Page 1

Technical Information

PVE Series 7

Electro-hydraulic Actuators

www.danfoss.com

Page 2

Technical Information

PVE Series 7 — Electro-Hydraulic Actuators

Revision history Table of revisions

Date Changed Rev

February 2021 Corrected data in PVEM, PVEA, PVEH, and PVES technical sections 0310

June 2020 Minor changes throughout 0309

Changed document number from 'BC00000378' to 'BC218286485446' XX

March 2020 Various updates to data. 0307

April 2019 All reaction times tables, notes changes. 0204

December 2018 New image on page 5-6. 0203

July 2018 Minor update. 0202

June 2018 PVE actuation, connector image changes. 0201

May 2018 Restored missing information. 0105

April 2018 Minor updates. 0104

February 2017 Added detailed Fault Monitoring description 0103

January 2017 Minor updates 0102

November 2016 First edition 0101

2 | © Danfoss | February 2021 BC218286485446en-000310

Page 3

Technical Information

PVE Series 7 — Electro-Hydraulic Actuators

Contents

PVE Electrical Actuator

PVE Series 7 Electrical Actuator................................................................................................................................................... 5

PVE Series 7 variants overview.................................................................................................................................................... 6

Safety in Systems..............................................................................................................................................................................8

PVEO

PVEO Schematics and Dimensions..........................................................................................................................................11

PVEO Technical Data.....................................................................................................................................................................11

PVEO Reaction Times....................................................................................................................................................................12

PVEO Variants for PVG..................................................................................................................................................................13

PVEO-HP

PVEO-HP Schematics and Dimensions...................................................................................................................................16

PVEO-HP Technical Data..............................................................................................................................................................16

PVEO-HP Reaction Times.............................................................................................................................................................17

PVEO-HP Variants for PVG...........................................................................................................................................................18

PVEM

PVEM Schematics and Dimensions......................................................................................................................................... 20

PVEM Technical Data.................................................................................................................................................................... 20

PVEM Reaction Times................................................................................................................................................................... 22

PVEM Hysteresis and Ripple.......................................................................................................................................................22

PVEM Variants for PVG................................................................................................................................................................. 23

PVEA

PVEA Schematics and Dimensions.......................................................................................................................................... 25

PVEA Technical Data.....................................................................................................................................................................25

PVEA Reaction Times.................................................................................................................................................................... 27

PVEA Hysteresis and Ripple........................................................................................................................................................27

PVEA Variants for PVG.................................................................................................................................................................. 28

PVEH

PVEH Schematics and Dimensions.......................................................................................................................................... 30

PVEH Technical Data.....................................................................................................................................................................30

PVEH Reaction Times....................................................................................................................................................................32

PVEH Hysteresis and Ripple........................................................................................................................................................32

PVEH Variants for PVG.................................................................................................................................................................. 33

PVES

PVES Schematics and Dimensions...........................................................................................................................................36

PVES Technical Data......................................................................................................................................................................36

PVES Reaction Times.....................................................................................................................................................................38

PVES Hysteresis and Ripple........................................................................................................................................................ 38

PVES Variants for PVG...................................................................................................................................................................39

Connector Overview

Connector Overview.....................................................................................................................................................................40

Fault Monitoring and Reaction

Generic Fault Reaction.................................................................................................................................................................42

Fault Reaction Overview..............................................................................................................................................................43

Error Pin Specification.................................................................................................................................................................. 43

Functionality Overview

Standard and Fixed US 0-10 Vdc.............................................................................................................................................. 44

PWM Voltage Control..............................................................................................................................................................45

Ramp (-R)...........................................................................................................................................................................................47

Quick Reaction (-Q)........................................................................................................................................................................48

Float B-Port (-FLB).......................................................................................................................................................................... 49

Float A-Port (-FLA)..........................................................................................................................................................................50

PVE Power Save.............................................................................................................................................................................. 50

Special Features

Direction Indication (-DI).............................................................................................................................................................51

©

Danfoss | February 2021 BC218286485446en-000310 | 3

Page 4

Technical Information

PVE Series 7 — Electro-Hydraulic Actuators

Contents

Dedicated Float Pin (UF)..............................................................................................................................................................53

Spool Position (SP).........................................................................................................................................................................54

Neutral Power-OFF (NP)...............................................................................................................................................................55

Disable Mode...................................................................................................................................................................................56

Performance Overview

PVE S7 Reaction Times................................................................................................................................................................. 57

Hysteresis and Ripple................................................................................................................................................................... 57

Current Consumption.................................................................................................................................................................. 58

Oil Consumption............................................................................................................................................................................ 58

Dimension Overview

Dimension Overview for PVE Series 7.....................................................................................................................................59

4 | © Danfoss | February 2021 BC218286485446en-000310

Page 5

Technical Information

PVE Series 7 — Electro-Hydraulic Actuators

PVE Electrical Actuator

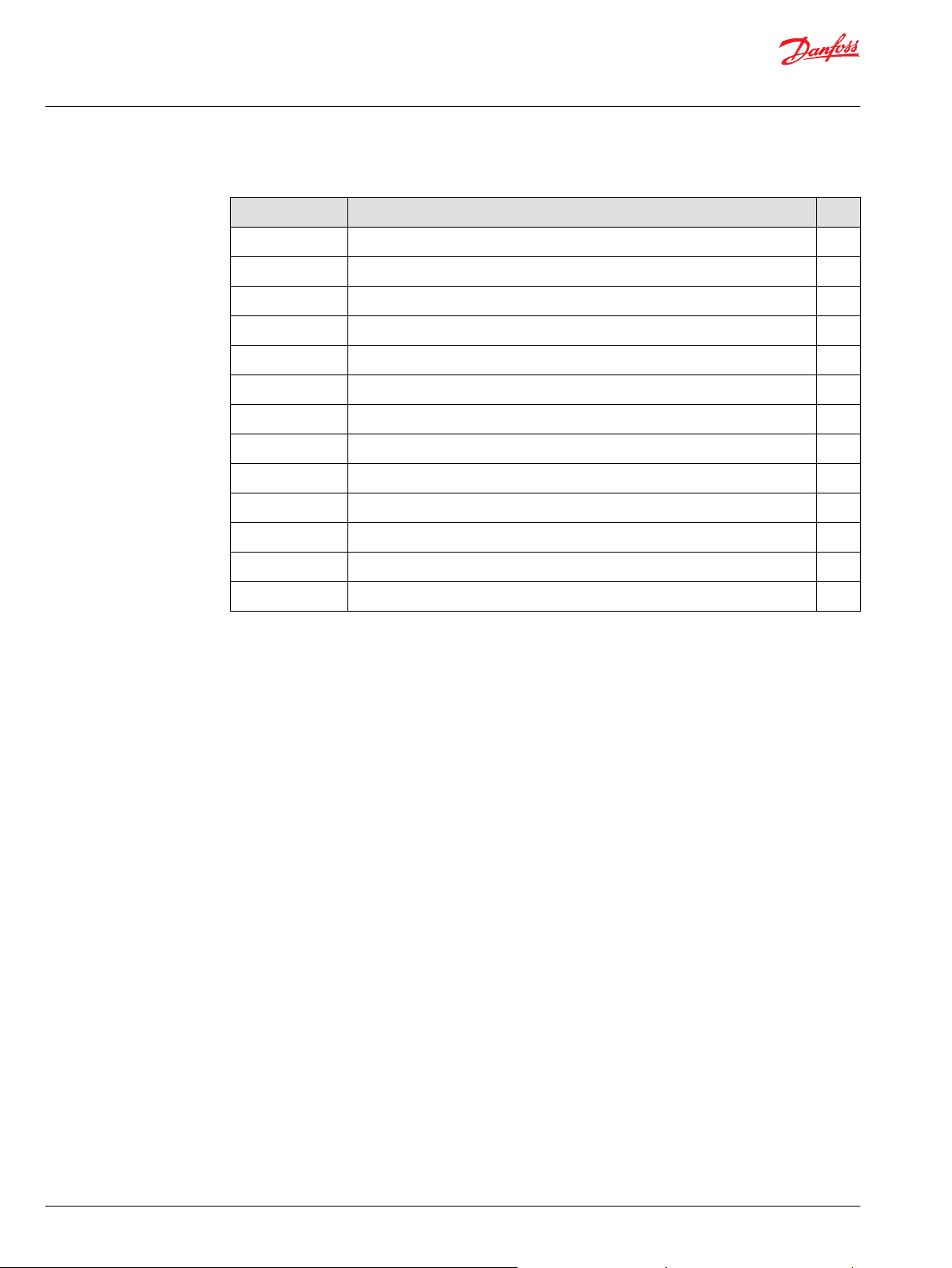

PVE Series 7 Electrical Actuator

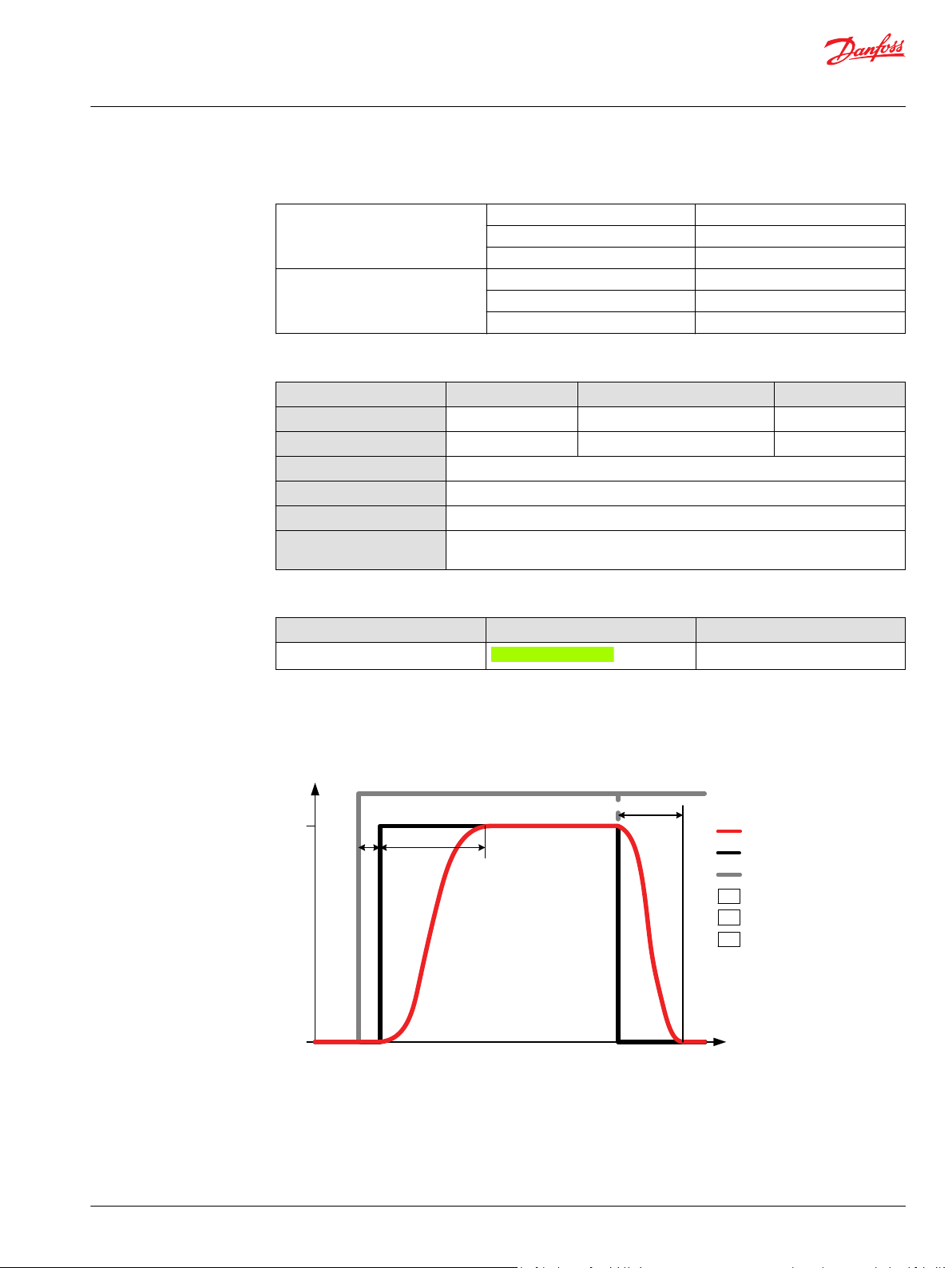

The analog PVE Series 7 is an electro-hydraulic actuator used to control a single work section of a PVG

proportional valve group. The PVE Series 7 actuator program includes variants with different

performance levels and features for PVG 32/100/120/128/256.

The actuator positions the main spool in a PVG work section in order to control either the flow or the

pressure of the oil distributed to/from the work function. The control signal to the actuator is an analog

voltage signal, enabling the user to operate the work function remotely by means of a joystick, a

controller or the similar.

The analog PVE Series 7 actuator program features five different main hydraulic principle variants (PVEO/

PVEM/PVEA/PVEH/PVES). The different hydraulic principles combined with the different solenoid valve

regulation principles determine whether the actuator controls the spool proportionally according to a

demand signal or ON/OFF according to a voltage signal.

The electro-hydraulic solenoid valve bridge of the actuator is available in different designs utilizing

different regulation principles, depending on performance variant. The actuator positions the main spool

by distributing pilot oil pressure to either side of it, pressurizing one side by pilot pressure while relieving

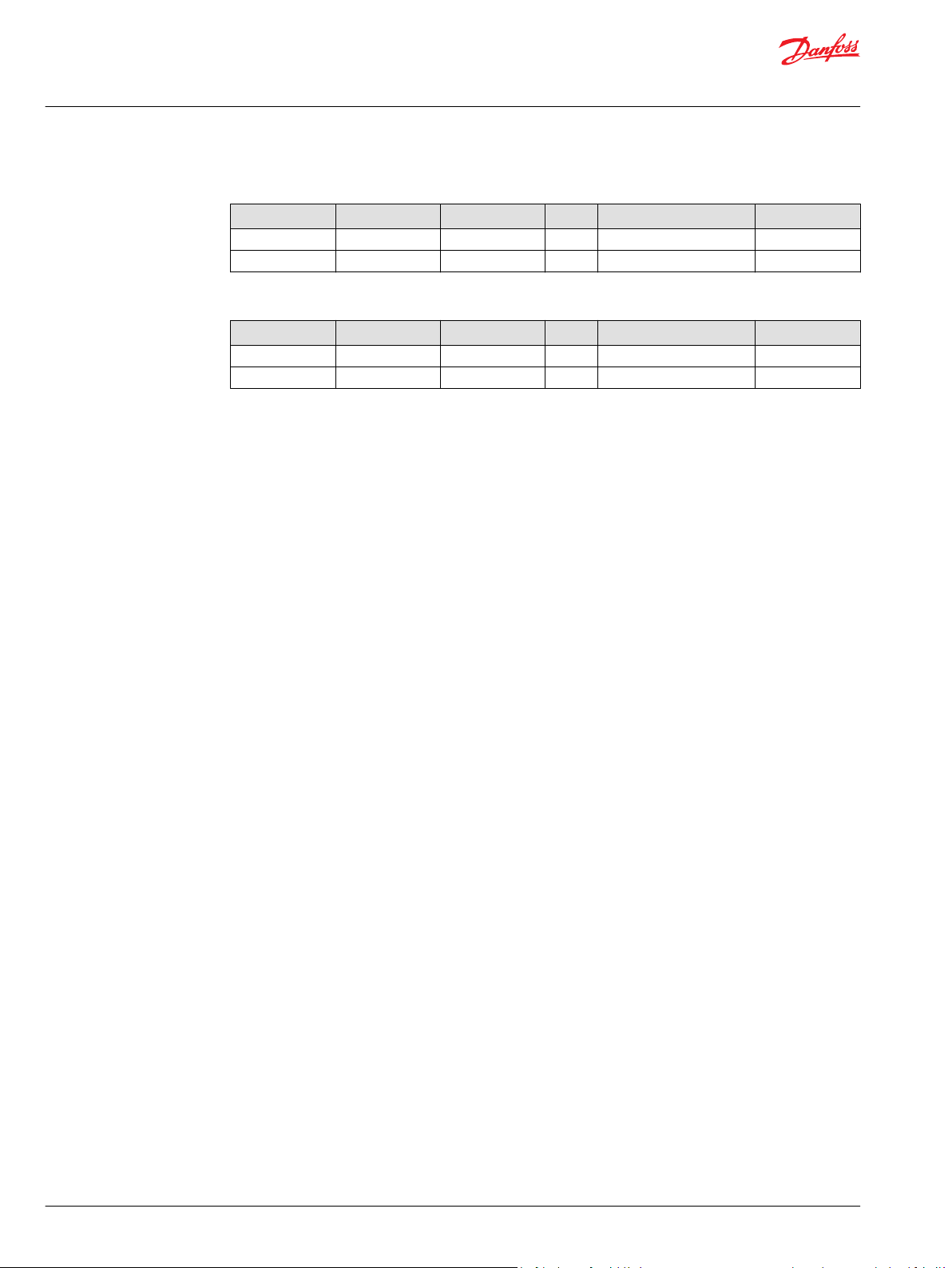

the opposite side to tank and vice versa, as illustrated below. All proportional actuators feature a closedloop spool control and continuous fault monitoring.

PVG 32 with PVEO/PVEM (PVEO without LVDT)

©

Danfoss | February 2021 BC218286485446en-000310 | 5

Page 6

P109195

P109195

Technical Information

PVE Series 7 — Electro-Hydraulic Actuators

PVE Electrical Actuator

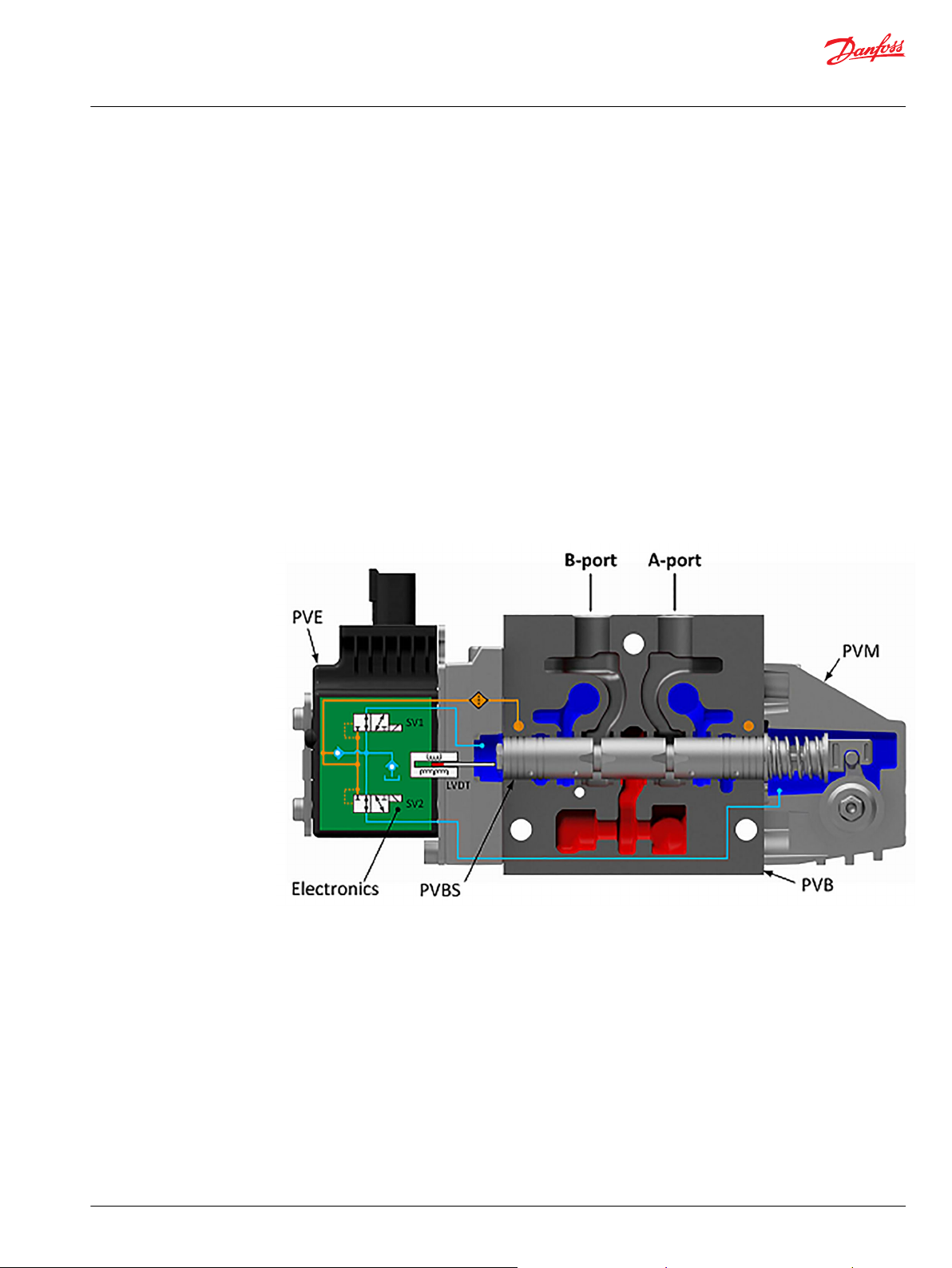

PVG 32 with PVEH/PVES

PVEA has the same housing as PVEO/PVEM and similar hydraulic principle as PVEH/PVES, but with fixed

orifices instead of NO2 and NO4.

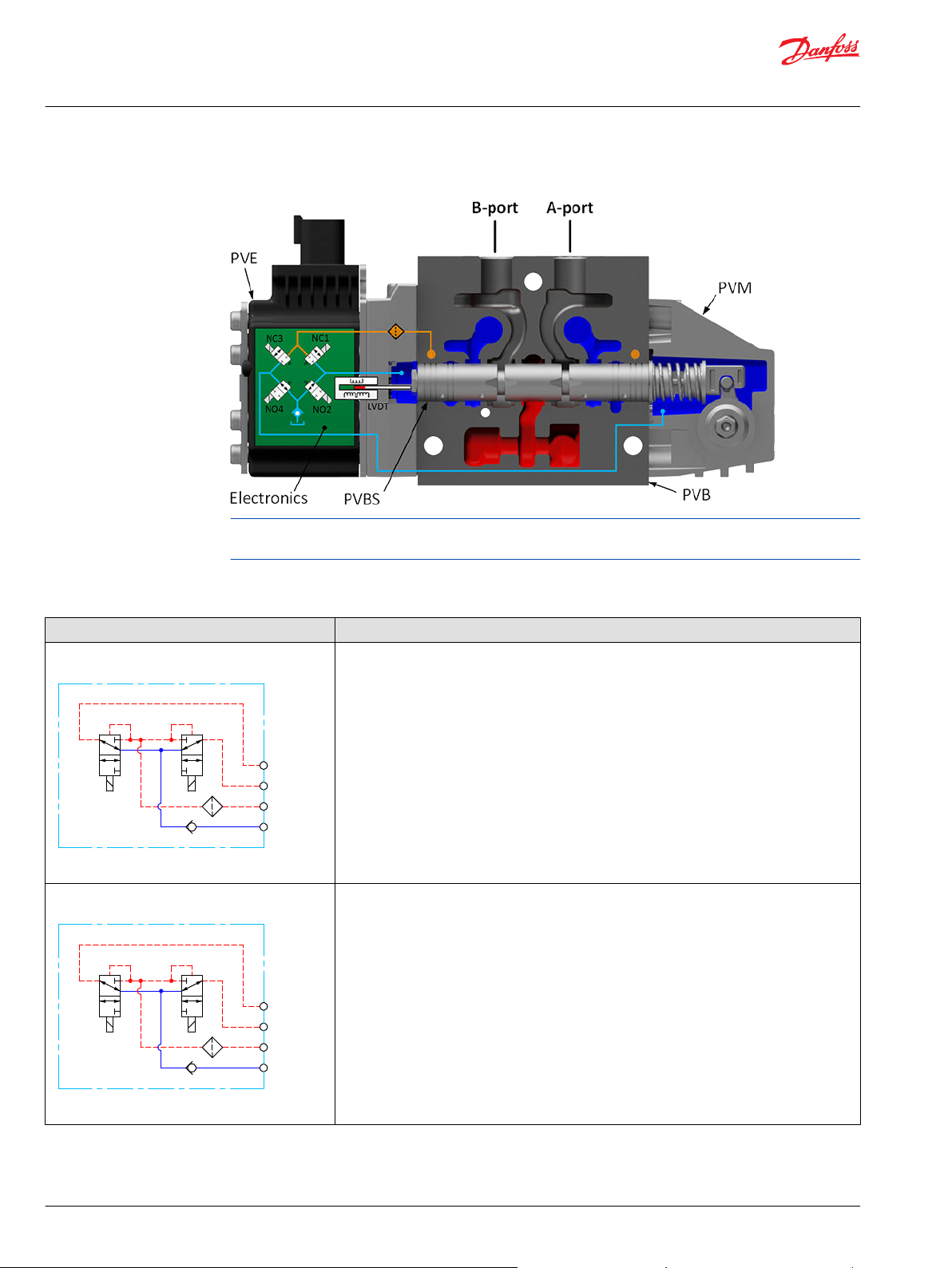

PVE Series 7 variants overview

Schematic Description

PVEO schematic

PVEO-HP schematic

PVEO – ON/OFF voltage control for non-proportional functions, see PVEO

Neutral position or max. spool stroke according to control signal

•

12 VDC or 24 VDC supply voltage

•

DEUTSCH, AMP or DIN/Hirschman connectors

•

Standard PVE pilot oil pressure of 13.5 bar [196 psi]

•

LED only indicating Power ON or Power OFF

•

Ramp (-R) or Direction Indication output (-DI) functionality

•

PVEO-HP – ON/OFF voltage control for non-proportional functions, see PVEO-HP

Neutral position or max. spool stroke according to control signal

•

12 VDC or 24 VDC supply voltage

•

DEUTSCH, AMP or DIN/Hirschman connectors

•

To be used with PVH/PVHC pilot oil pressure of 25 bar

•

LED only indicating Power ON or Power OFF

•

6 | © Danfoss | February 2021 BC218286485446en-000310

Page 7

P109196

P109197

P109198

P109199

Technical Information

PVE Series 7 — Electro-Hydraulic Actuators

PVE Electrical Actuator

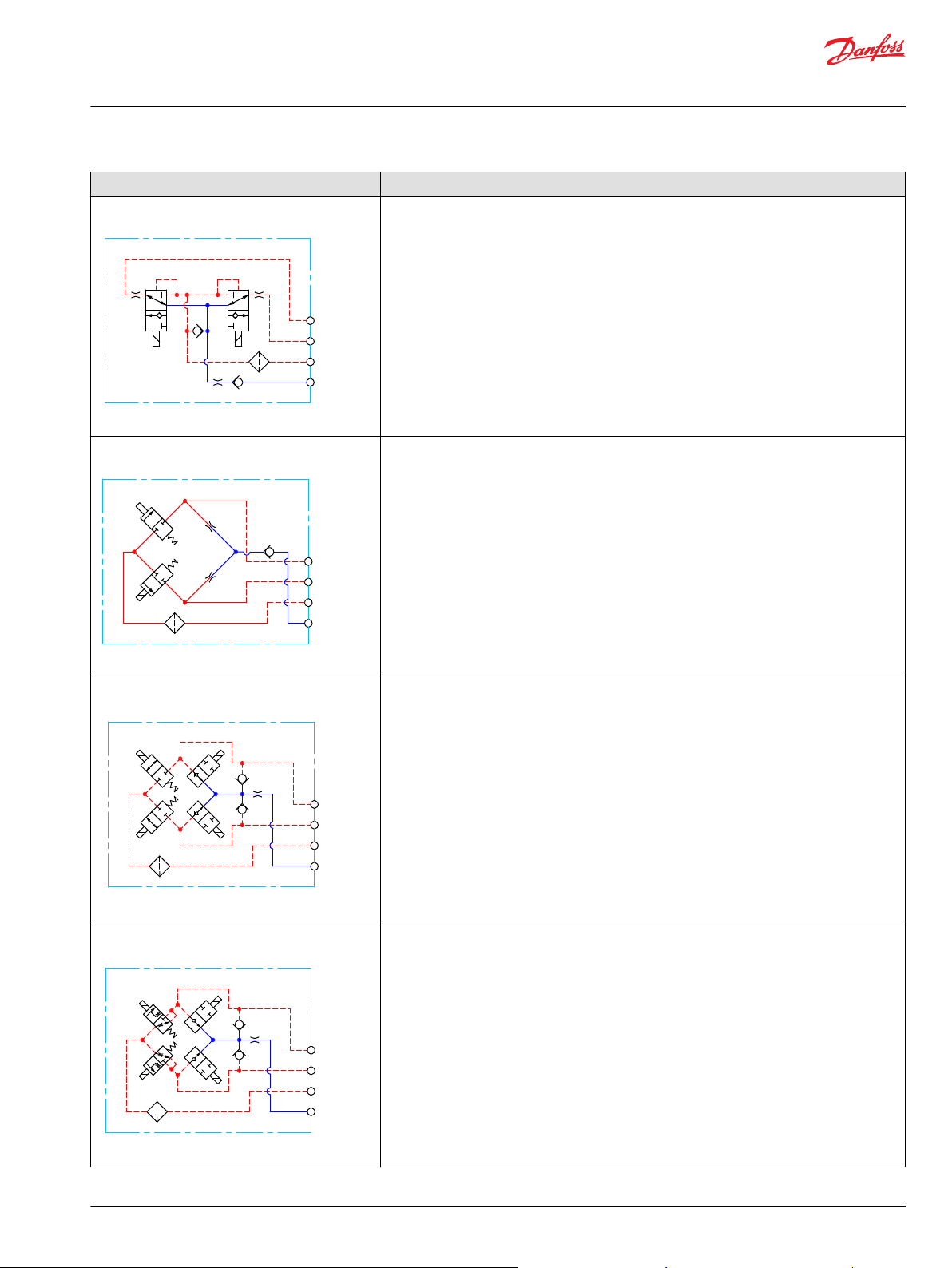

Schematic Description

PVEM schematic

PVEM – proportional spool control for functions with medium performance demands, see PVEM

9–32 VDC multi-voltage power supply

•

DIN or Hirschman connectors

•

Standard PVE pilot oil pressure of 13.5 bar [196 psi]

•

LED indicating error state and passive fault monitoring

•

Float (-F), quick Ramp (-R) or Quick reaction functionality (-Q)

•

PVEA schematic

PVEH schematic

PVEA – proportional spool control for functions with high performance demands, see PVEA

9–32 VDC multi-voltage power supply

•

Variants available with DEUTSCH or AMP connectors

•

Standard PVE pilot oil pressure of 13.5 bar [196 psi]

•

LED indicating error state and active or passive fault monitoring

•

Direction Indication output (-DI) or Neutral Power-Off (-NP) functionality

•

PVEH – proportional spool control for functions with high performance demands, see PVEH

9–32 VDC multi-voltage power supply

•

DEUTSCH, AMP or DIN/Hirschman connectors

•

Standard PVE pilot oil pressure of 13.5 bar [196 psi]

•

LED indicating error state and active or passive fault monitoring

•

Float (-F), Direction Indication output (-DI), Neutral Power-Off (-NP), Spool Position output (-SP)

•

or 0-10 VDC control signal (-U) functionality

PVES Schematic

©

Danfoss | February 2021 BC218286485446en-000310 | 7

PVES – proportional spool control for functions with high performance and reaction demands,

see PVES

9–32 VDC multi-voltage power supply

•

Analog voltage control signal 25-75% of supply voltage

•

DEUTSCH, AMP or DIN/Hirschman connectors

•

Standard PVE pilot oil pressure of 13.5 bar [196 psi]

•

LED indicating error state and active or passive fault monitoring

•

Variants available with Spool Position output (-SP) or 0-10 VDC control signal (-U) functionality

•

Page 8

W

Technical Information

PVE Series 7 — Electro-Hydraulic Actuators

PVE Electrical Actuator

Safety in Systems

All types and brands of control valves, including proportional valves, can fail. Therefore, the necessary

protection against the serious consequences of a functional failure should always be built into the

system.

General safety considerations

For each application an assessment should be made for the consequences of the system in case of

pressure failure and uncontrolled or blocked movements.

Warning

Because the proportional valve is used in many different applications and under different operating

conditions, it is the sole responsibility of the manufacturer to ensure that all performance, safety and

warning requirements of the application is met in his selection of products and complies with relevant

machine specific and generic standards.

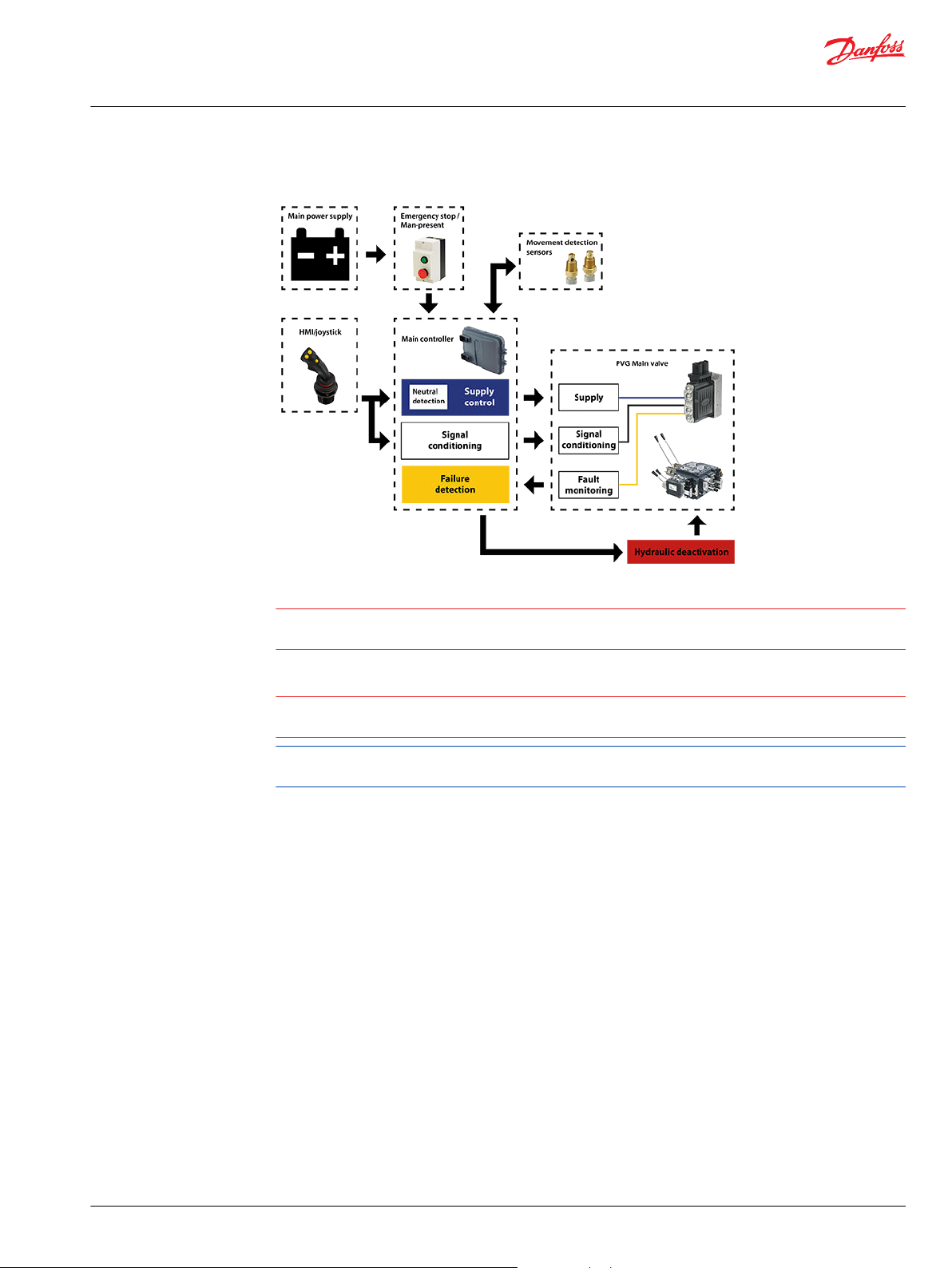

Control system example

An example of a control system using an aerial lift is shown below:

Aerial lift

This example breaks down the control system into smaller bits explaining the architecture in depth. Even

though many Danfoss components are used in the PVG control system.

The function of the control system is to use the output from the PVE together other external sensors to

ensure the PLUS+1 main controllers correct function of the aerial lift.

8 | © Danfoss | February 2021 BC218286485446en-000310

Page 9

W

C

Technical Information

PVE Series 7 — Electro-Hydraulic Actuators

PVE Electrical Actuator

Electrical block diagram

Warning

It is the responsibility of the equipment manufacturer that the control system incorporated in the

machine is declared as being in conformity with the relevant machine directives.

Caution

A mix of electrical actuation and hydraulic actuation on the same valve stack is not safe. PVE and PVH are

designed for different pilot pressure.

Cost-free repairs, as mentioned in Danfoss General Conditions of Sale, are carried out only at Danfoss or

at service shops authorized by Danfoss.

©

Danfoss | February 2021 BC218286485446en-000310 | 9

Page 10

21

0

Pp

LVDT

LED Circuit /

Microcontroller

Power

Supply

PVEO-DI

A

B

DI_B

DI_A

LED

Udc

Ramp Ramp

SV1 SV2

P109126

Technical Information

PVE Series 7 — Electro-Hydraulic Actuators

PVEO

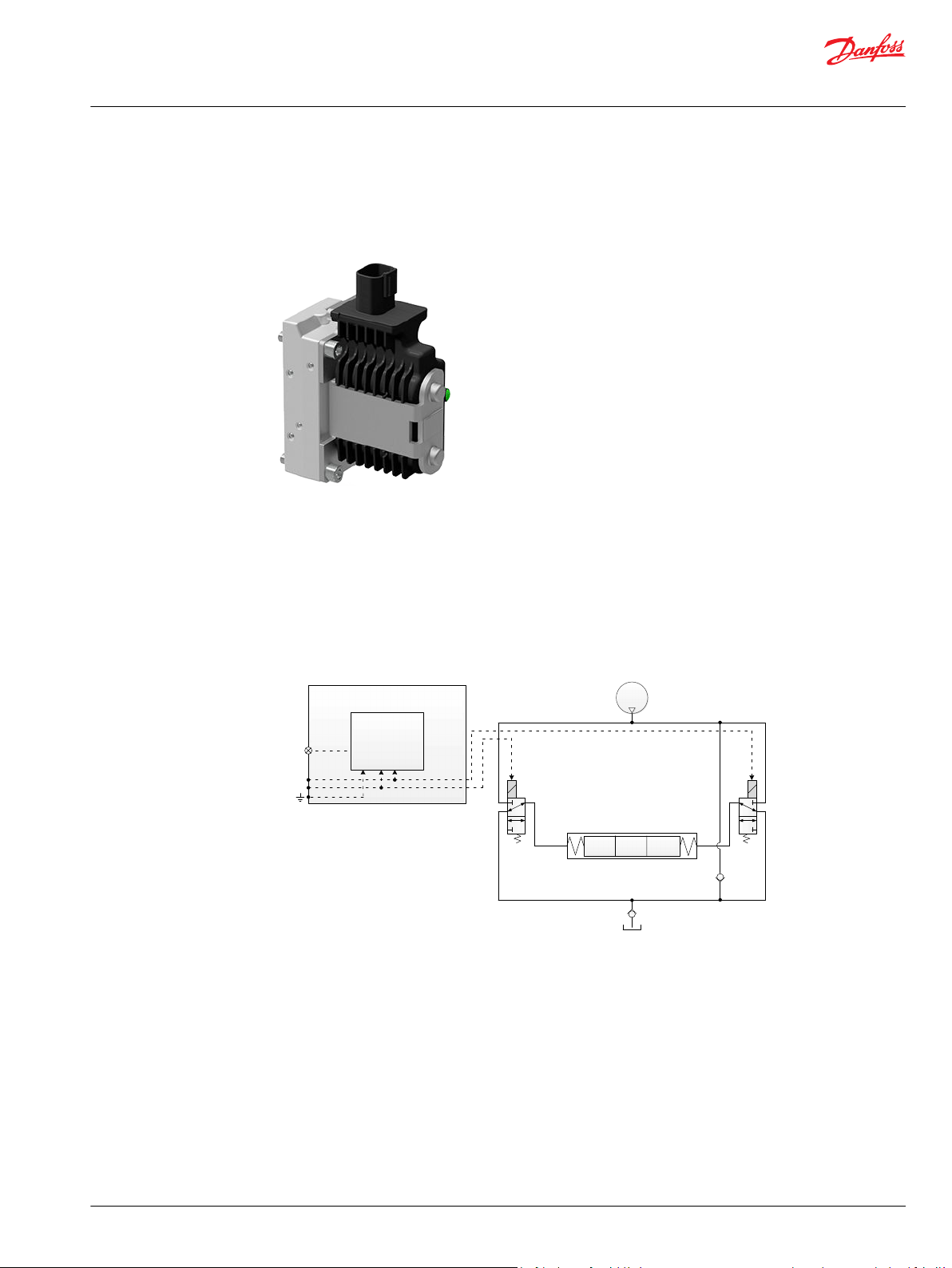

The PVEO actuator is a non-proportional ON/OFF control actuator with open-loop spool control primarily

used to control simple ON/OFF work functions where a proportional control of speed or oil flow is not a

requirement

The PVEO is available in two different performance variants, the standard PVEO and the PVEO-R with

ramp.

PVEO

PVEO functionality

The standard PVEO functionality includes the simplest electric circuit of the PVE Series 7 actuator

program, using a fixed 12 Vdc or 24 Vdc supply voltage or signal voltage and a simple LED circuit to

control the LED light indicating Power ON/OFF.

The PVEO-DI variant includes an LVDT spool position monitor and a more advanced electric circuit with

an embedded micro-controller and separate power supply to handle the Direction Indication

functionality.

An energization of solenoid valve SV1 and a simultaneous de-energization of SV2 will cause the main

spool to move to the right direction and vice versa. If both SV1 and SV2 are energized or de-energized

simultaneously, the main spool stays locked in its neutral position.

10 | © Danfoss | February 2021 BC218286485446en-000310

Page 11

P109195

P109200

101 [3.98]

45 [1.77]

89 [3.5]

P109231

Technical Information

PVE Series 7 — Electro-Hydraulic Actuators

PVEO

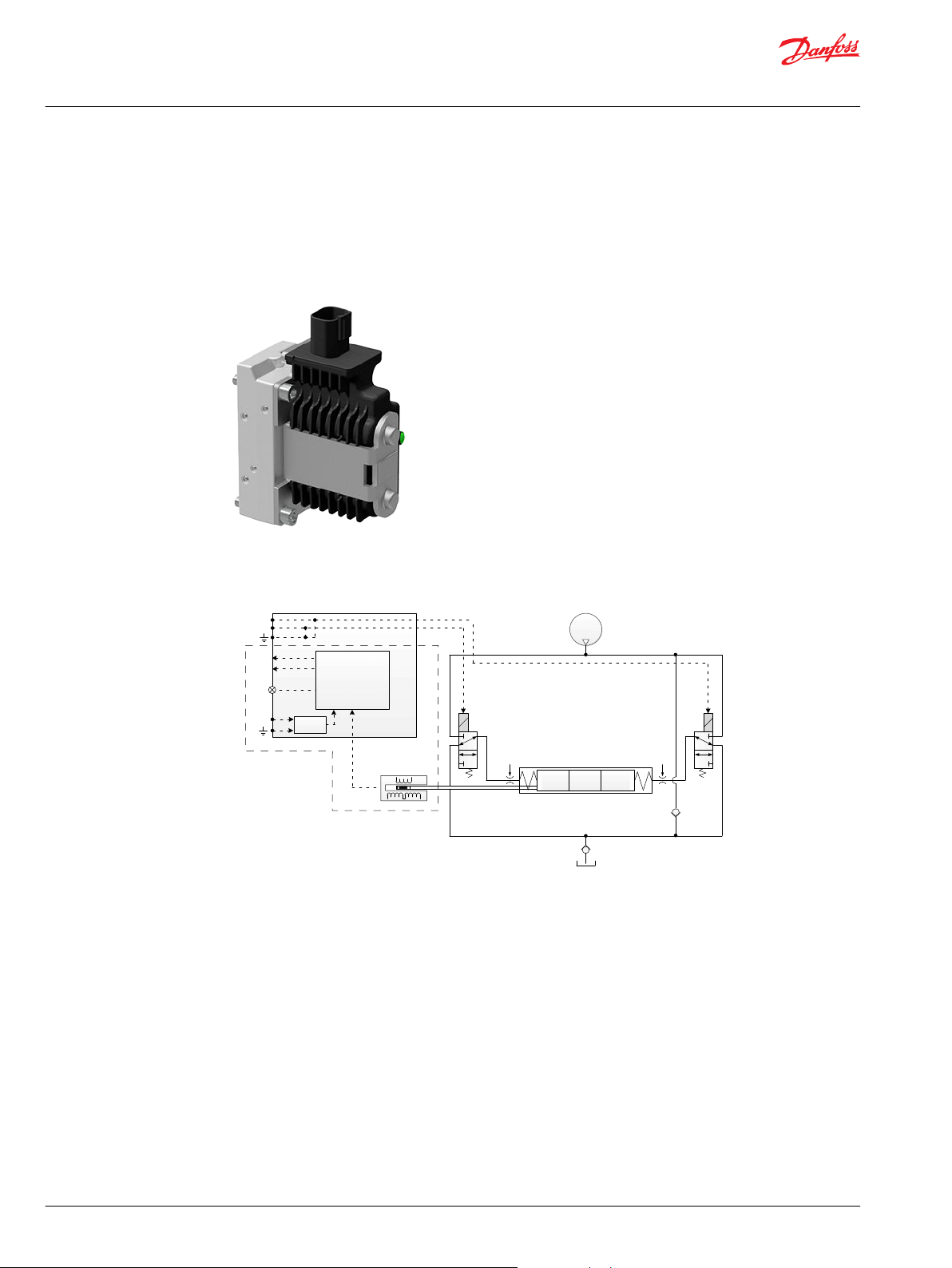

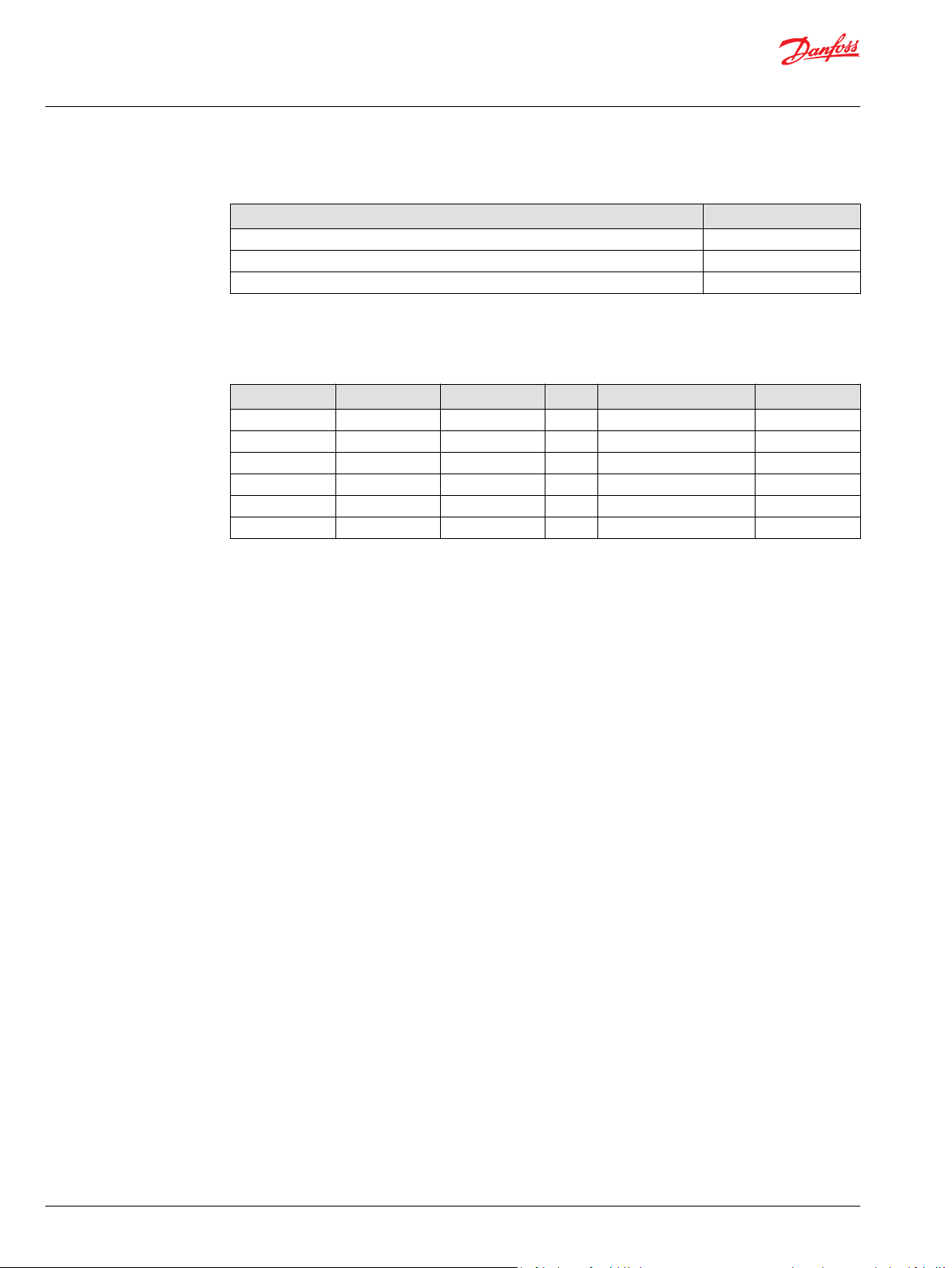

PVEO Schematics and Dimensions

Schematics

PVEO PVEO-R

Dimensions

PVEO Connector height

DEU = 24 mm [0.94 in]

DIN = 13 mm [0.51 in]

PVEO Technical Data

Control Specification

Description Type Value

Supply Voltage (Udc) Rated 12 Vdc 24 Vdc

Range 11 to 15 Vdc 22 to 30 Vdc

Max. ripple 5%

Current Consumption Typical 708 mA 361 mA

Minimum 430 mA 220 mA

Maximum 944 mA 482 mA

©

Danfoss | February 2021 BC218286485446en-000310 | 11

Page 12

100

0

Spool Position [%]

Time

T0 T1

T2

Spool Position

PFC (%)

Supply Voltage (UDC)

Max. spool pos. to neutral

T2

Neutral to max. spool pos.

T1

Boot-up

T0

P301823

Technical Information

PVE Series 7 — Electro-Hydraulic Actuators

PVEO

Operating Conditions

Description Type Value

Pilot Pressure Nominal 13.5 bar [196 psi]

Oil Consumption Neutral 0.0 l/min [0.0 gal/min]

Max T-port pressure Static 25 bar [365 psi]

Max T-port pressure Intermittent 40 bar [580 psi]

Storage Temperature Ambient -50 to +90°C [-58 to +194°F]

Operating Temperature Ambient -40 to +90°C [-40 to +194°F]

Oil Viscosity Operating range 12 to 75 cSt [65 to 347 SUS]

Oil Cleanliness Maximum 18/16/13 (according to ISO 4406)

Minimum 10.0 bar [145 psi]

Maximum 15.0 bar [218 psi]

Locked position 0.0 l/min [0.0 gal/min]

Actuating 0.9 l/min [0.24 gal/min]

Actuating (PVEO-R) 0.3 l/min [0.08 gal/min]

Minimum 4 cSt [39 SUS]

Maximum 460 cSt [2128 SUS]

PVEO Reaction Times

LED characteristic

Color LED characteristic Description

Green constant Power ON

Reaction times

12 | © Danfoss | February 2021 BC218286485446en-000310

Page 13

Technical Information

PVE Series 7 — Electro-Hydraulic Actuators

PVEO

Definition of Step Response

Reaction PVG 32 PVG 128/256

T0 – Boot-up 0 0 0 0

T1 – Neutral to max. spool stroke @ Power ON/ @

PVEO Variants for PVG

Constant U

T2 – Max. spool stroke to neutral @ Power OFF/@

Constant U

PVG 32/100 Variants

Part number Type

11166843 PVEO 1x4 DEU 67 12 Vdc Standard

11166838 PVEO 1x4 DEU 67 24 Vdc Standard

11166866 PVEO 1x4 AMP 66 12 Vdc Standard

11166837 PVEO 1x4 AMP 66 24 Vdc Standard

11166836 PVEO 1x4 DIN 65 12 Vdc Standard

11166743 PVEO 1x4 DIN 65 24 Vdc Standard

11166753 PVEO-R 1x4 DEU 67 12 Vdc Ramp

11166754 PVEO-R 1x4 DEU 67 24 Vdc Ramp

11166867 PVEO-R 1x4 AMP 66 12 Vdc Ramp

11166776 PVEO-R 1x4 AMP 66 24 Vdc Ramp

11166831 PVEO-R 1x4 DIN 65 12 Vdc Ramp

11166908 PVEO-R 1x4 DIN 65 24 Vdc Ramp

11168740

11166869

1

Includes Direction Indication special feature

DC

DC

1

1

PVEO-DI 2x4 AMP 66 12 Vdc Standard

PVEO-DI 2x4 AMP 66 24 Vdc Standard

Connector

PVEO

PVEO-DI

110 ms 325 ms 375 ms 520 ms

110 ms 340 ms 350 ms 600 ms

PVEO-R A port B port

IP Udc Functionality

PVG 120 Variants

Part number Type

11166755 PVEO 1x4 DEU 67 12 Vdc Standard

11166757 PVEO 1x4 DEU 67 24 Vdc Standard

11166815 PVEO 1x4 AMP 66 12 Vdc Standard

11166816 PVEO 1x4 AMP 66 24 Vdc Standard

11166822 PVEO 1x4 DIN 65 12 Vdc Standard

11166744 PVEO 1x4 DIN 65 24 Vdc Standard

11166882 PVEO-R 1x4 AMP 66 24 Vdc Ramp

11166909 PVEO-R 1x4 DIN 65 24 Vdc Ramp

Connector

IP Udc Functionality

PVG 128/256 Variants

Part number Type

11186328 PVEO 1x4 DEU 67 12 Vdc Standard

11186330 PVEO 1x4 DEU 67 24 Vdc Standard

©

Danfoss | February 2021 BC218286485446en-000310 | 13

Connector

IP Udc Functionality

Page 14

Technical Information

PVE Series 7 — Electro-Hydraulic Actuators

PVEO

PVG 128/256 Variants (continued)

Part number Type

11186331 PVEO 1x4 DIN 65 12 Vdc Standard

11186342 PVEO 1x4 DIN 65 24 Vdc Standard

PVG 60 Variants

Part number Type

11166939 PVEO 1x4 DIN 65 12 Vdc Standard

11166940 PVEO 1x4 DIN 65 24 Vdc Standard

Connector

Connector

IP Udc Functionality

IP Udc Functionality

14 | © Danfoss | February 2021 BC218286485446en-000310

Page 15

21

0

Pp

LED

A

B

LED Circuit

SV1 SV2

P109130

Technical Information

PVE Series 7 — Electro-Hydraulic Actuators

PVEO-HP

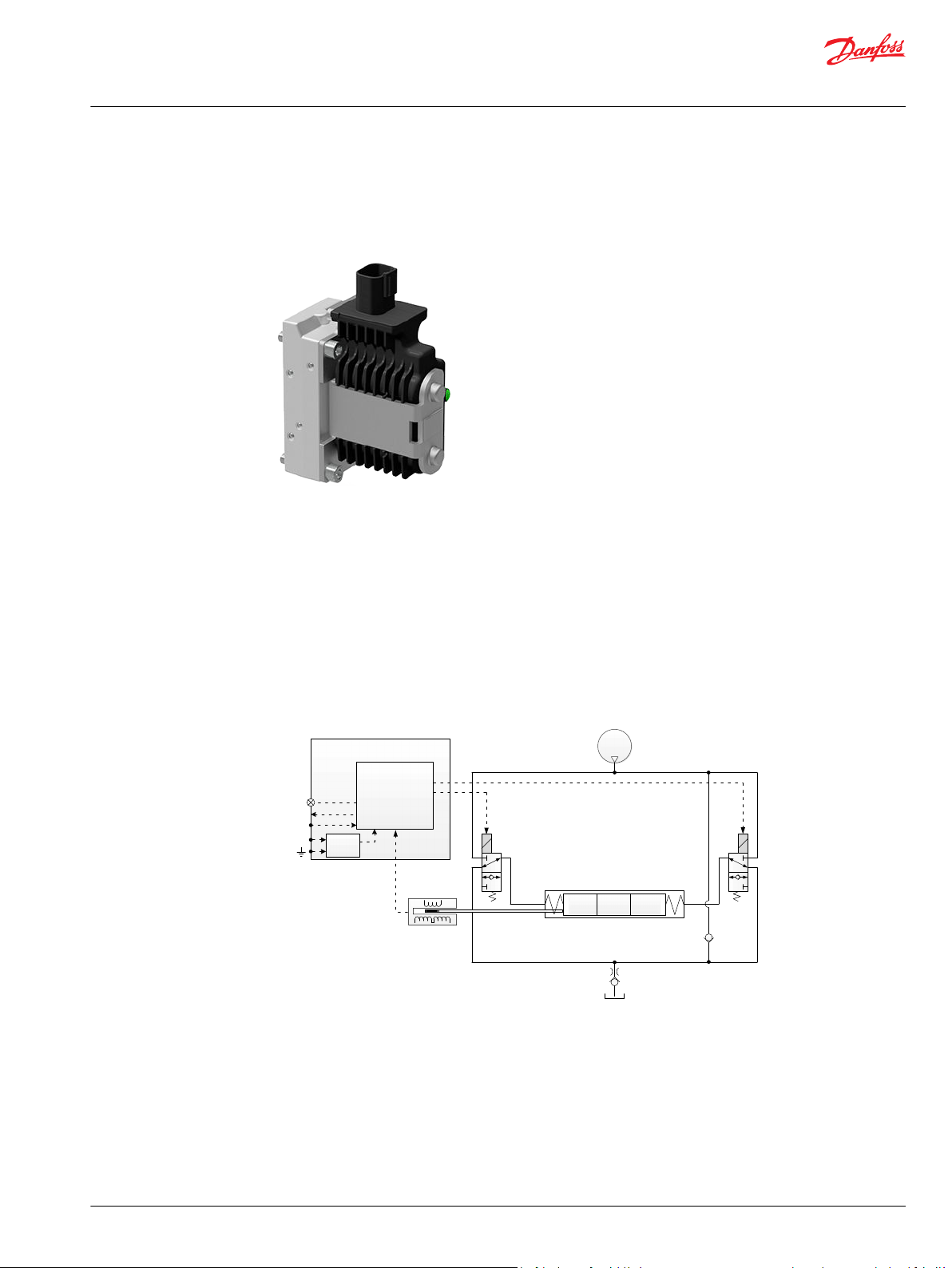

The PVEO-HP actuator is a non-proportional ON/OFF control actuator with open-loop spool control

primarily used to control simple ON/OFF work functions where a proportional control of speed or oil flow

is not a requirement.

PVEO-HP

All variants are available with following features:

Neutral position or max. spool stroke according to control signal

•

12 VDC or 24 VDC supply voltage

•

DEUTSCH, AMP or DIN/Hirschman connectors

•

PVH/PVHC pilot oil pressure of 25 bar [362.6 psi]

•

LED only indicating Power ON or Power OFF

•

PVEO-HP functionality diagram

The standard PVEO/PVEO-HP functionality includes the simplest electric circuit of the PVE actuator

program, using a fixed 12 VDC or 24 VDC supply voltage or signal voltage and a simple LED circuit to

control the LED light indicating Power ON/OFF.

An energization of solenoid valve SV1 and a simultaneous de-energization of SV2 will cause the main

spool to move to the right direction and vice versa. If both SV1 and SV2 are energized or de-energized

simultaneously, the main spool stays locked in its neutral position.

©

Danfoss | February 2021 BC218286485446en-000310 | 15

Page 16

P109195

101 [3.98]

45 [1.77]

89 [3.5]

P109231

Technical Information

PVE Series 7 — Electro-Hydraulic Actuators

PVEO-HP

PVEO-HP Schematics and Dimensions

Schematics

PVEO-HP

Dimensions

PVEO-HP Connector height

DEU = 24 mm [0.94 in]

AMP = 17 mm [0.67 in]

DIN = 13 mm [0.51 in]

For more information on dimensions, please see Dimension Overview for PVE Series 7 on page 59.

PVEO-HP Technical Data

Control Specification

Description Type 12 V

Supply Voltage (UDC) Range 11 to 15 V

Max. ripple 5%

Current Consumption Typical 1093 mA 555 mA

Minimum 660 mA 340 mA

Maximum 1458 mA 740 mA

16 | © Danfoss | February 2021 BC218286485446en-000310

DC

DC

24 V

DC

22 to 30 V

DC

Page 17

100

0

Spool Position [%]

Time

T0 T1

T2

Spool Position

PFC (%)

Supply Voltage (UDC)

Max. spool pos. to neutral

T2

Neutral to max. spool pos.

T1

Boot-up

T0

P301823

Technical Information

PVE Series 7 — Electro-Hydraulic Actuators

PVEO-HP

Technical data

Pilot pressure Nominal 25 bar [363 psi]

Fluid consumption Neutral 0 l/min [0 US gal/min]

Technical specification

Parameter Minimum Recommended range Maximum

Fluid temperature

Fluid viscosity

Fluid cleanliness

Operating temperature

Max. T-port pressure (static)

Max T-port pressure

(intermittent)

Minimum 21 bar [305 psi]

Maximum 25 bar [363 psi]

Locked position 0 l/min [0 US gal/min]

Actuating 0.9 l/min [0.24 US gal/min]

-30°C [-22°F] 30 to 60°C [86 to 140°F] 90° [194°F]

4 mm2/s [39 SUS] 12 to 75 mm2/s [65 to 347 SUS] 460 mm2/s [2128 SUS]

23/19/16 (according to ISO 4406)

Ambient: -40 to 90°C [-40 to 194°F]

25 bar [365 psi]

40 bar [ 580 psi]

PVEO-HP Reaction Times

LED characteristic

Color LED characteristic Description

Green constant Power ON

Reaction times

©

Danfoss | February 2021 BC218286485446en-000310 | 17

Page 18

Technical Information

PVE Series 7 — Electro-Hydraulic Actuators

PVEO-HP

Definition of Step Response

Reaction PVEO-HP

T0 – Boot-up 0

T1 – Neutral to max. spool stroke @ Power ON/@ Constant U

T2 – Max. spool stroke to neutral @ Power OFF/@ Constant U

PVEO-HP Variants for PVG

PVG 32/100 variants

Part number Type

11166765 PVEO-HP 1x4 DEU 67 12 Vdc Standard

11166766 PVEO-HP 1x4 DEU 67 24 Vdc Standard

11166763 PVEO-HP 1x4 AMP 66 12 Vdc Standard

11187524 PVEO-HP 1x4 AMP 66 24 Vdc Standard

11187551 PVEO-HP 1x4 DIN 65 12 Vdc Standard

11187562 PVEO-HP 1x4 DIN 65 24 Vdc Standard

Connector

DC

DC

IP Udc Functionality

90 ms

70 ms

18 | © Danfoss | February 2021 BC218286485446en-000310

Page 19

21

0

Pp

LVDT

SV2SV1

Micro-

controller

Power

Supply

U

DC

U

S

Error

LED

P109132

Technical Information

PVE Series 7 — Electro-Hydraulic Actuators

PVEM

The PVEM actuator is a proportional control actuator with closed-loop spool control primarily used to

control work functions with medium performance requirements. The PVEM is available in three different

performance variants, the standard PVEM, the PVEM-R with ramp and the PVEM-Q with quick reaction.

PVEM

Variants are available with following features:

11-32 VDC milti-voltage power supply

•

Analog voltage control signal 25–75% of supply voltage

•

DIN/Hirschman connectors

•

Standard PVE pilot oil pressure of 13.5 bar [196 psi]

•

LED indicating error state and passive fault monitoring

•

Float (-F), quick Ramp (-R) or Quick reaction functionality (-Q)

•

PVEM functionality

The PVE functionality includes an electric circuit with a closed-loop logic. An embedded micro-controller

processes the signal voltage and the LVDT feedback signal and regulates the solenoid valves accordingly.

An energization of solenoid valve SV1 and a simultaneous de-energization of SV2 will cause the main

spool to move to the right direction and vice versa. If both SV1 and SV2 are energized or de-energized

simultaneously, the main spool stays locked in its neutral position.

©

Danfoss | February 2021 BC218286485446en-000310 | 19

Page 20

P109196

P109201

101 [3.98]

45 [1.77]

89 [3.5]

P109232

Technical Information

PVE Series 7 — Electro-Hydraulic Actuators

PVEM

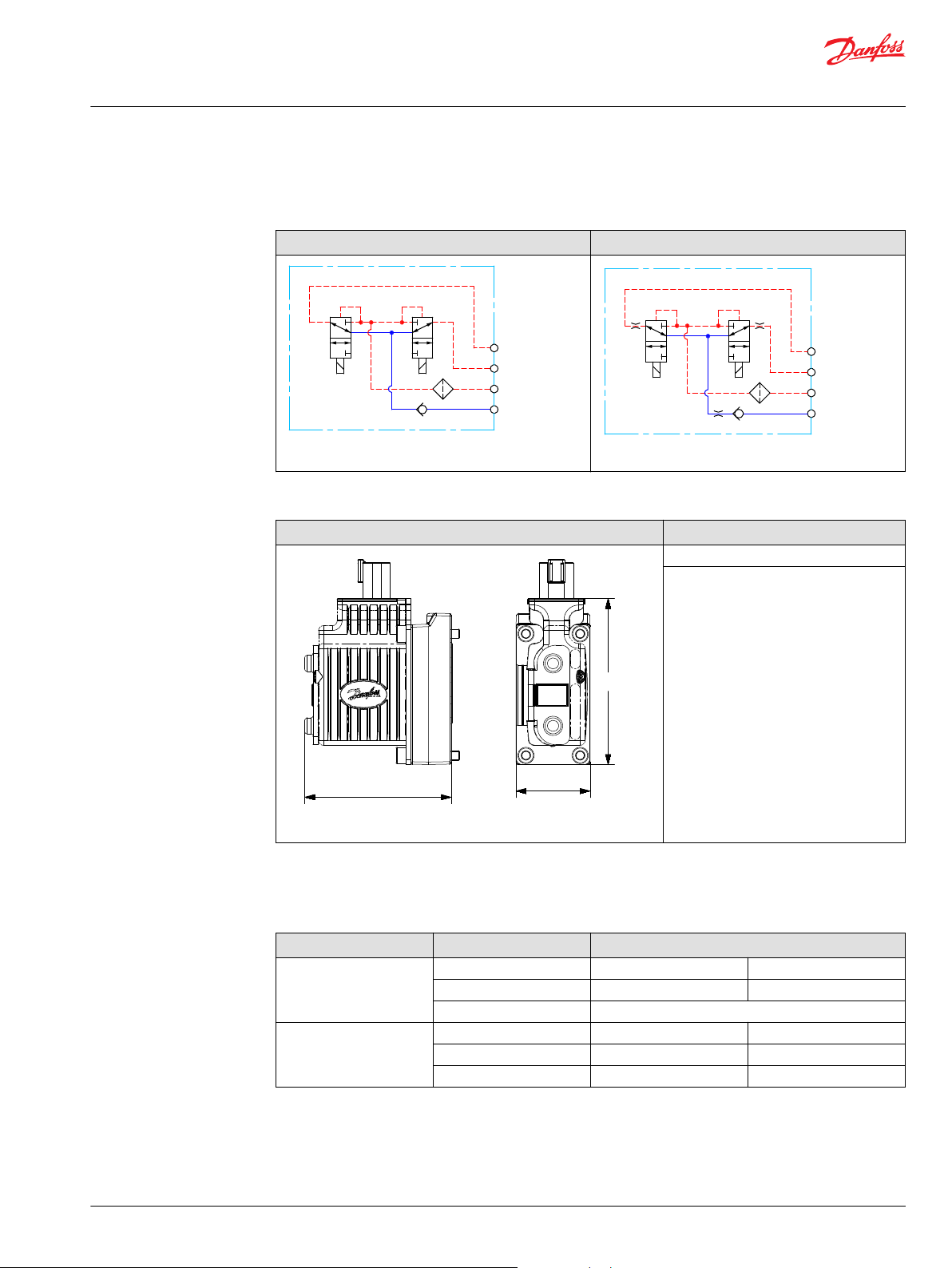

PVEM Schematics and Dimensions

Schematics

PVEM/PVEM-FLB/PVEM-R PVEM-Q

Dimensions

PVEM Connector height

DEU = 24 mm [0.94 in]

AMP = 17 mm [0.67 in]

DIN = 13 mm [0.51 in]

For more information on dimensions, please see Dimension Overview for PVE Series 7 on page 59.

PVEM Technical Data

Control Specification

Description Type Value

Supply Voltage (UDC) Rated Range 11 to 32 V

Max. ripple 5%

Signal Voltage PWM (US) Neutral US = 0.5 UDC = 50% DUT

Q: P to A US = (0.5 to 0.25) UDC = 50% to 25% DUT

Q: P to B US = (0.5 to 0.75) UDC = 50% to 75% DUT

Input Impedance Rated 12 kΩ

Input Capacitance Rated 1 nF

20 | © Danfoss | February 2021 BC218286485446en-000310

DC

Page 21

Technical Information

PVE Series 7 — Electro-Hydraulic Actuators

PVEM

Current consumption

Description @ 12 V

PWM Frequency (US) recommended > 200 Hz > 200 Hz

Current Consumption 690 mA 350 mA

Pilot pressure

Minimum Nominal Maximum

10.0 bar [145 psi] 13.5 bar [196 psi] 15.0 bar [218 psi]

Fluid consumption

Neutral/Locked position Actuating (PVEM-R) Actuating (PVEM-Q) Actuating

0 l/min 0.3 l/min 1.0 l/min

Technical specification

Parameter Minimum Recommended range Maximum

Fluid temperature

Fluid viscosity

Fluid cleanliness

Operating temperature

Max. T-port pressure

static / intermittent

DC

[0.26 US gal/min][0.08 US

gal/min]

-30°C [-22°F] 30 to 60°C [86 to 140°F] 90° [194°F]

4 mm2/s [39 SUS] 12 to 75 mm2/s [65 to 347 SUS] 460 mm2/s [2128 SUS]

23/19/16 (according to ISO 4406)

Ambient: -40 to 90°C [-40 to 194°F]

25 / 40 bar

[365 / 580 psi]

@ 24 V

DC

0.5 l/min

[0.13 US gal/min]

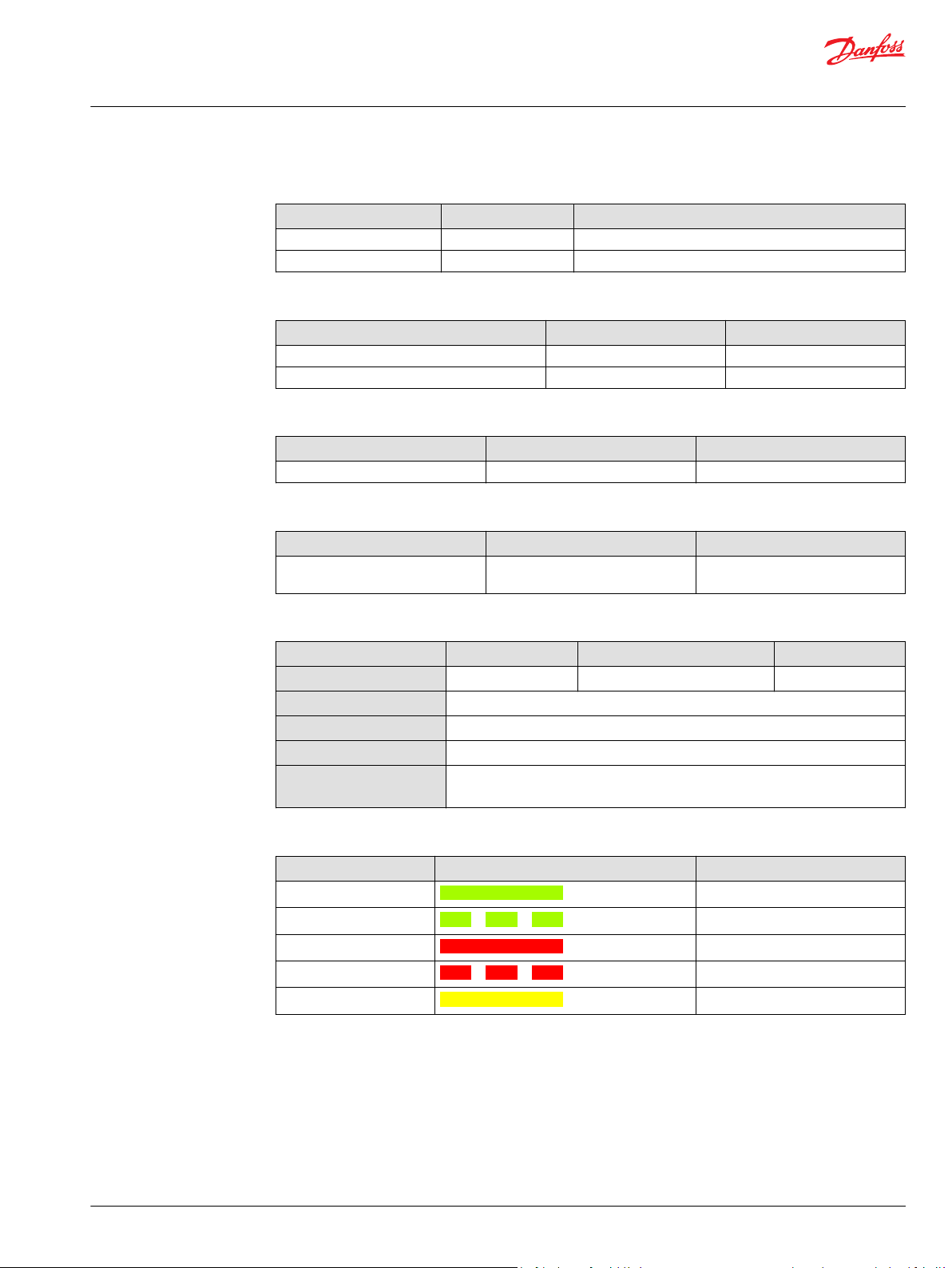

LED characteristic

Color LED characteristic Description

Green constant No error – Actuating

Green flashing @ 1.5 Hz Neutral – Power save

Red constant Internal error

Red flashing @ 1.5 Hz External or Float error

©

Danfoss | February 2021 BC218286485446en-000310 | 21

Page 22

100

0

Spool Position [%]

Time

T0 T1

T2

Spool Position

PFC (%)

Supply Voltage (UDC)

Max. spool pos. to neutral

T2

Neutral to max. spool pos.

T1

Boot-up

T0

P301823

Us [%]

100

0

Spool Position [%]

100

(0.75 ∙ U dc)

BP

h

50

(0.50 ∙ U dc)

vFixed pos.

Spool Position

Technical Information

PVE Series 7 — Electro-Hydraulic Actuators

PVEM

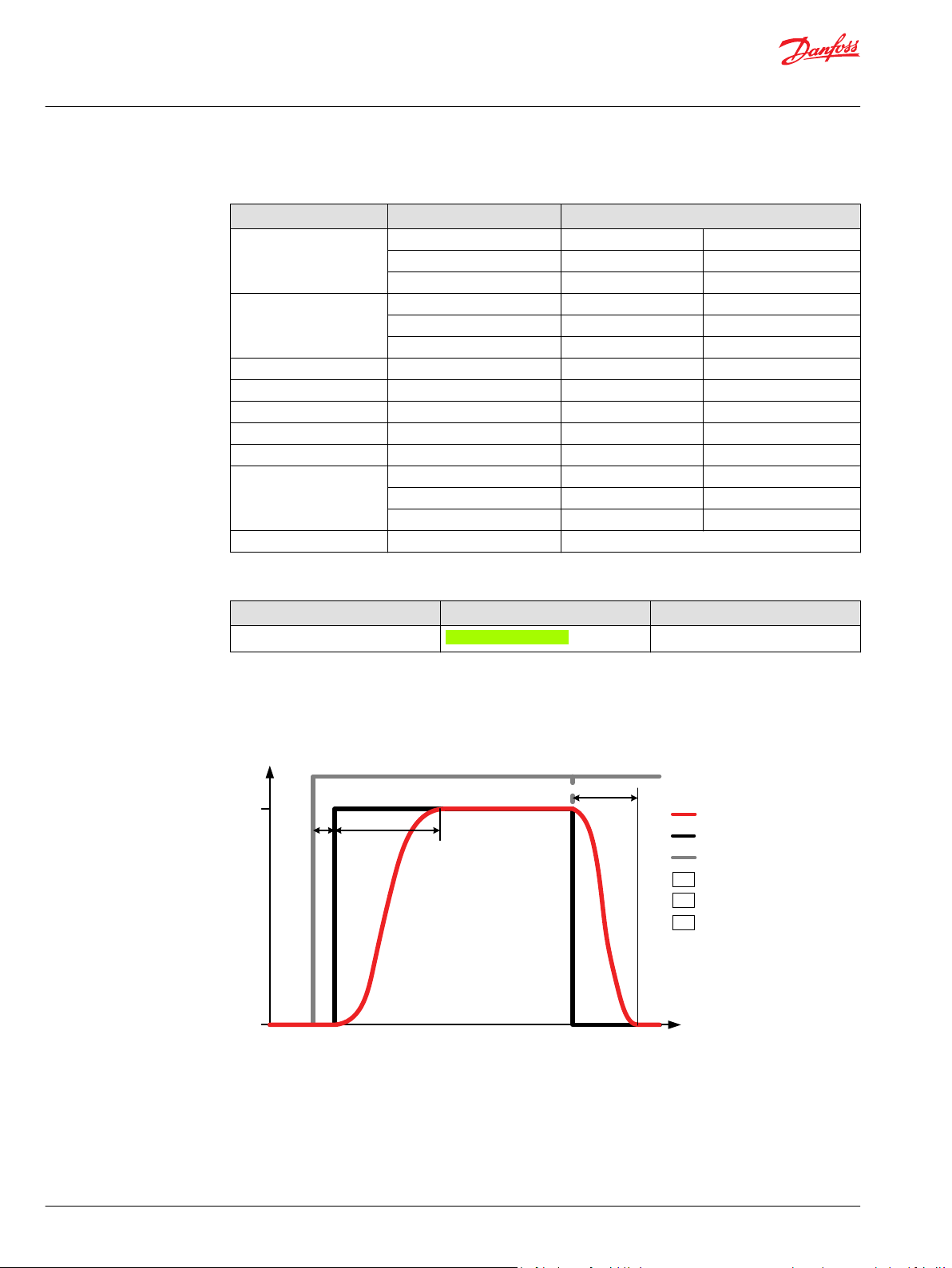

PVEM Reaction Times

Reaction times

PVEM Hysteresis and Ripple

Definition of Step Response

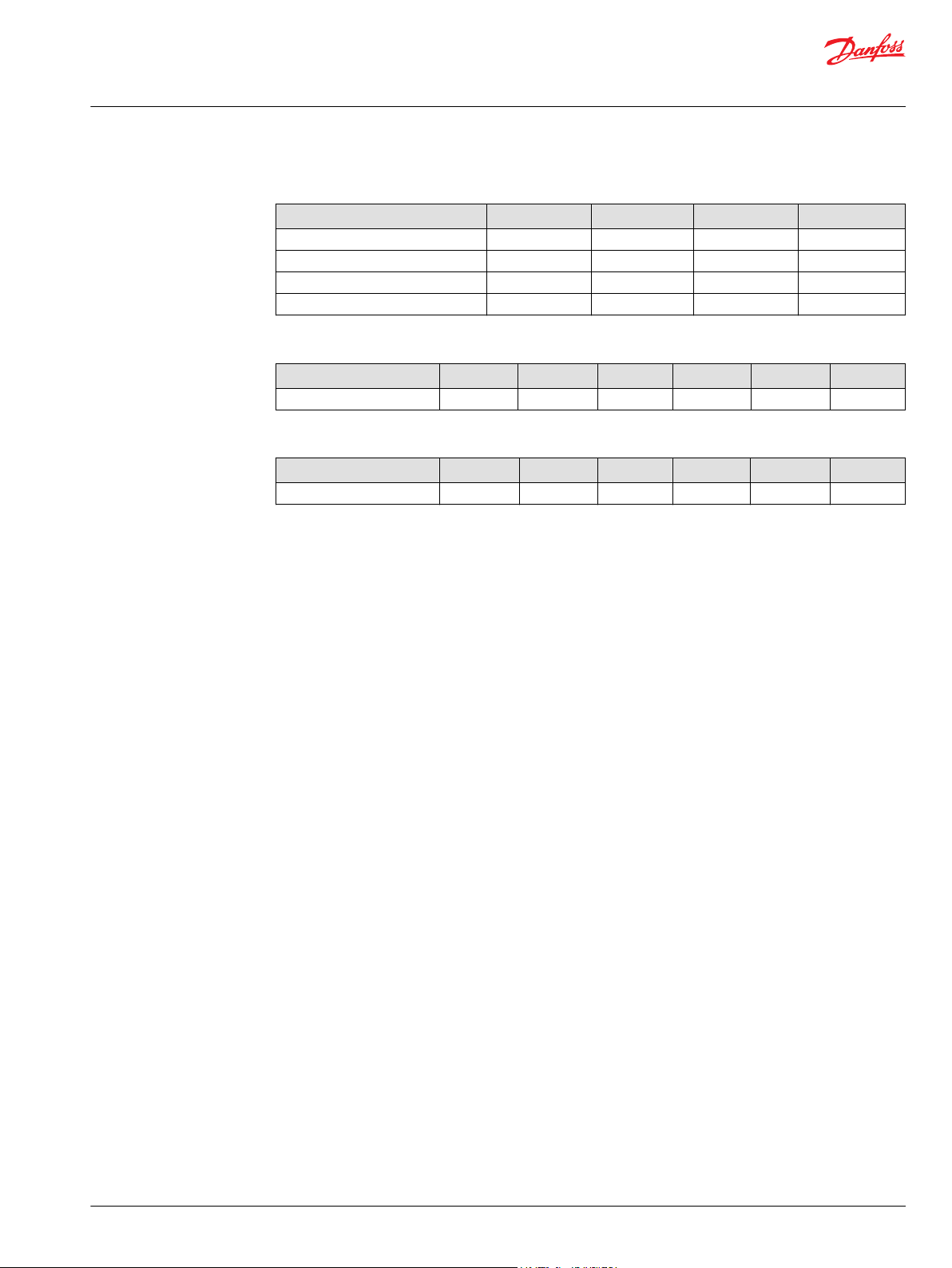

Reaction PVEM-R PVEM/PVEM-FLB PVEM-Q

T0 – Boot-up 15 ms 15 ms 15 ms

T1 – Neutral to max. spool stroke @ Power ON 325 ms 225 ms 125 ms

T2 – Max. spool stroke to neutral @ Power OFF 110 ms 110 ms 110 ms

T1 – Neutral to max. spool stroke @ Constant U

T2 – Max. spool stroke to neutral @ Constant U

DC

DC

310 ms 210 ms 110 ms

90 ms 90 ms 90 ms

Description Type PVEM

Hysteresis (h) Rated [%] 15

Steady state ripple @ fixed US (v) Rated [mm] 0.0

For more information on hysteresis and ripple, see Hysteresis and Ripple.

22 | © Danfoss | February 2021 BC218286485446en-000310

Page 23

Technical Information

PVE Series 7 — Electro-Hydraulic Actuators

PVEM

PVEM Variants for PVG

PVG 32/100 Variants

Part number Type

11166829 PVEM 1x4 DIN 65 Passive Standard

11166852 PVEM-FLB 1x4 DIN 65 Passive Float B-port

11166845 PVEM-R 1x4 DIN 65 Passive Ramp

11166853 PVEM-Q 1x4 DIN 65 Passive Quick Reaction

Connector

IP

Fault Monitoring

Functionality

©

Danfoss | February 2021 BC218286485446en-000310 | 23

Page 24

21

0

Pp

Micro-

controller

Power

Supply

NP

DI_B

DI_A

Udc

LED

Error

Us

Udc

2

Special

Features

NC1 NC3

LVDT

P109147

Technical Information

PVE Series 7 — Electro-Hydraulic Actuators

PVEA

The PVEA actuator is a proportional control actuator with a closed-loop spool control primarily used to

control work functions with above medium performance requirements.

PVEA

11-32 VDC multi-voltage power supply

•

Analog voltage control signal 25–75% of supply voltage

•

Standard PVE pilot oil pressure of 13.5 bar [196 psi]

•

DEUTSCH or AMP connectors

•

LED indicating error state and active or passive fault monitoring

•

Direction Indication output (-DI) or Neutral Power-Off (-NP) functionality

•

PVEA-DI functionality

PVEA-DI functionality

The PVE functionality includes an electric circuit with a closed-loop logic. An embedded micro-controller

processes the signal voltage and the LVDT feedback signal and regulates the solenoid valves accordingly.

A continuous modulation of solenoid valve NC1 and a simultaneous de-energization of NC3 causes the

main spool to move to the right direction and vice versa. When the main spool is stroked to the far right,

a simultaneous modulation of both NC1 and NC3 balances the main spool in its stroked position. The

main spool oscillates in its stroked position at a frequency corresponding to the modulation frequency.

When both NC1 and NC3 are de-energized, the main spool moves back to its neutral position by means

of the main spool neutral spring and the hydraulic principle.

24 | © Danfoss | February 2021 BC218286485446en-000310

Page 25

P109197

101 [3.98]

45 [1.77]

89 [3.5]

P109232

Technical Information

PVE Series 7 — Electro-Hydraulic Actuators

PVEA

PVEA Schematics and Dimensions

Schematics

PVEA

Dimensions

PVEA Connector height

DEU = 24 mm [0.94 in]

AMP = 17 mm [0.67 in]

DIN = 13 mm [0.51 in]

For more information on dimensions, see Dimension Overview for PVE Series 7 on page 59.

PVEA Technical Data

Control Specification

Description Type Value

Supply Voltage (UDC) Rated Range 11 to 32 V

Max. ripple 5%

Signal Voltage PWM (US) Neutral US = 0.5 UDC = 50% DUT

Q: P to A US = (0.5 to 0.25) UDC = 50% to 25% DUT

Q: P to B US = (0.5 to 0.75) UDC = 50% to 75% DUT

Input Impedance Rated 12 kΩ

Input Capacitance Rated 1 nF

©

Danfoss | February 2021 BC218286485446en-000310 | 25

DC

Page 26

Technical Information

PVE Series 7 — Electro-Hydraulic Actuators

PVEA

Current consumption

Description @ 12 V

PWM Frequency (US) recommended > 1000 Hz > 1000 Hz

Current Consumption 290 mA 150 mA

Pilot pressure

Minimum Nominal Maximum

10.0 bar [145 psi] 13.5 bar [196 psi] 15.0 bar [218 psi]

Fluid consumption

Neutral Locked position Actuating

0 l/min 0 l/min 1.0 l/min

Technical specification

Parameter Minimum Recommended range Maximum

Fluid viscosity

Fluid cleanliness

Storage temperature

Operating temperature

Max. T-port pressure

static / intermittent

DC

4 mm2/s [39 SUS] 12 to 75 mm2/s [65 to 347 SUS] 460 mm2/s [2128 SUS]

18/16/13 (according to ISO 4406)

Ambient: -50 to 90°C [-58 to 194°F]

Ambient: -40 to 90°C [-40 to 194°F]

25 / 40 bar

[365 / 580 psi]

@ 24 V

DC

[0.26 US gal/min]

LED characteristic

Color LED characteristic Description

Green constant No error – Actuating

Green flashing @ 1.5 Hz Neutral – Power save

Red constant Internal error

Red flashing @ 1.5 Hz External or Float error

26 | © Danfoss | February 2021 BC218286485446en-000310

Page 27

100

0

Spool Position [%]

Time

T0 T1

T2

Spool Position

PFC (%)

Supply Voltage (UDC)

Max. spool pos. to neutral

T2

Neutral to max. spool pos.

T1

Boot-up

T0

P301823

Us [%]

100

0

Spool Position [%]

100

(0.75 ∙ U dc)

BP

h

50

(0.50 ∙ U dc)

vFixed pos.

Spool Position

Technical Information

PVE Series 7 — Electro-Hydraulic Actuators

PVEA

PVEA Reaction Times

Reaction times

PVEA Hysteresis and Ripple

Reaction PVG 32 (PVEA)

T0 – Boot-up [ms] 50 ms

T1 – Neutral to max. spool stroke @ Power ON 355 ms

T2 – Max. spool stroke to neutral @ Power OFF 260 ms

T1 – Neutral to max. spool stroke @ Constant U

T2 – Max. spool stroke to neutral @ Constant U

DC

DC

305 ms

210 ms

Spool position vs. supply (%)

Description Type PVEA

Hysteresis (h) Rated [%] 2

Steady state ripple @ fixed Us (v) Rated [mm] 0.3

For more information on hysteresis and ripple, see Hysteresis and Ripple.

©

Danfoss | February 2021 BC218286485446en-000310 | 27

Page 28

Technical Information

PVE Series 7 — Electro-Hydraulic Actuators

PVEA

PVEA Variants for PVG

PVG 32/100 Variants

Part number Type

11177346 PVEA 1x4 DEU 67 Passive Standard

11177347 PVEA 1x4 DEU 67 Active Standard

11177353 PVEA 1x4 AMP 66 Passive Standard

11177348 PVEA 1x4 AMP 66 Active Standard

11177345

11177357

11177356

11177355

1

Includes Neutral Power-OFF special feature

2

Includes Direction Indication special feature

1

2

2

2

PVEA-NP 1x6 DEU 67 Active Standard

PVEA-DI 2x4 DEU 67 Active Standard

PVEA-DI 2x4 AMP 66 Passive Standard

PVEA-DI 2x4 AMP 66 Active Standard

Connector

IP

Fault monitoring

Functionality

28 | © Danfoss | February 2021 BC218286485446en-000310

Page 29

21

0

Pp

Micro-

controller

Power

Supply

U

S

Special

Features

SP

NP

Uf

DI_B

DI_A

Udc

2

LED

Error

Udc

NC1 NC3

NO4

NO2

LVDT

P109148

Technical Information

PVE Series 7 — Electro-Hydraulic Actuators

PVEH

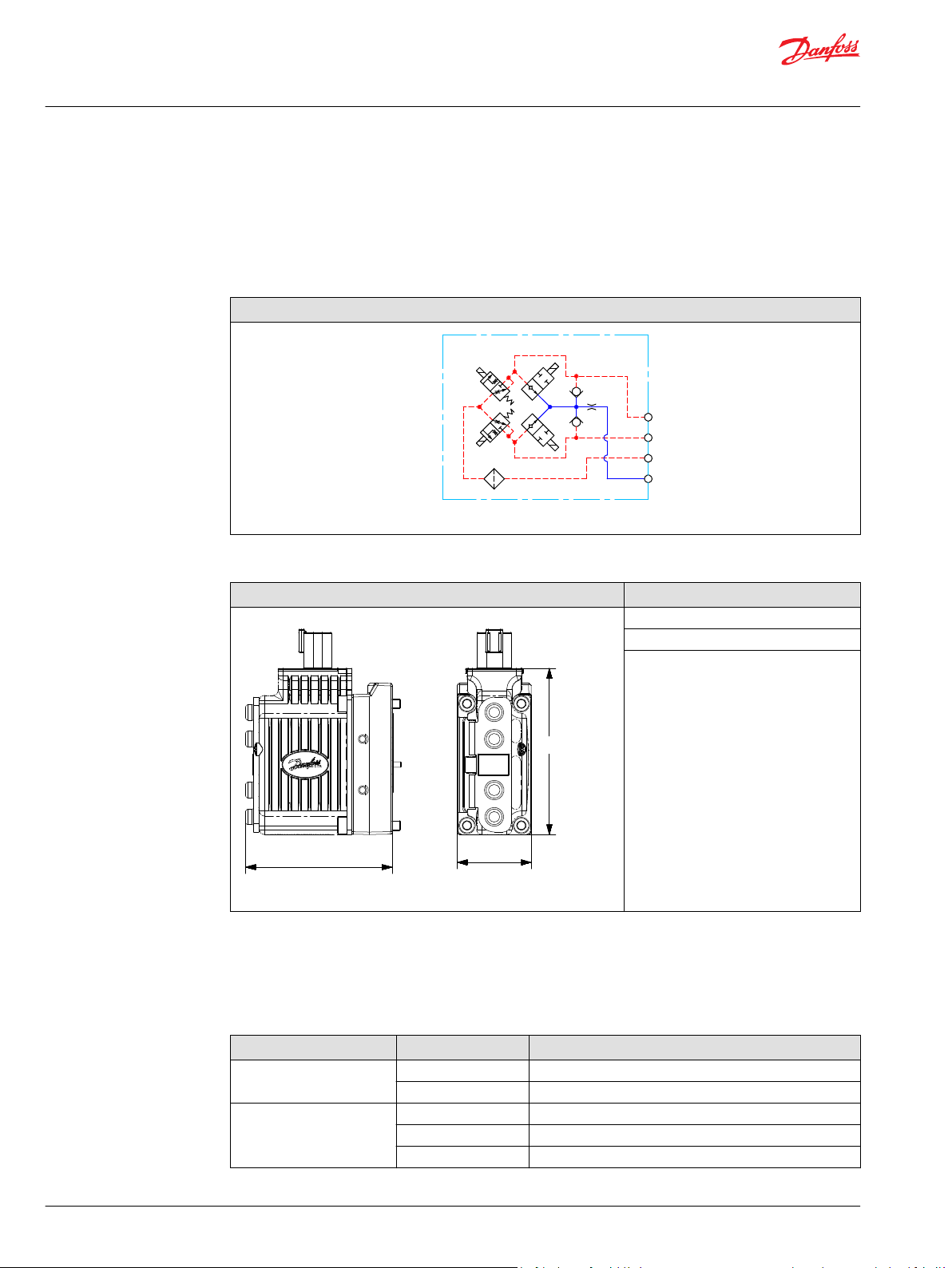

The PVEH actuator is a proportional control actuator with closed-loop spool control primarily used to

control work functions with high performance requirements.

PVEH

11-32 VDC multi-voltage power supply

•

Analog voltage control signal 25–75% of supply voltage

•

Standard PVE pilot oil pressure of 13.5 bar [196 psi]

•

DEUTSCH, AMP or DIN/Hirschman connectors

•

LED indicating error state and active or passive fault monitoring

•

Float (-F), Direction Indication output (-DI), Neutral Power-Off (-NP), Spool Position output (-SP) or

•

0-10 VDC control signal (-U) functionality

PVEH functionality

PVEH functionality

The PVE functionality includes an electric circuit with a closed-loop logic. An embedded micro-controller

processes the signal voltage and the LVDT feedback signal and regulates the solenoid valves accordingly.

A continuous modulation of solenoid valves NC1 and NO4 together with a simultaneous energization of

NO2 and de-energization of NC3 causes the main spool to move to the right direction and vice versa.

When the main spool is stroked to the far right, a simultaneous energization of both NO2 and NO4 and

de-energization of both NC1 and NC3 balances the main spool in its stroked position. An emergency stop

activated when the spool is stroked will cause all solenoid valves to de-energize causing the main spool

©

Danfoss | February 2021 BC218286485446en-000310 | 29

Page 30

P109198

101 [3.98]

45 [1.77]

89 [3.5]

P109233

Technical Information

PVE Series 7 — Electro-Hydraulic Actuators

PVEH

to move back to its neutral position by means of the main spool neutral spring and the hydraulic

principle.

PVEH Schematics and Dimensions

Schematics

PVEH

PVEH Technical Data

Dimensions

PVEH Connector height

DEU = 24 mm [0.94 in]

DIN = 13 mm [0.51 in]

Control Specification

Description Type Value

Supply Voltage (UDC) Rated Range 11 to 32 V

Max. ripple 5%

Signal Voltage PWM (US) Neutral US = 0.5 UDC = 50% DUT

Q: P to A US = (0.5 to 0.25) UDC = 50% to 25% DUT

Q: P to B US = (0.5 to 0.75) UDC = 50% to 75% DUT

Input Impedance Rated 12 kΩ

Input Capacitance Rated 1 nF

DC

30 | © Danfoss | February 2021 BC218286485446en-000310

Page 31

Technical Information

PVE Series 7 — Electro-Hydraulic Actuators

PVEH

Current consumption

Description @ 12 V

PWM Frequency (US) recommended > 1000 Hz > 1000 Hz

Current Consumption 540 mA 270 mA

Max. DI Current 200 mA 200 mA

Pilot pressure

Minimum Nominal Maximum

10.0 bar [145 psi] 13.5 bar [196 psi] 15.0 bar [218 psi]

Fluid consumption

Neutral Locked position Actuating

0.0 l/min 0.0 l/min 0.7 l/min

Technical specification

Parameter Minimum Recommended range Maximum

Fluid viscosity

Fluid cleanliness

Storage temperature

Operating temperature

Max. T-port pressure

static / intermittent

DC

4 mm2/s [39 SUS] 12 to 75 mm2/s [65 to 347 SUS] 460 mm2/s [2128 SUS]

18/16/13 (according to ISO 4406)

Ambient: -50 to 90°C [-58 to 194°F]

Ambient: -40 to 90°C [-40 to 194°F]

25 / 40 bar

[365 / 580 psi]

@ 24 V

DC

[0.18 US gal/min]

LED Characteristic

Color LED Characteristic Description

Green constant No error – Actuating

Green flashing @ 1.5 Hz Neutral – Power save

Red constant Internal error

Red flashing @ 1.5 Hz External or Float error

Yellow Disable mode

©

Danfoss | February 2021 BC218286485446en-000310 | 31

Page 32

100

0

Spool Position [%]

Time

T0 T1

T2

Spool Position

PFC (%)

Supply Voltage (UDC)

Max. spool pos. to neutral

T2

Neutral to max. spool pos.

T1

Boot-up

T0

P301823

Us [%]

100

0

Spool Position [%]

100

(0.75 ∙ U dc)

BP

h

50

(0.50 ∙ U dc)

vFixed pos.

Spool Position

Technical Information

PVE Series 7 — Electro-Hydraulic Actuators

PVEH

PVEH Reaction Times

Reaction times

PVEH Hysteresis and Ripple

Reaction PVG 32 PVG 128/256

T0 – Boot-up [ms] 40 ms 40 ms

T1 – Neutral to max. spool stroke @ Power ON [ms] 155 ms 400 ms

T2 – Max. spool stroke to neutral @ Power OFF [ms] 130 ms 300 ms

T1 – Neutral to max. spool stroke @ Constant UDC [ms] 115 ms 380 ms

T2 – Max. spool stroke to neutral @ Constant UDC [ms] 90 ms 270 ms

Spool position vs. supply (%)

Description Type PVEH

Hysteresis (h) Rated [%] 4

Steady state ripple @ fixed Us (v) Rated [mm] 0.0

32 | © Danfoss | February 2021 BC218286485446en-000310

Page 33

Technical Information

PVE Series 7 — Electro-Hydraulic Actuators

PVEH

PVEH Variants for PVG

PVG 32/100 variants

Part number Type

11166732 PVEH 1x4 DEU 67 Passive Standard

11166775 PVEH 1x4 DEU 67 Active Standard

11166825 PVEH 1x4 AMP 66 Passive Standard

11166818 PVEH 1x4 AMP 66 Active Standard

11166824 PVEH 1x4 DIN 65 Passive Standard

11166817 PVEH 1x4 DIN 65 Active Standard

11166832

11166821

11166770

11166772

11166840 PVEH-FLB 1x4 DEU 67 Passive Float B-port

11166742 PVEH-FLB 1x4 DEU 67 Active Float B-port

11166839 PVEH-FLB 1x4 DIN 65 Active Float B-port

11166841

11168738

11168739

11166773

11166750

11166835

11166820

11166819

1

Includes Disable Mode special feature

2

Includes Dedicated Float Pin (UF) special feature

3

Includes Spool Position special feature

4

Includes Neutral Power-Off special feature

5

Includes Direction Indication special feature

1

1

1

1

2

2

2

3

4

5

5

5

PVEH-U 1x4 AMP 66 Passive Fixed US 0-10 V

PVEH-U 1x4 AMP 66 Active Fixed US 0-10 V

PVEH-U 1x4 DIN 65 Passive Fixed US 0-10 V

PVEH-U 1x4 DIN 65 Active Fixed US 0-10 V

PVEH-FLA 1x6 DEU 67 Active Float A-port

PVEH-FLA 1x6 AMP 66 Passive Float A-port

PVEH-FLA 1x6 AMP 66 Active Float A-port

PVEH-SP 1x6 DEU 67 Active Standard

PVEH-NP 1x6 DEU 67 Fast active Standard

PVEH-DI 2x4 DEU 67 Active Standard

PVEH-DI 2x4 AMP 66 Passive Standard

PVEH-DI 2x4 AMP 66 Active Standard

Connector

IP

Fault monitoring

Functionality

dc

dc

dc

dc

PVG 120 variants

Part number Type

11166760 PVEH 1x4 DEU 67 Passive Standard

11166814 PVEH 1x4 AMP 66 Passive Standard

11166801 PVEH 1x4 AMP 66 Active Standard

11166813 PVEH 1x4 DIN 65 Passive Standard

11166777 PVEH 1x4 DIN 65 Active Standard

11166771

11166767

1

Includes Disable Mode special feature

©

Danfoss | February 2021 BC218286485446en-000310 | 33

1

1

PVEH-U 1x4 DIN 65 Passive Fixed US 0-10 V

PVEH-U 1x4 DIN 65 Active Fixed US 0-10 V

Connector

IP

Fault monitoring

Functionality

dc

dc

Page 34

Technical Information

PVE Series 7 — Electro-Hydraulic Actuators

PVEH

PVG 128/256 variants

Part number Type

11186325 PVEH 1x4 DEU 67 Passive Standard

11186326 PVEH 1x4 DEU 67 Active Standard

11186321 PVEH 1x4 DIN 65 Passive Standard

11186322 PVEH 1x4 DIN 65 Active Standard

11186323

11186324

1

Includes Disable Mode special feature

PVG 60 variants

Part number Type

11166910 PVEH 1x4 DIN 65 Active Float B-port

1

1

PVEH-U 1x4 DIN 65 Passive Fixed US 0-10 Vdc

PVEH-U 1x4 DIN 65 Active Fixed US 0-10 Vdc

Connector

Connector

IP

IP

Fault monitoring

Fault monitoring

Functionality

Functionality

34 | © Danfoss | February 2021 BC218286485446en-000310

Page 35

21

0

Pp

Micro-

controller

Power

Supply

Special

Features

SP

LED

Error

Us

Udc

NC1 NC3

NO2 NO4

LVDT

P109149

Technical Information

PVE Series 7 — Electro-Hydraulic Actuators

PVES

The PVES actuator is a proportional control actuator with closed-loop spool control primarily used to

control work functions with very high performance requirements.

PVES

11-32 VDC multi-voltage power supply

•

Analog voltage control signal 25–75% of supply voltage

•

Standard PVE pilot oil pressure of 13.5 bar [196 psi]

•

DEUTSCH, AMP or DIN/Hirschman connectors

•

LED indicating error state and active or passive fault monitoring

•

Spool Position output (-SP) or 0-10 VDC control signal (-U) functionality

•

PVES functionality

PVES functionality

The PVE functionality includes an electric circuit with a closed-loop logic. An embedded micro-controller

processes the signal voltage and the LVDT feedback signal and regulates the solenoid valves accordingly.

A continuous modulation of solenoid valves NC1 and NO4 together with a simultaneous energization of

NO2 and de-energization of NC3 causes the main spool to move to the right direction and vice versa.

When the main spool is stroked to the far right, a simultaneous energization of both NO2 and NO4 and

de-energization of both NC1 and NC3 balances the main spool in its stroked position. An emergency stop

activated when the spool is stroked will cause all solenoid valves to de-energize causing the main spool

©

Danfoss | February 2021 BC218286485446en-000310 | 35

Page 36

P109199

101 [3.98]

45 [1.77]

89 [3.5]

P109235

Technical Information

PVE Series 7 — Electro-Hydraulic Actuators

PVES

to move back to its neutral position by means of the main spool neutral spring and the hydraulic

principle.

PVES Schematics and Dimensions

Schematic

PVES

PVES Technical Data

Dimensions

PVES Connector height

DEU = 24 mm [0.94 in]

AMP = 17 mm [0.67 in]

DIN = 13 mm [0.51 in]

For information on dimensions, see Dimension Overview for PVE Series 7 on page 59.

Control Specification

Description Type Value

Supply Voltage (UDC) Rated Range 11 to 32 V

Signal Voltage PWM (US) Neutral US = 0.5 UDC = 50% DUT

Max. ripple 5%

Q: P to A US = (0.5 to 0.25) UDC = 50% to 25% DUT

Q: P to B US = (0.5 to 0.75) UDC = 50% to 75% DUT

DC

36 | © Danfoss | February 2021 BC218286485446en-000310

Page 37

Technical Information

PVE Series 7 — Electro-Hydraulic Actuators

PVES

Control Specification (continued)

Description Type Value

Input Impedance Rated 12 kΩ

Input Capacitance Rated 1 nF

Current consumption

Description @ 12 V

PWM Frequency (US) recommended > 1000 Hz > 1000 Hz

Current Consumption 560 mA 280 mA

Pilot pressure

Minimum Nominal Maximum

10.0 bar [145 psi] 13.5 bar [196 psi] 15.0 bar [218 psi]

Fluid consumption

Neutral Locked position Actuating

0.03 l/min

[0.106 US gal/min]

0.01 l/min

[0.026 US gal/min]

DC

@ 24 V

DC

0.8 l/min

[0.21 US gal/min]

Technical specification

Parameter Minimum Recommended range Maximum

Fluid viscosity

Fluid cleanliness

Storage temperature

Operating temperature

Max. T-port pressure

static / intermittent

4 mm2/s [39 SUS] 12 to 75 mm2/s [65 to 347 SUS] 460 mm2/s [2128 SUS]

18/16/13 (according to ISO 4406)

Ambient: -50 to 90°C [-58 to 194°F]

Ambient: -40 to 90°C [-40 to 194°F]

25 / 40 bar

265 / 580 psi

LED Characteristic

Color LED Characteristic Description

Green constant No error – Actuating

Green flashing @ 1.5 Hz Neutral – Power save

Red constant Internal error

Red flashing @ 1.5 Hz External or Float error

Yellow Disable mode

©

Danfoss | February 2021 BC218286485446en-000310 | 37

Page 38

100

0

Spool Position [%]

Time

T0 T1

T2

Spool Position

PFC (%)

Supply Voltage (UDC)

Max. spool pos. to neutral

T2

Neutral to max. spool pos.

T1

Boot-up

T0

P301823

Us [%]

100

0

Spool Position [%]

100

(0.75 ∙ U dc)

BP

h

50

(0.50 ∙ U dc)

vFixed pos.

Spool Position

Technical Information

PVE Series 7 — Electro-Hydraulic Actuators

PVES

PVES Reaction Times

Reaction times

PVES Hysteresis and Ripple

Reaction PVES

T0 – Boot-up [ms] 45 ms

T1 – Neutral to max. spool stroke @ Power ON 170 ms

T2 – Max. spool stroke to neutral @ Power OFF 135 ms

T1 – Neutral to max. spool stroke @ Constant U

T2 – Max. spool stroke to neutral @ Constant U

DC

DC

125 ms

90 ms

Description Type PVES

Hysteresis (h) Rated [%] <0.5

Steady state ripple @ fixed US (v) Rated [mm] 0.2

The stated values are preliminary values and can be subject to change once an increased statistical basis

is achieved.

For more information on hysteresis and ripple, see Hysteresis and Ripple.

38 | © Danfoss | February 2021 BC218286485446en-000310

Page 39

Technical Information

PVE Series 7 — Electro-Hydraulic Actuators

PVES

PVES Variants for PVG

PVG 32/100 variants

Part number Type

11166748 PVES 1x4 DEU 67 Passive Standard

11166864 PVES 1x4 DEU 67 Active Standard

11166859 PVES 1x4 AMP 66 Passive Standard

11166858 PVES 1x4 AMP 66 Active Standard

11166849 PVES 1x4 DIN 65 Passive Standard

11166857 PVES 1x4 DIN 65 Active Standard

11166745

11166747

11166752

1

Includes Disable Mode special feature

2

Includes Spool Position special feature

PVG 120 variants

Part number Type

11166761 PVES 1x4 DEU 67 Passive Standard

11166762 PVES 1x4 DIN 65 Passive Standard

1

1

2

PVES-U 1x4 DEU 67 Passive Fixed Us 0-10 Vdc

PVES-U 1x4 AMP 66 Active Fixed Us 0-10 Vdc

PVES-SP 1x6 DEU 67 Passive Standard

Connector

Connector

IP

IP

Fault monitoring

Fault monitoring

Functionality

Functionality

©

Danfoss | February 2021 BC218286485446en-000310 | 39

Page 40

213

4

213

4

4

312

3

2

1

4

5

6

Pin no.

1

2

3

4

Pin no.

1

2

3

4

B

A

6

5

4

3

2

1

12

3

4

Technical Information

PVE Series 7 — Electro-Hydraulic Actuators

Connector Overview

Connector Overview

1 x 4 DEUTSCH 2 x 4 DEUTSCH 1 x 6 DEUTSCH

1 x 4 AMP 2 x 4 AMP 1 x 6 AMP 1 x 4 DIN/Hirschman

PVEO-DI 4-pin AMP Connector

Pinout Pin 1 Pin 2 Pin 3 Pin 4

2x4 AMP (A) UDC_A UDC_B GND GND

2x4 AMP (B) DI-B DI-A GND U

PVEM 4-pin DIN Connector

Pinout Pin 1 Pin 2 Pin 3 Pin 4

1x4 DIN U

DC

U

S

Error GND

PVEO, PVEO-R and PVEO-HP 4-pin Connector

Pinout Pin 1 Pin 2 Pin 3 Pin 4

1x4 AMP UDC_A UDC_B GND GND

1x4 DEUTSCH UDC_A GND GND UDC_B

1x4 DIN UDC_A UDC_B - GND

PVEA/PVEH/PVES

Pinout Pin 1 Pin 2 Pin 3 Pin 4

1x4 AMP U

1x4 DEUTSCH U

1x4 DIN U

S

S

DC

U

DC

Error GND U

U

S

GND Error

Error GND

40 | © Danfoss | February 2021 BC218286485446en-000310

DC2

DC

Page 41

Technical Information

PVE Series 7 — Electro-Hydraulic Actuators

Connector Overview

PVEA-DI and PVEH-DI 4-pin Connector

Pinout Pin 1 Pin 2 Pin 3 Pin 4

2x4 AMP (A) U

2x4 AMP (B) DI-A DI-B GND U

2x4 DEUTSCH (A) U

2x4 DEUTSCH (B) U

PVEH-FLA 6-pin Connector

Pinout Pin 1 Pin 2 Pin 3 Pin 4 Pin 5 Pin 6

1x6 AMP U

PVEH-SP and PVES-SP 6-pin Connector

Pinout Pin 1 Pin 2 Pin 3 Pin 4 Pin 5 Pin 6

1x6 DEUTSCH U

S

S

DC2

S

S

U

DC

Error - SP GND U

U

DC

Error GND U

GND DI-A DI-B

GND Error Float -

GND Error

DC2

DC

DC

©

Danfoss | February 2021 BC218286485446en-000310 | 41

Page 42

Technical Information

PVE Series 7 — Electro-Hydraulic Actuators

Fault Monitoring and Reaction

All proportional control PVE Series 7 actuators feature:

Integrated fault monitoring

•

Detecting spool stroke inconsistencies

•

Detecting internal hardware defects

•

Detecting demand signal inconsistencies

•

Fault reaction depending on the type of fault monitoring

•

Generic

‒

Specific

‒

Passive and active fault monitoring refers to whether or not the actuator is reacting on the error when it

is detected.

Active fault monitoring

No matter what kind of error is detected, the solenoid valves will be disabled and the operation that the

valves/spool controls will stop immediately and spool will go to neutral position. Active fault monitoring

keeps a “memory” of the error, even if it is no longer registered. The active fault monitoring does not have

Auto Recovery because of this “memory” and a reboot/restart will therefore be required to reactivate the

solenoid valves.

With an active fault monitoring the following scenarios will take place when an error is detected/occurs:

•

The LED light will switch from green to red and the error pin output will go high

•

The solenoid valves will be disabled and the operation that the valves/spool controls will stop

immediately

•

The active fault monitoring does not have Auto Recovery, so when the error is fixed/no longer is

registered a reboot/restart of the PVE is required to reactivate it.

Generic Fault Reaction

Passive fault monitoring

Passive fault monitoring does not disable the solenoid valves when an error is detected. It will continue

to operate despite that an error was detected. When the error no longer is registered the passive fault

monitoring will “forget” the error and continue as if the error was never there.

With a passive fault monitoring the following conditions will happen when an error is detected/occurs:

The LED light will switch from green to red and the error pin output will go high

•

The solenoid valves will continue operating at the set point given at the time of the error

•

Only exception is if the error is caused by the supply voltage (UDC) being either above or below

‒

the allowed range or if the temperature measured on the internal electronics board is higher than

allowed. In these cases, the solenoid valves will be disabled.

All PVE actuators with fault monitoring are triggered by the following main events:

Control Signal Monitoring

Transducer/LVDT Supervision

Supervision of Spool Position

The Control signal voltage (US) is continuously monitored.

The permissible range is between 15% and 85% of the supply voltage (UDC).

Outside this range the PVE will switch into an error state. A disconnected U

pin (floating) is recognized as a neutral set point.

The internal LVDT wires are monitored. If the signals are interrupted or shortcircuited, the PVE will switch into an error state.

The actual position must always correspond to the demanded position (US).

If the actual spool position is further out from neutral than the demanded

spool position or in opposite direction, the PVE will switch into an error state.

Spool position closer to neutral and in same direction will not cause an error

state – the situation is considered in control.

S

42 | © Danfoss | February 2021 BC218286485446en-000310

Page 43

Technical Information

PVE Series 7 — Electro-Hydraulic Actuators

Fault Monitoring and Reaction

Fault Reaction Overview

Float Position Monitoring

Temperature Monitoring

Float position must be entered or left within a time limit.

A too high delay on the 1x6 pin float PVE will cause an error state – this is

relevant for the 1x6 pin PVEH-F actuators only.

When the temperature is too high the PVE LED will light constant red and

solenoid valves will be disabled.

All entries have an Auto Recovery feature unless marked otherwise.

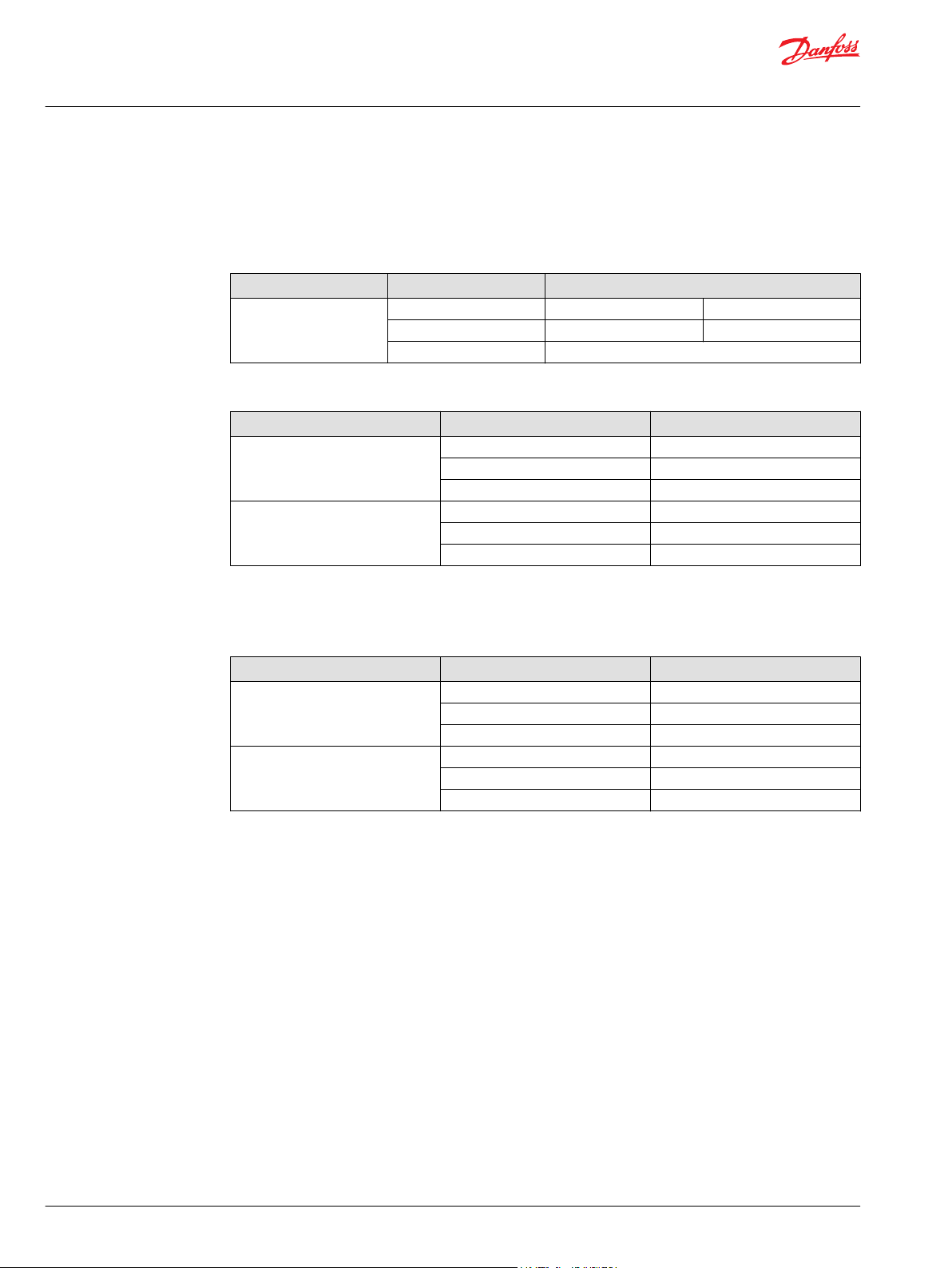

Description Monitoring LED Solenoid

Spool not at setpoint Active

Unable to reach float

position

U dc > max. Active Disabled - - -

U dc < min. Active ———— Disabled - - -

Us out of range Active

LVDT error Active

Temp > max. Active

*

Does not have Auto Recovery

*

Passive - High 250 750

*

Active

Passive - High 1000 1000

Passive Disabled - - -

Passive ———— Disabled - - -

*

Passive - High 250 750

*

Passive - High 250 750

*

Passive Disabled High 250 750

valves

Disabled High 500 750

Disabled High 1000 1000

Disabled High 500 750

Disabled High 500 750

Disabled High 250 750

Error pin

output

Fault reaction time

PVEM/H/S PVEA

Error Pin Specification

All proportional control PVE Series 7 actuators feature an error pin, indicating when an error is detected/

occurs, according to the Fault Reaction Overview table. The specifications of the error pin is shown

below.

Description No error Error

Output state Low High

Output voltage <2 Vdc ~Udc

Output current Max. 100 mA

©

Danfoss | February 2021 BC218286485446en-000310 | 43

Page 44

Technical Information

PVE Series 7 — Electro-Hydraulic Actuators

Functionality Overview

Standard and Fixed US 0-10 Vdc

All standard proportional actuator variants (PVEM/PVEA/PVEH/PVES) can be controlled by an analog

signal voltage (Us) or a PWM controlled signal voltage (Us) proportional to the supply voltage (Udc).

PVEO

Description Type Value

Supply voltage (Udc) Rated 12 Vdc 24 Vdc

PVEM/PVEA/PVEH/PVES

Description Type Value

Supply voltage (Udc) Rated 11 to 32 Vdc

Signal voltage (Us) Neutral Us = 0.5 ∙ Udc

Range 11 to 15 Vdc 22 to 30 Vdc

Max. ripple 5%

Range 11 to 32 Vdc

Max. ripple 5%

Q: P to A US = (0.5 to 0.25) ∙ Udc

Q: P to B US = (0.5 to 0.75) ∙ Udc

The PVEH-U and PVES-U variants are controlled by a fixed 0-10 Vdc signal voltage (Us), directly

compatible with standard PLC control.

PVEH-U

Description Type Value

Supply voltage (Udc) Rated 11 to 32 Vdc

Range 11 to 32 Vdc

Max. ripple 5%

Signal voltage (Us) Neutral Us = 5 V

Q: P to A 5 V to 2.5 V

Q: P to B 5 V to 7.5 V

44 | © Danfoss | February 2021 BC218286485446en-000310

Page 45

[mm]

PVM

BP

0 1 2 3 4 5 6 7

AP

[in]

PVM

00.040.080.120.160.200.240.28 0 0.04 0.08 0.12 0.16 0.20 0.24 0.28

PVEA/M/H/S

0.50.450.40.350.30.25

U

s

U

DC

0.5 0.55 0.6 0.65 0.7 0.75

PWM

[%]

PVEP

0-1020304050607080 0-10 20 30 40 50 60 70 80

PVEH-U/S-U

52.5 5 7.5

[V]

AA

A

B

C

D

E

F

AA

A

B

C

D

E

F

10

20

30

40

50

60

70

80

90

100

110

120

130

5

10

15

20

25

30

[l/min] [US gal/min]

01234567

P109151

Time

Udc

Udc

2

GND

V

1

V

2

t

1

T

P109152

Demand Signal (Us)

Supply Voltage (Udc)

Supply Voltage (Udc)

Technical Information

PVE Series 7 — Electro-Hydraulic Actuators

Functionality Overview

Performance

PWM Voltage Control

The PVEM/PVEA/PVEH/PVES actuator variants can be controlled by a PWM controlled signal voltage (Us)

proportional to the supply voltage (Udc).

The V1 and V2 must be symmetrical around Udc/2 and V1 must be equal to or less than Udc.

PVEM Control Specification

Description Type Value

Supply Voltage (Udc) Rated 11 to 32 Vdc

©

Danfoss | February 2021 BC218286485446en-000310 | 45

Range 11 to 32 Vdc

Max. ripple 5%

Page 46

Technical Information

PVE Series 7 — Electro-Hydraulic Actuators

Functionality Overview

PVEM Control Specification (continued)

Description Type Value

Signal Voltage PWM (Us) Neutral Us = 50% DUT

PWM Frequency (Us) Recommended > 200 Hz

PVEA/PVEH/PVES Control specification

Description Type Value

Supply Voltage (Udc) Rated 11 to 32 Vdc

Signal Voltage PWM (Us) Neutral Us = 50% DUT

PWM Frequency (Us) Recommended > 1000 Hz

Q: P to A Us = 50% to 25% DUT

Q: P to B Us = 50% to 75% DUT

Range 11 to 32 Vdc

Max. ripple 5%

Q: P to A Us = 50% to 25% DUT

Q: P to B Us = 50% to 75% DUT

46 | © Danfoss | February 2021 BC218286485446en-000310

Page 47

21

0

Pp

LED Circuit

LED

A

B

Ramp Ramp

SV1

SV2

P109210

21

0

Pp

LVDT

SV2SV1

Micro-

controller

Power

Supply

LED

Error

Us

Udc

P109153

Technical Information

PVE Series 7 — Electro-Hydraulic Actuators

Functionality Overview

Ramp (-R)

The Ramp functionality is a rate limitation of the spool stroke, resulting in extended reaction times and in

some cases a smoother control of the main spool compared to the standard PVEO variant. The Ramp

functionality of a PVEO-R variant is achieved purely hydraulically by implementing two orifices working

on both sides of the main spool (integrated in the actuator). The Ramp functionality of a PVEM-R variant is

achieved in the regulation principle.

PVEO with ramp functionality (PVEO-R)

PVEM with ramp functionality (PVEM-R)

For reaction times, see PVE S7 Reaction Times on page 57

©

Danfoss | February 2021 BC218286485446en-000310 | 47

Page 48

21

0

Pp

LVDT

SV2SV1

Micro-

controller

Power

Supply

U

DC

U

S

Error

LED

Technical Information

PVE Series 7 — Electro-Hydraulic Actuators

Functionality Overview

Quick Reaction (-Q)

The Quick Reaction functionality of the PVEM-Q variant results in shorter reaction times and a more rapid

or aggressive control of the main spool compared to the standard PVEM variant. The Quick Reaction

functionality of a PVEM-Q is achieved by replacing the combined orifice and check valve with a check

valve in the connection to tank and changing the regulation principle.

PVEM with quick reaction functionality (PVEM-Q)

For reaction times, see PVE S7 Reaction Times on page 57.

48 | © Danfoss | February 2021 BC218286485446en-000310

Page 49

[mm]

PVM

BP

0 1 2 3 4 5 6 7

10

20

30

40

50

60

70

80

90

100

110

120

130

5

10

15

20

25

30

[l/min] [US gal/min]

[in]

PVM

0 0.04 0.08 0.12 0.16 0.20 0.24 0.28

PVEM-FLB/H-FLB

U

s

U

DC

0.5 0.55 0.6 0.65 0.7

AA

A

B

C

D

E

8

0.31

0.75

P109155

Technical Information

PVE Series 7 — Electro-Hydraulic Actuators

Functionality Overview

Float B-Port (-FLB)

The Float B-Port functionality enables the proportional PVEM-FLB/PVEH-FLB actuator variants to enter the

main spool into a float position. The PVE actuators with Float B-Port functionality is compatible with the

dedicated main spools with electronic float in B-port.

PVE Type PVBS Type Standard FC Float Control

PVEM-FLB (1x4 pin)

PVEH-FLB (1x4 pin)

Float in B-port functionality

Deadband 1.5 mm

Max. B-port flow 4.8 mm

Us = (0.35 → 0.65) ∙ U

DC

Us = 0.75 ∙ U

DC

©

Danfoss | February 2021 BC218286485446en-000310 | 49

Page 50

AA

A

B

C

D

E

AP

10

20

30

40

50

60

70

80

90

100

110

120

130

5

10

15

20

25

30

[l/min] [US gal/min]

[mm]

PVM

01234567

[in]

PVM

00.040.080.120.160.200.240.28

PVEH-FLA

Us

U dc

0.50.550.60.650.7

8

0.31

0.75

P109154

Technical Information

PVE Series 7 — Electro-Hydraulic Actuators

Functionality Overview

Float A-Port (-FLA)

The Float A-Port functionality enables the proportional PVEH-FLA actuator variants to enter the main

spool into a float position. The PVE actuators with Float A-Port functionality is compatible with the

dedicated main spools with electronic float in A-port.

PVE Type PVBS Type Standard Flow Control Float Control

PVEH-FLA (1x6 pin) Deadband 1.7 mm Us = (0.25 → 0.75) ∙ Udc U dc to dedicated float pin

Max. B-port flow 8.0 mm

(UF)

PVE Power Save

All proportional actuator variants feature a Power Save mode, de-energizing the solenoid valve bridge.

The Power Save mode is entered when the signal voltage (Us) and the LVDT spool position has been in

neutral for 750 ms. As soon as the signal voltage (Us) or the LVDT spool position is out of neutral the PVE

will leave its Power Save mode and re-energize the solenoid valve bridge as usual.

The Power Save mode results in increased power efficiency by reducing the current consumption of the

PVE actuators in neutral position. The Power Save mode has no effect on the performance of the PVE

actuator.

50 | © Danfoss | February 2021 BC218286485446en-000310

For current consumption values, please see chapter Current Consumption.

Page 51

21

0

Pp

LVDT

LED Circuit /

Microcontroller

Power

Supply

PVEO-DI

A

B

DI_B

DI_A

LED

Udc

Ramp Ramp

SV1 SV2

P109126

21

0

Pp

Micro-

controller

Power

Supply

NP

DI_B

DI_A

Udc

LED

Error

Us

Udc

2

Special Features

NC1 NC3

LVDT

P109147

21

0

Pp

Micro-

controller

Power

Supply

U

S

Special

Features

SP

NP

Uf

DI_B

DI_A

Udc

2

LED

Error

Udc

NC1 NC3

NO4

NO2

LVDT

P109148

Technical Information

PVE Series 7 — Electro-Hydraulic Actuators

Special Features

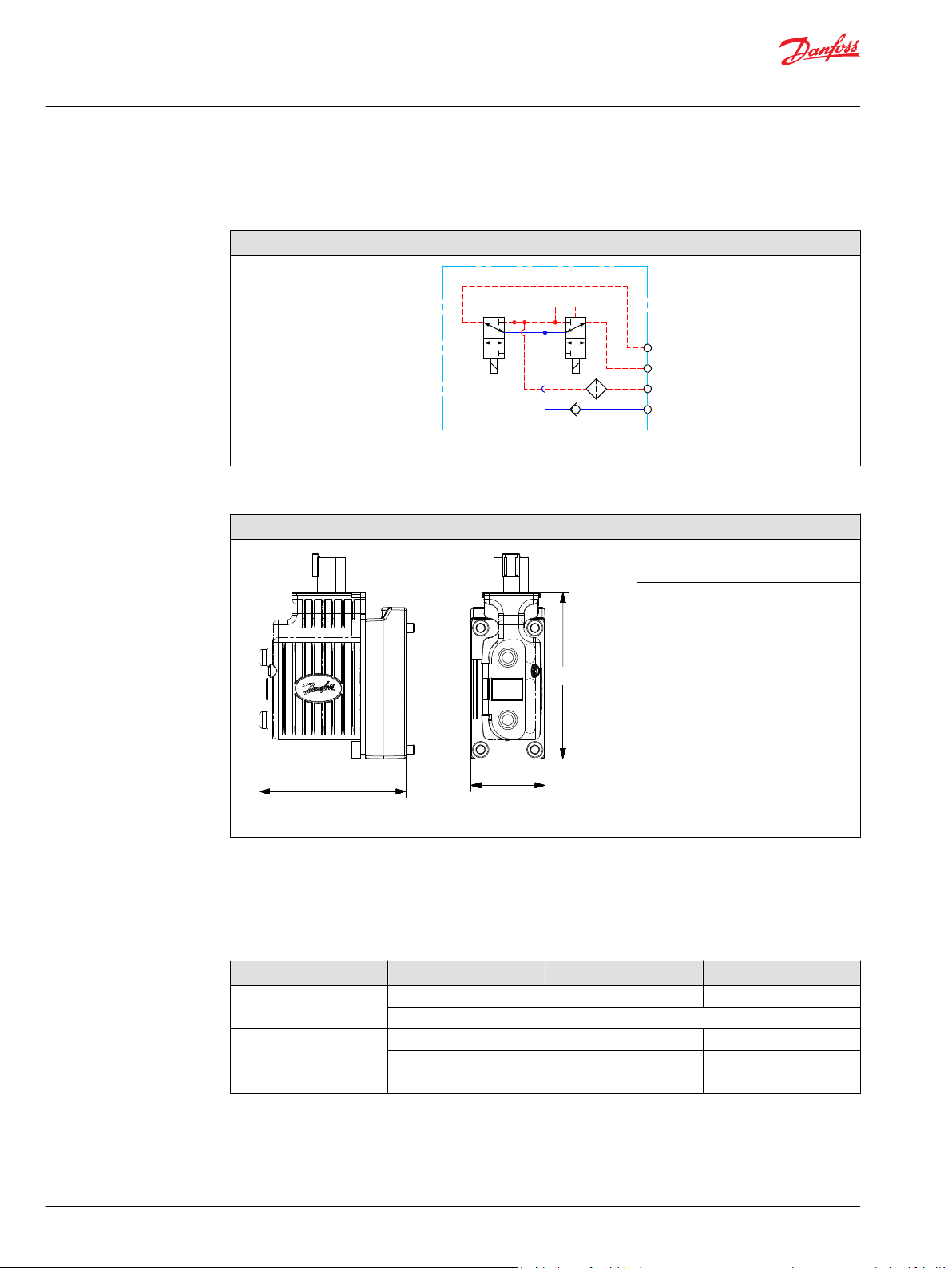

Direction Indication (-DI)

The PVEO-DI/PVEA-DI/PVEH-DI actuator variants feature an integrated Direction Indication output

derived from the LVDT spool position, indicating the state of the main spool (neutral, A-port or B-port).

PVEO-DI functionality

PVEA-DI functionality

PVEH functionality

The Direction Indication feature uses a dual power supply with the 2x4 pin AMP and DEUTSCH

connectors as shown in the chapter Connector Overview on page 40.

©

Danfoss | February 2021 BC218286485446en-000310 | 51

Page 52

DI-A low

DI-B high

DI-A high

DI-B low

Spool position ‘x’

mm [in]

B-port

PVBS away from PVE

A-port

PVBS towards PVE

0.4 0.8-0.8 -0.4 0

Technical Information

PVE Series 7 — Electro-Hydraulic Actuators

Special Features

When both DI_A and DI_B signals are High the main spool is in its neutral position.

When the DI_A signal goes Low and the DI_B signal stays High, the main spool is moving in the A-port

direction, and vice versa. The relation between the direction indication feedback and the output signal is

shown below.

Direction indication feedback

DI signals a1, a2 –0.8 mm ± 0.4 mm 0.8 mm ± 0.4 mm

Max. DI load 200 mA

DI High @ 20 mA > UDC – 1.5 V

DI High @ 100 mA > UDC – 2.0 V

DI Low < 0.2 V

A-Port B-Port

DC

DC

DC

52 | © Danfoss | February 2021 BC218286485446en-000310

Page 53

21

0

Pp

Micro-

controller

Power

Supply

U

S

Special

Features

SP

NP

Uf

DI_B

DI_A

Udc

2

LED

Error

Udc

NC1 NC3

NO4

NO2

LVDT

P109148

Technical Information

PVE Series 7 — Electro-Hydraulic Actuators

Special Features

Dedicated Float Pin (UF)

The Dedicated Float Pin (UF) feature is related to the PVEH-FLA actuator variant enabling the user to

move the main spool into its float position by power. The PVEH-FLA uses 1x6 pin AMP orDEUTSCH

connectors.

•

Normal operation: Low or not connected

•

High Float

•

Input range: U

•

Max. voltage: 32 V

PVEH-FLA functionality diagram

DC

DC

©

Danfoss | February 2021 BC218286485446en-000310 | 53

Page 54

21

0

Pp

Micro-

controller

Power

Supply

U

S

Special

Features

SP

NP

Uf

DI_B

DI_A

Udc

2

LED

Error

Udc

NC1 NC3

NO4

NO2

LVDT

P109148

21

0

Pp

Micro-

controller

Power

Supply

Special

Features

SP

LED

Error

Us

Udc

NC1 NC3

NO2 NO4

LVDT

P109149

Spool travelSpool travel

1.25V

7 mm

100%

B port

7 mm

100%

A port

0 mm

Neutral

2.5V

3.75V

Usp

Us

Us

Us

Usp

Usp

25% U

DC

50% U

DC

75% U

DC

Technical Information

PVE Series 7 — Electro-Hydraulic Actuators

Special Features

Spool Position (SP)

The Spool Position (SP) feature available in the PVEH-SP/PVES-SP actuator variants enables the user to

derive from the LVDT spool position of the main spool by means of an analog voltage signal on the

dedicated spool position (SP) output pin.

PVEH-SP functionality diagram

PVES-SP functionality diagram

Spool Position feedback

SP feedback signal from 0.5 to 4.0 VDC inverted in

direction relative to US 2.5 VDC as the neutral value

SP from neutral to maximum stroke (mm)

SP maximum load is 0.5 mA

Output range for A-port: 2.5 – 1.25 VDC and for B-port:

2.5 – 3.75 V

DC