

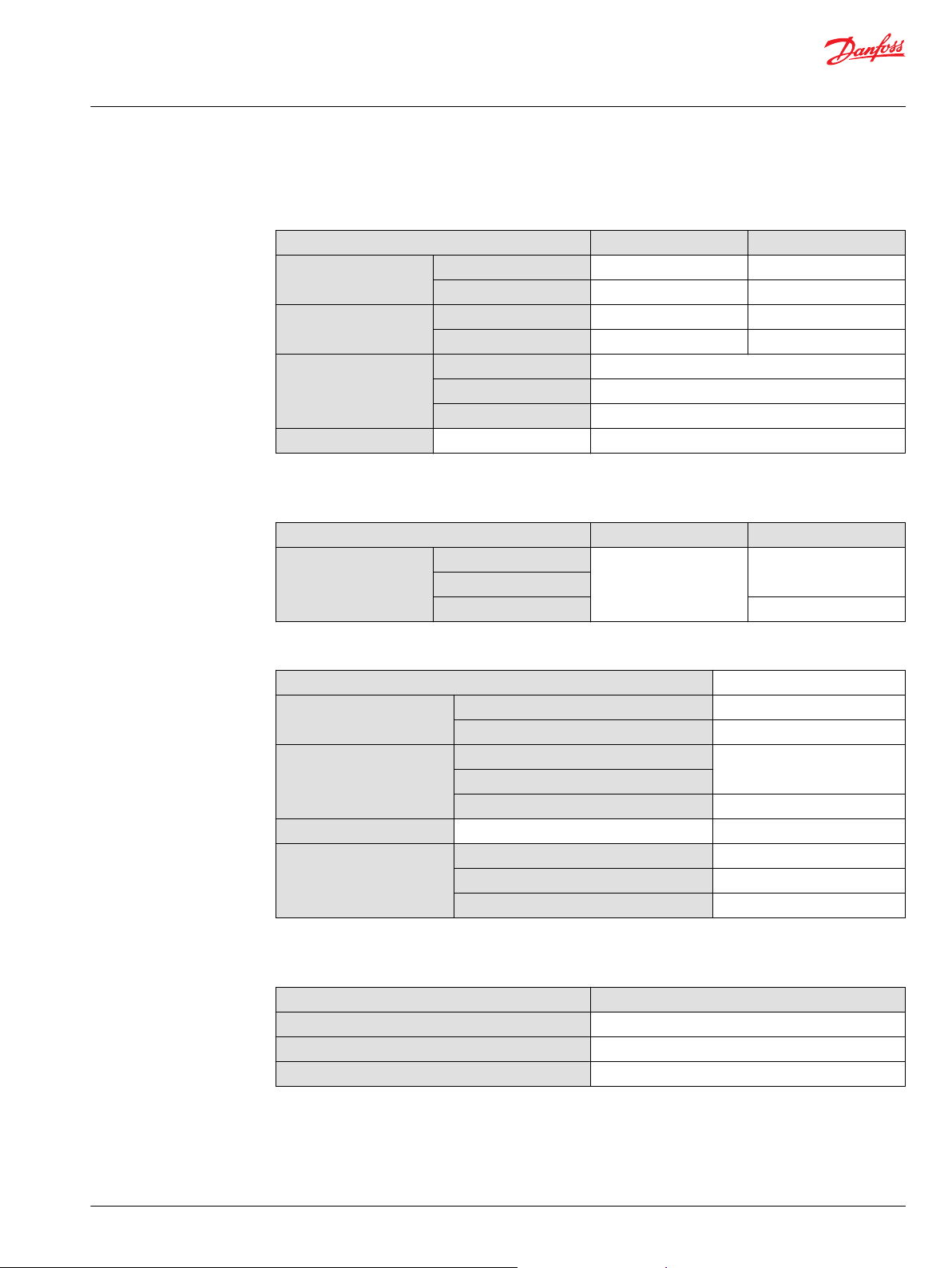

Operating data overview

Electrical data

Voltage 12 V

Current consumption Operating

Neutral - Power state

Energy consumption Operating

Neutral - Power state

Supply voltage (V

) Nominal

bat

Range

Maximum ripple

CAN bus

*

PVED communicating on CAN bus, but not fully operable.

Alive 5.5 – 36 V

520 mA 260 mA

80 mA 45 mA

6.24 W 6.24 W

1 W 1.1 W

11 – 32 V

9 – 35.9 V

5%

Temperature range

Min. Max.

Temperature Ambient

Oil

Storage 110°C

–40°C

DC

DC

DC

*

DC

24 V

DC

90°C

Hydraulic data

Pilot pressure

Tank pressure Continues

Intermittent

Oil consumption Electrical de-energized

Spool locked position

Continuous changing spool position

Contamination

(ISO 4406) 23/19/16

Viscosity range Nominal

Minimum

Maximum

*

PVED have reduced operating performance

Government regulations

Description Standard

Low Voltage

EMC Directive

Safety

2006/95/EC

2004/108/EC

ISO4413:2010

13.5 ± 1.5 bar

25 bar

40 bar

0 l/min

0.7 l/min

12 – 75 mm2/s

4.2 – 12 mm2/s

75 – 1000 mm2/s

*

©

Danfoss | October 2021 BC187186484889en-000107 | 5

CAN-H

GND

Vbat+

CAN-L

1 CAN-L

2

Vbat+

3

GND

4 CAN-H

4

3

2

1

V310451.A

2 CAN-L

3 Vbat+

4 GND

1 CAN-H

3 Vbat+

4 GND

2 CAN-L

1 CAN-H

Technical Information

PVED-CC Series 5 ISObus

Technical data

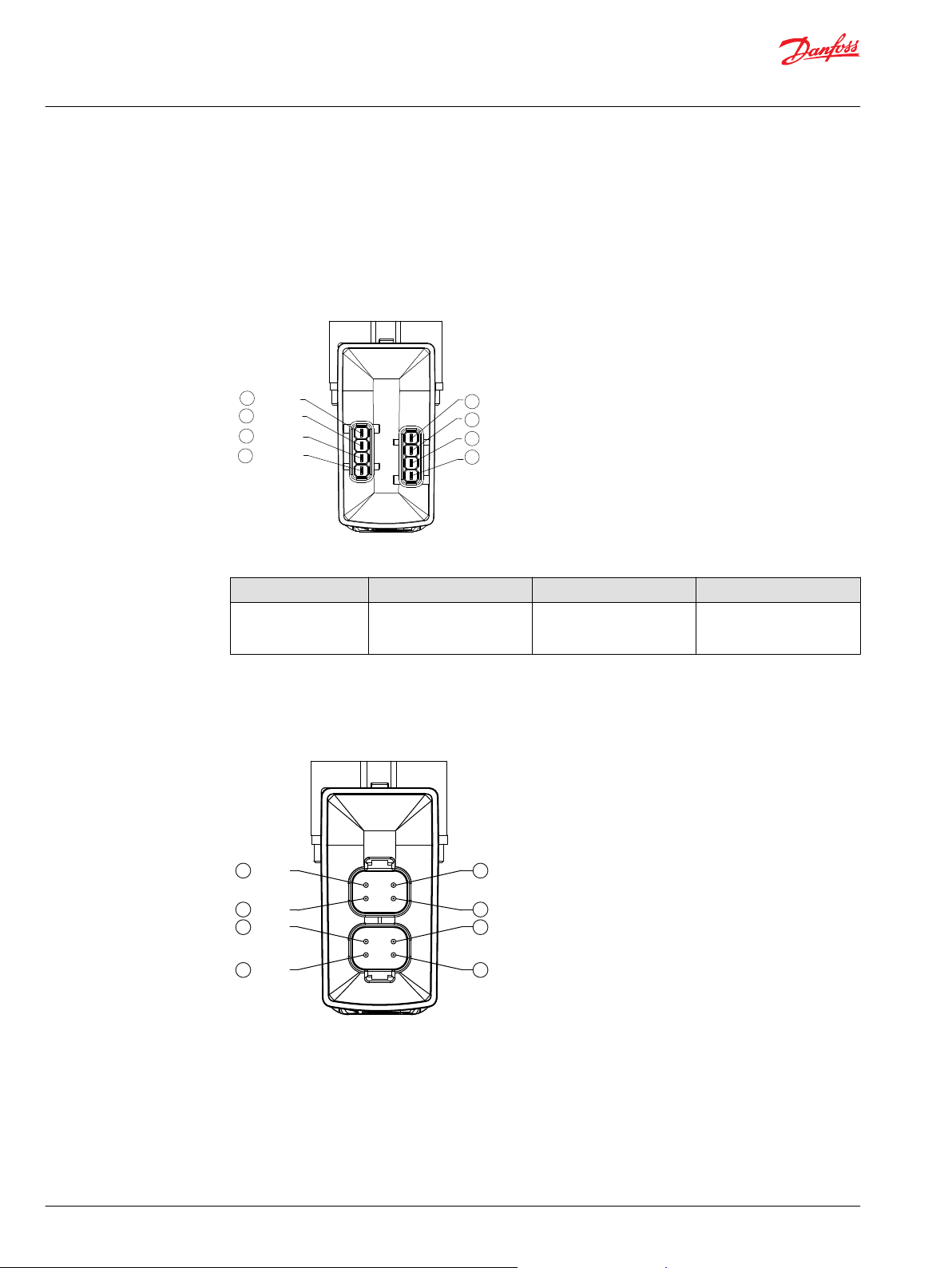

Connectors

Available 2x4 pin connectors: AMP Junior Power Timer andDEUTSCH DT06-4S-E003. Pins are internally

connected in pairs between connectors. Mating connectors are not supplied by Danfoss.

AMP connector

AMP Junior Power Timer (2x4 pin)

Terminal Seal Housing IP rating

929930-1

(4 pcs)

*

There is no black/gray coding of the connector

828901-1

(4 pcs)

Pinout:

1. CAN Low

2. Vbat+

3. GND

4. CAN High

2-967059-1 (gray) or

1-967059-1 (black)

*

IP66

DEUTSCH connector

DT06-4S-E003 (2x4 pin)

Pinout:

1. CAN High

2. CAN Low

3. Vbat+

4. GND

IP rating: IP67; IP69K without connector

6 | © Danfoss | October 2021 BC187186484889en-000107

Width

Depth

Height

V310 454.A

Technical Information

PVED-CC Series 5 ISObus

Technical data

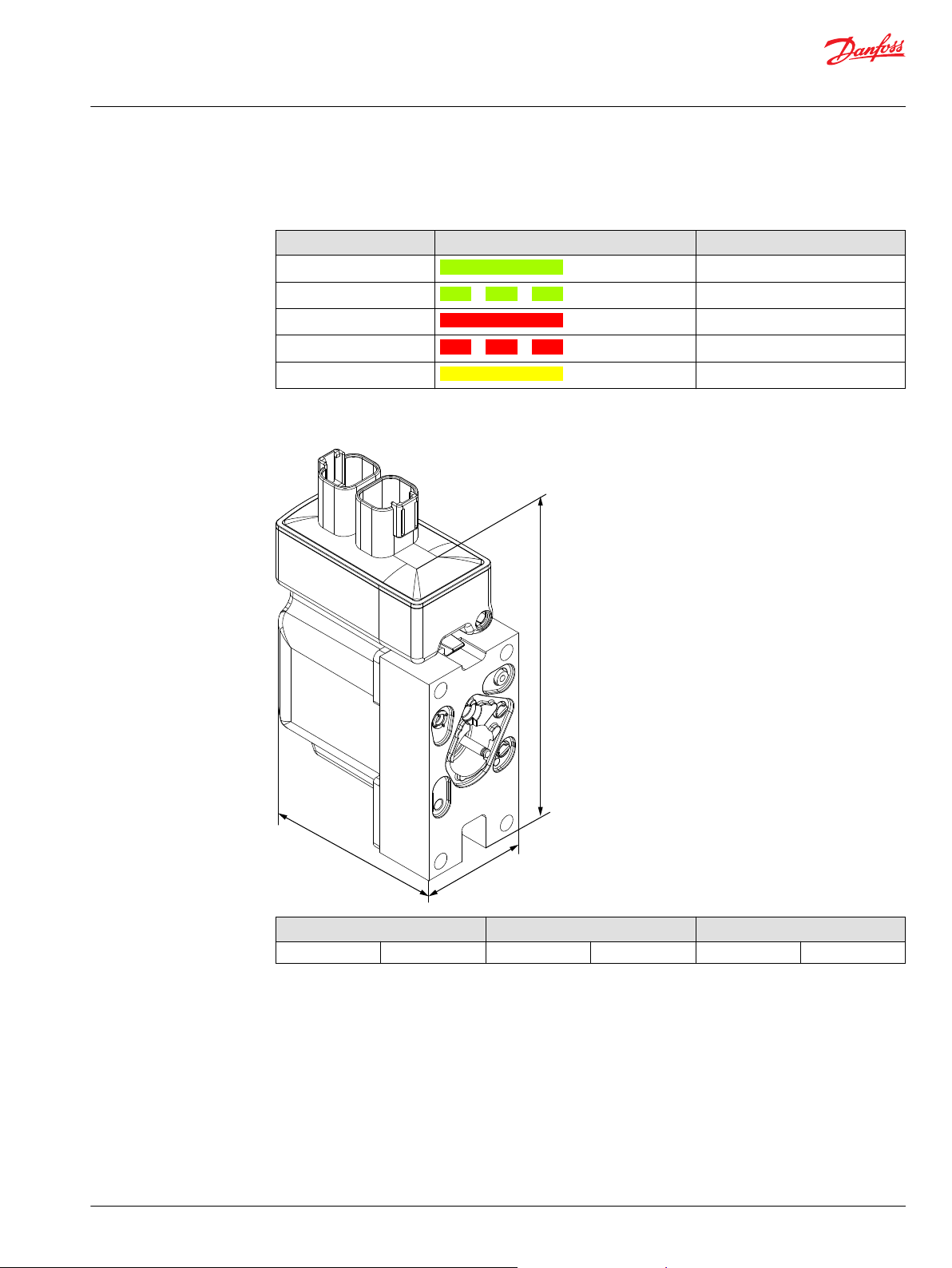

LED coloring for PVED-CC Series 5

LED Characteristic

Color LED Characteristic Description

Green constant No error – Actuating

Green flashing @ 1.5 Hz Neutral – Power save

Red constant Internal error

Red flashing @ 1.5 Hz External or Float error

Yellow Disable mode

Physical dimensions

Depth Width Height

85 mm [3.35 in] 45 mm [1.77 in] 116 mm [4.57 in]

*

Excluding connector height

©

Danfoss | October 2021 BC187186484889en-000107 | 7

*

PFC [%]

100

0

Spool Position [%]

100

BP

h

0

v

Fixed

position

Spool Position

P301822

100

0

Spool Position [%]

Time

T0 T1

T2

Spool Position

PFC (%)

Supply Voltage (UDC)

Max. spool pos. to neutral

T2

Neutral to max. spool pos.

T1

Boot-up

T0

P301823

Technical Information

PVED-CC Series 5 ISObus

Technical data

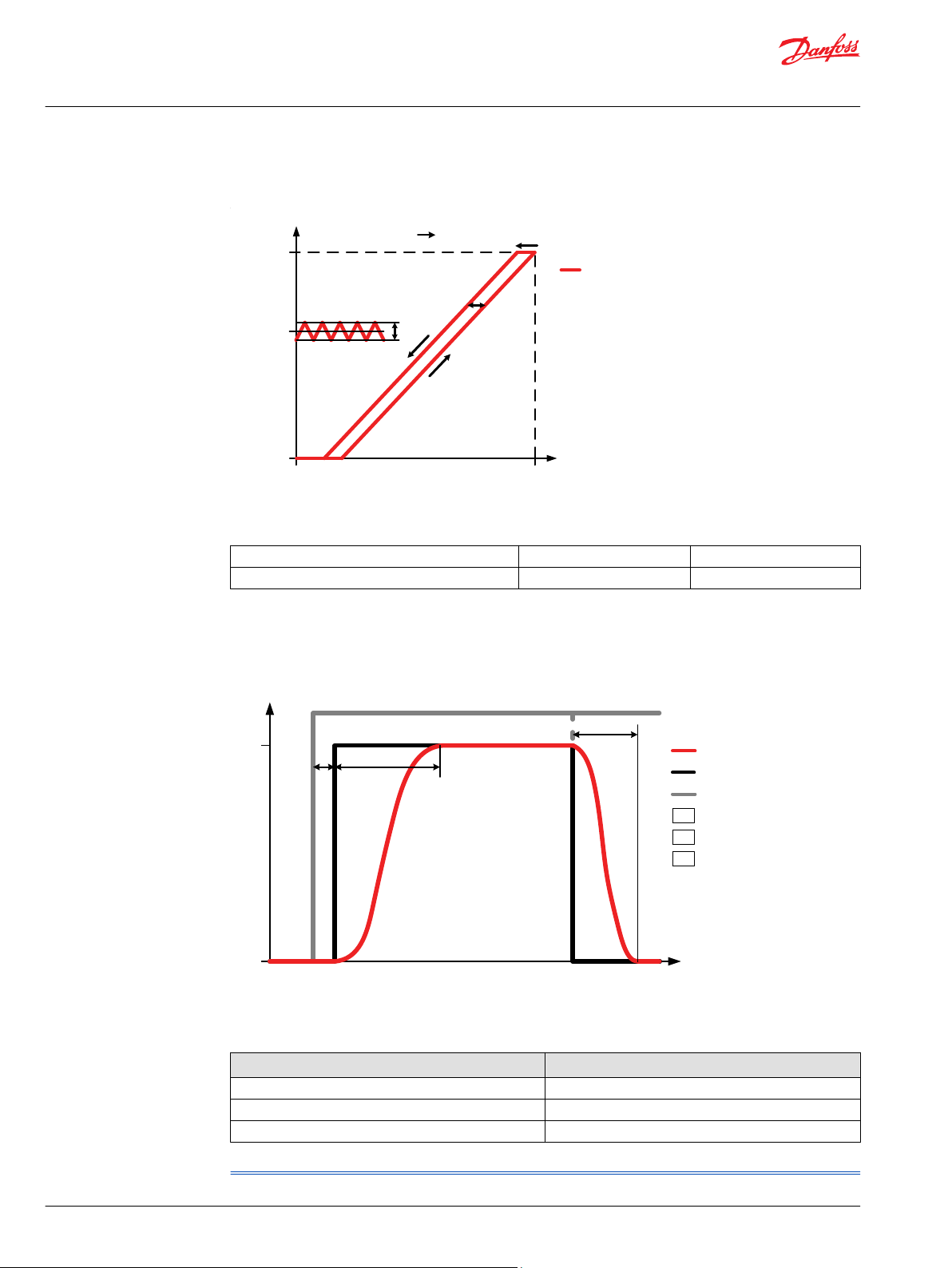

PVED-CC Hysteresis and Ripple

Definition of hysteresis

Hysteresis (h) Rated [%] 1.45%

Steady state ripple at constant command signal Rated [%] 0.29%

PVED-CC Reaction Times

Reaction times

Definition of Step Response

Reaction Time (nominal)

T0 – Boot-up 440 ms

T1 – Constant PFC command 177 ms

T2 – Constant PFC command 114 ms

*

Including Power-On-Self-Test (POST) and safety sub-system initialization.

*

8 | © Danfoss | October 2021 BC187186484889en-000107

Technical Information

PVED-CC Series 5 ISObus

Communication

PVED-CC ISObus message overview

Message ID Message type DLC Translation Direction

0x18EEFFyy*PVED-CC Address claim on

0x0CFE3xyy*PGN: Auxiliary Valve

0x0CFE1xyy*PGN: Auxiliary Valve

0x18FE68yy*PGN: Vehicle Fluid

0x18FECAyy*PGN: Diagnostic Message 1

0x18EAxxyy*PGN: Diagnostic Message 2

0x18FECByy*DM2 data on page 16 8 Rx On request

0x18EAxxyy*PGN: Diagnostic Message 3

0x18EAFFyy*DM 3 data on page 18 3 Rx On request

0x18EAxxyy*PGN: Diagnostic Message 4

0x1CEBxxyy*DM4 on page 19 8 Rx On request

0x18EAxxyy*PGN: Diagnostic Message 11

0x18E8FFyy*DM 11 data on page 23 8 Rx On request

0x18DFFFyy*PGN: Diagnostic Message 13

*

x = destination address (0x0-0xF), yy = source address

page 9

Command on page 10

Estimated Flow on page

11

Temperature on page 12

on page 13

on page 15

on page 18

on page 18

on page 22

on page 23

8 Claim address on CAN

bus

3 or 8 Auxiliary valve command Tx Controller

= AVC DLC Auxiliary Valve Estimated

Flow

8 Vehicle fluid temperature Tx Controller

8 Active Diagnostic

Trouble Code

3 Previously Active

Diagnostic Trouble

Codes

3 Reset of Previously Active

Diagnostic Trouble

Codes

6 Freeze Frame Parameters Tx On request

3 Reset of Active

Diagnostic Trouble

Codes

8 Stop/Start broadcast Tx On request

(from

controller)

Rx On power-up

Rx Configurable

Rx 1000 ms/event

Tx On request

Tx On request

Tx On request

Timing

dependent

Recommended:

100 ms

Recommended:

100 ms

dependent

triggered

PVED-CC Address claim

Upon power-up the PVED will log onto the CAN bus network by claiming the address is has been given

upon parameterization.

Frame format

Msg ID DLC Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7 Byte 8

0x18EEFFyy*8 Name

*

yy = source address

Address claim data

Byte 1 0x01 Identity number

Byte 2 0x00

Byte 3 0x20

Byte 4 Danfoss = 0x39

Byte 5 0x08 Bit 8 to 4: Function Instance (0x00)

©

Danfoss | October 2021 BC187186484889en-000107 | 9

0x07

Name assigned by Danfoss

0x001

Bits 16 to 13: Identity number

Bits 12 to 1: Manufacturer Code

Bits 3 to 1: ECU Instance (0x0x1)

Technical Information

PVED-CC Series 5 ISObus

Communication

Commanded address

Byte 6 0xFF Function (0xFF)

Byte 7 0x02 Bits 8 to 2: Vehicle System (0x01)

Bit 1: Reserved (0x01)

Byte 8 0x20 Bit 8: Arbitrary address (0x00)

Bits 7 to 5: Industry Group – Agriculture and Forestry

Bits 4 to 1: Vehicle system instance (0x00)

(0x02)

Commanded address enables the master to rename the PVED.

Only one PVED with same address can be present at the network at a time.

Frame format

Message ID DLC Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7 Byte 8

BAM 0x1CECFFyy*8 BAM No of bytes No of

DT 1 0x1CEBFFyy*8 Sequence Name

DT 2 0x1CEBFFyy*8 Sequence Name

*

yy = source address

cont.

New

node ID

packets

Reserved

Reserved PGN

Upon receiving new node ID the PVED will perform a reset of itself. After reset it will claim the new

address.

PGN: Auxiliary Valve Command

The Auxiliary Valve Command (abbreviated AVC) is the command value sent from a master controller to

control the PVED. The PVE will only accept messages with correct node ID and ignore any AVC commands

if invalid.

Frame format

*

**

AVC data

Msg ID DLC Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7 Byte 8

0x0CFE3xyy*3 or 8

x = destination address (0x0-0xF), yy = source address

Both DLC of 3 or 8 is valid for AVC message. Any other DLC will cause the PVED to raise an error flag.

**

PFC Reserved Valve

state

Reserved

Transmission rate: 100ms (recommended)

Transmission rate range: Recommended minimum Tx = 10ms

Recommended maximum Tx = AVC Timeout/2

*

Byte 1

Port Flow

Command

Request port flow as a percentage of full

flow Resolution:

Valid range: 0-100%

0.4%/bit

0 - 250

0x00 – 0xFA

10 | © Danfoss | October 2021 BC187186484889en-000107

Technical Information

PVED-CC Series 5 ISObus

Communication

Byte 2 Reserved (FF)

**

Byte 3

Byte 4 Reserved (FF)

Byte 5

Byte 6

Byte 7

Byte 8

*

PFC = 0 is interpreted as a neutral command

**

In blocked state the value in PFC is ignored

Valve state Bits 8 and 7: Fail safe mode – block (0x00) supported

Bits 6 and 5: Reserved

Bits 4 to 1: Valve state:

Blocked (neutral) = 0b0000

Extend = 0b0001

Retract = 0b0010

Float = 0b0011

Hand operation = 0b1010

Emergency stop = 0b1110

Linked fault flags

Fault SPN FMI

AVC not recieved within timeout period 298985 19

Invalid data in AVC 520676 19

PGN: Auxiliary Valve Estimated Flow

The Auxiliary Valve Estimated Flow (abbreviated AVEF) is the feedback sent from the PVED to the master

controller telling the assumed flow/spool position.

Frame format

Msg ID DLC Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7 Byte 8

0x0 CFE1xyy*3 or 8

*

x = destination address (0x0-0xF), yy = source address

**

The DLC will follow that of the AVC PGN.

Default transmission rate: 100ms (recommended)

Transmission rate range: Minimum Tx = 10ms

**

Extend

port flow

Retract

port flow

Valve

state

Reserved

Maximum Tx = 10 000ms

©

Danfoss | October 2021 BC187186484889en-000107 | 11

Technical Information

PVED-CC Series 5 ISObus

Communication

AVEF data

Byte 1 Extend port flow

Estimated flow out of extend port as a percentage of full flow

Resolution: 1%/bit

Offset: 125

0x7D

Date range: 0-100%

125 - 225

0x7D – 0xE1

Byte 2 Retract port flow

Estimated flow out of retract port as a percentage of full flow

Resolution: 1%/bit

Offset: 125

0x7D

Date range: 0-100%

125 - 225

0x7D – 0xE1

Byte 3 Valve state Bits 8 and 7: Fail safe mode – 0b00 and 0b01 is supported but safe state is always

blocked

Bits 6 and 5: Reserved

Bits 4 to 1: Valve state: Block (neutral) = 0b0000

Extend = 0b0001

Retract = 0b0010

Float = 0b0011

Hand operation = 0b1010

Error = 0b1110

Byte 4 Reserved (FF)

Byte 5

Byte 6

Byte 7

Byte 8

PGN: Vehicle Fluid Temperature

The Vehicle Fluid Temperature can be used as input for the temperature dependent spool timeout. If the

PGN VFT is not received by the actuator within 10000ms the onboard temperature sensor will be used as

trigger.

Frame format

Msg ID DLC Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7 Byte 8

0x18FE68yy*8 Temperature Data not of importance

*

yy = source address

12 | © Danfoss | October 2021 BC187186484889en-000107

Technical Information

PVED-CC Series 5 ISObus

Communication

PGN: Diagnostic Message 1

VFT data

Byte 1 Temperature in °Celsius Resolution: 1 °C/bit

Offset: 40

0x28

Date range: -40-120 °C

0 - 160

0x00 – 0xA0

Byte 2 Reserved (FF)

Byte 3

Byte 4

Byte 5

Byte 6

Byte 7

Byte 8

The Active trouble code message (abbreviated DM1) is used by the PVED to transmit an active fault onto

the CAN bus and give as a periodic status message.

Frame format

Msg ID DLC Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7 Byte 8

0x18CEFAyy*8 Lamp

*

yy = source address

status

Flash

status

Fault information Occurrence

counter

Reserved

Default transmission rate: 1000ms (Can be disabled) / event triggered

DM1 data

Byte 1 Lamp status

Used by controller – not related to the actuator LED

No fault (default state): 0x00

Warning and Info type

faults:

Critical or Severe type

faults:

Byte 2 Flash status

Used by controller – not

related to the actuator LED

Byte 3 Fault information Bits 24 to 6: SPN of active fault

Byte 4 Bits 5 to 1: FMI of active fault

Byte 5

Byte 6 Occurrence counter (OC) Bit 8: Conversion method

Byte 7 Reserved (FF)

Byte 8

Amber lamp: 0x04

Red lamp: 0x10

Flashing: 0xFF

Bits 7-1: Occurrence counter

Number of times the active fault has

appeared previously

©

Danfoss | October 2021 BC187186484889en-000107 | 13

Technical Information

PVED-CC Series 5 ISObus

Communication

In the event of multiple faults happening simultaneously the PVED will use the Broadcast Announce

Message (BAM) transport protocol.

The BAM message size depends on the number of previous faults.

Frame format

Msg ID DLC Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7 Byte 8

0x1CECFFyy*8 BAM No of bytes No of

0x1CEBFFyy*8 Sequence Lamp

0x1CEBFFyy*8 Sequence Fault 2 cont. Fault 3

0x1CEBFFyy*8 Sequence Fault 4 BAM cont.

*

yy = source address

status

Reserved Fault 1 Fault 2

packets

Reserved DM 1 PGN

Transport protocol from J1939-21

BAM Byte 1 BAM

Byte 2 Number of bytes

Byte 3

Byte 4 Number of packets

How many messages are sent in the complete BAM

Byte 5 Reserved (FF)

Byte 6 DM 1 PGN (0x00FECA)

Byte 7

Byte 8

Data Transfer DT1 Byte 1 Sequence

Identification number of the BAM message in the BAM sequence

Byte 2 Lamp status

Used by controller – not related to the actuator LED

Info or warning type

faults:

Critical or severe type

faults:

Byte 3 Reserved (FF)

Byte 4 Fault information of

Byte 5 Bits 5 to 1: FMI of fault

Byte 6

Byte 7 Occurrence counter

Byte 8 Fault information of fault 2

fault 1

Number of times the active fault has appeared previously

SPN of fault

Amber lamp: 0x04

Red lamp: 0x10

Bits 24 to 6: SPN of fault

14 | © Danfoss | October 2021 BC187186484889en-000107

Technical Information

PVED-CC Series 5 ISObus

Communication

Data Transfer DT2 Byte 1 Sequence

Identification number of the BAM message in the BAM sequence

Byte 2 Fault information of

Byte 3 Bits 5 to 1: FMI of fault

Byte 4 Occurrence counter

Byte 5 Fault information of

Byte 6 Bits 5 to 1: FMI of fault

Byte 7

Byte 8 Occurrence counter

Data Transfer DT3 Byte 1 Sequence

Byte 2 Fault information of

Byte 3 Bits 5 to 1: FMI of fault

Byte 4

Byte 5 Occurrence counter

Byte 6 BAM continued

Byte 7

Byte 8

fault 2 cont.

Number of times the active fault has appeared previously

fault 3

Number of times the active fault has appeared previously

Identification number of the BAM message in the BAM sequence

fault 3

Number of times the active fault has appeared previously

Bits 24 to 6: SPN of fault

Bits 24 to 6: SPN of fault

Bits 24 to 6: SPN of fault

PGN: Diagnostic Message 2

The Previously Active Diagnostic Trouble Codes (abbreviated DM2) is used to trigger the PVED to

transmit all previously active fault onto the CAN bus.

Frame format

Request frame format

Msg ID DLC Byte 1 Byte 2 Byte 3

0x18EAxxyy

*

xx = destination address (0x80-0x8F), yy = source address

*

3 Request PGN LSB Request PGN MSB 0x00

0xCB 0xFE

Response frame format

Msg ID DLC Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7 Byte 8

0x18FECByy*8 Lamp

*

yy = source address

status

Flash

status

Fault information Occurrence

counter

Reserved

Transmission rate: on request

©

Danfoss | October 2021 BC187186484889en-000107 | 15

Technical Information

PVED-CC Series 5 ISObus

Communication

DM2 data

Byte 1 Lamp status

Used by controller – not related to the actuator LED

No fault (default state): 0x00

Warning and Info type

faults:

Critical or Severe type

faults:

Byte 2 Flash status

Used by controller – not

related to the actuator LED

Byte 3 Fault information Bits 24 to 6: SPN of active fault

Byte 4 Bits 5 to 1: FMI of active fault

Byte 5

Byte 6 Occurrence counter (OC)

Number of times the active fault has appeared previously

Byte 7 Reserved (FF)

Byte 8

Amber lamp: 0x04

Red lamp: 0x10

Flashing: 0xFF

In the event of Multiple previously active faults the PVED will use the Broadcast Announce Message

(BAM) transport protocol.

The BAM message size depends on the number of previous faults.

Frame format

Msg ID DLC Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7 Byte 8

0x1CECFFyy*8 BAM No of bytes No of

0x1CEBFFyy*8 Sequence Lamp

0x1CEBFFyy*8 Sequence Fault 2 cont. Fault 3

0x1CEBFFyy*8 Sequence Fault 4 BAM cont.

*

yy = source address

status

Reserved Fault 1 Fault 2

packets

Reserved DM 2 PGN

Transport protocol from J1939-21

BAM Byte 1 BAM

Byte 2 Number of bytes

Byte 3

Byte 4 Number of packets

How many messages are sent in the complete BAM

Byte 5 Reserved (FF)

Byte 6 DM 2 PGN (0x00FECB)

Byte 7

Byte 8

16 | © Danfoss | October 2021 BC187186484889en-000107

Technical Information

PVED-CC Series 5 ISObus

Communication

Data Transfer DT1 Byte 1 Sequence

Identification number of the BAM message in the BAM sequence

Byte 2 Lamp status

Used by controller – not related to the actuator LED

Info or warning type

faults:

Critical or severe type

faults:

Byte 3 Reserved (FF)

Byte 4 Fault information of

Byte 5 Bits 5 to 1: FMI of fault

Byte 6

Byte 7 Occurrence counter

Byte 8 Fault information of fault 2

Data Transfer DT2 Byte 1 Sequence

Byte 2 Fault information of

Byte 3 Bits 5 to 1: FMI of fault

Byte 4 Occurrence counter

Byte 5 Fault information of

Byte 6 Bits 5 to 1: FMI of fault

Byte 7

Byte 8 Occurrence counter

Data Transfer DT3 Byte 1 Sequence

Byte 2 Fault information of

Byte 3 Bits 5 to 1: FMI of fault

Byte 4

Byte 5 Occurrence counter

Byte 6 BAM continued

Byte 7

Byte 8

fault 1

Number of times the active fault has appeared previously

SPN of fault

Identification number of the BAM message in the BAM sequence

fault 2 cont.

Number of times the active fault has appeared previously

fault 3

Number of times the active fault has appeared previously

Identification number of the BAM message in the BAM sequence

fault 3

Number of times the active fault has appeared previously

Amber lamp: 0x04

Red lamp: 0x10

Bits 24 to 6: SPN of fault

Bits 24 to 6: SPN of fault

Bits 24 to 6: SPN of fault

Bits 24 to 6: SPN of fault

Busy response

If the BAM session is unavailable due to ongoing transmission of DM1 or DM2 messages a busy response

will be transmitted.

Msg ID DLC Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7 Byte 8

0x18E8FFyy*8 Control

*

yy = source address

©

Danfoss | October 2021 BC187186484889en-000107 | 17

byte

0x02 0xFF 0xFF 0x05 0xCB 0xFE 0x00

0x00 Reserved Address busy

acknowledge

Requested PGN

Technical Information

PVED-CC Series 5 ISObus

Communication

PGN: Diagnostic Message 3

The Clear/Reset of Previously Active Diagnostic Trouble Codes (abbreviated DM3) is used by the

controller to clear the diagnostics log within the PVED

Frame format

Request frame format

Msg ID DLC Byte 1 Byte 2 Byte 3

0x18EAxxyy

*

xx = destination address (0x80-0x8F), yy = source address

*

3 Request PGN LSB Request PGN MSB 0x00

0xCC 0xFE

Response frame format

Msg ID DLC Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7 Byte 8

0x18E8FFyy*8 Control

*

yy = source address

byte

0x00 Reserved Address

acknowledge

Request PGN

PGN: Diagnostic Message 4

Transmission rate: on request

DM 3 data

Byte 1 Control byte Positive acknowledge: 0x00

Busy: 0x02

Byte 2 0x00

Byte 3 Reserved (FF)

Byte 4

Byte 5 Address acknowledge

Source address of requestor

Byte 6 DM 3PGN (0x00FECC)

Byte 7

Byte 8

The Freeze Frame Parameters (abbreviated DM4) is used to trigger the PVED to transmit all current and

previously active faults of a specific fault code stored in the diagnostic history onto the CAN bus.

Request frame format

Msg ID DLC Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6

0x18EAxxyy

*

xx = destination address (0x80-0x8F), yy = source address

*

6 DM4 PGN LSB DM4 PGN 2

0xCD 0xFE 0x00

byte

nd

DM4 PGN MSB SPN/FMI

18 | © Danfoss | October 2021 BC187186484889en-000107

Technical Information

PVED-CC Series 5 ISObus

Communication

Timeouts

•

No message received by actuator after last packet was transmitted: 1250ms

•

No message received by actuator after a hold the connection open message was received:

1050ms

Transmission rate: on request

DM4

Response frame format

No entries of the requested fault code

The actuator diagnostic history does not contain any record of the requested fault code.

Msg ID DLC Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7 Byte 8

0x18FECDyy*8 0x00 0x00 0x00 0x00 0xFE 0xFF (Reserved)

*

yy = source address

Entries of requested fault code found

Actuator request to establish connection

Msg ID DLC Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7 Byte 8

0x1CECxxyy*8 Control

*

xx = destination address (0x80-0x8F), yy = source address

**

maximum number of packets that can be sent to one DM4 request = 8

byte

0x10 0xCD 0xFE 0x00

Total no of bytes with

data available

Total no if

packet

Number

of

packets

that can

be sent to

one

request

Request PGN (DM4)

**

Master ECU to establish connection

Msg ID DLC Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7 Byte 8

0x1CECxxyy*8 Control

*

xx = destination address (0x80-0x8F), yy = source address

**

Must be equal to byte 5 in the actuator request to establish connection – if master ECU is busy set to 0x00

meaning the connection is maintained open until timeout, but no data will be transmitted until new message

arrives.

byte

0x11 0xFF 0xFF 0xCD 0xFE 0x00

Total no

of

packets

can be

**

sent

Next

packet no

Reserved Request PGN (DM4)

After the connection is established the PVED will transmit the content of the diagnostic history. The

following frames will be sent for all occurrences of the enquired fault.

©

Danfoss | October 2021 BC187186484889en-000107 | 19

Technical Information

PVED-CC Series 5 ISObus

Communication

Diagnostic history frame format

Msg ID DLC Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7 Byte 8

0x1CEBxxyy*8 Sequence no Length SPN/FMI Occurren

ce / fault

status

0x1CEBxxyy*8 Sequence no Operating time 1st occurrence

Operating time last occurrence

Fault ID Operating

time 1st

occurrence

cont.

0x1CEBxxyy*8 Sequence no Environmental data for 1st fault record

0x1CEBxxyy*8 Sequence no

0x1CEBxxyy*8 Sequence no

0x1CEBxxyy*8 Sequence no

0x1CEBxxyy*8 Sequence no

0x1CEBxxyy*8 Sequence no

0x1CEBxxyy*8 Sequence no

*

xx = destination address (0x80-0x8F), yy = source address

Diagnostic history data

Message 1 Byte 1 Sequence number

Byte 2 Freeze Frame Length

Byte 3 Fault information Bits 24 to 6: SPN of fault

Byte 4 Bits 5 to 1: FMI of fault

Byte 5

*

Byte 6

Byte 7

Byte 8

Message 2 Byte 1 Sequence number

Byte 2

Byte 3

Byte 4

Byte 5

Byte 6

Byte 7

Byte 8

Message 3 Byte 1 Sequence number

Byte 2 Valve state upon fault occurrence

Byte 3 Set point at fault occurrence

Byte 4

Byte 5 Demand value at fault occurrence

Byte 6

Byte 7 Spool position at fault occurence

Byte 8

Occurrence count and current state

Bits 8 to 2: Number of times the active fault has appeared previously

Bit 1: Current state of the fault

code

*

Fault ID

*

Operating time of 1st occurrence of the fault (LSB)

*

Operating time of 1st occurrence of the fault

*

*

*

Operating time of last occurrence of the fault

*

*

*

0 = previous fault

1 = currently active fault

20 | © Danfoss | October 2021 BC187186484889en-000107

Technical Information

PVED-CC Series 5 ISObus

Communication

Diagnostic history data (continued)

Message 4 Byte 1 Sequence number

Byte 2 Battery voltage

Byte 3

Byte 4 Operating time

Byte 5

Byte 6

Byte 7

Byte 8 Last spool position before fault occurrence

Message 5 Byte 1 Sequence number

Byte 2 Last demand value before fault occurrence

Byte 3 2nd to last spool position before fault occurrence

Byte 4 2nd to last demand value before fault occurrence

Byte 5 3rd to last spool position before fault occurrence

Byte 6 3rd to last demand value before fault occurrence

Byte 7 4th to last spool position before fault occurrence

Byte 8 4th to last demand value before fault occurrence

Message 6 Byte 1 Sequence number

Byte 2 5th to last spool position before fault occurrence

Byte 3 5th to last demand value before fault occurrence

Byte 4 6th to last spool position before fault occurrence

Byte 5 6th to last demand value before fault occurrence

Byte 6 7th to last spool position before fault occurrence

Byte 7 7th to last demand value before fault occurrence

Byte 8 8th to last spool position before fault occurrence

Message 7 Byte 1 Sequence number

Byte 2 8th to last demand value before fault occurrence

Byte 3 9th to last spool position before fault occurrence

Byte 4 9th to last demand value before fault occurrence

Byte 5 File number

Byte 6

Byte 7 Line number

Byte 8

Message 8 Byte 1 Sequence number

Byte 2 PCB temperature

Byte 3 Reserved (0xFF)

Byte 4

Byte 5

Byte 6

Byte 7 Checksum

Byte 8

*

Fields are different from the J1939 standard

©

Danfoss | October 2021 BC187186484889en-000107 | 21

Technical Information

PVED-CC Series 5 ISObus

Communication

Master ECU to terminate connection upon receiving last packet with end of message acknowledge

Msg ID DLC Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7 Byte 8

0x1CECxxyy*8 Control

*

xx = destination address (0x80-0x8F), yy = source address

byte

0x13 0xFF 0xCD 0xFE 0x00

Total number of data

bytes received

Total

number

of

packets

received

Reserved Request PGN (DM4)

Abort connection

Both master ECU and PVED can abort the connection at any time

Abort message frame format

Msg ID DLC Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7 Byte 8

0x1CECxxyy*8 Control byte Abort

0xFF 0xFF 0xFF 0xFF 0xCD 0xFE 0x00

*

xx = destination address (0x80-0x8F), yy = source address

reason

Reserved Request PGN (DM4)

PGN: Diagnostic Message 11

Abort message data

Byte 1 Control byte 0xFF

Byte 2 Abort reason 1: Already in one or more connections and cannot

support another

2: System resources needed to perform other tasks –

session terminated

3: Timeout occurred - session terminated

Byte 3 Reserved 0xFF

Byte 4

Byte 5

Byte 6 Request PGN (DM4) 0xCD

Byte 7 00xFE

Byte 8 0x00

The Clear/Reset of Active Diagnostic Trouble Codes (abbreviated DM 11) is used as command along with

two consecutive blocked states to recover to active state when the fault state has been entered due to a

non-severe fault.

DM 11 support can be enabled/disabled by the PLUS+1® Service Tool.

Frame format

Request frame format

Msg ID DLC Byte 1 Byte 2 Byte 3

0x18EAxxyy

*

x = destination address (0x80-0x8F), yy = source address

*

3 Request PGN LSB Request PGN MSB 0x00

0xD3 0xFE

22 | © Danfoss | October 2021 BC187186484889en-000107

Technical Information

PVED-CC Series 5 ISObus

Communication

Answer frame format

Msg ID DLC Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7 Byte 8

0x18E8FFyy*8 Control

*

yy = source address

byte

0x00 Reserved Address

acknowledge

Request PGN

Transmission rate: on request

DM 11 data

Byte 1 Control byte Positive acknowledge: 0x00

Negative acknowledge: 0x01

Byte 2 0x00

Byte 3 Reserved (FF)

Byte 4

Byte 5 Address acknowledge

Source address of requestor

Byte 6 DM 11 PGN (0x00FED3)

Byte 7

Byte 8

PGN: Diagnostic Message 13

The Start Diagnostics message (abbreviated DM 13) is used to bring the PVED from Inactive Control State

to full operational mode.

DM 13 support can be enabled/disabled by the PLUS+1® Service Tool.

Frame format

Request frame format

Msg ID DLC Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7 Byte 8

0x18DFFFyy*8 Network

*

yy = source address

type

0xFD

Reserved

Transmission rate: on request

©

Danfoss | October 2021 BC187186484889en-000107 | 23

Technical Information

PVED-CC Series 5 ISObus

Parameters

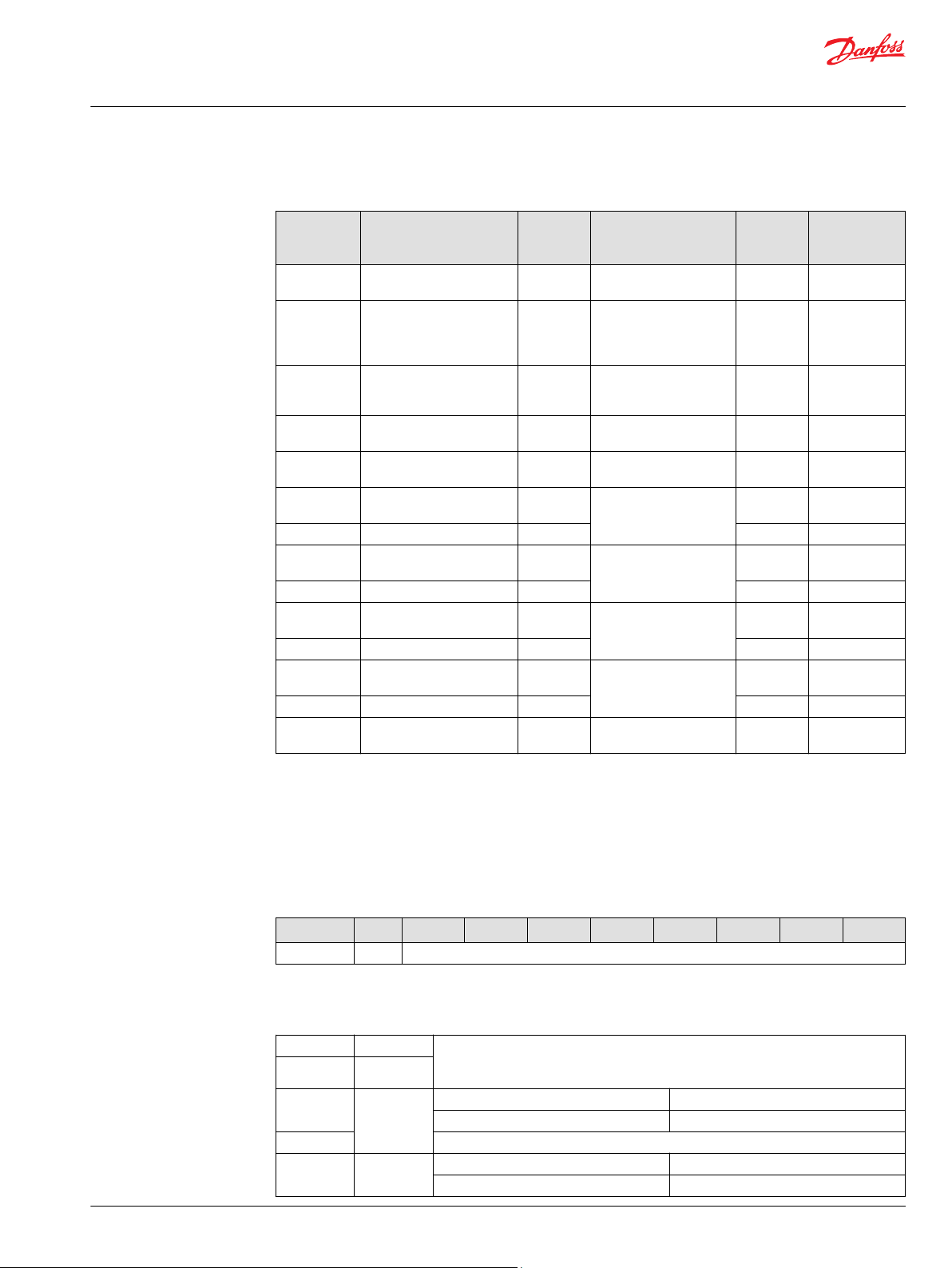

Parameter overview

The following parameters can be configured within a PVED-CC Series 5 ISOBUS to tailor the behavior to

the exact need of the function which it controls. All parameters can be changed using the PLUS+1

®

Service Tool.

Parameter overview

Parameter Description Range Default

NodeID (source

address)

Vehicle serial

number

Scaling of port flow

command* – Extend

Scaling of port flow

command* – Retract

Dead band offset* –

Extend

Source address of the PVED 128 - 143 128

0x80-0x8F 0x80

Free fields to enter vehicle serial number or other

machine specific data

Scaling of the spool stroke. 100% scaling = 7mm spool

stroke

Scaling of the spool stroke. 100% scaling = 7mm spool

stroke

Spool stroke when given a PFC of 1.

Dead band offset is superimposed on top of the spool

curve dead band jump.

free (23 positions) blank

Resolution: 0.4%

0-100% 100%

0-250 250

0x00-0xFA 0xFA

Resolution: 0.4%

0-100% 100%

0-250 250

0x00-0xFA 0xFA

0-100% 0

0x00-0x64 0x00

Dead band offset* –

Retract

Progressivity curve

- Extend

Progressivity curve -

*

Retract

Ramp up* - Extend Time to stroke spool from neutral to full stroke.

Ramp down* Extend

Ramp up* - Retract Time to stroke spool from neutral to full stroke.

Ramp down* Retract

Invert ports

*

Spool stroke when given a PFC of 1.

Dead band offset is superimposed on top of the spool

curve dead band jump.

*

Pre-defined curves to change flow from linear to

progressive

Pre-defined curves to change flow from linear to

progressive

Full stroke is defined by the scaling parameter.

Time to stroke spool from full stroke to neutral.

Full stroke is defined by the scaling parameter

Full stroke is defined by the scaling parameter

Time to stroke spool from full stroke to neutral.

Full stroke is defined by the scaling parameter

Inverts PFC Inverted/not

0-100% 0

0x00-0x64 0x00

1-16 1

1-16 1

Resolution: 16 ms

0-4000 ms 0 ms

0-250 0

0x00-0xFA 0x00

Resolution: 16 ms

0-4000 ms 0 ms

0-250 0

0x00-0xFA 0x00

Resolution: 16 ms

0-4000 ms 0 ms

0-250 0

0x00-0xFA 0x00

Resolution: 16 ms

0-4000 ms 0 ms

0-250 0

0x00-0xFA 0x00

Not inverted

inverted

24 | © Danfoss | October 2021 BC187186484889en-000107

Technical Information

PVED-CC Series 5 ISObus

Parameters

Parameter overview (continued)

Parameter Description Range Default

Power Save Reduce power consumption by making the PVED enter a

sleep mode when in neutral.

Time delay configurable

ON/OFF ON

Power save entry

delay

Low voltage

reaction delay

AVEF transmit time How often is the AVEF transmitted onto the bus Resolution: 1 ms

AVC timeout Timeout period for receiving the AVC message from the

Support DM13 Choose whether or not Start Diagnostics (DM13

Float ramp time Time to stroke the spool from full flow to float position Resolution: 1 ms

Float threshold

Support DM11 Choose whether or not Reset of Active DTCs (DM11) is

Temperature

dependent spool

timeout

Temperature

dependent spool

timeout float addon

DM1 status

transmission

Enable KWP2000 Enable actuator to respond to KWP2000 protocol

KWP2000 ID Respond to global or specific KWP2000 messages Global/specific Global

Time the spool has to stay in neutral position before

power save mode is entered

Time from voltage drops below acceptable limit (9VDC)

to the DM1 is transmitted

master

message) is required to have the PVED operate

*

Minimum PFC needed to be received by the PVED before

allowed to enter float

required to leave fault state

Allowed time to stroke the spool from full stroke to

neutral for in a 10 °C temperature interval from -40 to

+130 °C

Time added to temperature dependent timeout to reach

float position

Transmission of DM1 message will occur either as status

each 1000 ms or by fault event

messages

Resolution: 100 ms

0-8000 ms 500 ms

0-80 50

0x00-0x50 0x32

Resolution: 100 ms

0-2000 ms 1000 ms

0-20 10

0x00-0x14 0x0A

0-10000 ms 100 ms

0-10000 100

0x00-0x2710 0x64

Resolution: 1 ms

0-10000 ms 300 ms

0-10000 300

0x00-0x2710 0x12C

Enable/disable Disable

0-500 ms 0 ms

0-500 0

0x00-0x1F4 0x00

Resolution: 0.4%

0-100% 0%

0-250 0

0x00-0xFA 0x00

Enable/disable Enable

Resolution: 100 ms

0-25500 ms See graph

0-255

0x00-0xFF

Resolution: 1%

0-100% 100%

0-255 255

0x00-0xFF 0xFF

Status message /

event triggered

Enable/disable Enable

below

Status

message

©

Danfoss | October 2021 BC187186484889en-000107 | 25

P301 824A

-40 to -30 °C-40 to -30 °C-40 to -30 °C

-30 to -20 °C-30 to -20 °C-30 to -20 °C

-20 to -10 °C-20 to -10 °C-20 to -10 °C

-10 to 0 °C-10 to 0 °C-10 to 0 °C

0 to 10 °C0 to 10 °C0 to 10 °C

10 to 20 °C10 to 20 °C10 to 20 °C

20 to 30 °C20 to 30 °C20 to 30 °C

30 to 40 °C30 to 40 °C30 to 40 °C

40 to 50 °C40 to 50 °C40 to 50 °C

50 to 60 °C50 to 60 °C50 to 60 °C

60 to 70 °C60 to 70 °C60 to 70 °C

70 to 80 °C70 to 80 °C70 to 80 °C

80 to 90 °C80 to 90 °C80 to 90 °C

90 to 100 °C90 to 100 °C90 to 100 °C

100 to 110 °C100 to 110 °C100 to 110 °C

110 to 120 °C110 to 120 °C110 to 120 °C

120 to 130 °C120 to 130 °C120 to 130 °C

000

100010001000

200020002000

300030003000

400040004000

500050005000

600060006000

700070007000

800080008000

Technical Information

PVED-CC Series 5 ISObus

Parameters

Parameter overview (continued)

Parameter Description Range Default

KWP2000 message

timeout

Timeout period for receiving KWP2000 message from the

master

Resolution: 1 sec

0-255 sec 5 sec

0-255 5

0x00-0xFF 0x05

Reserved bits in

Chooses wether the reserved bits in byte 3 of AVEF is 0 or10/1 1

AVEF byte 3

*

Part of Process Data and can be modified at runtime.

Timeout as a function of temperature

PVED-CC ISObus Process data

Process Data is part of the parameters in the PVED-CC Series 5 ISOBUS. These data can be changed at

runtime using the CAN bus messages shown.

Process data messages

Message ID Message type DLC Control Byte (Byte 1)

*

*

Write Command 8 0x00

Read Command 8 0x10

0x0CCBxxyy

0x0CCBxxyy

*

xx = destination address (0x80-0x8F), yy = source address

Process data overview

Data Dictionary column Process Data Parameter

0 Scaling of PFC – Extend

1 Scaling of PFC – Retract

3 Progressivity Curve – Extend

4 Dead band Offset – Extend

5 Dead band Offset – Retract

6 Progressivity Curve – Retract

8 Ramp up – Extend

26 | © Danfoss | October 2021 BC187186484889en-000107

Technical Information

PVED-CC Series 5 ISObus

Parameters

Data Dictionary column Process Data Parameter

9 Ramp down – Extend

10 Ramp up – Retract

11 Ramp down – Retract

12 Invert ports

13 Float Threshold

14 Commit to EEPROM

15 Restore Factory Settings

Setpoint transfer feature: Write process data

The write process data will change the behavior of the PVED, and thereby the valve, at runtime by

changing the value of a given parameter.

Frame format

Write frame format

Msg ID DLC Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7 Byte 8

0x0CCBxxyy*8 Control

*

xx = destination address (0x80-0x8F), yy = source address

Byte

Count

number

Impleme

nt type

and

position

Data

dictionary

row /

column

Process data variable

parameters

Not used

Write data

Byte 1 Control Byte (0x00)

Byte 2 Count number (0x00)

Byte 3 Implement type and position (0x00)

Byte 4 Data dictionary Bits 8-5: Data dictionary row (0x06)

Bits 4-1: Data dictionary column

Byte 5 Process data variable (0x00)

Byte 6

Byte 7 Not used by PVED (0x00)

Byte 8

Linked fault flags

Fault SPN FMI

Process data out of range 298983 2

Process data out of range at boot-up 520579 2

Read frame format

Msg ID DLC Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7 Byte 8

0x0CCCBxxyy*8 Control

*

xx = source address

Byte

Count

number

Impleme

nt type

and

position

Data

dictionary

row /

column

Process data variable

parameters

Not used in PVED

Transmission rate: on request

©

Danfoss | October 2021 BC187186484889en-000107 | 27

Technical Information

PVED-CC Series 5 ISObus

Parameters

Read data

Byte 1 Control Byte (0x10)

Byte 2 Count number (0x00)

Byte 3 Implement type and position (0x00)

Byte 4 Data dictionary Bits 8-5: Data dictionary row (0x06)

Bits 4-1: Data dictionary column

Byte 5 Process data variable

Byte 6

Byte 7 Not used by PVED (0x00)

Byte 8

28 | © Danfoss | October 2021 BC187186484889en-000107

Technical Information

PVED-CC Series 5 ISObus

Diagnostics

PVED-CC (ISObus) Diagnostics log

The PVED-CC Series 5 contains a diagnostic log saving the occurrence of all faults listed below (sorted in

asending order by SPN). The faults are transmitted onto the CAN bus through the DM1 message upon

occurrence and previously active faults can be enquired through the DM2 message. The complete list of

active and previously active faults can be seen in the PLUS+1® Service Tool.

Diagnostics log

FaultIDFault Description SPN FMI Severity SPN + FMI byte values as

4 Supply voltage above upper limit Actuator supply voltage above

5 Supply voltage below lower limit Actuator supply voltage below

34 Memory (flash) corrupted Actuator component fault. 628 12 SEVERE 0x74 0x02 0x0C

32 Memory (RAM) corrupted Actuator component fault. 1557 12 SEVERE 0x15 0x06 0x0C

42 PSM buffer overload Actuator component fault. 298965 11 SEVERE 0xD5 0x8F 0x8B

39 PSM operation fault Actuator component fault. 298966 11 SEVERE 0xD6 0x8F 0x8B

57 Loss and recovery of CAN bus

connection

3 Interpolation fault Actuator component fault. 298968 11 SEVERE 0xD8 0x8F 0x8B

53 Commit-to-EEPROM invalid cmd. Command Commit-to-EEPROM

58 AVC not recieved within timeout

period

61 Float threshold set point not given Setpoint less than float threshold

49 Actual main spool position exceeds

set point recieved.

48 Main spool not in neutral at boot up. Main spool not at neutral position in

47 Float not reached. Main spool cannot reach float

29 POST fault Power On Self-Test failed. Actuator

27 Handshake bootup fault. Actuator component fault. 298993 11 SEVERE 0xF1 0x8F 0x8B

63 Stack usage >90% Actuator component fault. 298996 2 CRITICAL 0xF4 0x8F 0x82

62 Solenoid driver validation fault Actuator component fault. 298997 2 CRITICAL 0xF5 0x8F 0x82

35 Memory (EEPROM) communication

fault

2 Parameter truncation change Value of parameter changed due to

1 Internal calculation fault Actuator component fault. 299004 11 SEVERE 0xFC 0x8F 0x8B

0 Software Initialisation fault Software could not initialize. Check

12 Handshake not received by safeUC Actuator component fault. 299007 11 SEVERE 0xFF 0x8F 0x8B

13 Transducer signal frequency out of

range.

specified upper limit. Please ensure

sufficient power supply.

specified lower limit. Please ensure

sufficient power supply.

CAN bus connection to the actuator

failed but recovered. Please verify

connection.

out of valid range.

Auxillary Valve Command not

recived by actuator before timeout

specified

given when commanded into float

position.

Main spool stroke further away from

neutral than demanded by setpoint.

(Dependent on timeout value).

the module at time of bootup.

position.

cannot start up.

Actuator component fault. 299001 12 CRITICAL 0xF9 0x8F 0x8C

truncation.

that no active errors are present on

CAN bus.

Actuator component fault. 299008 8 SEVERE 0x00 0x90 0x88

627 3 WARNING 0x73 0x02 0x03

627 4 WARNING 0x73 0x02 0x04

298967 19 WARNING 0xD7 0x8F 0x93

298983 2 INFO 0xE7 0x8F 0x82

298985 19 WARNING 0xE9 0x8F 0x93

298986 19 WARNING 0xEA 0x8F 0x93

298988 7 CRITICAL 0xEC 0x8F 0x87

298989 7 CRITICAL 0xED 0x8F 0x87

298990 7 CRITICAL 0xEE 0x8F 0x87

298992 12 SEVERE 0xF0 0x8F 0x8C

299002 11 SEVERE 0xFA 0x8F 0x8B

299005 11 SEVERE 0xFD 0x8F 0x8B

seen in DM1/DM2 frames

Byte 3 Byte 4 Byte 5

©

Danfoss | October 2021 BC187186484889en-000107 | 29

Technical Information

PVED-CC Series 5 ISObus

Diagnostics

Diagnostics log (continued)

FaultIDFault Description SPN FMI Severity SPN + FMI byte values as

14 Safety demodulator A: signal out of

range

16 Safety-controller PSU out of range Actuator component fault. 299010 2 SEVERE 0x02 0x90 0x82

18 Safety-controller fuse bit fault Actuator component fault. 299011 2 SEVERE 0x03 0x90 0x82

15 Safety demodulator B: signal out of

range

17 Safety-controller: Voltage reference

out of range

19 Safety-controller spool position

cross validation fault

20 Safety switch state fault Actuator component fault. Not able

51 SPI buffer overload Actuator component fault. 299020 2 INFO 0x0C 0x90 0x82

52 SPI communication fault Actuator component fault. 299021 2 SEVERE 0x0D 0x90 0x82

25 Handshake bootup fault. Actuator component fault. 299022 12 SEVERE 0x0E 0x90 0x8C

26 Safety switch state fault. Actuator component fault. 299023 12 SEVERE 0x0F 0x90 0x8C

31 Spool position cross validation fault Actuator component fault. 299025 2 SEVERE 0x11 0x90 0x82

28 Safety-controler initialization fault. Actuator component fault. 299026 12 WARNING 0x12 0x90 0x8C

30 Safety-controller task scheduling

fault

38 Memory (EEPROM) corrupted Actuator component fault. 299029 12 SEVERE 0x15 0x90 0x8C

64 CRC fault The Operator has not approved the

65 Invalid hardware version. Actuator component fault. 520448 2 SEVERE 0x00 0xF1 0xE2

56 AVEF from Work Function actuators

not recieved within timeout period

55 Corrupted data received by Inlet

actuator

54 COMM : Running number validation

for AVC and AVEF

41 Memory (EEPROM) CRC fault Actuator component fault. 520576 2 INFO 0x80 0xF1 0xE2

37 PWM calibration Actuator component fault. 520577 2 SEVERE 0x81 0xF1 0xE2

40 Config sector CRC fault Actuator component fault. 520578 2 SEVERE 0x82 0xF1 0xE2

33 Memory (EEPROM) invalid

parameter

43 Average operating temp above

limit.

44 Current temp above upper limit. The current temperature the

6 5V PSU out of range Actuator component fault. 520582 2 SEVERE 0x86 0xF1 0xE2

7 Spool position calculation fault Actuator component fault. 520583 2 SEVERE 0x87 0xF1 0xE2

50 LVDT supply frequency out-of-range Actuator component fault. 520584 2 SEVERE 0x88 0xF1 0xE2

8 V reference signal out of range. Actuator component fault. 520585 2 SEVERE 0x89 0xF1 0xE2

Actuator component fault. 299009 2 SEVERE 0x01 0x90 0x82

Actuator component fault. 299012 2 SEVERE 0x04 0x90 0x82

Actuator component fault. 299013 2 SEVERE 0x05 0x90 0x82

Actuator component fault. 299014 2 SEVERE 0x06 0x90 0x82

to perform safe operation!

Actuator component fault. 299028 12 SEVERE 0x14 0x90 0x8C

data change

Auxillary Valve Estimated Flow not

recived from Work Function

actuators by Inlet actuator before

timeout specified

CRC or DLC data received from Inlet

actuator is corrupted

The running number for Auxillary

Valve Command nd Auxillary Valve

Estimated Flow could not be

validated.

One or more configured EEPROM

parameters out of specified range.

The average detected operating

temperature is above the upper

limit specified.

actuator operates in is above

specified operation limit.

299015 12 SEVERE 0x07 0x90 0x8C

299030 2 SEVERE 0x16 0x90 0x82

520449 19 WARNING 0x01 0xF1 0xF3

520450 19 CRITICAL 0x02 0xF1 0xF3

520451 19 CRITICAL 0x03 0xF1 0xF3

520579 2 SEVERE 0x83 0xF1 0xE2

520580 16 WARNING 0x84 0xF1 0xF0

520581 0 CRITICAL 0x85 0xF1 0xE0

seen in DM1/DM2 frames

Byte 3 Byte 4 Byte 5

30 | © Danfoss | October 2021 BC187186484889en-000107

Technical Information

PVED-CC Series 5 ISObus

Diagnostics

Diagnostics log (continued)

FaultIDFault Description SPN FMI Severity SPN + FMI byte values as

9 GND signal unstable. Actuator component fault. 520586 3 SEVERE 0x8A 0xF1 0xE3

60 Safety switch state fault Actuator component fault. Not able

to perform safe operation!

10 Demodulator A: signal out of range Actuator component fault. 520588 2 SEVERE 0x8C 0xF1 0xE2

11 Demodulator B: signal out of range Actuator component fault. 520589 2 SEVERE 0x8D 0xF1 0xE2

45 Current temp below lower limit. The current temperature the

actuator operates in is below

specified operation limit.

46 Main spool cannot return to neutral Main spool cannot return back to

neutral by neutral command

setpoint.

36 Fault overload More than three faults were raised

simultaneously.

59 AVC data recieved invalid Auxillary Valve Command input

recieved by actuator. Invalid state

and/or flow request sent from

controller.

520587 12 SEVERE 0x8B 0xF1 0xEC

520590 1 CRITICAL 0x8E 0xF1 0xE1

520591 7 CRITICAL 0x8F 0xF1 0xE7

520592 0 SEVERE 0x90 0xF1 0xE0

520676 19 WARNING 0xE4 0xF1 0xF3

seen in DM1/DM2 frames

Byte 3 Byte 4 Byte 5

Diagnostic history

With occurrence of severe faults the actuator must always be repowered.

With multiple occurrences of severe faults replace actuator.

In addition to the diagnostic log, the PVED-CC Series 5 holds a record of the last 16 faults occurred. The

faults are stored in a FIFO buffer.

Besides the fault code the history also contains more information on the behavior and state of the valve

upon fault occurrence. The diagnostic history can be seen in the PLUS+1® Service Tool.

Parameter Description

Fault ID ID number of the fault raised

Valve State State of device upon fault occurrence

Current set point Set point upon fault occurrence

Current spool position Spool position upon fault occurrence

Battery voltage Battery voltage upon fault occurrence

Operating time Operating time upon fault occurrence

Setpoint and spool position history Last 9 setpoint and spool positions prior to fault

Temperature Temperature upon fault occurrence

*

Operating time is logged every 6 minutes when the power to the PVED is ON

†

Temperature is either received through PGN: VFT or onboard PCB temperature sensor

occurrence

*

†

Temperature histogram

The PVED-CC Series 5 logs the temperature and time each 6 minutes. This temperature record is used to

make a temperature histogram.

The temperature used is the one received in the PGN: Vehicle Fluid Temperature. If no PGN:VFT is

received the PVED uses the onboard PCB temperature sensor.

The Temperature Histogram can be seen in the PLUS+1® Service Tool.

©

Danfoss | October 2021 BC187186484889en-000107 | 31

Danfoss

Power Solutions GmbH & Co. OHG

Krokamp 35

D-24539 Neumünster, Germany

Phone: +49 4321 871 0

Danfoss

Power Solutions ApS

Nordborgvej 81

DK-6430 Nordborg, Denmark

Phone: +45 7488 2222

Danfoss

Power Solutions (US) Company

2800 East 13th Street

Ames, IA 50010, USA

Phone: +1 515 239 6000

Danfoss

Power Solutions Trading

(Shanghai) Co., Ltd.

Building #22, No. 1000 Jin Hai Rd

Jin Qiao, Pudong New District

Shanghai, China 201206

Phone: +86 21 2080 6201

Products we offer:

Hydro-Gear

www.hydro-gear.com

Daikin-Sauer-Danfoss

www.daikin-sauer-danfoss.com

Cartridge valves

•

DCV directional control

•

valves

Electric converters

•

Electric machines

•

Electric motors

•

Gear motors

•

Gear pumps

•

Hydraulic integrated

•

circuits (HICs)

Hydrostatic motors

•

Hydrostatic pumps

•

Orbital motors

•

PLUS+1® controllers

•

PLUS+1® displays

•

PLUS+1® joysticks and

•

pedals

PLUS+1® operator

•

interfaces

PLUS+1® sensors

•

PLUS+1® software

•

PLUS+1® software services,

•

support and training

Position controls and

•

sensors

PVG proportional valves

•

Steering components and

•

systems

Telematics

•

Danfoss Power Solutions is a global manufacturer and supplier of high-quality hydraulic and

electric components. We specialize in providing state-of-the-art technology and solutions

that excel in the harsh operating conditions of the mobile off-highway market as well as the

marine sector. Building on our extensive applications expertise, we work closely with you to

ensure exceptional performance for a broad range of applications. We help you and other

customers around the world speed up system development, reduce costs and bring vehicles

and vessels to market faster.

Danfoss Power Solutions – your strongest partner in mobile hydraulics and mobile

electrification.

Go to www.danfoss.com for further product information.

We offer you expert worldwide support for ensuring the best possible solutions for

outstanding performance. And with an extensive network of Global Service Partners, we also

provide you with comprehensive global service for all of our components.

Local address:

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

already on order provided that such alterations can be made without subsequent changes being necessary in specifications already agreed.

All trademarks in this material are property of the respective companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

©

Danfoss | October 2021 BC187186484889en-000107

Loading...

Loading...