Page 1

V310115.A

Installation Guide

Electrical Actuating Module

PVE series 4 for PVG 32 and PVG 100

PVE for PVG 32 and PVG 100:

157R9 915

Oliestrømmens retning for

standard monterede grupper.

Oil ow direction for standard

assembled groups.

Richtung des Ölstroms für

Standard-Baugruppen.

Sens du débit pour ensembles

standard.

For Technical Information, see Danfoss.com.

157R9 915

to application

to tank

P→A

V310348A

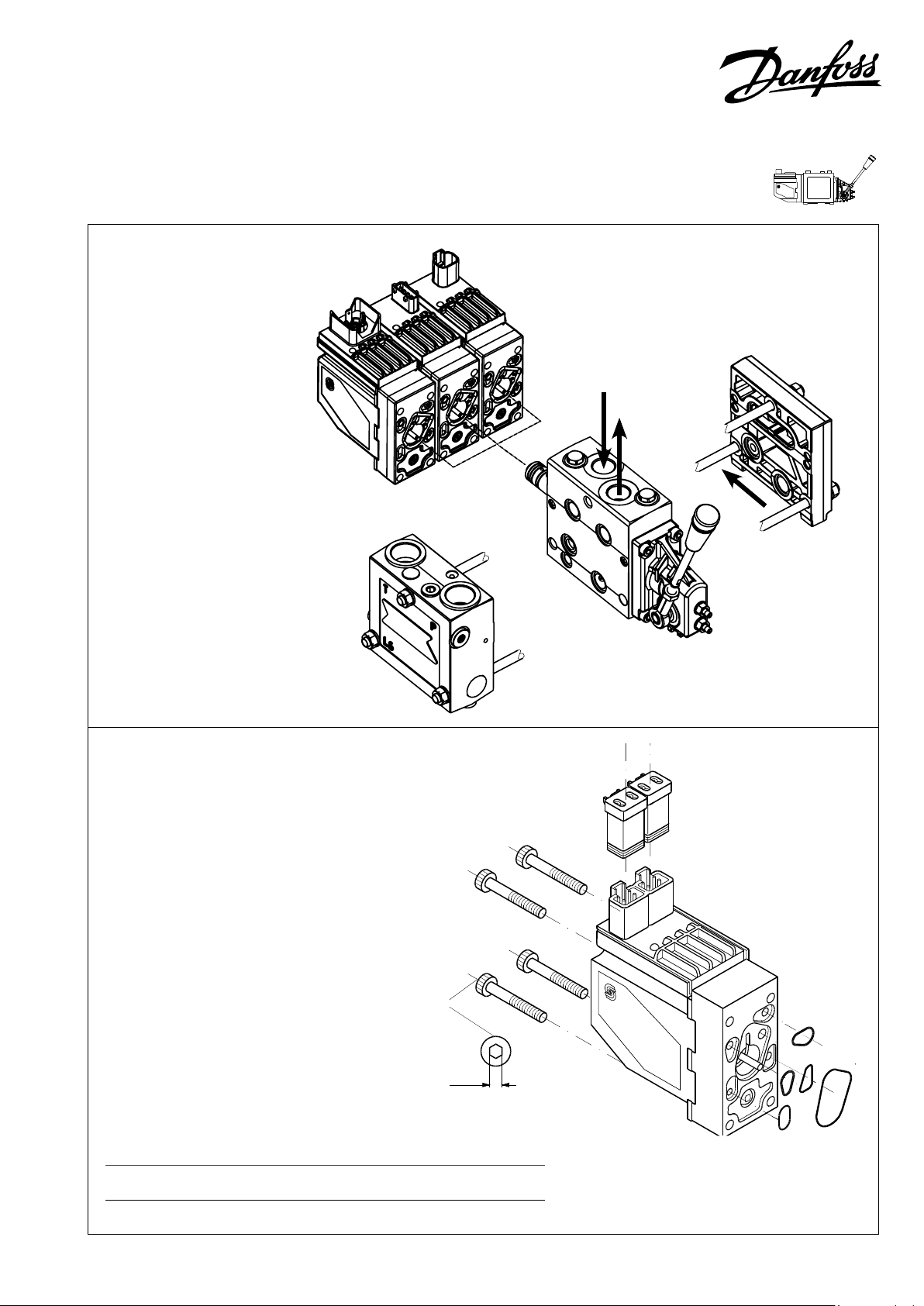

Mounting PVE

Instruktionen dækker

Instruction covers

Anleitung umfasst

l'instruction couvre

Danfoss actuators PVEA, PVEH, PVEM, PVEO, PVEP,

PVES, PVEU Variants -R, -DI, -SP, -F.

Connectors Deutsch, AMP, DIN/Hirschmann.

For full documentation see Technical Information, PVE

Series 4 for PVG 32, PVG 100 and PVG 120, 520L0553 on

www. Danfoss.com

5 [0.2]

• Protect LVDT-pin if present

• Ensure O-rings are in place

• Ensure gasket when using AMP and DIN/Hirschmann connector

• Do not over torque

WWarning

PVEA is not for use on PVG 100.

8 ±0.5 N•m

[70 ±4.4 lbf•in]

© Danfoss, 2014-03 520L0619 • Rev EB • Mar 2014 1

Page 2

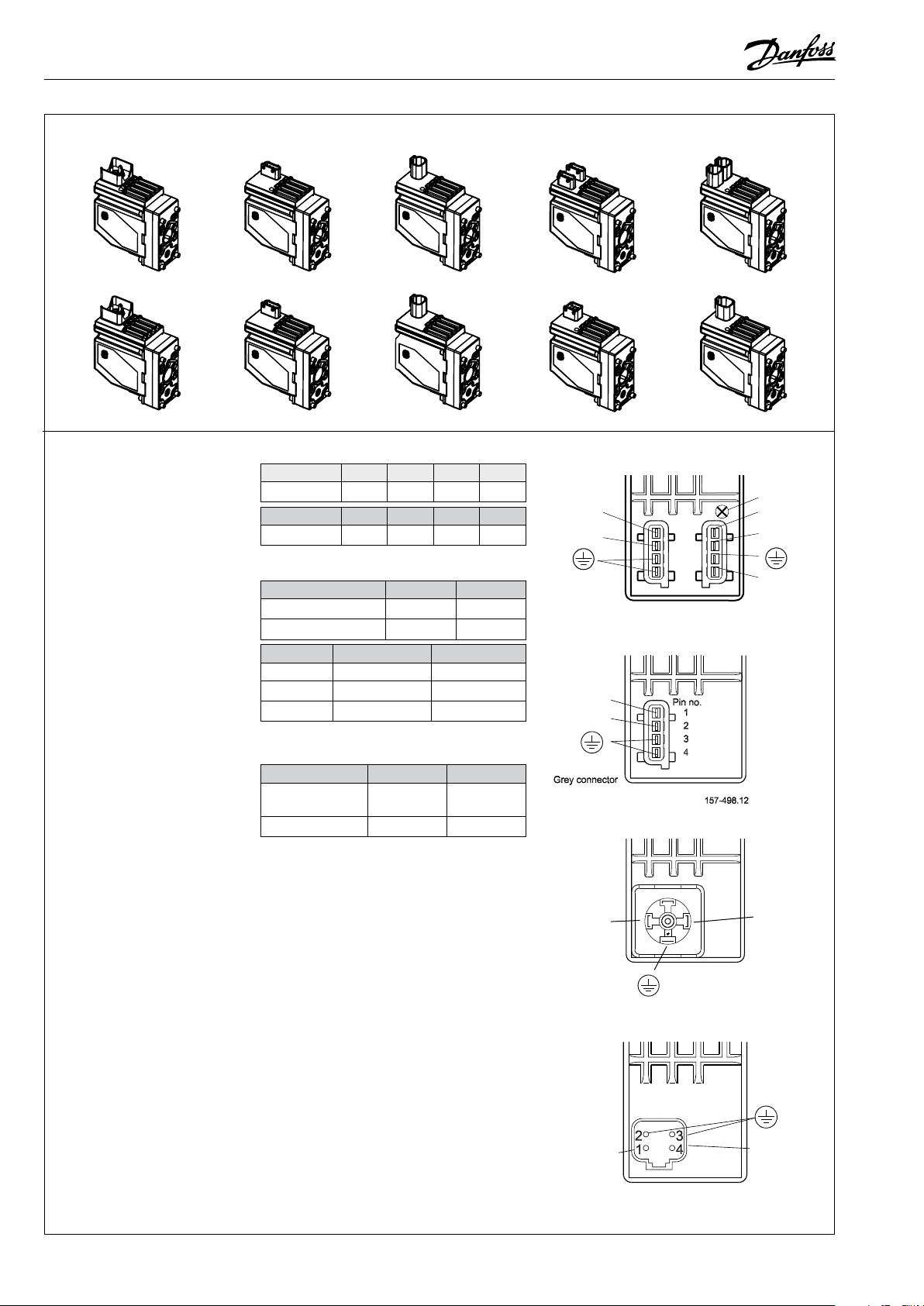

PVEO/PVEO-R

PVEO-DI

All PVE variants. PVEO and PVEO-R are without LVDT

Version ON/OFF Connection PVEO with direction indication (DI)

y Ground pins are internally

connected.

y Pin 3 is not connected on

Hirschmann/DIN version of

Connector 1 A UDCB UDCGnd Gnd

AMP (grey)

Connector 2 DI-B DI-A Gnd U

AMP (black)

p 1 p 2 p 3 p 4

DC 2

p 1 p 2 p 3 p 4

PVEO.

y U

supplies electronics for

DC2

feedback signal on PVEO-DI.

Connection PVEO standard

Connector A B

AMP/Hirschmann/DIN

Deutsch

pin 1 pin 2

pin 1 pin 4

Function A (pin 1) B (pin 2)

Neutral 0 0

Q: P → A

Q: P → B

U

DC

0 U

0

DC

Control all PVEO

Connector A B

AMP

Hirschmann/DIN

Deutsch

DI general note

Til DI udførelserne er det nødvendigt at have 2 U

forsyner elektronikken og

• U

DC

forsyner magnetventilerne

• U

DC2

De to jordforbundne stikben er internt forbundet.

Der kan med fordel anvendes to separate strømforsyninger (jvf. tekniske informationer for PVE serie 4)

-tilslutninger (UDC og U

DC

pin 1 pin 2

pin 1 pin 4

):

DC2

AMP version of PVEO–DI

U

A U

DC

DC

U

B U

DC

DC

Grey connector

Pin no.

1

2

3

4

LED

DI-B

DI-A

U

Black connector

AMP version of PVEO/PVEO–R

A U

DC

B U

DC

Hirschmann/DIN version of PVEO / PVEO–R

B U

3

1

DC

2

A U

U

DC2

P301 104

DC

DC

On DI versions two U

will supply the electronics and

• U

DC

will supply the solenoid valves

• U

DC2

The two ground pins are internally connec ted.

connections (UDC and U

DC

With advantages two separate power supplies can be used, see also Technical information for PVE series 4.

Die DI Ausführungen fordern zwei U

versorgt die Elektronik und

• U

DC

versorgt die Magnetventile

• U

DC2

De zwei Erdungsstecker sind intern verbunden.

-Anschlüsse (UDC und U

DC

) are necessary.

DC2

157-502.11

Deutsch version of PVEO /PVEO-R

):

DC2

Es kann mit Vor teil zwei separate Stromversorgungen verwendet werden (vgl. technische Informationen

für PVE Serie 4)

Pour les versions DI deux raccordements U

• U

• U

Les deux bornes masse sont reliées intéreurement.

alimente l’électronique

DC

alimente les électrodistributeurs

DC2

(UDC et U

DC

) sont nécessaires.

DC2

A U

B U

DC

DC

L’emploi de deux sources d’alimentation séparées a des avantages, voir Information Technique pour PVE

série 4

2 520L0619 • Rev EB • Mar 2014 © Danfoss, 2014-03

Page 3

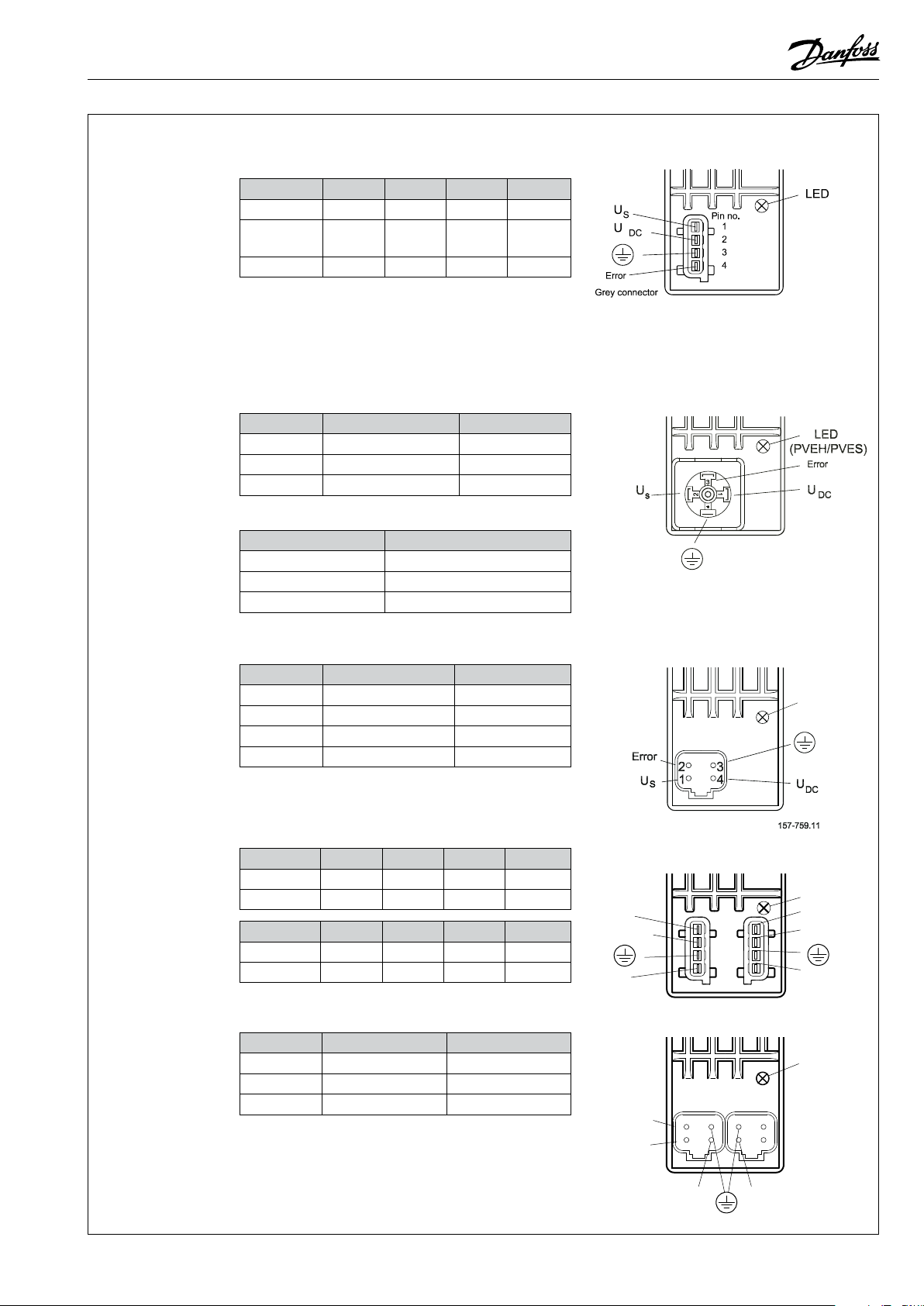

Proportional

PVEA-DI/PVEH-DI

PVEA-DI/PVEH-DI

Version

Standard PVE

Connection PVEA/PVEH/PVEM/PVES/PVEU - also with

oat B four pin

Connector U

AMP

Hirschmann/

DIN

Deutsch

pin 1 pin 2 pin 3 pin 4

pin 2 pin 1 gnd pin 3

pin 1 pin 4 pin 3 pin 2

S

U

DC

Gnd Error

y On PVEM the error pin is not used and not connected

(pin 3 Hirschmann/DIN).

y Ground pins are internally connected.

AMP version PVEA/PVEH/PVES/PVEU

Control (US) for standard mounted

PVEA/ PVEH/ PVEM/ PVES

Function

Neutral 0,5 • U

Q: P → A 0,5 → 0,25 • U

Q: P → B 0,5 → 0,75 • U

Voltage relative PWM

DC

DC

DC

50%

50% → 25%

50% → 75%

Control (US) for standard mounted PVEU

Function

Neutral 5 V

Q: P → A 5 V → 2,5 V

Q: P → B 5 V → 7,5 V

PVEU

Control (US) for standard mounted PVEH/PVEM

oat B four pin version

Function

Neutral 0,5 • U

Q: P → A 0,5 → 0,34 • U

Q: P → B 0,5 → 0,65 • U

Float 0,75 • U

Voltage relative PWM

DC

DC

DC

DC

50%

50% → 34%

50% → 65%

75%

Standard PVE with DI

Connection PVE with direction indication (DI)

Connector 1 U

AMP (grey)

Deutsch

S

p 1 p 2 p 3 p 4

p 1 p 4 p 3 p 2

Connector 2 DI-B DI-A Gnd U

AMP (black)

Deutsch

p 1 p 2 p 3 p 4

p 4 p 3 p 2 p 1

U

DC 1

Gnd Error

Control (US) for standard mounted PVEA–DI/ PVEH–DI

Function

Neutral 0,5 • U

U

S

DC

Q: P → A 0,5 → 0,25 • U

Q: P → B 0,5 → 0,75 • U

DC

DC

PWM

50%

50% → 25%

50% → 75%

y Ground pins are internally connected.

y U

only supplies electronics for feedback signal and

DC2

error pin on PVEA-DI / PVEH-DI. Two separate power

sources can be used.

DC 2

Hirschmann/DIN version PVEH/PVEM/PVES/

PVEH oat B/PVEM oat B

Deutsch version PVEA/PVEH/PVES/PVEU/

PVEH oat B

LED

AMP version PVEA–DI/PVEH–DI

U

S

U

DC1

Error

Grey connector

Pin no.

1

2

3

4

LED

DI-B

DI-A

U

DC2

Black connector

Deutsch version PVEA–DI/PVEH–DI

LED

Error

U

3

2

1

S

2

4

1

U

DC

DI-A

3

4

DI-B

U

DC2

© Danfoss, 2014-03 520L0619 • Rev EB • Mar 2014 3

Page 4

connec

PVES-SP

Proportional

Fl

No con-

PVEH-F

Version

Standard PVE with SP

Connection PVE with Spool Position (SP)

Connector U

Deutsch

Error SP Gnd U

S

p 1 p 2 p 4 p 5 p 6

Deutsch version PVES–SP

DC

LED

Control (US) for standard mounted PVES-SP

Function

Neutral 0,5 • U

Q: P → A 0,5 → 0,25 • U

Q: P → B 0,5 → 0,75 • U

U

S

DC

DC

DC

PWM

50%

50% → 25%

50% → 75%

Error

Not

ted

U

4

3

5

2

6

1

s

Spool position

U

PVE with separate Float pin

Connection PVEH with oat A six pin

Connector US (control) UDC (power) Float Ground Error

AMP

Deutsch

Control (U

) for standard mounted PVEH/PVEM oat A six

S

pin 1 pin 2 pin 5 pin 3 pin 4

pin 1 pin 6 pin 3 pin 5 pin 2

AMP with separate oat pin

pin version

Function

Neutral 0,5 • U

Q: P → A 0,5 → 0,25 • U

Q: P → B 0,5 → 0,75 • U

Float U

Voltage relative PWM

DC

DC

DC

on Float pin

DC

50%

50% → 25%

50% → 75%

Not connected

Float

Error

DC

LED

Deutsch version with separate oat pin

oat

Error

U

s

4

3

5

2

6

1

PWM controled PVE – PVEP

Connection PVEP

Connector PWM A Error PWM B Gnd U

Deutsch

p 1 p 2 p 3 p 5 p 6

DC

Deutsch version with PVEP

Control (US) for standard mounted PVEP

Function

Neutral < 10% < 10%

Q: P → A 10% → 80% < 10%

Q: P → B < 10% 10% → 80%

PWM A PWM B

4 520L0619 • Rev EB • Mar 2014 © Danfoss, 2014-03

LED

nection

U

DC

157-779

LED

Page 5

Safety and Monitoring

Fault monitoring overview

Spool Position Feedback

(-SP)

Typ e

PVEO

PVEM

Fault

monitoring

No fault

monitoring

Delay before

error out

Error mode

Error

output

status

- - - - -

Fault

output on

1)

PVE

LED light

No fault Low < 2 V Green -

DC

DC

DC

Flashing red

Constant red

Flashing red

Constant red

Constant red

Input signal faults

Close loop fault

No fault Low < 2 V Green Input signal faults

PVEA

PVEH

PVEP

PVES

PVEU

Active

Passive

500 ms

(PVEA: 750 ms)

250 ms

(PVEA: 750 ms)

Close loop fault

PVE

Float

Active

six pin

1) Measured between fault output pin and ground.

500 ms Float not active

750 ms Float still active

High ∼U

High ~U

High ~U

The –SP functionality is a 0,5V to 4,5V inverted feedback with 2,5V as neutral value.

Spool Position Feedback

75% U

Us

DC

Usp

sp

U

4.5V

Us

Memory

(reset

needed)

-

YesTransducer (LVDT)

NoTransducer (LVDT)

Yes

Direction Indication

Feedback (-DI)

Usp

2.5V

0.5V

7 mm

100%

B port

Spool travelSpool travel

50% U

25% U

DC

DC

7 mm

100%

A port

Us

0 mm

Neutral

As shown in the gure, both “DI-A” and “DI-B” signals are “High” when the spool is inneutral

position. When the spool is moving in the A direction, the “DI-A” signal goes “Low” and the “DI-B”

signal stays “High”. The reverse is true when the spool is moved in the B direction.

Direction Indication Feedback (-DI)

DI-A high

DI-A low

DI-B high

DI-B low

Spool position ‘x’

A-port

PVBS towards PVE

0.4 0.8-0.8 -0.4 0

PVBS away from PVE

B-port

mm [in]

Both direction indication signals go low when the error indicator goes high.

Values for both Direction Indicators, pin A and pin B

Transition to low from high 0.8 ± 0.1 mm [0.031 in]

Transition to high from low 0.4 ± 0.1 mm [0.015 in]

Transition to low both pins error pin goes high

Maximum load of “DI-A” , “DI-B” 50 mA

Volt age U

Volt age U

Volt age low < 0.2 V

© Danfoss, 2014-03 520L0619 • Rev EB • Mar 2014 5

high by load 20 mA > UDC –1.5 V

DC

high by load 50 mA > UDC –2.0 V

DC

Page 6

Technical data

Følgende tekniske data bygger på typiske testresultater. Der anvendes mineralsk olie med en viskositet på

21 mm2/s [102 SUS] og en temperatur på 50°C [122°F].

The following technical data are from typical test results. For the hydraulic system a mineral based

hydraulic oil with a viscosity of 21 mm2/s [102 SUS] and a temperature of 50°C [122°F] were used.

Folgende technische Daten bauen auf typische Testergebnisse. Es wurde Mineralöl mit einer Viskosität

von 21 mm

2

/s [102 SUS] und einer Temperatur von 50°C [122°F] verwendet.

Les caractéristiques techniques suivantes sont tirées de résultats de tests typiques. Pour le système

lique, on a utilisé une huile minérale d’une viscosité de 21

hydrau

de

50°C [122°F]

.

mm2/s [102 SUS] et à une température

PVEO, PVEM

Supply voltage U

DC

Current consumption at rated voltage 0.65 A @ 12 V 0.33 A @ 24 V

Signal voltage (PVEM)

Signal current at rated voltage (PVEM) 0.25 mA 0.50 mA

Input impedance in relation to 0.5 • U

Power consumption 8 W

rated 12 V DC 24 V DC

range 11 V to 15 V 22 V to 30 V

max. ripple 5%

neutral 0.5 x U

A-port ↔ B-port 0.25 • UDC to 0.75 • U

DC

DC

DC

12 KΩ

PVEA, PVEH, PVEP, PVES, PVEU

Supply voltage U

Current consumption

at rated voltage PVEH/PVEP/PVES/PVEU (PVEA)

Signal voltage

Signal current

at rated voltage 0.25 mA to 0.70 mA

Input impedance in relation to 0.5 • U

Input capacitor 100 ηF

Power consumption PVEH/PVEP/PVES/PVEU (PVEA) 7 (3.5) W

rated / range 11 V to 32 V

DC

max. ripple 5%

0.57 (0.28) A @ 12 V 0.3 (0.15) A @ 24 V

PVEA/PVEH/PVES - neutral 0.5 x U

PVEA/PVEH/PVES - A-port ↔ B-port 0.25 • UDC to 0.75 • U

PVEU - neutral 5V

PVEU - A-port ↔ B-port 2.5V to 7.5V

PVEP - neutral A< 10%, B < 10%

PVEP - A-port 10%<A<80%, B< 10%

PVEP - B-port A< 10%, 10%<B<80%

DC

12 KΩ

DC

DC

Oil viscosity

Oil

viscosity

range

12

[65

–

75 mm2/s

–

347 SUS]

min. 4 mm

max. 460 mm

2

/s [39 SUS]

2

/s [2128 SUS]

Oil temperature

Oil

temperature

range 30 – 60˚C [86 – 140˚F]

min. -30˚C [-22˚F]

max. 90˚C [194˚F]

Operating temperature

Ambient -30 – 60˚C [-22 – 140˚F]

Bemærk: Maksimum opstartsviskositet

Note: Max. start up viscosity 2500 mm

Beachte: Maximale Viskosität bei Inbetriebnahme

Remarque : Viscosité maximale au démarrage 2500 mm

2

/s

2

/s

Stock -40 – 90˚C [-40 – 194˚F]

Recommended long

time storage in

10 – 30˚C [50 – 86˚F]

packaging

Pilot pressure

Filtering in the hydraulic system

Required

operating

cleanliness level

18/16/13

(ISO 4406, 1999 version)

Pilot pressure

(relative to T

pressure)

Grade of enclosure

Bemærk: I særligt udsatte maskiner anbefales der besk yttelse med en skærm.

Beachte: In besonders ausgesetz ten Maschinen wird Schutz in Form von

elektrischer Abschirmung empfohlen.

NB: In particularly exposed applications, protec tion by screen is recommended.

Remarque: Pour les applications particulièrement exposées, il est recommandé

d’installer une protection par écran.

Connector version

AMP JPT IP 66

Hirschmann IP 65

Deutsch IP 67

* According to the international standard IEC 529.

6 520L0619 • Rev EB • Mar 2014 © Danfoss, 2014-03

nom. 13.5 bar [196 psi]

min. 10 bar [145 psi]

max. 15 bar [217 psi]

*

Page 7

Udluftning

V310109.A

Hvis gruppen er monteret vertikalt, anbefales det at udlufte ved

justerskruer (Pos.A)

Bemærk: Ved PVEA kan det, pga.dens hydrauliske opbygning, være

påkrævet at foretage udluftning.

Bleeding

If the group is installed vertically, it is recommended to bleed it at the

adjusting screws (Pos.A)

Note: Because of the hydraulic build-up of PVEA, it may be necessary to

bleed the PVEK.

Entlüftung

Wenn die Gruppe vertikal montiert ist, empfehlen wir an den

Justierschrauben zu entlüften (Pos.A)

Beachte: Wegen des hydraulischen Aufbaus von PVEA kann eine Entlüftung

erforderlich sein.

Purge

Si l'ensemble est monté verticalement, il est recommandé de le purger au

moyen des vis d'ajustage (Pos.A)

Nb! En raison du système hydraulique des PVEAs il peut s'avérer nécessaire

de purger.

170[6.69]

T P

100*[4]

A

LS

Beskyttelse

Alle PVE-moduler overholder tæthedsgrad IP65 i henhold til

IEC 529. Det anbefales dog, at PVE’en på særligt udsatte steder

beskyttes i form af en afskærmning eller lignende.

Protection

All PVE modules comply with protection class IP65 in

accordance with IEC 529. However, in particularly exposed

applications protection in the form of screening is

recommended.

Schutzart

Alle PVE-Module erfüllen die Schutzart IP65 gemäß IEC 529.

Es ist jedoch empfehlenswert, der PVE in besonders

ausgesetzten Einsatzbereichen mit einer Abschirmung oder

dergleichen zu schützen.

Protection

Tous les modules PVE possèdent le degré de protection IP65

conformément à la IEC 529. Dans les zones particulièrement

exposées, il est cependant conseillé de protéger le PVE à l’aide

d’un écran ou d’un dispositif similaire.

WWarning

Alle mærker og typer af retningsventiler – også proportional ventiler – kan svigte og forårsage alvorlig skade. Det er derfor vigtigt at analysere

maskinen i alle enkeltheder.

Da proportionalventiler anvendes under mange forskellige driftsbetingelser og i mange forskellige maskiner, er det alene maskinproducentens

ansvar at træe det endelige produktvalg og sikre at samtlige maskinens krav til ydelse, sikkerhed og advarsler er opfyldt.

Ved valg af reguleringssystem – og sikkerhedsniveau – kan man f.eks. støtte sig til EN954-1 (sikkerhedsrelaterede bestanddele i

reguleringssystemet.)

Alle Fabrikate und Typen von Wegeventilen – einschließlich Proportionalventile – können versagen und schlimme Unfälle verursachen. Es ist

daher wichtig, die Anwendung in allen Details zu analysieren.

Weil Proportionalventile unter vielen unterschiedlichen Arbeitsbedingungen und in vielen verschiedenen Anwendungen benutzt werden, trägt

allein der Maschinenhersteller die Verantwortung für seine endgültige Wahl von Produkt, und er ist ebenfalls dafür verantwortlich, dass alle

Leistungs-, Sicherheits- und Warnungsanforderungen an seine Maschine erfüllt sind.

Zur Wahl vom Reglersystem und Sicherheitsniveau kann man sich z.B. auf EN954-1 stützen.

All marks and brands of valves – inclusive proportional valves – can fail and cause serious damage. It is therefore important to analyse all aspects

of the application.

Because the proportional valves are used in many dierent operation conditions and applications, the manufacturer of the application is alone

responsible for making the nal selection of the products – and assuring that all performance, safety and warning requirements of the

application are met.

The process of choosing the control system – and safety level – could e.g. be governed by EN 954-1 (Safety related parts of control system). See

also Technical information for PVE series 4.

Tous les distributeurs - y compris les distributeurs proportionnels - peuvent tomber en panne et entraîner de sérieux dommages. C’est la raison

pour laquelle il est important d’analyser chaque aspect de l’application. Les vannes proportionnelles étant utilisées dans de nombreuses

conditions d’exploitation et applications diérentes, le fabricant de l’application porte l’entière responsabilité de la sélection nale des produits

et du respect des exigences en matière de rendement, de sécurité et d’avertissement. Le choix du système de commande – et du niveau de

sécurité – peut être fait par exemple sur la base de la norme EN 954-1 (parties du système de commande relatives à la sécurité). Se reporter

également à Information technique pour PVE série 4.

© Danfoss, 2014-03 520L0619 • Rev EB • Mar 2014 7

Page 8

Connector code numbers

Accessories

Part number Name

157B 4992 AMP CONNECTING KIT (GREY) 4 pin with housing, contact and wire sealing

157B4993 AMP CONNECTING KIT (BLACK) 4 pin with housing, contact and wire sealing

984L3165 EL-PLUG, ON-OFF black Hirschmann DIN connector set*

Set of seals code numbers

Part number Name Actuator

157B 4997 Set of seals PVE for PVG 32/ PVG 100

155G 8519 Set of seals PVE for PVG 120

110 6123 5 Set of seals PVHC for PVG 32/ PVG 100

Cables code numbers

Feature Wire colors

Connector pin 1 pin 2 pin 3 pin 4 pin 5 pin 6

Deutsch

AMP

AMP/black coding 4 pin white blue yellow red — — 4 m 157B49 95

4 pin white blue yellow red — — 4 m 110 074 98

6 pin white blue yellow red black green 4 m 11007513

4 pin white blue yellow red — — 4 m 157B499 4

6 pin white red black yellow green blue 5 m 157B4974

Length Code number

8 520L0619 • Rev EB • Mar 2014 © Danfoss, 2014-03

Loading...

Loading...