Page 1

Technical Information

PVEA-CI and PVEO-CI Series 6

Electro-hydraulic Actuators

www.danfoss.com

Page 2

Technical Information

PVEA-CI and PVEO-CI Series 6 Electro-hydraulic Actuators

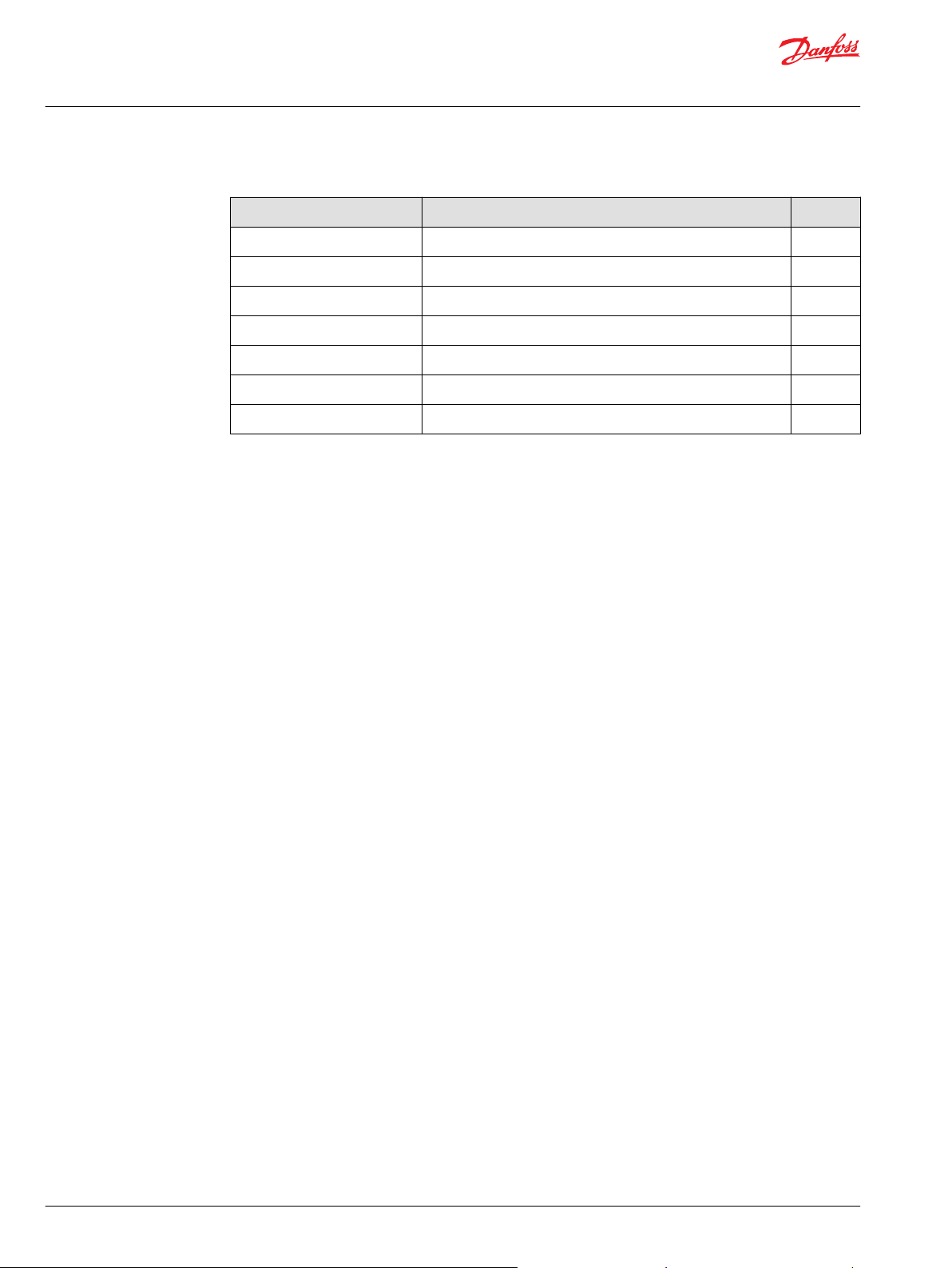

Revision history Table of revisions

Date Changed Rev

July 2018 Heartbeat message node change. 0106

May 2018 add use case 5 and 6 0105

Oct 2017 Minor edits 0104

Jun 2017 Appended Accessory table 0103

September 2015 Updated EMCY message table 0102

November 2015 Changing Node ID corrected 0001

June 2015 First edition 0000

2 | © Danfoss | July 2018 BC00000337en-US0106

Page 3

Technical Information

PVEA-CI and PVEO-CI Series 6 Electro-hydraulic Actuators

Contents

PVEA-CI and PVEO-CI Introduction

Configurable parameters...............................................................................................................................................................5

PVE-CI Communication.................................................................................................................................................................. 6

PVEA-CI and PVEO-CI connector.................................................................................................................................................7

Accessory.............................................................................................................................................................................................7

ISOBUS/J1939 Communication Protocol

Parameter Group Number (PGN)................................................................................................................................................8

Auxiliary Valve Command (AVC).................................................................................................................................................8

Auxiliary Valve Estimated Flow (AVEF)..................................................................................................................................... 9

PVE-CI Diagnostics.........................................................................................................................................................................10

Diagnostic Message 1 (DM1)................................................................................................................................................10

Diagnostic Message 2 (DM2)................................................................................................................................................11

Broadcast Announce Message (BAM)............................................................................................................................... 12

Diagnostic Message 3 (DM3)................................................................................................................................................12

Changing Node ID......................................................................................................................................................................... 12

Commanded address according to ISOBUS/J1939 .....................................................................................................13

PVE-CI Address claim...............................................................................................................................................................13

Address claim request.............................................................................................................................................................14

Commanded address (ISOBUS/J1939)..............................................................................................................................14

ISOBUS/J1939 error codes.......................................................................................................................................................... 15

CANopen Communication Protocol

NMT operations.............................................................................................................................................................................. 17

Boot-up protocol............................................................................................................................................................................18

NMT services supported..............................................................................................................................................................18

State feedback values...................................................................................................................................................................19

LSS slave............................................................................................................................................................................................ 20

PVE-CI switch state global..................................................................................................................................................... 20

PVE-CI switch state selective................................................................................................................................................ 21

Configure Node ID....................................................................................................................................................................22

Configure bit timing parameters........................................................................................................................................ 22

Activate bit timing parameters............................................................................................................................................23

PVE-CI store configurations.................................................................................................................................................. 23

PVE-CI identify non-configured remote slave................................................................................................................24

Identify non-configured slave..............................................................................................................................................24

Fast scan.......................................................................................................................................................................................24

State behavior............................................................................................................................................................................24

PVE-CI heartbeat protocol.....................................................................................................................................................25

Fault handling............................................................................................................................................................................25

PDO mapping procedure.......................................................................................................................................................26

Object dictionary - communication profile..........................................................................................................................26

Device type................................................................................................................................................................................. 26

Error register...............................................................................................................................................................................26

Predefined error field.............................................................................................................................................................. 26

COB-ID SYNC.............................................................................................................................................................................. 27

Manufacturer software version........................................................................................................................................... 27

Store parameters...................................................................................................................................................................... 27

Restore default parameters...................................................................................................................................................28

COB-ID EMCY..............................................................................................................................................................................29

Producer heartbeat time........................................................................................................................................................29

Identity object............................................................................................................................................................................29

PVE-CI emergency consumer...............................................................................................................................................29

RPDO parameter....................................................................................................................................................................... 29

RPDO mapping..........................................................................................................................................................................30

TPDO parameter....................................................................................................................................................................... 30

TPDO mapping..........................................................................................................................................................................30

Object dictionary ...........................................................................................................................................................................30

Standardized device profile..................................................................................................................................................30

Unified Diagnostic Services (UDS) lite....................................................................................................................................32

©

Danfoss | July 2018 BC00000337en-US0106 | 3

Page 4

Technical Information

PVEA-CI and PVEO-CI Series 6 Electro-hydraulic Actuators

Contents

UDS - message ID formation.................................................................................................................................................32

UDS – read data by identifier............................................................................................................................................... 32

UDS – write data by identifier.............................................................................................................................................. 33

UDS – change Node ID .......................................................................................................................................................... 34

UDS – ECU identification........................................................................................................................................................35

PVEA-CI Series 6 diagnostics

LED Characteristic..........................................................................................................................................................................36

Use cases

Use case 1 - Boot-up to operation mode...............................................................................................................................37

Use case 2 - Operation Mode – Error – Operation Mode.................................................................................................37

Use case 3 - Change Node ID globally....................................................................................................................................38

Use case 4 - Change Node ID for specific Node.................................................................................................................. 39

Use Case 5 – Change of baud rate 250 kbit/s to 500 kbit/s:........................................................................................... 41

Use Case 6 – Align cob-id to new configured node id:.................................................................................................... 42

4 | © Danfoss | July 2018 BC00000337en-US0106

Page 5

Technical Information

PVEA-CI and PVEO-CI Series 6 Electro-hydraulic Actuators

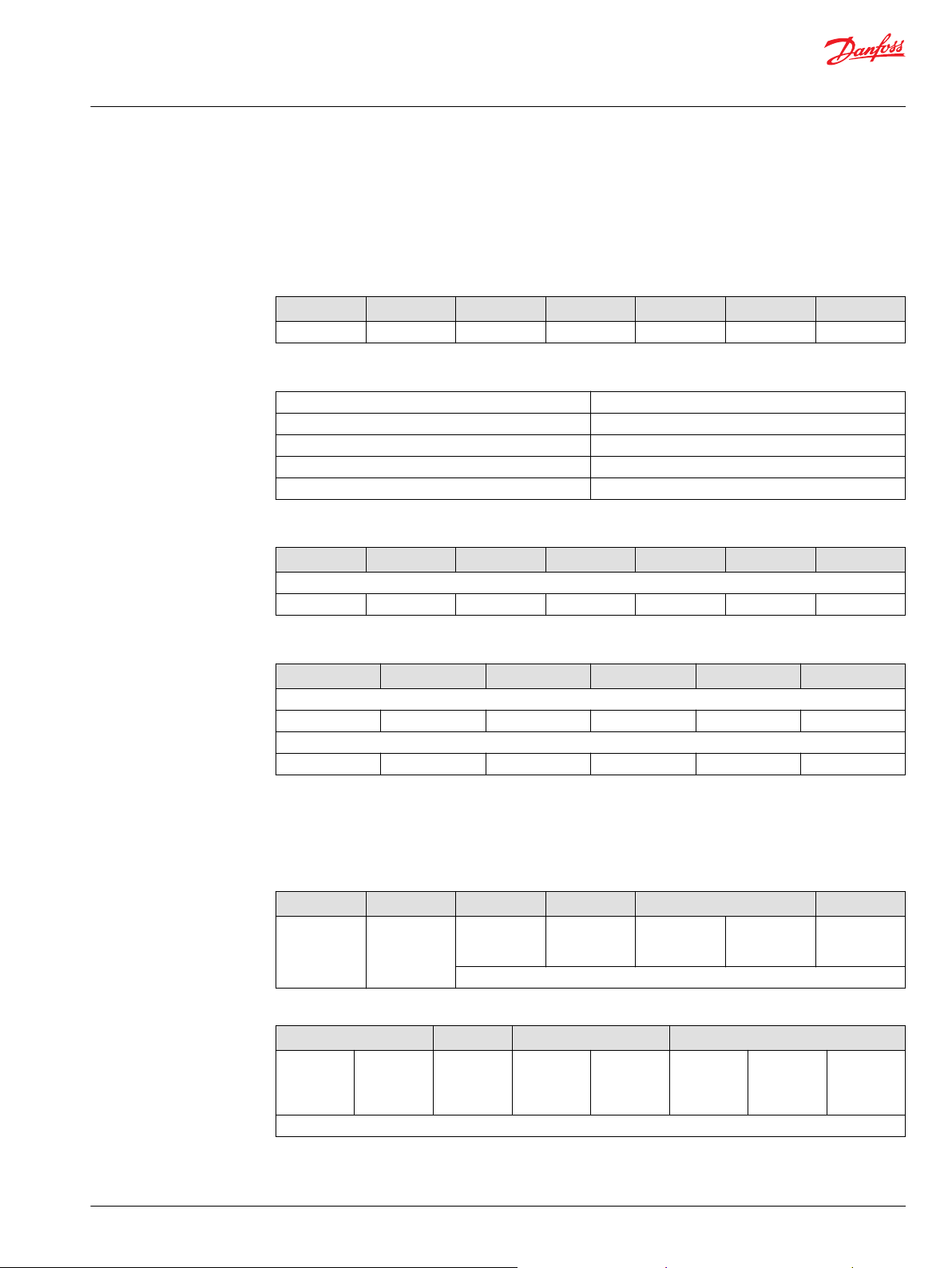

PVEA-CI and PVEO-CI Introduction

The PVEA-CI and PVEO-CI Series 6 are digitally controlled actuators for the PVG 16 family based on the

hydraulic concept known from the analog versions of PVEA and PVEO Series 6.

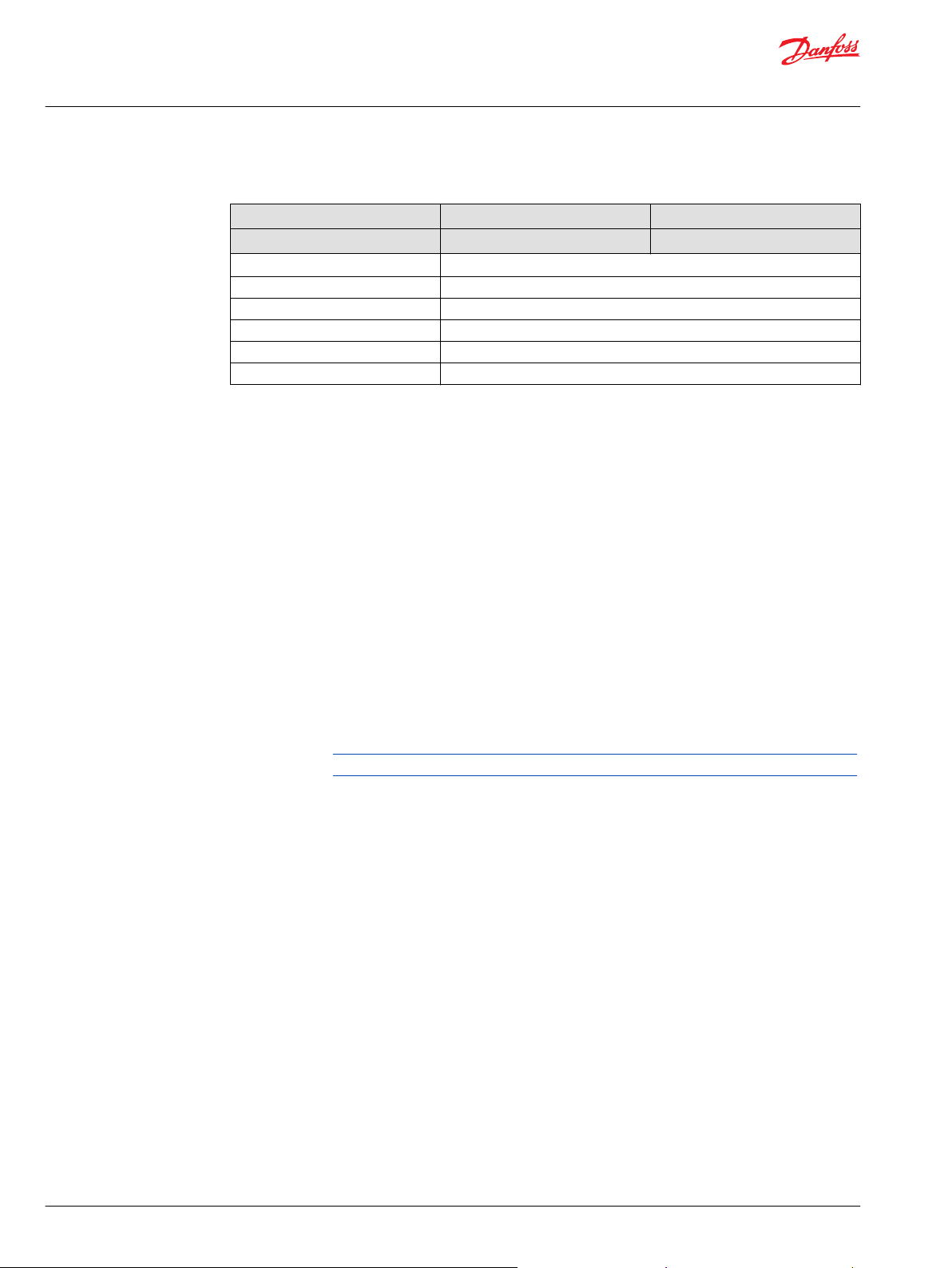

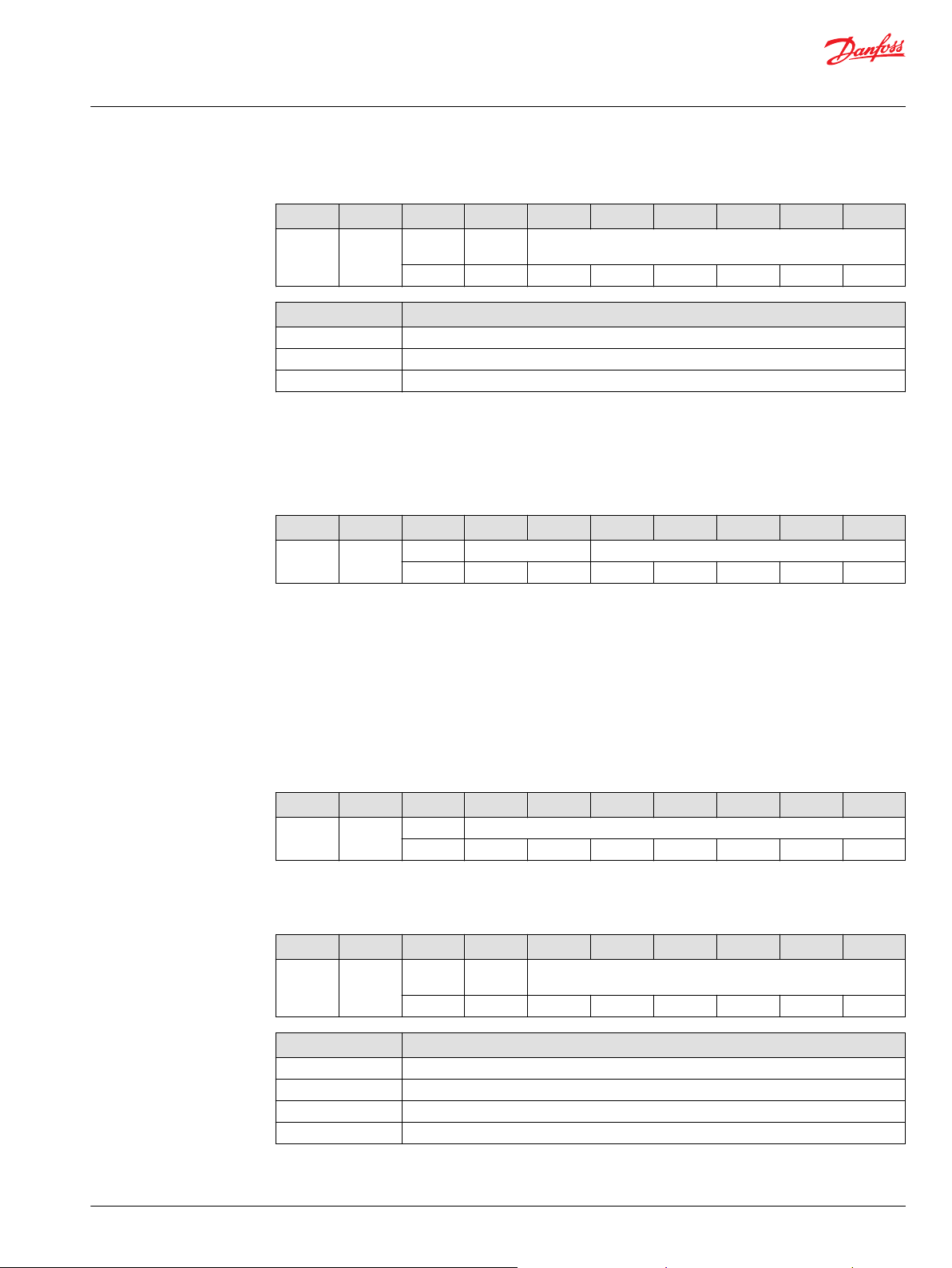

PVEA-CI and PVEO-CI Series 6

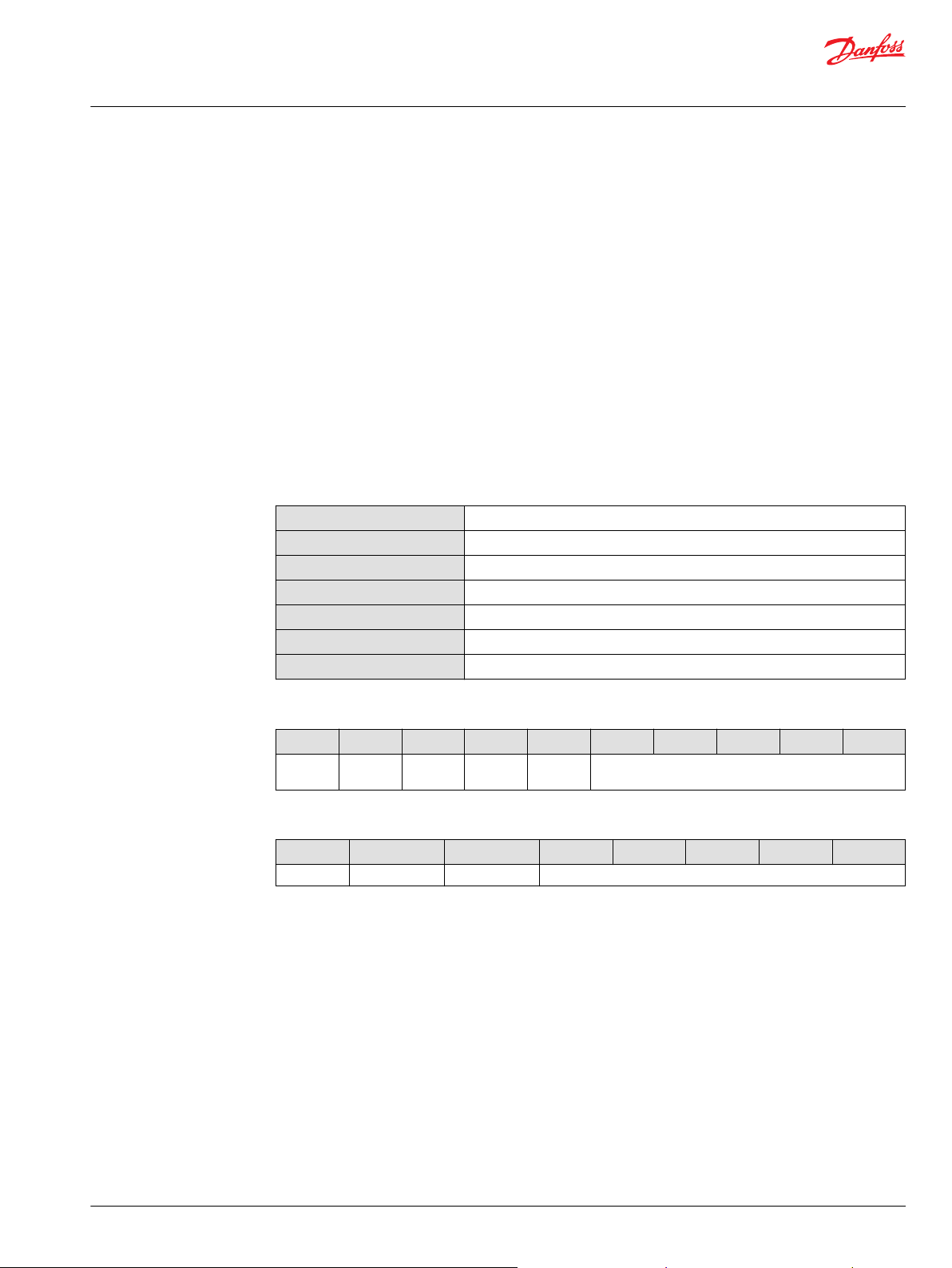

Configurable parameters

Communication protocols available for PVE-CI:

ISO 11783 part 7

•

J1939-21, -71, -73, -81

•

CANopen according to:

CiA 301 version 4.2.0

•

CiA 305 version 1.5.2

•

CiA 408 version 3.0.0

•

Choose and configure the following parameters for the PVE-CI in order to fit into your system.

J1939/ISObus

PVE-CI type PVEO-CI PVEA-CI

Part number 11124002 11121945

Node ID range

0x80-0x8F (128-143)

©

Danfoss | July 2018 BC00000337en-US0106 | 5

Page 6

Technical Information

PVEA-CI and PVEO-CI Series 6 Electro-hydraulic Actuators

PVEA-CI and PVEO-CI Introduction

CANopen

PVE-CI type PVEO-CI PVEA-CI

Part number 11149443 11149437

Node ID range

Heartbeat default 0x00 = off

Heartbeat range 0x00-0x7FFF (0-32767)

COB-ID SYNC default 0x80

TPDO transmission default 0xFF event driven

TPDO transmission range 0x07-0xF0 (1-240)

*

For more information see PVE-CI heartbeat protocol on page 25.

**

For more information see COB-ID SYNC on page 27.

***

For more information see TPDO parameter on page 30.

PVE-CI Communication

The Controller Area Network or simply the CAN bus is an intelligent and efficient bus communication

where highly important messages have priority without any delaying message collisions.

The PVE-CI is available with ISOBUS/SAE J1939 baud rate fixed to 250 Kbps or CANopen default baud rate

= 250 Kbps.

The following states are valid in both communication protocols:

0x01-0x7F (1-127)

*

**

***

Blocked

Extend

Retract

Float

Hand

operation

• The spool and the two normally closed solenoid valves inside the actuator (PVE) are

in neutral position.

• The actuator (PVE) will enter power save mode after 200 ms in blocked state.

• Power Save mode de-energizes the solenoids, while being in blocked state. As soon

as a non-neutral set-point is received by the actuator (PVE) or the spool is moved

the Power Save mode is aborted.

The blocked position is considered to be the safe state for the PVE and valve.

• The extend direction is defined as the spool moving away from the PVE and

entering the B-port side.

• The feedback signal equals positive values.

• The retract direction is defined as the spool moving towards the actuator and

entering the A-port side.

• The feedback signal equals negative values.

• The float state is defined as the spool being actuated fully in the side of the B-port.

• When float position is achieved both A- and B-ports are connected to tank in order

to allow oil flow back and forwards between tank and the work port connections.

• Hand operation mode will de-activate the solenoid valves inside the PVE.

• The feedback signal will be transmitted when the spool is moved manually e.g. by a

lever.

• Any failures related to the spool position are ignored and will not be transmitted

nor logged by internal diagnostics. The introduction of any other failures will result

in a normal reaction and recovery pattern where a DM1 message is transmitted, etc.

6 | © Danfoss | July 2018 BC00000337en-US0106

Page 7

2 3

41

Technical Information

PVEA-CI and PVEO-CI Series 6 Electro-hydraulic Actuators

PVEA-CI and PVEO-CI Introduction

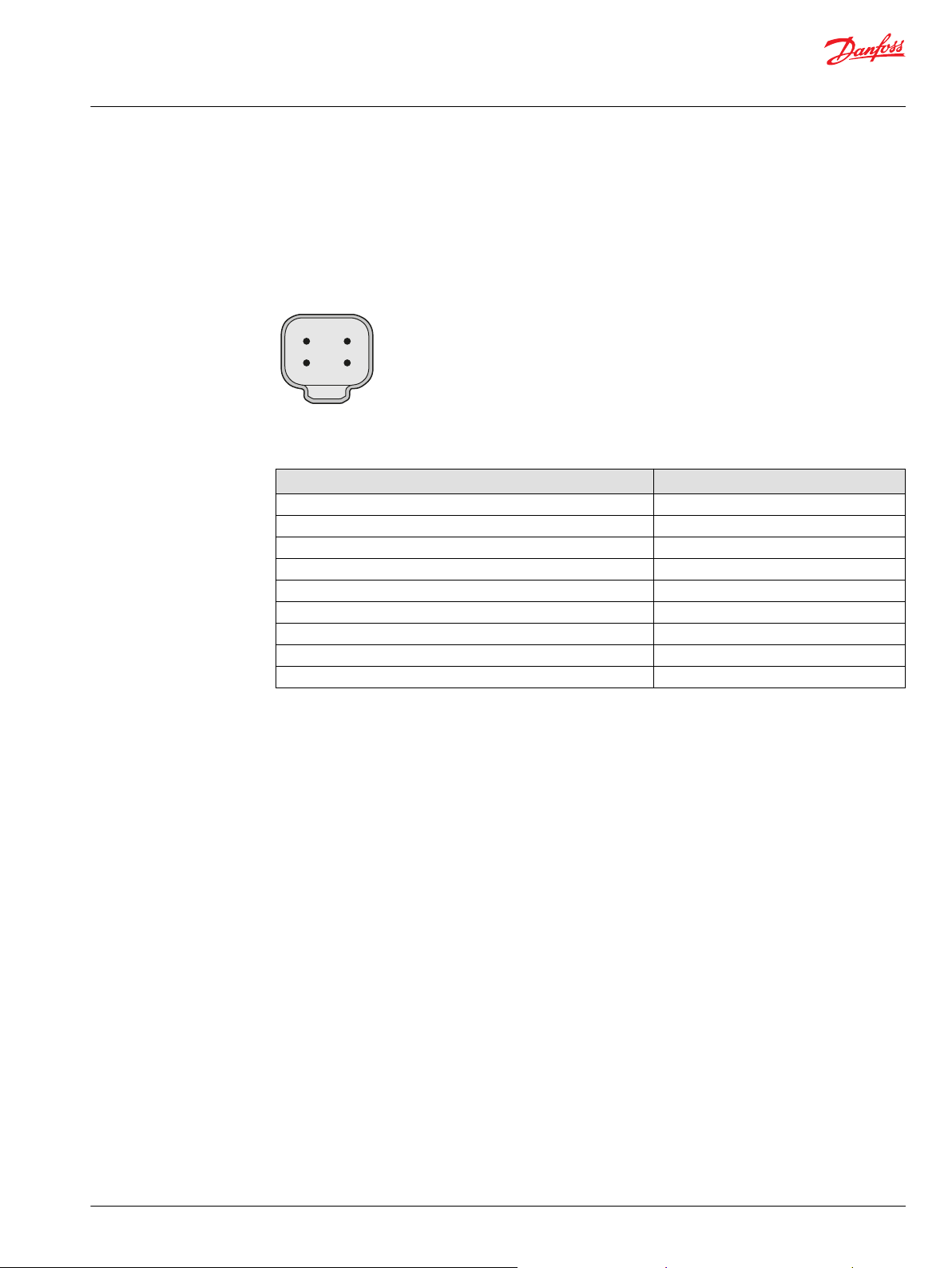

PVEA-CI and PVEO-CI connector

Accessory

*

Emergency

Solenoid is disabled.

stop

1 x 4 pin DEUTSCH

Description Code Number

Loop cable 100mm, DEUTSCH 4-PIN 11007531

Loop cable 175mm, DEUTSCH 4-PIN 11095622

Loop cable 350mm, DEUTSCH 4-PIN 11111916

Cable 4000mm, DEUTSCH 4-PIN 11095741

Seal kit for PVE-CI 11133165

Seal kit for PVM 157B3999

CG 150-2* (CAN gateway) 11153051

Termination Dummy 11007563

120 Ω terminator 11007561

Only to be used with PLUS+1® Service Tool version 7.1.10 or newer.

4-pin layout

1. CAN_High

2. CAN_Low

3. V

BAT

4. V

NEG

©

Danfoss | July 2018 BC00000337en-US0106 | 7

Page 8

Technical Information

PVEA-CI and PVEO-CI Series 6 Electro-hydraulic Actuators

ISOBUS/J1939 Communication Protocol

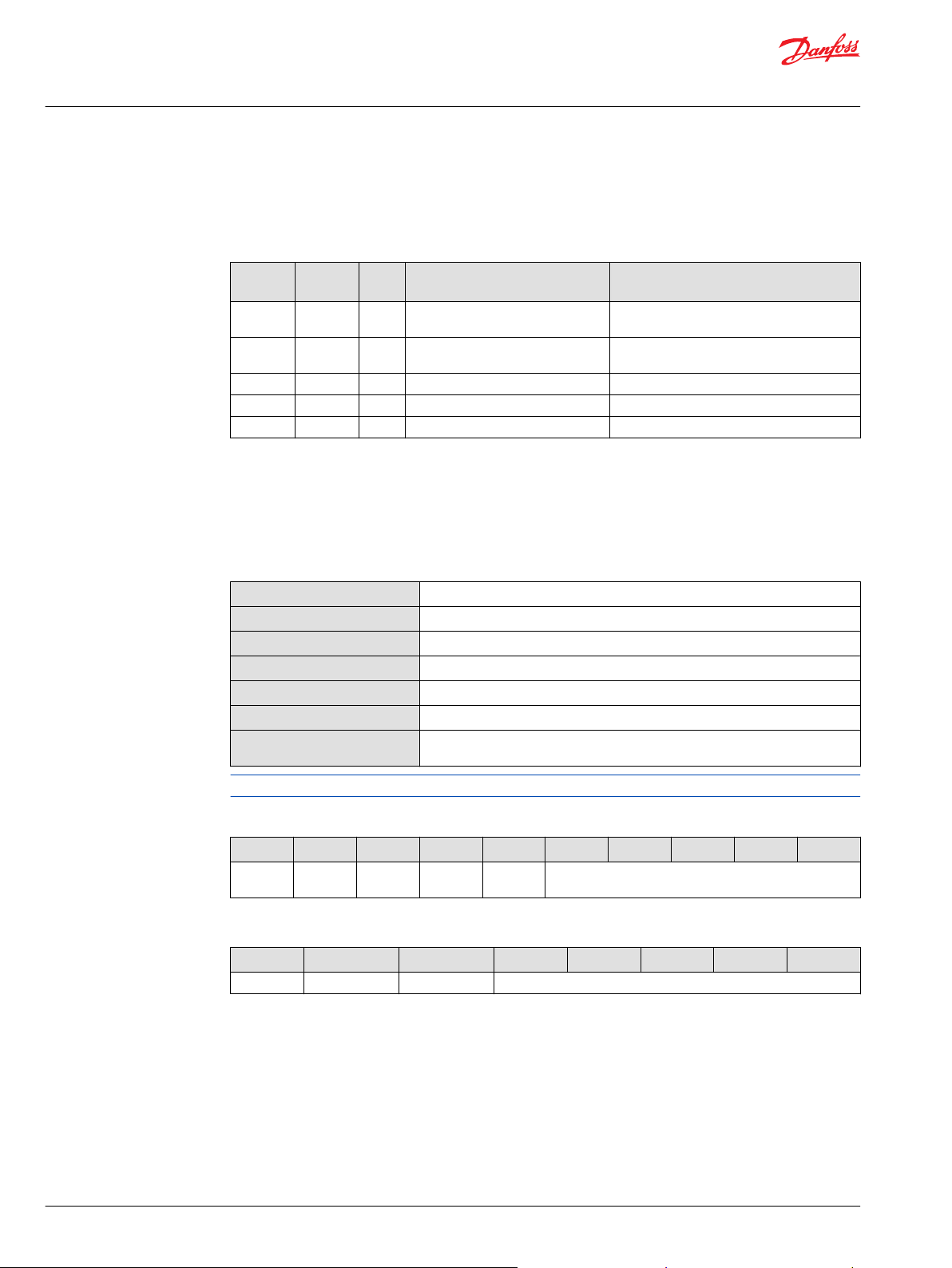

Parameter Group Number (PGN)

Parameter group number overview

PGN

(hex)

0x0CFE3x

yy

0x0CFE1x

yy

0x18FECA DM1 8 Active fault 1000 ms/event based

0x18FECB DM2 8 Request previous active faults On request

0x18EA00 DM3 3 Clear error log On request

*

x = Node ID (0x80-0x8F), yy = Source address

**

Auxiliary Valve Command (AVC)

The Auxiliary Valve Command ( AVC) is the command value sent from a master controller to control the

PVE. Message that provides control of the flow through the auxiliary valve number 0.

*

*

A time guarding error will occour if the PVE does not see a AVC within 250 ms.

Message

type

AVC 8 Auxillary Valve Command 250 ms fixed timeout

AVEF 8 Auxillary Valve Estimated Flow Transmission rate: 100 ms

DLC Translation Timing

**

Data length

Data page

PDU format

PDU specific

Default priority

Parameter group number

Transmission repetition rate

8 bytes

0

254

48

3

65072 (00FE3016)

100 ms between messages for each valve or when a parameter is required to

change state

The PVE will only accept messages with correct Node ID and ignore any AVC commands if invalid.

Frame format

Msg ID DLC Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7 Byte 8

CFE3xxx 8 PFC Reserved Valve

state

Reserved

AVC data

Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7 Byte 8

PFC Reserved (FF) Valve state Reserved (FF)

Port Flow

Command

Request port flow as a percentage of full flow. PFC = 0 is interpreted as a neutral

command.

(PFC)

Resolution: 0.4% per bit

Valid range: 0 → 100%; 0 → 250; 0x00 – 0xFA

Valve state

In blocked state the value in PFC is ignored.

8 | © Danfoss | July 2018 BC00000337en-US0106

Page 9

Technical Information

PVEA-CI and PVEO-CI Series 6 Electro-hydraulic Actuators

ISOBUS/J1939 Communication Protocol

• Bits 8 and 7: Fail safe mode – only blocked (0x00) supported

• Bits 6 and 5: Reserved

• Bits 4 to 1:

Block (neutral) = 0b0000

‒

Extend = 0b0001

‒

Retract = 0b0010

‒

Float = 0b0011

‒

Hand operation = 0b1010

‒

Emergency stop = 0b1110

‒

Auxiliary Valve Estimated Flow (AVEF)

The Auxiliary Valve Estimated Flow (AVEF) is the feedback sent from the PVE-CI to the master controller

telling the assumed flow/spool position. Message that provides the estimated flow of auxiliary valve

number 0.

Data length

Data page

PDU format

PDU specific

Default priority

Parameter group number

Transmission repetition rate

Frame format

Msg ID DLC Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7 Byte 8

CFE1xxx 8 Extend

port flow

AVEF data

Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7 Byte 8

EPF RPF Valve state Reserved

Extend Port Flow (EPF)

8 bytes

0

254

16

3

65040 (00FE1016)

100 ms (from PVE)

Retract

port flow

Estimated flow out of extend port as a percentage of full flow.

Valve

state

Reserved

• Resolution: 1% per bit

• Offset: 125; 0x7D

• Valid range: 0 → 100%; 125 → 225;

Retract Port Flow (RPF) Estimated flow out of retract port as a percentage of full flow.

• Resolution: 1% per bit

• Offset: 125; 0x7D

• Valid range: 0 → 100%; 125 → 225; 0x7D - 0xE10x7D - 0xE1

Valve state

©

Danfoss | July 2018 BC00000337en-US0106 | 9

In blocked state the value in PFC is ignored.

Page 10

Technical Information

PVEA-CI and PVEO-CI Series 6 Electro-hydraulic Actuators

ISOBUS/J1939 Communication Protocol

• 0x7D -Bits 8 and 7: Fail safe mode – only blocked (0x00) supported

• Bits 6 and 5: Reserved

• Bits 4 to 1:

Block (neutral) = 0b0000

‒

Extend = 0b0001

‒

Retract = 0b0010

‒

Float = 0b0011

‒

Hand operation = 0b1010

‒

Emergency stop = 0b1110

‒

No additional system related information will be transmitted in the AVEF.

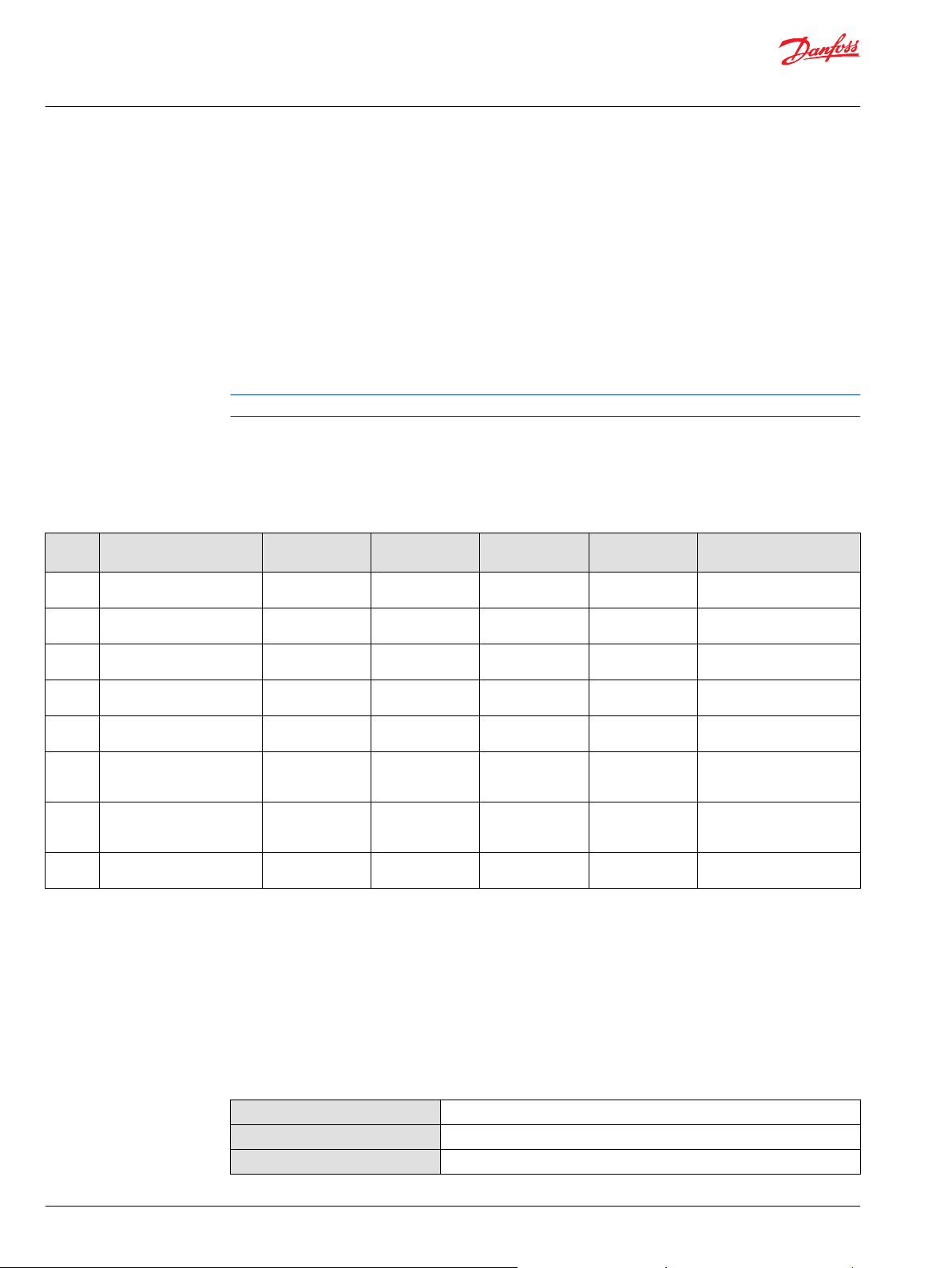

PVE-CI Diagnostics

The following error codes are available on the bus from the PVE-CI:

Error codes

Priority Error DTC (Diagnostic

1 Spool not at set point 0x878FEC External Critical Shutdown Two neutral set-points and

2 Spool cannot reach float 0x878FEE External Critical Shutdown Two neutral set-points and

3 Internal Error 0x8B8FFA Internal Severe Shutdown Two neutral set-points and

4 CAN bus Error 0x938FD7 External Warning Shutdown Two neutral set-points and

5 Temperature Error (120°C in

250 ms)

6 Power supply exceeds

specification (36 VDC for

2000 ms)

7 Power supply is below

specification (9 VDC for 2000

ms)

8 Time guarding error 0x938FE9 External Warning Shutdown Two neutral set-points and

trouble code)

0x908FF1 External Warning Shutdown Two neutral set-points and

0x030273 External Warning Shutdown Two neutral set-points and

0x040273 External Warning Shutdown Two neutral set-points and

Source of Error Lamp Status Regulation Recovery

spool in neutral

spool in neutral

spool in neutral

spool in neutral

spool in neutral

spool in neutral

spool in neutral

spool in neutral

CAN bus

Error

If there is a bus-off situation the LED will turn red and a DM1 message will be generated.

However the message cannot be send due to the bus-off and the application controller will

not receive a DM1 message in the event of this error. The PVEA-CI will contribute on the bus

again when the bus-off situation is gone.

Diagnostic Message 1 (DM1)

The active troubleshooting code Diagnostic Message 1 (DM1) is used by the PVE-CI to transmit an

active fault onto the CAN bus. The PVE-CI will broadcast one fault at a time on the CAN bus. The highest

error priority will be the one broadcasted.

PGN

Transmission timing rate

Maximum of faults

0x18CEFA

1000 ms or event based

127

10 | © Danfoss | July 2018 BC00000337en-US0106

Page 11

Technical Information

PVEA-CI and PVEO-CI Series 6 Electro-hydraulic Actuators

ISOBUS/J1939 Communication Protocol

The DM 1 messages will still be transmitted after the occurrence of the 127th fault, but the fault counter

will not increment.

DM1 frame format

Msg ID DLC Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7 Byte 8

18CEFAyy

*

yy = Source address.

*

8 Lamp

status

Flash

status

Lamp status Used by controller – not related to the LED.

• No fault (default state): 0x00

• Warning type faults–Amber lamp: 0x04

• Critical or severe type faults–Red lamp: 0x10

Flash status Used by controller – not related to LED. Flashing: 0xFF

Fault information Occurrence

counter

Reserved

Fault information

• Bits 24 to 6: SPN of active fault

• Bits 5 to 1: FMI if active fault

Occurrence counter Number of times the active fault has appear previously.

Diagnostic Message 2 (DM2)

The Previous active trouble code Diagnostic Message 2 (DM2) is used by the controller to command the

PVE-CI to transmit all previously active faults.

PGN

Transmission timing rate

Maximum of faults

0x18CEFB

On request

127

DM2 frame format

Msg ID DLC Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7 Byte 8

18CEFCBxx 8 Lamp

status

Flash

status

Fault information Occurrence

counter

Reserved

Lamp status Used by controller – not related to the LED.

• Info or Warning type faults–Amber lamp: 0x04

• Critical or severe type faults–Red lamp: 0x10

Flash status Used by controller – not related to LED. Flashing: 0xFF

Fault information

• Bits 24 to 6: SPN of active fault

• Bits 5 to 1: FMI if active fault

Occurrence counter Number of times the active fault has appear previously.

©

Danfoss | July 2018 BC00000337en-US0106 | 11

Page 12

Technical Information

PVEA-CI and PVEO-CI Series 6 Electro-hydraulic Actuators

ISOBUS/J1939 Communication Protocol

Broadcast Announce Message (BAM)

The frame format will be in Broadcast Announce Message (BAM) if more than one single fault occurs.

The BAM message size depends on the number of previously active faults.

BAM frame format

BAM Msg ID DLC Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7 Byte 8

1CECFFxx 8 BAM No. of bytes No. of

DT1 1CEBFFxx 8 Sequence Lamp

status

DT2 1CEBFFxx 8 Sequence Fault 2 cont. Fault 3

DT3 1CEBFFxx 8 Sequence Fault 4 BAM continued

Number of packets How many messages are sent in the complete BAM.

Sequence Identification number of the BAM message in the BAM sequence.

Lamp status Used by controller – not related to the LED.

• Info or Warning type faults–Amber lamp: 0x04

• Critical or severe type faults–Red lamp: 0x10

packets

Reserved DM2 PGN (0x00FECB)

Reserved Fault 1 Fault 2

Changing Node ID

Occurrence counter Number of times the active fault has appear previously.

Fault information of the Fault 1

and 3

Fault information of the Fault 2

• Bits 24 to 6: SPN of active fault

• Bits 5 to 1: FMI if active fault

• Bits 16 to 6: SPN of active fault

• Bits 5 to 1: FMI if active fault

Diagnostic Message 3 (DM3)

The Clear previous active trouble code name Diagnostic Message 3 (DM3) is used by the controller to

clear the error log within the PVE-CI.

PGN

Transmission timing rate

DM3 frame format

Msg ID DLC Byte 1 Byte 2 Byte 3

18EAxxxx 3 0xCC 0xFE 0x00

The Node ID parameter can be programmed by using:

0x18EA00

On request

12 | © Danfoss | July 2018 BC00000337en-US0106

Page 13

Technical Information

PVEA-CI and PVEO-CI Series 6 Electro-hydraulic Actuators

ISOBUS/J1939 Communication Protocol

The Service Tool.

•

Commanded address according to ISOBUS/J1939.

•

Commanded address according to ISOBUS/J1939

Frame format

Msg ID DLC Byte 1 Byte 2 Byte 3 Byte 4 Byte 5

0x1BC7888x 5 0x04 0x2E 0x10 0x01 Node ID

Node ID data

Byte 1 Fixed

Byte 2 Fixed

Byte 3 Fixed

Byte 4 Fixed

Byte 5 Node ID Range: 0x80 to 0x8F

Example of changing Node ID from 0x83 to 0x86

Msg ID DLC Byte 1 Byte 2 Byte 3 Byte 4 Byte 5

Application controller

0x1BC78883 5 0x04 0x2E 0x10 0x01 0x86

Example of response from the PVE when changing the Node ID

Msg ID DLC Byte 1 Byte 2 Byte 3 Byte 4

Positive response (same for all nodes)

0x1BC408F1 4 0x03 0x6E 0x10 0x01

Negative response

0x1BC408F1 4 0x03 0x7F 0x2E 0x31

PVE-CI Address claim

Before a device can participate in sending CAN messages on a network, claim its address. The PVE-CI

transmits its device address together with the device name to the network at boot-up.

The Address Claim message contains the following information

Msg ID DLC Byte 1 Byte 2 Byte 3 Byte 4

0x18EEFFyy*8 Identity

*

yy is the Source address = Node ID (80-8F)

Byte 5 Byte 6 Byte 7 Byte 8

Function

Instance (5

bits)

NAME

ECU Instance

(3 bits)

Number (LSB)

NAME

Function (8

bits)

Identity

Number (2nd

byte)

Vehicle

System (7

bits)

Manufacturer

Code (3 LSB)

Reserved (1

bits)

Arbitrary

Adress

Capable (1

bit)

Identity

Number (5

MSB)

Industry

Group (3

bits)

Manufacturer

Code (MSB)

Vehicle

System

Instance (4

bits)

©

Danfoss | July 2018 BC00000337en-US0106 | 13

Page 14

Technical Information

PVEA-CI and PVEO-CI Series 6 Electro-hydraulic Actuators

ISOBUS/J1939 Communication Protocol

Address claim request

The Address claim message can be requested by the master using a request PGN

0x00EE00

Transmission rate: On request.

Frame Format for Request PGN message

Msg ID DLC Byte 1 Byte 2 Byte 3

0x18EAxxxx (Request

PGN)

Response: On sending the address claim request the PVE-CI sends address claim message.

Both specific and global requests for address claim are supported.

Commanded address (ISOBUS/J1939)

Commanded address is used to Change the Node ID of the valve by using the “Name field” broadcasted

in the address claim message. This commanded address request is sent via a BAM once the commanded

address is matched and the Node ID is valid. This will make the valve reset and announce itself with the

new Node ID.

Only a sub-set of J1939-81 is supported.

The three supported capabilities according to J1939-81, Appendix B are:

Support Commanded Address

•

Address Configuration Capability

•

Name Retained Across Power-up Cycles

•

3 Requested PGN (LSB) Requested PGN (MSB) 0x00

0x00 0xEE

Frame format

PGN DLC Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7 Byte 8

0xFED8 NAME Node ID

Node ID data

DLC

Byte 1 Name (see address claim)

Byte 2

Byte 3

Byte 4

Byte 5

Byte 6

Byte 7

Byte 8 Node ID Range: 0x80 to 0x8F

Example of changing Node ID in the PVEA-CI with name “01 00 20 07 08 FF 02 20” to Node ID 0x81:

Msg ID DLC Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7 Byte 8

BAM 0x1CECFFxx 8 0x20 0x09 0x00 0x02 0xFF 0xD8 0xFE 0x00

BAM No of

bytes

DT1 0x1CEBFFxx 8 0x01 0x01 0x00 0x20 0x07 0x08 0xFF 0x02

Seq. NAME

No of

bytes

No of

packets

Reserved PGN (0x00FED8)

14 | © Danfoss | July 2018 BC00000337en-US0106

Page 15

Technical Information

PVEA-CI and PVEO-CI Series 6 Electro-hydraulic Actuators

ISOBUS/J1939 Communication Protocol

Msg ID DLC Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7 Byte 8

DT2 0x1CEBFFxx 8 0x02 0x20 0x81 0xFF 0xFF 0xFF 0xFF 0xFF

Seq NAME New

ISOBUS/J1939 error codes

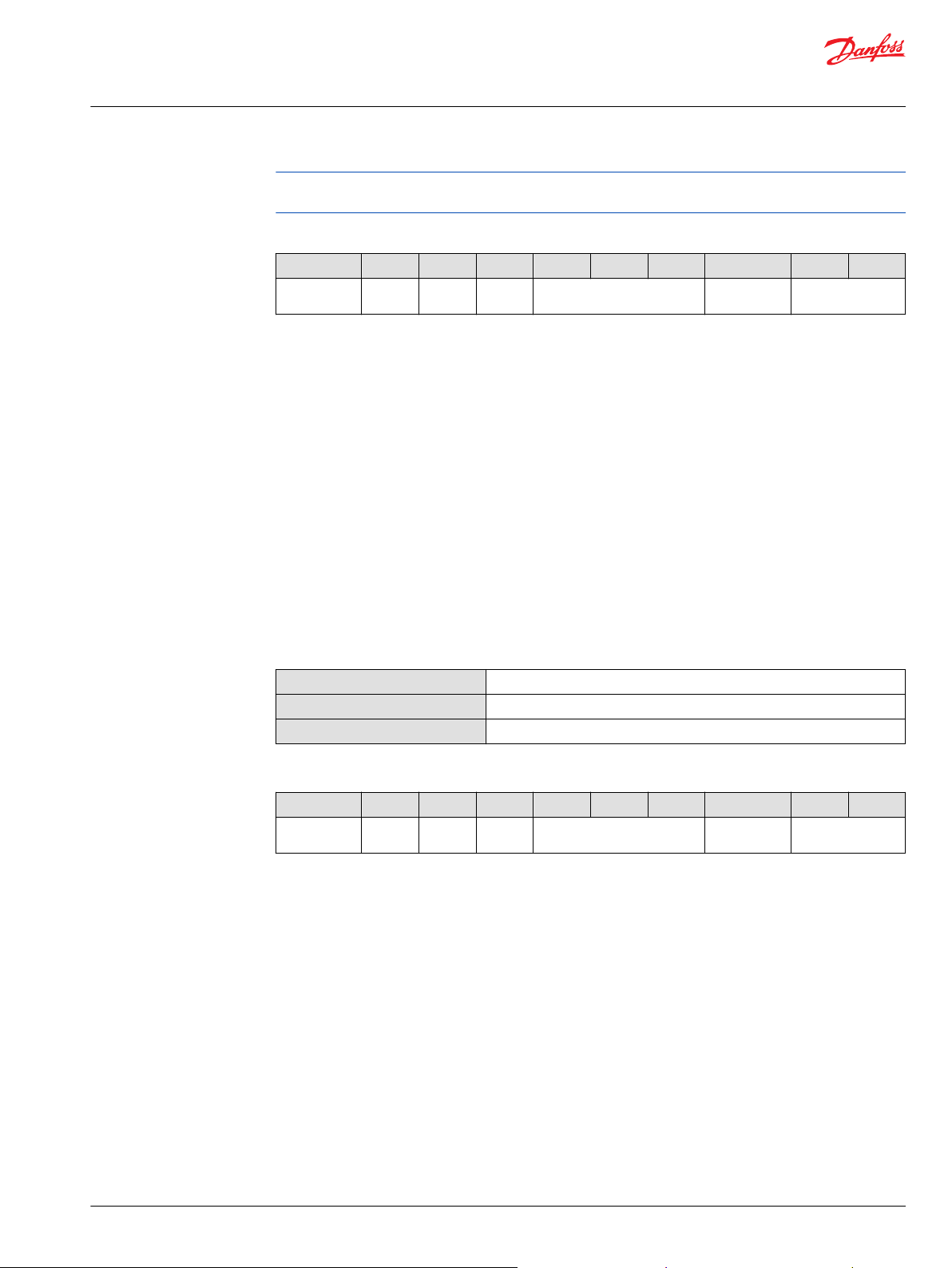

Error codes

Priority Error J1939 DTC Source of

1 Spool not at set point 0x878FEC External Critical Active

2 Spool cannot reach float 0x878FEE External Critical Active

3 Internal Error 0x8B8FFA Internal Severe Active

4

5 Temperature Error 0x908FF1 External Warning Shut Down

6 Power supply exceeds specification 0x030273 External Warning Shut Down

7 Power supply is below specification 0x040273 External Warning Shut Down

8 Time guarding error 0x938FE9 External Warning Active

CAN bus Error

applicati

on Node

ID (0x81)

Fault

0x938FD7 External Warning Active

Lamp

Status

Regulation

©

Danfoss | July 2018 BC00000337en-US0106 | 15

Page 16

Technical Information

PVEA-CI and PVEO-CI Series 6 Electro-hydraulic Actuators

CANopen Communication Protocol

The CANopen interface version of PVE-CI is compliant with the following CANopen standards and

includes the EDS file with the object dictionary listed below. The EDS file can be found on

www.powersolutions.danfoss.com. At the end of this document you will find use cases showing the most

common features.

•

Use case 1 - Boot-up to operation mode on page 37

•

Use case 2 - Operation Mode – Error – Operation Mode on page 37

•

Use case 3 - Change Node ID globally on page 38

•

Use case 4 - Change Node ID for specific Node on page 39

The standard supported are:

•

CiA 301 version 4.2.0

•

CiA 305 version 1.5.2

•

CiA 408 version 3.0.0

EDS file object dictionary

1000 Device type

1001 Error register

1003 Predefined error field

1005 COB-ID SYNC

100A Manufacturer software version

1010 Store parameters

1011 Restore default parameters

1014 COB-ID EMCY

1017 Producer heartbeat time

1018 Identity object

1028 Emergency consumer

1400 RPDO parameter

1600 RPDO mapping

1800 TPDO parameter

1A00 TPDO – profile specific mapping 2

2001 Error: supply voltage too high

2002 Error: supply voltage too low

200F Error: temperature too high

2019 Error: CAN error

201D Error: spool not at set-point/float not reached

2023 Error: set-point timeout

2040 Error: internal error

3300 Manufacturer specific set-point - 8 bit

3301 Manufacturer specific actual value - 8 bit

3302 Manufacturer specific actual inverted value - 8 bit

3303 Manufacturer specific set-point - 16 bit

3304 Manufacturer specific actual value - 16 bit

6040 Device control word

6041 Device status word

6042 Device mode

6052 Device serial number

6053 Device description

605F Device capability

16 | © Danfoss | July 2018 BC00000337en-US0106

Page 17

Device state machine Communication state machine

Reset

Application

DEVICE_MODE_

ACTIVE

NOT_READY

INIT

DISABLED

HOLD

FAULT_REACTION

FAULT

FAULT_HOLD

Reset

communication

Initialisation

Initialising

Pre-Operational

Operational

Stopped

Power on

D0

C1

C15

C16

C9

C10

C12

C13

C14

C11

C2

C3

C4

C5

C8

C6

C7

D8

D8

D8

D8

D10

D11

D12

D1

D2

D3

D4

D7

D6

D5 D9

P301 813

Not used

Not used

Not used

Technical Information

PVEA-CI and PVEO-CI Series 6 Electro-hydraulic Actuators

CANopen Communication Protocol

EDS file object dictionary (continued)

6300 vpoc_set_point

6301 vpoc_actual_value

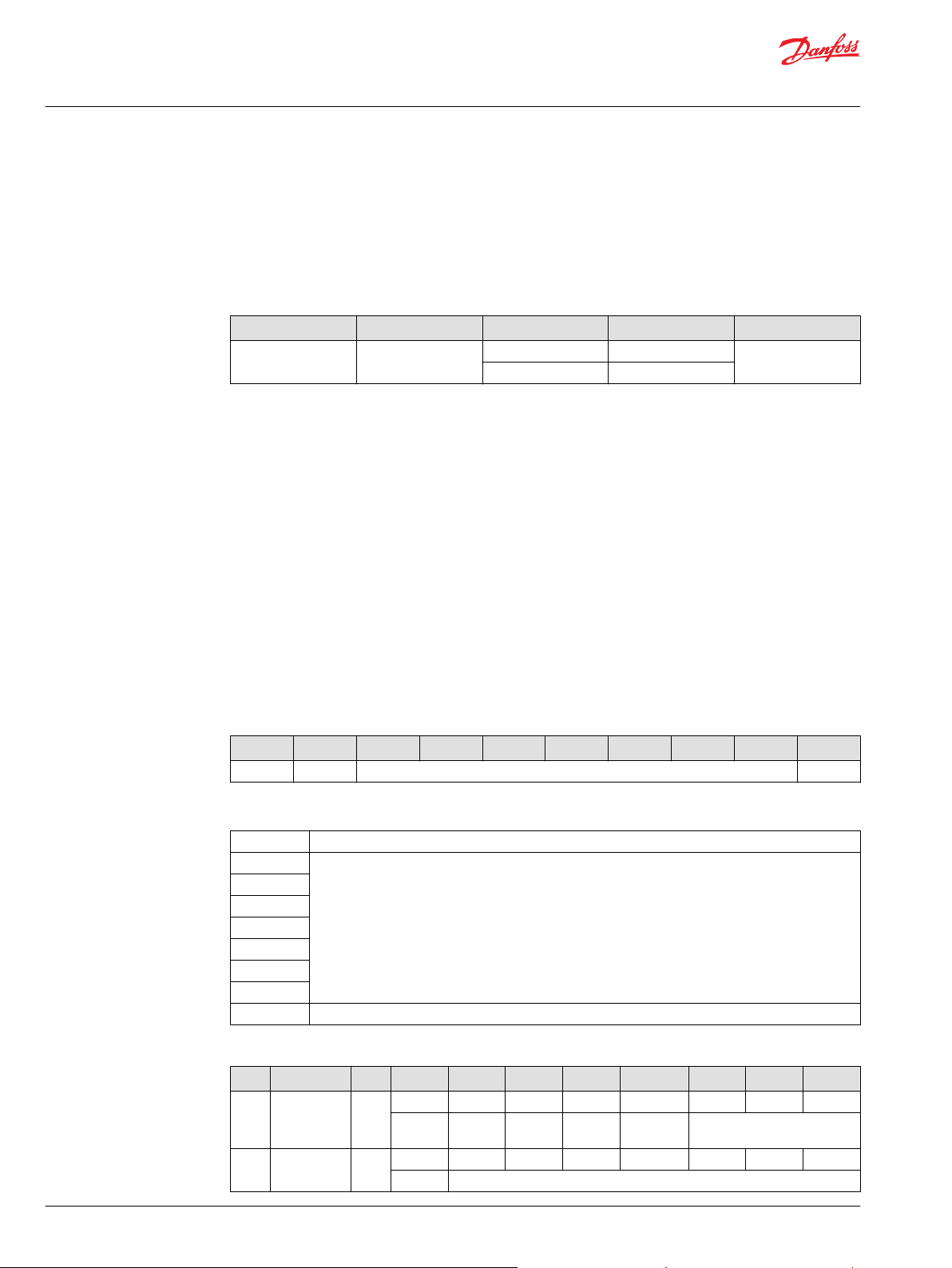

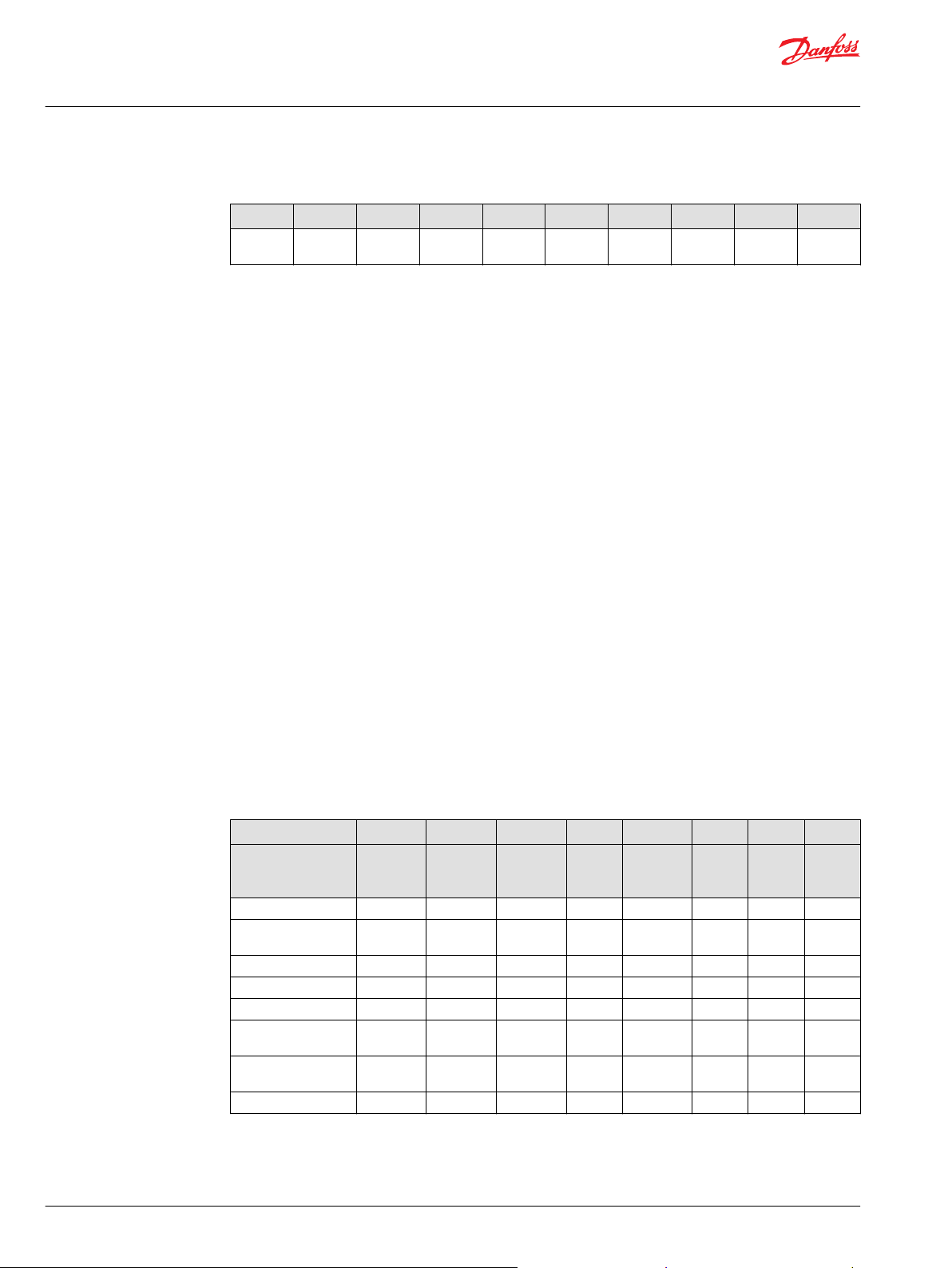

NMT operations

NMT (communication state machine) operations can drive the device state machine.

The next diagram shows the relationship between the communication state machine and the device

state machine.

Device State Machine and Communication State Machine

Following table summarizes the impact of the Communication State Machine on Device State Machine.

Action in CSM Transition Impact on DSM

Reset Communication C14, C13, C12 Device changes state to fault hold

State change from Preoperational to

©

Danfoss | July 2018 BC00000337en-US0106 | 17

stopped

State change from operational to

Stopped

Reset Application C9, C10, C11 Device goes to initialization state

The PVE-CI is working according to the device state.

Following table shows the PVE-CI behavior depending on the state

State vs. Function Set-Point Input Transmit

NOT_READY Not Applicable

INIT X YES NO NO NO

DISABLED X YES NO NO NO

HOLD X YES NO NO NO

DEVICE_MODE_ACTIVE Full operational YES YES YES YES

DEVICE_MODE_ACTIVE Hand operation YES NO NO NO

C5 Device changes state to fault reaction

C8 Device changes state to fault reaction

TPDO

Spool

Monitoring

Spool

Control

Set-Point Time

guarding

Page 18

Technical Information

PVEA-CI and PVEO-CI Series 6 Electro-hydraulic Actuators

CANopen Communication Protocol

State vs. Function Set-Point Input Transmit

TPDO

FAULT Not Applicable

FAULT_HOLD X YES NO NO NO

FAULT_REACTION Not Applicable

Spool

Monitoring

Spool

Control

Set-Point Time

guarding

The PVE-CI can be initialized by using NMT services, started monitored, reset or stopped. The PVE-CI valve

supports following NMT states:

Initialization PVE-CI implements only “Initializing Sub-State”. After initialization of communication

parameters the state will be pre-operational.

Pre-Operational In NMT state = communication via SDO’s are possible.

Operational All the communication objects are active.

Stopped All the communication objects are stopped except heartbeat.

Following table shows the message format for NMT services .

COB-D DLC Byte 0 Byte 1

NMT Command 0x000 2 NMT Command Destination Node ID

If a global message needs to be sent then use 0x00 as destination Node ID

The NMT service has direct impact on the device state machine (see Device State Machine and

Communication State Machine on page 17).

Boot-up protocol

NMT services supported

Upon power-up the PVED will log onto the CAN bus network by broadcasting the nodeID it has been

given upon parametrization.

Frame format

Msg ID DLC Byte 0

0x700 + nodeID 1 NMT State

0x00

Start remote Node

The NMT master uses this service to start the remote node. The new NMT state is operational.

Start remote Node

COB-ID DLC Byte 0 Byte 1

0x000 2 NMT Command Specifier 0x01

*

*

All = 0, 1 Slave = COB-ID

Slave Node ID

This service is unconfirmed. Here after the PVE-CI goes in operational mode and accepts the Rx PDO’s.

Stop remote device

The NMT master uses this service to stop the remote device. Once the device is stopped it does not

accept the Rx PDO’s.

18 | © Danfoss | July 2018 BC00000337en-US0106

Page 19

Technical Information

PVEA-CI and PVEO-CI Series 6 Electro-hydraulic Actuators

CANopen Communication Protocol

Stop remote Node

COB-ID DLC Byte 0 Byte 1

0x000 2 NMT Command Specifier Slave Node ID

This service is unconfirmed.

Enter pre-operational

The NMT master uses this service to enter pre-operational state.

Enter pre-operational

COB-ID DLC Byte 0 Byte 1

0x000 2 NMT Command Specifier Slave Node ID

Reset application

The NMT master uses this service to perform a software reset.

0x02

0x80

State feedback values

Reset application

COB-ID DLC Byte 0 Byte 1

0x000 2 NMT Command Specifier Slave Node ID

0x81

Reset communication

The NMT master uses this service to reset the communication state machine. The entire CANopen library

is reset and reinitialized on receiving reset communication command.

Reset communication

COB-ID DLC Byte 0 Byte 1

0x000 2 NMT Command specifier Slave Node ID

0x82

Identifier example - frame

COB-ID DLC Byte 0 Byte 1 Byte 2 Byte 3

0x180 + Node ID 4 Current state 0x00 Spool position*Spool position

*

spool position value = ±16384 (float=32767)

*

Identifier example - INIT state

COB-ID DLC Byte 0 Byte 1 Byte 2 Byte 3

0x180 + Node ID 4 0x08 0x00 Spool position Spool position

Identifier example - Disabled

COB-ID DLC Byte 0 Byte 1 Byte 2 Byte 3

0x180 + Node ID 4 0x09 0x00 Spool position Spool position

©

Danfoss | July 2018 BC00000337en-US0106 | 19

Page 20

Technical Information

PVEA-CI and PVEO-CI Series 6 Electro-hydraulic Actuators

CANopen Communication Protocol

Identifier example – Hold

COB-ID DLC Byte 0 Byte 1 Byte 2 Byte 3

0x180 + Node ID 4 0x0B 0x00 Spool position Spool position

Identifier Example - Active

COB-ID DLC Byte 0 Byte 1 Byte 2 Byte 3

0x180 + Node ID 4 0x0F 0x00 Spool position Spool position

Identifier example – Fault hold

COB-ID DLC Byte 0 Byte 1 Byte 2 Byte 3

0x180 + Node ID 4 0x03 0x00 Spool position Spool position

Device control word

The device takes following transitions on writing device control word.

Transition Number

D2 INIT to DISABLED Activate DISABLED xxx1

D3 DISABLED TO HOLD Activate HOLD xx11

D4 HOLD TO ACTIVE Activate ACTIVE x111

D5 ACTIVE TO HOLD Deactivate Active x0xx

D6 HOLD TO DISABLED Deactivate Hold x00x

D7 DISABLED TO INIT Deactivate Disabled x000

D11 FAULT HOLD TO HOLD Reset Fault Hold 0011 → 1011

*

See Device State Machine and Communication State Machine on page 17

**

R: Status word ready (bit 3), M: Status word device mode active enable (Bit 2), H: Status word Hold activated (Bit 2),

Status word disabled (Bit 0)

*

Transition Device Control Command RMHD** (x = don’t care)

LSS slave

The PVE-CI Series CiA 305 3.0.0 support the LSS slave functionality.

All LSS commands to be sent by Standard COB-ID: 0x7E5. Will respond with the standard feedback

message COB-ID: 0x7E4

PVE-CI switch state global

Only one CANopen slave can be connected to the bus while changing the Node ID globally.

This command sets the device to LSS configuration mode. This is unconfirmed service.

LSS Cmd

COB-D DLC Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

0x7E5 8 CS Mode Reserved

0x04 XX 0x00 0x00 0x00 0x00 0x00 0x00

20 | © Danfoss | July 2018 BC00000337en-US0106

Page 21

Technical Information

PVEA-CI and PVEO-CI Series 6 Electro-hydraulic Actuators

CANopen Communication Protocol

LSS modes

Value Mode description

0x00 Switch to LSS wait state

0x01 Switch to LSS configuration state

0x02 Reserved

PVE-CI switch state selective

LSS master device switches the LSS slave device into LSS configuration state, whose LSS address is equal

to the one that is specified in the command.

LSS Cmd

COB-ID DLC Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

0x7E5 8 CS Vendor ID Reserved

0x40 LSB XX XX MSB 0x00 0x00 0x00

LSS Cmd

COB-ID DLC Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

0x7E5 8 CS Product Code Reserved

0x41 LSB XX XX MSB 0x00 0x00 0x00

LSS Cmd

COB-ID DLC Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

0x7E5 8 CS Revision Number Reserved

0x42 LSB XX XX MSB 0x00 0x00 0x00

LSS Cmd

COB-ID DLC Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

0x7E5 8 CS Serial Number Reserved

0x43 LSB XX XX MSB 0x00 0x00 0x00

The device will respond with the message below when it has entered configuration mode.

Response

COB-ID DLC Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

0x7E4 8 CS Reserved

0x44 0x00 0x00 0x00 0x00 0x00 0x00 0x00

Follow the below sequence of LSS commands to send a PVE-CI into configuration mode (See Use case 4 -

Change Node ID for specific Node on page 39 for an example)

COB-ID DLC CS and Data Comments

0x7E5 8 40 19 00 00 01 00 00 00 LSS Address – Vendor ID [OD Index 0x1018

0x7E5 8 41 00 00 36 53 00 00 00 LSS Address – Product Code [OD Index

0x7E5 8 42 30 01 00 00 00 00 00 LSS Address – Revision Number [OD Index

Sub index 0x01]

0x1018 Sub index 0x02]

0x1018 Sub index 0x03]

©

Danfoss | July 2018 BC00000337en-US0106 | 21

Page 22

Technical Information

PVEA-CI and PVEO-CI Series 6 Electro-hydraulic Actuators

CANopen Communication Protocol

COB-ID DLC CS and Data Comments

0x7E5 8 43 xx xx xx xx 00 00 00 LSS Address – Serial Number [OD Index

0x7E4 8 44 00 00 00 00 00 00 00 Response [Device has entered into

Configure Node ID

LSS slave is configured to a new Node ID provided in the command below. The PVE-CI confirms the

success or failure of the service. (Configure new Node ID Use case 3 - Change Node ID globally on page

38).

LSS Cmd

COB-ID DLC Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

0x7E5 8 CS Node ID Reserved

0x11 XX 0x00 0x00 0x00 0x00 0x00 0x00

Node ID: Valid Node ID in range 0x01 – 0x7F.

Response to service:

0x1018 Sub index 0x04]

configuration mode]

Response

COB-ID DLC Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

0x7E4 8 CS Error

Code

0x11 XX 0x00 0x00 0x00 0x00 0x00 0x00

Error Code Description

0x00 No Error

0x01 Node ID out of range

0x02 – 0xFF Reserved

Reserved

Configure bit timing parameters

LSS slave is configured to the new bit rate provided in the command below. The PVE-CI confirms the

success or failure of the service.

LSS Cmd

COB-ID DLC Byte 0 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

0x7E5 8 CS Table

Selector

0x13 XX 0x00 0x00 0x00 0x00 0x00 0x00

Table

Index

Reserved

For bit timing Table Selector ‘0x00’ should be used. The PVE-CI supports following bit rates:

Table Index Bit Rate

2 500 kbps

3 250 kbps

4 125 kbps

Response to the service:

22 | © Danfoss | July 2018 BC00000337en-US0106

Page 23

Technical Information

PVEA-CI and PVEO-CI Series 6 Electro-hydraulic Actuators

CANopen Communication Protocol

Response

COB-ID DLC Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

0x7E4 8 CS Error

Code

0x13 XX 0x00 0x00 0x00 0x00 0x00 0x00

Error Code Meaning

0x00 No Error

0x01 Bit rate not supported

0x02 – 0xFF Reserved

Activate bit timing parameters

This service activates simultaneously the bit rate at the LSS communication interface of all CANopen

devices in the network.

LSS Cmd

COB-ID DLC Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

0x7E5 8 CS Switch Delay Reserved

0x15 LSB MSB 0x00 0x00 0x00 0x00 0x00

Reserved

Each LSS slave device copies the pending bit rate to the active bit rate value, after ‘Switch Delay’ (given in

ms, in multiples of 1 ms) has elapsed. Therefore in response to this service device changes its bit rate after

‘Switch Delay’.

PVE-CI store configurations

LSS master device requests the LSS slave device to store the configured local layer settings to EEPROM

with this service. Configured local layer settings include configured new Node ID and new Bit Rate. The

PVE-CI confirms the success or failure of the service.

LSS Cmd

COB-ID DLC Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

0x7E5 8 CS Reserved

0x17 0x00 0x00 0x00 0x00 0x00 0x00 0x00

Response to service:

Response

COB-ID DLC Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

0x7E4 8 CS Error

Code

0x17 XX 0x00 0x00 0x00 0x00 0x00 0x00

Error Code Meaning

0x00 No Error

0x01 Storage configuration not supported

0x02 Storage media access error

0x03 – 0xFF Reserved

Reserved

©

Danfoss | July 2018 BC00000337en-US0106 | 23

Page 24

Technical Information

PVEA-CI and PVEO-CI Series 6 Electro-hydraulic Actuators

CANopen Communication Protocol

PVE-CI identify non-configured remote slave

LSS slave devices to identify themselves by means of the 'LSS identify non-configured slave' service, who

got stuck in NMT Initialization state and who have no active node-ID.

The service is unconfirmed.

LSS Cmd

COB-ID DLC Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

0x7E5 8 CS Reserved

0x4C 0x00 0x00 0x00 0x00 0x00 0x00 0x00

Identify non-configured slave

LSS slave device indicates that it is an LSS slave device that got stuck in NMT Initialization state and no

active node-ID. This service is executed in case a LSS identify non-configured remote slave service was

initiated by the LSS master device. The service is unconfirmed.

Response to Identify Non-Configured Remote Slave service:

Response

COB-ID DLC Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

0x7E4 8 CS Reserved

0x50 0x00 0x00 0x00 0x00 0x00 0x00 0x00

Fast scan

By means of this service the LSS master requests all un-configured LSS slaves to identify themselves.

LSS Cmd

COB-ID DLC Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

0x7E5 8 CS ID Number Bit Chek LSS Sub LSS Next

0x51 XX XX XX XX XX XX XX

For information on bit fields refer to ‘CiA CANopen: Layer setting service and protocol’.

Specified sequence of commands for fast scan

CAN ID DLC CS and Data Comments

0x7E5 8 51 19 00 00 01 00 00 01 Fast scan Vendor ID [OD Index 0x1018 Sub index 0x01]

0x7E5 8 51 00 00 36 53 00 01 02 Fast scan Product Code [OD Index 0x1018 Sub index

0x7E5 8 51 30 01 00 00 00 02 03 Fast scan Revision Number [OD Index 0x1018 Sub index

0x7E5 8 51 xx xx xx xx 00 03 04 Fast scan Serial Number [OD Index 0x1018 Sub index

0x02]

0x03]

0x04]

State behavior

Following table specifies the service supported for the various LSS states.

LSS Service LSS Waiting LSS Configuration

Switch State Global Yes Yes

Switch State Selective Yes No

Configure Node ID No Yes

Configure Bit Timing Parameter No Yes

24 | © Danfoss | July 2018 BC00000337en-US0106

Page 25

Technical Information

PVEA-CI and PVEO-CI Series 6 Electro-hydraulic Actuators

CANopen Communication Protocol

LSS Service LSS Waiting LSS Configuration

Activate Bit Timing Parameter No Yes

Store Configuration No Yes

Identify Non-Configured Remote Slave No Yes

Identify Non-Configured Slave No Yes

Fast Scan No Yes

PVE-CI heartbeat protocol

PVE-CI supports the heartbeat protocol for error control services. The heartbeat mechanism can be

established by configuring the PVE-CI as a heartbeat producer, and the object dictionary entry Producer

heartbeat time.

The value denotes the cyclic time at which the heartbeat is produced in ms.

•

If the value of the object dictionary entry is 0, the heartbeat message is not sent.

•

If the value is different from zero then the heartbeat message is transmitted cyclically.

The resolution of the heartbeat message is 10 ms and is configured at 1000 ms.

Heartbeat period

COB-ID DLC Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

0x600+Node ID 8 0x2B 0x17 0x10 0x00 0x64 0x00 0x00 0x00

Heartbeat message

COB-ID DLC Byte 0

0x700 + Node ID 1 State

Boot-up message is transmitted cyclically with communication state in byte 0. Following are the possible

values of state in the boot-up message.

Boot-up message state values

Boot-up Stopped Operational Preoperational

0x00 0x04 0x05 0x7F

Fault handling

On occurrence of a fault PVE-CI emits an EMCY message. The emergency message contains information

on error code, error register and occurrence counters.

EMCY message

COB-ID DLC Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

0x80 +

Node ID

8 Error

code

(LSB)

Error

code

(MSB)

Error

register

Error

occurrenc

e counter

0x00 0x00 0x00 0x00

The fault is then written to Error history (Predefined error field OD entry: 0x1003). The most recent index

is written to first index. The PVE-CI maintains 8 entries of error history.

A Reset EMCY message is transmitted on deactivation of all the errors in the system. The PVE-CI transmits

also a reset of EMCY during Boot-up.

©

Danfoss | July 2018 BC00000337en-US0106 | 25

Page 26

Technical Information

PVEA-CI and PVEO-CI Series 6 Electro-hydraulic Actuators

CANopen Communication Protocol

Reset EMCY message

COB-ID DLC Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

0x80 +

Node ID

The PVE-CI enters FAULT HOLD MODE on activation of active fault. To leave FAULT HOLD MODE, reset

fault command should be given (see Use case 2 - Operation Mode – Error – Operation Mode on page 37).

The device leaves FAULT HOLD only if there is no error in the system

PDO mapping procedure

Following is a recommended procedure for the mapping of a PDO:

1. Disable the PDO by setting the valid bit to 1 of sub index 1, RPDO parameter (OD 0x1400)

2. Disable RPDO mapping by setting the sub index (number of entries) 0x00 to 00

3. Set the sub index (number of entries) to number of intended mapped objects

4. Modify the mapping by changing the values of corresponding indexes

5. Create the RPDO by setting valid bit to 0 of sub index 1, RPDO parameter (OD 0x1400)

8 0x00 0x00 0x00 0x00 0x00 0x00 0x00 0x00

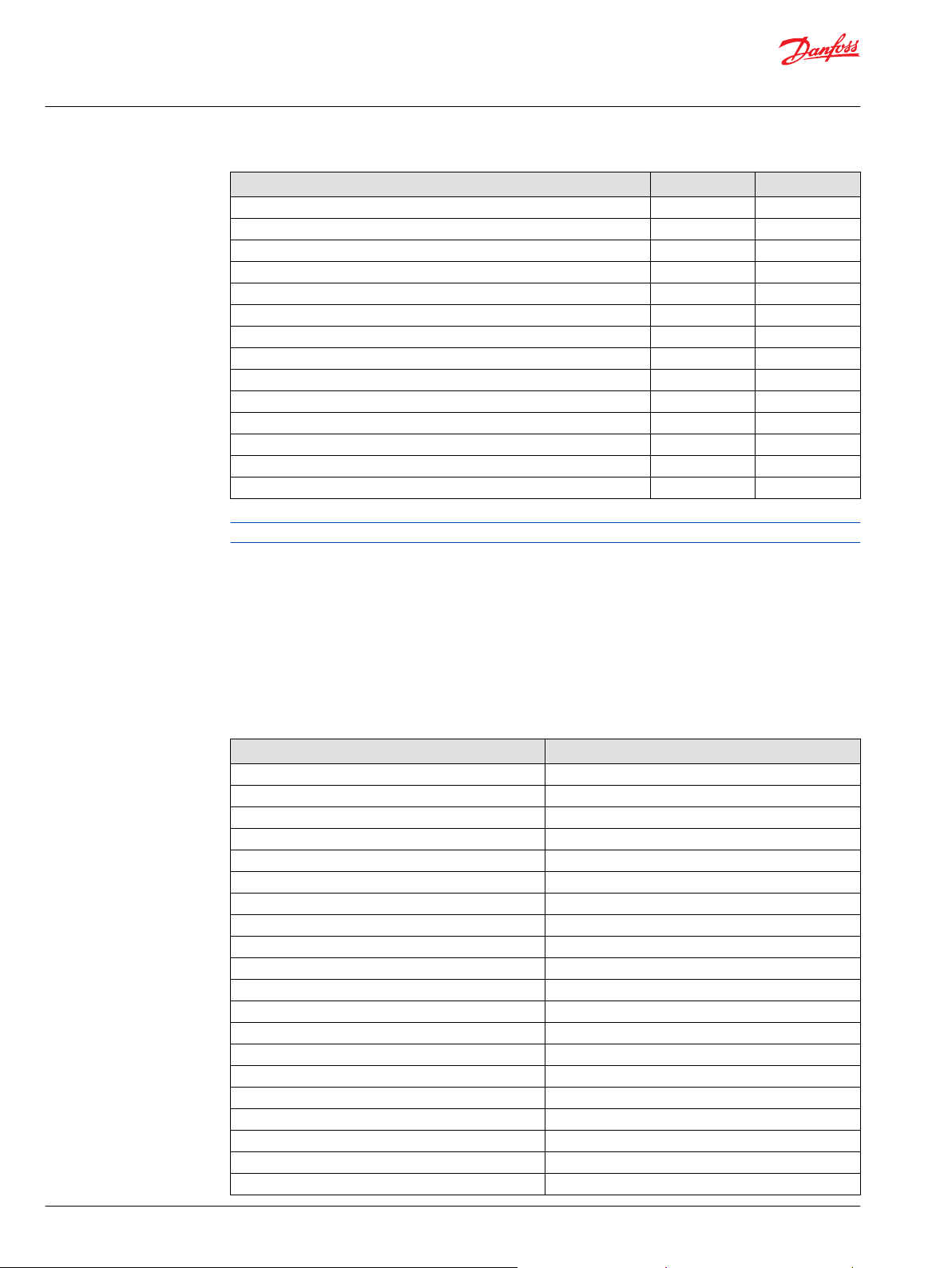

Object dictionary - communication profile

Device type

Object dictionary entry: 0x1000.

This object provides information on device type and its functionality. PVE-CI responds with value 0x198

indicating that DS408 profile is implemented.

Error register

Object dictionary entry: 0x1001.

This object provides a bitmap of the type of errors present in the system. It is also a part of the EMCY

object.

Following table shows the bitmap of error register in PVE-CI.

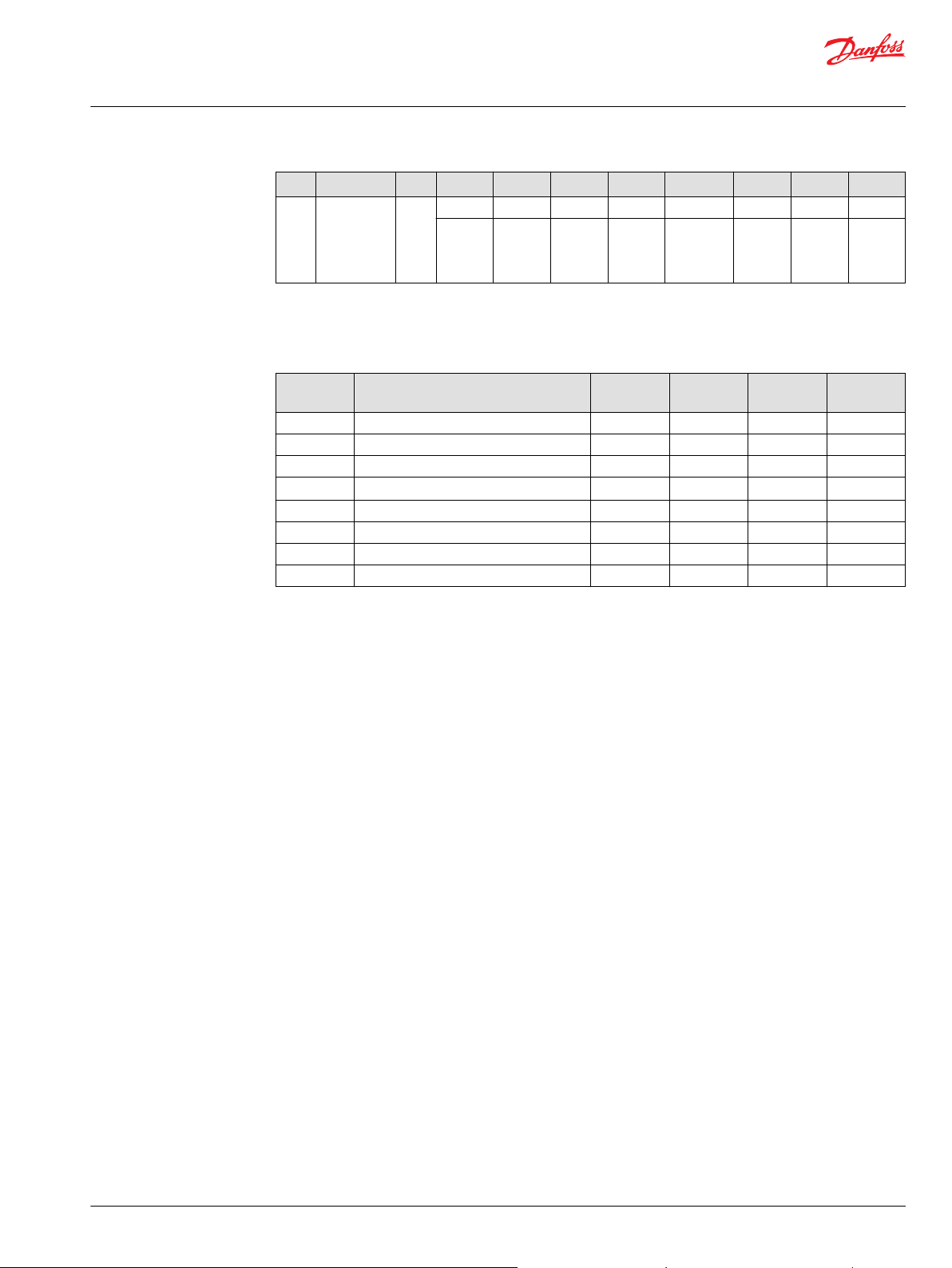

Type Bit7 Bit6 Bit5 Bit4 Bit3 Bit2 Bit1 Bit0

Error Manufac-

Spool not at set point x x

Spool cannot reach

float

Internal Error x

CAN bus Error x x

Temperature Error x x

Power supply

exceeds specification

Power supply is

below specification

Time guarding error x x

turer

specific

Reserved Device

profile

specific

x x

Com Tempe-

rature

Voltage Current Generic

Error

x x

x x

Predefined error field

Object dictionary entry: 0x1003.

26 | © Danfoss | July 2018 BC00000337en-US0106

Page 27

Technical Information

PVEA-CI and PVEO-CI Series 6 Electro-hydraulic Actuators

CANopen Communication Protocol

Sub Index: 1 to 8. Predefined error field maintains the “Error History” of the errors the PVE-CI supports 8

level deep error history:

•

On occurrence of any new error, it is written at sub-index 1 in the history.

•

If the entire history is filled, the array is overwritten with new errors.

•

If no error has occurred in the system, then read access produces an ABORT message.

•

Sub-index 0 contains number of actual errors that are recorded.

•

Writing 0x00 to sub-index 0 deletes the entire error history.

Field is of following format.

Bits 16-31 Bits 0-15

Error Occurrence counter Error Code

COB-ID SYNC

Object dictionary entry: 0x1005.

This object indicates the message ID of the sync message that is received by the library. This COB-ID can

be changed dynamically during runtime via SDO write. A new CAN filter is then configured and the sync

message is accepted by new message ID.

Manufacturer software version

Object dictionary entry: 0x100A.

PVE-CI responds with following string:

APP-_S6m1_M_Rxxx_CANOPEN-_111yyyyy_-rrr_zzzzzz

Where

xxx is version number.

yyyyy is part number.

zzzzzz is Firmware date.

Store parameters

Object dictionary entry: 0x1010.

Sub Index: 0x01.

On writing 0x65766173 to this object, PVE-CI stores values of following parameters from process image to

non-volatile memory (EEPROM).

Object Index Sub Index

COB-ID Sync 0x1005 Producer heartbeat time 0x1017 EMCY consumer 0x1028 0x01

RPDO COB-ID 0x1400 0x01

RPDO transmission type 0x1400 0x02

RPDO number of entries 0x1600 0x00

1st application object – device control word 0x1600 0x01

2nd application object – set-point 0x1600 0x02

3rd application object – dummy 0x1600 0x03

4th application object – dummy 0x1600 0x04

5th application object – dummy 0x1600 0x05

6th application object – dummy 0x1600 0x06

©

Danfoss | July 2018 BC00000337en-US0106 | 27

Page 28

Technical Information

PVEA-CI and PVEO-CI Series 6 Electro-hydraulic Actuators

CANopen Communication Protocol

Object Index Sub Index

7th application object – dummy 0x1600 0x07

8th application object – dummy 0x1600 0x08

TPDO COB-ID 0x1800 0x01

TPDO – transmission type 0x1800 0x02

TPDO number of entries 0x1A00 0x00

1st application object – device status word 0x1A00 0x01

2nd application object – set-point 0x1A00 0x02

3rd application object – dummy 0x1A00 0x03

4th application object – dummy 0x1A00 0x04

5th application object – dummy 0x1A00 0x05

6th application object – dummy 0x1A00 0x06

7th application object – dummy 0x1A00 0x07

8th application object – dummy 0x1A00 0x08

Device description 0x6053 -

Wait ≥ 500ms before software reset.

Restore default parameters

Object dictionary entry: 0x1011.

PVE-CI supports the object “restore default parameters”.

Sub Index: 0x01

Upon writing value 0x64616F6C to sub Index 0x01, PVE-CI prepares itself to restore the default

parameters on next boot-up.

Following are the default values of parameters.

Parameter Default value

COB-ID Sync 0x80

Producer heartbeat time 0x00

EMCY consumer 0x80000000

RPDO COB-ID $NODE_ID+0x00000200

RPDO Transmission type 0xFF

RPDO Number of entries 0x02

RPDO mapping parameter 1 0x60400010

RPDO mapping parameter 2 0x63000110

RPDO mapping parameter 3 0x00010001

RPDO mapping parameter 4 0x00010001

RPDO mapping parameter 5 0x00010001

RPDO mapping parameter 6 0x00010001

RPDO mapping parameter 7 0x00010001

RPDO mapping parameter 8 0x00010001

TPDO COB-ID $NODE_ID+0x00000180

TPDO Transmission type 0xFF

TPDO Number of entries 0x02

TPDO mapping parameter 1 0x60410010

TPDO mapping parameter 2 0x63010110

TPDO mapping parameter 3 0x00010001

28 | © Danfoss | July 2018 BC00000337en-US0106

Page 29

Technical Information

PVEA-CI and PVEO-CI Series 6 Electro-hydraulic Actuators

CANopen Communication Protocol

Parameter Default value

TPDO mapping parameter 4 0x00010001

TPDO mapping parameter 5 0x00010001

TPDO mapping parameter 6 0x00010001

TPDO mapping parameter 7 0x00010001

TPDO mapping parameter 8 0x00010001

Device Description PVEA-CI S6 / PVEO-CI S6

Sub Index: 0x05

Writing value 0x73646B70 to Sub-Index 0x05 clears all the error occurrence counters.

Clearing of Error occurrence counters takes at least 50 ms.

COB-ID EMCY

Object dictionary entry: 0x1014.

This object is read only object and represents the COB-ID of EMCY message.

The value is Node ID + 0x80.

Producer heartbeat time

Object dictionary entry: 0x1017.

This object holds the value of heartbeat producer in ms when a non-zero value is written to this object

the PVE-CI valve starts producing the heartbeat message with frequency equal to this value in ms.

Minimum resolution is 10 ms.

Identity object

Object dictionary entry: 0x1018.

The identity object provides general information of the PVE-CI. The following sub-indexes are

implemented:

•

Sub-index 0: Highest sub-index supported. This value is 3.

•

Sub-index 1: Vendor ID. This value is 0x0100 0019.

•

Sub-index 2: Product code: This value is 0x5336 0000.

•

Sub-index 3: Revision number: This value is a binary coded decimal encoded software version

number (i.e. version R1.31 becomes 0x0001 001F).

PVE-CI emergency consumer

Object dictionary entry: 0x1028.

PVE-CI uses the EMCY consumer as emergency stop message. The PVE -CI enters into fault state if:

•

the valve is in active state (TR8)

•

an error code of 0x1000 is received

The error message will be ignored if the above listed conditions are not fulfilled.

The Sub Entry at index 0x01 represents COB-ID of emergency consumer. This is kept as 0x80000000 by

default, which means disabled. This COB-ID must be configured before sending emergency consumer.

RPDO parameter

Object dictionary entry: 0x1400.

This parameter is used to describe the RPDO. It describes the COB-ID of RPDO and transmission type.

If Transmission type is fixed at 0xFF.

©

Danfoss | July 2018 BC00000337en-US0106 | 29

Page 30

Technical Information

PVEA-CI and PVEO-CI Series 6 Electro-hydraulic Actuators

CANopen Communication Protocol

To change COB-ID one has to disable the PDO before writing a new value.

RPDO mapping

Object dictionary entry: 0x1600.

RPDO is mapped to device control word and Set point by default (Default parameter setting). The

parameter value is stored and read from EEPROM during boot-up.

Following parameters can be mapped:

1. 6040,00 Device control word

2. 3300,00 Manufacturer specific set-point – 8bit

3. 3303,00 Manufacturer specific set-point – 16bit

4. 6042,00 Device mode

5. 6300,01 vpoc_set_point_value

TPDO parameter

Object dictionary entry: 0x1800.

This parameter is used to describe the TPDO. It describes the COB-ID used by TPDO and transmission

type:

•

If transmission type is 0xFF = the transmission event is driven and one TPDO is transmitted for every

RPDO.

•

If transmission type is set to 0x01-0xF0 = the transmission of TPDO is event driven (cyclic every Nth

sync). Other values are unsupported.

Object dictionary

You need to disable the PDO before changing the COB-ID.

TPDO mapping

Object dictionary entry: 0x1A00.

TPDO is mapped to Device status word and VPOC actual value by default (Default parameter setting). The

parameter value is stored and read from EEPROM during boot-up.

Following parameters can be mapped:

1. 3301,00 Manufacturer specific actual value

2. 3302,00 Manufacturer specific actual inverted value

3. 3304,00 Device status word

4. 6301,00 Vpoc_actual_value

Standardized device profile

Device control word

Object dictionary entry: 0x6040.

This Entry holds the value of device control word the 7 difference transitions are listed below. The control

word controls the device state machine.

PVE-CI performs the following transitions on writing device control word

Transition Number Transition Device Control Command RMHD

D 2 INIT to DISABLED Activate DISABLED xxx1

D 3 DISABLED TO HOLD Activate HOLD xx11

D 4 HOLD TO ACTIVE Activate ACTIVE x111

30 | © Danfoss | July 2018 BC00000337en-US0106

Page 31

Technical Information

PVEA-CI and PVEO-CI Series 6 Electro-hydraulic Actuators

CANopen Communication Protocol

PVE-CI performs the following transitions on writing device control word (continued)

Transition Number Transition Device Control Command RMHD

D 5 ACTIVE TO HOLD Deactivate Active x0xx

D 6 HOLD TO DISABLED Deactivate Hold x00x

D 7 DISABLED TO INIT Deactivate Disabled x000

D 11 FAULT HOLD TO HOLD Reset Fault Hold 1011

Device status word

Object dictionary entry: 0x6041.

This object represents the state of device state machine. Following tables shows the states and

representation in status word.

Device State RMHD

INIT 1000 Initializations successful, device function disabled, communication

DISABLED 1001 Device function disabled

HOLD 1011 Valve in factory mode, device function disabled

ACTIVE 1111 Solenoids active

FAULT HOLD 0011 Active error is present in the system, solenoids disabled

*

R: Status word ready (bit 3), M: Status word device mode active enable (Bit 2), H: Status word Hold activated (Bit 2),

Status word disabled (Bit 0)

*

representation

Conditions

enabled

Object name Object dictionary entry Object description Comment

Device mode 0x6042 0X01 = Full operational

0x02 = Hand operation

Device Serial Number 0x6052 Visible string read from the

EEPROM

Device Description 0x6053 Displays string (PVEA-CI

S6 / PVEO-CI S6) depending

on variant type

Device Capability 0x605F Capabilities of the PVEA-CI

S6 The value of this object

is 0x0500 0000

Vpoc_set_point 0x6300 Actual set point position

range of -16384 (-100%) to

16384 (100%)

Vpoc_actual_value 0x6301 Actual spool position

scaled in range of -16384

(-100%) to 16384 (100%)

The object is guarded for

any other values than

these.

Write up to 10 characters

Hydraulic proportional

valve with closed loop

spool position monitoring

A value of 32767 represents

float

A value of 32767 represents

float

Manufacturer specific

Error - Supply Voltage

Too High

Error - Supply Voltage

Too Low

Error - Temperature

Too High

Object

dictionary

entry

0x2001 Error: supply voltage

0x2002 Error: supply voltage

0x200F Error: temperature

Object description Emergency

error code

0x3411 0x05 0x7F

too high

0x3412 0x05 0x7F

too low

0x8301 0x09 0x7F

crosses boundaries of

-40 °C to 120 °C

Error register Maximum

occurrence

counter

©

Danfoss | July 2018 BC00000337en-US0106 | 31

Page 32

Technical Information

PVEA-CI and PVEO-CI Series 6 Electro-hydraulic Actuators

CANopen Communication Protocol

Error - CAN Error 0x2019 Error on the CAN bus 0x8140 0x11 0x7F

Error - Spool not at

Set-point / Float Not

Reached

Error - Set-point

Timeout

Error - Internal Error 0x2024 Internal error 0x1000 0x01 0x7F

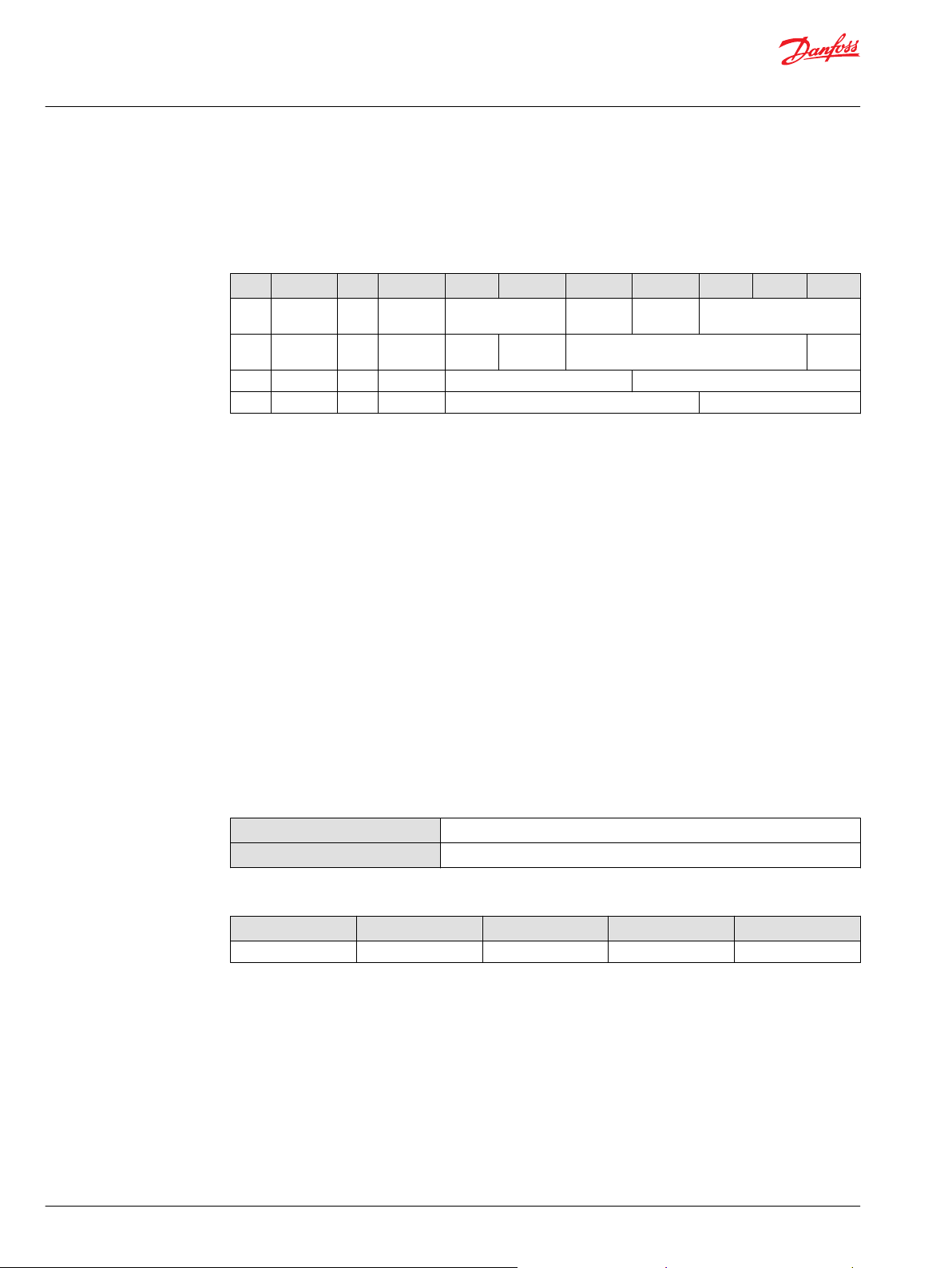

Unified Diagnostic Services (UDS) lite

The UDS protocol is supported by application for following services:

1. Read Data by Identifier

2. Write data by Identifier

UDS - message ID formation

UDS message ID’s are formed as shown below.

Request message ID

Following table shows message ID formation for message to node ID 0x05 on net 0 from node 0xF1.

29 Bit CAN Identifier

Priority Extended

28 27 26 25 24 23 22 21 19 18 11 10 8 7 0

1 1 0 1 1 1 1 000 11110001 000 00000101

0x1BC028F1

Object

dictionary

entry

0x201D Spool position error 0x8305 0x21 0x7F

0x2023 Spool position not

Data Page

Object description Emergency

reached within

timeout

Data

Page

Type of Service

(TOS)

error code

0x8003 0x91 0x7F

Error register Maximum

occurrence

counter

Source Address Destination Address

Net Node Net Node

Response message ID

Following table shows a response message from node 0x05 to 0xF1.

29 Bit CAN Identifier

Priority Extended

Data Page

28 27 26 25 24 23 22 21 19 18 11 10 8 7 0

1 1 0 1 1 1 1 000 00000101 000 11110001

0x1BC028F1

Data

Page

Type of Service

(TOS)

Source Address Destination Address

Net Node Net Node

UDS – read data by identifier

The PVE-CI supports the read data by identifier command. This service is used for reading out ECU data

from a node. Some identifiers are predefined in the standard and some are specific for the ECU.

Service ID: 0x22.

Service request

Msg ID DLC Byte 0 Byte 1 Byte 2 Byte 3

UDS Request Message ID 0x04 0x03 0x22 ID

32 | © Danfoss | July 2018 BC00000337en-US0106

Page 33

Technical Information

PVEA-CI and PVEO-CI Series 6 Electro-hydraulic Actuators

CANopen Communication Protocol

Positive response

Msg ID DLC Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 - Byte 7

UDS Response Message ID xx Number

Negative response

Msg ID DLC Byte 0 Byte 1 Byte 2 Byte 3

UDS Response Message ID 4 3 0x7F 0x22 Error

Error codes

Error Code Error Message Error Cause

0x13 Incorrect Message Length Length of the request message is incorrect

0x22 Conditions not correct Operating conditions of the server are not met

0x31 Request Out of Range Read Identifier not supported by ECU

of bytes

0x62 ID Data

to follow

in frame

Code

UDS – write data by identifier

PVE-CI supports write data by identifier command. This service writes data to a particular node of ECU.

Service ID: 0x2E.

Service request – Data Bytes 1

Msg ID DLC Byte 0 Byte 1 Byte 2 Byte 3 Byte 4

UDS Request Message ID 0x05 0x04 0x2E ID Data

Service request – Data Bytes 2

Msg ID DLC Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5

UDS Request Message ID 0x06 0x05 0x2E ID Data Data

Service request – Data Bytes 3

Msg ID DLC Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6

UDS Request

Message ID

0x07 0x06 0x2E ID Data Data Data

Service request – Data Bytes 4

Msg ID DLC Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 - Byte 7

UDS Request Message ID 0x08 0x07 0x2E ID Data

Positive response

Msg ID DLC Byte 0 Byte 1 Byte 2 Byte 3

UDS Response Message ID 4 5 0x6E ID

©

Danfoss | July 2018 BC00000337en-US0106 | 33

Page 34

Technical Information

PVEA-CI and PVEO-CI Series 6 Electro-hydraulic Actuators

CANopen Communication Protocol

Negative response

Msg ID DLC Byte 0 Byte 1 Byte 2 Byte 3

UDS Response message ID 4 3 0x7F 0x2E Error

Error code

Error Code Error Message Error Cause

0x13 Incorrect Message Length Length of the message is wrong, DLC and PCI do not

0x22 Conditions not correct Operating conditions of the server are not met

0x31 Request Out of Range Data Identifier not supported by ECU / Address out of

0x33 Security Access Denied Server is not in unlocked state, Valve not in factory mode

0x72 Programming failure Cannot write to memory

UDS – change Node ID

Node ID can be changed with Identifier 0x1001.

Code

match

range

Sub-function

Identifier

0x 1001 Node ID R/W 0x01-0x7F 0x20 The boot loader uses the Node ID value

Name Access Value/Range Default Description

directly.

Node ID a restart of the PVE-CI Series 6 is

required.

Change of Node ID command

Msg Type Msg ID DLC Byte 0 Byte 1 Byte 2 Byte 3 Byte 4

Change Node ID UDS request messageID5 0x03 0x2E 0x01 0x10 Node ID

Example of Change of Node ID Command

Change Node ID from 0x20 to 0x21

Msg Type Msg ID DLC Byte 0 Byte 1 Byte 2 Byte 3 Byte 4

Change Node ID 0x1BC78820 5 0x04 0x2E 0x01 0x10 0x21

PVE replies with

Msg Type Msg ID DLC Byte 1 Byte 2 Byte 3 Byte 4

Change Node ID 0x1BC408F1 4 0x03 0x6E 0x01 0x10

Error messages sent on invalid situations while changing node id

Error Code Error Message Error Cause

0x11 Service Not supported Invalid SID

0x13 Invalid data length DLC is incorrect

0x31 Request out of range Node ID is out of valid range

0x72 Programming failure EEPROM write invalid

34 | © Danfoss | July 2018 BC00000337en-US0106

Page 35

Technical Information

PVEA-CI and PVEO-CI Series 6 Electro-hydraulic Actuators

CANopen Communication Protocol

Complete example of procedure of changing Node ID

CAN Id DLC PCI and Data Comments

0x1BC78820 5 04 2E 10 01 21 Write Node ID to 0x21

0x1BC408F1 4 03 6E 20 02 Positive response

UDS – ECU identification

PVE-CI supports the read of following ECU parameters for PLUS+1® Service Tool ECU Identification

Sub-function

Identifier

0xF010 Address format R 0xA5 0xA5 Fixed value

0xF1FA

0xF1FB

0xF1FC

0xF1FD

0xF192 ECU Hardware

0xF193 ECU Hardware

0xF194 ECU Software

0xF195 ECU Software

0xF18C ECU Serial

0xF18B ECU

Name Access Value/Range Default Description

Diagnostic file

identifier

number

version

number

version

number

manufacturing

date

R - Unique ID to

R 32bit integer - Part number

R Four character

alpha numeric

string. Left

adjusted. Padded

with whitespaces

R 32bit integer -

R Four character

alpha numeric

string. Left

adjusted. Padded

with whitespaces

R 32bit integer -

R BCD encoded

YY,MM,DD

-

-

-

identify the

interface of the

product

©

Danfoss | July 2018 BC00000337en-US0106 | 35

Page 36

Technical Information

PVEA-CI and PVEO-CI Series 6 Electro-hydraulic Actuators

PVEA-CI Series 6 diagnostics

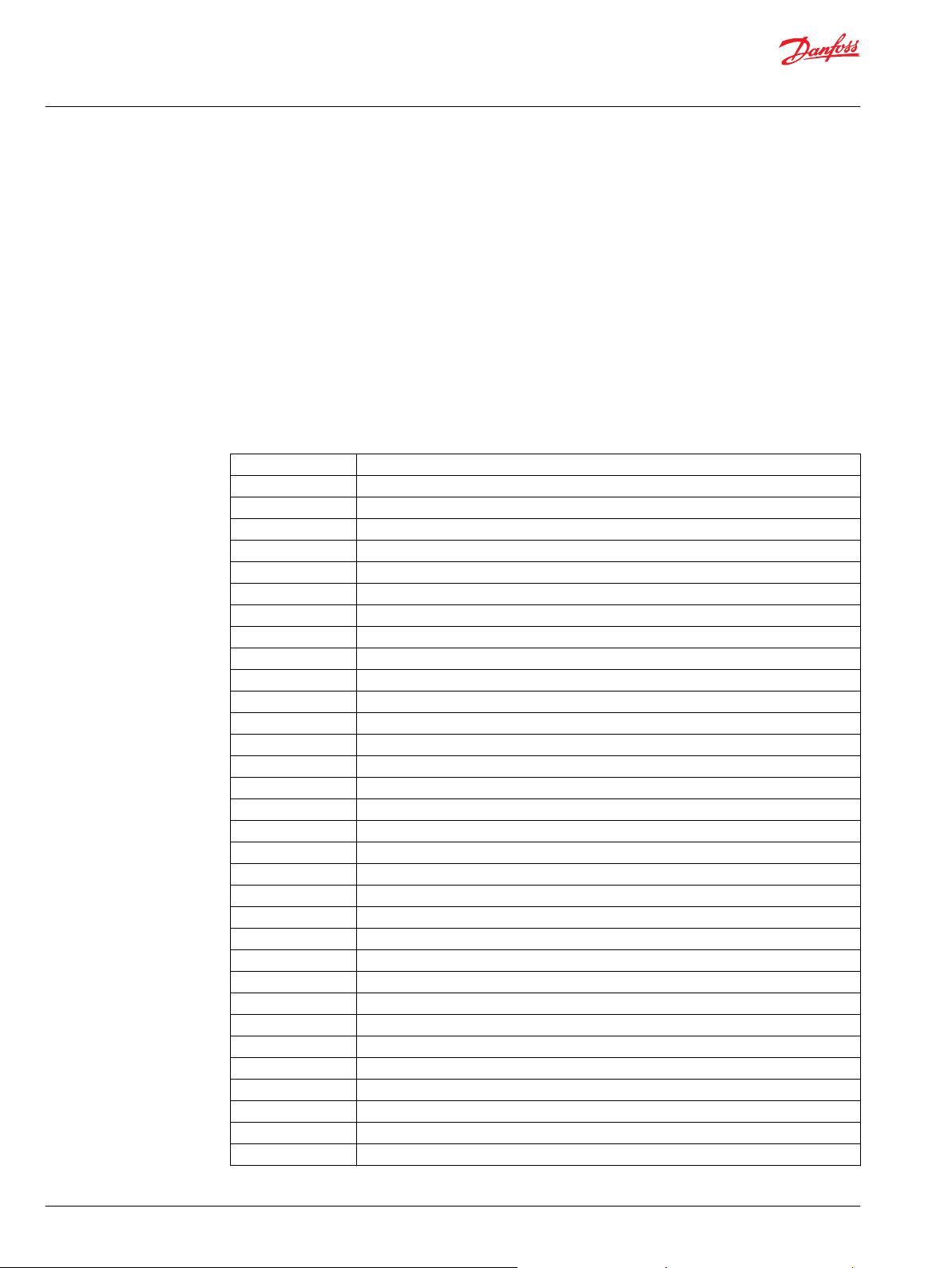

LED Characteristic

The color of the board LED reflects status of the highest priority error in PVE-CI.

LED Characteristic

Color LED Characteristic Description

Green constant No error – Actuating

Green flashing @ 1.5 Hz Neutral – Power save

Red constant Internal error

Red flashing @ 1.5 Hz External or Float error

Yellow Disable mode

36 | © Danfoss | July 2018 BC00000337en-US0106

Page 37

Technical Information

PVEA-CI and PVEO-CI Series 6 Electro-hydraulic Actuators

Use cases

Use case 1 - Boot-up to operation mode

The aim with this use case is to go from boot-up message to DEVICE_MODE_ACTIVE, and thereby be able

to control the PVE-CI.

Follow the steps below.

1. Power up the PVE-CI

Boot message from PVE-CI:

COB-ID DLC Byte 0

0x700 + Node ID*1 00

*

If Node ID = 0x10 then the COB-ID =0x710

Emergency message: No error from PVE-CI

COB-ID DLC Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

0x80 + Node ID 8 00 00 00 00 00 00 00 00

2. Bring the communication state machine (NMT) from Pre-operational to Operational by sending the

NMT start command.

COB-ID DLC Byte 0 Byte 1

0x00 2 01

*

00 = global message

*

00

3. Bring the device state machine (see Device State Machine and Communication State Machine on page

17) from state INIT to DEVICE_MODE_ACTIVE state by cyclic transmission (100ms) sending the

following message:

First transmission

•

COB-ID DLC Byte 0 Byte 1 Byte 2 Byte 3

0x200+ Node ID 4 0F 00 Set-point

PVE-CI enters DISABLED state.

Second transmission

•

COB-ID DLC Byte 0 Byte 1 Byte 2 Byte 3

0x200+ Node ID 4 0F 00 Set-point

PVE-CI enters HOLD state

Third transmission

•

COB-ID DLC Byte 0 Byte 1 Byte 2 Byte 3

0x200+ Node ID 4 0F 00 Set-point

PVE-CI enters DEVICE_MODE_ACTIVE state.

The PVE-CI will now react to set-point sent from the main controller.

Use case 2 - Operation Mode – Error – Operation Mode

The aim with this use case is to get back to DEVICE_MODE_ACTIVE after an error has occurred.

Assuming The PVEA-CI to be in DEVICE_MODE_ACTIVE state and receives set-points from the main

controller by cyclic transmission (100ms) sending the following message.

COB-ID DLC Byte 0 Byte 1 Byte 2 Byte 3

0x200+ Node ID 4 0F 00 Set-point

Error: The supply voltage drops under the specified range (11VDC-32VDC).

©

Danfoss | July 2018 BC00000337en-US0106 | 37

Page 38

Technical Information

PVEA-CI and PVEO-CI Series 6 Electro-hydraulic Actuators

Use cases